Abstract

The way to improve the properties (resistance to washing, delamination, and rubbing off) of the PEDOT:PSS coating applied on wool fabric without reduction of its electrical conductivity by introducing a commercially available combination of low formaldehyde content melamine resins into the printing paste is presented in this paper. Primarily, to improve the hydrophilicity and dyeability of wool fabric, the samples were modified using low-pressure nitrogen (N2) gas plasma. Two commercially available PEDOT:PSS dispersions were used to treat wool fabric by the exhaust dyeing and screen printing methods, respectively. Spectrophotometric measurements of the color difference (ΔE*ab) and visual evaluation of woolen fabric dyed and printed with PEDOT:PSS in different shades of the blue color showed that the sample modified with N2 plasma obtained a more intense color compared to the unmodified one. SEM was used to examine the surface morphology and a cross-sectional view of wool fabric that had undergone various modifications. SEM image shows that the dye penetrates deeper into the wool fabric after plasma modification using dyeing and coating methods with a PEDOT:PSS polymer. In addition, with a Tubicoat fixing agent, HT coating looks more homogeneous and uniform. The chemical structure spectra of wool fabrics coated with PEDOT:PSS were investigated using FTIR-ATR characterization. The influence of melamine formaldehyde resins on the electrical properties, resistance to washing, and mechanical effects of PEDOT:PSS treated wool fabric was also evaluated. The resistivity measurement of the samples containing melamine-formaldehyde resins as an additive did not show a significant decrease in electrical conductivity, while the electrical conductivity was maintained after the washing and rubbing test as well. The best results of electrical conductivity for investigated wool fabrics before and after washing and mechanical action were determined for samples subjected to the combined processing–surface modification by low-pressure N2 plasma, dyeing by exhaust with PEDOT:PSS, and coating by the screen-printing method of PEDOT:PSS and a 3 wt.% melamine formaldehyde resins mixture.

1. Introduction

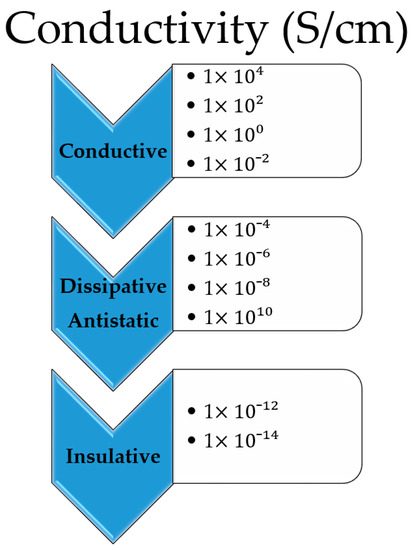

The next major advancement in technology in the contemporary period will likely be wearable electronics and conductive materials, which will surpass portable devices. Conductive fabrics can be utilized to incorporate sensors capable of sensing and responding to external stimuli [1,2,3,4,5]. The stimuli and responses can have a variety of causes, including chemical, thermal, magnetic, and electrical [1]. The development of lightweight, flexible parts and fibrous structures with a high electrical conductivity that can withstand the stresses of wearing, and caring for the textile is a critical obstacle to the success of wearable e-textile technology [2,6]. In fact, there are several obstacles to be overcome in the quickly expanding field of electronic textiles, or e-textiles, due to the rigidity and weight of metallic conductors [2,7]. Electrostatic discharge terminology glossary (ESD ADV1.0) defines conductive materials as “a material that has a surface resistance of less than 1.0 × 104 Ω or volume resistance of less than 1.0 × 104 Ω”. In order to combine electronic devices, such as sensors [8,9,10,11,12], antennas [7,13], and energy storage devices [14,15,16], new technology has been used in textile construction. Electrostatic discharge (ESD) is a very common and easily attainable phenomenon in the realm of alternative nonmetal-based conductive fabrics [17,18,19,20]. Components for smart textiles need to have a conductivity that is significantly higher than the electrostatic discharge range to replace metallic conductors in fabrics that effectively transmit information and support computing. According to the ESD Association standard [21], dissipative materials have conductivities between 1 10−11 S/cm and 1 10−4 S/cm. Contrarily, conductive materials are those that have conductivity greater than 1 10−4 S/cm (Figure 1). To create lightweight materials that potentially replace metallic fabrics, higher conductivity must be combined with good mechanical qualities [21].

Figure 1.

Conductivity ranges for different applications [17,21].

