Abstract

This paper presents the results of research on the technical–economic optimization of FDM parameters (Lh—layer height and Id—infill density percentage) for the manufacture of tensile and compression samples from recycled materials (r) of PETG (polyethylene terephthalate glycol) and ASA (acrylonitrile styrene acrylate) in the context of the transition to a circular economy. To carry out our technical–economic study, the fundamental principle of value analysis was used, which consists of maximizing the ratio between Vi and Cp, where Vi represents the mechanical characteristic (tensile strength or compressive strength) and Cp represents the production cost. The results of this study showed that, in the case of tensile samples manufactured by recycled PETG (rPETG), the parameter that significantly influences the results of the Vi/Cp ratios is Lh (the height of the layer), while for the samples manufactured additively from recycled ASA (rASA), the parameter that decisively influences the tensile strength is Id (the infill density percentage). In the case of compression samples manufactured by FDM from recycled PETG (rPETG) and recycled ASA (rASA), the parameter that signified influences the results of the Vi/Cp ratios is Id (the infill density percentage). Following the optimization of the FDM parameters, using multiple-response optimization, we identified the optimal parameters for the manufacture of parts by FDM from rPETG and rASA: Lh = 0.20 mm and Id = 100%. The results of this study demonstrated that the use of recycled plastics from PETG and ASA lends itself to a production and consumption model based on a circular economy.

Keywords:

3D printing; FDM; value analysis; printing parameters; optimization; rPETG; rASA; tensile; compressive 1. Introduction

In the current economic context, reducing production costs is essential for achieving companies’ financial objectives, and to achieve these goals, optimizing manufacturing processes plays a major role [1,2,3,4,5,6,7,8]. At the same time, finding solutions for efficient waste management is a global challenge [9,10,11,12,13,14,15,16,17,18,19]. Additive manufacturing technologies stand out globally due to the following advantages they have compared to conventional manufacturing technologies: low operating costs, simplicity of use, and efficiency of material use [20,21,22,23,24,25,26,27,28,29,30,31]. The concept of production and consumption based on a circular economy promotes sustainability by increasing the lifespan of materials, as they are recovered and reused, thus reducing the amount of waste, the amount of energy required for the manufacture of materials, and production costs [32,33,34,35,36,37,38,39,40,41,42]. There is significant interest in the research on implementing the circular economy-based production and consumption model in the field of additive manufacturing technologies through thermoplastic extrusion; however, studies focused on recycled materials made from PETG (polyethylene terephthalate glycol) and ASA (acrylonitrile styrene acrylate) are limited.

In [37], an experimental study on the optimization of FDM parameters (layer height: 0.18, 0.25, and 0.33 mm; filling pattern: solid, sparse double dense, and hexagonal; orientation angle: 0, 45, and 90 degrees; printing plane: XY, XZ, and YZ; part position: 1, 5, and 9) was presented with the aim of reducing the post-processing time and energy consumption without affecting the dimensional accuracy of the additively manufactured parts from ASA. The optimization of the FDM parameters resulted in the following optimal solutions: layer height: 0.33 mm; filling pattern: sparse double dense; orientation angle: 90 degrees; printing plane: XY; part position: 9.

DePalma et al. [43] presented the results of research on the evaluation of the use of additive manufacturing technologies by the extrusion of plastics (FDM) and selective laser sintering (SLS) in the context of the circular economy. The conclusions of the study showed that in the case of SLS, by reusing PA12 (polyamide 12), the cost of a part can be reduced by 10%, and in the case of FDM, by reusing ABS, the cost of a part can be reduced by up to 80%. At the same time, the study presented the problem of polymer degradation during the printing cycle due to the reuse of materials.

The authors of [44] presented an investigation into the ecological and economic impacts of additive manufacturing technologies on supply chains in the case of tire production. The conclusions of the study showed that the implementation of additive manufacturing technologies in the production process led to an increase in the company’s profitability, production costs were more efficient by 51–61%, and the amount of carbon emissions was reduced by 9–10%.

In [45], a study on the optimization of FDM parameters for the manufacture of PLA lattice structures was presented. To carry out the study, compression specimens were manufactured by FDM according to the ASTM D695 standard; subsequently, all specimens were tested in compression using a speed of 2 mm/min. The optimization of the parameters was performed using the Taguchi method. The conclusions of the study showed that the maximum modulus of elasticity was obtained for the specimens manufactured with the following parameters: layer height, Lh = 0.10 mm; extruder temperature, Et = 205 °C; printing speed, Ps = 50 mm/s; platform temperature, Pt = 60 °C. The results of the ANOVA (analysis of variance) showed that the parameter that decisively influences the compressive strength (Cs) is Lh (layer height).

