Bio-Based and Nanostructured Polymers for Sustainable Protection of Cultural Heritage and Medicinal Crops: Convergence of Heritage Science, Circular Bioeconomy, and Environmental Protection

Abstract

1. Introduction

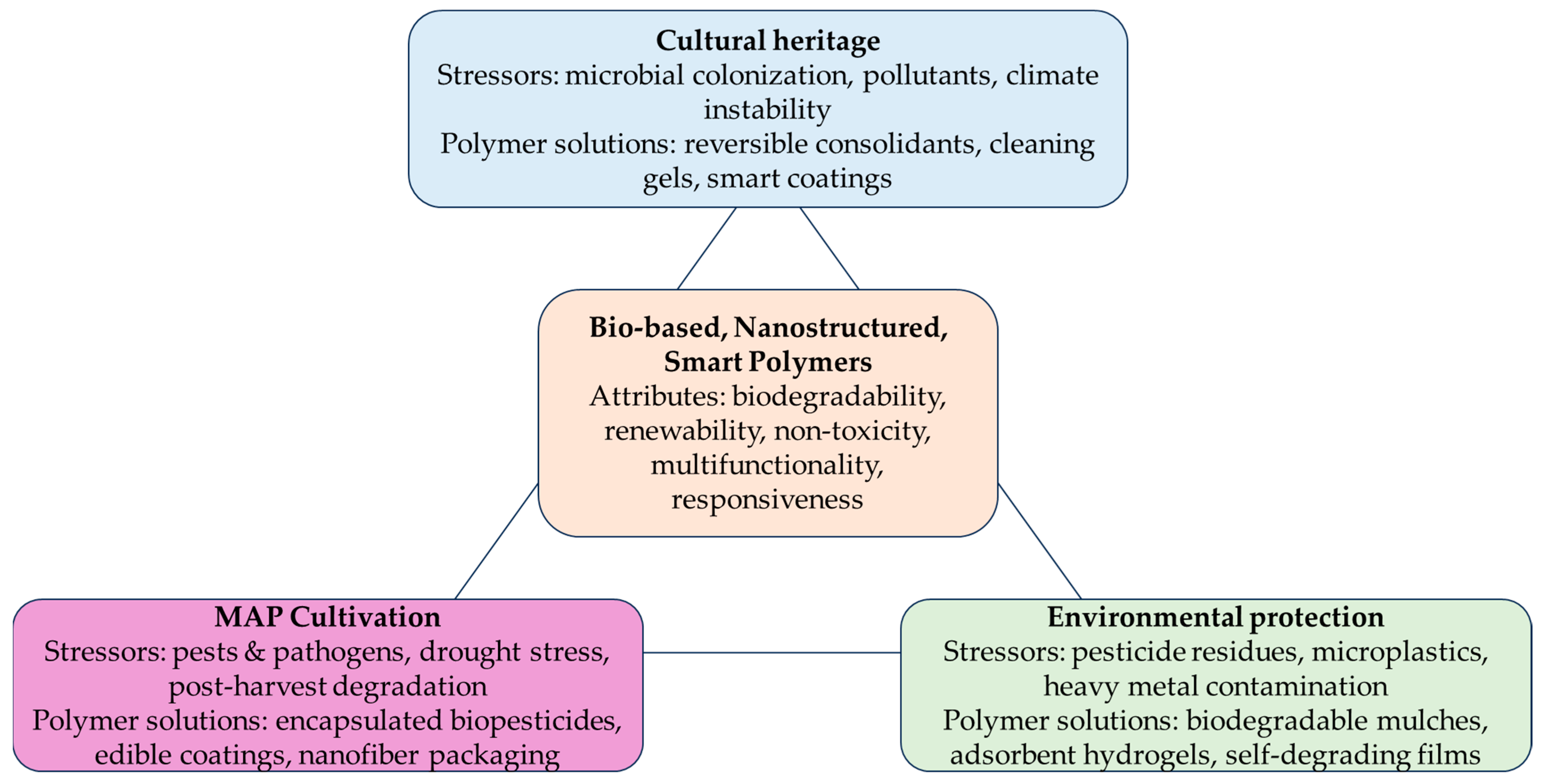

2. Polymers at the Crossroads of Heritage, Agriculture, and Environment

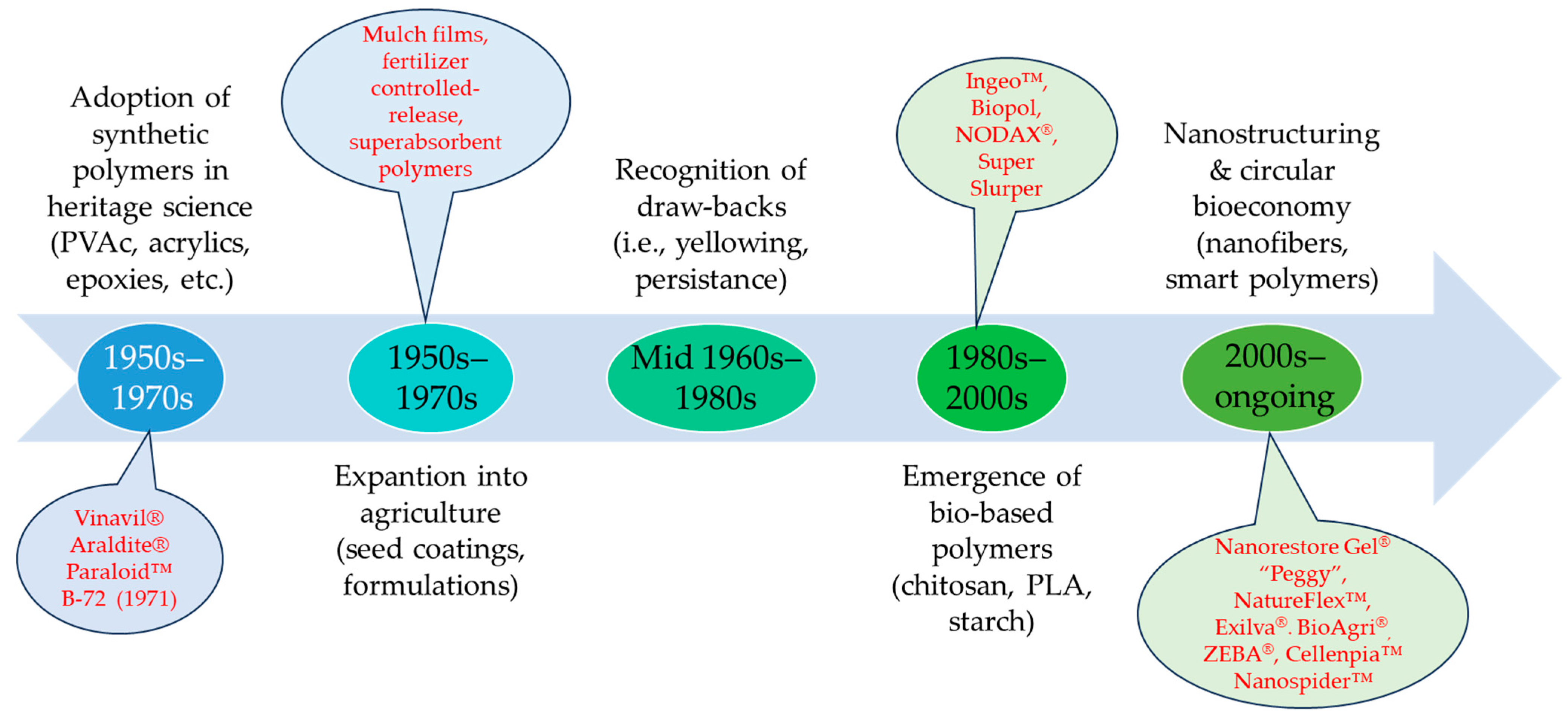

2.1. A Historical Perspective: Synthetic Polymers in Heritage Conservation and Agriculture

2.2. The Challenges of Traditional Polymeric Materials

2.2.1. Lack of Reversibility and Incompatibility in Heritage Conservation

2.2.2. Environmental Persistence and Waste Accumulation

2.2.3. Microplastics and Toxicological Concerns

2.3. The Rise in Bio-Based Polymers as Sustainable Alternatives

2.3.1. Chitosan

2.3.2. Cellulose Derivatives

2.3.3. Starch

2.3.4. Polylactic Acid (PLA)

2.3.5. Lignin

2.3.6. Proteins

2.4. Nanostructuring: Enhancing Performance Through Design

2.4.1. Nanofibers

2.4.2. Nanocapsules and Nanoparticles

2.4.3. Nanocomposites

2.4.4. Smart and Responsive Polymers

2.5. Polymeric Materials at the Crossroads

3. Polymeric Systems for Cultural Heritage Protection

3.1. Requirements of Conservation Polymers

3.2. Bio-Based Polymers in Conservation

3.3. Nanostructured Polymeric Systems in Heritage Science

3.4. Discussion and Perspectives

4. Polymeric Systems for Sustainable Protection of Medicinal and Aromatic Plants (MAPs)

4.1. Challenges in MAP Cultivation

4.1.1. Pest and Pathogen Threats

4.1.2. Climate Stress and Post-Harvest Degradation

4.1.3. High Value of Essential Oils and Phenolic Compounds

4.2. Polymers in Crop Protection

4.3. Nanostructured Polymeric Systems in Crop Protection

4.4. Circular Bioeconomy Aspects

4.5. Perspectives

5. Polymeric Systems for Environmental Protection: The Convergence Point

5.1. Environmental Risks Common to Heritage and MAPs

5.1.1. Microbial Colonization

5.1.2. Airborne Pollutants

5.1.3. Climate-Induced Degradation

5.1.4. Pesticide Residues and Plastic Contamination

5.2. Polymers as Environmental Protectors

5.3. The Bridge Between Domains

5.4. Polymeric Systems—The Convergence Point

6. Transdisciplinary Synergies and Future Perspectives

6.1. Shared Scientific Challenges

6.2. Technological Convergence

6.3. Research and Innovation Opportunities

6.4. Toward a Shared Future

- Life-cycle thinking as standard practice. Past mistakes—like the widespread use of acrylics and epoxies—show that materials celebrated as solutions can later become problems. Designing with end-of-life in mind must become the norm. Researchers must ask: what residues remain after degradation? How do nanoparticles interact with soil microbiomes or aquatic ecosystems? Such questions must be answered before large-scale adoption.