Conductive textiles can be made using natural and chemical fibers with conductive additives, such as conductive polymers, metals, oxides, and carbon. Intrinsically conductive polymers (ICPs), such as polyaniline (PANI), polypyrrole (PPy), and poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT:PSS) can be used to create conductive coatings or tracks on textiles [22]. These ICPs can be applied to textiles through conventional methods, such as exhaust dyeing, coating, or screen printing, and may be fixed with a binder or directly reacted with the functional groups of the fibers [23,24,25,26,27,28]. When creating electrically conductive textiles, it is crucial to take into account the characteristics of wearing comfort, breathability, flexibility, softness, resilience to repeated washings, and mechanical elements during daily use. In this study, wool fabric was modified with conductive polymer PEDOT:PSS with low-formaldehyde melamine resins to create not only conductive but also flexible and wearable textile. Wool is a natural protein fiber composed of 18 amino acids with amino and carboxy groups and sulfur, linking adjacent macromolecules by cross-disulfide bonds. Wool fibers are usually dyed with acid dyes. Because of the PSS negatively charged sulfonate ions (-SO3-) interactions with the cationic amine groups of the wool fibers, PEDOT:PSS is referred to as a “conducting acid dye” [25,29] that may attach to protein fibers and dye them in various shades of blue [27]. There are several advantages for the PEDOT:PSS water-soluble polyelectrolyte system for textile applications, including electrical conductivity, applicability with traditional textile technologies, commercial availability, water solubility, stability, and high visible light transmittance [30]. A disadvantage influenced by the solubility of the conductive polymer component polystyrene sulfonate (PSS) in water causes the formed coating to peel off from the textile, thus decreasing its resistance [22,23,29] to wet treatments. It is also important to evaluate the ability of the PEDOT:PSS coating on wool fabric to retain its conductivity and resistance to rubbing and washing [31,32,33,34,35]. Physical and chemical testing, as well as color change measurement, can help to determine the durability of PEDOT:PSS coating on textile materials under different processing conditions and inform about the most appropriate treatment with this conductive polymer [31,36]. Modification, etching, activation, cleaning and hydrophilicity of the wool fiber surface were performed using low-pressure nitrogen (N2) gas plasma [37,38,39,40]. Scanning electron microscopy (SEM) was used to analyze the surface morphology, defects, contaminants, and roughness of textile materials. It helps to characterize the microstructure of fibers and yarns, as well as the surface texture and finish of textiles [34,35,40,41]. FTIR-ATR spectroscopy was used to identify the chemical bonds present in the sample and to determine the chemical composition of the investigated sample [37,42,43,44,45].

The novelty of this work is to design and characterize electrically conductive textiles coated with a formulation containing a water dispersion of PEDOT:PSS as a conductive additive and increased resistance to mechanical and wet effects such as dry rubbing and washing.

2. Materials and Methods

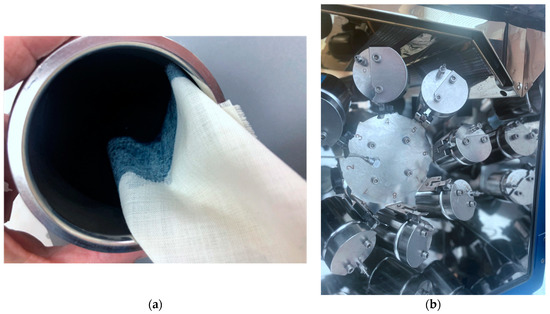

A 100% wool fabric used as the substrate for this research was acquired from JSC “Drobė” (Kaunas, Lithuania). The Junior Plasma System 004/123 (Europlasma, Oudenaarde, Belgium) is a low-pressure plasma apparatus that was used to modify the wool fabric samples with N2 gas. The chosen process parameters were as follows: processing duration of 3 min, pressure of 0.4 mbar, discharge power of 200 W, and N2 gas flow of 0.01 L/min (Figure 2).

Figure 2.

Junior Plasma System 004/123 (Europlasma, Oudenaarde, Belgium).

