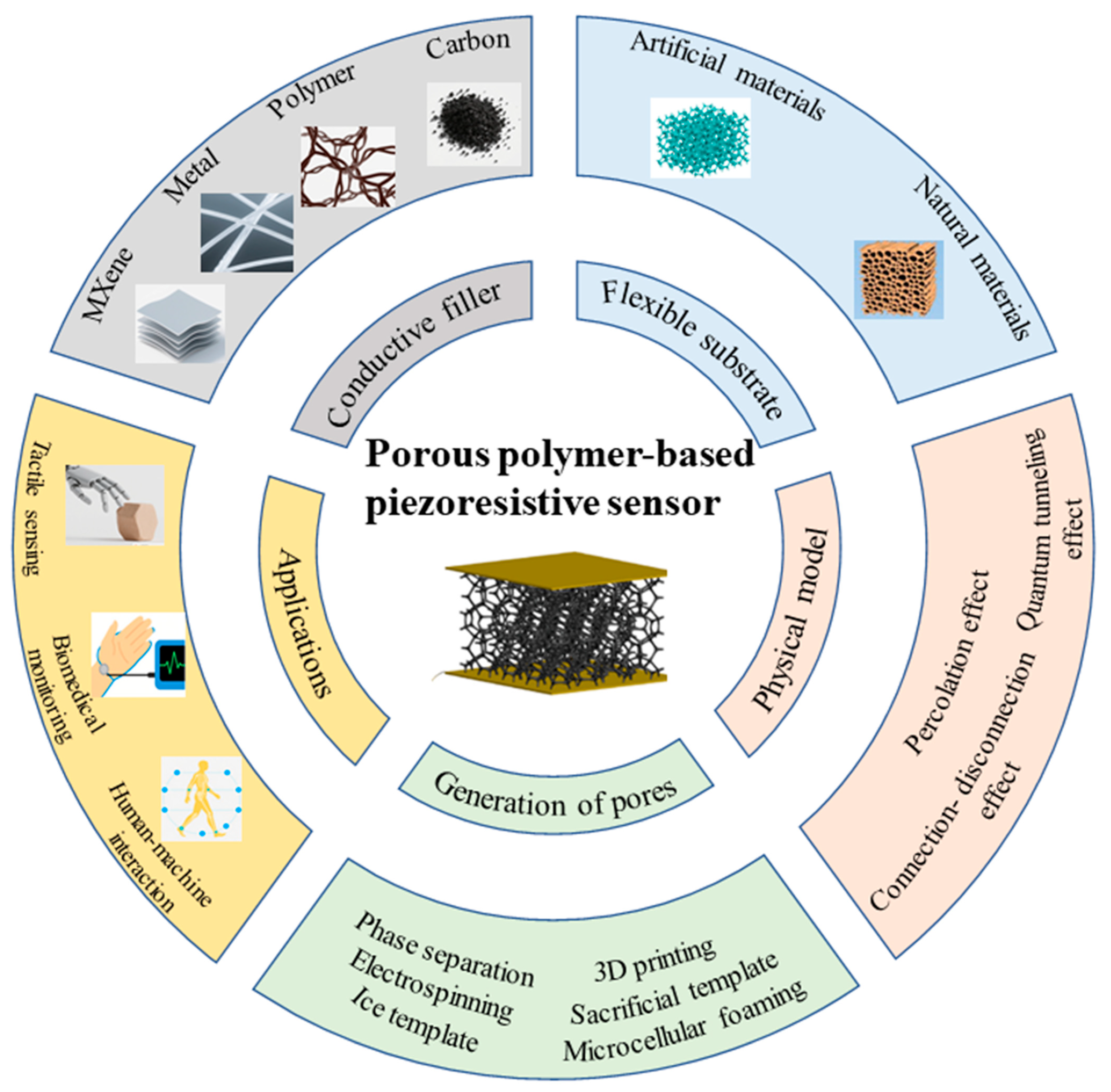

Recent Advances in Porous Polymer-Based Flexible Piezoresistive Pressure Sensors

Abstract

1. Introduction

2. Performance Metrics and Physical Mechanism of Piezoresistive Sensing

2.1. Performance Metrics

2.1.1. Sensitivity

2.1.2. Linearity

2.1.3. Response/Recovery Time

2.1.4. Long-Term Stability

2.1.5. Detection Limit

2.2. Physical Mechanism of Piezoresistive Effect

3. Fabrication Techniques of Porous Structures

3.1. Phase Separation

3.2. Three-Dimensional Printing

3.3. Electrospinning

3.4. Sacrificial Template Method

3.5. Ice Template Method

3.6. Microcellular Foaming

4. Conductive Fillers

4.1. Carbon-Based Conductors

4.2. Polymer Conductors

4.3. Metal Conductors

4.4. MXene

5. Substrate Materials for Porous Polymer-Based Flexible Piezoresistive Pressure Sensors

5.1. Artificial Polymer Materials

5.1.1. Silicone Materials

5.1.2. PU

5.1.3. PI

5.2. Natural Polymer Materials

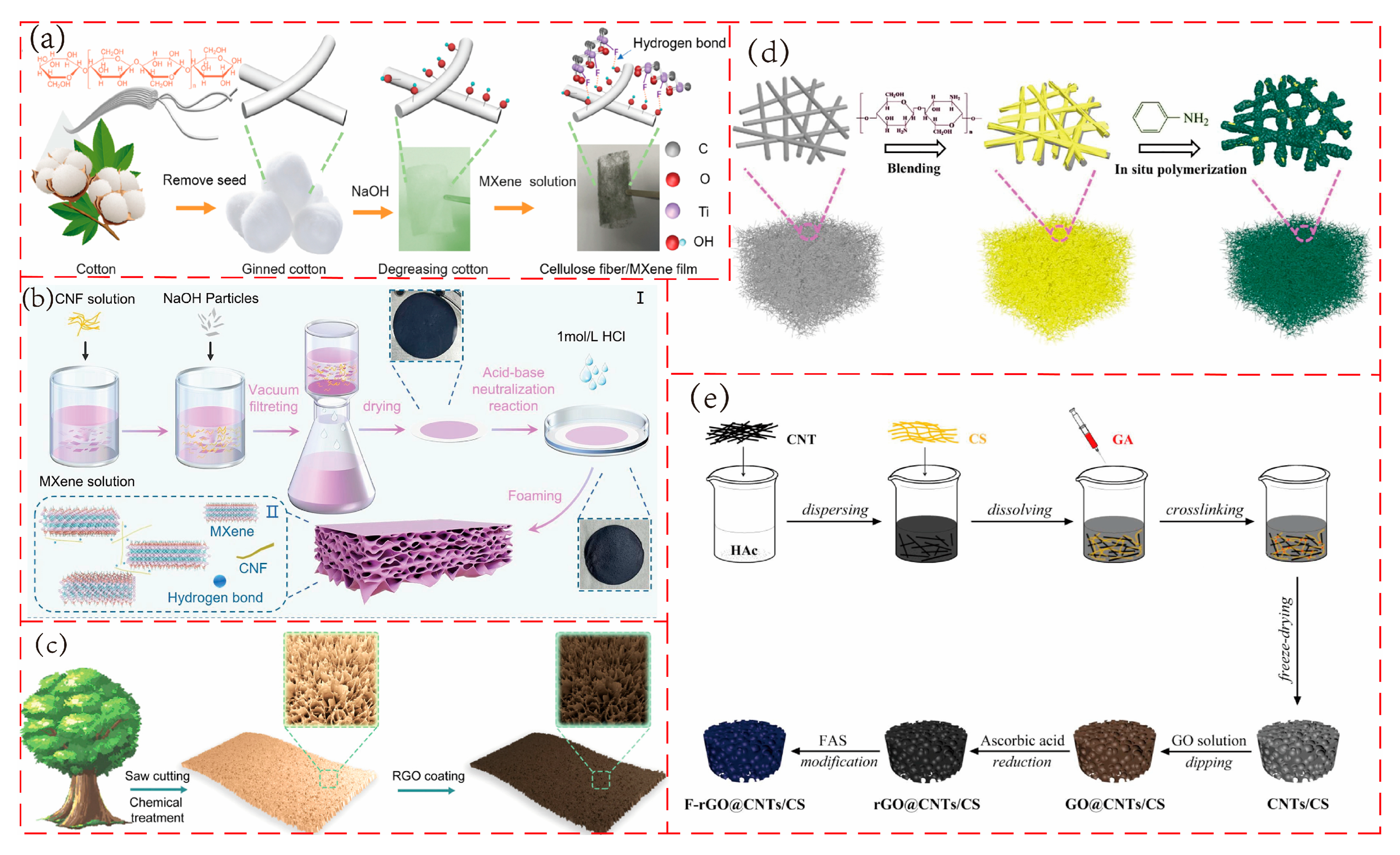

5.2.1. Cellulose/Natural Wood

5.2.2. Chitosan

6. Application of Porous Polymer-Based Flexible Piezoresistive Pressure Sensors

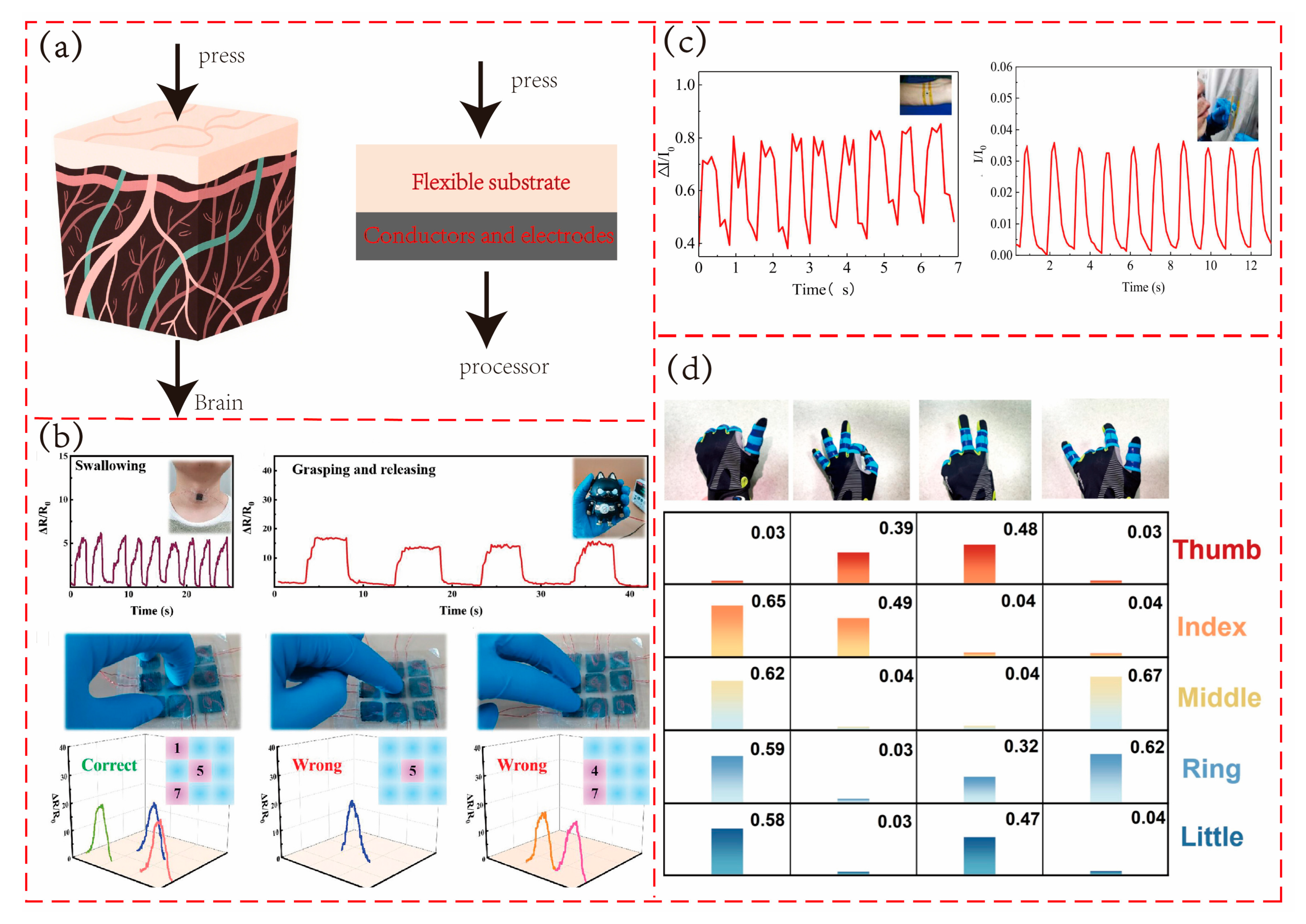

6.1. Tactile Sensing

6.2. Biomedical Monitoring

6.3. Human–Machine Interaction

7. Summary and Outlook

- (1)

- The development of new porous materials, exploring the potential for multi-material composites, and optimizing the composite processes of conductive fillers and substrates. In parallel, future research should also consider the environmental impact of substrate materials, including quantified biodegradability and lifecycle assessments, to better compare natural and synthetic porous polymers and guide the sustainable development of next-generation sensors.

- (2)

- The advancement of low-cost, scalable fabrication technologies to facilitate the translation of basic research into practical applications.

- (3)

- The focus lies on developing composite materials that can maintain relatively stable sensitivity under extreme operating conditions (e.g., extreme temperatures, high fatigue, etc.). Equally important is the establishment of standardized testing protocols and benchmarks to systematically evaluate fatigue and failure modes, which will ensure sensor reliability and enable fair comparison across studies.

- (4)

- The integration of multifunctional sensing capabilities into porous piezoresistive platforms represents another important future direction. Beyond pressure and strain, future designs should aim to incorporate additional modalities such as temperature or humidity into a single architecture. This can be achieved by leveraging hierarchical structures, heterogeneous composites, or hybrid sensing mechanisms, enabling simultaneous and decoupled detection of multiple stimuli. Such multifunctional platforms would significantly broaden the applicability of porous piezoresistive sensors in intelligent healthcare, robotics, and structural monitoring.