- Policy alignment as catalyst. From the EU Green Deal to the Farm-to-Fork Strategy, policy frameworks are moving rapidly toward pesticide reduction, circularity, and green chemistry. Polymer research that aligns with these frameworks will move faster from prototype to practice. For example, biodegradable mulches in MAP cultivation directly contribute to pesticide reduction targets, while reversible coatings align with UNESCO principles for cultural heritage.

- Transdisciplinarity as necessity. Effective progress requires not just collaboration between chemists and conservators, but also agronomists, environmental engineers, economists, and ethicists. Predictive modeling of material aging must be integrated with socio-economic studies of farmer adoption or museum budgets. This ensures that innovations are both technically sound and practically viable.

- Cultural reframing. Polymers must move in the public imagination from being “symbols of pollution” to “symbols of responsible innovation”. Communicating stories of how polymers can protect a medieval manuscript, a lavender field, and a river ecosystem simultaneously can shift perceptions and build public trust.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| BC | Bacterial Nanocellulose |

| CDA | Cellulose Diacetate |

| CMC | Carboxymethyl Cellulose |

| CNC | Cellulose Nanocrystals |

| CNF | Cellulose Nanofibrils |

| CSNPs | Chitosan Nanoparticles |

| Ce-CMEO-NPs | Chitosan Nanoparticles loaded with Cymbopogon martinii Essential Oil |

| DON | Deoxynivalenol |

| ESEM-EDX | Environmental Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy |

| EU | European Union |

| FTIR | Fourier Transform Infrared Spectroscopy |

| HPC | Hydroxypropyl Cellulose |

| ICOMOS | International Council on Monuments and Sites |

| LNPs | Lignin Nanoparticles |

| LOX | Lipoxygenase |

| MAPs | Medicinal and Aromatic Plants |

| MMT | Montmorillonite |

| NGO | Non-Governmental Organization |

| PCDNH | Physically Crosslinked Double-Network Hydrogel |

| PHA | Polyhydroxyalkanoates |

| PLA | Polylactic Acid |

| PPO | Polyphenol Oxidase |

| PVAc | Poly(vinyl acetate) |

| ROS | Reactive Oxygen Species |

| SDGs | Sustainable Development Goals |

| SO2 | Sulfur Dioxide |

| UNESCO | United Nations Educational, Scientific and Cultural Organization |

| ZEA | Zearalenone |

References

- Gonçalves, R.; Serra, J.; Reizabal, A.; Correia, D.M.; Fernandes, L.C.; Brito-Pereira, R.; Lizundia, E.; Costa, C.M.; Lanceros-Méndez, S. Biobased polymers for advanced applications: Towards a sustainable future. Progr. Polym. Sci. 2025, 162, 101934. [Google Scholar] [CrossRef]

- Beena Unni, A.; Muringayil Joseph, T. Enhancing Polymer Sustainability: Eco-Conscious Strategies. Polymers 2024, 16, 1769. [Google Scholar] [CrossRef] [PubMed]

- Toma, D.-I.; Manaila-Maximean, D.; Fierascu, I.; Baroi, A.M.; Matei, R.I.; Fistos, T.; Chican, I.E.; Fierascu, R.C. Applications of Natural Polymers in the Grapevine Industry: Plant Protection and Value-Added Utilization of Waste. Polymers 2025, 17, 18. [Google Scholar] [CrossRef]

- Baglioni, M.; Poggi, G.; Chelazzi, D.; Baglioni, P. Advanced Materials in Cultural Heritage Conservation. Molecules 2021, 26, 3967. [Google Scholar] [CrossRef]

- Brandt, J.; Kanaki, E.; Fischer, D.; Herm, C. Evaluation of the Composition, Thermal and Mechanical Behavior, and Color Changes of Artificially and Naturally Aged Polymers for the Conservation of Stained Glass Windows. Polymers 2023, 15, 2595. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Liu, T.; Zhang, B. The preservation damage of hydrophobic polymer coating materials in conservation of stone relics. Prog. Org. Coat. 2013, 76, 1127–1134. [Google Scholar] [CrossRef]

- Doni, M.; Fierascu, I.; Fierascu, R.C. Recent Developments in Materials Science for the Conservation and Restoration of Historic Artifacts. Appl. Sci. 2024, 14, 11363. [Google Scholar] [CrossRef]

- Khalil, I.; Üzümcüoğlu, D. Advancing Sustainability and Heritage Preservation Through a Novel Framework for the Adaptive Reuse of Mediterranean Earthen Houses. Sustainability 2025, 17, 6447. [Google Scholar] [CrossRef]

- Lewicka, K.; Szymanek, I.; Rogacz, D.; Wrzalik, M.; Łagiewka, J.; Nowik-Zając, A.; Zawierucha, I.; Coseri, S.; Puiu, I.; Falfushynska, H.; et al. Current Trends of Polymer Materials’ Application in Agriculture. Sustainability 2024, 16, 8439. [Google Scholar] [CrossRef]

- Derpsch, R.; Kassam, A.; Reicosky, D.; Friedrich, T.; Calegari, A.; Basch, G.; Gonzalez-Sanchez, E.; dos Santos, D.R. Nature’s laws of declining soil productivity and Conservation Agriculture. Soil Secur. 2024, 14, 100127. [Google Scholar] [CrossRef]

- Govil, S.; Long, N.V.D.; Escribà-Gelonch, M.; Hessel, V. Controlled-release fertiliser: Recent developments and perspectives. Ind. Crops Prod. 2024, 219, 119160. [Google Scholar] [CrossRef]

- Verma, K.; Sarkar, C.; Saha, S. Exploration of Biodegradable Polymeric Particles in Agriculture: A Holistic Approach for Sustainable Farming. Environ. Sci. Adv. 2025, 4, 409–431. [Google Scholar] [CrossRef]

- Oliver-Cuenca, V.; Salaris, V.; Muñoz-Gimena, P.F.; Agüero, Á.; Peltzer, M.A.; Montero, V.A.; Arrieta, M.P.; Sempere-Torregrosa, J.; Pavon, C.; Samper, M.D.; et al. Bio-Based and Biodegradable Polymeric Materials for a Circular Economy. Polymers 2024, 16, 3015. [Google Scholar] [CrossRef]

- Sheraz, M.; Sun, X.-F.; Siddiqui, A.; Hu, S.; Song, Z. Research Advances in Natural Polymers for Environmental Remediation. Polymers 2025, 17, 559. [Google Scholar] [CrossRef] [PubMed]

- Ziani, K.; Ioniță-Mîndrican, C.-B.; Mititelu, M.; Neacșu, S.M.; Negrei, C.; Moroșan, E.; Drăgănescu, D.; Preda, O.-T. Microplastics: A Real Global Threat for Environment and Food Safety: A State of the Art Review. Nutrients 2023, 15, 617. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Ali, S.; Zaman, W. Innovative Adsorbents for Pollutant Removal: Exploring the Latest Research and Applications. Molecules 2024, 29, 4317. [Google Scholar] [CrossRef]

- Zioui, D.; Salazar, H.; Aoudjit, L.; Martins, P.M.; Lanceros-Méndez, S. Polymer-Based Membranes for Oily Wastewater Remediation. Polymers 2020, 12, 42. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of Biodegradable Plastics: New Problem or Solution to Solve the Global Plastic Pollution? Curr. Res. Green Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Radu, I.-C.; Vadureanu, A.-M.; Cozorici, D.-E.; Blanzeanu, E.; Zaharia, C. Advancing Sustainability in Modern Polymer Processing: Strategies for Waste Resource Recovery and Circular Economy Integration. Polymers 2025, 17, 522. [Google Scholar] [CrossRef] [PubMed]

- Vela Almeida, D.; Kolinjivadi, V.; Ferrando, T.; Roy, B.; Herrera, H.; Vecchione Gonçalves, M.; Van Hecken, G. The “Greening” of Empire: The European Green Deal as the EU first agenda. Polit. Geogr. 2023, 105, 102925. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Nallapaneni, M.K. Europe Moves toward Pragmatic Sustainability: A More Human and Fraternal Approach. Sustainability 2024, 16, 6161. [Google Scholar] [CrossRef]

- Fallah Shayan, N.; Mohabbati-Kalejahi, N.; Alavi, S.; Zahed, M.A. Sustainable Development Goals (SDGs) as a Framework for Corporate Social Responsibility (CSR). Sustainability 2022, 14, 1222. [Google Scholar] [CrossRef]

- Jaramillo, F.; Desormeaux, A.; Hedlund, J.; Jawitz, J.W.; Clerici, N.; Piemontese, L.; Rodríguez-Rodriguez, J.A.; Anaya, J.A.; Blanco-Libreros, J.F.; Borja, S.; et al. Priorities and Interactions of Sustainable Development Goals (SDGs) with Focus on Wetlands. Water 2019, 11, 619. [Google Scholar] [CrossRef]