The PEDOT:PSS commercial products Clevios F ET and Clevisios SV3 (Heraeus Holding GmbH, Hanau, Germany) were chosen because of their suitable chemical composition and viscosity for our dyeing/coating methods. The PEDOT:PSS with ethylenediol (5–10%) commercial additive water dispersion Clevios F ET was used to dye wool fabric samples that had not been treated, or that had been treated with N2 plasma (13 cm × 20 cm) in various shades of blue using the exhaust dyeing method (Figure 3a). Using Clevios F ET at various pH levels, dyeing was performed at 90 °C for 30 min. After dyeing, samples were dried in a lab drying-thermosetting machine called the TFOS IM 350 (Roaches International, Batley, UK) for three minutes at 100 °C. The Clevios F ET dyed and undyed wool fabrics samples were printed using the flat screen-printing method with the commercial PEDOT:PSS water dispersion Clevios S V3 (Heraeus Holding GmbH, Hanau, Germany) and dried at 100 °C for 3 min in a drying–thermosetting machine TFOS IM 350. Cross-linking can be used to stabilize films and improve delamination on the fabrics. However, some of them, such as glycidoxy propyltrimethoxysilane (GOPS), require high curing temperatures (140 °C for 1 h) and have an adverse impact on conductivity values [46]. Our research has shown that wool fabric turns yellow at temperatures above 105 °C. Melamine formaldehyde resin systems are used for textiles to produce highly durable coatings, especially for impregnation against moisture [41]. For this reason, some of the investigated samples were treated with a low formaldehyde content melamine resin named Tubicoat fixing agent HT (CHT Germany GmbH, Tübingen), which does not require high curing temperatures and can improve the properties of PEDOT:PSS coatings on wool fabric, such as washing resistance, delamination resistance, and mechanical resistance, without compromising it electrical conductivity [41,43,44].

Figure 3.

Wool fabric sample immersed into PEDOT:PSS water dispersion (a), views of cups in laboratory dyeing apparatus, Ahiba Nuance ECO (b).

Clevios S V3 and 3 wt.% Tubicoat fixing agent HT were used to screen print the wool fabric samples for this purpose. The samples were then dried at 100 °C for 5 min in a lab drying–thermosetting machine called the TFOS IM 350. The codification of samples treated using different methods is shown in Table 1.

Table 1.

Codification of samples processed by various methods.

2.1. SEM Analysis

SEM microscopy and FTIR-ATR (attenuated total reflection) spectroscopy have been used to study the surface of fully coated samples. With scanning electron microscopy (SEM), Quanta 200 FEG (FEI, Eindhoven, The Netherlands), at 20 keV (low vacuum), magnifications of 500× and 5000× work distances of 6.0 mm, low vacuum pressures of 80 Pa, and large-field detectors (LFD), the surface morphology of the coated wool fabric was examined.

2.2. Fourier Transform Infrared Spectroscopy with Attenuated Total Internal Reflectance (FTIR-ATR)

Utilizing FTIR-ATR spectroscopy (FTIR Perkin Elmer Frontier, MA, USA), chemical bonding analyses of untreated and plasma-treated wool samples dyed with Clevios F ET and coated with Clevios SV 3 were carried out. By analyzing the infrared spectra of the tested samples, which were measured using FTIR-ATR spectroscopy in ATR reflection mode (spectrum range: 600–4000 cm−1, resolution: 1 cm), it was possible to investigate the structural modifications that had taken place in the samples.

2.3. Evaluation of the Durability of Conductive PEDOT:PSS Coating after Washing

Each without and with N2 plasma-modification samples after dyeing with Clevios F ET and coating with Clevios SV 3 (see Table 1) were washed and dried 5 cycles. The method used for the five wash cycles according to ISO 13688:2013 [47]. Samples were washed with Scourotester Computex (Budapest, Hungary), washing temperature 40 °C (method A1S) and duration 30 min (ISO EN 105-C06) [48]. Washed wool fabrics were line dried in ambient atmosphere.

2.4. Color Fastness to Rubbing in the Conditioning Atmosphere

A testing instrument with two different sizes of rubbing fingers and a reciprocating straight rubbing action was used to determine the color fastness against dry rubbing. The specimen and rubbing cloth were subjected to a standard environment of (20 ± 2) °C and (65 ± 4)% for at least 4 h prior to testing [49]. Each specimen was secured to the testing device’s base such that its long axis would align with the device’s track. To minimize specimen movement, a space was established between the baseplate of the test fixture and the specimen and between the baseboard of the testing device and the specimen. When laid flat on the tip of the finger, the weaving of a conditioned rubbing cloth is parallel to the direction of finger rubbing. On the dry specimen, a track measuring 104 ± 3 mm in length was rubbed 20 times in a straight line, 10 times forward and 10 times back, at a rate of one cycle per second, with a downward force of 9 ± 0.2 N [50]. Following testing, the staining of the rubbing cloth was evaluated using a grey scale for staining in proper lighting [51].

2.5. Evaluation of Color Change

The color change of dyed and coated samples after washing was evaluated on a grey scale. Tests for color fastness were performed according to the grey scale for determining changes in the color of textiles. Pairs of matte-finish gray color chips (or samples of matte-finish grey fabric) make up the basic scale, which has five stages. An enhanced scale also has four half-steps, making a total of 9 steps. The standard offers a precise colorimetric scale definition that can be used to compare samples that may have altered with newly prepared working referents [52].

