Enabling Industrial Re-Use of Large-Format Additive Manufacturing Molding and Tooling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

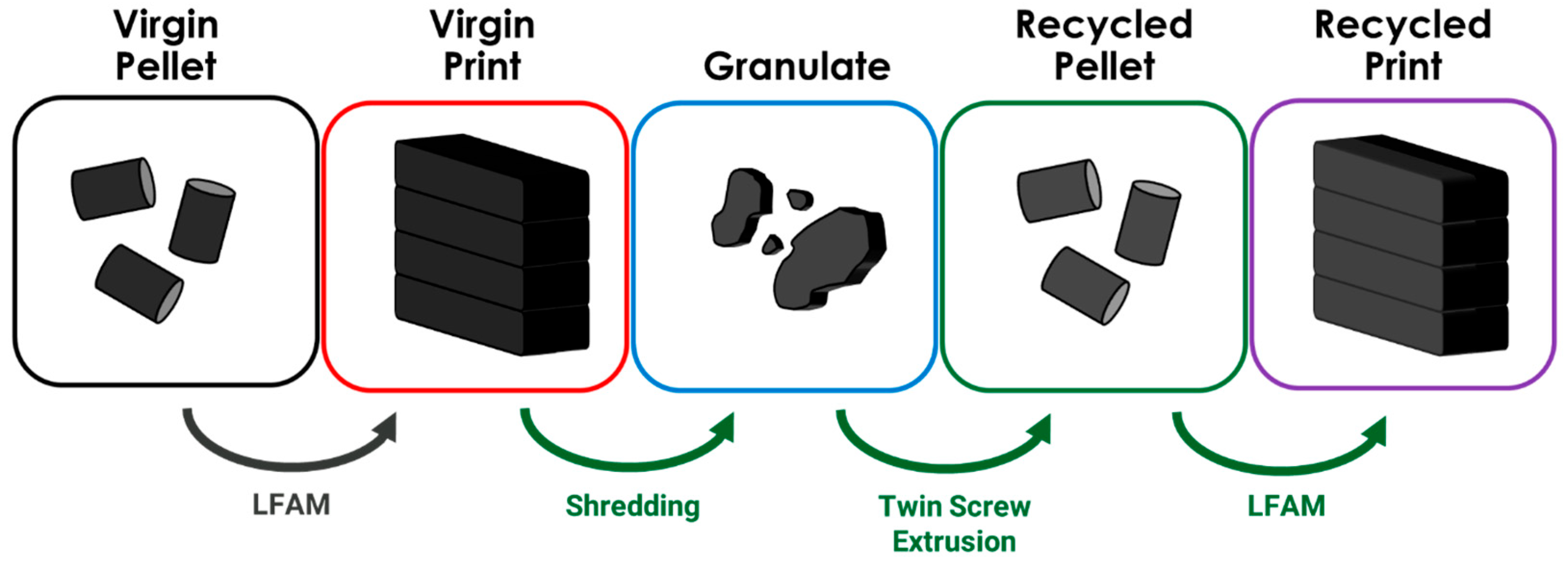

2.2. Material Processing

2.3. Shredding

2.4. Twin Screw Extrusion

2.5. Large-Format Additive Manufacturing (LFAM)

2.6. Fiber Length and Granulate Analysis

2.7. Mechanical Testing

2.8. Thermogravimetric Analysis (TGA)

2.9. Dynamic Mechanical Analysis (DMA)

2.10. Coefficient of Thermal Expansion (CTE)

2.11. Gel Permeation Chromatography (GPC)

2.12. Pycnometry

2.13. Scanning Electron Microscopy

2.14. Statistical Analysis

3. Results and Discussion

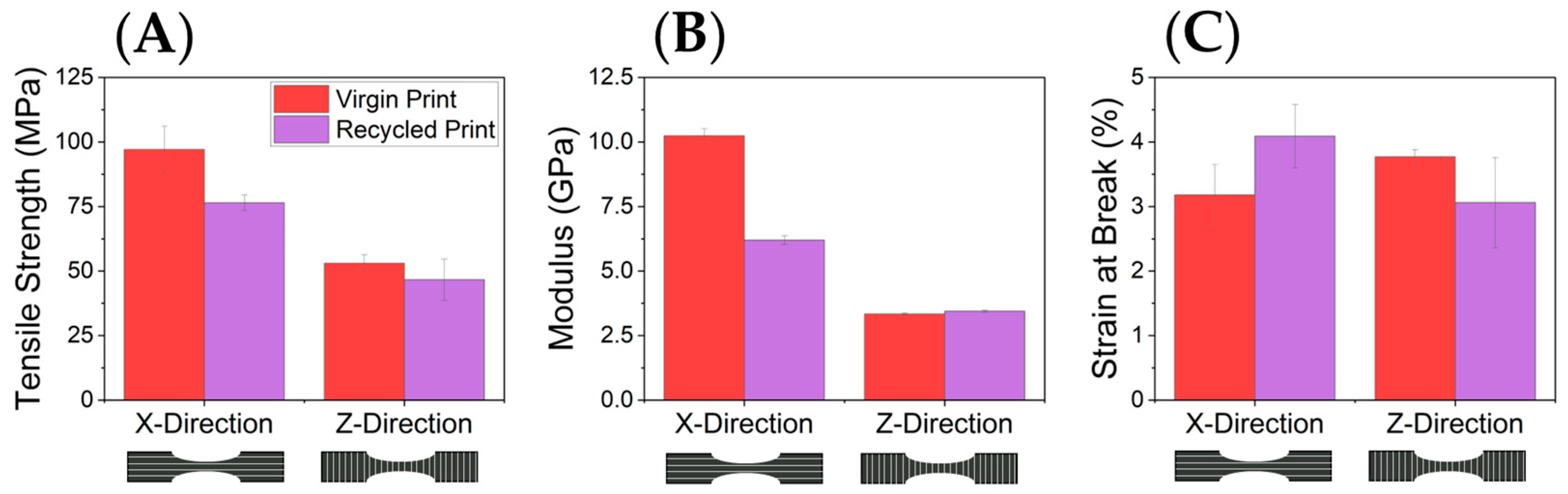

3.1. Mechanical Performance

3.2. Particle Size Analysis and Density

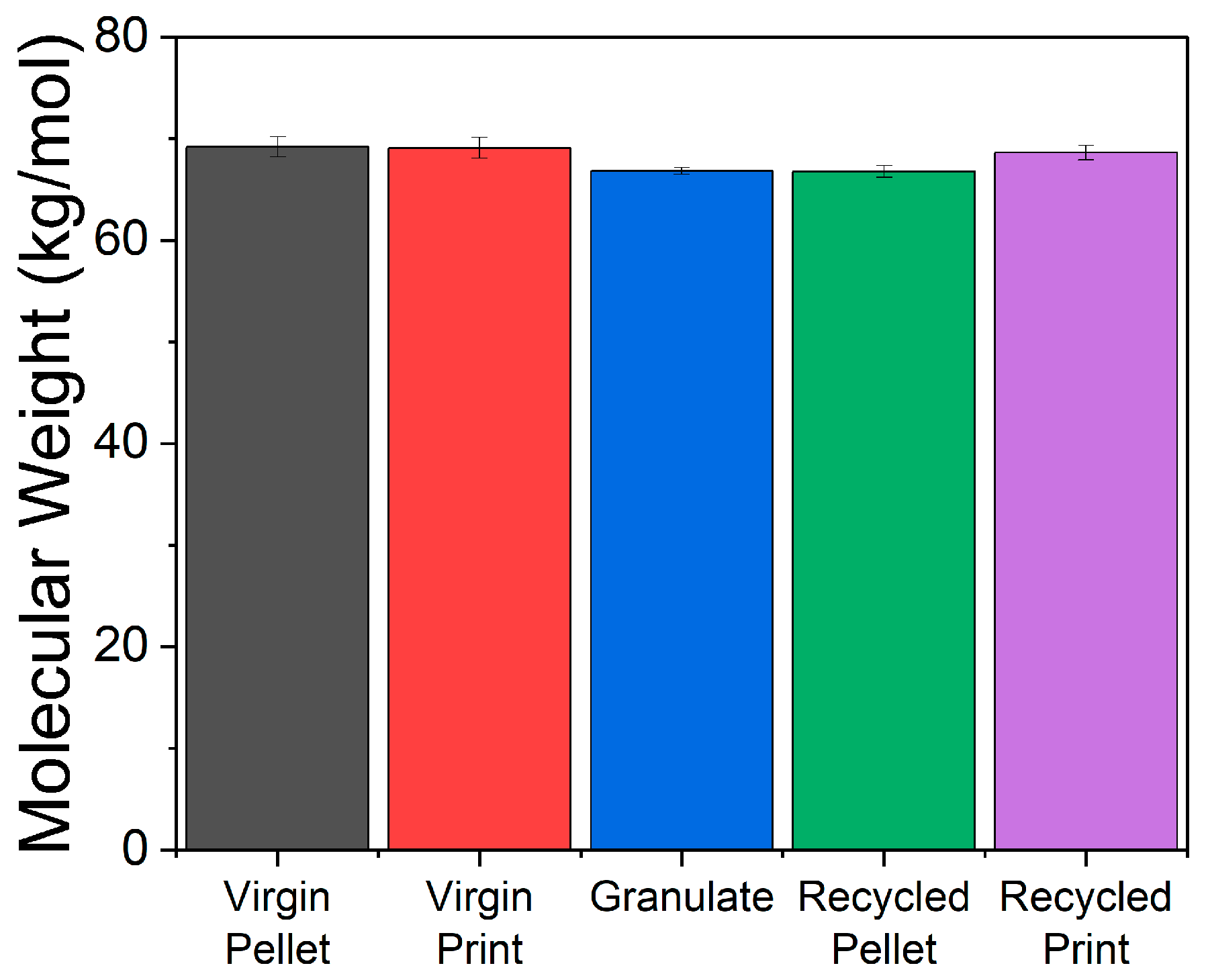

3.3. Molecular Weight Analysis

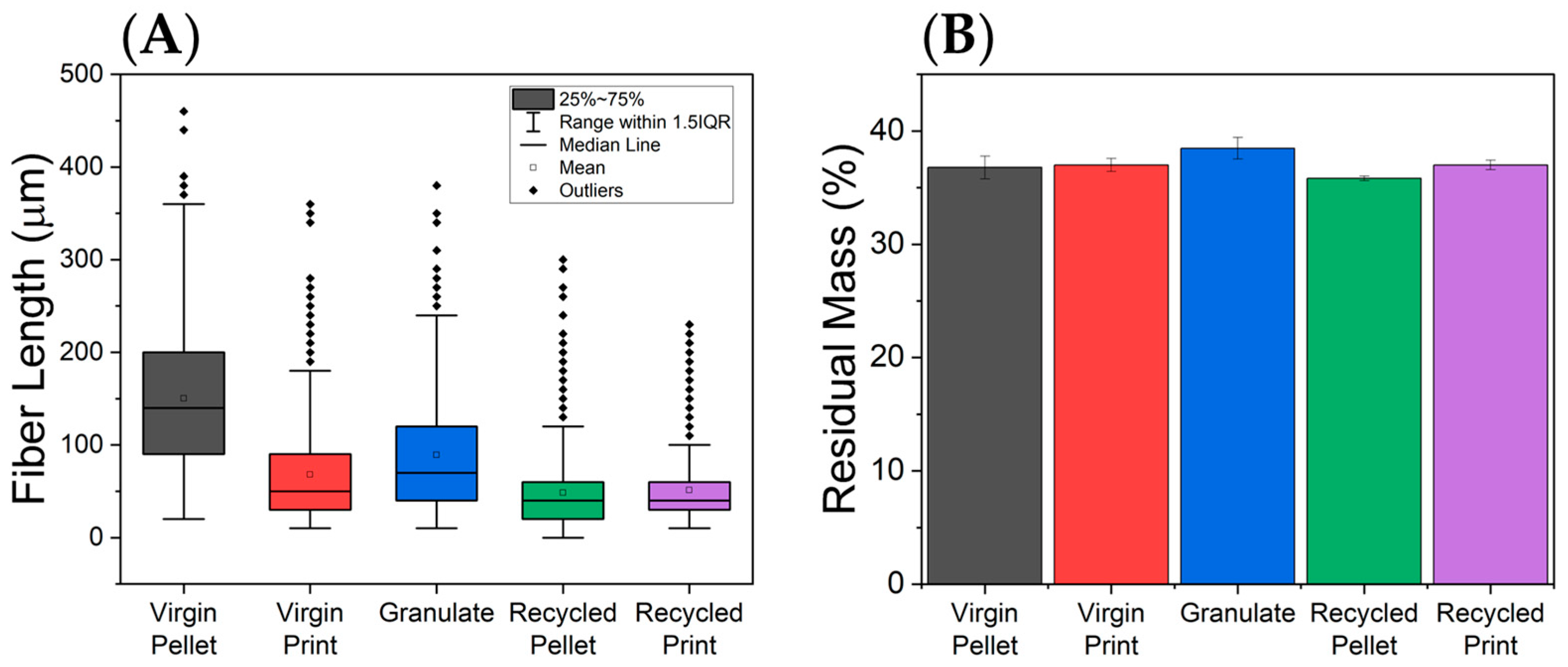

3.4. Fiber Length Analysis and Fiber Content