- (5)

- Another promising direction is improving signal fidelity and integration. Emerging approaches such as the incorporation of machine learning algorithms for signal processing and pattern recognition, as well as the integration of porous piezoresistive sensors with flexible or miniaturized electronic systems, can enhance data accuracy, reduce noise, and enable real-time intelligent analysis. These strategies will facilitate seamless integration into wearable devices, robotic systems, and industrial monitoring platforms, thereby advancing the practical applicability of porous piezoresistive sensors.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Shang, J.-C.; Wang, W.-F.; Yang, Y.-F.; Yuan, Y.-N.; Lei, H.-S.; Fang, D.-N. Polyurethane sponges-based ultrasensitive pressure sensor via bioinspired microstructure generated by pre-strain strategy. Compos. Sci. Technol. 2022, 221, 109308. [Google Scholar] [CrossRef]

- Huang, W.; Li, H.Q.; Zheng, L.Z.; Lai, X.J.; Guan, H.; Wei, Y.; Feng, H.Y.; Zeng, X.R. Superhydrophobic and high-performance wood-based piezoresistive pressure sensors for detecting human motions. Chem. Eng. J. 2021, 426, 130837. [Google Scholar] [CrossRef]

- Zhai, Y.; Yu, Y.F.; Zhou, K.K.; Yun, Z.G.; Huang, W.J.; Liu, H.; Xia, Q.J.; Dai, K.; Zheng, G.Q.; Liu, C.T.; et al. Flexible and wearable carbon black/thermoplastic polyurethane foam with a pinnate-veined aligned porous structure for multifunctional piezoresistive sensors. Chem. Eng. J. 2020, 382, 122985. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, M.; Zhang, C.; Wei, Z.; Wang, Y.; Gao, C.; Zhu, J.; Gao, J.; Shen, M.; Gao, Q. A breathable and reliable thermoplastic polyurethane/Ag@K2Ti4O9 composite film with an asymmetrical porous structure for wearable piezoresistive sensors. J. Mater. Chem. C 2022, 10, 12986–12997. [Google Scholar] [CrossRef]

- Yang, M.; Yang, Z.; Lv, C.; Wang, Z.; Lu, Z.; Lu, G.; Jia, X.; Wang, C. Electrospun bifunctional MXene-based electronic skins with high performance electromagnetic shielding and pressure sensing. Compos. Sci. Technol. 2022, 221, 109313. [Google Scholar] [CrossRef]

- Yuan, N.; Wang, C.; Ji, J.; Zhou, K. A wearable and sensitive carbon black-porous polydimethylsiloxane based pressure sensor for human physiological signals monitoring. J. Mater. Sci. Mater. Electron. 2021, 32, 27656–27665. [Google Scholar] [CrossRef]

- Sharma, S.; Chhetry, A.; Sharifuzzaman, M.; Yoon, H.; Park, J.Y. Wearable Capacitive Pressure Sensor Based on MXene Composite Nanofibrous Scaffolds for Reliable Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2020, 12, 22212–22224. [Google Scholar] [CrossRef]

- Han, Z.Y.; Cheng, Z.Q.; Chen, Y.; Li, B.; Liang, Z.W.; Li, H.F.; Ma, Y.J.; Feng, X. Fabrication of highly pressure-sensitive, hydrophobic, and flexible 3D carbon nanofiber networks by electrospinning for human physiological signal monitoring. Nanoscale 2019, 11, 5942–5950. [Google Scholar] [CrossRef]

- Gao, F.-L.; Min, P.; Gao, X.-Z.; Li, C.; Zhang, T.; Yu, Z.-Z.; Li, X. Integrated temperature and pressure dual-mode sensors based on elastic PDMS foams decorated with thermoelectric PEDOT:PSS and carbon nanotubes for human energy harvesting and electronic-skin. J. Mater. Chem. A 2022, 10, 18256–18266. [Google Scholar] [CrossRef]

- Pang, Y.; Tian, H.; Tao, L.Q.; Li, Y.X.; Wang, X.F.; Deng, N.Q.; Yang, Y.; Ren, T.L. Flexible, Highly Sensitive, and Wearable Pressure and Strain Sensors with Graphene Porous Network Structure. ACS Appl. Mater. Interfaces 2016, 8, 26458–26462. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.D.; Cao, X.H.; Wang, Y.L.; Zheng, G.Q.; Dai, K.; Liu, C.T.; Shen, C.Y. Conductive herringbone structure carbon nanotube/thermoplastic polyurethane porous foam tuned by epoxy for high performance flexible piezoresistive sensor. Compos. Sci. Technol. 2017, 149, 166–177. [Google Scholar] [CrossRef]

- Javidi, R.; Moghimi Zand, M.; Alizadeh Majd, S. Designing wearable capacitive pressure sensors with arrangement of porous pyramidal microstructures. Micro Nano Syst. Lett. 2023, 11, 13. [Google Scholar] [CrossRef]

- Han, C.; Zhang, H.; Chen, Q.; Li, T.; Kong, L.; Zhao, H.; He, L. A directional piezoelectric sensor based on anisotropic PVDF/MXene hybrid foam enabled by unidirectional freezing. Chem. Eng. J. 2022, 450, 138280. [Google Scholar] [CrossRef]

- Yang, P.; Shi, Y.; Li, S.; Tao, X.; Liu, Z.; Wang, X.; Wang, Z.L.; Chen, X. Monitoring the Degree of Comfort of Shoes In-Motion Using Triboelectric Pressure Sensors with an Ultrawide Detection Range. ACS Nano 2022, 16, 4654–4665. [Google Scholar] [CrossRef]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory, technology and applications of piezoresistive sensors: A review. Sens. Actuator A-Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Jung, Y.; Jung, K.; Park, B.; Choi, J.; Kim, D.; Park, J.; Ko, J.; Cho, H. Wearable piezoresistive strain sensor based on graphene-coated three-dimensional micro-porous PDMS sponge. Micro Nano Syst. Lett. 2019, 7, 20. [Google Scholar] [CrossRef]

- Zhai, W.; Xia, Q.; Zhou, K.; Yue, X.; Ren, M.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Multifunctional flexible carbon black/polydimethylsiloxane piezoresistive sensor with ultrahigh linear range, excellent durability and oil/water separation capability. Chem. Eng. J. 2019, 372, 373–382. [Google Scholar] [CrossRef]

- Cai, J.H.; Li, J.; Chen, X.D.; Wang, M. Multifunctional polydimethylsiloxane foam with multi-walled carbon nanotube and thermo-expandable microsphere for temperature sensing, microwave shielding and piezoresistive sensor. Chem. Eng. J. 2020, 393, 124805. [Google Scholar] [CrossRef]

- Tang, Y.M.; Guo, Q.Q.; Chen, Z.M.; Zhang, X.X.; Lu, C.H. In-situ reduction of graphene oxide-wrapped porous polyurethane scaffolds: Synergistic enhancement of mechanical properties and piezoresistivity. Compos. Part A-Appl. Sci. Manuf. 2019, 116, 106–113. [Google Scholar] [CrossRef]

- He, Y.; Zhao, L.D.; Zhang, J.L.; Liu, L.Y.; Liu, H.; Liu, L. A breathable, sensitive and wearable piezoresistive sensor based on hierarchical micro-porous PU@CNT films for long-term health monitoring. Compos. Sci. Technol. 2020, 200, 108419. [Google Scholar] [CrossRef]

- Wen, L.; Nie, M.; Wang, C.; Zhao, Y.n.; Yin, K.; Sun, L. Multifunctional, Light-Weight Wearable Sensor Based on 3D Porous Polyurethane Sponge Coated with MXene and Carbon Nanotubes Composites. Adv. Mater. Interfaces 2021, 9, 2101592. [Google Scholar] [CrossRef]

- Song, R.; Ren, P.; Liu, Y.; Zhu, Y.; Dong, J.; O'Connor, B.T. Stretchable Organic Transistor Based Pressure Sensor Employing a Porous Elastomer Gate Dielectric. Adv. Mater. Technol. 2023, 8, 2202140. [Google Scholar] [CrossRef]

