Abstract

Industrial hemp (Cannabis sativa L.) is gaining renewed interest as a sustainable source of natural fibres, particularly in regions like Belgium, where well-established flax processing infrastructure exists. However, region-specific data on varietal performance for long fibre production remain limited, hindering large scale adoption by both farmers and processors. This study aimed to assess the agronomic performance of early- and late-flowering hemp varieties under temperate maritime conditions through a three-year field trial at two sites in Flanders (Belgium). The evaluation focused on key parameters including emergence rate, plant morphology, long fibre yield and quality. Results showed that successful crop establishment is critical, as poor emergence influenced stem diameter (increasing with decreasing emergence) and leads to reduced long fibre yields by up to 50% between tested sites. Significant yield differences between trial years were present at both sites, with the biomass yield ranging from 10.7 to 14.5 and from 7.8 to 9.6 t ha−1 for Bottelare and Beitem, respectively. Under favourable conditions, long fibre yields reached up to 2.4 t ha−1 for late-flowering and 2.1 t ha−1 for early- and mid-late-flowering varieties. In Western Europe, early to mid-late flowering varieties are generally favoured. Among these, the mid-late flowering variety Bialobrzeskie demonstrated strong yield potential. Overall, fibre quality across varieties was comparable to that of flax.

1. Introduction

In recent years, there has been a resurgence in the cultivation of industrial hemp (Cannabis sativa L.), specifically for its fibre. Since 1980, hemp cultivation for all purposes in Western Europe has increased sixfold [1]. This renewed interest is primarily driven by the growing demand for sustainable and eco-friendly materials. As an annual, fast-growing crop with minimal nutrient input requirements, and limited need for crop protection,, hemp is often considered as a promising candidate in the global shift towards more natural and renewable production systems [2,3,4,5].

Hemp fibres can be used for a diverse array of industrial applications, including textiles, composites, and insulation materials, with fibre quality and end use strongly influenced by agronomic and harvest practices, for example, sowing density affects fibre fineness [2,6,7]. Therefore, the cultivation practices and further processing for high-quality primary (long) fibres differ significantly from those aimed at producing technical or total fibre. For optimal long fibre production, a high plant density at harvest (200–300 plants/m2) is needed to promote the growth of fine stems [7,8]. Fertilisation requirements are modest [9,10,11], and optimal harvest timing is typically when 50% of the crop is in flower to ensure high primary fibre content [12,13]. In Belgium, a region traditionally known for flax production, there is potential to integrate hemp into existing post-harvest flax processing infrastructure for long fibre extraction [14,15,16]. Furthermore, two specialised hemp harvesting machines were developed in Flanders, cutting the hemp stems in two pieces of 1 m and laying them parallelly on the field for dew-retting [17]. The dew-retting process of hemp is a crucial step before fibre extraction on a flax scutching line and strongly influences fibre quality. The process is weather dependent and takes around 4–8 weeks [2,18]. Yield and fibre quality depend on multiple factors, including variety selection, harvest and retting timing, and the settings of the fibre extraction line [14,19,20,21,22].

But, despite the potential of hemp as a fibre crop, its adoption in Belgium remains limited. One of the primary challenges is the high variability in fibre yield and quality, which is influenced not only by agronomic practices but also by varietal characteristics [23]. Most hemp varieties are photoperiod-sensitive, resulting in location- and climate-dependent timing of flowering [24]. Previous studies have shown that flowering time significantly affects stem and fibre yields, with late-flowering varieties generally producing higher yields [14,24]. In addition, flowering time—which determines the harvest date—also affects the timing of the retting period, with late-flowering varieties initiating and completing retting later in the season. As a result, field operations are extended into a period with increased likelihood of late-season rainfall, which can hinder the ability to achieve the recommended maximum bailing moisture content of 15%. Although over 100 hemp varieties are listed in the EU common catalogue of hemp varieties [25], region-specific data on their performance for long fibre production under temperate maritime conditions are scarce. Only a limited number of these varieties are well known for their suitability for long fibre production, while for the majority, little to no performance data related to fibre yield or quality are available.

This study presents the results of a three-year field trial conducted at two sites in Flanders (Belgium), aiming to assess the performance of selected early-, mid-late- and late-flowering Cannabis sativa L. varieties for long fibre production. Key agronomic parameters, including emergence rate, fibre yield, and fibre quality, were evaluated. The goal is to identify varieties best suited for consistent and high-quality long fibre production under local agro-climatic conditions. By addressing the gap in regional performance data, this research supports informed variety selection and agronomic optimization for a more sustainable hemp fibre value chain in Western Europe.

2. Materials and Methods

2.1. Field Trial Set Up

Field trials were conducted over three consecutive growing seasons (2021–2023) at two sites in Flanders, Belgium. At Bottelare (HOGENT/UGent; 50.96° N, 3.75° E), trials were successfully completed each year. At Beitem (INAGRO, Beitem; 50.90° N, 3.12° E), trials were conducted in 2021 and 2022. In 2023 a trial was initiated but not completed due to soil crusting after sowing, leading to very low germination rates (6–11%) and was therefore excluded for statistical analysis. The prevailing soil type at both sites is sandy loam. Detailed soil characteristics of the experimental fields are presented in Table 1.

Table 1.

Soil characteristics of the experimental sites shown for the different cultivation years (BOTT = Bottelare; BEIT = Beitem).

