Heat and Mass Transfer Kinetics on the Chemical and Sensory Quality of Arabica Coffee Beans

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Roasting Procedures

2.3. Medium Infrared (MID) Spectroscopy

2.4. Cupping of Sensory Evaluation

2.5. Statistical Analysis

3. Results and Discussion

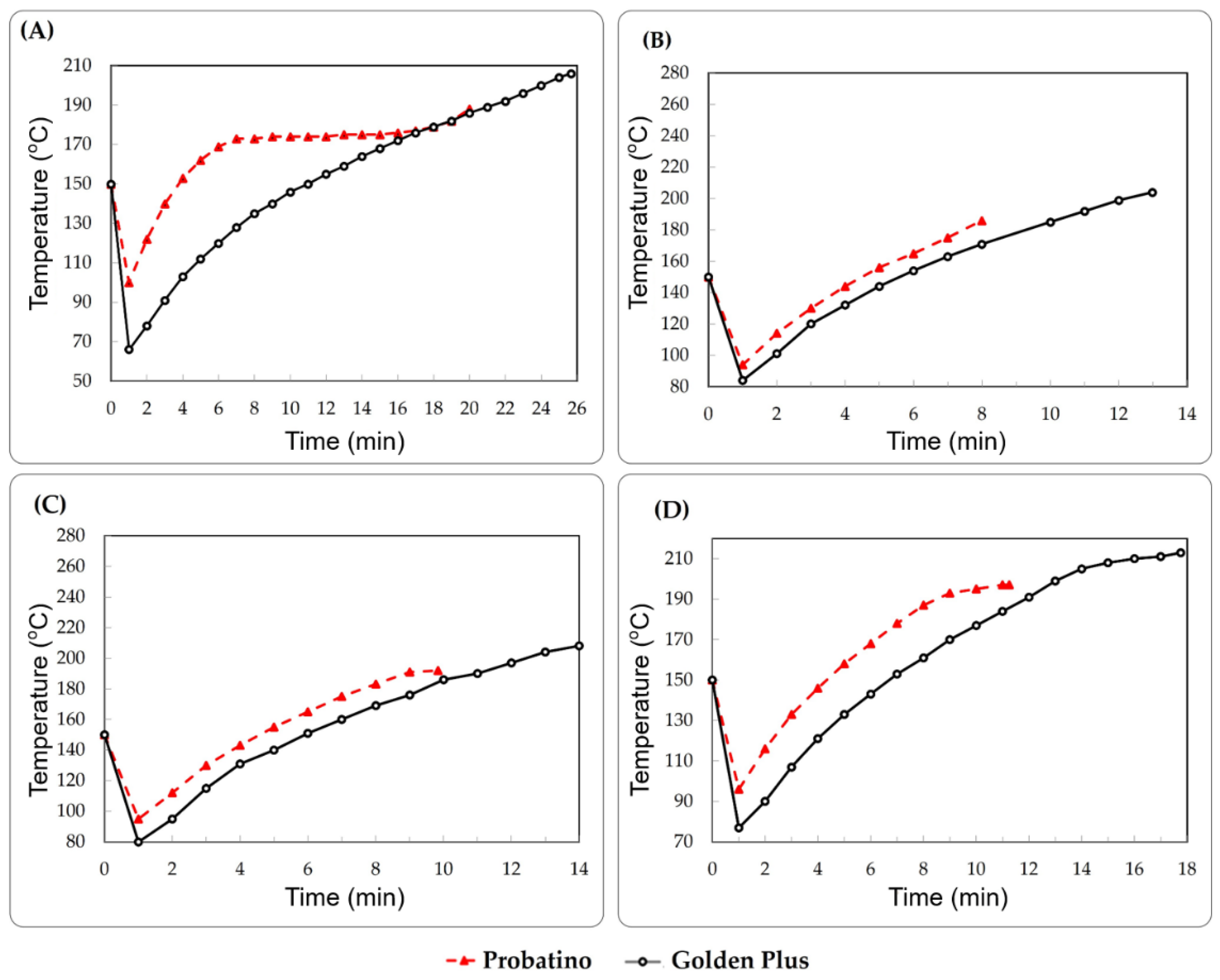

3.1. Roasting Profiles

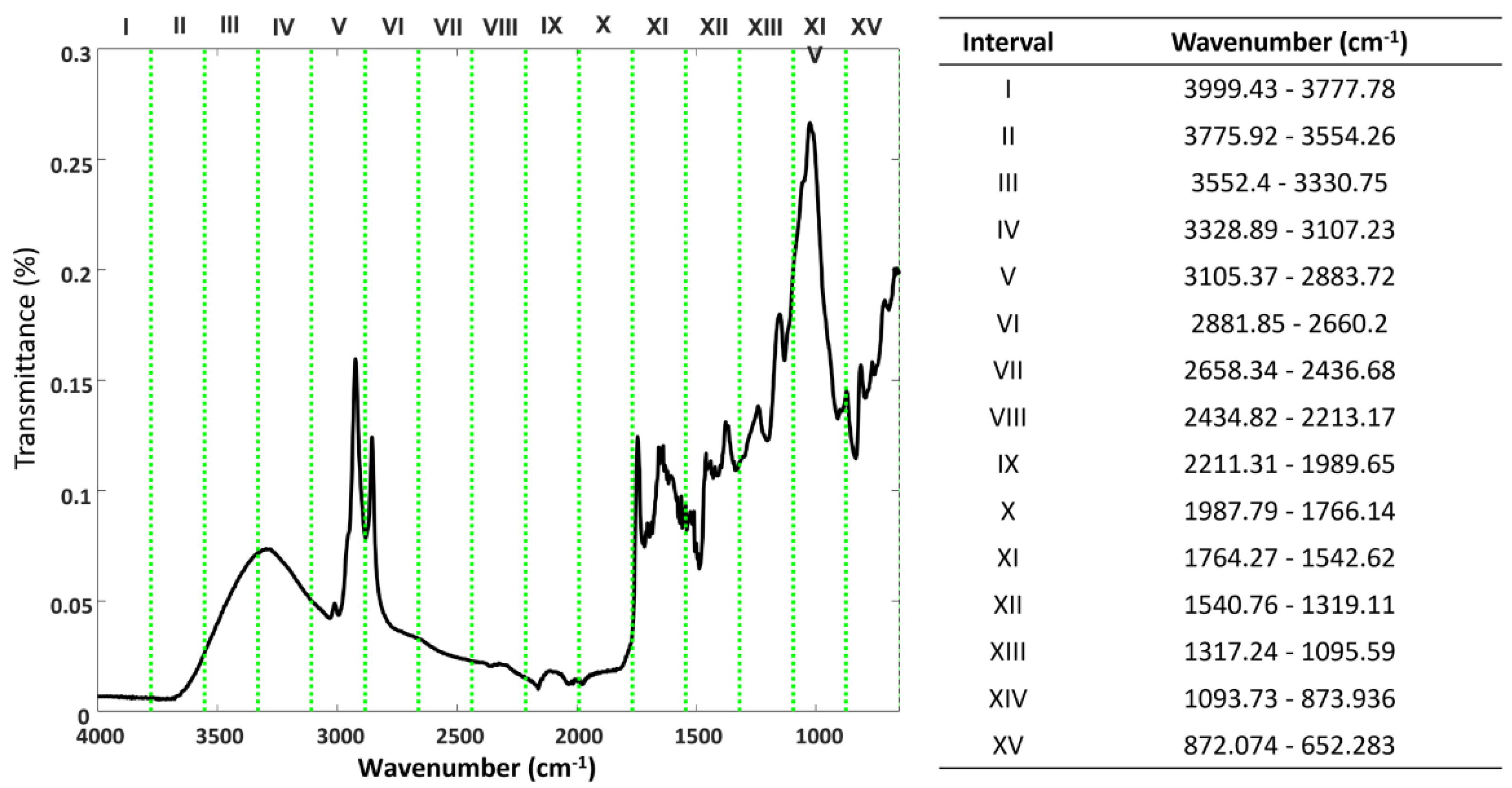

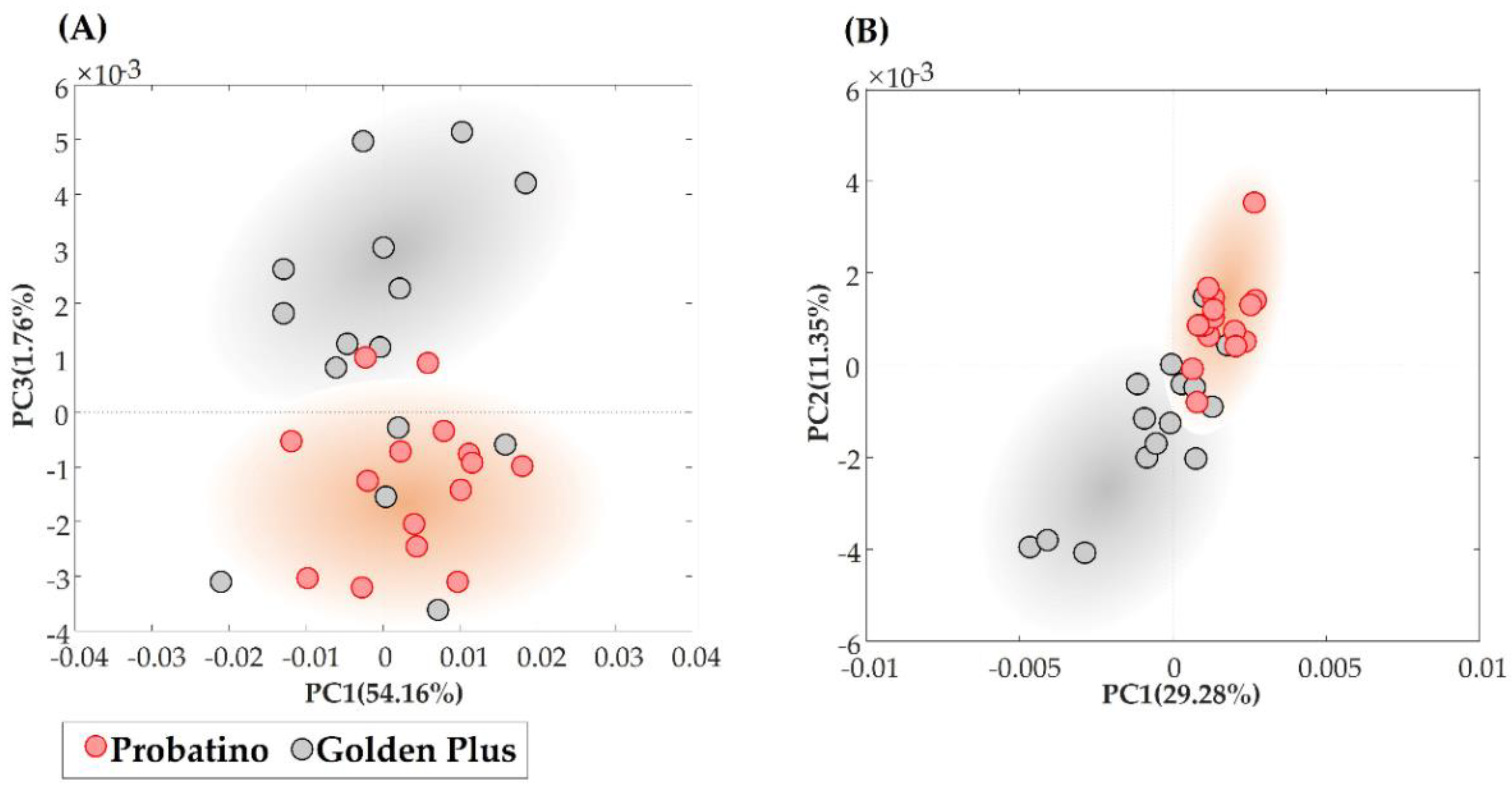

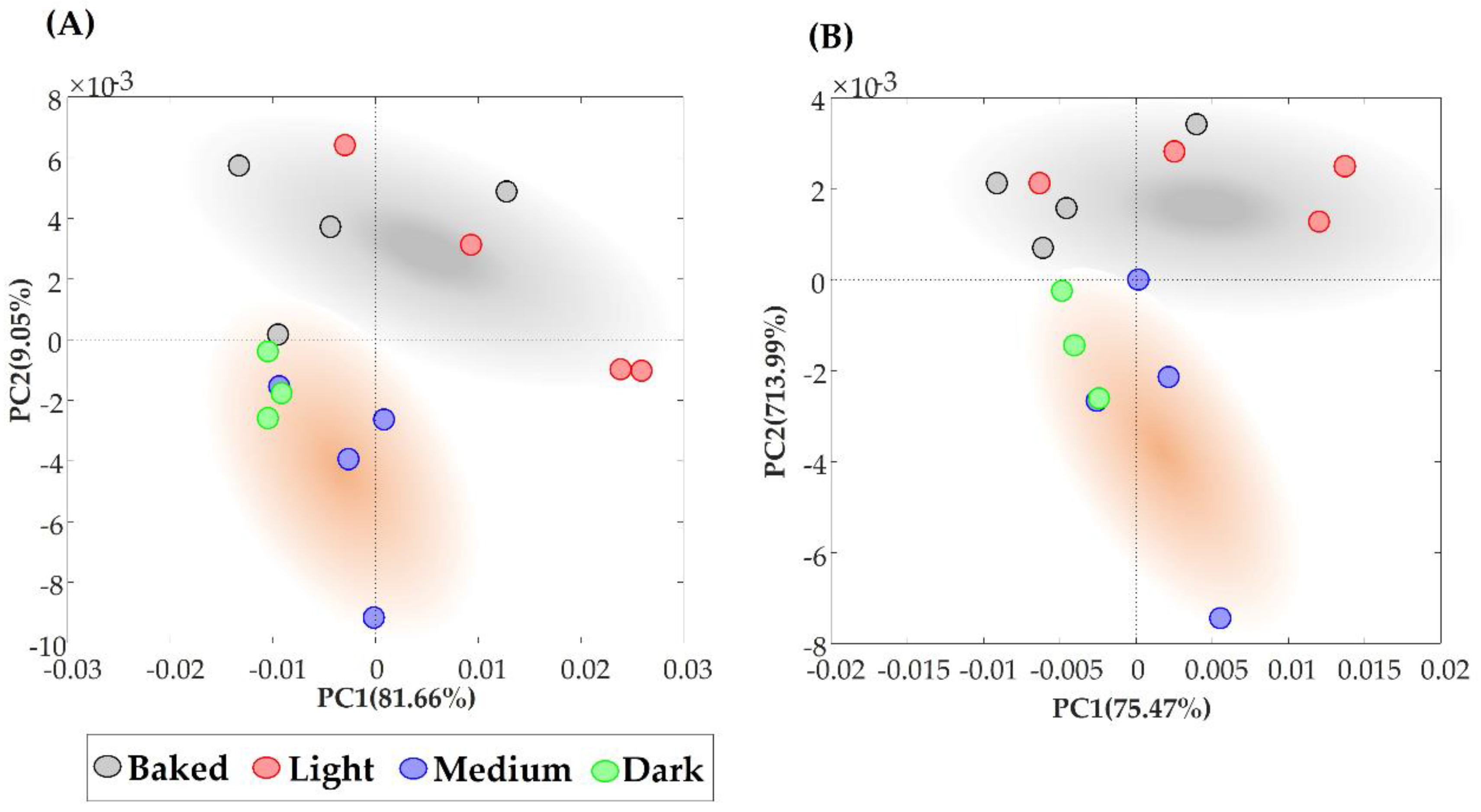

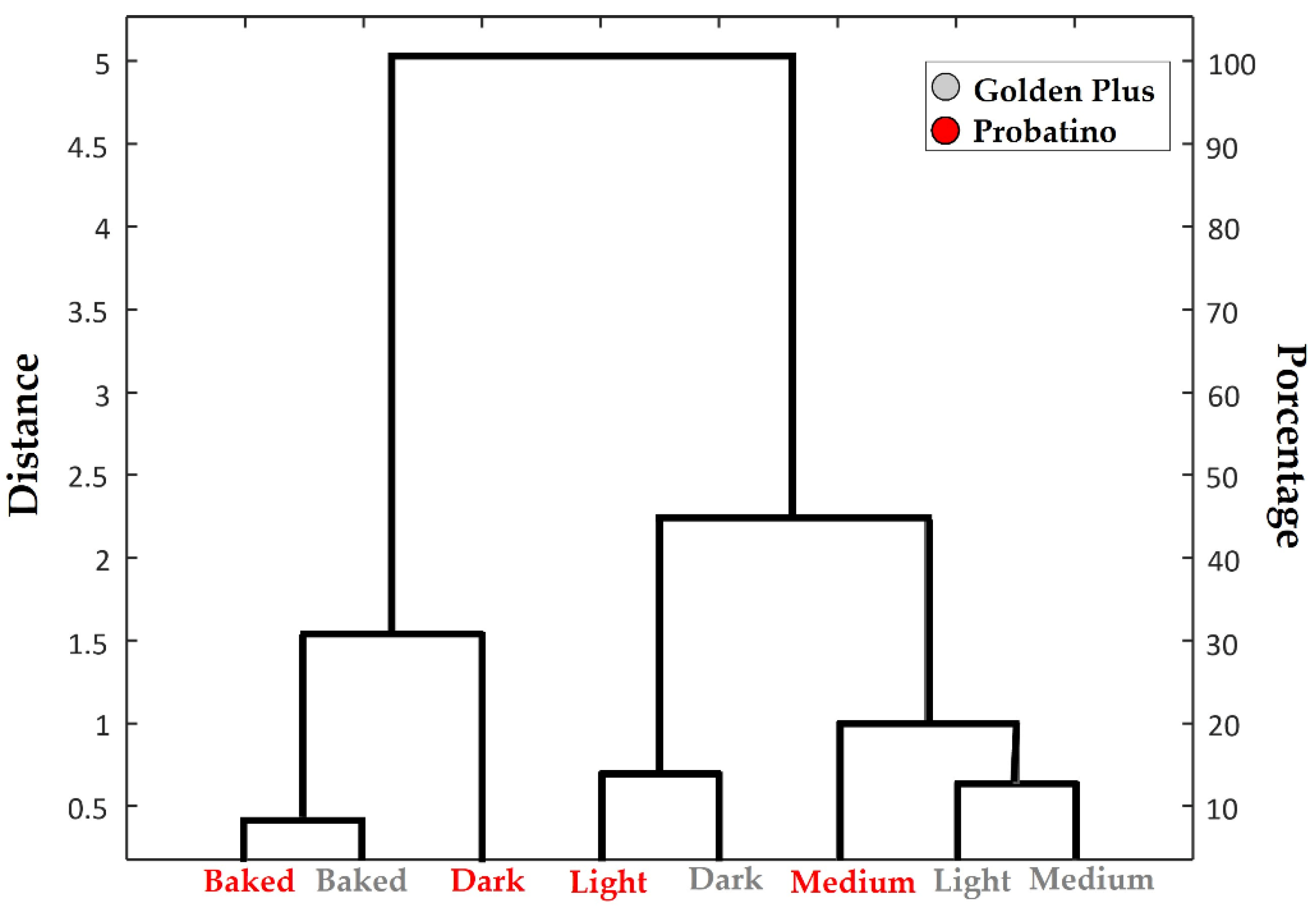

3.2. Chemical Profiles