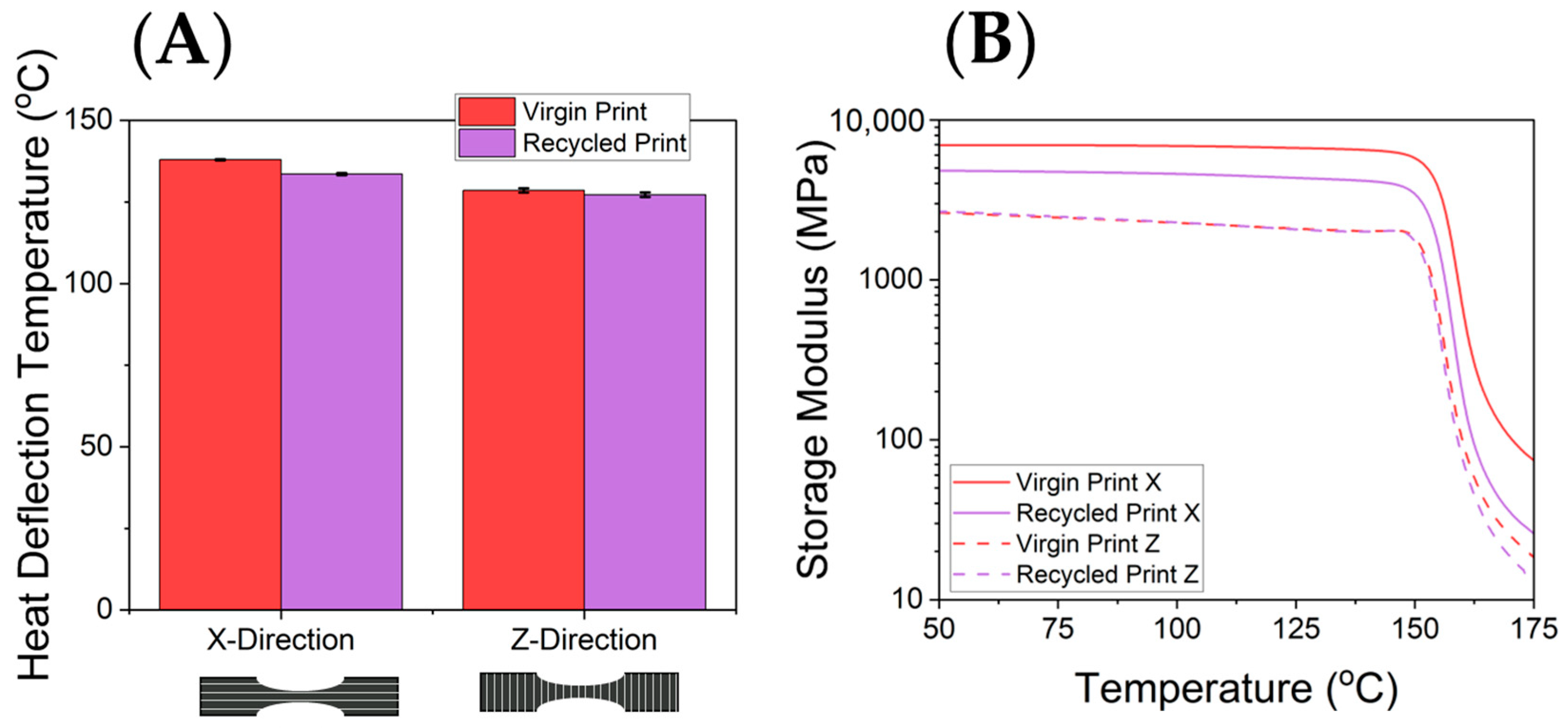

3.5. Thermomechanical Performance

3.6. Coefficient of Thermal Expansion

4. Conclusions

- Mechanical recycling significantly reduced fiber length, with a 55.0% decrease observed during the transition from virgin pellets to virgin prints due to thermomechanical shear in the nozzle.

- Recycled prints exhibited a further 24.6% reduction in average fiber length compared to virgin prints, while fiber lengths remained largely unaffected during shredding.

- This reduction in fiber length correlated with a 21% drop in X-direction tensile strength, a 39% reduction in tensile modulus, and a 6.8% increase in X-direction CTE.

- Conversely, Z-direction modulus improved by 4%, Z-direction strength remained unchanged, and sample density increased, indicating reduced bead porosity.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Egbo, M.K. A fundamental review on composite materials and some of their applications in biomedical engineering. J. King Saud Univ.-Eng. Sci. 2021, 33, 557–568. [Google Scholar] [CrossRef]

