Study on the Liquid Transport on the Twisted Profile Filament/Spun Combination Yarn in Knitted Fabric

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Twisted Profiled Filament/Spun Combination Yarn and Fabric

2.2. Scanning Electron Microscopy (SEM) Analysis

2.3. Yarn and Fabric Physical Properties

2.4. Vertical Wicking Test

2.5. Droplet Diffusion Test

2.6. Moisture Management Transport Test

3. Results and Discussion

3.1. Surface Characterization

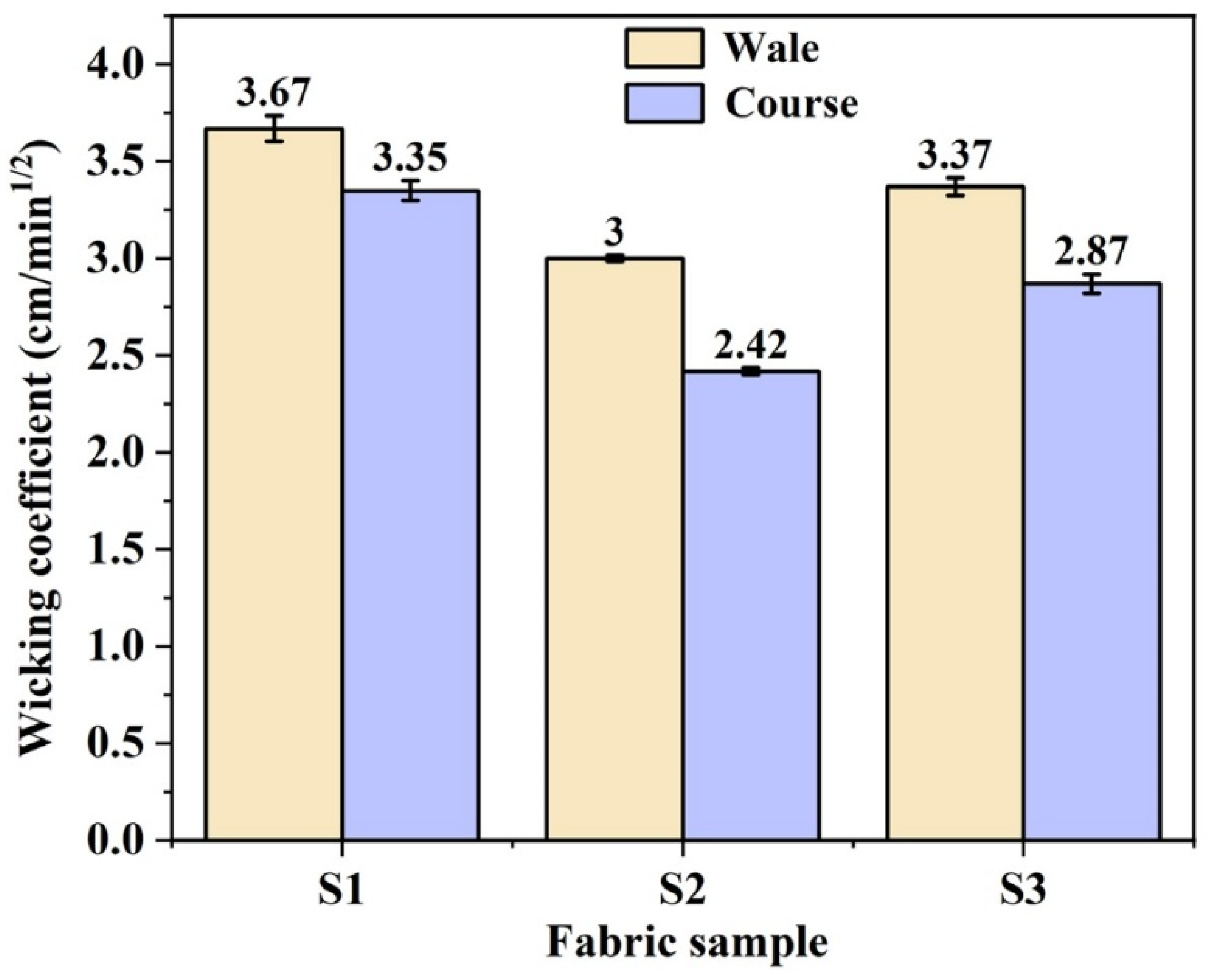

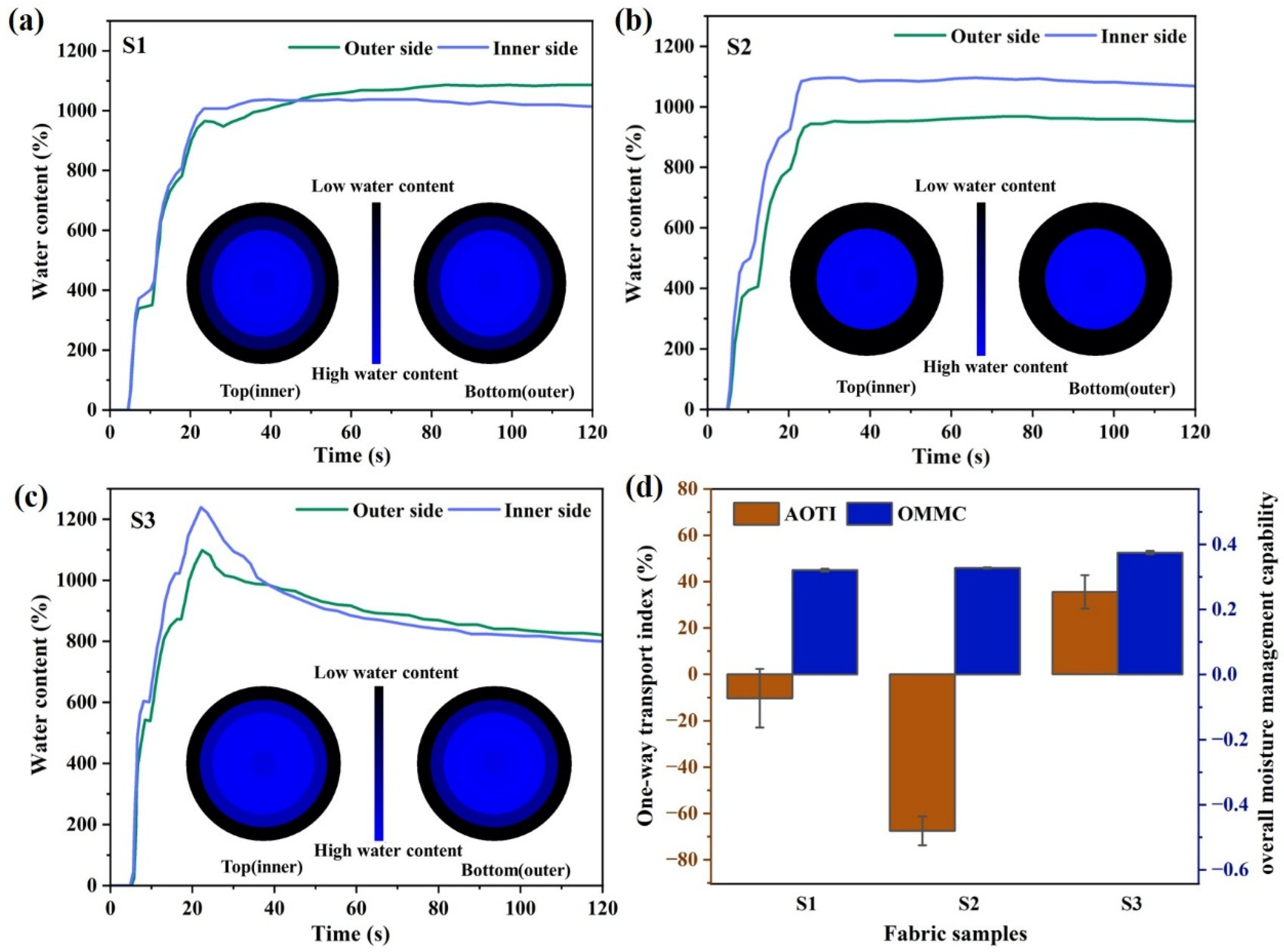

3.2. Comparison of Wicking

3.3. Interpretation of Wicking Behavior of Twisted Combination Yarn

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ullah, H.M.K.; Lejeune, J.; Cayla, A.; Monceaux, M.; Campagne, C.; Devaux, É. A review of noteworthy/major innovations in wearable clothing for thermal and moisture management from material to fabric structure. Text. Res. J. 2022, 92, 3351–3386. [Google Scholar] [CrossRef]

- Öner, E.; Atasağun, H.G.; Okur, A.; Beden, A.R.; Durur, G. Evaluation of moisture management properties on knitted fabrics. J. Text. Inst. 2013, 104, 699–707. [Google Scholar] [CrossRef]

