Abstract

Orchard thinning can avoid biennial bearing and improve fruit quality, which is a necessary agronomic section in orchard management. The existing methods of artificial fruit thinning and chemical spraying are no longer suitable for the development of modern agriculture. With the continuous acceleration of the construction process of modern orchards, blossom thinning mechanization has become an inevitable trend in the development of the orchard flower and fruit management. Based on relevant reports in the past 20 years, the paper discusses the current level of development of mechanized blossom thinning technologies and equipment in orchards from three aspects: mechanism research, machine development, and intelligent upgrading. Firstly, for thinning mechanism research, three directions were investigated: the rope flexible hitting force, thinning agronomic requirements, and the fruit tree growth model between thinning and fruit yields. Secondly, for marketable machine developments, two types of machines were investigated: the hand-held thinner and tractor-mounted thinner. The hand-held thinner is mainly suitable for traditional old orchards with a messy canopy structure, especially in the interior and top of the canopy. The tractor-mounted thinner is mainly suitable for orchards with the same crown structure, such as the hedge type, trunk type, and V-type. Thirdly, for equipment intelligent upgrading, the research of the intelligent detection algorithm for inflorescence on the fruit tree was investigated, for species including the apple, pear, citrus, grape, litchi, mango, and apricot. Finally, combining the advantages and disadvantages of the research, the authors propose thoughts and prospects, which can provide a reference for the design and applications of orchard mechanized blossom thinning.

1. Introduction

China has an orchard area of over 12 million hectares and a total output of nearly 300 million tons, making it the largest fruit producer and consumer in the world [,,]. With the continuous expansion of the orchard planting area and the increasing requirements for large-scale management, the importance of mechanized orchards is becoming increasingly prominent. However, the research on related technologies started late and had a poor foundation, resulting in an orchard comprehensive mechanization rate of less than 30% [,]. Especially in some agronomic sections with a high labor demand, high labor intensity, and tight agricultural seasons, mechanization has not been achieved. Moreover, China is facing an aging population of orchard farmers []. The lack of efficient and labor-saving agricultural equipment has become a bottleneck that restricts the development of the fruit industry.

Thinning can avoid biennial bearing and improve fruit quality, which is a necessary agronomic section in pear orchard management [,]. The existing methods of artificial fruit thinning and chemical spraying are no longer suitable for the development of modern agriculture. Artificial fruit thinning consumes labor and time, wastes tree nutrients, and has a high-risk factor for tree-top operations []. The application of chemical thinning pollutes the environment, and the agents are easily affected by factors such as the spraying time, preparation concentration, and working site environment [,,]. As a result, they are rarely used in actual field operations. Orchard thinning, as a key step in increasing orchard yields, still relies on manual operations. Manual operation is time-consuming and inefficient, and the experience requirements for agricultural operators in blossom thinning work are still high. With the continuous acceleration of the construction process of modern orchards, blossom thinning mechanization has become an inevitable trend in the development of orchard flower and fruit management.

Based on relevant reports in the past 20 years, the paper discusses the current level of development of mechanized blossom thinning technologies and equipment in orchards from three aspects: mechanism research, machine development, and intelligent upgrading. Combining the advantages and disadvantages of the research, the authors propose thoughts and prospects on orchard mechanized blossom thinning.

2. Mechanism Research

2.1. Thinning Force

The process of striking is complicated, which is the dynamic impact, friction, and vibration behavior of a flexible rope interacting with branches, inflorescences, and young fruits of fruit trees. It is difficult to estimate the impact force of the thinning rope on branches and inflorescence, and the damage degree of non-target parts such as branches and leaf buds is also difficult to estimate. Scholars have carried out relevant research on the flexible impact mechanism.

Hu et al. used a universal materials tester to measure the tensile and shear forces of apple branches’ pedicel node and receptacles corolla node []. After repeated tests, the results showed that the average maximum tensile and shear force of the branches pedicel node in full bloom period were 3.5 N and 2.82 N, respectively. The average maximum tensile force that the receptacles corolla nodes can bear is 1.6 N. Combined with the ADAMS multi-body dynamics simulation, Hu’s team also designed a performance test bench for the end actuator of the thinner. They tested the impact force of three kinds of thinning ropes made of a solid rubber strip, hollow vinyl strip, and nylon braid under different lengths, wire diameters, and speeds of the thinning shaft [,,,,]. The optimal parameters of the actuator are as follows: the material of the thinning rope is solid rubber, the length is 20 cm, the linear diameter is 5 mm, the rotational speed of the spindle is 960 r/min, and the impact force of the thinning rope on the test branch is 5.39 N. Starting from the mechanical characteristics of peach branches, Yuan et al. obtained the stress curve of the branches and the shear strength of the branches is 6 MPa. Meanwhile, they established a rigid–flexible coupling multi-body dynamics model for the striking force of branches, analyzed the striking force of the thinning rope on branches at different rotational speeds, and concluded that the striking force range of the thinning rope is 3.3–7.6 N when the rotating speed of the spindle is 240–480 r/min [,,]. Assirelli A. et al. studied the thinning power of young peach fruit, when the fruits were 20–40 mm in size and different angles were evaluated to simulate the various ways in which the thinner hits the fruits []. The analysis of the different angles showed that, on average, the fruits are detached more easily if the force is applied with a 90° angle, respective to the fruit position on the branch. On the other hand, if the force is applied with an angle of 0°, the average force required is three times higher.

2.2. Thinning Agronomy

The research of the thinning mechanism should not only solve the problem of flexible hitting, but should also solve the problem of thinning agronomy. Due to the different species of fruit trees, the number of flower buds contained in their inflorescence is different, and their agronomic requirements for thinning are also different. The apple, pear, and grape belong to a mixed inflorescence and there are multiple flower buds on one inflorescence, while the peach and nectarine belong to a single inflorescence and there is only one flower bud on one inflorescence. Is the effect of thinning better in the bud stage or in the full bloom stage? Is removing the side flower better than the center flower when thinning the apple tree? What is the appropriate setting for the proportion of inflorescence thinning? Relevant scholars have conducted research on such thinning agronomic issues.

Sidhu et al. compared artificial bud extinction and blossom thinning in the ‘Scilate’ Apple; the results demonstrated that artificial bud extinction consistently outperformed blossom thinning in terms of an improved fruit set, return bloom, and fruit weight. The fruit quality parameters, such as flesh firmness, total soluble solids, dry matter content, malic acid content, and fruit shape, were also improved under the artificial bud extinction regime []. Oliveira et al. evaluate the effect of shoot heading and of thinning in different development stages of flowers and fruits on the fruit production and quality of the ‘BRS Kampai’ peach. The results showed that thinning during flowering and at the beginning of fruit growth increases the fruit size, and that shoot heading reduces plant production, but does not significantly increase the fruit size []. Szot et al. evaluate the effect of the crop load, thinning practices, and position in the tree crown on the quantity and quality of the ‘Szampion’ apple []. The thinning treatments were performed at the pink bud stage and full bloom stage, leaving only the king flower or lateral flower. The best results in terms of the regularity of yielding and high-quality fruits after thinning at the pink bud stage to the king flower were obtained. Han et al. studied the effects of berry thinning on bunch compactness, grape sugar accumulation, and subsequent wine quality in the Vitis vinifera L. Cabernet Sauvignon []. Based on the decreasing proportion of berries in one bunch, the treatment was designated as a 25% decrease and a 50% decrease. The results showed that the different berry thinning treatment lowered bunch compactness accordingly; the content of sugar, anthocyanins, total phenols, and the mass of mature berries were all significantly enhanced with a decreasing compactness at the same harvested time. Nie et al. studied the effects of blossom thinning on the fruit setting rate and fruit quality of apple inflorescences at different periods []. The test results showed that the thinning technique had a better fruit setting rate of apple inflorescences, fruit weight per fruit, color index, finish index, and soluble solid content than the traditional technique. Hua et al. took the Tainong No. 1 mango tree, aged 6 to 8 years, as the test material to study the optimal date of blossom thinning of the mango. The test results showed that the blossom thinning effect was better at the early bloom stage [].