Different monoecious hemp varieties (Table 2) were sown in randomized complete block design with four replicates (‘plots’) per variety at a density of 400 seeds per m2 (determined by the thousand grain weight). Seed viability was determined under laboratory conditions for each variety prior to sowing (>90%). Sowing was done by drilling seeds at a maximum depth of 2 cm in a rototilled seedbed using an experimental plot sowing machine, with a sowing distance between rows of 12.5 cm. The minimal plot size over the years was 15 m2. Fertilization was estimated at 75–100 kg N ha−1, 40 kg P2O5 ha−1, 110 K2O kg ha−1 and 30 kg MgO ha−1.

Table 2.

List of origin and earliness of tested hemp varieties. Several of these varieties were also reported in [14].

As preferred in the Belgian climate, sowing is preferably carried out in the beginning of May, however in 2021 due to the wet spring, sowing was only possible in June. An overview of the sowing dates, harvest dates and storing time per trial is shown in Table 3 and the weather overview is shown in Figure 1.

Table 3.

Overview of the timeframe of taken measurements in different trials, with the growth period shown in days after sowing (DAS) and the retting time shown as days after harvest (DAH).

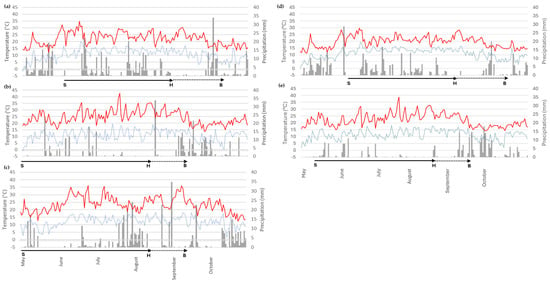

Figure 1.

Weather of the three trials in Bottelare (2021 (a); 2022 (b); 2023 (c)) and two trials in Beitem (2021 (d); 2022 (e)). The minimum and maximum temperatures are shown in blue and red, respectively. The precipitation is shown in grey bars (see right axis). The growth period of hemp is shown in the form of an arrow, where sowing (S) and harvest (H) and bailing (B) are shown. The dotted line represents the retting period.

2.2. Plant Measurements and (Fibre) Yield Estimation

Measurements in each trial were conducted 30 days after sowing (DAS) and the day before harvest. Plant density was determined by counting the second row of each plot (10 m). The counted values were used to determine the number of plants per square meter, using the row spacing. The ratio of plants m−2 and seed rate was used to determine the emergence (30 DAS). Plant length and stem diameter were also determined for 10 plants per plot. The diameter was measured at stubble height (10 cm above ground level).

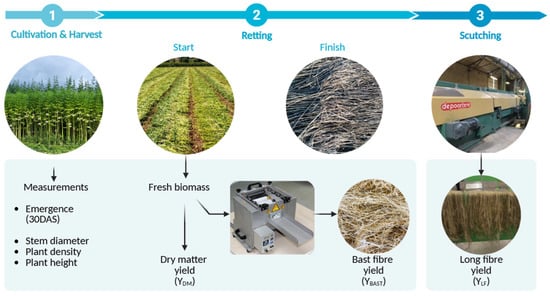

Within 1 week after the start of flowering, stems were harvested and the dry matter yield (DM-Yield; YDM), bast fibre content (BFC) and bast fibre yield (YBAST)—a proxy for potential total fibre yield—were determined as described in Vandepitte et al. [14].

After harvest the remaining stems were spread out in parallel in the field for dew-retting. Stems were left in the field for four to seven weeks and turned manually one to two times during the entire retting period. When the straw coloured greyish-brown and fibres could easily be peeled off the stem, the straw per plot was air-dried and stored in a barn up to four months. In February–March, the retted straw bundles, cut at a maximal length of 1 m, were scutched in a nearby industrial flax processing line (Van de Bilt zaden NV; manufacturer: De Poortere). The standard flax processing settings were used, except for the reduction in turbine speed from 200 to 150 (in 2022) and 145 (in 2023) rotations per minute. Per experimental plot harvested, the initial straw weight, and the weight of long fibre extracted on the flax line were measured. Means of long fibre were extrapolated to tons per hectare (t ha−1), ‘long fibre’ yield, henceforth abbreviated as YLF, respectively. Due to a processing error after scutching the straw of season 2021, the YLF and LFC could not be determined. These yields were therefore only measured for the 2022 and 2023 harvest. A graphic overview of taken measurements and determined yields is shown in Figure 2.

Figure 2.

Graphical overview of measurements and yield determination of trials.

2.3. Fibre Quality Analysis

Fibre quality analysis was done on the scutched long fibre from trial year 2022 as described in Vandepitte et al. [14], with adjustments. The mean linear density, tensile strength and elongation at break of the long scutched hemp were evaluated. A total of 63 fibres were analysed per treatment (3 plots*3 repeats/plot*7 fibres). For comparison, a sample of field-retted scutched flax fibre cultivated in 2022, processed on the same scutching line (yet at the higher, standard turbine speed of 200 rotations per minute), was also tested. Based on expert evaluation a flax sample was selected (pers. comm. Bart Depourcq; variety unknown; quality 55223). Measurements were made according to ISO 5079 [26] and ISO 1973 [27].