- Tan, E.; Lamers, P. Circular Bioeconomy Concepts—A Perspective. Front. Sustain. Food Syst. 2021, 5, 701509. [Google Scholar] [CrossRef]

- Fistos, T.; Fierascu, I.; Manaila-Maximean, D.; Fierascu, R.C. Advancements in Stone Object Restoration Using Polymer-Inorganic Phosphate Composites for Cultural Heritage Preservation. Polymers 2024, 16, 2085. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.; Shi, Q.; Peng, T.; Cao, X.; Lv, Y. Research Progress on the Synthesis of Nanostructured Photocatalysts and Their Environmental Applications. Nanomaterials 2025, 15, 681. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Maio, A.; Sutera, F.; Gulino, E.F.; Morreale, M. Degradation and Recycling of Films Based on Biodegradable Polymers: A Short Review. Polymers 2019, 11, 651. [Google Scholar] [CrossRef]

- Khallaf, M.K.; El-Midany, A.A.; El-Mofty, S.E. Influence of acrylic coatings on the interfacial, physical, and mechanical properties of stone-based monuments. Prog. Org. Coat. 2011, 72, 592–598. [Google Scholar] [CrossRef]

- Sena da Fonseca, B. Current Trends in Stone Consolidation Research: An Overview and Discussion. Buildings 2023, 13, 403. [Google Scholar] [CrossRef]

- Feller, R.L.; Stolow, N.; Jones, E.H. On the Picture Varnish and Their Solvents; The Press of Case Western Reserve University: London, UK, 1971; p. 122. [Google Scholar]

- Centenaro, S.; Franceschin, G.; Cattaruzza, E.; Traviglia, A. Consolidation and Coating Treatments for Glass in the Cultural Heritage Field: A Review. J. Cult. Herit. 2023, 64, 132–143. [Google Scholar] [CrossRef]

- Zhao, X.; Li, X.; Zhang, S.; Niu, Q.; Li, Z.; Xue, C. Investigation of Whitening Mechanism on Cultural Relic Surfaces Treated with Paraloid B72. Coatings 2024, 14, 1240. [Google Scholar] [CrossRef]

- Karayannidou, E.G.; Achilias, D.S.; Sideridou, I.D. Cure kinetics of epoxy–amine resins used in the restoration of works of art from glass or ceramic. Eur. Polym. J. 2006, 42, 3311–3323. [Google Scholar] [CrossRef]

- Lazzari, M.; López-Morán, T. Aging of a Poly(vinyl acetate)-Based White Glue and Its Durability in Contemporary Artworks. Polymers 2024, 16, 1712. [Google Scholar] [CrossRef]

- Novak, M.; Ormsby, B. Poly(Vinyl Acetate) Paints: A Literature Review of Material Properties, Ageing Characteristics, and Conservation Challenges. Polymers 2023, 15, 4348. [Google Scholar] [CrossRef]

- Licchelli, M.; Marzolla, S.J.; Poggi, A.; Zanchi, C. Crosslinked fluorinated polyurethanes for the protection of stone surfaces from graffiti. J. Cult. Herit. 2011, 12, 34–43. [Google Scholar] [CrossRef]

- Lawrencia, D.; Wong, S.K.; Low, D.Y.S.; Goh, B.H.; Goh, J.K.; Ruktanonchai, U.R.; Soottitantawat, A.; Lee, L.H.; Tang, S.Y. Controlled Release Fertilizers: A Review on Coating Materials and Mechanism of Release. Plants 2021, 10, 238. [Google Scholar] [CrossRef]

- Lestido-Cardama, A.; Sendón, R.; Bustos, J.; Nieto, M.T.; Paseiro-Losada, P.; de Quirós, A.R.B. Food and beverage can coatings: A review on chemical analysis, migration, and risk assessment. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3558–3611. [Google Scholar] [CrossRef]

- Yao, L.; Baharum, A.; Yu, L.J.; Yan, Z.; Badri, K.H. A Vegetable-Oil-Based Polyurethane Coating for Controlled Nutrient Release: A Review. Coatings 2025, 15, 665. [Google Scholar] [CrossRef]

- Evenson, R.E.; Gollin, D. Assessing the Impact of the Green Revolution, 1960 to 2000. Science 2003, 300, 758–762. [Google Scholar] [CrossRef] [PubMed]

- Shah, J.A.; Vendl, T.; Aulicky, R.; Frankova, M.; Stejskal, V. Gel Carriers for Plant Extracts and Synthetic Pesticides in Rodent and Arthropod Pest Control: An Overview. Gels 2022, 8, 522. [Google Scholar] [CrossRef]

- Yusoff, S.N.M.; Kamari, A.; Aljafree, N.F.A. A Review of Materials Used as Carrier Agents in Pesticide Formulations. Int. J. Environ. Sci. Technol. 2016, 13, 2977–2994. [Google Scholar] [CrossRef]

- Kamali Tabrizi, S.; Abdelmonem, M.G. Contemporary construction in historical sites: The missing factors. Front. Arch. Res. 2024, 13, 487–504. [Google Scholar] [CrossRef]

- Litchfield, R.E.; Critchlow, G.W.; Wilson, S. Surface cleaning technologies for the removal of crosslinked epoxide resin. Int. J. Adhes. Adhes. 2006, 26, 295–303. [Google Scholar] [CrossRef]

- Kim, J.-E.; Lee, J.-M.; Hyun, J.-H.; Jeong, J.-H.; Kim, J.-D. A Study on the Laser Removal of Epoxy Coatings on SS400 Surface by Beam Scanning Patterns. Coatings 2021, 11, 1510. [Google Scholar] [CrossRef]

- Artesani, A.; Di Turo, F.; Zucchelli, M.; Traviglia, A. Recent Advances in Protective Coatings for Cultural Heritage—An Overview. Coatings 2020, 10, 217. [Google Scholar] [CrossRef]

- Musacchi, J.; Silva, H.M.A.R.; Cabral-Fonseca, S.; Esteves, L.; Delgado Rodrigues, J.; Rodrigues, M.P.; Pereira, S.R.M. Adhesion of Historic Tile Fragments in Outdoor Architectural Settings. Buildings 2024, 14, 375. [Google Scholar] [CrossRef]

- Chelazzi, D.; Chevalier, A.; Pizzorusso, G.; Giorgi, R.; Menu, M.; Baglioni, P. Characterization and Degradation of Poly(Vinyl Acetate)-Based Adhesives for Canvas Paintings. Polym. Degrad. Stab. 2014, 107, 314–320. [Google Scholar] [CrossRef]

- Demoulin, T.; Scherer, G.W.; Girardet, F.; Flatt, R.J. Thermo-Mechanical Compatibility of Viscoelastic Mortars for Stone Repair. Materials 2016, 9, 56. [Google Scholar] [CrossRef]

- Tian, H.; Wang, L.; Zhu, X.; Zhang, M.; Li, L.; Liu, Z.; Abolfathi, S. Biodegradation of microplastics derived from controlled release fertilizer coating: Selective microbial colonization and metabolism in plastisphere. Sci. Total Environ. 2024, 920, 170978. [Google Scholar] [CrossRef]

- Dasari, V.V.; Suresh, A.K. The Plastic Problem in Research Laboratories: A Call for Sustainability. ACS Sustain. Resour. Manag. 2025, 2, 564–568. [Google Scholar] [CrossRef]

- Hahn, S.; Hennecke, D. What can we learn from biodegradation of natural polymers for regulation? Environ. Sci. Eur. 2023, 35, 50. [Google Scholar] [CrossRef]

- Moore, C.J. Synthetic Polymers in the Marine Environment: A Rapidly Increasing, Long-Term Threat. Environ. Res. 2008, 108, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Osman, A.I.; Hosny, M.; Eltaweil, A.S.; Omar, S.; Elgarahy, A.M.; Farghali, M.; Yap, P.S.; Wu, Y.S.; Nagandran, S.; Batumalaie, K.; et al. Microplastic sources, formation, toxicity and remediation: A review. Environ. Chem. Lett. 2023, 21, 2129–2169. [Google Scholar] [CrossRef] [PubMed]

- Campanale, C.; Massarelli, C.; Savino, I.; Locaputo, V.; Uricchio, V.F. A detailed review study on potential effects of microplastics and additives of concern on human health. Int. J. Environ. Res. Public Health 2020, 17, 1212. [Google Scholar] [CrossRef]

- Tumwesigye, E.; Nnadozie, C.F.; Akamagwuna, F.; Noundou, X.S.; Nyakairu, G.W.; Odume, O.N. Microplastics as vectors of chemical contaminants and biological agents in freshwater ecosystems: Current knowledge status and future perspectives. Environ. Pollut. 2023, 330, 121829. [Google Scholar] [CrossRef]

- Stoica, M.; Bichescu, C.I.; Crețu, C.-M.; Dragomir, M.; Ivan, A.S.; Podaru, G.M.; Stoica, D.; Stuparu-Crețu, M. Review of Bio-Based Biodegradable Polymers: Smart Solutions for Sustainable Food Packaging. Foods 2024, 13, 3027. [Google Scholar] [CrossRef] [PubMed]

- Román-Doval, R.; Torres-Arellanes, S.P.; Tenorio-Barajas, A.Y.; Gómez-Sánchez, A.; Valencia-Lazcano, A.A. Chitosan: Properties and Its Application in Agriculture in Context of Molecular Weight. Polymers 2023, 15, 2867. [Google Scholar] [CrossRef]

- Dai, L.; Wang, X.; Zhang, J.; Li, C. Application of Chitosan and Its Derivatives in Postharvest Coating Preservation of Fruits. Foods 2025, 14, 1318. [Google Scholar] [CrossRef]