In [46], a study on the optimization of FDM printing parameters for the manufacture of parts from PLA (polylactic acid) reinforced with CGF (continuous glass fiber) was presented. The conclusions of the study showed that the maximum percentage of impregnation with CGF is 45%, and the optimal parameters of FDM for the manufacture of parts from polylactic acid (PLA) reinforced with continuous glass fiber (CGF) are as follows: nozzle diameter, Nd = 1.20 mm; printing speed, Ps = 4 mm/s; and extruder temperature, Et = 210 °C.

In [47], a study on the optimization of FDM parameters was presented [extrusion temperature Te = (190; 210; 230) °C, layer height Lh = (0.10; 0.20; 0.30) mm; print speed, Ps = (40; 60; 80) mm/s; infill density, Id = (30; 60; 90)%], with the aim of maximizing the mechanical characteristics as well as the quality characteristics of the parts manufactured from PLA. The research results showed that the optimal parameters of FDM were as follows: Te = 220 °C; Lh = 0.10 mm; Ps = 60 mm/s; and Id = 90%.

In [48], a study on the optimization of the manufacturing parameters of FDM (extrusion temperature Te; print speed Ps; layer height Lh) was presented in order to minimize the energy consumption required for the manufacture of parts from rPET and PLA without affecting the mechanical characteristics. For the manufacture of tensile specimens from PLA, the following manufacturing parameters were used: Te = (180; 200; 220) °C; Ps = (30; 50; 60; 70) mm/s; Lh = (0.10; 0.20; 0.30) mm. After optimizing the parameters, the following settings were presented: Te = 200 °C; Ps = 60 mm/s; Lh = 0.20 mm. The manufacture of rPET tensile specimens was carried out with the following parameters: Te = (220; 240; 260) °C; Ps = (30; 50; 60; 70) mm/s; Lh = (0.10; 0.20; 0.30) mm. After optimizing the parameters, the following settings were presented: Te = 240 °C, Ps = 60 mm/s, Lh = 0.20 mm. The results of this study demonstrated that recycled materials can be used in additive technology applications by extruding plastics without affecting the mechanical characteristics. At the same time, this study showed that printing parameters affect the energy consumption of the FDM printer, as well as the characteristics of the parts.

This paper presents the results of the technical–economic study on the optimization of FDM parameters (Lh—layer height and Id—infill density percentage) for the manufacturing of tensile and compression samples using recycled materials (r) from PETG and ASA. The uniqueness of this research lies in the utilization of the value analysis (AV) principle, which aims to maximize the values of the ratios of the value in use (Vi) to the production cost (Cp). This study also highlights the opportunities for using recycled materials in the context of the transition to a circular economy.

2. Materials and Methods

The parameters used for manufacturing tensile and compression samples by FDM include the following: part orientation (Po); extruder temperature (Et); platform temperature (Pt); printing speed (Ps); infill pattern (Ip); layer height (Lh); infill density (Id); and plate adhesion (Pa).

The variable parameters of FDM used in the manufacture of tensile and compression samples from rPETG and rASA include the following: the layer height, Lh = (0.10; 0.15; 0.20) mm, and the infill density percentage, Id = (50; 75; 100) %. The mechanical properties of tensile and compression samples manufactured from rPETG were previously determined by the authors in the works [38,39]; the mechanical properties of compression samples manufactured from rASA were determined by the authors in the work [40], and the results of the breaking strengths of tensile samples manufactured additively from rPETG are presented in this work.

Using the FDM parameters summarized in Table 1, 54 tensile samples (27 of rPETG and 27 of rASA) were fabricated on the Anycubic Pro Max 2.0 3D printer (Shenzhen, China) according to ASTM D638-14 [49] and 90 compression samples (45 of rPETG and 45 of rASA) according to ISO 604:2002 [50]. All 54 tensile samples and 90 compression samples fabricated from Everfil rPETG and rASA filaments on the 3D printer Anycubic Pro Max 2.0 3D were tested by the authors on the Barrus White 20 kN universal testing machine (Budapest, Hungary) in the laboratories of the Faculty of Mechanical and Electrical Engineering of the Petroleum–Gas University of Ploiesti.

Table 1.

FDM printing parameters used to manufacture tensile and compressive samples from rPETG and rASA.

Table 1 presents the FDM printing parameters used to manufacture tensile and compressive samples from rPETG and rASA [38,39,40].

Using the results obtained from the experimental determinations of tensile and compressive strength, the production cost for each set of samples and the fundamental principle of value analysis, presented in Relation (1), a technical–economic study on the optimization of FDM parameters for the manufacture of rPETG and rASA samples was conducted. The fundamental principle of value analysis involved in maximizing the ratio between the value in use (Vi) and the production cost (Cp) [41,42].

where Vi represents the use value (mechanical characteristic), and Cp represents the production cost expressed in monetary units.

The optimization of the ratio between Vi and Cp was performed using Minitab 19 software.