- Yang, J.Y.; Ye, Y.S.; Li, X.P.; Lv, X.Z.; Chen, R.J. Flexible, conductive, and highly pressure-sensitive graphene-polyimide foam for pressure sensor application. Compos. Sci. Technol. 2018, 164, 187–194. [Google Scholar] [CrossRef]

- Ma, Z.H.; Meng, B.; Wang, Z.Y.; Yuan, C.C.; Liu, Z.W.; Zhang, W.G.; Peng, Z.C. A triboelectric-piezoresistive hybrid sensor for precisely distinguishing transient processes in mechanical stimuli. Nano Energy 2020, 78, 105216. [Google Scholar] [CrossRef]

- da Silva, F.A.G.; de Araújo, C.M.S.; Alcaraz-Espinoza, J.J.; de Oliveira, H.P. Toward flexible and antibacterial piezoresistive porous devices for wound dressing and motion detectors. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1063–1072. [Google Scholar] [CrossRef]

- Wan, Y.Q.; Qin, N.; Wang, Y.F.; Zhao, Q.B.; Wang, Q.; Yuan, P.C.; Wen, Q.; Wei, H.; Zhang, X.Y.; Ma, N. Sugar-templated conductive polyurethane-polypyrrole sponges for wide-range force sensing. Chem. Eng. J. 2020, 383, 123103. [Google Scholar] [CrossRef]

- Peng, S.H.; Wu, S.Y.; Yu, Y.Y.; Xia, B.; Lovell, N.H.; Wang, C.H. Multimodal Capacitive and Piezoresistive Sensor for Simultaneous Measurement of Multiple Forces. ACS Appl. Mater. Interfaces 2020, 12, 22179–22190. [Google Scholar] [CrossRef]

- Li, X.P.; Li, Y.; Li, X.F.; Song, D.K.; Min, P.; Hu, C.; Zhang, H.B.; Koratkar, N.; Yu, Z.Z. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets. J. Colloid Interface Sci. 2019, 542, 54–62. [Google Scholar] [CrossRef]

- Guan, X.; Wang, Z.Y.; Zhao, W.Y.; Huang, H.Y.; Wang, S.P.; Zhang, Q.; Zhong, D.X.; Lin, W.N.; Ding, N.; Peng, Z.C. Flexible Piezoresistive Sensors with Wide-Range Pressure Measurements Based on a Graded Nest-like Architecture. ACS Appl. Mater. Interfaces 2020, 12, 26137–26144. [Google Scholar] [CrossRef]

- Guo, W.; Ma, Z.; Chen, Z.; Hua, H.; Wang, D.; Elhousseini Hilal, M.; Fu, Y.; Lu, P.; Lu, J.; Zhang, Y.; et al. Thin and soft Ti3C2Tx MXene sponge structure for highly sensitive pressure sensor assisted by deep learning. Chem. Eng. J. 2024, 485, 149659. [Google Scholar] [CrossRef]

- Serban, B.-C.; Cobianu, C.; Dumbravescu, N.; Buiu, O.; Bumbac, M.; Nicolescu, C.M.; Cobianu, C.; Brezeanu, M.; Pachiu, C.; Serbanescu, M. Electrical Percolation Threshold and Size Effects in Polyvinylpyrrolidone-Oxidized Single-Wall Carbon Nanohorn Nanocomposite: The Impact for Relative Humidity Resistive Sensors Design. Sensors 2021, 21, 1435. [Google Scholar] [CrossRef]

- Qiao, Z.; Wei, A.; Wang, K.; Luo, N.; Liu, Z. Study of flexible piezoresistive sensors based on the hierarchical porous structure CNT /PDMS composite materials. J. Alloys Compd. 2022, 917, 165503. [Google Scholar] [CrossRef]

- Wu, J.J.; Li, H.Q.; Lai, X.J.; Chen, Z.H.; Zeng, X.R. Conductive and superhydrophobic F-rGO@CNTs/chitosan aerogel for piezoresistive pressure sensor. Chem. Eng. J. 2020, 386, 123998. [Google Scholar] [CrossRef]

- Mu, C.; Guo, X.; Zhu, T.; Lou, S.; Tian, W.; Liu, Z.; Jiao, W.; Wu, B.; Liu, Y.; Yin, L.; et al. Flexible strain/pressure sensor with good sensitivity and broad detection range by coupling PDMS and carbon nanocapsules. J. Alloys Compd. 2022, 918, 165696. [Google Scholar] [CrossRef]

- Ma, Q.; Xiao, D.-Y.; Xie, Y.-X. Multi-scale modeling of flexible piezoresistive porous sensors. Eur. J. Mech. A-Solids 2025, 112, 105651. [Google Scholar] [CrossRef]

- Simmons, J.G. Generalized formula for the electric tunnel effect between similar electrodes separated by a thin insulating film. J. Appl. Phys. 1963, 34, 1793–1803. [Google Scholar] [CrossRef]

- Yu, B.; Huang, Z.; Fang, D.; Yu, S.; Fu, T.; Tang, Y.; Li, Z. Biomimetic Porous Fluoropolymer Films with Brilliant Whiteness by Using Polymerization-Induced Phase Separation. Adv. Mater. Interfaces 2021, 9, 2101485. [Google Scholar] [CrossRef]

- Liang, G.W.; Yu, S.D.; Huang, Z.J.; Wu, K.J.; Fu, T.; Tang, Y.; Li, Z.T. High-Transmittance and High-Haze Composite Particle-Free Optical Diffusers Enabled by Polymerization-Induced Phase Separation. Adv. Photon. Res. 2021, 2, 2100185. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, K.J.; Yu, S.D.; Chen, J.C.; Ding, X.R.; Rao, L.S.; Li, Z.T. Bioinspired high-scattering polymer films fabricated by polymerization-induced phase separation. Opt. Lett. 2020, 45, 2918–2921. [Google Scholar] [CrossRef]

- Yu, S.; Chen, J.; Gomard, G.; Hölscher, H.; Lemmer, U. Recent Progress in Light-Scattering Porous Polymers and Their Applications. Adv. Opt. Mater. 2023, 11, 2203134. [Google Scholar] [CrossRef]

- Qian, K.; Zhou, J.; Miao, M.; Wu, H.; Thaiboonrod, S.; Fang, J.; Feng, X. Highly Ordered Thermoplastic Polyurethane/Aramid Nanofiber Conductive Foams Modulated by Kevlar Polyanion for Piezoresistive Sensing and Electromagnetic Interference Shielding. Nano-Micro Lett. 2023, 15, 88. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Li, C.G.; Yang, J.L.; Wang, P.F.; Yue, J.L.; Huang, X.Z.; Wang, J.; Tang, X.Z. Holey, anti-impact and resilient thermoplastic urethane/carbon nanotubes fabricated by a low-cost “vapor induced phase separation” strategy for the detection of human motions. Compos. Part A-Appl. Sci. Manuf. 2020, 136, 105974. [Google Scholar] [CrossRef]

- Liu, H.; Dong, M.Y.; Huang, W.J.; Gao, J.C.; Dai, K.; Guo, J.; Zheng, G.Q.; Liu, C.T.; Shen, C.Y.; Guo, Z.H. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J. Mater. Chem. C 2017, 5, 73–83. [Google Scholar] [CrossRef]

- Gong, T.; Jia, J.; Sun, X.-R.; Li, W.-D.; Ke, K.; Bao, R.-Y.; Yang, W. Design strategy for hierarchical structure of carbon black on microporous elastomer surface toward stretchable and compressive strain sensors. Carbon 2023, 206, 53–61. [Google Scholar] [CrossRef]