2.3. Thinning Model

In order to study the relationship between thinning and fruit yield, relevant scholars established the fruit tree growth model and theory. Iwanami et al. developed a theoretical model using the ‘Fuji’ apple to explain the relationships among the timing of thinning, crop load, fruit weight, and bloom return []. The rate of flower-bud formation in the current year could be explained by a regression model of the timing of the thinning, crop load, and rate of flower-bud formation in the previous year. The fruit weight in the current year could be explained by a regression model of the timing of the thinning, crop load, rate of flower-bud formation, and shoot length in the current year and the previous year. Pellerin et al. proposes that thinning is a partial transfer of potential flower buds from one year to the next year and estimates the maximum repeatable sequence of flower buds without biennial bearing []. Manfrini et al. investigate the feasibility of a spatial analysis in apple orchards to assist growers with decision making []. A variation in the spatial distribution of the fruit load prior to the thinning was observed, indicating a possibility to spatially and differentially manage the orchard. No spatial variation in the fruit number was observed prior to the harvest, indicating that thinning had removed the previously-observed spatial variation in the crop load. Reginato et al. assessed the relationship between crop load and fruit size or crop load and yield efficiency by a regression analysis for nectarines and cling peaches []. With this methodology, the predicted crop value can be established for different growing conditions leading to an improved crop load management. This will permit growers to optimize the net return that can be obtained for a specific orchard. Understanding how crop value is affected by crop load for different cultivars can lead to better decisions in the design and establishment of new orchards.

3. Machine Development

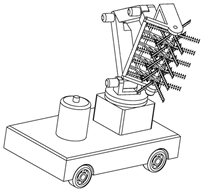

3.1. Hand-Held Thinner

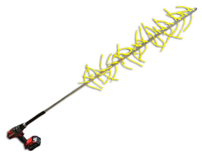

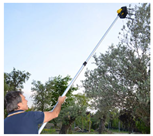

The hand-held thinner belongs to the semi-mechanized orchard management equipment, which is mainly composed of an energy supply device, operating lever, and thinning action actuator. According to the operating principle of the thinning action actuator, it can be divided into three kinds: an impact type, finger brush type, and vibration type. During the operation, the operator holds the operation lever and thins the target’s inflorescences, or vibrates the canopy branches according to the agronomic requirements of the fruit tree to reduce the blossoms and fruits. The operator determines the percentage of inflorescences and young fruits that need to be removed by subjectively judging. Because of the small structure and portability, operators can directly carry the work in hand. The hand-held thinner is mainly suitable for traditional old orchards with a messy canopy structure, especially in the interior and top of the canopy.

The string type thinner is widely used, and there are many marketable products. It is controlled by a DC motor to control the speed of the spindle, so as to control the hitting force of the rope on the target inflorescence. The electric hand-held blossom thinner made by Infaco Co. Ltd. (Cahuzac sur Vère, France) has a rotary head with a five-finger comb and is powered by a 48 V electric motor; it was equipped with a portable battery bag which facilitated worker mobility in the field []. The orchard blossom thinner made by Cinch Co. Ltd. (Shelby Township, MI, USA) has two types of electric and manual for customers to choose; the installation hole on the spindle is reserved for the rope and is used to adjust the density of the rope according to the flower intensity. It is used on peach, cherry, apple, plum, apricot, and nectarine varietals []. The AF 100 electronic blossom/young fruit thinner made by Lakewoodproducts Co. Ltd. (Wellington, New Zealand) is particularly effective with stone fruit, such as nectarines, apricots, peaches, and plums. Its loop is made from high strength flexible rubber fitted on a shaft and the rubber loops will adapt to the location to remove the blossom without damaging the leaves or bark []. For the electric finger blossom/young fruit thinner, the rotation of the finger dial was controlled by the motor, and the target blossom/young fruit falls off in the friction and impact action with the finger brush. The Giulivo-plus electric finger thinner, made by Volpi Co. Ltd. (Casalromano, Italy), had a head with six rotating fingers and was powered by a 12 V electric motor; electricity was supplied by a 12 V, 75 Ah car battery, which remained on the ground, and a 15 m long electric extension cord []. For the shaking thinning device, the vibration was formed by the CAM mechanism action, acting on the branches of fruit trees, which is used for picking and thinning small fruit by acting on the branches of fruit trees. The hand-held shaker made by Campagnola Co. Ltd. in Italy is an air compressor which provided pressure between 1.0 and 1.2 MPa. The mobility of this device was limited due, in part, to the presence of the flexible hose that fed the compressed air to the shaker []. The marketable production of the hand-held thinner is shown in Table 1.

Table 1.

Marketable productions of the hand-held thinner.

Relevant scientific research institutions have also designed their own hand-held thinners. Most of them are improved designs of market products and exist in the form of patents. Fruit varieties include citrus, apple, pear, peach, grape, kiwi, grape, etc. The example patent of the hand-held thinner is shown in Table 2 [,,,,,,,,,]. Researchers also carried out field tests on the performance of the hand-held thinners. Lei et al. developed a hand-held electric rotating rope blossom thinner for the ‘Cuiguan’ pear orchard: its spindle speed is from 0–900 r/min and extension rod length range is from 0.95 to 1.6 m. Compared with the hand thinning, the thinner can shorten the thinning time of the small canopy layer orchard by 30.71% and the Y-trellis orchard by 48.68%, respectively [,]. Wang et al. developed a hand-held mechanical thinning device suitable for the apple, stone fruits, and sweet cherry, with its spindle speed from 500 to 3000 r/min. Field test results indicated that the test device could remove 61.1%, 30.8%, and 18.0% of flowers on a single branch with a swipe of around 0.5 m/s under high, medium, and low speed settings, respectively [,]. Martin et al. tested the Giulivo-plus electric finger thinner and the Campagnola hand-held shaker on a peach tree. The results indicated that the finger thinner reduced the time by 46% and the shaker reduced the time by 28%; two thinners reduced the crop load by 38% and increased the mass of the fruit by 47% at harvest compared to non-thinned trees []. After that, Martin et al. developed a hand-held fruit thinner prototype: it had a rotating cylinder with 10 flexible cords, placed at the top of a pole 2 m in length. They carried out a field test with the Infaco and Giulivo-plus thinner in peach orchards; there is no differences among them in terms of thinning time and the number of fruits per cm2 of the trunk cross-sectional area at harvesting. Hand thinning took 385 h/ha, and mechanical thinning reduced this time by 89%. The cost of hand thinning was 4.8 €/tree, whereas the cost of mechanical thinning ranged from 0.4 to 1.1 €/tree [,]. Spornberger et al. tested the portable thinner and manual thinning in organically managed cherry orchards at the stage of a pea size; the portable thinner showed a high thinning effect, and because of lower costs, it is more suitable for farmers than the hand thinning of flowers or fruits [].

Table 2.

Patent of the hand-held thinner.

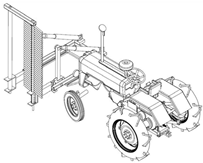

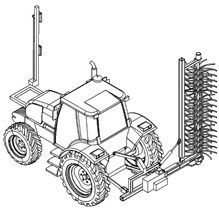

3.2. Tractor-Mounted Thinner

The tractor-mounted thinner belongs to the mechanized blossom and fruit management equipment. The whole machine is operated by the tractor and the rotating power of the spindle is provided by the tractor hydraulic mechanism. The marketable productions are divided into three kinds according to the structure of the thinning arm: the single spindle, multiple spindles, and horizontal rotary spindle. The working mechanism between the thinning rope and the inflorescence is that of the hitting, rubbing, and vibrating. According to the fruit species, crown type, and other agronomic parameters, operators adjust the tractor advancing speed, the spindle operation angle, the spindle rotational speed, and the density of the thinning rope, so as to reasonably select the thinning intensity. The tractor-mounted thinner is mainly suitable for orchards with the same crown structure, such as the hedge type, trunk type, and V-type.

At present, the Darwin series orchard single spindle string blossom thinner made by Fruit Tec Co., Ltd. is the mainstream one in the market. The production is shown in Table 3 []. The Darwin S is mounted on the front of the tractor, so a better view of the spindle is ensured and thus, the operator can guide the spindle more easily on the tree canopy. The spindle rotational speed can be comfortably and continuously adjusted with buttons on the control unit in the driver’s cabin to be optimally adapted to the driving speed. The Darwin PT is attached to a front loader directly and is designed to work mainly in the V-type canopy tree. The spindle has a tilt angle of 180°; this allows it to be lifted to the height of the tree-tops and work horizontally over the trees. If the vase trees are very wide, there is also the possibility of tilting the spindle into the tree’s interior. The Darwin SmaArt replaces the subjective estimation of the blooming strength with the eye with objective detection by camera. To do this, a camera in front of the thinning spindle detects the blossom density of each individual tree and passes on the data to the on-board computer in real time. Using a thinning algorithm, the computer then calculates the optimum spindle speed and controls the thinning unit. As an option, the system can be combined with a GPS receiver. Using the GPS system, it is possible to detect each individual tree and to assign the data, such as the number of blossoms and the spindle speed, to the tree and to compare it later with the yield data.

Table 3.

Darwin series single spindle string blossom thinner.