2.6. Color Intensity Measurements

The color difference (ΔE*ab) of the unmodified and modified plasma, Clevios F ET dyed and Clevios S V3 printed samples (Table 1) after washing and rubbing tests were evaluated with Datacolor Microflash MF 45 IR spectrophotometer (Datacolor AG, Rotkreus, Switzerland) [53] (Figure 4). The wavelength range of the apparatus was: visible range 400–700 nm and infrared range 700–1100 nm, geometry type 0°/45°, illuminant and observer conditions D65/10°, area of view 3.2 mm, number of readings per sample—4 and number of measured layers of fabric—4. The standard atmosphere temperature (20 ± 2) °C and relative humidity (65 ± 4)% were used to keep the samples prior to testing [49]. The standard deviation was roughly 1, and measurements were done on 5 elementary samples.

Figure 4.

Spectrophotometer Datacolor Microflash MF 45 IR.

The average of 4 readings per sample was recorded, and the standard deviation was approx. ±1σ, namely, color yield (K/S), the substrate absorption function (K), the scattering function of background (S), and the reflectance (R) in the visible spectrum (400–700 nm). Other color parameters, such as L*, indicate the difference between darkness (where L* = 0) and lightness (where L* = 100); C* represents the saturation/chroma of the color; a*, the red/green coordinate is the difference between red (+a*) and green (−a*); h is the hue angle (h sample minus h standard), which is the difference in hue; b* is the yellow/blue coordinate, which is the difference between blue (−b*) and yellow (+b*).

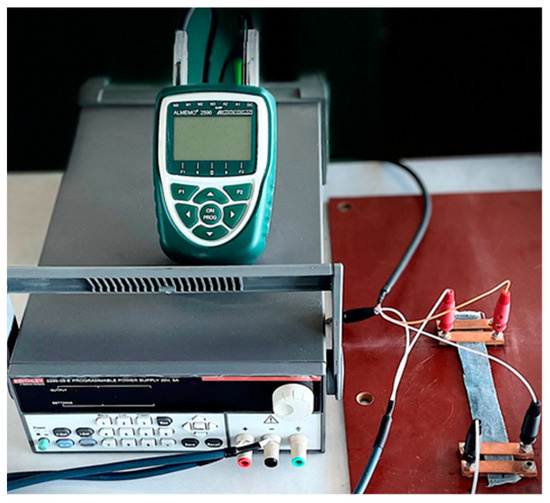

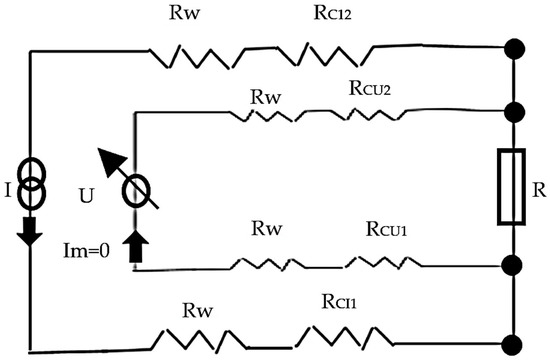

2.7. Evaluation of Electrical Properties

Electrical resistance measurements, which are the inverse of electrical conductivity measurements, were used to identify all fabrics created for this study. Before testing, the specimens were left for at least 24 h in standard atmosphere conditions (20 °C and 65% RH) [49]. The voltage measurements were provided in the same conditions. The linear resistance was measured six times in 1 min, every 10 s, and the distance between the voltage electrodes is (d) 10 cm, and a sample width of 2 cm (Figure 5). Measurements were made according to the Four Point Kelvin method [54]. The electric current (I) is 0.01 ÷ 0.001 A, the resulting voltage (U) and the sample resistance (R) is calculated according to Formula (2), and the linear resistance (RL) is calculated according to Formulas (1 and 3) (Figure 6).

Figure 5.

Electrical resistance measurement. The electrodes were positioned and covered the entire width of the conductive track, as illustrated in the image.

Figure 6.

Detailed scheme for the “four electrode−four wire method”; the four electrodes (contacts) are visualized by the four nodes indicated in the scheme.

I is the applied current in amperes; U is the measured voltage in volts, and Im is the current in the voltage measurement circuit (equivalent to zero)

RCI1 and RCI2 are the contact resistances in the current circuit in ohms; RCU1 and RCU2 are the contact resistance in the voltage circuit in ohms; RW is the wire resistance in ohms.