- Fischer, R.; Schlepütz, C.M.; Rossi, R.M.; Derome, D.; Carmeliet, J. Wicking through complex interfaces at interlacing yarns. J. Colloid Interface Sci. 2022, 626, 416–425. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.H.; Takatera, M. Effects of hydrophobic yarns on liquid migration in woven fabrics. Text. Res. J. 2015, 85, 479–486. [Google Scholar] [CrossRef]

- Lu, Y.; Hong, Q.; Sun, F.; Gao, W.; Xu, C. Effect of yarn structure on the liquid moisture transport in yarns. J. Text. Inst. 2022, 113, 1826–1831. [Google Scholar] [CrossRef]

- Mhetre, S.; Parachuru, R. The effect of fabric structure and yarn-to-yarn liquid migration on liquid transport in fabrics. J. Text. Inst. 2010, 101, 621–626. [Google Scholar] [CrossRef]

- Suganthi, T.; Senthilkumar, P. Moisture-management properties of bi-layer knitted fabrics for sportswear. J. Ind. Text. 2018, 47, 1447–1463. [Google Scholar] [CrossRef]

- Saeed, A.; Iqbal, K.; Maqsood, H.S.; Basit, A. Thermal and Comfort Properties of Polyester/micro-polyester and Cotton/regenerated Fibers Blended Knitted Fabrics. J. Nat. Fibers 2022, 19, 9190–9200. [Google Scholar] [CrossRef]