- Zhgun, A.; Avdanina, D.; Shagdarova, B.; Nuraeva, G.; Shumikhin, K.; Zhuikova, Y.; Il’ina, A.; Troyan, E.; Shitov, M.; Varlamov, V. The Application of Chitosan for Protection of Cultural Heritage Objects of the 15–16th Centuries in the State Tretyakov Gallery. Materials 2022, 15, 7773. [Google Scholar] [CrossRef]

- Silva-Castro, I.; Casados-Sanz, M.; Alonso-Cortés, A.L.; Martín-Ramos, P.; Martín-Gil, J.; Acuña-Rello, L. Chitosan-Based Coatings to Prevent the Decay of Populus spp. Wood Caused by Trametes versicolor. Coatings 2018, 8, 415. [Google Scholar] [CrossRef]

- Jiang, M.; Yao, J.; Guo, Q.; Yan, Y.; Tang, Y.; Yang, Y. Recent Advances in Paper Conservation Using Nanocellulose and Its Composites. Molecules 2025, 30, 417. [Google Scholar] [CrossRef] [PubMed]

- Hansini, A.M.P.; Galpaya, G.D.C.P.; Gunasena, M.D.K.M.; Abeysundara, P.M.; Kirthika, V.; Bhagya, L.; Gunawardana, H.D.C.N.; Koswattage, K.R. From Nature to Innovation: Advances in Nanocellulose Extraction and Its Multifunctional Applications. Molecules 2025, 30, 2670. [Google Scholar] [CrossRef]

- Agbna, G.H.D.; Zaidi, S.J. Hydrogel Performance in Boosting Plant Resilience to Water Stress—A Review. Gels 2025, 11, 276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Lu, Y.; Gao, S.; Wu, S. Sustainable and Efficient Wastewater Treatment Using Cellulose-Based Hydrogels: A Review of Heavy Metal, Dye, and Micropollutant Removal Applications. Separations 2025, 12, 72. [Google Scholar] [CrossRef]

- Chamorro, A.F.; Palencia, M.; Combatt, E.M. Starch Hydrogels for Slow and Controlled-Release Fertilizers: A Review. Polymers 2025, 17, 1117. [Google Scholar] [CrossRef]

- Borges, I.D.; Casimiro, M.H.; Macedo, M.F.; Sequeira, S.O. Adhesives used in paper conservation: Chemical stability and fungal bioreceptivity. J. Cult. Herit. 2018, 34, 53–60. [Google Scholar] [CrossRef]

- Lama, E.; Veneranda, M.; Prieto-Taboada, N.; Hernando, F.L.; Laso, M.D.R.; Madariaga, J.M. A first evaluation of the usefulness of Kudzu starch in cultural heritage restoration. Sci. Rep. 2020, 10, 15598. [Google Scholar] [CrossRef]

- An, C.; Sun, C.; Li, N.; Huang, B.; Jiang, J.; Shen, Y.; Wang, C.; Zhao, X.; Cui, B.; Wang, C.; et al. Nanomaterials and nanotechnology for the delivery of agrochemicals: Strategies towards sustainable agriculture. J. Nanobiotechnol. 2022, 20, 11. [Google Scholar] [CrossRef]

- Ocak, Y.; Sofuoglu, A.; Tihminlioglu, F.; Böke, H. Sustainable bio-nano composite coatings for the protection of marble surfaces. J. Cult. Herit. 2015, 16, 299–306. [Google Scholar] [CrossRef]

- Ganzagh, S.G.; Yousefi, A.R.; Rahdar, A.; Mohammadi, M. Lignin-based nanoencapsulation for sustainable herbicide delivery: Controlled release and bioactivity of 2,4-D and MCPA compared to commercial formulations. Sci. Rep. 2025, 15, 24532. [Google Scholar] [CrossRef]

- Kapuge Dona, N.L.; Smith, R.C. Tailoring Polymer Properties Through Lignin Addition: A Recent Perspective on Lignin-Derived Polymer Modifications. Molecules 2025, 30, 2455. [Google Scholar] [CrossRef] [PubMed]

- Yadav, P.; Mahapatra, U.; Sharma, R.; Rustagi, S.; Katyal, M.; Sharma, M.; Nayak, P.K.; Nath, P.C.; Sridhar, K. Recent advances in plant protein-based sustainable edible film and coatings for applications in the food-pharma industry—Opportunities and challenges: A review. Int. J. Biol. Macromol. 2025, 296, 139698. [Google Scholar] [CrossRef]

- Purewal, S.S.; Kaur, A.; Bangar, S.P.; Singh, P.; Singh, H. Protein-Based Films and Coatings: An Innovative Approach. Coatings 2024, 14, 32. [Google Scholar] [CrossRef]

- Caruso, M.R.; D’Agostino, G.; Milioto, S.; Cavallaro, G.; Lazzara, G. A review on biopolymer-based treatments for consolidation and surface protection of cultural heritage materials. J. Mater. Sci. 2023, 58, 12954–12975. [Google Scholar] [CrossRef]

- Mansoor, Z.; Tchuenbou-Magaia, F.; Kowalczuk, M.; Adamus, G.; Manning, G.; Parati, M.; Radecka, I.; Khan, H. Polymers Use as Mulch Films in Agriculture—A Review of History, Problems and Current Trends. Polymers 2022, 14, 5062. [Google Scholar] [CrossRef] [PubMed]

- Serrano-Ruiz, H.; Martin-Closas, L.; Pelacho, A.M. Biodegradable plastic mulches: Impact on the agricultural biotic environment. Sci. Total Environ. 2021, 750, 141228. [Google Scholar] [CrossRef]

- Zhuang, X.C.; Wang, F.; Hu, X. Biodegradable polymers: A promising solution for green energy devices. Eur. Polym. J. 2024, 204, 112696. [Google Scholar] [CrossRef]

- Musa, A.A.; Bello, A.; Adams, S.M.; Onwualu, A.P.; Anye, V.C.; Bello, K.A.; Obianyo, I.I. Nano-Enhanced Polymer Composite Materials: A Review of Current Advancements and Challenges. Polymers 2025, 17, 893. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wang, J.; Zeng, L.; Qiao, Z.; Liu, X.; Liu, H.; Zhang, J.; Ding, J. Fabrication of Electrospun Polymer Nanofibers with Diverse Morphologies. Molecules 2019, 24, 834. [Google Scholar] [CrossRef] [PubMed]

- Al-Gaoudi, H.A.; Brandt, J.; Michler, G.H.; Asran, A.S. Electrospun nanofiber composites as a novel preservation coating with antimicrobial and antifungal functions for the archaeological linen textiles. J. Text. Inst. 2024, 116, 1858–1869. [Google Scholar] [CrossRef]

- Colín-Orozco, J.; Colín-Orozco, E.; Valdivia-Barrientos, R. Production of Nanofibers by Electrospinning as Carriers of Agrochemical. Fibers 2024, 12, 64. [Google Scholar] [CrossRef]

- Dallaev, R.; Papež, N.; Allaham, M.M.; Holcman, V. Biodegradable Polymers: Properties, Applications, and Environmental Impact. Polymers 2025, 17, 1981. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, N.; Rajput, V.D.; Mandzhieva, S.; Minkina, T.; Saharan, B.S.; Kumar, D.; Sadh, P.K.; Duhan, J.S. Advances in Biopolymeric Nanopesticides: A New Eco-Friendly/Eco-Protective Perspective in Precision Agriculture. Nanomaterials 2022, 12, 3964. [Google Scholar] [CrossRef]

- Asadzadeh, F.; Ghorbanzadeh, S.; Poursattar Marjani, A.; Gholami, R.; Asadzadeh, F.; Lotfollahi, L. Assessing polylactic acid nanofibers with cellulose and chitosan nanocapsules loaded with chamomile extract for treating gram-negative infections. Sci. Rep. 2024, 14, 22336. [Google Scholar] [CrossRef]

- Ferreira, R.R.; Souza, A.G.; Quispe, Y.M.; Rosa, D.S. Essential oils loaded-chitosan nanocapsules incorporation in biodegradable starch films: A strategy to improve fruits shelf life. Int. J. Biol. Macromol. 2021, 188, 628–638. [Google Scholar] [CrossRef]

- Cirone, M.; Figoli, A.; Galiano, F.; La Russa, M.F.; Macchia, A.; Mancuso, R.; Ricca, M.; Rovella, N.; Taverniti, M.; Ruffolo, S.A. Innovative Methodologies for the Conservation of Cultural Heritage against Biodeterioration: A Review. Coatings 2023, 13, 1986. [Google Scholar] [CrossRef]

- Cutajar, J.D.; Steindal, C.C.; Caruso, F.; Joseph, E.; Frøysaker, T. Spectral- and Image-Based Metrics for Evaluating Cleaning Tests on Unvarnished Painted Surfaces. Coatings 2024, 14, 1040. [Google Scholar] [CrossRef]

- Armaković, S.J.; Armaković, S.; Savanović, M.M. Photocatalytic Application of Polymers in Removing Pharmaceuticals from Water: A Comprehensive Review. Catalysts 2024, 14, 447. [Google Scholar] [CrossRef]

- Gallucci, N.; De Cristofaro, I.; Krauss, I.R.; D’Errico, G.; Paduano, L. Eco-sustainable delivery strategies to drive agriculture forwards. Curr. Opin. Colloid Interface Sci. 2025, 77, 101917. [Google Scholar] [CrossRef]

- Menichetti, A.; Ramacciotti, F.; Sciutto, G.; Focarete, M.L.; Montalti, M.; Prati, S.; Gualandi, C. Nanofibrous photothermal materials from natural resources: A green approach for artwork restoration. ACS Appl. Mater. Interfaces 2024, 16, 69829–69838. [Google Scholar] [CrossRef]