In recent years, scholars have carried out a large number of tests in apple, peach, and plum orchards with the Darwin series thinner. The range of the optimal working speed is 6 to 18 km/h, and the range of the spindle rotation speed is 150 to 450 r/min. Accurate working parameters need to be obtained in the field according to the fruit tree species, the shape of the canopy, and the period of blossom thinning. Wallis et al. evaluated the risk of fire blight development and spread after Darwin 300 blossom thinning in apple orchards. The results demonstrate that the use of the thinner should, therefore, be limited to orchards with no history of disease in the last 3 years and on days when predicted weather is not suitable for tree infection; there is a low risk for fire blight development and spread by mechanical thinning under an early blossom stage, especially when paired with a subsequent bactericide application [,]. Penzel et al. translated the Darwin 250 spindle rotational frequency to average kinetic energy. At a high flower set, thinning treatments of 0.23 J and 0.33 J were adequate settings to reduce crop load in ‘Elstar’ and 0.33 J in ‘Gala’ without yield loss []. Lordan et al. evaluated the working performance of Darwin 250 in ‘Gala’, ‘Golden Delicious’, and ‘Fuji’ apple orchards; two prediction models were developed to adjust the right tractor and spindle rotational speeds depending on the initial number of flower clusters []. Theron et al. evaluated chemical thinning with the Darwin thinner during the plum blossom stage; the method increased the fruit drop, fruit size, and fruit weight []. Cline et al. tested the Darwin 300 and hand thinning in apple and peach orchards; the result showed that mechanical thinning represents a viable method for initial crop load reduction, coupled with hand thinning after fruit, set to reach a final optimal production [,]. Baugher et al. tested the Darwin 300 in V-shaped and open-center trained peach orchards; they demonstrated that the mechanical thinner reduces labor requirements and improves fruit size [,,,,].

Other companies also make related productions, such as the Eclairvale series orchard thinner (as shown in Table 4) made by La Canne Vale Co., Ltd. (Narbonne, France) []. The machine can be adopted to be both semi-mounted and mounted, to perform the thinning operation adequately: the total mass of the tractor with or without front ballast must guarantee the stability of a 3 m rear overhang. It has a freely rotating rotor onto which semi-rigid rods are attached. Its rotation occurs through the penetration of the rods into the canopy and the advancement of the tractor, which induces a slow rotation and rubbing of the rods against the branches, which causes some of the blossom or green fruit to fall. Rods are made of flexible glass fibers with a soft plastic end cap; it is the only wearing part and each rod can be easily replaced in less than one minute. Assirelli et al. tested the Eclairvale thinner in apricot and peach orchards [,,]. In the apricot, the machine removed 20.8% of flowers and 43.6% of fruit, allowing 48% time-saving in the follow-up fruit manual thinning as compared with the hand thinning. In the peach, mechanical thinning at blooming time removed 63% of flowers, allowing 42.4% time-saving in the follow-up fruit manual thinning as compared with the hand thinning. Fruit damages always remained below the economic thresholds to marketable production or to the plant.

Table 4.

Eclairvale thinner.

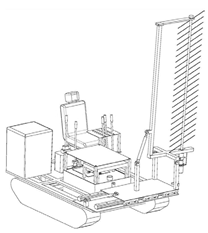

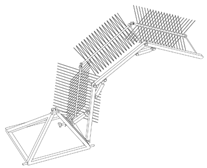

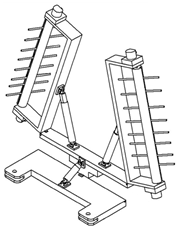

The FLEXITREE three-arm blossom thinner made by Clemens Co. Ltd. (Wittlich, Germany), is shown in Table 5, which is linked in front of a tractor []. Three arms are installed flexibly in different positions of the vertical rod and its structure can be changed by adjusting, which has the advantage of more penetration into the canopy. The device is flexibly configurable and can be perfectly adapted to the crown structure and different tree heights by means of various adjustment options. Lei et al. designed a three-arm tractor-mounted flower thinner named TTBT-300 for ‘Y’ trellis and trunk-type pear orchards; the field test showed that the thinner can save at least 60% of artificial fruit thinning time and the profitable area was 0.58 hm2 [,]. Blanke et al. designed a three-arm tractor-mounted flower thinner named Bonner for plums and apples. In the plum orchard, the yield of Class one fruits increased per tree from 47% in the un-thinned controls up to 69%; the fruit mass was enlarged from 28 g in the un-thinned control to 30–32 g [,]. In the apple orchard, the portion of Class one fruits bigger than 70 mm was increased by 10% without yield loss and it reduced the subsequent hand thinning by, respectively, 32.5% [,]. They also proposed an integrated coefficient of thinning (ICT) to develop the critical parameters of the machine. The optimum values are 10–40, where an ICT > 50 led to tree damage and ICT < 8 led to sub-optimum thinning efficacy [,].

Table 5.

Three-arm blossom thinner.

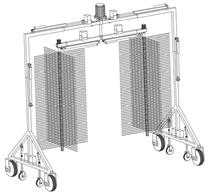

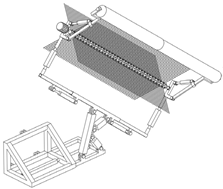

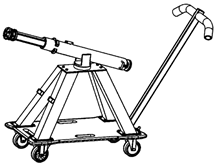

The spiked-drum shaker made by the United States Department of Agriculture consisted of several panels of radially spaced nylon rods bolted to plates on a central spindle, as shown in Table 6. Schupp et al. evaluated the double spiked-drum shaker on the peach; it reduced peach crop load by an average of 36%, decreased follow-up hand thinning time by 20% to 42%, and increased fruit in higher market value size categories by 35% []. Miller et al. evaluated the single and double spiked-drum shaker on the peach to reduce the cost and time required for hand thinning peaches. At the 60% full blossom stage, the double-spiked drum shaker reduced crop load by 27% and the single spiked-drum shaker reduced crop load by 9%; they removed an average of 37% of the green fruit [].

Table 6.

Spiked-drum shaker.

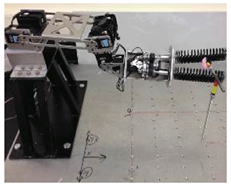

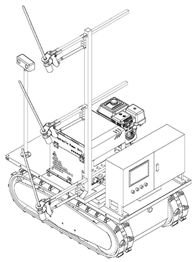

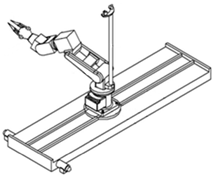

Other innovative thinners are shown in Table 7, and they belong to physical impact thinning. The one-rotor orchard horizontal rotary thinner made by Phil Brown Welding Co. Ltd. can be carried on a standard forklift tractor []. The rotor was driven by a hydraulic with a variable speed, and the ropes can be easily replaced when worn. Aasted et al. developed a system using an LIDAR to sense the canopy and automatically control the position of a modified Darwin string thinner position to maintain engagement []. They found that the laser control system performed similarly to the joystick control for the blossom counts. Though the laser system was slightly less engaged on the lower canopy, the overall scaffold performance was much closer. Lyons et al. developed a visual blossom thinning system []. It consisted of kinematic targeting and heuristic programming, a robotic arm, and a pomologically designed end-effector. The robotic arm had a consistent range of −1.26 cm to +1.57 cm vector magnitude per target location, and the end-effector brushes had a consistent range of −2.97 cm to +3.04 cm per target location. Li et al. developed a profiling control system for the litchi blossom thinner; the spatial position of the spindle could be adjusted by the translational screw and profile adjusting screw. The test results show that the dynamic mean errors of the translational screw and profile adjusting screw were 0.17 and 0.07 cm, respectively; the actuators have good position-adjusting accuracy and the proposed profiling control system can meet the requirements of real-time control [,]. Wouters et al. established a set of multi-spectral camera systems for the detection of pear inflorescence, which can identify pear inflorescence in six bands of visible and near infrared spectra []. The test results show that approximately 87% of the visible floral buds were detected correctly with a low false discovery rate (<16%).

Table 7.

Other innovative thinners.

In the patent, orchard blossom thinners are shown in Table 8. There are mainly four kinds: the single spindle string thinner has an angle adjusting device, multi-arm profiling thinner, multi-sensors automatic thinner, and machine vision intelligent thinner. The blossom thinner angle adjusting device is designed for the single spindle string thinner, aiming at adjusting the spindle angle to adapt to different tree canopies. The multi-arm profiling thinner is a pure mechanism innovation model, which realizes fruit tree canopy profiling through mechanism deformation. The multi-sensors automatic thinner adds sensors such as the radar, infrared probe, and ultrasonic probe to the existing blossom thinning equipment to realize the operation of the spindle angle and rotation speed adjusting. The machine vision intelligent thinner is a kind of intelligent blossom thinning equipment, which replaces human eyes with a high-definition camera, replaces the human brain with a deep learning convolutional neural network, and replaces the human hand with a mechanical flower thinning arm. At present, most of the patented products are a conceptual design, which has a certain theoretical basis. Some prototypes have been successfully developed, but there is still a certain distance to commercialization.