- Guruprasad, R.; Vivekanandan, M.; Arputharaj, A.; Saxena, S.; Chattopadhyay, S. Development of cotton-rich/polylactic acid fiber blend knitted fabrics for sports textiles. J. Ind. Text. 2015, 45, 405–415. [Google Scholar] [CrossRef]

- Zubair, M.; Hussain, T.; Hussain, S. Development of polyester/cellulosic blend woven fabric for better comfort. Ind. Text. 2016, 67, 359–364. [Google Scholar]

- He, C.X.; Zhang, R.Y.; Ma, Y.X.; Lei, M.; Li, Y.L.; Cheng, L.D. Structure design and spinning technology of the non-uniform bicomponent yarn with moisture absorption and fast drying. Shanghai Text. Sci. Tech. 2020, 48, 26–29. [Google Scholar]

- Mao, N.; Peng, H.; Quan, Z.; Zhang, H.; Wu, D.; Qin, X.; Wang, R.; Yu, J. Wettability Control in Tree Structure-Based 1D Fiber Assemblies for Moisture Wicking Functionality. ACS Appl. Mater. Interfaces 2019, 11, 44682–44690. [Google Scholar] [CrossRef]

- Su, C.I.; Fang, J.X.; Chen, X.H.; Wu, W.Y. Moisture absorption and release of profiled polyester and cotton composite knitted fabrics. Text. Res. J. 2016, 77, 764–769. [Google Scholar] [CrossRef]