- Abshirini, M.; Marashizadeh, P.; Saha, M.C.; Altan, M.C.; Liu, Y. Three-Dimensional Printed Highly Porous and Flexible Conductive Polymer Nanocomposites with Dual-Scale Porosity and Piezoresistive Sensing Functions. ACS Appl. Mater. Interfaces 2023, 15, 14810–14825. [Google Scholar] [CrossRef]

- Zhu, G.; Dai, H.; Yao, Y.; Tang, W.; Shi, J.; Yang, J.; Zhu, L. 3D Printed Skin-Inspired Flexible Pressure Sensor with Gradient Porous Structure for Tunable High Sensitivity and Wide Linearity Range. Adv. Mater. Technol. 2021, 7, 2101239. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Haghniaz, R.; Rashidi, A.; Ahadian, S.; Sheikhi, A.; Chen, J.; Khademhosseini, A.; Milani, A.S.; Hoorfar, M.; et al. 3D-Printed Ultra-Robust Surface-Doped Porous Silicone Sensors for Wearable Biomonitoring. ACS Nano 2020, 14, 1520–1532. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, X.; Liu, J.; Liu, X.; Zhang, C. 3D Printing of Anisotropic Piezoresistive Pressure Sensors for Directional Force Perception. Adv. Sci. 2024, 11, 2309607. [Google Scholar] [CrossRef]

- Qin, Z.; Lv, Y.; Fang, X.; Zhao, B.; Niu, F.; Min, L.; Pan, K. Ultralight polypyrrole crosslinked nanofiber aerogel for highly sensitive piezoresistive sensor. Chem. Eng. J. 2022, 427, 131650. [Google Scholar] [CrossRef]

- Wu, S.Y.; Zhang, J.; Ladani, R.B.; Rayindran, A.R.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Novel Electrically Conductive Porous PDMS/Carbon Nanofiber Composites for Deformable Strain Sensors and Conductors. ACS Appl. Mater. Interfaces 2017, 9, 14207–14215. [Google Scholar] [CrossRef]

- Huang, W.J.; Dai, K.; Zhai, Y.; Liu, H.; Zhan, P.F.; Gao, J.C.; Zheng, G.Q.; Liu, C.T.; Shen, C.Y. Flexible and Lightweight Pressure Sensor Based on Carbon Nanotube/Thermoplastic Polyurethane-Aligned Conductive Foam with Superior Compressibility and Stability. ACS Appl. Mater. Interfaces 2017, 9, 42266–42277. [Google Scholar] [CrossRef]

- Xie, M.; Qian, G.; Yu, Y.; Chen, C.; Li, H.; Li, D. High-performance flexible reduced graphene oxide/polyimide nanocomposite aerogels fabricated by double crosslinking strategy for piezoresistive sensor application. Chem. Eng. J. 2024, 480, 148203. [Google Scholar] [CrossRef]

- Ren, L.; Dong, Y.; Dong, L.; Liu, T.; Tan, W. Carnauba Wax-Assisted Preparation of Eco-Friendly Aerogels by the Ambient Pressure Drying Method and their Applications for Photothermal Evaporation and Dye Wastewater Treatment. Adv. Mater. Technol. 2023, 8, 2202078. [Google Scholar] [CrossRef]

- Li, X.; Li, S.; Wu, M.; Weng, Z.; Ren, Q.; Xiao, P.; Wang, L.; Zheng, W. Multifunctional polyether block amides/carbon nanostructures piezoresistive foams with largely linear range, enhanced and humidity-regulated microwave shielding. Chem. Eng. J. 2023, 455, 140860. [Google Scholar] [CrossRef]

- Yu, S.D.; Fritz, B.; Johnsen, S.; Busko, D.; Richards, B.S.; Hippler, M.; Wiegand, G.; Tang, Y.; Li, Z.T.; Lemmer, U.; et al. Enhanced Photoluminescence in Quantum Dots-Porous Polymer Hybrid Films Fabricated by Microcellular Foaming. Adv. Opt. Mater. 2019, 7, 1900223. [Google Scholar] [CrossRef]

- Fei, Y.P.; Chen, F.; Fang, W.; Hejna, A.; Xu, L.X.; Liu, T.; Zhong, M.Q.; Yang, J.T.; Kuang, T.R. Conductive thermoplastic polyurethane nanocomposite foams derived from a cellulose/MWCNTs aerogel framework: Simultaneous enhancement of piezoresistance, strength, and endurance. J. Mater. Chem. C 2021, 9, 13103–13114. [Google Scholar] [CrossRef]

- Yu, S.; Guo, B.; Johnsen, S.; Wiegand, G.; Lemmer, U.; Guo, X.; Zhang, M.; Li, Y.; Sprau, C.; Hölscher, H.; et al. Nanoporous Polymer Reflectors for Organic Solar Cells. Energy Technol. 2021, 10, 2100676. [Google Scholar] [CrossRef]

- Huang, A.; Yang, Z.; Zhu, Y.; Tan, B.; Song, Y.; Guo, Y.; Liu, T.; Peng, X. A unique, flexible, and porous pressure sensor with enhanced sensitivity and durability by synergy of surface microstructure and supercritical fluid foaming. Appl. Surf. Sci. 2023, 618, 156661. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.Y.; Gao, L.; Wang, Y.; Liu, C.X.; Liu, P. Pressure-sensitive carbon black/graphene nanoplatelets-silicone rubber hybrid conductive composites based on a three-dimensional polydopamine-modified polyurethane sponge. J. Mater. Sci.-Mater. Electron. 2017, 28, 9495–9504. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, J. Flexible Capacitive Pressure Sensor Based on a Double-Sided Microstructure Porous Dielectric Layer. Micromachines 2022, 14, 111. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.D.; Han, Y.Y.; Zhang, X.X.; Zhou, Z.H.; Lu, C.H. Large-Area Compliant, Low-Cost, and Versatile Pressure-Sensing Platform Based on Microcrack-Designed Carbon Black@Polyurethane Sponge for Human-Machine Interfacing. Adv. Funct. Mater. 2016, 26, 6246–6256. [Google Scholar] [CrossRef]

- Yan, T.; Wu, Y.T.; Yi, W.; Pan, Z.J. Recent progress on fabrication of carbon nanotube-based flexible conductive networks for resistive-type strain sensors. Sens. Actuator A-Phys. 2021, 327, 112755. [Google Scholar] [CrossRef]

- Zhang, S.D.; Sun, K.; Liu, H.; Chen, X.Y.; Zheng, Y.J.; Shi, X.Z.; Zhang, D.B.; Mi, L.W.; Liu, C.T.; Shen, C.Y. Enhanced piezoresistive performance of conductive WPU/CNT composite foam through incorporating brittle cellulose nanocrystal. Chem. Eng. J. 2020, 387, 124045. [Google Scholar] [CrossRef]

- He, Y.; Wu, D.; Zhou, M.; Zheng, Y.; Wang, T.; Lu, C.; Zhang, L.; Liu, H.; Liu, C. Wearable Strain Sensors Based on a Porous Polydimethylsiloxane Hybrid with Carbon Nanotubes and Graphene. ACS Appl. Mater. Interfaces 2021, 13, 15572–15583. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Sun, X.; Guo, X.; Zhang, J.; Li, H.; Chen, L.; Wu, J.; Shi, Y.; Pan, L. A Wide-Range-Response Piezoresistive–Capacitive Dual-Sensing Breathable Sensor with Spherical-Shell Network of MWCNTs for Motion Detection and Language Assistance. Nanomaterials 2023, 13, 843. [Google Scholar] [CrossRef]