2.4. Statistical Analysis

Statistical analysis was carried out to assess the effects of site, year and variety on biometric treats (Emergence, Plant height, Stem diameter, Plant density), DM-Yield (YDM), bast fibre content (BFC) and yield (YBAST), long fibre content (LFC) and yield (YLF). A linear mixed-effects model was fitted with site as fixed effect, while year and block were included as nested random effects. Next, the effects for year and variety were analysed for each site separately. A standard linear model with year as fixed effect was used. To evaluate the influence of variety, a linear mixed-effects model with variety as fixed effect, and year and block as nested random effects. Pairwise comparisons for significant effects were conducted using estimated marginal means (EM Means) if needed, with a Holm–Bonferroni correction to control for the increased risk of Type I errors due to multiple comparisons.

The fibre quality of trial 2022 was analysed by general linear model (GLM), with variety as fixed factor. If the influence of one factor on a dependent variable was significant, means were compared by pairwise t-tests with Tukey HSD (alfa = 0.05). Diagnostic plots were performed to test the normality of residuals and the homoscedasticity. When these assumptions were violated, raw data were submitted to transformation. All analyses were performed in R using RStudio (version RStudio 2024.12.1).

3. Results

3.1. Effect of Site on (Fibre) Yield

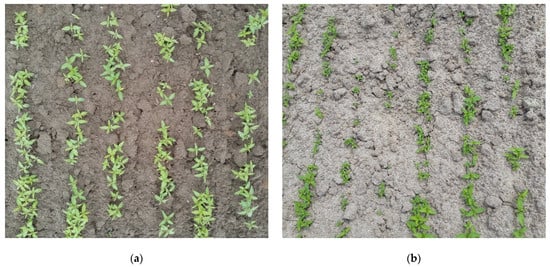

Identical field trials were conducted at two sites and post hoc analysis showed substantial differences between both sites (Supplementary Table S1). Beitem recorded emergence rates of 15–28%, whereas, Bottelare exhibited significantly higher rates of 57–79%, despite the use of the same seed lot, identical seeding density, and overall similar soil characteristics across both sites (Figure 3). The difference in emergence therefore resulted in a plant density of 80 and 240 plants/m2, respectively, and although plant height was not significantly affected, it had a notable impact on final stem diameter (Table 4). Bottelare achieved a significantly higher dry matter yield (YDM) after harvest. Additionally, bast fibre content was slightly but significantly higher in Bottelare.

Figure 3.

The difference in emergence is visually notable between the two sites, Bottelare (a) and Beitem (b).

Table 4.

Data of field trials (2021–2022–2023) conducted in Bottelare (BOTT) and Beitem (BEIT). (YDM = dry matter yield; BFC = Bast fibre content; YBAST = bast fibre yield; LFC= long fibre content; YLF = long fibre yield).

Notably, these differences were reflected most strongly in the long fibre yield—the primary yield component of interest for textile applications. Here, the significantly higher emergence rate in Bottelare corresponded to significantly higher long fibre yields. This increment was primarily attributed to the higher long fibre content of stems produced in Bottelare.

Due to the big differences in emergence and plant density between sites, the trial results are not directly comparable and will be reported and discussed separately.

3.2. Effect of Year on (Fibre) Yield

In 2021, a particularly wet spring delayed sowing of the trials at both sites (Figure 1). During the growth period, 87% and 85% of the total recorded precipitation fell within the first 60 days after sowing in Bottelare and Beitem, respectively. In contrast, the weather pattern in 2023 differed significantly. While a similar total precipitation amount was recorded in Bottelare, the timing was markedly different. Most of the rainfall occurred after the vegetative phase, primarily during the flowering period in August. Only 79 mm (32%) of the total precipitation fell within the first 60 days of growth. The 2022 trial experienced distinctly different conditions and can be classified as a “dry” year. Total precipitation was approximately half that recorded in the other years (Table 5). During this period, dry days accounted for 74% and 59% of the total growth days in Bottelare and Beitem, respectively.

Table 5.

Amount of precipitation (mm), growth period (days), and percentage of dry days during the growing season for early- and late-flowering varieties, shown for Bottelare and Beitem separately.

Due to the substantial differences in emergence observed between the two sites, the effect of year was analysed separately for each site. Nonetheless, similar trends were observed across both sites for trials conducted during the same years. Emergence rates varied significantly between years, with the lowest values recorded in 2021 and the highest in 2022 (Table 6). The lower emergence in 2021, was associated with an increased stem diameter and increased plant height (although not significant in Bottelare). The highest dry matter yield, and consequently biomass production, was obtained in 2022, followed by 2023. Bast fibre content remained consistent across years, ranging between 33.6% and 36.7%, with no significant differences detected. The highest total bast fibre yield was recorded in 2022, exceeding the yields observed in 2021 and 2023. For long fibre yield, which was only assessed in 2022 and 2023 (Bottelare), the highest value was likewise recorded in 2022. In 2023 (Bottelare) both bast and long fibre yield were significantly lower. However, these yields remained relatively high for hemp cultivation. The long fibre content did not differ significantly across years in Bottelare (Supplementary Table S2).

Table 6.

Mean values of variety trial shown per year for Bottelare (BOTT) and Beitem (BEIT) separately.