3.3. Sensory Profiles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anastácio, L.M.; Silva, M.C.S.; Debona, D.G.; Veloso, T.G.R.; Entringer, T.L.; Bullergahn, V.B.; Luz, J.M.R.; Moreli, A.P.; Megumi, M.C.; Pereira, L.L. Relationship between physical changes in the coffee bean due to roasting profiles and the sensory attributes of the coffee beverage. Eur. Food Res.Technol. 2022, 248, 1–13. [Google Scholar] [CrossRef]

- Schenker, S.; Rothgeb, T. The roast-creating the beans’ signature. In The Craft and Science of Coffee; Elsevier Inc.: Amsterdam, The Netherlands, 2017; Volume 1, pp. 245–271. [Google Scholar]

- Debona, D.G.; Oliveira, E.C.S.; Ten Caten, C.S.; Guarçoni, R.C.; Moreira, T.R.; Pereira, L.L.; Moreli, A.P. Sensory analysis and mid-infrared spectroscopy for discriminating roasted specialty coffees. Coffee Sci. 2021, 16, 161878. [Google Scholar] [CrossRef]

- Pramudita, D.; Araki, T.; Sagara, Y.; Tambunan, A.H. Roasting and Colouring Curves for Coffee Beans with Broad Time-Temperature Variations. Food Bioprocess Technol. 2017, 10, 1509–1520. [Google Scholar] [CrossRef]

- Vosloo, J. Heat and Mass Transfer Model for a Coffee Roasting Process. Master’s Thesis, North-West University, Potchefstroom Campus of the North-West, Potchefstroom, South Africa, 2017. [Google Scholar]