- Ahmed, A.; Singh, A.; Young, S.-J.; Gupta, V.; Singh, M.; Arya, S. Synthesis techniques and advances in sensing applications of reduced graphene oxide (rGO) Composites: A review. Compos. Part A-Appl. Sci. Manuf. 2023, 165, 107373. [Google Scholar]

- Zhou, H.; Zheng, L.; Meng, Q.; Tang, R.; Wang, Z.; Dang, B.; Shen, X.; Sun, Q. A flexible hydrogel tactile sensor with low compressive modulus and dynamic piezoresistive response regulated by lignocellulose/graphene aerogels. J. Mater. Chem. C 2021, 9, 12895–12903. [Google Scholar] [CrossRef]

- Lü, X.Z.; Yu, T.T.; Meng, F.C.; Bao, W.M. Wide-Range and High-Stability Flexible Conductive Graphene/Thermoplastic Polyurethane Foam for Piezoresistive Sensor Applications. Adv. Mater. Technol. 2021, 6, 2100248. [Google Scholar] [CrossRef]

- Guan, H.; Dai, X.J.; Ni, L.; Hu, J.H.; Wang, X.Q. Highly Elastic and Fatigue-Resistant Graphene-Wrapped Lamellar Wood Sponges for High-Performance Piezoresistive Sensors. ACS Sustain. Chem. Eng. 2021, 9, 15267–15277. [Google Scholar] [CrossRef]

- Lv, B.; Chen, X.T.; Liu, C.G. A Highly Sensitive Piezoresistive Pressure Sensor Based on Graphene Oxide/Polypyrrole@Polyurethane Sponge. Sensors 2020, 20, 1219. [Google Scholar] [CrossRef] [PubMed]

- Strítesky, S.; Marková, A.; Vítecek, J.; Safaríková, E.; Hrabal, M.; Kubác, L.; Kubala, L.; Weiter, M.; Vala, M. Printing inks of electroactive polymer PEDOT:PSS: The study of biocompatibility, stability, and electrical properties. J. Biomed. Mater. Res. Part A 2018, 106, 1121–1128. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Zhang, H.; Xie, M.; Duan, X. PEDOT:PSS: From conductive polymers to sensors. Nanotechnol. Precis. Eng. 2021, 4, 045004. [Google Scholar] [CrossRef]

- Zeng, R.; Wang, W.; Chen, M.; Wan, Q.; Wang, C.; Knopp, D.; Tang, D. CRISPR-Cas12a-driven MXene-PEDOT:PSS piezoresistive wireless biosensor. Nano Energy 2021, 82, 105711. [Google Scholar] [CrossRef]

- Gao, X.-Z.; Gao, F.-L.; Liu, J.; Li, Y.; Wan, P.; Yu, Z.-Z.; Li, X. Self-Powered Resilient Porous Sensors with Thermoelectric Poly(3,4-ethylenedioxythiophene):Poly(styrenesulfonate) and Carbon Nanotubes for Sensitive Temperature and Pressure Dual-Mode Sensing. ACS Appl. Mater. Interfaces 2022, 14, 43783–43791. [Google Scholar] [CrossRef]

- Ding, Y.C.; Yang, J.; Tolle, C.R.; Zhu, Z.T. Flexible and Compressible PEDOT:PSS@Melamine Conductive Sponge Prepared via One-Step Dip Coating as Piezoresistive Pressure Sensor for Human Motion Detection. ACS Appl. Mater. Interfaces 2018, 10, 16077–16086. [Google Scholar] [CrossRef]

- Sun, Y.G. Silver nanowires—Unique templates for functional nanostructures. Nanoscale 2010, 2, 1626–1642. [Google Scholar] [CrossRef] [PubMed]

- Guan, P.Y.; Xu, Z.M.; Lin, X.; Chen, N.; Tong, H.; Ha, T.J.; Chu, D.W. Recent Progress in Silver Nanowires: Synthesis and Applications. Nanosci. Nanotechnol. Lett. 2018, 10, 155–166. [Google Scholar] [CrossRef]

- Yi, Y.; Liu, E.Z.; Deng, H. Porous flexible piezoresistive sensor using liquid metal for low pressure detection. Sens. Actuator A-Phys. 2024, 375, 115536. [Google Scholar] [CrossRef]

- Ma, C.; Ma, M.G.; Si, C.L.; Ji, X.X.; Wan, P.B. Flexible MXene-Based Composites for Wearable Devices. Adv. Funct. Mater. 2021, 31, 2009524. [Google Scholar] [CrossRef]

- Lei, D.; Liu, N.; Su, T.; Zhang, Q.; Wang, L.; Ren, Z.; Gao, Y. Roles of MXene in Pressure Sensing: Preparation, Composite Structure Design, and Mechanism. Adv. Mater. 2022, 34, 2110608. [Google Scholar] [CrossRef]

- Pei, Y.; Zhang, X.; Hui, Z.; Zhou, J.; Huang, X.; Sun, G.; Huang, W. Ti3C2TX MXene for Sensing Applications: Recent Progress, Design Principles, and Future Perspectives. ACS Nano 2021, 15, 3996–4017. [Google Scholar] [CrossRef]

- Wang, Y.; Yue, Y.; Cheng, F.; Cheng, Y.; Ge, B.; Liu, N.; Gao, Y. Ti3C2Tx MXene-Based Flexible Piezoresistive Physical Sensors. ACS Nano 2022, 16, 1734–1758. [Google Scholar] [CrossRef]

- Jiang, D.; Zhang, J.; Qin, S.; Wang, Z.; Usman, K.A.S.; Hegh, D.; Liu, J.; Lei, W.; Razal, J.M. Superelastic Ti3C2Tx MXene-Based Hybrid Aerogels for Compression-Resilient Devices. ACS Nano 2021, 15, 5000–5010. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.-L.; Liu, J.; Li, X.-P.; Ma, Q.; Zhang, T.; Yu, Z.-Z.; Shang, J.; Li, R.-W.; Li, X. Ti3C2Tx MXene-Based Multifunctional Tactile Sensors for Precisely Detecting and Distinguishing Temperature and Pressure Stimuli. ACS Nano 2023, 17, 16036–16047. [Google Scholar] [CrossRef]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Transition Metal Carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef] [PubMed]

- Lipatov, A.; Alhabeb, M.; Lukatskaya, M.R.; Boson, A.; Gogotsi, Y.; Sinitskii, A. Effect of Synthesis on Quality, Electronic Properties and Environmental Stability of Individual Monolayer Ti3C2 MXene Flakes. Adv. Electron. Mater. 2016, 2, 1600255. [Google Scholar] [CrossRef]

- Lai, Q.T.; Zhao, X.H.; Sun, Q.J.; Tang, Z.; Tang, X.G.; Roy, V.A.L. Emerging MXene-Based Flexible Tactile Sensors for Health Monitoring and Haptic Perception. Small 2023, 19, 2300283. [Google Scholar] [CrossRef]

- Lei, J.C.; Zhang, X.; Zhou, Z. Recent advances in MXene: Preparation, properties, and applications. Front. Phys. 2015, 10, 276–286. [Google Scholar] [CrossRef]