- Schweizer, K.; Bhandari, S.; Lopez-Anido, R.A.; Korey, M.; Tekinalp, H. Recycling Large-Format 3D Printed Polymer Composite Formworks Used for Casting Precast Concrete–Technical Feasibility and Challenges. J. Compos. Constr. 2024, 28, 1–16. [Google Scholar] [CrossRef]

- Sproul, E.; Williams, M.; Rencheck, M.L.; Korey, M.; Ennis, B. Life Cycle Assessment of Wind Turbine Blade Recycling Approaches in the United States. In Proceedings of the 43rd Risø International Symposium on Materials Science: Composite for Wind Energy: Manufacturing, Operation and End-of-Life, Roskilde, Denmark, 4–7 September 2023. [Google Scholar]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Air, A.; Shamsuddoha, M.; Gangadhara Prusty, B. A review of Type V composite pressure vessels and automated fibre placement based manufacturing. Compos. Part B Eng. 2023, 253, 110573. [Google Scholar] [CrossRef]

- Thermoplastic Composites Market Size, Share & Industry Analysis, By Fiber Type (Glass Fiber-reinforced Polymer, Carbon Fiber-reinforced Polymer, and Others), By Resin Type (Polypropylene (PP), Polyamide (PA), Polyetheretherketone (PEEK), and Others), By Application (Transportation, Construction, Electrical & Electronics, Sports & Leisure, and Others), and Regional Forecast, 2024–2032. 2025, Fortune Business Insights. Available online: https://www.fortunebusinessinsights.com/thermoplastic-composites-market-110534 (accessed on 5 June 2025).

- Global Thermoset Composites Market Size By Fiber Type, By Resin Type, By Geographic Scope And Forecast. 2025, Verified Market Research. Available online: https://www.verifiedmarketresearch.com/product/thermoset-composites-market/ (accessed on 5 June 2025).

- Liu, X.Q.; Huang, W.; Jiang, Y.H.; Zhu, J.; Zhang, C.Z. Preparation of a bio-based epoxy with comparable properties to those of petroleum-based counterparts. Express Polym. Lett. 2012, 6, 293–298. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Rathore, N.; Panwar, N.L. Environmental impact and waste recycling technologies for modern wind turbines: An overview. Waste Manag. Res. 2023, 41, 744–759. [Google Scholar] [CrossRef]

- Henao, Y.; Grubert, E.; Korey, M.; Bank, L.C.; Gentry, R. Life Cycle Assessment and Life Cycle Cost Analysis of Repurposing Decommissioned Wind Turbine Blades as High-Voltage Transmission Poles. J. Constr. Eng. Manag. 2024, 150, 1–15. [Google Scholar] [CrossRef]

- Hartwig, G.; Evans, D. Nonmetallic Materials and Composites at Low Temperatures 3, 1st ed.; Plenum Press: New York, NY, USA, 1986. [Google Scholar]

- Dahltram C250CF Thermoplastic Pellet Mid Temp 25 kgs. Available online: https://estore.airtechintl.com/print-techr.html (accessed on 5 June 2025).