- Bottazzi, D.; Farina, S.; Milani, M.; Montorsi, L. A numerical approach for the analysis of the coffee roasting process. J. Food Eng. 2012, 112, 243–252. [Google Scholar] [CrossRef]

- Fabbri, A.; Cevoli, C.; Romani, S.; Rosa, M.D. Numerical model of heat and mass transfer during roasting coffee using 3D digitised geometry. Procedia Food Sci. 2011, 1, 742–746. [Google Scholar] [CrossRef][Green Version]

- Kokolj, U.; Škerget, L.; Ravnik, J. A numerical model of the shortbread baking process in a forced convection oven. Appl. Therm. Eng. 2017, 111, 1304–1311. [Google Scholar] [CrossRef]

- Huang, J.-P. Theoretical Thermotics: Transformation Thermotics and Extended Theories for Thermal Matamaterials, 1st ed.; Springer Nature: Singapore, 2020; p. 272. [Google Scholar]

- Pereira, L.L.; Moreira, T.R. Quality Determinants In Coffee Production, 1st ed.; Springer Nature: Cham, Switzerland, 2021; p. 443. [Google Scholar]

- Robert, V.D. Microwaves in the Food Processing Industry, 1st ed.; Food Science and Technology; Academic Press: London, UK, 1985; p. 234. [Google Scholar]

- SCA-Specialty Coffee Association of American. Protocols 23. 2008. Available online: http://www.scaa.org/PDF/resources/cupping-protocols.pdf (accessed on 15 July 2021).