Table 8.

Example patent of the tractor-mounted thinner.

4. Intelligent Upgrading

With the maturity and development of technologies such as artificial intelligence, 5G, the internet of things, and blockchain, agriculture will usher in a new period of development. The development of intelligent agricultural machinery and equipment has become a focus of the industry, especially the innovative application of machine vision intelligence technology represented by deep learning in the field of agricultural mechanization. The number and position of inflorescence among individual fruit trees vary, and fixed machine operation parameters cannot ensure the consistency of flower cluster density among different tree bodies. The excessive removal of inflorescence will reduce the yield of fruit trees, while too low of a removal will increase the subsequent workload of manual fruit selection. The machine operation method based on human eye evaluation cannot solve the above problems very well. In the research of intelligent detection algorithms for inflorescence on fruit trees, relevant researchers have made certain attempts.

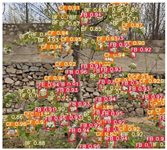

In the field of deep learning inflorescence recognition, the apple has been the main research target. Researchers have compared the accuracy and detection time of various models for detecting the apple’s flower intensity and growth status. Chen et al. proposed an apple inflorescence recognition algorithm based on Yolov5s, which incorporated a cooperative attention mechanism, bottleneck module, and CIOU loss function []. The model achieved an mAP value of 94.90%, which improved upon Faster R-CNN, Yolov3, Yolov4, and Yolov5 by 1.98%, 7.1%, 5.42%, and 2.53%, respectively. Shang et al. used machine vision and Yolov5s to detect apple flowers under different weather, colors, and light conditions []. The model achieved an mAP increase of 8.15%, 9.75%, and 9.68% compared to the Yolov4, SSD, and Faster-RCNN models, respectively. Additionally, the model size decreased by 94.23%, 84.54%, and 86.97%, respectively, and the detection speed increased by 126.71%, 32.30%, and 311.28%, respectively. Wang et al. proposed a phenology distribution estimation method named DeepPhenology for apple flowers based on CNNs using RGB images []. The model efficiently mapped the flower distribution on an image-level, row-level, and block-level, achieving an average Kullback–Leibler divergence value of 0.23 over all validation sets and an average KL value of 0.27 over all test sets. Tian et al. proposed an instance segmentation model for detecting and segmenting apple flowers with three different levels of growth status: bud, semi-open, and fully open []. The model improved upon Mask Scoring ReCNN with a U-Net backbone, achieving a precision of 96.43%, recall of 95.37%, F1 score of 95.90%, mean average precision of 0.594, and mean intersection over union of 91.55%. Farjon et al. proposed an estimator for apple blooming levels based on Faster R-CNN, achieving a high agreement level (0.78–0.93) between the algorithm blooming estimation and human judgments of several experts []. Wu et al. proposed a deep learning algorithm for the real-time and accurate detection of apple flowers based on the channel pruned Yolov4 []. The model achieved an mAP of 97.31%, higher than Faster R-CNN, Tiny-Yolov2, Yolov3, SSD 300, and EfficientDet-D0 algorithms by 12.21%, 15.56%, 14.19%, 5.67%, and 7.79%, respectively. Table 9 shows the performance of each algorithm. There have been several studies conducted by researchers to detect apple inflorescence using image processing methods. For instance, Zhang et al. proposed a novel strategy that combined UAV and ground-based RGB image data to detect flowering intensities in a Dutch Elstar apple orchard []. Their approach yielded a R2 of 0.7 and a RMSE lower than 20, indicating a high correlation between the image-derived flower index, the white index, and the in-field counts of the cluster number. Liu et al. developed an accurate estimation model for apple fuzzy clustering with a complex background, which showed a high reliability and applicability []. The model estimates flower quantity quickly and accurately with an overall accuracy rate of 92%. Črtomir et al. developed an apple yield forecast hybrid model based on artificial neural networks []. The forecast of the hybrid method showed a higher accuracy than an image analysis. Aggelopoulou et al. developed an image processing-based algorithm that predicts tree yield by analyzing the picture of the tree at full blossom []. Their test results indicated that the potential yield could be predicted early in the season from flowering distribution maps, and could be used for orchard management during the growing season. Overall, these studies demonstrate the potential of image processing methods for detecting and predicting apple inflorescence, which could be beneficial for orchard management and improving yields.

Table 9.

Apple inflorescence recognition and detection.

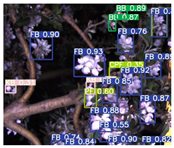

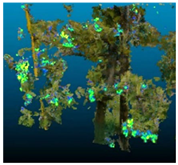

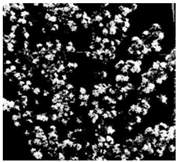

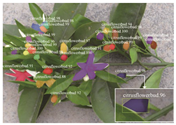

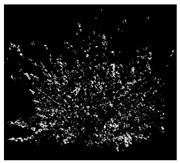

In addition to the apple, researchers have also conducted studies on inflorescence detection and classification in other fruit trees such as pear, citrus, grape, litchi, mango, and apricot. For example, Xia et al. proposed a pear inflorescence recognition algorithm Ghost-Yolov5s-BiFPN based on Yolov5s to address the problem of inflorescence detection and classification in intelligent pear orchard production []. Their field test results showed that the mAP and recall rate were improved by 4.2% and 2.7%, respectively, compared with the original Yolov5s network, and the detection time and model parameters were reduced by 9 ms and 46.63%, respectively. Zhou et al. proposed a density classification of the pear flower images method based on the improved density peak clustering algorithm; it adopted the soft statistics method for density calculation, which had continuity and was more accurate for density classification []. Lyu et al. proposed a lightweight citrus recognition model using cascade fusion Yolov4-CF, which achieved a frame rate of 30 FPS on the FPGA side and could meet the demands of real-time monitoring for florescence information []. Deng et al. proposed an instance segmentation algorithm, in which the mask-RCNN can simplify the relatively complex object segmentation by simple detection []. Du et al. proposed a new method to locate the clamping points of fruit stems for table grape thinning based on an improved Mask-CNN []. Their test results showed that the location accuracy was 90% and the total time was 0.3 s, and the maximum location error in x, y, and the total location error were 10, 12, and 16 pixels, respectively. Lin et al. proposed a method using multicolumn-CNN to calculate the number of litchi blossoms by generating a density map []. Their approach achieved a mean absolute error of 16.29 and a mean square error of 25.40, which outperformed traditional counting methods using target detection. Wang et al. presented two machine vision methods for assessing the flowering intensity of mango orchards []. The correlation coefficient between their methods and human visual counts ranged from 0.78, indicating a strong agreement. Underwood et al. designed a mobile terrestrial scanning system for almond orchards that can efficiently map flower and fruit distributions and estimate the yield for individual trees []. The lidar canopy volume showed the strongest linear relationship to yield, with an R2 of 0.77 for 39 tree samples spanning two years. Horton et al. developed an image processing algorithm to detect peach blossoms on trees []. Their method achieved an average detection rate of 84.3%, demonstrating its effectiveness in detecting peach blossoms. Inflorescence recognition and the detection of other fruits are shown in Table 10.

Table 10.

Inflorescence recognition and the detection of other fruits.

5. Conclusions and Future Perspectives

Blossom thinning mechanization is an inevitable trend in the development of flower and fruit management in orchards. However, due to the constraints of canopy shapes and terrains, marketable mechanized blossom thinning equipment cannot be operated in the field, and the operation method is still in the stage of artificial thinning. Even in modern orchards that are suitable for mechanization, thinners are random hitting operations and cannot be finely tuned for different fruit trees. The phenomenon of leakage and excessive thinning often occurs, and the economic benefits are not maximized. In order to further enhance the mechanization level of orchard production management, promote the healthy development of the fruit industry, and comprehensively promote the construction of a smart fruit industry, research on orchard blossom thinning machinery can focus on the following aspects.

5.1. Orchard Planting Pattern

To achieve mechanization in orchard production management, the first step is to ensure that equipment can enter the orchard. The unity of orchard planting patterns is crucial, and consistent canopy shapes of fruit trees can ensure the smooth entry of blossom thinning arms into the interior of the canopy for operation. Strict planting standards must be established for the spacing between ridges, rows, plants, and turning spaces to ensure the flexible movement of thinners. Existing old orchards need to be upgraded and renovated through methods such as transplanting, pruning branches, and traction to enable machinery to enter the orchard. When constructing a new orchard, it is necessary to fully consider the issue of mechanized operations and equip it with tractor roads and related supporting facilities. Orchard contiguous planting areas should be moderately scaled up for production and establish replicable and scalable cultivation models suitable for mechanized operations. Improving the level of mechanized production in orchards requires the integration of agricultural machinery and agronomy.