- Li, X.D.; Li, X.; Liu, T.; Lu, Y.; Shang, C.S.; Ding, X.K.; Zhang, J.C.; Feng, Y.J.; Xu, F.J. Wearable, Washable, and Highly Sensitive Piezoresistive Pressure Sensor Based on a 3D Sponge Network for Real-Time Monitoring Human Body Activities. ACS Appl. Mater. Interfaces 2021, 13, 46848–46857. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Ma, Y.; Jia, G.; Zhao, S.; Yue, Y.; Cheng, F.; Zhang, C.; Cao, M.; Xiong, Y.; Shen, P.; et al. Bionic MXene based hybrid film design for an ultrasensitive piezoresistive pressure sensor. Chem. Eng. J. 2022, 431, 133458. [Google Scholar] [CrossRef]

- Li, W.; Jin, X.; Han, X.; Li, Y.R.; Wang, W.Y.; Lin, T.; Zhu, Z.T. Synergy of Porous Structure and Microstructure in Piezoresistive Material for High-Performance and Flexible Pressure Sensors. ACS Appl. Mater. Interfaces 2021, 13, 19211–19220. [Google Scholar] [CrossRef]

- Xia, H.; Wang, L.; Zhang, H.; Wang, Z.; Zhu, L.; Cai, H.; Ma, Y.; Yang, Z.; Zhang, D. MXene/PPy@PDMS sponge-based flexible pressure sensor for human posture recognition with the assistance of a convolutional neural network in deep learning. Microsyst. Nanoeng. 2023, 9, 155. [Google Scholar] [CrossRef]

- Tang, Z.; Jia, S.; Zhou, C.; Li, B. 3D Printing of Highly Sensitive and Large-Measurement-Range Flexible Pressure Sensors with a Positive Piezoresistive Effect. ACS Appl. Mater. Interfaces 2020, 12, 28669–28680. [Google Scholar] [CrossRef]

- Ma, Z.L.; Wei, A.J.; Ma, J.Z.; Shao, L.; Jiang, H.E.; Dong, D.D.; Ji, Z.Y.; Wang, Q.; Kang, S.L. Lightweight, compressible and electrically conductive polyurethane sponges coated with synergistic multiwalled carbon nanotubes and graphene for piezoresistive sensors. Nanoscale 2018, 10, 7116–7126. [Google Scholar] [CrossRef]

- Xu, S.M.; Li, X.Y.; Sui, G.P.; Du, R.N.; Zhang, Q.; Fu, Q. Plasma modification of PU foam for piezoresistive sensor with high sensitivity, mechanical properties and long-term stability. Chem. Eng. J. 2020, 381, 122666. [Google Scholar] [CrossRef]

- Cao, W.; Luo, Y.; Dai, Y.; Wang, X.; Wu, K.; Lin, H.; Rui, K.; Zhu, J. Piezoresistive Pressure Sensor Based on a Conductive 3D Sponge Network for Motion Sensing and Human–Machine Interface. ACS Appl. Mater. Interfaces 2023, 15, 3131–3140. [Google Scholar] [CrossRef]

- Shi, W.; Chen, S.; Lin, Y.; Zhang, G.; Peng, Z.; Liu, Z.; Shi, H.; Yan, X.; Liu, L. Piezoresistive fibers with record high sensitivity via the synergic optimization of porous microstructure and elastic modulus. Chem. Eng. J. 2022, 441, 136046. [Google Scholar] [CrossRef]

- Zhang, F.; Feng, Y.Y.; Qin, M.M.; Gao, L.; Li, Z.Y.; Zhao, F.L.; Zhang, Z.X.; Lv, F.; Feng, W. Stress Controllability in Thermal and Electrical Conductivity of 3D Elastic Graphene-Crosslinked Carbon Nanotube Sponge/Polyimide Nanocomposite. Adv. Funct. Mater. 2019, 29, 1901383. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, W.L.; Wang, Z.; Wang, J.N.; Huang, T.; Dong, J.; Zhang, Q.H. Flexible PEDOT:PSS/polyimide aerogels with linearly responsive and stable properties for piezoresistive sensor applications. Chem. Eng. J. 2020, 395, 125115. [Google Scholar] [CrossRef]

- Dai, Y.; Wu, X.Y.; Liu, Z.S.; Zhang, H.B.; Yu, Z.Z. Highly sensitive, robust and anisotropic MXene aerogels for efficient broadband microwave absorption. Compos. Part B-Eng. 2020, 200, 108263. [Google Scholar] [CrossRef]

- Pu, L.; Liu, Y.; Li, L.; Zhang, C.; Ma, P.; Dong, W.; Huang, Y.; Liu, T. Polyimide Nanofiber-Reinforced Ti3C2Tx Aerogel with “Lamella-Pillar” Microporosity for High-Performance Piezoresistive Strain Sensing and Electromagnetic Wave Absorption. ACS Appl. Mater. Interfaces 2021, 13, 47134–47146. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhang, X.B.; Yang, T.T.; Shi, K.X.; Han, Y.; Song, X.L.; Yao, H.Y.; Song, Y. High-efficiency preparation of large-sized MXene nanosheets for flexible piezoresistive sensors with high sensitivity and wide strain range. Chem. Eng. J. 2025, 515, 163779. [Google Scholar] [CrossRef]

- Liu, H.; Chen, X.Y.; Zheng, Y.J.; Zhang, D.B.; Zhao, Y.; Wang, C.F.; Pan, C.F.; Liu, C.T.; Shen, C.Y. Lightweight, Superelastic, and Hydrophobic Polyimide Nanofiber /MXene Composite Aerogel for Wearable Piezoresistive Sensor and Oil/Water Separation Applications. Adv. Funct. Mater. 2021, 31, 2008006. [Google Scholar] [CrossRef]

- Pu, L.; Ma, H.; Dong, J.; Zhang, C.; Lai, F.; He, G.; Ma, P.; Dong, W.; Huang, Y.; Liu, T. Xylem-Inspired Polyimide/MXene Aerogels with Radial Lamellar Architectures for Highly Sensitive Strain Detection and Efficient Solar Steam Generation. Nano Lett. 2022, 22, 4560–4568. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Yan, T.; Pan, Z. Review of flexible strain sensors based on cellulose composites for multi-faceted applications. Cellulose 2020, 28, 615–645. [Google Scholar] [CrossRef]

- Guan, H.; Meng, J.W.; Cheng, Z.Y.; Wang, X.Q. Processing Natural Wood into a High-Performance Flexible Pressure Sensor. ACS Appl. Mater. Interfaces 2020, 12, 46357–46365. [Google Scholar] [CrossRef]

- Pan, H.; Chen, G.; Chen, Y.; Di Carlo, A.; Mayer, M.A.; Shen, S.; Chen, C.; Li, W.; Subramaniam, S.; Huang, H.; et al. Biodegradable cotton fiber-based piezoresistive textiles for wearable biomonitoring. Biosens. Bioelectron. 2023, 222, 114999. [Google Scholar] [CrossRef]

- Zhang, X.H.; Wang, Y.J.; Zhang, L.; Zhang, X.R.; Guo, Y.J.; Hao, B.; Qin, Y.Q.; Li, Q.; Fan, L.; Dong, H.L.; et al. Facile preparation of porous MXene/cellulose nanofiber composite for highly-sensitive flexible piezoresistive sensors in e-skin. Chem. Eng. J. 2025, 505, 159369. [Google Scholar] [CrossRef]

- Huang, J.Y.; Li, D.W.; Zhao, M.; Ke, H.Z.; Mensah, A.; Lv, P.F.; Tian, X.J.; Wei, Q.F. Flexible electrically conductive biomass-based aerogels for piezoresistive pressure/strain sensors. Chem. Eng. J. 2019, 373, 1357–1366. [Google Scholar] [CrossRef]