- Craig, A.P.; Botelho, B.G.; Oliveira, L.S.; Franca, A.S. Mid infrared spectroscopy and chemometrics as tools for the classification of roasted coffees by cup quality. Food Chem. 2018, 245, 1052–1061. [Google Scholar] [CrossRef]

- Marin, E.P. Infrared Spectroscopy and Its Applications. Degree Thessis, Universidade Estadual Paulista, Rio Claro, Brazil, 2013. [Google Scholar]

- Belchior, V.; Botelho, B.G.; Casal, S.; Oliveira, L.S.; Franca, A.S. FTIR and Chemometrics as Effective Tools in Predicting the Quality of Specialty Coffees. Food Anal. Methods 2020, 13, 275–283. [Google Scholar] [CrossRef]

- Pereira, L.L.; Guarçoni, R.C.; Pinheiro, P.F.; Osório, V.M.; Pinheiro, C.A.; Moreira, T.R.; ten Caten, C.S. New propositions about coffee wet processing: Chemical and sensory perspectives. Food Chem. 2020, 310, 125943. [Google Scholar] [CrossRef]

- Chu, B.; Yu, K.; Zhao, Y.; He, Y. Development of Noninvasive Classification Methods for Different Roasting Degrees of Coffee Beans Using Hyperspectral Imaging. Sensors 2018, 18, 1259. [Google Scholar] [CrossRef]

- De Luca, S.; de Filippis, M.; Bucci, R.; Magrì, A.D.; Magrì, A.L.; Marini, F. Characterization of the effects of different roasting conditions on coffee samples of different geographical origins by HPLC-DAD, NIR and chemometrics. Microchem. J. 2016, 129, 348–361. [Google Scholar] [CrossRef]

- Atilla. Atilla 2 kg Gold Plus. 2020. Available online: https://www.atilla.com.br/p/atilla-2kg-gold-plus/ (accessed on 24 May 2020).

- Probatino. Probat: Product Data Sheet Probatino, Type 2. 2020. Available online: https://probatleogap.com.br/produtos/torradores/cafes-especiais/probatino/ (accessed on 24 May 2020).

- Pavia, D.L.; Lampman, G.M.; Kriz, G.S. Introduction to Spectroscopy; Thomson Learning: New York, NY, USA, 2020; p. 733. [Google Scholar]

- Silverstein, R.M.; Webster, F.X.; Kiemle, D.J. Spectrometric Identification of Organic Compounds, 7th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2005; p. 530. [Google Scholar]

- Tavares, K.M.; Pereira, R.G.F.A.; Nunes, C.A.; Pinheiro, A.C.M.; Rodarte, M.P. Espectroscopia no infravermelho médio e análise sensorial aplicada à detecção de adulteração de café torrado por adição de cascas de café. Quim Nova 2012, 35, 1164–1168. [Google Scholar] [CrossRef]

- CQI. Coffee Quality Institute. 2022. Available online: https://www.coffeeinstitute.org/ (accessed on 24 October 2020).

- Okamura, M.; Soga, M.; Yamada, Y.; Kobata, K.; Kaneda, D. Development and evaluation of roasting degree prediction model of coffee beans by machine learning. Procedia Comput. Sci. 2021, 192, 4602–4608. [Google Scholar] [CrossRef]

- Bustos-Vanegas, J.D.; Corrêa, P.C.; Martins, M.A.; Baptestini, F.M.; Campos, R.C.; de Oliveira, G.H.H.; Nunes, E.H.M. Developing predictive models for determining physical properties of coffee beans during the roasting process. Ind. Crops Prod. 2018, 112, 839–845. [Google Scholar] [CrossRef]

- Schenker, S.; Handschin, S.; Frey, B.; Perren, R.; Escher, F. Pore Structure of Coffee Beans Affected by Roasting Conditions. J. Food Sci. 2000, 65, 452–457. [Google Scholar] [CrossRef]

- Zhu, M.; Long, Y.; Ma, Y.; Huang, Y.; Wan, Y.; Yu, Q.; Xie, J.; Chen, Y. Investigation of thermal contaminants in coffee beans induced by roasting: A kinetic modeling approach. Food Chem. 2022, 378, 32063. [Google Scholar] [CrossRef]

- Park, S.; Jo, A.; Lee, K.G. Effect of various roasting, extraction and drinking conditions on furan and 5-hydroxymethylfurfural levels in coffee. Food Chem. 2021, 358, 129806. [Google Scholar] [CrossRef]

- Grzelczyk, J.; Fiurasek, P.; Kakkar, A.; Budryn, G. Evaluation of the thermal stability of bioactive compounds in coffee beans and their fractions modified in the roasting process. Food Chem. 2022, 387, 132888. [Google Scholar] [CrossRef]

- Kang, G.W.; Piao, Z.; Ko, J.Y. Effects of water types and roasting points on consumer liking and emotional responses toward coffee. Food Qual. Prefer. 2022, 101, 104631. [Google Scholar] [CrossRef]

- Alessandrini, L.; Romani, S.; Pinnavaia, G.; Rosa, M.D. Near infrared spectroscopy: An analytical tool to predict coffee roasting degree. Anal. Chim. Acta 2008, 625, 95–102. [Google Scholar] [CrossRef]

- Cestari, A. Development of a fast and simple method to identify pure Arabica coffee and blended coffee by Infrared Spectroscopy. J. Food Sci. Technol. 2021, 58, 3645–3654. [Google Scholar] [CrossRef] [PubMed]