3.3. Effect of Variety on (Fibre) Yield

The emergence rate, assessed 30 days after sowing (30DAS), varied significantly between the two sites. Despite this variation, similar trends are observed across both locations. In Beitem, differences between varieties are not statistically significant, whereas in Bottelare, Muka 76 and Santhica 27 show significantly higher emergence rates than Bialobrzeskie and Fibror 79 (Table 7, with detailed post hoc comparisons in Supplementary Table S3). The stem diameter is mainly influenced by emergence rate and plant density at harvest, rather than by variety itself. In Bottelare, Muka 76 had the highest emergence rate, which correlates with its smallest stem diameter. In Bottelare, plant height differences are mainly determined by the differences in vegetative cycle of the tested varieties and do not vary much between varieties with similar flowering times. This trend is less pronounced in Beitem, although a similar pattern can be seen for two of three late-flowering varieties. Overall, the plant height ranges between 200 and 234 cm, which falls within the optimal length for hemp as a long fibre crop.

Table 7.

Measurements at emergence and before harvest (diameter, height and plant density) shown for Bottelare and Beitem separately.

Similar to plant height, differences in biomass at harvest (YDM) between early- and late-flowering varieties were more pronounced in Bottelare than in Beitem (Supplementary Table S4). Among the tested varieties, the late-flowering varieties Santhica 70 and Muka 76 produced the highest biomass at both locations.

The bast fibre content, determined from green unretted stems, served as an estimate of the total fibre content present at harvest. This total fibre content showed minimal variation between varieties, except for USO 31, which consistently exhibited the lowest bast fibre content at both sites (Table 8). The bast fibre yield (YBAST), an estimate of total fibre yield, was higher in late-flowering varieties. As with biomass, the difference was more pronounced in Bottelare (Supplementary Table S4).

Table 8.

Yields of varieties in two sites (BOTT = Bottelare; BEIT = Beitem). Dry matter yield (YDM), bast fibre content (BFC) and bast fibre yield (YBAST).

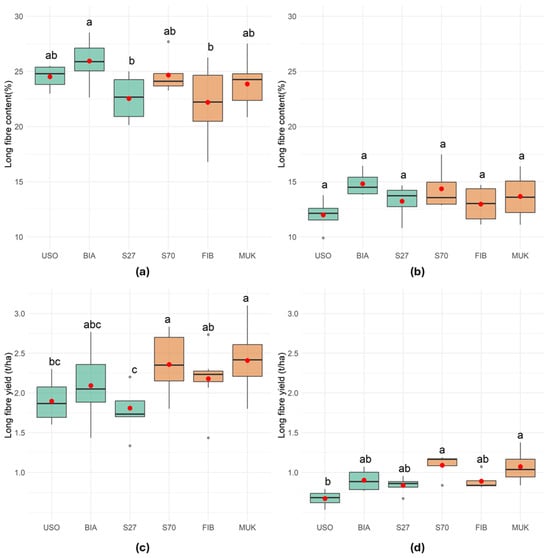

The long fibre content, obtained after scutching the retted straw on a flax scutching unit, ranges from 22% to 26% in Bottelare and from 12% to 15% in Beitem. In Bottelare, the differences between varieties are statistically significant, Bialobrzeskie (a mid–late-flowering variety) exhibiting the highest long fibre content (26%) (Figure 4a). In Beitem, a similar trend was observed, though the differences are not statistically significant (Figure 4b). The long fibre yield (YLF), an extrapolation of the weight of fibres obtained after scutching, varies significantly between varieties. Late-flowering varieties generally produced higher long fibre yields due to their extended growing cycle, which resulted in greater biomass and straw production. This trend was consistent across both sites (Supplementary Table S4). However, among early- and mid–late-flowering varieties, Bialobrzeskie achieved the highest long fibre yield at both locations. Overall, Santhica 70 and Muka 76 produced the highest long fibre yields (Figure 4c,d).

Figure 4.

Long fibre content (a,b) and yield (c,d) of varieties shown for both sites separately (Bottelare (a,c); Beitem (b,d)), early- and mid–late-flowering varieties are shown in green, and late-flowering varieties are shown in orange. The boxplots are based on the raw data, the red dots represent the estimated marginal means, different letters represent significant differences between varieties determined by Holm–Bonferonni (p < 0.05).

3.4. Effect of Variety on Long Fibre Bundle Quality

Fibre quality was evaluated using long fibres produced in 2022 in Bottelare. For comparison, a flax sample from the same year—classified as quality 5 by an experienced scorer—was analysed using identical methods. The fibre bundle length ranged from 138 to 173 mm, with no significant variation observed between the tested hemp varieties (Table 9). Linear density, defined by fibre mass and length (where a lower tex value indicates finer fibres), varied from 2.33 tex in Bialobrzeskie to 3.40 tex in Fibror 79. However, these differences were not statistically significant (Supplementary Table S5). Notably, the linear density of the flax sample was within the same range as that of the hemp varieties. Elongation at break was higher in all hemp varieties compared to the flax sample, ranging from 1.43% to 2.18%. Significant differences in applied force were detected between USO 31 and Bialobrzeskie, with Bialobrzeskie exhibiting lower strength. This trend was also reflected in breaking tenacity, where USO 31 recorded the highest value (49.72 cN/tex) and Bialobrzeskie the lowest (40.36 cN/tex).

Table 9.

Long fibre bundle quality of tested varieties for trial year 2022 in Bottelare.