- Machado, T.O.; Grabow, J.; Sayer, C.; de Araújo, P.H.H.; Ehrenhard, M.L.; Wurm, F.R. Biopolymer-based nanocarriers for sustained release of agrochemicals: A review on materials and social science perspectives for a sustainable future of agri- and horticulture. Adv. Colloid Interface Sci. 2022, 303, 102645. [Google Scholar] [CrossRef] [PubMed]

- Demirel, O.; Kolgesiz, S.; Yuce, S.; Hayat Soytaş, S.; Koseoglu-Imer, D.Y.; Unal, H. Photothermal Electrospun Nanofibers Containing Polydopamine-Coated Halloysite Nanotubes as Antibacterial Air Filters. ACS Appl. Nano Mater. 2022, 5, 18127–18137. [Google Scholar] [CrossRef]

- Antonelli, F.; Galotta, G.; Sidoti, G.; Zikeli, F.; Nisi, R.; Petriaggi, B.D.; Romagnoli, M. Cellulose and Lignin Nano-Scale Consolidants for Waterlogged Archaeological Wood. Front. Chem. 2020, 8, 32. [Google Scholar] [CrossRef]

- Zabot, G.L.; Schaefer Rodrigues, F.; Polano Ody, L.; Vinícius Tres, M.; Herrera, E.; Palacin, H.; Córdova-Ramos, J.S.; Best, I.; Olivera-Montenegro, L. Encapsulation of Bioactive Compounds for Food and Agricultural Applications. Polymers 2022, 14, 4194. [Google Scholar] [CrossRef]

- Guerra, F.D.; Attia, M.F.; Whitehead, D.C.; Alexis, F. Nanotechnology for Environmental Remediation: Materials and Applications. Molecules 2018, 23, 1760. [Google Scholar] [CrossRef]

- Wu, W.; Dong, Z.; He, J.; Yu, J.; Zhang, J. Transparent Cellulose/Laponite Nanocomposite Films. J. Mater. Sci. 2016, 51, 4125–4133. [Google Scholar] [CrossRef]

- Shojaeiarani, J.; Bajwa, D.S.; Ryan, C.; Kane, S. Enhancing UV-shielding and mechanical properties of polylactic acid nanocomposites by adding lignin coated cellulose nanocrystals. Ind. Crops Prod. 2022, 183, 114904. [Google Scholar] [CrossRef]

- Melinte, V.; Stroea, L.; Chibac-Scutaru, A.L. Polymer Nanocomposites for Photocatalytic Applications. Catalysts 2019, 9, 986. [Google Scholar] [CrossRef]

- Lazarova, K.; Bozhilova, S.; Ivanova, S.; Christova, D.; Babeva, T. Moisture-Responsive Polymer Films on Flexible Substrates for Optical Sensing of Humidity. Eng. Proc. 2020, 2, 19. [Google Scholar] [CrossRef]

- Mikhailidi, A.; Ungureanu, E.; Tofanica, B.-M.; Ungureanu, O.C.; Fortună, M.E.; Belosinschi, D.; Volf, I. Agriculture 4.0: Polymer Hydrogels as Delivery Agents of Active Ingredients. Gels 2024, 10, 368. [Google Scholar] [CrossRef]

- Sun, S. Enzyme-Embedded Biodegradable Plastic for Sustainable Applications: Advances, Challenges, and Perspectives. ACS Appl. Bio Mat. 2025, 8, 1785–1796. [Google Scholar] [CrossRef]

- Guo, M.; Li, G.; Cai, M.; Hou, X.; Huang, K.; Tang, J.; Guo, C.F. A Tough Hydrogel Adhesive for the Repair of Archeological Pottery. Nano Lett. 2023, 23, 1371–1378. [Google Scholar] [CrossRef]

- Morrow, M.; Sharma, V.; Singh, R.K.; Watson, J.A.; Maltais-Landry, G.; Hochmuth, R.C. Impact of Polymer-Coated Controlled-Release Fertilizer on Maize Growth, Production, and Soil Nitrate in Sandy Soils. Agronomy 2025, 15, 455. [Google Scholar] [CrossRef]

- Markiewicz, A.; Koda, E.; Kiraga, M.; Wrzesiński, G.; Kozanka, K.; Naliwajko, M.; Vaverková, M.D. Polymeric Products in Erosion Control Applications: A Review. Polymers 2024, 16, 2490. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.K.; Oh, S.H.; Song, M.O.; Jang, S.; Kang, S.J.; Kwak, S.K.; Jin, J. Wholly bio-based, ultra-tough, transparent PLA composites reinforced with nanocellulose and nanochitin. Compos. Part B Eng. 2024, 281, 111563. [Google Scholar] [CrossRef]

- Taher, M.A.; Hasan, K.M.F.; Zhu, J. Novel transparent lignin/epoxy resin nanocomposite film development with enhanced UV resistance performance. Appl. Polym. Sci. 2024, 141, e55307. [Google Scholar] [CrossRef]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef]

- Cosentino, L.; Fernandes, J.; Mateus, R. Fast-Growing Bio-Based Construction Materials as an Approach to Accelerate United Nations Sustainable Development Goals. Appl. Sci. 2024, 14, 4850. [Google Scholar] [CrossRef]

- Elnaggar, A. Nine principles of green heritage science: Life cycle assessment as a tool enabling green transformation. Herit. Sci. 2024, 12, 7. [Google Scholar] [CrossRef]

- Rindler, A.; Vay, O.; Hansmann, C.; Konnerth, J. Adhesive-related warping of thin wooden bi-layers. Wood Sci. Technol. 2019, 53, 1015–1033. [Google Scholar] [CrossRef]

- Yan, Y.; Tang, Y.; Yang, Y. Chemical Conservation of Paper-Based Cultural Heritage. Molecules 2025, 30, 122. [Google Scholar] [CrossRef]

- Bassi, M.; Sassoni, E.; Franzoni, E. Experimental Study on an Innovative Biopolymeric Treatment Against Salt Deterioration of Materials in Cultural Heritage. Front. Mat. 2021, 8, 583112. [Google Scholar] [CrossRef]

- Freitas, P.A.V.; González-Martínez, C.; Chiralt, A. Stability and Composting Behaviour of PLA–Starch Laminates Containing Active Extracts and Cellulose Fibres from Rice Straw. Polymers 2024, 16, 1474. [Google Scholar] [CrossRef]

- Yilmaz Atay, H. Antibacterial Activity of Chitosan-Based Systems. In Functional Chitosan; Jana, S., Jana, S., Eds.; Springer: Singapore, 2019; pp. 457–489. [Google Scholar] [CrossRef]

- El-Gamal, R.; Nikolaivits, E.; Zervakis, G.I.; Abdel-Maksoud, G.; Topakas, E.; Christakopoulos, P. The Use of Chitosan in Protecting Wooden Artifacts from Damage by Mold Fungi. Electron. J. Biotechnol. 2016, 24, 70–78. [Google Scholar] [CrossRef]

- Marques, A.P.S.; Almeida, R.O.; Pereira, L.F.R.; Carvalho, M.G.V.S.; Gamelas, J.A.F. Nanocelluloses and Their Applications in Conservation and Restoration of Historical Documents. Polymers 2024, 16, 1227. [Google Scholar] [CrossRef] [PubMed]

- Sonaglia, E.; Schifano, E.; Sharbaf, M.; Uccelletti, D.; Felici, A.C.; Santarelli, M.L. Bacterial Nanocellulose Hydrogel for the Green Cleaning of Copper Stains from Marble. Gels 2024, 10, 150. [Google Scholar] [CrossRef]

- Ali, M.A.; Ali, M.F.; Ciliberto, E.; Greco, E.; Mello, D.; Viscuso, E. A new method for the preparation of gelatin nanolayer: A possible approach to the in situ consolidation of damaged gelatin photographic emulsions. Appl. Phys. A 2016, 122, 552. [Google Scholar] [CrossRef]

- Chelazzi, D.; Badillo-Sanchez, D.; Giorgi, R.; Cincinelli, A.; Baglioni, P. Self-regenerated silk fibroin with controlled crystallinity for the reinforcement of silk. J. Colloid Interface Sci. 2020, 576, 230–240. [Google Scholar] [CrossRef]

- Watcharakitti, J.; Win, E.E.; Nimnuan, J.; Smith, S.M. Modified Starch-Based Adhesives: A Review. Polymers 2022, 14, 2023. [Google Scholar] [CrossRef]

- Compart, J.; Singh, A.; Fettke, J.; Apriyanto, A. Customizing Starch Properties: A Review of Starch Modifications and Their Applications. Polymers 2023, 15, 3491. [Google Scholar] [CrossRef]

- Prisby, R.; Luchini, A.; Liotta, L.A.; Solazzo, C. Wheat-Based Glues in Conservation and Cultural Heritage: (Dis)solving the Proteome of Flour and Starch Pastes and Their Adhering Properties. J. Proteome Res. 2024, 23, 1649–1665. [Google Scholar] [CrossRef]

- Lamuraglia, R.; Campostrini, A.; Ghedini, E.; De Lorenzi Pezzolo, A.; Di Michele, A.; Franceschin, G.; Menegazzo, F.; Signoretto, M.; Traviglia, A. A New Green Coating for the Protection of Frescoes: From the Synthesis to the Performances Evaluation. Coatings 2023, 13, 277. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Zhang, Z.; Zhang, B. The application of thymol-loaded chitosan nanoparticles to control the biodeterioration of cultural heritage sites. J. Cult. Herit. 2022, 53, 206–211. [Google Scholar] [CrossRef]