- Barbin, D.F.; Felicio, A.L.d.S.M.; Sun, D.W.; Nixdorf, S.L.; Hirooka, E.Y. Application of infrared spectral techniques on quality and compositional attributes of coffee: An overview. Food Res. Int. 2014, 61, 23–32. [Google Scholar] [CrossRef]

- Reis, N.; Franca, A.S.; Oliveira, L.S. Discrimination between roasted coffee, roasted corn and coffee husks by Diffuse Reflectance Infrared Fourier Transform Spectroscopy. Food Sci. Technol. 2013, 50, 715–722. [Google Scholar] [CrossRef]

- Pavia, D.L.; Lampman, G.M.; Kriz, G.S. Introduction to Spectroscopy; Thomson Learning: Orlando, FL, USA, 2014; p. 784. [Google Scholar]

- Assis, C.; Pereira, H.V.; Amador, V.S.; Augusti, R.; de Oliveira, L.S.; Sena, M.M. Combining mid infrared spectroscopy and paper spray mass spectrometry in a data fusion model to predict the composition of coffee blends. Food Chem. 2019, 281, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Lee, L.W.; Cheong, M.W.; Curran, P.; Yu, B.; Liu, S.Q. Modulation of coffee aroma via the fermentation of green coffee beans with Rhizopus oligosporus: II Effects of different roast levels. Food Chem. 2016, 211, 925–936. [Google Scholar] [CrossRef]

- Poisson, L.; Blank, I.; Dunkel, A.; Hofmann, T. The chemistry of roasting—Decoding flavor formation. In The Craft and Science of Coffee; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 273–309. [Google Scholar]

- Debona, D.G.; Pinheiro, P.F.; Pinheiro, C.A.; Gomes, W.S.; Abreu, R.O.; Moreli, A.P.; Siqueira, E.A.; Pereira, L.L. Avaliação da composição química de café arabica submetido a diferentes perfis de torra. IFES Ciênc. 2020, 3, 124–133. [Google Scholar] [CrossRef]

- Noor, N.; Shah, A.; Gani, A.; Massodi, F.A. Microencapsulation of caffeine loaded in polysaccharide based delivery systems. Food Hydrocoll. 2018, 82, 312–321. [Google Scholar] [CrossRef]

- Nogueira, M.; Trugo, L.C. Distribuição de isômeros de ácido clorogênico e teores de cafeína e trigonelina em cafés solúveis brasileiros. Ciência e Tecnol. Aliment. 2003, 23, 296–299. [Google Scholar] [CrossRef]

- Obeidat, S.M.; Hammoudeh, A.Y.; Alomary, A.A. Application of ftir spectroscopy for assessment of green coffee beans according to their origin. J. Appl. Spectrosc. 2018, 84, 977–981. [Google Scholar] [CrossRef]

- Williamson, K.; Hatzakis, E. Evaluating the effect of roasting on coffee lipids using a hybrid targeted-untargeted NMR approach in combination with MRI. Food Chem. 2019, 299, 125039. [Google Scholar] [CrossRef]

- Chindapan, N.; Soydok, S.; Devahastin, S. Roasting Kinetics and Chemical Composition Changes of Robusta Coffee Beans During Hot Air and Superheated Steam Roasting. J. Food Sci. 2019, 84, 292–302. [Google Scholar] [CrossRef] [PubMed]

- Giacalone, D.; Degn, T.K.; Yang, N.; Liu, C.; Fisk, I.; Münchow, M. Common roasting defects in coffee: Aroma composition, sensory characterization and consumer perception. Food Qual. Prefer. 2019, 71, 463–474. [Google Scholar] [CrossRef]

- Yang, N.; Liu, C.; Liu, X.; Degn, T.K.; Munchow, M.; Fisk, I. Determination of volatile marker compounds of common coffee roast defects. Food Chem. 2016, 211, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, E.C.S.; da Luz, J.M.R.; de Castro, M.G.; Filgueiras, P.R.; Guarçoni, R.C.; de Castro, E.V.R.; da Silva, M.C.S.; Pereira, L.L. Chemical and sensory discrimination of coffee: Impacts of the planting altitude and fermentation. Eur. Food Res. Technol. 2022, 248, 659–669. [Google Scholar] [CrossRef]