- Verrey, J.; Wakeman, M.D.; Michaud, V.; Månson, J.A.E. Manufacturing cost comparison of thermoplastic and thermoset RTM for an automotive floor pan. Compos. Part A Appl. Sci. Manuf. 2006, 37, 9–22. [Google Scholar] [CrossRef]

- Simpson, T. With Additive Manufacturing, No Tooling Is Required, in Compositesworld. 2018. Available online: https://www.additivemanufacturing.media/articles/with-additive-manufacturing-no-tooling-is-required (accessed on 5 June 2025).

- Xu, W.; Jambhulkar, S.; Zhu, Y.; Ravichandran, D.; Kakarla, M.; Vernon, B.; Lott, D.G.; Cornella, J.L.; Shefi, O.; Miquelard-Garnier, G.; et al. 3D printing for polymer/particle-based processing: A review. Compos. Part B Eng. 2021, 223, 109102. [Google Scholar] [CrossRef]

- Roschli, A.; Post, B.K.; Chesser, P.C.; Sallas, M.; Love, L.J.; Gaul, K.T. Precast concrete molds fabricated with big area additive manufacturing. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Walker, R.; Webb, D.; Bhagia, S.; Black, N.; Collier, A.; Ozcan, S.; Kunc, V.; Duty, C. Enabling Recycling Of Composites: Understanding The Impacts Of Multiple Thermal Processing Cycles. In Proceedings of the SAMPE North America Conference & Exhibition, Seattle, WA, USA, 17–20 April 2023. [Google Scholar]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef]

- Armstrong, K.O.; Kamath, D.; Zhao, X.; Rencheck, M.L.; Tekinalp, H.; Korey, M.; Hun, D.; Ozcan, S. Life cycle cost, energy, and carbon emissions of molds for precast concrete: Exploring the impacts of material choices and additive manufacturing. Resour. Conserv. Recycl. 2023, 197, 107117. [Google Scholar] [CrossRef]

- Korey, M.; Rencheck, M.L.; Tekinalp, H.; Wasti, S.; Wang, P.; Bhagia, S.; Walker, R.; Smith, T.; Zhao, X.; Lamm, M.E.; et al. Recycling polymer composite granulate/regrind using big area additive manufacturing. Compos. Part B Eng. 2023, 256, 110652. [Google Scholar] [CrossRef]

- Song, R.; Telenko, C. Material and energy loss due to human and machine error in commercial FDM printers. J. Clean. Prod. 2017, 148, 895–904. [Google Scholar] [CrossRef]

- Walker, R.; Korey, M.; Hubbard, A.M.; Clarkson, C.M.; Corum, T.; Smith, T.; Hershey, C.J.; Lindahl, J.; Ozcan, S.; Duty, C. Recycling of CF-ABS machining waste for large format additive manufacturing. Compos. Part B Eng. 2024, 275, 111291. [Google Scholar] [CrossRef]

- Skelton, Z.I.; Jackson, A.G.; Lunn, P.A. Long term autoclave cycling of additive manufactured demonstration tool. In Proceedings of the SAMPE, Seattle, WA, USA, 17–20 April 2023. [Google Scholar]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Zhang, Y.; Pontikes, Y.; Lessard, L.; Willem van Vuure, A. Recycling and valorization of glass fibre thermoset composite waste by cold incorporation into a sustainable inorganic polymer matrix. Compos. Part B Eng. 2021, 223, 109120. [Google Scholar] [CrossRef]

- Coughlin, D.; Ludwig, C.; Ozcan, S.; Hartman, D.; Ginder, R. Controlled Pyrolysis: A Robust Scalable Composite Recycling Technology; The Institute for Advanced Composites Manufacturing Innovation: U.S. Department of Energy: Knoxville, TN, USA, 2021. [Google Scholar] [CrossRef]