5.2. Mechanical Structure of the Thinning Arm

Different planting regions have different cultivation requirements. To facilitate mechanized operations, horticultural researchers have innovated various canopy shapes suitable for mechanization, such as the trunk type, the open center type, the Y trellis type, and the hedgerow type. However, the existing thinning equipment has a single mechanical structure with a single spindle. For non-hedgerow orchards, the rope cannot enter the canopy of the fruit trees effectively, resulting in uneven thinning densities and interference. For existing old orchards, the hand-held electric thinner can be used due to limited conditions. For existing mechanized orchards, profiling thinning arms can be developed for different tree shapes so that the thinning axis can be flexibly adjusted according to the fruit tree canopy to maximize the operation efficiency.

5.3. Material of the Thinning Rope

The principle of the mechanized thinning operation lies in the mutual beating between the rope and the inflorescence. During this process, the rope also interacts with the branches, as well as between the ropes and spindle, involving physical actions such as collision, friction, entanglement, compression, shearing, etc., which raise durability and flexibility issues for rope materials. Choosing a good material for the rope is a key consideration for thinner development. The ideal rope should have good flexibility without causing excessive damage to the fruit tree. The best materials for this purpose are plastics and rubber, which come in various forms, such as polyethylene, polypropylene, nylon, etc. Selecting or modifying the material formulation from existing materials to find a suitable rope material for thinning operations is a future research focus.

5.4. Parameterized Thinning Operation Model

Currently, mechanized thinning in orchards simply relies on the subjective judgment of operators to control the tractor speed, spindle rotational speed, thinning distance, rope density, etc., which is inconvenient and results in a low thinning precision. Existing research has not considered the differences in biological characteristics of branches and inflorescence during the blossom period, nor has it conducted in-depth tests on the flexible motion trajectory and beating force of the rope using branch models. The combination of a computer virtual simulation and indoor test bench test is insufficient to study the interaction mechanism between the rope and the inflorescence. The construction of a parameterized thinning operation model is crucial. 3D printing technology can be used to produce a physical model of fruit tree branches and construct a thinning test platform. The ADAMS virtual simulation and high-speed photography trajectory capture test can be combined to study the motion trajectory of the rope beating action and the beating force on branches and inflorescences. By integrating 3D printing technology, high-speed photography, and film pressure sensing technology, a parameterized thinning operation model can be built for orchards.

5.5. Intelligent Thinning

The number and position of inflorescences vary between individual fruit trees. Fixed machine operation parameters cannot guarantee the consistency of inflorescence densities among each tree. A high inflorescence thinning rate will cause a reduced fruit production, while a low thinning rate will increase the workload of subsequent fruit thinning. Machine operation-based operator-subjective judgment cannot solve the above problems well. In recent years, deep learning neural networks have been extensively studied for flower recognition. By replacing human eyes with high-precision cameras and human brains with computer neural networks, fruit tree inflorescence multi-object recognition models based on deep learning algorithms such as Faster R-CNN, YOLO, and SSD have been developed, but most experimental studies are based on datasets and collect images at close distances. The future direction is to combine these with the thinner, in order to realize the recognition and positioning of the inflorescences in actual operations to achieve intelligent thinning.

Author Contributions

X.L. (Xiaohui Lei) and X.L. (Xiaolan Lyu) conceived the research idea; X.L. (Xiaohui Lei) wrote the paper; K.H., Y.Q., J.Z., and Y.S. processed the data; Q.Y., T.X., and A.H. reviewed and suggest the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (32201680), China Agriculture Research System of MOF and MARA (CARS-28-21), Jiangsu Modern Agricultural Machinery Equipment and Technology Demonstration Extension Fund (NJ2022-14), Jiangsu Agricultural Science and Technology Innovation Fund (CX(21)2025), National Key Research and Development Program of China (2022YFD2001400), National Science and Technology Development Program of China (NK2022160104), Jiangsu Policy-guided Plans (BX2019016), and Wuxi Science and technology development Fund (N20221003).

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank Xiaogang Li, Qingsong Yang, Zhonghua Wang, and Jialiang Kan (Institute of Pomology, Jiangsu Academy of Agricultural Science) for their help in orchard agronomy.

Conflicts of Interest

The authors declare no conflict of interest.

References

- National Bureau of Statistics of the People’s Republic of China. Chinese Statistical Yearbook; China Statistics Press: Beijing, China, 2023; 935p. [Google Scholar]

- Zheng, Y.J.; Chen, B.T.; Lyu, H.T.; Kang, F.; Jiang, S.J. Research progress of orchard plant protection mechanization technology and equipment in China. J. Trans. Chin. Soc. Agric. Eng. 2020, 36, 110–124. [Google Scholar]

- Zheng, Y.J.; Jiang, S.J.; Chen, B.T.; Lyu, H.T.; Wang, C.; Kang, F. Review on technology and equipment of mechanization in hilly orchard. J. Trans. Chin. Soc. Agric. Mech. 2020, 51, 1–20. [Google Scholar]

- Wang, W.H.; Wang, G.P.; Tian, L.M.; Li, X.G.; Lyu, X.L.; Zhang, Y.X.; Zhang, J.H.; Cao, Y.F. Fruit scientific research in new China in the past 70 years: Pear. J. Fruit Sci. 2019, 36, 1273–1282. [Google Scholar]

- Zhao, Y.; Xiao, H.R.; Mei, S.; Song, Z.Y.; Ding, W.Q.; Jin, Y.; Han, Y.; Xia, X.F.; Yang, G. Current status and development strategies of orchard mechanization production in China. J. Chin. Agric. Univ. 2017, 22, 116–127. [Google Scholar]

- Qiao, Z.X. Impact of Agricultural Labor Aging on Production Behavior of Apple Households: A Case Study from Shanxi and Gansu Province; Northwest A&F University: Xianyang, China, 2018; 202p. [Google Scholar]

- Rivero, R.; Sonsteby, A.; Heide, O.M.; Mage, F.; Remberg, S.F. Flowering phenology and the interrelations between phenological stages in apple trees (Malus domestica Borkh.) as influenced by the Nordic climate. Acta Agric. Svandinavica Section B-Soil Plant Sci. 2017, 67, 292–302. [Google Scholar]

- Pavanello, A.P.; Zoth, M.; Ayub, R.A. Manage of crop load to improve fruit quality in plums. Rev. Bras. Frutic. 2018, 40, 721. [Google Scholar] [CrossRef]

- Barreto, C.F.; Antunes, L.E.; Ferreira, L.V.; Navroski, R.; Benati, J.A.; Pereira, J.F. Mechanical flower thinning in peach trees. Rev. Bras. Frutic. 2019, 41, 465. [Google Scholar] [CrossRef]

- Robinson, T.L.; Lakso, A.N. Predicting chemical thinner response with a carbohydrate model. Acta Horticul. 2011, 903, 743–750. [Google Scholar] [CrossRef]

- Miller, S.S.; Tworkoski, T. Blossom thinning in apple and peach with an essential oil. HortScience 2010, 45, 1218–1225. [Google Scholar] [CrossRef]

- Hampson, C.; Bedford, K. Efficacy of blossom thinning treatments to reduce fruit set and increase fruit size of ambrosia and aurora golden gala (TM) apples. Can. J. Plant Sci. 2011, 91, 983–990. [Google Scholar] [CrossRef]

- Hu, C.Q.; Sun, C.H.; Xu, Y. Experiment and analysis of mechanical properties for branches pedicel node and receptacles corolla node of apple tree. J. Qingdao Agric. Univ. 2015, 32, 211–214. [Google Scholar]

- Sun, C.H.; Hu, C.Q.; Hou, Q.S.; Pan, Z.G. Simulation of mechanical thinning flower actuator based on ADAMS. J. Agric. Mech. Res. 2015, 37, 70–73. [Google Scholar]

- Hu, C.Q.; Sun, C.H.; Ji, J. Performance experiment and analysis on mechanical thinning flower actuator. J. Chin. Agric. Mech. 2015, 36, 24–28. [Google Scholar] [CrossRef]

- Hu, C.Q.; Sui, R.D. Fruit Tree Mechanical Blossom Thinning Machine Performance Test Bench. P. China CN103454077B, 4 May 2016. [Google Scholar]