RCI, RCV, and RW can be excluded due to the ”four electrode−four wire measurement” so that the resistance of the specimen can be calculated by the simple formula

R = U/I

The linear resistance RL, in ohm/m, is then calculated as

RL = R/d

The distance d between the voltage electrodes is 10 cm.

3. Results

3.1. SEM Analysis

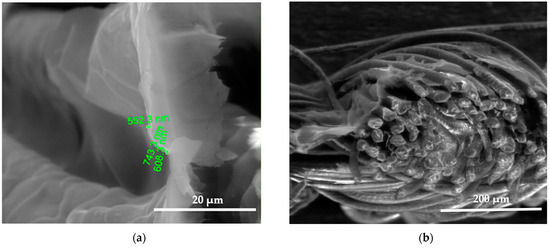

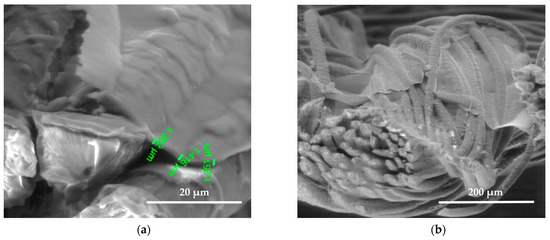

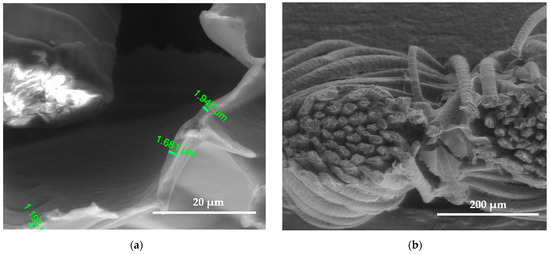

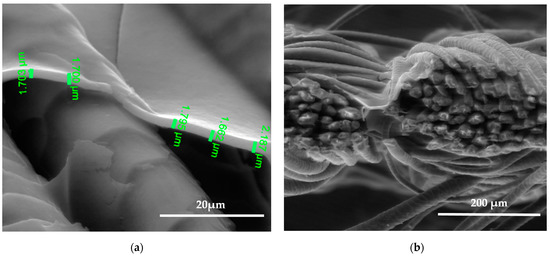

SEM images show the differences between unmodified and modified plasma wool samples with different coating combinations, according to Table 1. SEM images show that when comparing the samples without (S) and after plasma modification (PS, PFS), the thickness of the sample (S) coating is thinner at 0.552 ÷ 0.743 µm, uneven, and delaminated (Figure 7a,b), but after plasma modification of the sample (PS) we obtain a thicker coating 1.251 ÷ 1.416 µm, the sample is ignited more evenly, and the spaces between the threads are filled with a coating (Figure 8a,b) [37]. After plasma modification of samples (PFS) (Figure 9a,b), the coating is thicker at 1.193 ÷ 1.947 µm and more equal and well penetrated on the other side of the fabric in comparison to samples (PS) [38,39,40] without initial dyeing, the coating is only formed and visible on the surface (Figure 8b). Comparing samples without (S, PS, PFS) and with Tubicoat fixing agent HT (FSH), the coating thickness is 1.662 ÷ 2.187 µm (Figure 10a,b) and looks more homogeneous and uniform than without Tubicoat fixing agent HT (Figure 7, Figure 8 and Figure 9).

Figure 7.

SEM images of the wool fiber cross-section sample (S) with Clevios S V3 coating applied by the printing method. Magnification 5000× (a) and 500× (b).

Figure 8.

SEM images of the wool fiber cross-section sample (PS) N2 plasma-treated and Clevios S V3 screen printing method coating; magnification 5000× (a) and 500× (b).

Figure 9.

SEM images of the wool fiber cross-section sample (PFS) N2 plasma-treated Clevios F ET dyed and Clevios S V3 screen printing method coating; magnification 5000× (a) and 500× (b).

Figure 10.

SEM images of the wool fiber cross-section sample (PFSH) N2 plasma-treated Clevios F ET dyed and Clevios S V3 with Tubicoat fixing agent HT screen printing method coating; magnification 5000× (a) and 500× (b).