The production cost calculation of tensile and compression samples produced through FDM using rPETG and rASA was done utilizing Relation (2).

where represents the production cost (EUR); represents the material cost (EUR); represents the energy cost (EUR); represents the material quantity (g); represents teh material price (EUR/g); represents the printing time (h); represents the energy consumption (kW); and represents electricity price (EUR/kWh).

The following constant values were used for economic calculations: = 0.019 EUR/g (for rPETG); = 0.020 EUR/g (for rASA); = 0.25 kW/h; and = 0.23 kW/h [51,52]. The corresponding values for material consumption and printing time for each set of samples were generated using Cura Slicer software.

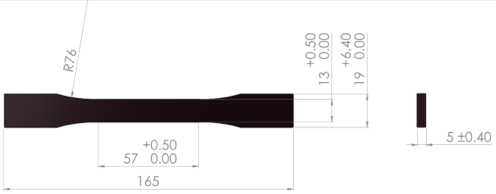

Table 2 shows the dimensions and test conditions for the tensile and compression samples, as referenced in [38,39,40,49,50].

Table 2.

Testing conditions and samples dimensions for experimental investigation.

3. Results and Discussion

3.1. Applications of Value Analysis for Analyzing the Mechanical Behavior of rPETG and rASA 3D-Printed Samples

3.1.1. Tensile Testing

Table 3 and Table 4 summarize the costs associated with materials (Cmat) and electrical energy (Cen), as well as the overall production cost (Cp).

Table 3.

Cost calculation for rPETG samples used for tensile testing.

Table 4.

Cost calculation for rASA samples used for tensile testing.

The FDM parameters considered (Lh—layer height and Id—infill density percentage) influence the tensile strength of samples manufactured from rPETG and rASA, as well as the electrical energy consumption [41,48]. The results of the Vi/Cp ratio are presented in Table 5 and Table 6.

Table 5.

Ratio determination Vi/Cp for tensile samples made from rPETG.

Table 6.

Ratio determination Vi/Cp for tensile samples made from rASA.

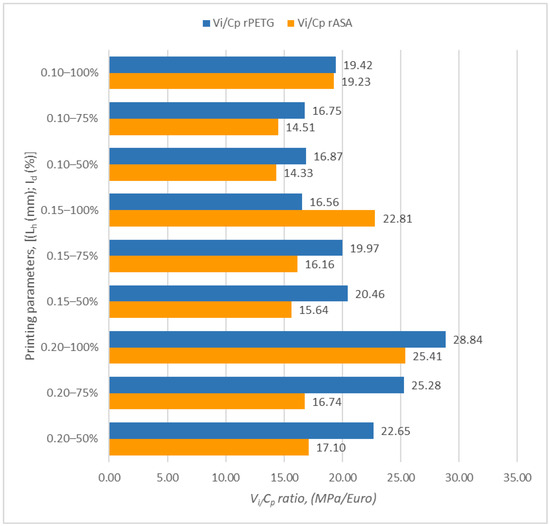

Figure 1 shows the charts illustrating the outcomes of the ratios between Vi and Cp of samples produced through FDM using filament from rPETG and rASA.

Figure 1.

Ratio determination Vi/Cp for tensile samples made from rPETG and rASA.

Upon examining Figure 1, it can be seen that the highest value (28.84 MPa/EUR) for Vi (tensile strength) relative to Cp (cost of production) was achieved for the samples created from rPETG, with a layer height of 0.20 mm and an infill density of 100%. For the samples produced from rASA, the peak value of the ratio between Vi and Cp was also obtained for the additively manufactured samples, which had a layer height of 0.20 mm and an infill density of 100%.

By comparing the minimum with the maximum result of the Vi/Cp ratios obtained for the samples manufactured from rPETG and those corresponding to the rASA samples, it was observed that the Vi/Cp ratios of the rPETG samples are superior by a percentage range between 11.87 and 13.49% compared to those obtained for the rASA samples.

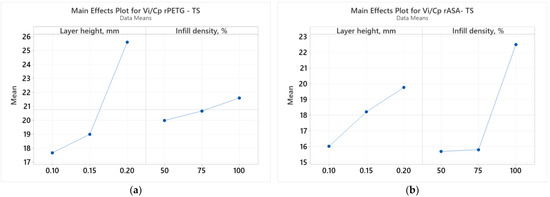

Figure 2 illustrates the relationships between the variable parameters of FDM (Lh and Id) and the ratio between tensile strength (Vi) and cost of production (Cp) [41].

Figure 2.

Main effects plots for tensile strength: (a) rPETG; (b) rASA.