- Hu, C.Q.; Sui, R.D. Hydraulic Fruit Tree Blossom Thinning Machine and Method Based on Machine Vision. P. China CN103081730B, 10 September 2014. [Google Scholar]

- Hu, C.Q.; Sui, R.D. Hydraulic transmission type fruit tree flower thinning machine based on machine vision and flower thinning method. P. China CN203120538U, 14 August 2013. [Google Scholar]

- Yuan, C.W.D. Design and Performance Test of Peach Blossom Thinning Machine; Hebei Agricultural University: Baoding, China, 2020; 64p. [Google Scholar]

- Wang, Q.D. Design and Research of Mechanical Blossom Thinning Device for the Dwarf Dense Fruit Trees; Hebei Agricultural University: Baoding, China, 2018; 71p. [Google Scholar]

- Yang, X.; Wang, P.F.; Li, J.P.; Liu, H.J.; Shao, J.Z.; Qian, J. Wide Row Close Planting Fruit Tree Blossom Thinning Machine. P. China CN210381974U, 24 April 2020. [Google Scholar]

- Assirelli, A.; Caracciolo, G.; Cacchi, M.; Sirri, S.; Pallottino, F.; Costa, C. Evaluation of the detachment force needed for mechanical thinning of green peach fruits. Sustainability 2018, 10, 2291. [Google Scholar] [CrossRef]

- Sidhu, R.S.; Bound, S.A.; Hunt, I. Crop load and thinning methods impact yield, nutrient content, fruit quality, and physiological disorders in ‘Scilate’ apples. Agronomy 2022, 12, 1989. [Google Scholar] [CrossRef]

- De Oliveira, P.D.; Bettio Marodin, G.A.; De Almeida, G.K.; Gonzatto, M.P.; Darde, D.C. Heading of shoots and hand thinning of flowers and fruits on ‘BRS Kampai’ peach trees. Pesqui. Agropecu. Bras. 2017, 52, 1006–1016. [Google Scholar] [CrossRef]

- Szot, I.; Lipa, T. Apple trees yielding and fruit quality depending on the crop load, branch type and position in the crown. Acta Sci. Pol. Hortoru. 2019, 18, 205–215. [Google Scholar] [CrossRef]

- Han, W.W.; Han, N.; He, X.; Zhao, X.J. Berry thinning to reduce bunch compactness improves fruit quality of Cabernet Sauvignon (Vitis vinifera L.). Sci. Hortic. 2019, 246, 589–596. [Google Scholar] [CrossRef]

- Nie, P.X.; Lu, C.; Xue, X.M.; Wang, G.P.; Wang, J.Z. Effects of apple inflorescence thinning at different periods on fruit set rate and fruit quality. J. Hebei Agric. Sci. 2013, 17, 27–29. [Google Scholar]

- Hua, M.; Deng, H.D.; Guo, L.J.; Feng, X.J.; Chen, L.M. Effects of mechanical flowerthinning and chemical fruit thinning on average seedless fruit weight and quality of ‘Tainong No.1′ mango. Chin. Tropic. Agric. 2021, 4, 42–46+80. [Google Scholar]

- Iwanami, H.; Moriya-Tanaka, Y.; Honda, C.; Hanada, T.; Wada, M. A model for representing the relationships among crop load, timing of thinning, flower bud formation, and fruit weight in apples. Sci. Hortic. 2018, 242, 181–187. [Google Scholar] [CrossRef]

- Pellerin, B.P.; Buszard, D.; Iron, D.; Embree, C.G.; Marini, R.P.; Nichols, D.S.; Neilsen, G.H.; Nelsen, D. A theory of blossom thinning to consider maximum annual flower bud numbers on biennial apple trees. Hortscience 2011, 46, 40–42. [Google Scholar] [CrossRef]

- Manfrini, L.; Taylor, J.A.; Grappadelli, L.C. Spatial analysis of the effect of fruit thinning on apple crop load. Eur. J. Hortic. Sci. 2009, 74, 54–60. [Google Scholar]

- Reginato, G.H.; De Cortazar, V.G.; Robinson, T.L. Predicted crop value for nectarines and cling peaches of different harvest season as a function of crop load. Hortscience 2007, 42, 239–245. [Google Scholar] [CrossRef]

- Infaco. Available online: https://www.infaco.com/fr/produits/eclaircisseuse-ec1700-powercoup-pw3/ (accessed on 22 April 2023).

- Cinch. Available online: https://blossomcinch.com/ (accessed on 22 April 2023).

- Lakewoodproducts. Available online: https://www.lakewoodproducts.co.nz/horticulture/electronic-blossom-thinners/ (accessed on 22 April 2023).

- Volpi. Available online: https://www.volpioriginale.it/en/product/giulivo-plus/ (accessed on 22 April 2023).

- Campagnola. Available online: https://www.campagnola.co.uk/engine-driven-hook-shaker/gsm-el-toro/ (accessed on 22 April 2023).

- Gong, H.J.; Li, J.W.; Wang, F.M.; Mo, Q.H.; Ye, K.Y.; Jiang, Q.S.; Liu, P.P.; Qi, B.B. Hand-Held Kiwi Fruit Thinning Device. P. China CN217308396U, 30 August 2022. [Google Scholar]

- Zhao, J.Z.; Wang, L.X.; Tang, H.; Shu, W.M. An Electric Knapsack Blossom Thinning Machine. P. China CN112930929A, 11 June 2021. [Google Scholar]

- Liu, K.Y.; Liu, Y.L.; Wang, X.D.; Li, J. Hand-Held Pomelo Blossom Thinning Device. P. China CN216492184U, 13 May 2022. [Google Scholar]

- Xyu, L.M.; Yan, C.G.; Ma, S.; Niu, C.; Zhao, S.J.; Wang, S.S.; Yuan, X.T. Hand-Held Bag-Shaped Flower and Fruit Thinning Device. P. China CN212677848U, 12 March 2021. [Google Scholar]

- Zhao, X.; Yang, Y.; Luo, L.J. Hand-Held Citrus Flower Thinning Machine. P. China CN211509900U, 18 September 2020. [Google Scholar]

- Chen, A.M.; Xyu, S.H.; Shang, Z. Electric Flower and Fruit Thinning Device. P. China CN210808375U, 23 June 2020. [Google Scholar]

- Chen, W. Device for Thinning Flower, Fruit and Small Grains Fruit. P. China CN209057550U, 5 July 2019. [Google Scholar]

- Zheng, J.G.; Zheng, J.Y.; Zheng, J.F.; Zheng, J.Y.; Zheng, L.M. Hand-Held Blossom Thinning Machine for Citrus. P. China CN208836605U, 10 May 2019. [Google Scholar]

- Lu, H.Z.; Li, J.; Yang, Z.; Wu, M.C.; Qiu, J.H. Ultrasonic Target Detection Orchard Thinning Machine. P. China CN102217493B, 22 August 2012. [Google Scholar]

- Yang, Z.; Li, J.; Lu, H.Z.; Lin, B.Q.; Tan, J.H.; Wang, W.Z. Electric Orchard Thinner Convenient for Manual Adjustment and Its Use Method. P. China CN102217492B, 7 November 2012. [Google Scholar]

- Lei, X.H.; Lyu, X.L.; Zhang, M.N.; Ma, Z.B.; Chang, Y.H.; Andreas, H. Test and research on electric rotating rope blossom thinner in ‘Cuiguan’ pear orchard. J. Chin. Agric. Mech. 2020, 41, 47–52. [Google Scholar]

- Zhang, B.B.; Ma, R.J.; Guo, L.; Yyu, M.L.; Song, H.F.; Zhang, G.P.; Feng, Z.R. Hand-Held Electric Blossom Thinning Device. P. China CN206791205U, 26 December 2017. [Google Scholar]

- Wang, M.; Wang, H.; Zhang, Q.; Lewis, K.M.; Scharf, P.A. A hand-held mechanical blossom thinning device for fruit trees. Appl. Eng. Agric. 2013, 29, 155–160. [Google Scholar] [CrossRef]

- Xyu, C.G.; Zhang, Q.; Zhuang, X.; He, H.Y. Portable Electric Equipment for Fruit Tree Blossom Thinning. P. China CN202617766U, 26 December 2012. [Google Scholar]

- Martin, B.; Torregrosa, A.; Brunton, J.G. Post-bloom thinning of peaches for canning with hand-held mechanical devices. Sci. Hortic. 2010, 125, 658–665. [Google Scholar] [CrossRef]

- Martin, B.; Torregrosa, A.; Brunton, J.G. Feasibility of peach bloom thinning with hand-held mechanical devices. Sci. Hortic. 2011, 129, 91–97. [Google Scholar] [CrossRef]

- Martin, B.; Torregrosa, A.; Aragon, R.; Brunton, J.G. Portable Mechanical Device for the Clarification of Flowers and Fruit Recience in Trees and Shrubs. P. Spanish ES200901448A, 2 June 2009. [Google Scholar]

- Spornberger, A.; Leder, L.; Bock, K.; Keppel, H.; Modl, P. Impact of thinning methods on yield, diseases and fruit quality of sweet cherries (Prunus avium L.) in organic growing. Erwerbs-Obstbau 2011, 53, 15–22. [Google Scholar] [CrossRef]

- Fruit-tec. Available online: https://fruit-tec.com/ (accessed on 20 July 2023).