- Machado, J.L.; Tomaz, M.A.; Luz, J.M.R.; Osório, V.M.; Costa, A.V.; Colodetti, T.V.; Debona, D.G.; Pereira, L.L. Evaluation of genetic divergence of coffee genotypes using the volatile compounds and sensory attributes profile. J. Food Sci. 2022, 87, 383–395. [Google Scholar] [CrossRef] [PubMed]

| Characteristics | Probat®-Probatino * | Atilla®-2 kg Gold Plus ** |

|---|---|---|

| Length (m) | 1.13 | 1.35 |

| Width (m) | 0.56 | 0.75 |

| Height (m) | 0.81 | 1.90 |

| Weight (kg) | 115 | 180 |

| Fuel type | Liquefied Petroleum Gas (LPG) | LPG |

| Power (kw) | 0.55 | 0.75 |

| Capacity (kg) | 0.8 to 1.2 | 2.0 |

| Roasting time (min) | 8 to 15 | 15 |

| Drum material | Carbon steel | Carbon steel |

| Drum wall type | Double | Single |

| Drum wall thickness (mm) | Not informed | 2 |

| Drum wall diameter (mm) | 200 (inner) | 285 |

| Drum wall lenght (mm) | 300 (inner) | 200 |

| Thermal insulation | Ceramic fiber | Absent |

| Atilla®-2 Kg Gold Plus | Probat®-Probatino | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Roasting Degrees | 1 Disk Scores | Roasting Time (min) | Heating Rate (°C·min−1) | Final Temp (°C) | Weight Loss (%) | Roasting Time (min) | Heating Rate (°C·min−1) | Final Temp (°C) | Weight Loss (%) |

| Baked | 80 | 25.67 | 6 | 206 | 9.8 b B | 20.00 | 5 | 188 | 12.7 a A |

| Light | 65 | 12.98 | 10 | 204 | 8.0 b B | 8.67 | 12 | 190 | 7.0 c A |

| Medium | 68 | 14.33 | 9 | 208 | 9.8 b A | 9.83 | 11 | 192 | 10.0 b A |

| Dark | 56 | 17.75 | 8 | 213 | 11.7 a A | 11.25 | 9 | 197 | 12.3 a A |

| Roasting Profiles | Roasters | Average 1 | ||||||

|---|---|---|---|---|---|---|---|---|

| Golden Plus | Probatino | |||||||

| Baked | 79.40 ± 2.43 | ab | A | 79.35 ± 2.96 | a | A | 79.38 ± 2.69 | a |

| Light | 80.60 ± 2.04 | ab | A | 82.10 ± 2.79 | a | A | 81.35 ± 2.41 | a |

| Medium | 82.70 ± 3.58 | a | A | 81.90 ± 1.24 | a | A | 82.30 ± 2.41 | a |

| Dark | 78.00 ± 2.76 | b | A | 81.20 ± 2.14 | a | A | 79.60 ± 2.45 | a |

| Average | 80.18 ± 2.7 | A | 81.14 ± 2.28 | A | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Debona, D.G.; Louvem, R.F.; Luz, J.M.R.d.; Nariyoshi, Y.N.; Castro, E.V.R.d.; Oliveira, E.C.d.S.; Guarconi, R.C.; Castro, M.G.d.; Oliveira, G.F.d.; Partelli, F.L.; et al. Heat and Mass Transfer Kinetics on the Chemical and Sensory Quality of Arabica Coffee Beans. Agronomy 2022, 12, 2880. https://doi.org/10.3390/agronomy12112880

Debona DG, Louvem RF, Luz JMRd, Nariyoshi YN, Castro EVRd, Oliveira ECdS, Guarconi RC, Castro MGd, Oliveira GFd, Partelli FL, et al. Heat and Mass Transfer Kinetics on the Chemical and Sensory Quality of Arabica Coffee Beans. Agronomy. 2022; 12(11):2880. https://doi.org/10.3390/agronomy12112880

Chicago/Turabian StyleDebona, Danieli Grancieri, Renata Falqueto Louvem, José Maria Rodrigues da Luz, Yuri Nascimento Nariyoshi, Eustaquio Vinicius Ribeiro de Castro, Emanuele Catarina da Silva Oliveira, Rogerio Carvalho Guarconi, Marina Gomes de Castro, Gustavo Falquetto de Oliveira, Fábio Luiz Partelli, and et al. 2022. "Heat and Mass Transfer Kinetics on the Chemical and Sensory Quality of Arabica Coffee Beans" Agronomy 12, no. 11: 2880. https://doi.org/10.3390/agronomy12112880

APA StyleDebona, D. G., Louvem, R. F., Luz, J. M. R. d., Nariyoshi, Y. N., Castro, E. V. R. d., Oliveira, E. C. d. S., Guarconi, R. C., Castro, M. G. d., Oliveira, G. F. d., Partelli, F. L., Silva, M. d. C. S. d., Bellon, A. P., & Pereira, L. L. (2022). Heat and Mass Transfer Kinetics on the Chemical and Sensory Quality of Arabica Coffee Beans. Agronomy, 12(11), 2880. https://doi.org/10.3390/agronomy12112880