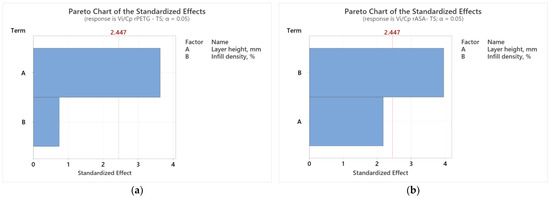

Figure 2 shows how the variable parameters (Lh and Id) affect the results of the Vi/Cp ratios for tensile samples made from rPETG (Figure 3a) and rASA (Figure 3b). In Figure 3a, the layer height (Lh) is the FDM parameter that decisively influences the results of the Vi/Cp ratios of the tensile samples produced from rPETG. In Figure 3b, we observe that the infill density percentage (Id) is the FDM variable parameter that has a significant influence on the results of the Vi/Cp ratios of the tensile samples manufactured from rASA. These conclusions are supported by the Pareto charts presented in Figure 3.

Figure 3.

Pareto charts for tensile strength: (a) rPETG; (b) rASA.

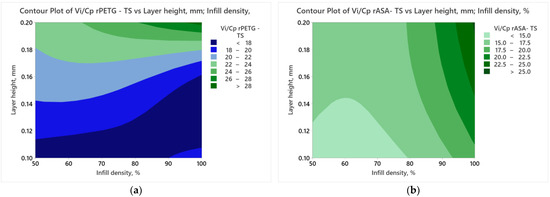

Figure 4 displays the contour plots obtained using the results of the Vi/Cp ratios of the additively manufactured samples of rPETG and rASA and the variable FDM parameters detailed in Table 1.

Figure 4.

Contour plots charts for tensile strength: (a) rPETG; (b) rASA.

Analyzing Figure 4a, increasing both FDM parameters (Lh and Id) simultaneously results in higher Vi/Cp ratios, attributed to the lower production cost associated with the samples manufactured at maximum layer height. Figure 4b, reveals that the highest values of the Vi/Cp for tensile samples manufactured from rASA are achieved by utilizing a 100% filling percentage (Id = 100%) and a layer height of 0.20 mm (Lh = 0.20 mm).

3.1.2. Compressive Testing

Table 7 and Table 8 summarize the results obtained by applying relation 1 and calculating the production cost for compression samples fabricated through FDM using 100% recycled material from rPETG and rASA. Additionally, Table 9 and Table 10 present the Vi/Cp results for compression samples manufactured via FDM from rPETG and rASA.

Table 7.

Cost calculation for rPETG samples used for compressive testing.

Table 8.

Cost calculation for rASA samples used for compressive testing.

Table 9.

Ratio determination Vi/Cp for compressive samples made from rPETG.

Table 10.

Ratio determination Vi/Cp for compressive samples made from rASA.

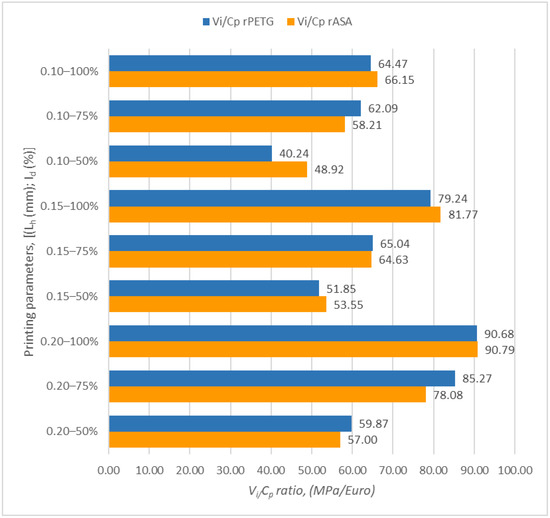

Figure 5 shows the graphical representation of the ratios between Vi (compressive strength) and Cp (cost of production) of the samples additively manufactured by FDM using rPETG and rASA.

Figure 5.

Ratio determination Vi/Cp for compressive samples made from rPETG and rASA.

Analyzing the bar chart from Figure 5, it can be observed that the maximum value (90.79 MPa/EUR) of the ratio between Vi (compressive strength) and Cp (cost of production) was obtained for the set of additively manufactured rASA samples with the maximum layer height, Lh = 0.20 mm, and a maximum infill density percentage, Id = 100%. The peak value of the report between Vi (compressive strength) and Cp (cost of production) of additively manufactured rPETG samples was obtained for samples manufactured with the parameters: Lh = 0.20 mm samples Id = 100%.

Comparing the results between minimum and maximum values of the Vi/Cp ratios obtained for the rASA samples with those corresponding to the rPETG samples, it is found that the Vi/Cp ratios of the rASA samples are higher by 0.12–17.75% compared to those of the rPETG FDM additively manufactured samples.

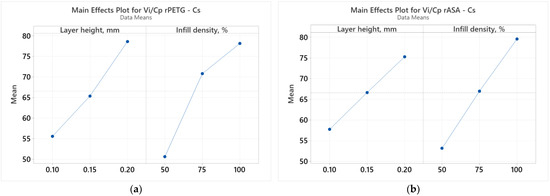

Figure 6 displays the results of the ANOVA analysis examining the relationship between the FDM parameters (Lh and Id) and the results of the ratios between the compressive strength (Vi) and the production cost (Cp).