- Wallis, A.E.; Miranda-Sazo, M.R.; Cox, K.D. Assessing and minimizing the development and spread of fire blight following mechanical thinning and pruning in apple orchards. Plant Dis. 2021, 105, 650–659. [Google Scholar] [CrossRef]

- Ngugi, H.K.; Schupp, J.R. Evaluation of the risk of spreading fire blight in apple orchards with a mechanical string blossom thinner. Hortscience 2009, 44, 863–865. [Google Scholar] [CrossRef]

- Penzel, M.; Pflanz, M.; Gebbers, R.; Zude-Sasse, M. Tree-adapted mechanical flower thinning prevents yield loss caused by over-thinning of trees with low flower set in apple. Eur. J. Hortic. Sci. 2021, 86, 88–98. [Google Scholar] [CrossRef]

- Lordan, J.; Alins, G.; Avila, G.; Torres, E.; Carbo, J.; Bonany, J.; Alegre, S. Screening of eco-friendly thinning agents and adjusting mechanical thinning on ‘Gala’, ‘Golden Delicious’ and ‘Fuji’ apple trees. Sci. Hortice. 2018, 239, 141–155. [Google Scholar] [CrossRef]

- Theron, K.I.; Steenkamp, H.; Steyn, W.J. Efficacy of ACC (1-aminocyclopropane-1-carboxylic acid) as a chemical thinner alone or combined with mechanical thinning for japanese plums (Prunus salacina). Hortscience 2017, 52, 110–115. [Google Scholar] [CrossRef]

- McClure, K.A.; Cline, J.A. Mechanical blossom thinning of apples and influence on yield, fruit quality and spur leaf area. Can. J. Plant Sci. 2015, 95, 887–896. [Google Scholar] [CrossRef]

- Sauerteig, K.A.; Cline, J.A. Mechanical blossom thinning of ‘Allstar’ peaches influences yield and quality. Sci. Hortic. 2013, 160, 243–250. [Google Scholar] [CrossRef]

- Baugher, T.A.; Ellis, K.; Remcheck, J.; Lesser, K.; Schupp, J.; Winzeler, E.; Reichard, K. Mechanical string thinner reduces crop load at variable stages of bloom development of peach and nectarine trees. Hortscience 2010, 45, 1327–1331. [Google Scholar] [CrossRef]

- Baugher, T.A.; Schupp, J.; Ellis, K.; Remcheck, J.; Winzeler, E.; Duncan, R.; Johnson, S.; Lewis, K.; Reighard, G.; Henderson, G.; et al. String blossom thinner designed for variable tree forms increases crop load management efficiency in trials in four united states peach-growing regions. Horttechnology 2010, 20, 409–414. [Google Scholar] [CrossRef]

- Baugher, T.A.; Schupp, J.R.; Lesser, K.M.; Hess-Reichard, K. Horizontal string blossom thinner reduces labor input and increases fruit size in peach trees trained to open-center systems. Horttechnology 2009, 19, 755–761. [Google Scholar] [CrossRef]

- Schupp, J.R.; Baugher, T.A. Peach blossom string thinner performance improved with selective pruning. Hortscience 2011, 46, 1486–1492. [Google Scholar] [CrossRef]

- Asteggiano, L.; Giordani, L.; Bevilacqua, A.; Vittone, G.; Pellegrino, S.; Costa, G. Bloom mechanical thinning improves fruit quality and reduces production costs in peach. Acta Hortic. 2015, 1084, 389–394. [Google Scholar] [CrossRef]

- La Canne Vale. Available online: https://www.lacannevale.fr (accessed on 20 July 2020).

- Assirelli, A.; Caracciolo, G.; Roccuzzo, G.; Stagno, F. New tools for mechanical thinning of apricot fruitlets. Agriculture 2021, 11, 1138. [Google Scholar] [CrossRef]

- Assirelli, A.; Giovannini, D.; Cacchi, M.; Sirri, S.; Baruzzi, G.; Caracciolo, G. Evaluation of a new machine for flower and fruit thinning in stone fruits. Sustainability 2018, 10, 4088. [Google Scholar] [CrossRef]

- Faugno, S.; Cacchi, M.; Sirri, S.; Caracciolo, G.; Giovannini, D.; Quacquarelli, I.; Civitarese, V.; Assirelli, A. Mechanical thinning of apricot fruitlets. Chemi. Eng. Trans. 2017, 58, 259–264. [Google Scholar]

- Clemens. Available online: https://www.clemens-online.com/en/products/ (accessed on 1 December 2022).

- Lei, X.H.; Lv, X.L.; Zhang, M.N.; Li, X.; Chang, Y.H.; Andreas, H. Development and test of three arms tractor-mounted flower thinner. J. Trans. Chin. Soc. Agric. Eng. 2019, 35, 31–38. [Google Scholar]

- Lei, X.H.; Lyu, X.L.; Zhang, M.N.; Lu, D.P.; Wang, S.L.; Chang, Y.H.; Zhong, D.X.; Shen, T.B. Performance evaluation of mechanical blossom thinning in trunk type pear orchard. Int. J. Agric. Biol. Eng. 2021, 14, 106–112. [Google Scholar] [CrossRef]

- Lammerich, S.; Kunz, A.; Damerow, L.; Blanke, M. Mechanical Crop Load Management (CLM) Improves Fruit Quality and Reduces Fruit Drop and Alternate Bearing in European Plum (Prunus domestica L.). Horticulturae 2020, 6, 52. [Google Scholar] [CrossRef]

- Seehuber, C.; Damerow, L.; Blanke, M. Regulation of source: Sink relationship, fruit set, fruit growth and fruit quality in European plum (Prunus domestica L.)-using thinning for crop load management. Plant Growth Regul. 2011, 65, 335–341. [Google Scholar] [CrossRef]

- Peifer, L.; Ottnad, S.; Kunz, A.; Damerow, L.; Blanke, M. Effect of non-chemical crop load regulation on apple fruit quality, assessed by the DA-meter. Sci. Hortic. 2018, 233, 526–531. [Google Scholar] [CrossRef]

- Damerow, L.; Kunz, A.; Blanke, M. Regulation of fruit set by mechanical flower thinning. Erwerbs-Obstbau 2007, 49, 1–9. [Google Scholar] [CrossRef]

- Hehnen, D.; Hanrahan, I.; Lewis, K.; McFerson, J.; Blanke, M. Mechanical flower thinning improves fruit quality of apples and promotes consistent bearing. Sci. Hortic. 2012, 134, 241–244. [Google Scholar] [CrossRef]

- Solomakhin, A.A.; Blanke, M. Mechanical flower thinning improves the fruit quality of apples. J. Sci. Food and Agric. 2010, 90, 735–741. [Google Scholar] [CrossRef]

- Schupp, J.R.; Baugher, T.A.; Miller, S.S.; Harsh, R.M.; Lesser, K.M. Mechanical thinning of peach and apple trees reduces labor input and increases fruit size. Horttechnology 2008, 18, 660–670. [Google Scholar] [CrossRef]

- Miller, S.S.; Schupp, J.R.; Baugher, T.A.; Wolford, S.D. Performance of mechanical thinners for bloom or green fruit thinning in peaches. Hortscience 2011, 46, 43–51. [Google Scholar] [CrossRef]

- Philbrownwelding. Available online: https://www.philbrownwelding.com/index.php/peach-blossom-thinner (accessed on 1 December 2022).