- Ma, W.; Cheng, L.; Liu, Y.; Psikuta, A.; Zhang, Y. Study on the thermo-physiological comfort properties of cotton/polyester combination yarn-based double-layer knitted fabrics. Text. Res. J. 2025, 95, 569–583. [Google Scholar] [CrossRef]

- Roy, M.D.; Sinha, S.K. Performance of wicking through yarn and fabric made from polyester fibers of different cross-sections. Inter. J. Text. Sci. 2014, 3, 43–44. [Google Scholar]

- Parada, M.; Derome, D.; Rossi, R.M.; Carmeliet, J. A review on advanced imaging technologies for the quantification of wicking in textiles. Text. Res. J. 2017, 87, 110–132. [Google Scholar] [CrossRef]

- Zhang, W.H.; Qian, X.M.; Fan, J.T.; Shi, Y.L.; Niu, L. Research progress on sweating rate distribution of human body. J. Text. Res. 2018, 39, 179–184. [Google Scholar]

- Machado-Moreira, C.A.; Smith, F.M.; van den Heuvel, A.M.; Mekjavic, I.B.; Taylor, N.A. Sweat secretion from the torso during passively-induced and exercise-related hyperthermia. Eur. J. Appl. Physiol. 2008, 104, 265–270. [Google Scholar] [CrossRef]

- Kim, H.S.; Michielsen, S.; Denhartog, E. New wicking measurement system to mimic human sweating phenomena with continuous microfluidic flow. J. Mater. Sci. 2020, 55, 7816–7832. [Google Scholar] [CrossRef]

- Weder, M. X-Ray Tomography Measurements of the Moisture Distribution in Multilayered Clothing Systems. Text. Res. J. 2006, 76, 18–26. [Google Scholar] [CrossRef]

- Zhu, C.H.; Takatera, M. A new thermocouple technique for the precise measurement of in-plane capillary water flow within fabrics. Text. Res. J. 2014, 84, 513–526. [Google Scholar] [CrossRef]

- Weder, M.; Brühwiler, P.A.; Herzig, U.; Huber, R.; Frei, G.; Lehmann, E. Neutron radiography measurements of moisture distribution in multilayer clothing systems. Text. Res. J. 2004, 74, 695–700. [Google Scholar] [CrossRef]

- Hamraoui, A.; Nylander, T. Analytical approach for the Lucas-Washburn equation. J. Colloid Interface Sci. 2002, 250, 415–421. [Google Scholar] [CrossRef]

- Cai, J.; Jin, T.; Kou, J.; Zou, S.; Xiao, J.; Meng, Q. Lucas-Washburn Equation-Based Modeling of Capillary-Driven Flow in Porous Systems. Langmuir 2021, 37, 1623–1636. [Google Scholar] [CrossRef] [PubMed]

- Parada, M.; Vontobel, P.; Rossi, R.M.; Derome, D.; Carmeliet, J. Dynamic Wicking Process in Textiles. Transp. Porous Media 2017, 119, 611–632. [Google Scholar] [CrossRef]

- Parada, M.; Zhou, X.; Derome, D.; Rossi, R.M.; Carmeliet, J. Modeling wicking in textiles using the dual porosity approach. Text. Res. J. 2019, 89, 3519–3528. [Google Scholar] [CrossRef]

- Hey-sang, K.; Stephen, M.; Emiel, D. Wicking in textiles at rates comparable to human sweating. Colloid Surface A 2021, 622, 1–9. [Google Scholar]

- Fischer, R.; Schlepütz, C.M.; Zhao, J.; Boillat, P.; Hegemann, D.; Rossi, R.M.; Derome, D.; Carmeliet, J. Wicking dynamics in yarns. J. Colloid Interface Sci. 2022, 625, 1–11. [Google Scholar] [CrossRef]

- ASTM D2256M-10; Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D1425/D1425M-14; Standard Test Method for Evenness of Textile Strands Using Capacitance Testing Equipment. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D5647-01; Standard Guide for Measuring Hairiness of Yarns by the Photo-Electric Apparatus. ASTM International: West Conshohocken, PA, USA, 2001.