4. Discussion

4.1. Effect of Site on (Fibre) Yield

Both sites have similar sandy loam soil types, which are known to be ideal for hemp growth [28,29]. The trials at both sites were sown around the same period, yet the cause of the relatively low emergence rates in Beitem remains unclear. Possible contributing factors could include seedbed preparation, or bird damage (e.g., birds eating freshly sown seeds). This finding underscores the importance of optimal sowing timing and proper soil preparation, as these factors may have contributed to the emergence variation despite overall similarities in site conditions.

The difference in emergence rates resulted in notable differences in plant morphology. In Beitem, plants developed thicker stem diameters despite having similar plant heights compared to those at the other site. Consequently, individual plants in Beitem were heavier. This increase in individual plant weight likely explains the significant differences in long fibre yield observed between the two sites. Research by Westerhuis et al. [12] demonstrated that unwanted secondary fibre production is closely tied to increased plant weight. Specifically, as individual plant size increases, the proportion of secondary fibres in the stem rises, which consequently reduces the proportion of primary, long fibres. This observation aligns with previous findings by Amaducci et al. [30] and van der Werf et al. [31] who reported that stems with greater dry weight tend to contain higher amounts of secondary fibres. Furthermore, Amaducci et al. [7] noted that reducing plant density, which encourages thicker stem development, further enhances the thickness of the secondary fibre layer. The limited difference in bast fibre content between the two sites likely reflects the relatively fixed total fibre content in the stem, which is largely genetically determined, as is also the case in flax [32]. This combined with the lower amount of long fibres obtained in Beitem, suggest the higher production of short fibres after scutching.

4.2. Effect of Year on (Fibre) Yield

In the literature, it is reported that hemp varieties require 500–700 mm of precipitation per annum for optimum yields, with 250–300 mm during the vegetative stage [28,33]. In our trials, total precipitation was significantly lower, with recorded values of 255 mm, 154 mm, and 245 mm in the three consecutive trial years. This aligns more closely with findings from other studies, which suggest that a lower precipitation threshold of around 320 mm may still be sufficient for acceptable yields [34]. Interestingly, in 2022, despite having the lowest precipitation (154 mm)—comparable to the medium water treatment in Gill et al. [34]—our trial achieved the highest yields, with biomass yields of 14.5 t ha−1 and 9.6 t ha−1 for Bottelare and Beitem respectively. Notably, no water stress symptoms such as biomass reduction were observed. This aligns with the results of Herppich et al. [35], who successfully cultivated the S27 variety (also used in the present study) in a period of drought and heat.

In 2021, dry biomass yield and bast fibre yield were significantly lower at both trial locations compared to the other years. This reduction may be attributed to the delayed sowing in 2021, caused by an unusually wet spring. Consequently, all varieties experienced a shorter vegetative growing period. In 2021, the early and late varieties had growth periods of 77 and 85–90 days, respectively, compared to approximately 90 and 110 days in the other trial years. This observation aligns with findings from Angelini et al. [36], which reported decreased fibre yields when sowing was postponed from April to June. Additionally, van der Werf [22] similarly predicted reduced crop yields due to delayed sowing using a crop growth model.

While considerable research exists on hemp’s response to water scarcity, the effects of excessive precipitation remain largely unexplored. In our trials, the excessive rainfall in 2021 resulted in stem lodging and breakage, along with increased incidence of Sclerotinia stem rot due to persistently wet conditions.

4.3. Effect of Variety on (Fibre) Yield

The emergence rate is a critical factor in hemp cultivation for fibre purposes, as a high plant density is generally recommended. Compared to other fibre crops like flax, hemp still exhibits a lower overall emergence rate [37]. Notably, this rate varies significantly between varieties. Among the tested varieties, Fibror 79 demonstrated the lowest emergence rate (Site 1: 57%; Site 2: 15%), while Muka 76 and Santhica 27 showed the highest rates.

Plant diameter appears to correlate more strongly with emergence rate and plant density at harvest than with variety itself. This observation aligns with previous findings by Westerhuis et al. [38]. In Bottelare, differences in plant height were primarily determined by the vegetative cycle of the tested varieties, with minimal variation within this factor. Although this trend was less pronounced in Beitem, a similar pattern was observed for two out of three late-flowering varieties. The less distinct trend in Beitem may be attributed to larger standard deviations in the data and the lower plant density, which generally promotes taller plants. These findings are consistent with other field trials that report comparable height differences between early- and late-flowering varieties [14].

Biomass yield patterns further support these observations. Early- and mid–late-flowering varieties consistently produced lower straw yields than late-flowering varieties, with this effect being more pronounced in Bottelare than in Beitem. These results are in line with previous studies [11,24,33]. Notably, the highest dry matter yield was observed for Santhica 70 (BOTT: 13.5 t ha−1; BEIT: 10.3 t ha−1), while the lowest yield was recorded for USO 31 (BOTT: 10.9 t ha−1; BEIT: 7.7 t ha−1) across both sites. While these results align with those of Vandepitte et al. [14], the reported straw yields in their study were lower (range: 6.14–10.01 t ha−1).

Santhica 70 and Muka 76 demonstrated promising results in Flanders, producing the highest bast and long fibre yields. However, late-flowering varieties may be less suitable for the temperate maritime climate due to the increased likelihood of wet post-summer months. The later harvest extends the retting period, increasing the risk of over-retting and complicating the drying and storage of retted straw [16]. Consequently, the mid-late-flowering variety Bialobrzeskie, which produced a relatively high yield of long fibres (1.70 t ha−1) and contained the highest amount of long fibres (26%), may be a promising alternative. As an earlier-flowering variety, Bialobrzeskie can be harvested and stored before the onset of the wetter conditions, thereby reducing the risk of retted straw losses.