Figure 6.

Main effects plots for compressive strength: (a) rPETG; (b) rASA.

Analyzing the graphs presented in Figure 6, it is observed that the variable FDM parameters (Lh and Id) significantly affect the results of the Vi/Cp ratios of compression samples additively manufactured from rPETG (Figure 6a) and rASA (Figure 6b). According to Figure 6a, both FDM parameters have a significant influence on the results of the Vi/Cp ratios of compression samples manufactured from rPETG; however, the parameter with a greater influence is the infill density percentage (Id). Studying the graphs from Figure 6b, we observe that the considered FDM parameters (Lh and Id) significantly influence the results of the Vi/Cp ratios of compression samples additively manufactured from rASA, but the infill density percentage (Id) is the parameter with biggest influence on the results of the Vi/Cp ratios. The same conclusions are drawn from the analysis of the Pareto charts presented in Figure 7.

Figure 7.

Pareto charts for compression strength: (a) rPETG; (b) rASA.

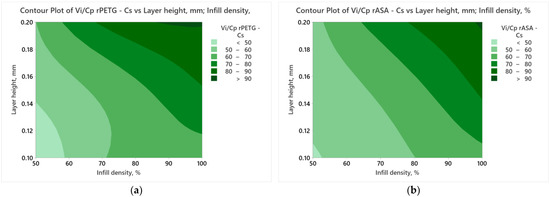

Figure 8 presents contour plots obtained using the results of the Vi/Cp ratios of the additively manufactured samples of rPETG and rASA and the variable FDM parameters presented in Table 1.

Figure 8.

Contour plots charts for compression strength: (a) rPETG; (b) rASA.

Following the analysis of Figure 8, it can be concluded that the ratios between Vi and Cp are significantly influenced by the higher values of Lh and Id.

3.2. Optimization of FDM Parameters Based on Value Analysis to Improve 3D Printing Efficiency for Samples Made of rPETG and rASA

For technical–economic optimization, we utilized the Minitab 19 software, the variable parameters of the FDM as presented in Table 1, and fundamental value analysis to maximize the Vi/Cp ratio.

The optimization objective is to maximize of the results of the ratios between Vi/Cp for both mechanical tests performed (tension and compression) and both materials used (rPETG and rASA). Table 11 presents the targets for achieving optimization.

Table 11.

Optimization goals for analyzed materials (rPETG and rASA).

Using Relations (3) and (4) the desirability calculation was performed [3], written as follows:

Table 12 presents the overall desirability values for the printing parameters corresponding to each material type studied.

Table 12.

Composite desirability.

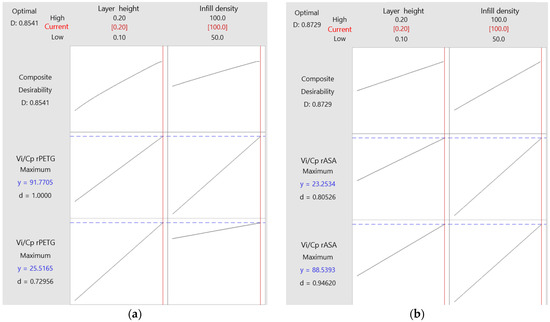

The graphs shown in Figure 9 illustrate the optimization of FDM variable parameters for producing rPETG and rASA samples [53].

Figure 9.

Optimization plots for 3D-printed materials: (a) rPETG; (b) rASA.

The optimization graphs for FDM printing parameters related to the additive manufacturing of tensile and compression samples made from rPETG and rASA are illustrated in Figure 9.

The solid vertical red lines indicate the current arrangement of the factors, and the red numbers presented on each column reflect their current levels. The dashed horizontal blue lines emphasize the responses linked to the current settings of the factors, while the blue numerical values represent the responses related to these settings.

4. Conclusions

This paper presents the results of a technical–economic study on the optimization of FDM parameters for manufacturing samples using recycled materials from PETG and ASA in the context of transitioning to a circular economy. To achieve this goal, we performed a multi-objective optimization with the aim of finding the optimal FDM parameters (Lh—layer height and Id—infill density percentage) for the manufacture of parts from rPETG and rASA Everfill brand with 100% recycled material. By applying the fundamental principle of value analysis, which focused on maximizing the Vi/Cp ratios, we used experimental data on tensile and compressive properties of additively manufactured rPETG and rASA samples, as well as production cost calculations, to optimize the FDM parameters for achieving the highest value in balancing mechanical characteristics and production cost.

Results from ANOVA analysis show that both FDM parameters considered (Lh—the height layer and Id—the infill density percentage) significantly impact the Vi/Cp ratios. In the case of tensile samples additively manufactured from rPETG, the parameter that significantly influences the results of the Vi/Cp ratios is Lh—the layer height, and in the case of compression samples manufactured from rPETG, the parameter that significantly influences the results of the Vi/Cp ratios is Id—the infill density percentage.