- Mamun, A.; Kiari, M.; Sabantina, L. A Recent Review of Electrospun Porous Carbon Nanofiber Mats for Energy Storage and Generation Applications. Membranes 2023, 13, 830. [Google Scholar] [CrossRef] [PubMed]

- Camargos, C.H.M.; Poggi, G.; Chelazzi, D.; Baglioni, P.; Rezende, C.A. Protective Coatings Based on Cellulose Nanofibrils, Cellulose Nanocrystals, and Lignin Nanoparticles for the Conservation of Cellulosic Artifacts. ACS Appl. Nano Mater. 2022, 5, 13245–13259. [Google Scholar] [CrossRef]

- Pedna, A.; Pinho, L.; Frediani, P.; Mosquera, M.J. Obtaining SiO2-Fluorinated PLA Bionanocomposites with Application as Reversible and Highly-Hydrophobic Coatings of Buildings. Prog. Org. Coat. 2016, 90, 91–100. [Google Scholar] [CrossRef]

- Chen, M.; Xiang, S.; Tang, H. Hydrogel Applications for Cultural Heritage Protection: Emphasis on Antifungal Efficacy and Emerging Research Directions. Gels 2025, 11, 606. [Google Scholar] [CrossRef]

- Mistretta, M.C.; la Mantia, F.P.; Titone, V.; Megna, B.; Botta, L.; Morreale, M. Durability of Biodegradable Polymers for the Conservation of Cultural Heritage. Front. Mater. 2019, 6, 151. [Google Scholar] [CrossRef]

- Huang, Q.; Zha, J.; Han, X.; Wang, H. Temporary Consolidation of Marine Artifact Based on Polyvinyl Alcohol/Tannic Acid Reversible Hydrogel. Polymers 2023, 15, 4621. [Google Scholar] [CrossRef]

- Omidian, H.; Babanejad, N. Bioinspired Polymers: Bridging Nature’s Ingenuity with Synthetic Innovation. Macromol 2024, 4, 190–212. [Google Scholar] [CrossRef]

- Wang, X.; Yue, J.; Huang, T. Experimental Research on Polymers for the Restoration of Cultural Relic Buildings. Buildings 2025, 15, 2036. [Google Scholar] [CrossRef]

- Pergola, M.; De Falco, E.; Belliggiano, A.; Ievoli, C. The Most Relevant Socio-Economic Aspects of Medicinal and Aromatic Plants through a Literature Review. Agriculture 2024, 14, 405. [Google Scholar] [CrossRef]

- Ayaz, M.; Li, C.-H.; Ali, Q.; Zhao, W.; Chi, Y.-K.; Shafiq, M.; Ali, F.; Yu, X.-Y.; Yu, Q.; Zhao, J.-T.; et al. Bacterial and Fungal Biocontrol Agents for Plant Disease Protection: Journey from Lab to Field, Current Status, Challenges, and Global Perspectives. Molecules 2023, 28, 6735. [Google Scholar] [CrossRef]

- Jangpangi, D.; Patni, B.; Chandola, V.; Chandra, S. Medicinal plants in a changing climate: Understanding the links between environmental stress and secondary metabolite synthesis. Front. Plant Sci. 2025, 16, 1587337. [Google Scholar] [CrossRef] [PubMed]

- Ganosi, E.; Barda, C.; Grafakou, M.-E.; Rallis, M.C.; Skaltsa, H. An In-Depth Stability Study of the Essential Oils from Mentha × piperita, Mentha spicata, Origanum vulgare, and Thymus vulgaris: The Impact of Thermal and Storage Conditions. Separations 2023, 10, 488. [Google Scholar] [CrossRef]

- Ali, A.; Chong, C.H.; Mah, S.H.; Abdullah, L.C.; Choong, T.S.Y.; Chua, B.L. Impact of Storage Conditions on the Stability of Predominant Phenolic Constituents and Antioxidant Activity of Dried Piper betle Extracts. Molecules 2018, 23, 484. [Google Scholar] [CrossRef]

- Batiha, G.E.-S.; Teibo, J.O.; Wasef, L.; Shaheen, H.M.; Akomolafe, A.P.; Teibo, T.K.A.; Al-Kuraishy, H.M.; Al-Garbeeb, A.I.; Alexiou, A.; Papadakis, M. A review of the bioactive components and pharmacological properties of Lavandula species. Naunyn-Schmiedeberg’s Arch. Pharmacol. 2023, 396, 877–900. [Google Scholar] [CrossRef]

- Hammoudi Halat, D.; Krayem, M.; Khaled, S.; Younes, S. A Focused Insight into Thyme: Biological, Chemical, and Therapeutic Properties of an Indigenous Mediterranean Herb. Nutrients 2022, 14, 2104. [Google Scholar] [CrossRef]

- Kowalczyk, A.; Twarowski, B.; Fecka, I.; Tuberoso, C.I.G.; Jerković, I. Thymol as a Component of Chitosan Systems—Several New Applications in Medicine: A Comprehensive Review. Plants 2024, 13, 362. [Google Scholar] [CrossRef]

- Sreelatha, S.; Kumar, N.; Rajani, S. Biological effects of Thymol loaded chitosan nanoparticles (TCNPs) on bacterial plant pathogen Xanthomonas campestris pv. campestris. Front. Microbiol. 2022, 13, 1085113. [Google Scholar] [CrossRef]

- Vitali, A.; Stringaro, A.; Colone, M.; Muntiu, A.; Angiolella, L. Antifungal Carvacrol Loaded Chitosan Nanoparticles. Antibiotics 2022, 11, 11. [Google Scholar] [CrossRef]

- Visan, A.I.; Negut, I. Coatings Based on Essential Oils for Combating Antibiotic Resistance. Antibiotics 2024, 13, 625. [Google Scholar] [CrossRef]

- Guzmán-Pincheira, C.; Moeini, A.; Oliveira, P.E.; Abril, D.; Paredes-Padilla, Y.A.; Benavides-Valenzuela, S. Development of Alginate-Chitosan Bioactive Films Containing Essential Oils for Use in Food Packaging. Foods 2025, 14, 256. [Google Scholar] [CrossRef]

- Ali, E.F.; Hassan, F.A.S.; Al-Harbi, M.S.; Ibrahim, O.H.M.; Abdul-Hafeez, E.Y.; Moussa, M.M. Impact of chitosan nanoparticles edible coating on shelf-life extension and postharvest quality of coriander herb. J. Food Process. Preserv. 2022, 46, e16238. [Google Scholar] [CrossRef]

- Kalagatur, N.K.; Ghosh, O.S.N.; Sundararaj, N.; Mudili, V. Antifungal activity of chitosan nanoparticles encapsulated with Cymbopogon martinii essential oil on plant pathogenic fungi Fusarium graminearum. Front. Pharmacol. 2018, 6, 610. [Google Scholar] [CrossRef]

- Sun, C.; Zeng, Z.; Cui, H.; Verheggen, F. Polymer-based nanoinsecticides: Current developments, environmental risks and future challenges. A review. Biotechnol. Agron. Société Environ. 2020, 24, 59–69. [Google Scholar] [CrossRef]

- Rather, A.H.; Wani, T.U.; Khan, R.S.; Pant, B.; Park, M.; Sheikh, F.A. Prospects of Polymeric Nanofibers Loaded with Essential Oils for Biomedical and Food-Packaging Applications. Int. J. Mol. Sci. 2021, 22, 4017. [Google Scholar] [CrossRef]

- Saito, H.; Yamashita, Y.; Sakata, N.; Ishiga, T.; Shiraishi, N.; Usuki, G.; Nguyen, V.T.; Yamamura, E.; Ishiga, Y. Covering Soybean Leaves with Cellulose Nanofiber Changes Leaf Surface Hydrophobicity and Confers Resistance Against Phakopsora pachyrhizi. Front. Plant Sci. 2021, 12, 726565. [Google Scholar] [CrossRef] [PubMed]

- Farias, B.V.; Pirzada, T.; Mathew, R.; Sit, T.L.; Opperman, C.; Khan, S.A. Electrospun polymer nanofibers as seed coatings for crop protection. ACS Sustain. Chem. Eng. 2019, 7, 19848–19856. [Google Scholar] [CrossRef]

- Selvam, T.; Rahman, N.M.M.A.; Olivito, F.; Ilham, Z.; Ahmad, R.; Wan-Mohtar, W.A.A.Q.I. Agricultural Waste-Derived Biopolymers for Sustainable Food Packaging: Challenges and Future Prospects. Polymers 2025, 17, 1897. [Google Scholar] [CrossRef] [PubMed]

- Vasile, C.; Baican, M. Lignins as Promising Renewable Biopolymers and Bioactive Compounds for High-Performance Materials. Polymers 2023, 15, 3177. [Google Scholar] [CrossRef] [PubMed]

- Silva, V.; Yang, X.; Fleskens, L.; Ritsema, C.J.; Geissen, V. Environmental and Human Health at Risk–Scenarios to Achieve the Farm to Fork 50% Pesticide Reduction Goals. Environ. Int. 2022, 165, 107296. [Google Scholar] [CrossRef]

- Mihai, F.-C.; Gündoğdu, S.; Markley, L.A.; Olivelli, A.; Khan, F.R.; Gwinnett, C.; Gutberlet, J.; Reyna-Bensusan, N.; Llanquileo-Melgarejo, P.; Meidiana, C.; et al. Plastic Pollution, Waste Management Issues, and Circular Economy Opportunities in Rural Communities. Sustainability 2022, 14, 20. [Google Scholar] [CrossRef]