To facilitate hemp’s full integration into agricultural practices in Western Europe, breeding efforts should prioritize early- and mid-late-flowering varieties with high long fibre yields. Additionally, improving flowering homogeneity is crucial, as the crop is currently harvested when approximately 50% of plants are flowering. Optimizing variety selection and development remains a key area for further research.

4.4. Effect of Variety on Long Fibre Bundle Quality

The fibre quality assessment in this study is based on samples cultivated in a single year (trial 2022) at one site (Bottelare). Therefore, the following conclusions must be carefully taken into account. The linear density values, directly affecting the linear density of produced yarns, observed in this study (ranging from 2.33 to 3.40 tex) are notably lower—indicating thinner fibres—than those previously reported by Vandepitte et al. [14], who documented values between 7.1 and 13.2 tex. This difference may be partly attributed to the manual manipulation of fibres during preparation for testing. Another possible factor is plant density, since Vandepitte at al. [14] reported lower long fibre yields, it is conceivable that their trial involved lower plant densities, which are known to result in thicker stems and, consequently, coarser fibres [7]. However, plant densities at harvest were not specified in their study. Environmental condition may also have influenced fibre fineness. Kwiatkowska et al. [39] demonstrated that the linear density of fibres increases with soil moisture, whereas the 2022 growing season was notably dry. This could have contributed to the production of finer fibres in the present study. Despite these potential influences, the overall trend remains consistent, with Bialobrzeskie producing the thinnest fibres followed by USO 31.

The elongation at break in this study (1.74%) aligns closely with values reported in other research, as reviewed by Zimniewska [2]. The mean breaking tenacity of fibres, which influences yarn breaking strength, in this trial (45.31 cN/tex) is comparable with results obtained in other studies [14,40]. However, unlike previous findings, Bialobrzeskie displayed lower tenacity in this study, while USO 31 showed a higher tenacity. This suggests potential year-to-year variation influenced by environmental conditions or testing differences, which impacts fibre strength as also observed with flax [14,41,42,43]. Nevertheless, the differences between all varieties are relatively minor. Notably, when compared to the flax sample tested in parallel, the hemp fibres demonstrated comparable quality, confirming their suitability for further processing into yarn. As previously highlighted by Sankari [42], hemp’s natural variability poses challenges for achieving consistent fibre properties. Factors such as batch-to-batch differences resulting from annual cultivation conditions can affect fibre uniformity. To mitigate this variability and ensure stable yarn production, blending hemp batches from multiple growing seasons is advisable.

5. Conclusions

This three-year variety trial conducted in Flanders highlights several important findings regarding hemp cultivation for long fibre production in Western Europe. The results underscore the crucial role for optimal sowing techniques and careful field preparation to optimize emergence, as poor emergence can reduce long fibre yields by up to 50%. When emergence conditions are favourable, relatively high long fibre yields can be achieved, reaching up to 2.4 t ha- for late-flowering varieties and 2.1 t ha- for early- and mid-late-flowering varieties. In temperate maritime regions early- and mid-late-flowering varieties are preferred over late-flowering ones due to their lower risk of over-retting in the typically wet post summer months. Among the tested varieties, Bialobrzeskie showed particular promise due to its mid-late flowering characteristics and high fibre yields. All tested varieties showed similar fibre quality compared to flax. To further improve fibre production in Western Europe, future breeding efforts should prioritize the development of early- and mid-late-flowering varieties with high long fibre contents and more uniform flowering times.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/agronomy15071521/s1, Table S1: Post hoc analysis of assessed parameters for different sites. Each line corresponds to a pairwise comparison. The asterisk corresponds to p values < 0.05 and NS stands for non-significant; Table S2: Post hoc analysis with Holm–Bonferonni adjustment of assessed parameters for different years, for each site separately. Each line corresponds to a pairwise comparison. The asterisk corresponds to p values < 0.05 and NS stands for non-significant; Table S3: Post hoc analysis with Holm–Bonferonni adjustment of assessed parameters for different varieties, for each site separately. Each line corresponds to a pairwise comparison. The asterisk corresponds to p values < 0.05 and NS stands for non-significant. Table S4: Yields of varieties categorised into their flowering times (Early, Mid-late and Late) in 2 sites (BOTT = Bottelare; BEIT = Beitem). The Dry matter yield (YDM), Bast fibre yield (YBAST) and Long fibre yield (YLF) are shown. Table S5: Post hoc analysis with Tukey HSD of assessed parameters for different varieties. Each line corresponds to a pairwise comparison. The asterisk corresponds to p values < 0.05 and NS stands for non-significant.

Author Contributions

Conceptualization, H.P., K.V., A.D.R., L.D.G. and V.T.; methodology, K.V., S.W., S.T. and S.V.; formal analysis, H.P.; investigation, H.P., K.V., S.W., S.T. and S.V.; data curation, H.P.; writing—original draft preparation, H.P.; writing—review and editing, S.W., S.T., S.V., A.D.R., L.D.G. and V.T.; visualization, H.P.; supervision, J.L., L.D.G. and V.T.; project administration, V.T.; funding acquisition, J.L., A.D.R., L.D.G. and V.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted within the ‘Hemp4Textiles’ project, funded as LA-Project by VLAIO (HBC.2019.2859; 2021–2024).