In the case of samples additively manufactured by FDM from rASA, the parameter that decisively influences the results of the Vi/Cp ratios of the tensile and compression samples is Id—the infill density percentage.

After optimizing the FDM process parameters, we found the following optimal parameters: Lh = 0.20 mm and Id = 100%.

The results of this study demonstrate that the use of recycled materials for the manufacture of parts by FDM represents a good technical and economic solution, with the price of recycled materials being significantly lower compared to that of virgin materials. By applying the optimal printing settings determined in this study, reduced production costs can be achieved without impacting quality and mechanical characteristics.

The authors aim to increase the lifespan of the materials used in this study by reusing the two materials and determining the number of reuses until a significant decrease in mechanical characteristics is observed. In order to achieve a holistic analysis, in a future paper, we will conduct a study that will analyze the impact of 3D printing parameters (layer height, infill density, print speed, and extrusion temperature) on the mechanical characteristics of the leathers. Additionally, a comparison will be made between the theoretical material and energy consumption (determined by the slicer) and the material and energy consumption determined from measurements.

Author Contributions

Conceptualization, D.G.Z., M.M. and D.V.I.; methodology, D.G.Z., M.M. and D.V.I.; validation, D.G.Z. and M.M.; formal analysis, D.G.Z.; investigation, D.G.Z., M.M. and D.V.I.; resources, D.G.Z., M.M. and D.V.I.; writing—original draft preparation, D.V.I.; writing—review and editing, D.G.Z., M.M. and D.V.I.; visualization D.G.Z., M.M. and D.V.I.; supervision, D.G.Z. and M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shahar, F.S.; Sultan, M.T.H.; Grzejda, R.; Łukaszewicz, A.; Oksiuta, Z.; Krishnamoorthy, R.R. Harnessing the Potential of Natural Composites in Biomedical 3D Printing. Materials 2024, 17, 6045. [Google Scholar] [CrossRef]

- Megersa, G.K.; Sitek, W.; Nowak, A.J.; Tomašić, N. Investigation of the Influence of Fused Deposition Modeling 3D Printing Process Parameters on Tensile Properties of Polylactic Acid Parts Using the Taguchi Method. Materials 2024, 17, 5951. [Google Scholar] [CrossRef] [PubMed]

- Addanki, M.; Patra, P.; Kandra, P. Recent Advances and Applications of Artificial Intelligence and Related Technologies in the Food Industry. Appl. Food Res. 2022, 2, 100126. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S. Additive Manufacturing: Recent Trends, Applications and Future Outlooks. Prog. Addit. Manuf. 2021, 7, 261–287. [Google Scholar] [CrossRef]

- Jatti, V.S.; Sapre, M.S.; Jatti, A.V.; Khedkar, N.K.; Jatti, V.S. Mechanical Properties of 3D-Printed Components Using Fused Deposition Modeling: Optimization Using the Desirability Approach and Machine Learning Regressor. Appl. Syst. Innov. 2022, 5, 112. [Google Scholar] [CrossRef]

- Rivera-López, F.; Pavón, M.M.L.; Correa, E.C.; Molina, M.H. Effects of Nozzle Temperature on Mechanical Properties of Polylactic Acid Specimens Fabricated by Fused Deposition Modeling. Polymers 2024, 16, 1867. [Google Scholar] [CrossRef] [PubMed]

- Almuflih, A.S.; Abas, M.; Khan, I.; Noor, S. Parametric Optimization of FDM Process for PA12-CF Parts Using Integrated Response Surface Methodology, Grey Relational Analysis, and Grey Wolf Optimization. Polymers 2024, 16, 1508. [Google Scholar] [CrossRef]

- Van, C.N.; Le Hoang, A.; Long, C.D.; Hoang, D.N. Surface Roughness in Metal Material Extrusion 3D Printing: The Influence of Printing Orientation and the Development of a Predictive Model. Eng. Technol. Appl. Sci. Res. 2023, 13, 11672–11676. [Google Scholar] [CrossRef]

- Dev, S.; Srivastava, R. Experimental investigation and optimization of FDM process parameters for material and mechanical strength. Mater. Today Proc. 2020, 26, 1995–1999. [Google Scholar] [CrossRef]

- Anh, N.T.; Quynh, N.X.; Tung, T.T. Study on Topology Optimization Design for Additive Manufacturing. Eng. Technol. Appl. Sci. Res. 2024, 14, 14437–14441. [Google Scholar] [CrossRef]

- Subramonian, S.; Kadirgama, K.; Al-Obaidi, A.S.M.; Salleh, M.S.M.; Vatesh, U.K.; Pujari, S.; Rao, D.; Ramasamy, D. Artificial Neural Network Performance Modeling and Evaluation of Additive Manufacturing 3D Printed Parts. Eng. Technol. Appl. Sci. Res. 2023, 13, 11677–11684. [Google Scholar] [CrossRef]