- Rahman, M.M.; Uddin, M.N.; Parvez, M.M.H.; Mohotadi, M.A.A.; Ferdush, J. Bio-Based Nanomaterials for Groundwater Arsenic Remediation: Mechanisms, Challenges, and Future Perspectives. Nanomaterials 2025, 15, 933. [Google Scholar] [CrossRef]

- Gadd, G.; Fomina, M.; Pinzari, F. Fungal biodeterioration and preservation of cultural heritage, artwork, and historical artifacts: Extremophily and adaptation. Microbiol. Mol. Biol. Rev. 2024, 88, e0020022. [Google Scholar] [CrossRef] [PubMed]

- Derksen, K.; Brimblecombe, P.; Piñar, G.; Waldherr, M.; Graf, A.; Haltrich, M.; Querner, P.; Sterflinger, K. Fungal Biodeterioration Risk in Monastic Libraries without Climate Control. Microorganisms 2024, 12, 1450. [Google Scholar] [CrossRef]

- Wei, G.; Guo, X.; Liang, Y.; Liu, C.; Zhang, G.; Liang, C.; Huang, Z.; Zheng, Y.; Chen, S.; Dong, L. Occurrence of fungi and mycotoxins in herbal medicines and rapid detection of toxin-producing fungi. Environ. Pollut. 2023, 333, 122082. [Google Scholar] [CrossRef]

- Wang, G.; Jiao, M.; Hu, J.; Xun, Y.; Chen, L.; Qiu, J.; Ji, F.; Lee, Y.-W.; Shi, J.; Xu, J. Quantitative Analysis of Fungal Contamination of Different Herbal Medicines in China. Toxins 2024, 16, 229. [Google Scholar] [CrossRef]

- Ruffolo, S.A.; La Russa, M.F.; Rovella, N.; Ricca, M. The Impact of Air Pollution on Stone Materials. Environments 2023, 10, 119. [Google Scholar] [CrossRef]

- Bai, Z.; Yan, Y. Dose–Response Functions for Assessing Corrosion Risks to Urban Heritage Materials from Air Pollution Under Climate Change: Insights from Europe and China. Buildings 2025, 15, 2271. [Google Scholar] [CrossRef]

- Mehmood, Z.; Yang, H.-H.; Awan, M.U.F.; Ahmed, U.; Hasnain, A.; Luqman, M.; Muhammad, S.; Sardar, A.A.; Chan, T.-Y.; Sharjeel, A. Effects of Air Pollution on Morphological, Biochemical, DNA, and Tolerance Ability of Roadside Plant Species. Sustainability 2024, 16, 3427. [Google Scholar] [CrossRef]

- Roy, A.; Mandal, M.; Das, S.; Popek, R.; Rakwal, R.; Agrawal, G.K.; Awasthi, A.; Sarkar, A. The Cellular Consequences of Particulate Matter Pollutants in Plants: Safeguarding the Harmonious Integration of Structure and Function. Sci. Total Environ. 2024, 914, 169763. [Google Scholar] [CrossRef]

- Asiminicesei, D.-M.; Fertu, D.I.; Gavrilescu, M. Impact of Heavy Metal Pollution in the Environment on the Metabolic Profile of Medicinal Plants and Their Therapeutic Potential. Plants 2024, 13, 913. [Google Scholar] [CrossRef]

- Carotenuto, M.R.; Chinnici, I.; Camuffo, D.; della Valle, A.; Prestileo, F.; Megna, B.; Cavallaro, G.; Lazzara, G. Climate Risk and Conservation Challenges at Palermo’s Specola Museum. Heritage 2024, 7, 7165–7187. [Google Scholar] [CrossRef]

- García-Caparrós, P.; Romero, M.J.; Llanderal, A.; Cermeño, P.; Lao, M.T.; Segura, M.L. Effects of Drought Stress on Biomass, Essential Oil Content, Nutritional Parameters, and Costs of Production in Six Lamiaceae Species. Water 2019, 11, 573. [Google Scholar] [CrossRef]

- Yasir, M.; Hossain, A.; Pratap-Singh, A. Pesticide Degradation: Impacts on Soil Fertility and Nutrient Cycling. Environments 2025, 12, 272. [Google Scholar] [CrossRef]

- Hasan, M.M.; Tarannum, M.N. Adverse impacts of microplastics on soil physicochemical properties and crop health in agricultural systems. J. Hazard. Mater. Adv. 2025, 17, 100528. [Google Scholar] [CrossRef]

- Darban, Z.; Shahabuddin, S.; Gaur, R.; Ahmad, I.; Sridewi, N. Hydrogel-Based Adsorbent Material for the Effective Removal of Heavy Metals from Wastewater: A Comprehensive Review. Gels 2022, 8, 263. [Google Scholar] [CrossRef]

- Tang, S.; Yang, J.; Lin, L.; Peng, K.; Chen, Y.; Jin, S.; Yao, W. Construction of Physically Crosslinked Chitosan/Sodium Alginate/Calcium Ion Double-Network Hydrogel and Its Application to Heavy Metal Ions Removal. Chem. Eng. J. 2020, 393, 124728. [Google Scholar] [CrossRef]

- Gulotta, D.; Saviello, D.; Gherardi, F.; Toniolo, L.; Anzani, M.; Rabbolini, A.; Goidanich, S. Setup of a sustainable indoor cleaning methodology for the sculpted stone surfaces of the Duomo of Milan. Herit. Sci. 2014, 2, 6. [Google Scholar] [CrossRef]

- El-Beltagi, H.S.; Basit, A.; Mohamed, H.I.; Ali, I.; Ullah, S.; Kamel, E.A.R.; Shalaby, T.A.; Ramadan, K.M.A.; Alkhateeb, A.A.; Ghazzawy, H.S. Mulching as a Sustainable Water and Soil Saving Practice in Agriculture: A Review. Agronomy 2022, 12, 1881. [Google Scholar] [CrossRef]

- Kamaly, N.; Yameen, B.; Wu, J.; Farokhzad, O.C. Degradable Controlled-Release Polymers and Polymeric Nanoparticles: Mechanisms of Controlling Drug Release. Chem. Rev. 2016, 116, 2602–2663. [Google Scholar] [CrossRef]

- Santhamoorthy, M.; Asaithambi, P.; Ramkumar, V.; Elangovan, N.; Perumal, I.; Kim, S.C. A Review on the Recent Advancements of Polymer-Modified Mesoporous Silica Nanoparticles for Drug Delivery Under Stimuli-Trigger. Polymers 2025, 17, 1640. [Google Scholar] [CrossRef]

- Mateus, D.; Costa, F.; de Jesus, V.; Malaquias, L. Biocides Based on Essential Oils for Sustainable Conservation and Restoration of Mural Paintings in Built Cultural Heritage. Sustainability 2024, 16, 11223. [Google Scholar] [CrossRef]

- Zhang, X.; Ismail, B.B.; Cheng, H.; Jin, T.Z.; Qian, M.; Arabi, S.A.; Liu, D.; Guo, M. Emerging chitosan-essential oil films and coatings for food preservation-A review of advances and applications. Carbohydr. Polym. 2021, 273, 118616. [Google Scholar] [CrossRef]

- Ma, S.; Li, A.; Pan, L. Application Progress of Multi-Functional Polymer Composite Nanofibers Based on Electrospinning: A Brief Review. Polymers 2024, 16, 2459. [Google Scholar] [CrossRef]

- Fincheira, P.; Hoffmann, N.; Tortella, G.; Ruiz, A.; Cornejo, P.; Diez, M.C.; Seabra, A.B.; Benavides-Mendoza, A.; Rubilar, O. Eco-Efficient Systems Based on Nanocarriers for the Controlled Release of Fertilizers and Pesticides: Toward Smart Agriculture. Nanomaterials 2023, 13, 1978. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, K.; Mickan, B.S.; O’Connor, J.; Gurung, S.K.; Moheimani, N.R.; Jenkins, S.N. Development of a controlled release fertilizer by incorporating lauric acid into microalgal biomass: Dynamics on soil biological processes for efficient utilisation of waste resources. J. Environ. Manag. 2023, 344, 118392. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Zhang, Z.; Yue, D.; Belko, V.O.; Maksimenko, S.A.; Deng, J.; Sun, Y.; Yang, Z.; Fu, Q.; Liu, B.; et al. Recent progress in degradation and recycling of epoxy resin. J. Mater. Res. Technol. 2024, 32, 2891–2912. [Google Scholar] [CrossRef]

- Chen, J.; Wu, J.; Raffa, P.; Picchioni, F.; Koning, C.E. Superabsorbent Polymers: From Long-Established, Microplastics Generating Systems, to Sustainable, Biodegradable and Future Proof Alternatives. Prog. Polym. Sci. 2022, 125, 101475. [Google Scholar] [CrossRef]

- Liu, L.; Xu, M.; Ye, Y.; Zhang, B. On the degradation of (micro) plastics: Degradation methods, influencing factors, environmental impacts. Sci. Total Environ. 2022, 806, 151312. [Google Scholar] [CrossRef] [PubMed]

- Engel, P. Reversibility—Minimal Intervention—Conservation-Codicology: Terminology as a Tool for Awareness Raising. J. Pap. Conserv. 2023, 24, 148–154. [Google Scholar] [CrossRef]

- Grillo, R.; Fraceto, L.F.; Amorim, M.J.B.; Scott-Fordsmand, J.J.; Schoonjans, R.; Chaudhry, Q. Ecotoxicological and regulatory aspects of environmental sustainability of nanopesticides. J. Hazard. Mater. 2021, 404, 124148. [Google Scholar] [CrossRef]

- Li, S.; Tang, J.; Jiang, L.; Jiao, L. Conservation of aged paper using reduced cellulose nanofibrils/aminopropyltriethoxysilane modified CaCO3 particles coating. Int. J. Biol. Macromol. 2023, 255, 128254. [Google Scholar] [CrossRef]