3.2. Evaluation of Conductive PEDOT: PSS Coating Durability after Washing Cycles

The photo images of plasma and PEDOT:PSS treated wool samples (F, PF, S, PS, FS, PFS, SH, FSH, PFSH) before and after five washing and drying cycles are present in Table 2. The color change analysis showed that the samples after plasma treatment are more than half-steps [52] when compared to other samples: F with PF, S with PS, and FSH with PFSH. This indicates that the plasma-treated samples became darker, possibly due to better absorption of PEDOT:PSS. After five washes, the plasma-treated samples (PF, PS, PFS, PSH) showed less color change compared to the untreated samples (F, S, FS, SH). Plasma treatment cleaned the surface of the wool fabric, and we assume that it increased the yield of absorbed PEDOT:PSS and resistance during washing as well [37,38,39,40]. When we compared unwashed with sample after five washes cycles (F, PF, S, PS, PFS), according to gray scale a color change was found about one stages or more [52]. Furthermore, comparing PEDOT: PSS coated samples with (SH, FSH, PFSH) and without Tubicoat fixing agent HT (S, FS, PFS) before and after five washes, the color change between washed and unwashed samples was less than half-steps according to grey scale. The received results showed that Tubicoat fixing agent HT increased the resistance to washing. The sample PFSH demonstrated the highest wash fastness and the lowest color changes after five washes (Table 2).

Table 2.

Sample photo images before and after 5 washing 40 °C and drying cycles [48].

3.3. Color Fastness to Dry Rubbing Analysis

Improved resistance to dry rubbing was obtained by using the same combination of with or without plasma modification, dyeing, and dyeing/coating with PEDOT:PSS with or without Tubicoat fixing agent HT. After dyeing with Clevios F ET, the color of the sample (F) was so dull that it was difficult to evaluate the rubbing test result, but it became more visible after plasma treatment (PF) (Table 3). Better dry rubbing resistance of samples (SH, PSH, FSH, PFSH) was obtained when 3 wt.% of Tubicoat fixing agent HT was added to the Clevios S V3 (Table 4). The tests carried out showed that the best resistance of rubbing was obtained with the combined modification (PFSH): plasma treatment, PEDOT:PSS dyeing and coating, and Tubicoat fixing agent HT adding (Table 4).

Table 3.

Wool samples with different modifications after rubbing tests [50].

Table 4.

Wool samples with different modifications with 3 wt.% of Tubicoat fixing agent HT after rubbing tests [50].

3.4. Measurements of Electrical Resistance

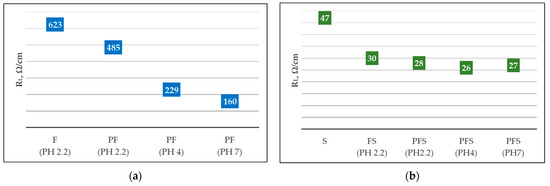

Comparison of plasma (160 Ω/cm) and no plasma (623 Ω/cm) treatments of wool fabrics (Figure 11a) resulted in an approximately 4 times lower linear resistance (RL). The pH change (2.2, 4, and 7) dyeing with Clevios F ET alone resulted in the lowest resistivity at pH 7 (160 Ω/cm) and was not influence the resistivity of newly formed coating with Cevios S V3 (Figure 11b). Plasma treatment, dyeing, and coating with PEDOT:PSS (sample PFS) resulted in almost a factor of two times lower linear resistivity measurements (26 ÷ 28 Ω/cm) compared with only coating Clevios SV 3 (sample S) (47 Ω/cm) (Figure 11a,b). Since changing the pH did not significantly affect the linear resistance reduction, we did not change the pH in further tests and used the original Clevios F ET.

Figure 11.

Measurements of the linear resistance (RL) of untreated and plasma-treated wool fabrics at different pH values of Clevios F ET (a), Clevios S V3, and Clevios F ET/Clevios S V3 (b).