- Park, H.S.; Tran, N.H.; Hoang, V.T.; Bui, V.H. Development of a Prediction System for 3D Printed Part Deformation. Eng. Technol. Appl. Sci. Res. 2022, 12, 9450–9457. [Google Scholar] [CrossRef]

- Tran, T.V.N.; Long, D.C.; Van, C.N. The Influence of Printing Materials on Shrinkage Characterization in Metal 3D Printing Using Material Extrusion Technology. Eng. Technol. Appl. Sci. Res. 2024, 14, 15356–15360. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Tensile Behavior of Samples made of PET-G. Eng. Technol. Appl. Sci. Res. 2024, 14, 13487–13492. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Compressive Behavior of PET-G Parts. Eng. Technol. Appl. Sci. Res. 2024, 14, 13592–13597. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Tensile Behavior of Samples made of ASA. Eng. Technol. Appl. Sci. Res. 2024, 14, 15975–15980. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Compressive Behavior of ASA Parts. Eng. Technol. Appl. Sci. Res. 2024, 14, 16237–16241. [Google Scholar] [CrossRef]

- Dias Gonçalves, V.P.; Vieira, C.M.F.; Simonassi, N.T.; Perissé Duarte Lopes, F.; Youssef, G.; Colorado, H.A. Evaluation of Mechanical Properties of ABS-like Resin for Stereolithography Versus ABS for Fused Deposition Modeling in Three-Dimensional Printing Applications for Odontology. Polymers 2024, 16, 2921. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Tao, Y.; Wang, Y. Shape-Memory Effect of 4D-Printed Gamma-Irradiated Low-Density Polyethylene. Crystals 2024, 14, 717. [Google Scholar] [CrossRef]

- Petruse, R.E.; Simion, C.; Bondrea, I. Geometrical and Dimensional Deviations of Fused Deposition Modelling (FDM) Additive-Manufactured Parts. Metrology 2024, 4, 411–429. [Google Scholar] [CrossRef]

- Kharate, N.; Anerao, P.; Kulkarni, A.; Abdullah, M. Explainable AI Techniques for Comprehensive Analysis of the Relationship between Process Parameters and Material Properties in FDM-Based 3D-Printed Biocomposites. J. Manuf. Mater. Process. 2024, 8, 171. [Google Scholar] [CrossRef]

- Hsieh, H.-H.; Yao, K.; Wang, C.-H.; Chen, C.-H.; Huang, S.-H. Using a Circular Economy and Supply Chain as a Framework for Remanufactured Products in the Rubber Recycling Industry. Sustainability 2024, 16, 2824. [Google Scholar] [CrossRef]

- Jabłońska, M.; Łastowska, O. Enhancing of Surface Quality of FDM Moulded Materials Through Hybrid Techniques. Materials 2024, 17, 4250. [Google Scholar] [CrossRef]

- Behseresht, S.; Park, Y.H.; Love, A.; Valdez Pastrana, O.A. Application of Numerical Modeling and Finite Element Analysis in Fused Filament Fabrication: A Review. Materials 2024, 17, 4185. [Google Scholar] [CrossRef] [PubMed]

- Atsani, S.I.; Sing, S.L. Optimization of Glass-Powder-Reinforced Recycled High-Density Polyethylene (rHDPE) Filament for Additive Manufacturing: Transforming Bottle Caps into Sound-Absorbing Material. Polymers 2024, 16, 2324. [Google Scholar] [CrossRef] [PubMed]

- Remache, A.; Pérez-Sánchez, M.; Hidalgo, V.H.; Ramos, H.M.; Sánchez-Romero, F.-J. Towards Sustainability in Hydraulic Machinery Manufacturing by 3D Printing. Processes 2024, 12, 2664. [Google Scholar] [CrossRef]

- Cândido, T.C.d.O.; Silva, D.N.d.; Borges, M.M.C.; Barbosa, T.G.; Trindade, S.O.D.d.; Pereira, A.C. 3D-Printed Electrochemical Sensors: A Comprehensive Review of Clinical Analysis Applications. Analytica 2024, 5, 552–575. [Google Scholar] [CrossRef]

- Kothandaraman, L.; Balasubramanian, N.K. Optimization of FDM printing parameters for square lattice structures: Improving mechanical characteristics. Mater. Today Proc. 2024, in press. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Fused deposition modelling for aeronautics: Techno-economic and environmental assessment for overhead locker supports replacement. Int. J. Adv. Manuf. Technol. 2023, 128, 3817–3840. [Google Scholar] [CrossRef]

- Iacob, D.V. Stadiul Actual al Cercetărilor în Domeniul Fabricației Additive. Ph.D. Thesis, Mechanical Engineering Department, Petroleum—Gas University, Ploiești, România, 2024. [Google Scholar]