- ISO 5084; Textiles—Determination of thickness of textiles and textile products. International Organization for Standardization: Geneva, Switzerland, 1996.

- ASTM D2654-89a; Standard Test Methods for Moisture in Textiles. ASTM International: West Conshohocken, PA, USA, 1989.

- Zhang, W.J.; Ji, F.; Zhang, R.Y.; Zhao, X.J.; Wang, N.; Wang, J.L.; Zhang, J.X. Study on relationship between capillary characteristics and moisture permeability of wool fabrics. J. Text. Res. 2019, 40, 67–72. [Google Scholar]

- FZ/T 01071; Textiles—Test Method for Capillary Effect. National Development and Reform Commission of the People’s Republic of China: Beijing, China, 2008.

- Ji, F. Preparation of Hygroscopic Fabric with a Uniform and Slow Exothermic Effect and Its Thermoregulation Evaluation. CN110274851B, 12 December 2020. [Google Scholar]

- AATCC 195; Liquid Moisture Management Properties of Textile Fabrics. American Association of Textile Chemists and Colorists: Research Triangle Park, NC, USA, 2011.

- Das, B.; Das, A.; Kothari, V.; Fanguiero, R.; Araujo, M.D. Fabrics. Moisture flow through blended fabrics—Effect of hydrophilicity. J. Eng. Fiber Fabr. 2009, 4, 20–28. [Google Scholar] [CrossRef]

| Yarn Code | Yarn Specification | Yarn Composition | Tensile Strength /(cN/dtex) | Elongation /(%) | EvennessCV /% | Hairiness (≥3 mm) |

|---|---|---|---|---|---|---|

| Y1 | 150D/144F | Profiled polyester filament | 3.24 | 17.35 | - | - |

| Y2 | 18.45 tex | Profiled polyester filament + Polyester/cotton 80%/20% | 3.15 | 13.33 | 9.57 | 4.6 |

| Y3 | 18.45 tex | Profiled polyester filament + Cotton 100% | 3.05 | 13.33 | 9.69 | 10.4 |

| Sample Code | Yarn Composition | Porosity /% | Course Density /5 cm | Wale Density /5 cm | Fabric Thickness /mm | Mass per Square Meter /(g·m−2) | Moisture Absorption Rate /% |

|---|---|---|---|---|---|---|---|

| S1 | Y1 | 64 | 64 | 96 | 0.61 | 124 | 0.27 |

| S2 | Y2 | 59 | 64 | 100 | 0.70 | 132 | 0.85 |

| S3 | Y3 | 59 | 64 | 99 | 0.69 | 130 | 2.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Zhang, R.; Yu, J. Study on the Liquid Transport on the Twisted Profile Filament/Spun Combination Yarn in Knitted Fabric. Polymers 2025, 17, 2065. https://doi.org/10.3390/polym17152065

Cui Y, Zhang R, Yu J. Study on the Liquid Transport on the Twisted Profile Filament/Spun Combination Yarn in Knitted Fabric. Polymers. 2025; 17(15):2065. https://doi.org/10.3390/polym17152065

Chicago/Turabian StyleCui, Yi, Ruiyun Zhang, and Jianyong Yu. 2025. "Study on the Liquid Transport on the Twisted Profile Filament/Spun Combination Yarn in Knitted Fabric" Polymers 17, no. 15: 2065. https://doi.org/10.3390/polym17152065

APA StyleCui, Y., Zhang, R., & Yu, J. (2025). Study on the Liquid Transport on the Twisted Profile Filament/Spun Combination Yarn in Knitted Fabric. Polymers, 17(15), 2065. https://doi.org/10.3390/polym17152065