- Stelzer, P.S.; Cakmak, U.; Eisner, L.; Doppelbauer, L.K.; Kállai, I.; Schweizer, G.; Prammer, H.K.; Major, Z. Experimental feasibility and environmental impacts of compression molded discontinuous carbon fiber composites with opportunities for circular economy. Compos. Part B Eng. 2022, 234, 109638. [Google Scholar] [CrossRef]

- Caltagirone, P.E.; Ginder, R.S.; Ozcan, S.; Li, K.; Gay, A.M.; Stonecash, J.; Steirer, K.X.; Cousins, D.; Kline, S.P.; Maxey, A.T.; et al. Substitution of virgin carbon fiber with low-cost recycled fiber in automotive grade injection molding polyamide 66 for equivalent composite mechanical performance with improved sustainability. Compos. Part B Eng. 2021, 221, 109007. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, P.; Yue, J.; Huan, H.; Bi, G.; Zhang, L. Recycling glass fibers from thermoset epoxy composites by in situ oxonium-type polyionic liquid formation and naphthalene-containing superplasticizer synthesis with the degradation solution of the epoxy resin. Compos. Part B Eng. 2023, 254, 110435. [Google Scholar] [CrossRef]

- Michener, J.; Saint-Vincent, P.; Cahill, J.; Drufva, E.; Valentino, H.; Kertesz, V.; Parks, J.; Demerdash, O.; Gainaru, C.; Bocharova, V.; et al. Discovery and engineering of nylon hydrolases for PA66 recycling. In Proceedings of the Enzyme Engineering XXVII, Singapore, 1–6 October 2023. [Google Scholar]

- Bocharova, V.; Drufva, E.E.; Cahill, J.F.; Popov, I.; Dishner, I.T.; Zhou, M.; Jung, G.S.; Ullman, A.M.; Carper, D.L.; Damron, J.T.; et al. Factors modulating the hydrolysis of Nylon-6,6 by a nylon hydrolase enzyme. Polym. Chem. 2025, 16, 1858–1868. [Google Scholar] [CrossRef]

- Ma, D.; Wang, Y.; Sarazen, M.L.; Boyer, C.; Saito, T.; Duan, H.; Huang, W. Catalysis for plastic deconstruction and upcycling. Cell Rep. Phys. Sci. 2024, 5, 102209. [Google Scholar] [CrossRef]

- Zhao, X.; Korey, M.; Li, K.; Copenhaver, K.; Tekinalp, H.; Celik, S.; Kalaitzidou, K.; Ruan, R.; Ragauskas, A.J.; Ozcan, S. Plastic waste upcycling toward a circular economy. Chem. Eng. J. 2022, 428, 131928. [Google Scholar] [CrossRef]

- Korey, M.; Sproul, E.; Rencheck, M.L.; Ennis, B.L. Development of wind turbine blade recycling baselines in the United States. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1293, 012018. [Google Scholar] [CrossRef]

- Romani, A.; Perusin, L.; Ciurnelli, M.; Levi, M. Characterization of PLA feedstock after multiple recycling processes for large-format material extrusion additive manufacturing. Mater. Today Sustain. 2024, 25, 100636. [Google Scholar] [CrossRef]

- Copenhaver, K.; Smith, T.; Armstrong, K.; Kamath, D.; Rencheck, M.; Bhagia, S.; Korey, M.; Lamm, M.; Ozcan, S. Recyclability of additively manufactured bio-based composites. Compos. Part B Eng. 2023, 255, 110617. [Google Scholar] [CrossRef]

- Wasti, S.; Hubbard, A.M.; Clarkson, C.M.; Johnston, E.; Tekinalp, H.; Ozcan, S.; Vaidya, U. Long coir and glass fiber reinforced polypropylene hybrid composites prepared via wet-laid technique. Compos. Part C Open Access 2024, 14, 100445. [Google Scholar] [CrossRef]

- Corum, T.; O’Connell, J.; Brackett, J.; Spender, R.; Hassen, A.; Duty, C. Characterizing the Thermal-Induced Distortion of Large-Scale Polymer Composite Printed Structures. In Proceedings of the the 33rd Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 25–27 July 2022. [Google Scholar]