- Baldassarre, F.; Schiavi, D.; Di Lorenzo, V.; Biondo, F.; Vergaro, V.; Colangelo, G.; Balestra, G.M.; Ciccarella, G. Cellulose Nanocrystal-Based Emulsion of Thyme Essential Oil: Preparation and Characterisation as Sustainable Crop Protection Tool. Molecules 2023, 28, 7884. [Google Scholar] [CrossRef] [PubMed]

| Domain | Synthetic Polymers (Limitations), [Reference] | Bio-Based Polymers (Advantages), [Reference] |

|---|---|---|

| Cultural Heritage | PVAc, acrylics, epoxies (poor reversibility, yellowing, embrittlement) [34,35] | Chitosan, cellulose, PLA (reversible, compatible, biodegradable) [75] |

| Agriculture | Seed/fertilizer coatings, mulching films (persistence, residues) [76] | Chitosan, starch, PLA (controlled release, biodegradable coatings) [77] |

| Environmental protection | Durable plastics (accumulation, microplastic pollution) [9] | Cellulose, PLA, proteins (adsorbents, biodegradable films, reduced footprint) [78] |

| Nanostructured System | Heritage Science Applications | Agriculture Applications | Environmental Applications |

|---|---|---|---|

| Nanofibers | Breathable protective coatings, antimicrobial materials [92] | Controlled release materials for fertilizers/pesticides [93] | Filtration, pollutant capture materials [94] |

| Nanocapsules | Deep penetration consolidants [95] | Encapsulation of essential oils, phenolics [96] | Encapsulation of remediation agents [97] |

| Nanocomposites | Transparent consolidants, reinforcement of fragile materials [98] | UV protection, nutrient release control [99] | Adsorbents, photocatalysts for pollutants [100] |

| Smart polymers | Humidity/light-responsive protective films [101] | Soil pH/moisture-triggered release systems [102] | Self-degrading plastics, adaptive remediation materials [103] |

| Polymer/System | Key Requirement(s) Addressed | Example of Application | Advantages | Limitations/ Challenges | Reference |

|---|---|---|---|---|---|

| Chitosan (Low-MW—25–45 kDa, 1%) | Antimicrobial protection, compatibility, non-alteration | Added to sturgeon-glue mock layers; inhibited multiple tempera-painting fungal strains | Effective against resistant fungi; did not affect optical/surface properties; biodegradable; reversible | Requires molecular weight optimization; needs real-artwork validation | [60] |

| Bacterial Nanocellulose (BC) hydrogel loaded with EDTA | Cleaning capability, compatibility, reversibility, sustainability | Green cleaning of copper stains on marble using BC hydrogels loaded with 1% w/v EDTA applied for 120 min | Biodegradable; high cleaning efficacy; chromatically safe (ΔE* < 5); peelable with no residue | Effective only with ≥1% EDTA and sufficient application time | [119] |

| Proteins (gelatin nanolayer/nanoparticles) | Compatibility, micro-scale consolidation | Stabilization of damaged gelatin photographic emulsions | Compatible with original binder; targeted consolidation | Requires characterization of long-term behavior | [120] |

| Proteins (self-regenerated silk fibroin films) | Mechanical reinforcement, compatibility, sustainability | Applied to aged silk textiles; tunable crystallinity/amorphousness restored ductility and strength | Fully compatible with silk; sustainable (waste silk source); tailored mechanical properties; reversible | Performance depends on fibroin concentration; requires optimization for each degradation state | [121] |

| Starch | Reversibility, flexibility, chemical stability | Paper and book conservation; hinging, mending, leafcasting, wall paintings | Durable yet flexible; reversible with moisture; chemically stable; simple proteome reduces risk of long-term alteration | Susceptible to dehydration (contraction, fracture); lower adhesion than flour pastes; potential microbial vulnerability | [125] |

| PLA/MMT bio-nanocomposite coatings | Hydrophobicity, durability, environmental sustainability, reversibility | Applied to Marmara marble to reduce water infiltration and pollution-induced sulfation | Increased water contact angle (from ~75° uncoated to 108° with PLA/MMT5); reduced capillary absorption by 46–66%; decreased water vapor transmission up to 59%; improved resistance to SO2-induced gypsum crust formation (4–5 × less than uncoated); preserved marble color at ≤5 wt% clay; biodegradable, reversible | At 7 wt% clay, poor dispersion caused color change (ΔE > 3) and reduced performance; requires optimization of filler concentration and long-term aging validation | [70] |

| Polymer System | Encapsulated/Active Agent | Target/Stressor | Application Mode | Key Outcomes | Reference |

|---|---|---|---|---|---|

| Chitosan nanoparticles (CSNPs) | Thymol | Xanthomonas campestris (Pammel 1895) Dowson 1939 (bacterial pathogen) | Foliar application | Eliminated bacteria at 500 µg/mL within 24 h; caused membrane disruption, ROS production, lipid peroxidation, and metabolic damage (lipids, proteins, nucleic acids). | [143] |

| Chitosan nanoparticles (CSNPs) | Carvacrol | Candida spp. (fungal model; antifungal protection) | In vitro assays (planktonic and biofilm) | Potent inhibition of planktonic growth, strongest against C. tropicalis and C. krusei; encapsulation improved antifungal efficacy compared to free carvacrol. | [144] |

| Chitosan nanoparticles (CSNPs) edible coating | — (coating film) | Post-harvest deterioration of coriander leaves | Edible coating | Extended shelf life >2×; preserved chlorophyll, carotenoids, proteins, and essential oils; reduced respiration, PPO/LOX activity; maintained antioxidant activity. | [147] |

| Chitosan nanoparticles (Ce-CMEO-NPs) | Cymbopogon martinii essential oil | Fusarium graminearum (fungal pathogen, mycotoxin producer) | Post-harvest storage of maize (model) | Nanoparticles (~450–480 nm) provided controlled EO release; superior fungal inhibition; reduced DON and ZEA mycotoxin accumulation; lowered EO dosage required. | [151] |

| Cellulose nanofibers (CNF) | — (surface coating) | Phakopsora pachyrhizi Syd. & P. Syd., (1914) (soybean rust fungus) | Foliar spray (0.1% CNF suspension) | Shifted leaf surface from hydrophobic to hydrophilic; inhibited germ-tube/appressoria formation; reduced lesions without inducing plant immunity. | [152] |

| Electrospun cellulose diacetate (CDA) nanofibers | Abamectin or fluopyram | Pests (abamectin) and fungal pathogens (fluopyram vs. Alternaria lineariae) | Seed coating (soybean) | Nanofiber coatings stable >2 weeks; no effect on germination; sustained AI release; fluopyram-loaded fibers suppressed fungal growth effectively. | [115] |

| Domain | Shared Challenge | Polymer-Based Solution | Cross-Domain Relevance |

|---|---|---|---|

| Cultural Heritage | Need for stability but also reversibility of treatments | Bio-based consolidants (e.g., chitosan, nanocellulose) with reversible solubility | Informs agriculture on designing carriers that persist during use but degrade safely |

| MAP Cultivation | Need for persistence in the field but no harmful residues | Controlled-release biodegradable carriers (PLA, starch, alginate) | Inspires conservation to use “time-limited” coatings or delivery systems |

| Environment | Pervasive pollution from persistent plastics and residues | Biodegradable mulches, adsorbent gels, self-degrading films | Encourages heritage and agriculture to adopt life-cycle design principles |

| All domains | Regulatory approval and ethical acceptance | Non-toxic, renewable polymers; standardized safety tests | Supports harmonization of regulations across heritage, food, and environment |

| All domains | Unpredictable performance under real conditions | AI modeling and digital twins for degradation and compatibility | Accelerates testing and adoption across multiple contexts |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fierascu, I.; Baroi, A.M.; Matei, R.I.; Fistos, T.; Chican, I.E.; Enascuta, C.E.; Avramescu, S.M.; Fierascu, R.C. Bio-Based and Nanostructured Polymers for Sustainable Protection of Cultural Heritage and Medicinal Crops: Convergence of Heritage Science, Circular Bioeconomy, and Environmental Protection. Polymers 2025, 17, 2582. https://doi.org/10.3390/polym17192582

Fierascu I, Baroi AM, Matei RI, Fistos T, Chican IE, Enascuta CE, Avramescu SM, Fierascu RC. Bio-Based and Nanostructured Polymers for Sustainable Protection of Cultural Heritage and Medicinal Crops: Convergence of Heritage Science, Circular Bioeconomy, and Environmental Protection. Polymers. 2025; 17(19):2582. https://doi.org/10.3390/polym17192582

Chicago/Turabian StyleFierascu, Irina, Anda Maria Baroi, Roxana Ioana Matei, Toma Fistos, Irina Elena Chican, Cristina Emanuela Enascuta, Sorin Marius Avramescu, and Radu Claudiu Fierascu. 2025. "Bio-Based and Nanostructured Polymers for Sustainable Protection of Cultural Heritage and Medicinal Crops: Convergence of Heritage Science, Circular Bioeconomy, and Environmental Protection" Polymers 17, no. 19: 2582. https://doi.org/10.3390/polym17192582

APA StyleFierascu, I., Baroi, A. M., Matei, R. I., Fistos, T., Chican, I. E., Enascuta, C. E., Avramescu, S. M., & Fierascu, R. C. (2025). Bio-Based and Nanostructured Polymers for Sustainable Protection of Cultural Heritage and Medicinal Crops: Convergence of Heritage Science, Circular Bioeconomy, and Environmental Protection. Polymers, 17(19), 2582. https://doi.org/10.3390/polym17192582