- Chen, D.-C.; Zheng, Q.-D.; Chen, C.-H. Optimization of Tensile Strength and Cost-Effectiveness of Polyethylene Terephthalate Glycol in Fused Deposition Modeling Using the Taguchi Method and Analysis of Variance. Polymers 2024, 16, 3133. [Google Scholar] [CrossRef] [PubMed]

- Aguirre, P.S.; Veiga, F.; Irijalba, M.; Villabona, E.; Rivero, P.J. Processing Parameter Setting Procedure for a Commercial Bowden Tube FDM Printer. J. Manuf. Mater. Process. 2024, 8, 236. [Google Scholar] [CrossRef]

- D’Addona, D.; Raykar, S.; Singh, D.; Kramar, D. Multi Objective Optimization of Fused Deposition Modeling Process Parameters with Desirability Function. Procedia CIRP 2021, 99, 707–710. [Google Scholar] [CrossRef]

- Nikam, M.; Pawar, P.; Patil, A.; Patil, A.; Mokal, K.; Jadhav, S. Sustainable Fabrication of 3D Printing Filament from Recycled PET Plastic. Mater. Today Proc. 2024, 103, 115–125. [Google Scholar] [CrossRef]

- Djonyabe Habiba, R.; Malça, C.; Branco, R. Exploring the Potential of Recycled Polymers for 3D Printing Applications: A Review. Materials 2024, 17, 2915. [Google Scholar] [CrossRef] [PubMed]

- Camposeco-Negrete, C. Optimization of FDM parameters for improving part quality, productivity and sustainability of the process using Taguchi methodology and desirability approach. Prog. Addit. Manuf. 2020, 5, 59–65. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Tensile Behavior of Specimens Manufactured by FDM from Recycled PETG in the Context of the Circular Economy Transition. Eng. Technol. Appl. Sci. Res. 2024, 14, 18681–18687. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study of the Optimization of FDM Parameters for the Manufacture of Compression Specimens from Recycled PETG in the Context of the Transition to the Circular Economy. Eng. Technol. Appl. Sci. Res. 2024, 14, 18774–18779. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. Study on the optimization of FDM parameters for the manufacture of compression specimens from recycled ASA in the context of the transition to the circular economy. Eng. Technol. Appl. Sci. Res. 2025, 15, 19898–19902. [Google Scholar]

- Iacob, D.V.; Zisopol, D.G.; Minescu, M. Technical-Economical Study on the Optimization of FDM Parameters for the Manufacture of PETG and ASA Parts. Polymers 2024, 16, 2260. [Google Scholar] [CrossRef] [PubMed]

- Zisopol, D.G. Ingineria Valorii; Editura Universitătății Petrol-Gaze din Ploiești: Ploiesti, Romania, 2004; ISBN 973-7965-96-5. [Google Scholar]

- DePalma, K.; Walluk, M.R.; Murtaugh, A.; Hilton, J.; McConky, S.; Hilton, B. Assessment of 3D Printing Using Fused Deposition Modeling and Selective Laser Sintering for a Circular Economy. J. Clean. Prod. 2020, 264, 121567. [Google Scholar] [CrossRef]

- Shahpasand, R.; Talebian, A.; Mishra, S. Investigating Environmental and Economic Impacts of the 3D Printing Technology on Supply Chains: The Case of Tire Production. J. Clean. Prod. 2023, 390, 135917. [Google Scholar] [CrossRef]

- Rahman, M.M.; Sultana, J.; Rayhan, S.; Ahmed, A. Optimization of FDM Manufacturing Parameters for the Compressive Behavior of Cubic Lattice Cores: An Experimental Approach by Taguchi Method. Int. J. Adv. Manuf. Technol. 2023, 129, 1329–1343. [Google Scholar] [CrossRef]

- Chen, K.; Yu, L.; Cui, Y.; Jia, M.; Pan, K. Optimization of Printing Parameters of 3D-Printed Continuous Glass Fiber Reinforced Polylactic Acid Composites. Thin-Walled Struct. 2021, 164, 107717. [Google Scholar] [CrossRef]

- Correlating FDM Printing Parameters with Mechanical Properties and Surface Quality of PLA Printouts—IOPscience. Available online: https://iopscience.iop.org/article/10.1088/2631-8695/ad8c16 (accessed on 27 November 2024).

- Raja, S.; Ali, R.M.; Karthikeyan, S.; Surakasi, R.; Anand, R.; Devarasu, N.; Sathish, T. Energy-Efficient FDM Printing of Sustainable Polymers: Optimization Strategies for Material and Process Performance. Appl. Chem. Eng. 2024, 7, 5537. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ISO 604:2002; Plastics: Determination of Compressive Properties. ISO: Geneva, Switzerland, 2002.

- Eurostat Statistics Explained. Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics (accessed on 25 September 2024).

- Available online: https://ultimaker.com/software/ultimaker-cura/ (accessed on 10 June 2024).

- Available online: https://www.minitab.com/en-us/ (accessed on 30 October 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).