- Singh, L.; Tripathy, K.; Bhattacharjee, M. Porous Microstructure-Assisted Flexible and Highly Sensitive Polymer Piezoresistive Pressure Sensor. Adv. Eng. Mater. 2022, 24, 2200500. [Google Scholar] [CrossRef]

- Veeralingam, S.; Praveen, S.; Vemula, M.; Badhulika, S. One-step synthesis of carbon-doped PPy nanoparticles interspersed in 3D porous melamine foam as a high-performance piezoresistive pressure, strain, and breath sensor. Mater. Chem. Front. 2022, 6, 570–579. [Google Scholar] [CrossRef]

- Ma, W.; Jiang, Z.; Lu, T.; Xiong, R.; Huang, C. Lightweight, elastic and superhydrophobic multifunctional nanofibrous aerogel for self-cleaning, oil/water separation and pressure sensing. Chem. Eng. J. 2022, 430, 132989. [Google Scholar] [CrossRef]

- Pierre Claver, U.; Zhao, G. Recent Progress in Flexible Pressure Sensors Based Electronic Skin. Adv. Eng. Mater. 2021, 23, 2001187. [Google Scholar] [CrossRef]

- Meng, K.; Xiao, X.; Wei, W.; Chen, G.; Nashalian, A.; Shen, S.; Xiao, X.; Chen, J. Wearable Pressure Sensors for Pulse Wave Monitoring. Adv. Mater. 2022, 34, 2109357. [Google Scholar] [CrossRef]

- Wang, Y.; Adam, M.L.; Zhao, Y.; Zheng, W.; Gao, L.; Yin, Z.; Zhao, H. Machine Learning-Enhanced Flexible Mechanical Sensing. Nano-Micro Lett. 2023, 15, 55. [Google Scholar] [CrossRef]

- Zhang, J.P.; Wei, S.; Liu, C.C.; Shang, C.; He, Z.Q.; Duan, Y.; Peng, Z.C. Porous nanocomposites with enhanced intrinsic piezoresistive sensitivity for bioinspired multimodal tactile sensors. Microsyst. Nanoeng. 2024, 10, 19. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, Q.; Wang, X.; Schubert, D.W.; Liu, X. Flexible, conductive, and anisotropic thermoplastic polyurethane/polydopamine /MXene foam for piezoresistive sensors and motion monitoring. Compos. Part A-Appl. Sci. Manuf. 2022, 155, 106838. [Google Scholar] [CrossRef]

- Yue, X.Y.; Fang, C.Q.; Yao, Q.Z.; Liu, C.T.; Shen, C.Y.; Liu, H. Tunable porous fiber-shaped strain sensor with synergistic conductive network for human motion recognition and tactile sensing. Chem. Eng. J. 2024, 491, 151853. [Google Scholar] [CrossRef]

| Category | Advantages | Disadvantages | Common Composite Processes |

|---|---|---|---|

| Carbon-Based Conductors | Low cost Excellent chemical stability | Some materials exhibit relatively lower conductivity. | Ultrasonic treatment method, Coating method, Blending method |

| Polymer Conductors | Good biocompatibility Good flexibility | Poor environmental stability Poor mechanical stability | Dipping method, chemical Polymerization method |

| Metal Conductors | Good electrical conductivity Easy to process | High cost Easy to oxidize | Dip-coating method |

| MXene | Excellent electrical conductivity Good mechanical properties | Serious pollution during preparation | Dipping method, Spraying method |

| Materials | Sensitivity (kPa−1) | GF | Pressure Range | Strain Range(%) | Response Time/Recovery Time (ms) | Compression Cycles (Times) | Ref. |

|---|---|---|---|---|---|---|---|

| CB/PDMS | 0.0048 (0–500 kPa) | / | 0–500 kPa | / | / | 500 | [46] |

| PDMS-based (with PEDOT:PSS conductive layer) | 9.51 (0–10 kPa); 0.045 (30–70 kPa); 0.17 (40–120 kPa) | / | 0–120 kPa | / | 50 | 1000 | [110] |

| PDMS/CNCs | 0.0082 (0–450 kPa) | / | 0–450 kPa | / | / | 2000 | [34] |

| PINF/MA | 22.32 (0–3 kPa); 2.63 (3–8 kPa) | / | 0–8 kPa | 0.1–50 | 482/321 | 1500 | [101] |

| C-PPy@MF | 2 (10–90 kPa) | / | 10–90 kPa | / | 160 | 5000 | [111] |

| ODA-rGO@PANF/CNTs | 33 (0–2 kPa); 4.1 (2–6 kPa) | 3.7 (0–17%); 1.418 (18–35%) | / | / | 220/140 | 1000 | [112] |

| GO/PPy@PU | 0.79 (0–2.5 kPa) | 2.1 (0–40% strain); 0.5 (40–80% strain) | 75 Pa–15 kPa | 2–85.5 | 70 | 10,000 | [70] |

| rGO@PU/ANFs | 1.06 (<40 kPa); 2.82(40–58 kPa) | −0.81 (0–56% strain); −5.27 (56–60% strain) | 0–58 kPa | 0–60 | / | 10,000 | [19] |

| PU@CNT | 51.53 (0.7–3 kPa) | / | 0–16 kPa | / | / | 8000 | [20] |

| RGO/PI | 0.36 (0–4 kPa); 0.01 (4–14 kPa) | / | 0–14 kPa | / | 80 | 1000 | [23] |

| PEDOT:PSS/PI | 0.021 (0–1 kPa); 0.054 (1–7 kPa); 0.019 (7–17 kPa) | / | 0–17 kPa | / | / | 200 | [99] |

| MXene/PI | 0.83 (0–5.3 kPa); 2.65 (5.3–27.1 kPa) | / | 0–27.1 kPa | 0–70 | / | 1000 | [102] |

| Polymer Matrix | Mechanical Robustness | Biocompatibility | Processability |

|---|---|---|---|

| PDMS | ★★★ | ★★★★ | ★★★★★ |

| PU | ★★★★ | ★★★★ | ★★★★ |

| PI | ★★★★★ | ★★★ | ★★★★ |

| Natural polymers | ★★★ | ★★★★★ | ★★★ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Xu, Z.; Zhang, J.; Wei, Y.; Peng, B.; Liang, G.; Yu, S. Recent Advances in Porous Polymer-Based Flexible Piezoresistive Pressure Sensors. Polymers 2025, 17, 2584. https://doi.org/10.3390/polym17192584

Huang J, Xu Z, Zhang J, Wei Y, Peng B, Liang G, Yu S. Recent Advances in Porous Polymer-Based Flexible Piezoresistive Pressure Sensors. Polymers. 2025; 17(19):2584. https://doi.org/10.3390/polym17192584

Chicago/Turabian StyleHuang, Junwei, Zhongxin Xu, Jing Zhang, Yujun Wei, Bo Peng, Guanwei Liang, and Shudong Yu. 2025. "Recent Advances in Porous Polymer-Based Flexible Piezoresistive Pressure Sensors" Polymers 17, no. 19: 2584. https://doi.org/10.3390/polym17192584

APA StyleHuang, J., Xu, Z., Zhang, J., Wei, Y., Peng, B., Liang, G., & Yu, S. (2025). Recent Advances in Porous Polymer-Based Flexible Piezoresistive Pressure Sensors. Polymers, 17(19), 2584. https://doi.org/10.3390/polym17192584