- Aasted, M.; Dise, R.; Baugher, T.A.; Schupp, J.R.; Heinemann, P.H.; Singh, S. Autonomous Mechanical Thinning Using Scanning LIDAR. In Proceedings of the 2011 ASABE Annual International Meeting, Louisville, KY, USA, 7–10 August 2011. [Google Scholar]

- Lyons, D.J.; Heinemann, P.H.; Schupp, J.R.; Baugher, T.A.; Liu, J. Development of a selective automated blossom thinning system for peaches. Trans. ASABE 2015, 58, 1447–1457. [Google Scholar]

- Li, J.; Xu, Y.; Xu, J.T.; Yang, Z.; Lu, H.Z. Design and experiment of control system for suspended electric flexible thinner. J. Trans. Chin. Soc. Agric. Eng. 2016, 32, 61–66. [Google Scholar]

- Li, J.; Lu, H.Z.; Yang, Z.; Zheng, S.Y. Design and experimental study of litchi flexible thinning mechanism. J. South Chin. Agric. Univ. 2013, 34, 431–435. [Google Scholar]

- Wouters, N.; De Ketelaere, B.; Deckers, T.; De Baerdemaeker, J.; Saeys, W. Multispectral detection of floral buds for automated thinning of pear. Comput. Electron. Agric. 2015, 113, 93–103. [Google Scholar] [CrossRef]

- Zhou, Y.; Pan, Y.F.; He, L.; Song, L.; Wang, Q.; Song, Z.S.; Wen, X.Y. A Tractive Blossom and Fruit Thinning Device. P. China CN113692872B, 6 January 2023. [Google Scholar]

- Yang, Z.; Ding, Y.H.; Li, J.; Xyu, X.; Duan, J.L.; Fu, H.; Jiang, Y.L.; Lin, J.Q.; Wang, B.; Liu, E.X.; et al. Orchard Cruise Blossom Thinning Device and Method. P. China CN111670715A, 30 June 2020. [Google Scholar]

- Hu, C.Q.; Sui, R.D. Blossom Thinner. P. China CN213245837U, 21 May 2021. [Google Scholar]

- Yang, Z.; Ding, Y.H.; Li, J.; Duan, J.L.; Xyu, X.; Jiang, Y.L.; Xiang, J.; Wang, T.Y.; Yyu, X.F.; Li, J.X.; et al. A litchi Profiling Blossom Mechanism. P. China CN110235641A, 1 August 2019. [Google Scholar]

- Lyu, X.L.; Lei, X.H.; Zhang, M.N.; Chang, Y.H.; Bai, Z.C.; Li, H. A Multi-Segment Arm Profiling Blossom and Fruit Thinning Device. P. China CN106857044B, 30 August 2022. [Google Scholar]

- Lei, X.H.; Lyu, X.L.; Zhang, M.N.; Ma, Z.B.; Shen, Q.Y.; Liu, W.H. An Electric Orchard Blossom Thinner. P. China CN211909757U, 13 November 2020. [Google Scholar]

- Yang, Z.; Ding, Y.H.; Liu, B.L.; Duan, J.L.; Xiong, J.T.; Li, J.; Xyu, X.; Jiang, Y.L.; Yuan, H.T.; Huang, G.S.; et al. Adaptive Blossom Thinner and Method. P. China CN113099870B, 14 June 2022. [Google Scholar]

- Lei, X.H.; Lyu, X.L.; Zhang, M.N.; Chang, Y.H. A Profiling Blossom Thinner and Method for Y Trellis Pear Orchard. P. China CN113243220B, 6 January 2023. [Google Scholar]

- Liu, P.; Gao, D.Z.; Zhu, Y.J.; Liu, L.P. A Blossom Thinning Arm Based on Image Recognition and Its Application Method. P. China CN111837701A, 30 October 2020. [Google Scholar]

- Wu, J.J.; Shang, Z.; Gong, W.J.; Wang, X.L. Electromagnetic Blossom Thinning Device for apple Tree Based on Computer Control. P. China CN209693537U, 29 November 2019. [Google Scholar]

- Liu, P.; Gao, D.Z.; Zhu, Y.J.; Liu, L.P.; Du, W.S. A Double Roller Intelligent Blossom Thinner Based on Machine Vision and Its Application Method. P. China CN111903370A, 10 November 2020. [Google Scholar]

- Chen, G.F.D. Research on Apple Flower Recognition and Detection Method Based on Deep Learning. Master’s Dissertation, Shandong Agricultural University, Tai’an, China, 2022. 80p. [Google Scholar]

- Shang, Y.Y.; Zhang, Q.R.; Song, H.B. Application of deep learning using Yolov5s to apple flower detection in natural scenes. J. Trans. Chin. Soc. Agric. Eng. 2022, 38, 222–229. [Google Scholar]

- Wang, X.; Tang, J.L.; Whitty, M. DeepPhenology: Estimation of apple flower phenology distributions based on deep learning. Comput. Electron. Agric. 2021, 185, 106123. [Google Scholar] [CrossRef]

- Tian, Y.N.; Yang, G.D.; Wang, Z.; Li, E.; Liang, Z.Z. Instance segmentation of apple flowers using the improved mask ReCNN model. Biosyst. Eng. 2020, 193, 264–278. [Google Scholar] [CrossRef]

- Farjon, G.; Krikeb, O.; Aharon, B.H.; Alchanatis, V. Detection and counting of flowers on apple trees for better chemical thinning decisions. Preci. Agric. 2020, 21, 503–521. [Google Scholar] [CrossRef]

- Wu, D.H.; Lv, S.C.; Jiang, M.; Song, H.B. Using channel pruning-based Yolov4 deep learning algorithm for the real-time and accurate detection of apple flowers in natural environments. Comput. Electron. Agric. 2020, 178, 105742. [Google Scholar] [CrossRef]

- Zhang, C.L.; Mouton, C.; Valente, J.; Kooistra, L.; van Ooteghem, R.; de Hoog, D.; van Dalfsen, P.; de Jong, P.F. Automatic flower cluster estimation in apple orchards using aerial and ground based point clouds. Biosyst. Eng. 2022, 221, 164–180. [Google Scholar] [CrossRef]

- Liu, S.X.; Sun, L.L.; Wang, Z.; Wang, R.R.; Zhang, H.J.; Wang, J.X. Fuzzy clustering accurate estimation model of apple tree flowers with complex background. J. Chin. Agric. Mech. 2017, 38, 74–81. [Google Scholar]

- Crtomir, R.; Urska, C.; Stanislav, T.; Denis, S.; Karmen, P.; Pavlovic, M.; Marjan, V. Application of neural networks and image visualization for early forecast of apple yield. Erwerbs-Obstbau. 2012, 54, 69–76. [Google Scholar] [CrossRef]

- Aggelopoulou, A.D.; Bochtis, D.; Fountas, S.; Swain, K.C.; Gemtos, T.A.; Nanos, G.D. Yield prediction in apple orchards based on image processing. Preci. Agric. 2011, 12, 448–456. [Google Scholar] [CrossRef]

- Xia, Y.; Lei, X.H.; Qi, Y.N.; Xyu, T.; Yuan, Q.C.; Pan, J.; Jiang, S.K.; Lyu, X.L. Detection of pear inflorescence based on improved Ghost-Yolov5s-BiFPN algorithm. Smart Agric. 2022, 4, 108–119. [Google Scholar]

- Zhou, G.H.; Sun, L.L.; Liang, F.F.; Zhang, X.H. Pear flower density classification based on improved density peak clustering algorithm. J. Trans. Chin. Soc. Agric. Eng. 2023, 39, 126–135. [Google Scholar]

- Lyu, S.L.; Zhao, Y.W.; Li, R.Y.; Li, Z.; Fan, R.J.; Li, Q.F. Embedded sensing system for recognizing citrus flowers using cascaded fusion Yolov4-CF + FPGA. Sensors 2022, 22, 1255. [Google Scholar] [CrossRef]

- Deng, Y.; Wu, H.R.; Zhu, H.J. Recognition and counting of citrus flowers based on instance segmentation. J. Trans. Chin. Soc. Agric. Eng. 2020, 36, 200–207. [Google Scholar]

- Du, W.S.; Wang, C.Y.; Zhu, Y.J.; Liu, L.P.; Liu, P. Fruit stem clamping points location for table grape thinning using improved mask R-CNN. J. Trans. Chin. Soc. Agric. Eng. 2022, 3, 169–177. [Google Scholar]

- Lin, J.Q.; Li, J.; Yang, Z.; Lu, H.Z.; Ding, Y.H.; Cui, H.J. Estimating litchi flower number using a multicolumn convolutional neural network based on a density map. Precis. Agric. 2022, 23, 1226–1247. [Google Scholar] [CrossRef]

- Wang, Z.L.; Underwood, J.; Walsh, K.B. Machine vision assessment of mango orchard flowering. Comput. Electron. Agric. 2018, 151, 501–511. [Google Scholar] [CrossRef]

- Underwood, J.P.; Hung, C.; Whelan, B.; Sukkarieh, S. Mapping almond orchard canopy volume, flowers, fruit and yield using lidar and vision sensors. Comput. Electron. Agric. 2016, 130, 83–96. [Google Scholar] [CrossRef]

- Horton, R.; Cano, E.; Bulanon, D.; Fallahi, E. Peach flower monitoring using aerial multispectral imaging. J. Imaging 2017, 3, 2. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).