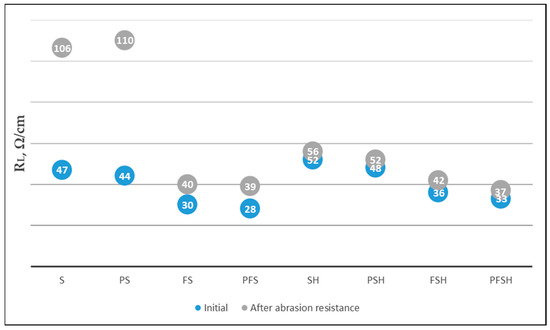

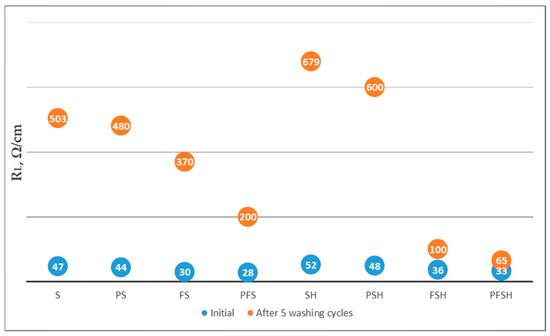

The linear resistance (RL) of all samples with the same chemical modifications with PEDOT:PSS after plasma treatment (PS, PFS, PSH, PFSH) were twice as low as without plasma treatment (S, FS, SH, FSH) (Figure 12). This is due to the better affinity and binding of PEDOT:PSS as a “conductive acid dye” [25] to the cationic amine sites of the wool fiber after plasma treatment. Samples with Tubicoat fixing agent HT (SH, PSH, PFSH) retained better electrical conductivity after washing and rubbing compared to those without Tubicoat fixing agent HT (S, PS, FS, PFS) (Figure 12). It is assumed that Tubicoat fixing agent HT as a cross-linker [55] affected the formed fabric surface film resistance to rubbing; through this, the resistance (33 Ω/cm) did not increase (Figure 12). After rubbing and washing testing, the PFSH sample linear resistivity values were, respectively, (37 Ω/cm) and (65 Ω/cm), and had the lowest resistivity compared to the other samples (Figure 12 and Figure 13). Similar resistance results were achieved by researchers of PANI-coated PET yarns ranging from 1.02 × 103 Ω (PANI-spun 10 wt.%) to 1.53 × 106 Ω (PANI-spun 3 wt.%) for a 10 cm long fiber [56,57]. In this report, a lower resistance of wool sample (PFSH) in comparison to the in situ polymerization PPy coated fabrics was obtained using the Tubicoat fixing agent HT and plasma treatment [55,56].

Figure 12.

Measurements of linear resistance (RL) untreated and after plasma treatment with different modifications of wool fabrics after rubbing testing.

Figure 13.

Linear resistance (RL) measurements on untreated and plasma-treated wool fabrics coated with different modifications of Clevios F ET and Clevios S V3 after five washing cycles.

3.5. Spectrophotometric Determination of Color Differences

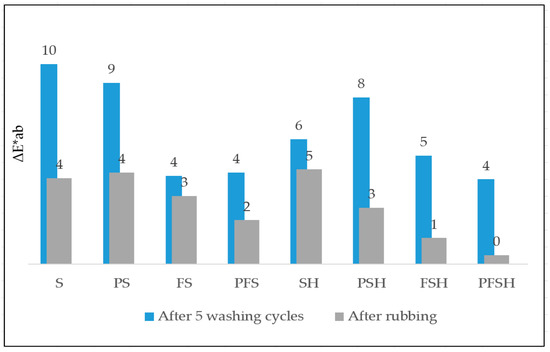

Samples (S, PS, FS, PFS, SH, PSH, FSH, PFSH) of the wool fabric of different modifications references were compared with the same samples after washing and rubbing tests and performing color differences tests with a spectrophotometer. The PFSH sample has the least color difference (ΔE*ab) before and after washing and rubbing, resulting in the best resistance to washing and rubbing treatments. Samples (PS, PFS, PSH, PFSH) after plasma modification compared to unmodified plasma (S, FS, SH, FSH) showed lower color differences (ΔE*ab) and better resistance to mechanical treatment and washing (Figure 14). Providing the complex modification of sample (FS) dyeing with Clevios F ET and coating Clevios S V3, a smaller color difference compared to samples (S) printed only with Clevios S V3 was obtained (Figure 14).

Figure 14.

Color difference (ΔE*ab) test results after washing and rubbing testing with PEDOT: PSS-modified wool fabric samples by various methods.

Table 5 displays the measured L*, a*, b*, C*, and h coordinates and K/S values at the maximum wavelength of 1100 nm. Color yield K/S shows a higher dyeing ability [58] to PEDOT:PSS of the tested wool fabric samples (Table 5). The received results showed that after plasma treatment, the values K/S of samples (PS, PFS, PSH, PFSH) were lower compared to the unmodified K/S samples (S, FS, SH, FSH), as well as after washing and rubbing tests (Table 5). Plasma modified sample (PFSH) compared with the unmodified (FSH) was darker in color (L* = 36), had bluer (h = 240), more saturated colors (C* = 7), and had greener (a* = −4) and bluer (b* = −6) shade (Table 5). After five washing cycles, sample PFSH became yellowish (b* = 4), reddish (a*= 2), had a saturated color (C* = 5), a darker (L* = 34) shade, and had higher dyeing ability (K/S = 36) (Table 5). The K/S value determines the difference between the color strength of the sample PFSH reference (K/S = 35) and of the same sample after the rubbing test (K/S = 37). After the rubbing test, the sample PFSH color coordinates did not change much and were: darker (L* = 38), bluer (h = 239), had the same saturated color (C* = 7), greener (a* = −4), and had a bluer (b* = −6) shade (Table 5). The received results showed that plasma treatment increased wool fiber’s ability to react with PEDOT:PSS. Furthermore, the Tubicoat fixing agent HT as cross-linker enhanced the sample’s (PFSH)) resistance to washing and rubbing treatments [42].