Data Availability Statement

Data are contained within the article and Supplementary Materials.

Acknowledgments

We are deeply grateful to Bart Depourcq for his excellent advice and management of scutching experiments at his company (Van de Bilt zaden en vlas B.V), which was essential for the results presented here. We would also like to thank Kevin de Witte, Veerle Derycke and Eva Wambacq for their support in managing field work, and the technical crew at the experimental farm in Bottelare and Inagro for assistance in field work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fao. FAOSTAT: Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 13 November 2023).

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Hemp Production in the EU. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 17 April 2025).

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial hemp fiber: A sustainable and economical alternative to cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023, 15, 6457. [Google Scholar] [CrossRef]

- Horne, M.R.L. Bast fibres. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 163–196. [Google Scholar] [CrossRef]

- Amaducci, S.; Zatta, A.; Pelatti, F.; Venturi, G. Influence of agronomic factors on yield and quality of hemp (Cannabis sativa L.) fibre and implication for an innovative production system. Field Crops Res. 2008, 107, 161–169. [Google Scholar] [CrossRef]

- Mariz, J.; Guise, C.; Silva, T.; Rodrigues, L. Hemp: From Field to Fiber—A Review. Textiles 2024, 4, 165–183. [Google Scholar] [CrossRef]

- Tang, K.; Struik, P.C.; Yin, X.; Calzolari, D.; Musio, S.; Thouminot, C.; Bjelková, M.; Stramkale, V.; Magagnini, G.; Amaducci, S. A comprehensive study of planting density and nitrogen fertilization effect on dual-purpose hemp (Cannabis sativa L.) cultivation. Ind. Crops Prod. 2017, 107, 427–438. [Google Scholar] [CrossRef]

- Finnan, J.; Burke, B. Nitrogen fertilization to optimize the greenhouse gas balance of hemp crops grown for biomass. GCB Bioenergy 2013, 5, 701–712. [Google Scholar] [CrossRef]

- Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C.; Venturi, G.; Cromack, H.T.H. Agronomy of fibre hemp (Cannabis sativa L.) in Europe. Ind. Crops Prod. 2000, 11, 107–118. [Google Scholar] [CrossRef]

- Westerhuis, W.; van Delden, S.H.; van Dam, J.E.G.; Pereira Marinho, J.P.; Struik, P.C.; Stomph, T.J. Plant weight determines secondary fibre development in fibre hemp (Cannabis sativa L.). Ind. Crops Prod. 2019, 139, 111493. [Google Scholar] [CrossRef]

- Mediavilla, V.; Leupin, M.; Keller, A. Influence of the growth stage of industrial hemp on the yield formation in relation to certain fibre quality traits. Ind. Crops Prod. 2001, 13, 49–56. [Google Scholar] [CrossRef]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for high-value textile applications: The effective long fiber yield and quality of different hemp varieties, processed using industrial flax equipment. Ind. Crops Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Ranalli, P.; Venturi, G. Hemp as a raw material for industrial applications. Euphytica 2004, 140, 1–6. [Google Scholar] [CrossRef]

- Pinsard, L.; Revol, N.; Pomikal, H.; De Luycker, E.; Ouagne, P. Production of Long Hemp Fibers Using the Flax Value Chain. Fibers 2023, 11, 38. [Google Scholar] [CrossRef]

- Pinsard, L. From Cultivars to Textile Application: Insight Into the Textile Hemp Value Chain; Institut National Polytechnique de Toulouse—INPT: Toulouse, France, 2023. [Google Scholar]

- Angulu, M.; Gusovius, H.-J. Retting of Bast Fiber Crops Like Hemp and Flax—A Review for Classification of Procedures. Fibers 2024, 12, 28. [Google Scholar] [CrossRef]

- Grégoire, M.; Bar, M.; De Luycker, E.; Musio, S.; Amaducci, S.; Gabrion, X.; Placet, V.; Ouagne, P. Comparing flax and hemp fibres yield and mechanical properties after scutching/hackling processing. Ind. Crops Prod. 2021, 172, 114045. [Google Scholar] [CrossRef]

- Gabrion, X.; Koolen, G.; Grégoire, M.; Musio, S.; Bar, M.; Botturi, D.; Rondi, G.; de Luycker, E.; Amaducci, S.; Ouagne, P.; et al. Influence of industrial processing parameters on the effective properties of long aligned European hemp fibres in composite materials. Compos. Part A Appl. Sci. Manuf. 2022, 157, 106915. [Google Scholar] [CrossRef]

- Tsaliki, E.; Moysiadis, T.; Kalivas, A.; Panoras, I.; Grigoriadis, I. Multi-Year Insights into Industrial Hemp Growth in a Mediterranean Climate. Agronomy 2024, 14, 1946. [Google Scholar] [CrossRef]

- van der Werf, H. Crop Physiology of Fibre Hemp (Cannabis sativa L.); Wageningen University and Research: Wageningen, The Netherlands, 1994. [Google Scholar]

- Amaducci, S.; Scordia, D.; Liu, F.H.; Zhang, Q.; Guo, H.; Testa, G.; Cosentino, S.L. Key cultivation techniques for hemp in Europe and China. Ind. Crops Prod. 2015, 68, 2–16. [Google Scholar] [CrossRef]

- Tang, K.; Struik, P.C.; Yin, X.; Thouminot, C.; Bjelková, M.; Stramkale, V.; Amaducci, S. Comparing hemp (Cannabis sativa L.) cultivars for dual-purpose production under contrasting environments. Ind. Crops Prod. 2016, 87, 33–44. [Google Scholar] [CrossRef]

- European Commission. EUPVP—COMMON CATALOGUE. Available online: https://ec.europa.eu/food/plant-variety-portal/index.xhtml (accessed on 17 April 2025).