- Corum, T.M.; O’Connell, J.C.; Brackett, J.C.; Hassen, A.A.; Duty, C.E. Measuring thermomechanical response of large-format printed polymer composite structures via digital image correlation. Addit. Manuf. 2024, 94, 104479. [Google Scholar] [CrossRef]

- Duty, C.; Ajinjeru, C.; Kishore, V.; Compton, B.; Hmeidat, N.; Chen, X.; Liu, P.; Hassen, A.A.; Lindahl, J.; Kunc, V. What makes a material printable? A viscoelastic model for extrusion-based 3D printing of polymers. J. Manuf. Process. 2018, 35, 526–537. [Google Scholar] [CrossRef]

- Butenegro, J.A.; Bahrami, M.; Abenojar, J.; Martinez, M.A. Recent Progress in Carbon Fiber Reinforced Polymers Recycling: A Review of Recycling Methods and Reuse of Carbon Fibers. Materials 2021, 14, 6401. [Google Scholar] [CrossRef] [PubMed]

- Boroujeni, A.Y.; Tehrani, M.; Nelson, A.J.; Al-Haik, M. Effect of carbon nanotubes growth topology on the mechanical behavior of hybrid carbon nanotube/carbon fiber polymer composites. Polym. Compos. 2016, 37, 2639–2648. [Google Scholar] [CrossRef]

- Fazeli, M.; Jayaprakash, S.; Baniasadi, H.; Abidnejad, R.; Lipponen, J. Recycled carbon fiber reinforced composites: Enhancing mechanical properties through co-functionalization of carbon nanotube-bonded microfibrillated cellulose. Compos. Part A Appl. Sci. Manuf. 2024, 180, 108097. [Google Scholar] [CrossRef]

- Aldosari, S.M.; AlOtaibi, B.M.; Alblalaihid, K.S.; Aldoihi, S.A.; AlOgab, K.A.; Alsaleh, S.S.; Alshamary, D.O.; Alanazi, T.H.; Aldrees, S.D.; Alshammari, B.A. Mechanical Recycling of Carbon Fiber-Reinforced Polymer in a Circular Economy. Polymers 2024, 16, 1363. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© This manuscript has been authored by UT-Battelle, LLC, under contract DE-AC05-00OR22725 with the US Department of Energy (DOE). The US government retains and the publisher, by accepting the article for publication, acknowledges that the US government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for US government purposes. DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (https://www.energy.gov/doe-public-access-plan).

Share and Cite

Korey, M.; Hubbard, A.M.; Haye, G.; Bedsole, R.; Skelton, Z.; Meshkat, N.; Anilal, A.L.S.; Slavny, K.; Copenhaver, K.; Corum, T.; et al. Enabling Industrial Re-Use of Large-Format Additive Manufacturing Molding and Tooling. Polymers 2025, 17, 2981. https://doi.org/10.3390/polym17222981

Korey M, Hubbard AM, Haye G, Bedsole R, Skelton Z, Meshkat N, Anilal ALS, Slavny K, Copenhaver K, Corum T, et al. Enabling Industrial Re-Use of Large-Format Additive Manufacturing Molding and Tooling. Polymers. 2025; 17(22):2981. https://doi.org/10.3390/polym17222981

Chicago/Turabian StyleKorey, Matthew, Amber M. Hubbard, Gregory Haye, Robert Bedsole, Zachary Skelton, Neeki Meshkat, Ashish L. S. Anilal, Kathryn Slavny, Katie Copenhaver, Tyler Corum, and et al. 2025. "Enabling Industrial Re-Use of Large-Format Additive Manufacturing Molding and Tooling" Polymers 17, no. 22: 2981. https://doi.org/10.3390/polym17222981

APA StyleKorey, M., Hubbard, A. M., Haye, G., Bedsole, R., Skelton, Z., Meshkat, N., Anilal, A. L. S., Slavny, K., Copenhaver, K., Corum, T., Bones, D. X., Gramlich, W. M., Duty, C., & Ozcan, S. (2025). Enabling Industrial Re-Use of Large-Format Additive Manufacturing Molding and Tooling. Polymers, 17(22), 2981. https://doi.org/10.3390/polym17222981