- ISO 5079; Textile Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres. International Organization of Standardization: Geneva, Switzerland, 2020.

- ISO 1973; Textile Fibres—Determination of Linear Density—Gravimetric Method and Vibroscope Method. International Organization for Standardization: Geneva, Switzerland, 2021.

- Adesina, I.; Bhowmik, A.; Sharma, H.; Shahbazi, A. A Review on the Current State of Knowledge of Growing Conditions, Agronomic Soil Health Practices and Utilities of Hemp in the United States. Agriculture 2020, 10, 129. [Google Scholar] [CrossRef]

- Vessel, J.; Black, C.A. Soil Type and Soil Management Factors in Hemp Production; Agricultural Experiment Station, Iowa State College of Agriculture and Mechanic Arts: Ames, IA, USA, 1947. [Google Scholar]

- Amaducci, S.; Federica, P.; Bonatti, P.M. Fibre Development in Hemp (Cannabis sativa L.) as Affected by Agrotechnique. J. Ind. Hemp 2005, 10, 31–48. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Harsveld van der Veen, J.E.; Bouma, A.T.M.; ten Cate, M. Quality of hemp (Cannabis sativa L.) stems as a raw material for paper. Ind. Crops Prod. 1994, 2, 219–227. [Google Scholar] [CrossRef]

- Silska, G.; Górecki, T. Fiber Content of the Flax Germplasm (Linum usitatissimum L.) Originating from Different Parts of the World. J. Nat. Fibers 2023, 20, 2164108. [Google Scholar] [CrossRef]

- Cosentino, S.L.; Riggi, E.; Testa, G.; Scordia, D.; Copani, V. Evaluation of European developed fibre hemp genotypes (Cannabis sativa L.) in semi-arid Mediterranean environment. Ind. Crops Prod. 2013, 50, 312–324. [Google Scholar] [CrossRef]

- Gill, A.R.; Loveys, B.R.; Cowley, J.M.; Hall, T.; Cavagnaro, T.R.; Burton, R.A. Physiological and morphological responses of industrial hemp (Cannabis sativa L.) to water deficit. Ind. Crops Prod. 2022, 187, 115331. [Google Scholar] [CrossRef]

- Herppich, W.B.; Gusovius, H.-J.; Flemming, I.; Drastig, K. Effects of Drought and Heat on Photosynthetic Performance, Water Use and Yield of Two Selected Fiber Hemp Cultivars at a Poor-Soil Site in Brandenburg (Germany). Agronomy 2020, 10, 1361. [Google Scholar] [CrossRef]

- Angelini, L.G.; Tavarini, S.; Di Candilo, M. Performance of New and Traditional Fiber Hemp (Cannabis sativa L.) Cultivars for Novel Applications: Stem, Bark, and Core Yield and Chemical Composition. J. Nat. Fibers 2016, 13, 238–252. [Google Scholar] [CrossRef]

- Karimzadeh Soureshjani, H.; Bahador, M.; Tadayon, M.; Ghorbani Dehkordi, A. Modelling seed germination and seedling emergence of flax and sesame as affected by temperature, soil bulk density, and sowing depth. Ind. Crops Prod. 2019, 141, 111770. [Google Scholar] [CrossRef]

- Westerhuis, W.; Amaducci, S.; Struik, P.C.; Zatta, A.; Dam, V.J.E.G.; Stomph, T.J. Sowing density and harvest time affect fibre content in hemp (Cannabis sativa L.) through their effects on stem weight. Ann. Appl. Biol. 2009, 155, 225–244. [Google Scholar] [CrossRef]

- Kwiatkowska, E.; Zimniewska, M.; Różańska, W.; Puchalski, M.; Przybylska, P. Assessing the Impact of Drought Stress on Hemp (Cannabis sativa L.) Fibers. Materials 2024, 17, 4198. [Google Scholar] [CrossRef]

- Decker, A.; Tritter, A.; Sarazin, V.; Drean, J.-Y.; Harzallah, O. Effect of the Cultivar on the Development Hemp Stem and Textile Fiber in the East of France; Springer Nature Singapore: Singapore, 2024; pp. 97–106. [Google Scholar] [CrossRef]

- Amarasinghe, P.; Pierre, C.; Moussavi, M.; Geremew, A.; Woldesenbet, S.; Weerasooriya, A. The morphological and anatomical variability of the stems of an industrial hemp collection and the properties of its fibres. Heliyon 2022, 8, e09276. [Google Scholar] [CrossRef] [PubMed]

- Sankari, H.S. Comparison of bast fibre yield and mechanical fibre properties of hemp (Cannabis sativa L.) cultivars. Ind. Crops Prod. 2000, 11, 73–84. [Google Scholar] [CrossRef]

- Pisupati, A.; Willaert, L.; Goethals, F.; Uyttendaele, W.; Park, C.H. Variety and growing condition effect on the yield and tensile strength of flax fibers. Ind. Crops Prod. 2021, 170, 113736. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).