Table 5.

Following washing and rubbing testing, we compared the L* a* b* C* h color coordinates and the maximal K/S values of unwashed plasma and PEDOT:PSS treated samples.

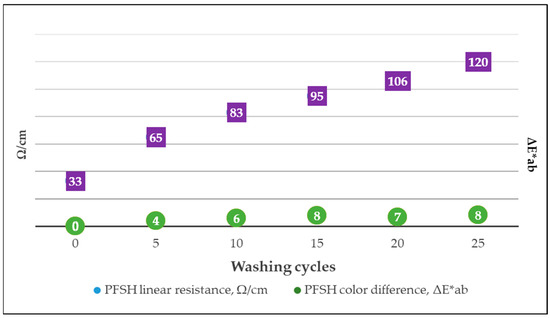

The sample PFSH with the best resistance to rubbing and washing was selected, and additionally, 25 washing cycles were carried out, measuring the linear resistance and color differences after every five washing cycles. The value of ∆E*ab shows that the magnitude of the color differences after the washing cycles is not very wide; after 15 washing cycles, the value remains almost constant at ∆E*ab of approximately eight. Moreover, the RL of sample PFSH before washing was 33 Ω/cm (Figure 15). The RL steadily increased to 120 Ω/cm when the 25 washing cycles were carried out, but the material was still electrically conductive (Figure 15) and could be classified as a dissipative material and used for protective workwear [59].

Figure 15.

Linear resistance results with color difference comparison after 25 washing cycles of sample PFSH.

3.6. Fourier Transform Infrared Spectroscopy with Attenuated Total Internal Reflectance (FTIR-ATR) Mode Measurement

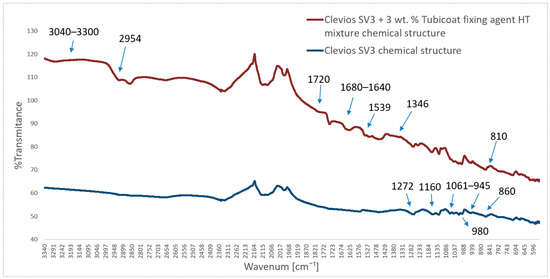

FTIR-ATR spectra of the chemical structure of the pristine Clevios S V3 and composition of Clevios S V3 + 3 wt.% Tubicoat fixing agent HT spectra are presented in Figure 16. The principal absorption peaks of the PEDOT:PSS water dispersion in the form of Clevios S V3 were discovered at 1160 cm−1, corresponding to the symmetric and asymmetric stretch vibrations of the PSS sulfonic acid group, and the peaks were around 1030 cm−1, corresponding to the asymmetric stretching vibrations of benzene sulfonate [39,55,60]. The C–S bond stretching vibrations in the thiophene ring are responsible for the absorption peaks at approx. 860 and 980 cm−1 [61,62], as well as the C–O–C stretching at 1061 and 945 cm−1 and the C=C and C–C stretching in the quinoidal structure of PEDOT at 1272 cm−1 [35,63,64] (Figure 16).

Figure 16.

ATR infrared spectra of the Clevios S V3 with Tubicoat fixing agent HT and Clevios S V3 chemical structure.

IR spectra of sample Clevios S V3 + 3 wt.% Tubicoat fixing agent HT can be found in melamine resin from the band between 3040 and 3300 cm−1, with poor signal intensity, suggesting the potential O–H bond stretching vibration and N–H stretching vibration in primary aryl amines. These bands demonstrated that the cross-linking of formaldehyde and melamine was successful. The stretching vibration of C–H corresponds to the band of 2954 cm−1. Additionally, the methane vibration is represented by the new peak at roughly 1346 cm−1 [63,65]. The wavenumbers of amino-substituted triazines, which would exhibit a distinct absorption band in the range 1680–1640 cm−1, can be because of the reduced number of unreacted amino groups in the resin structure. The absorption band at 810 cm−1 corresponds to the out-of-plane bending vibrations of C–H bonds. Another clue that a tiny amount of aldehyde is still not engaged in the cross-linking process of melamine resin is the faint signal detected at 1720 cm−1 (a band characteristic for the C=O group) (Figure 16).

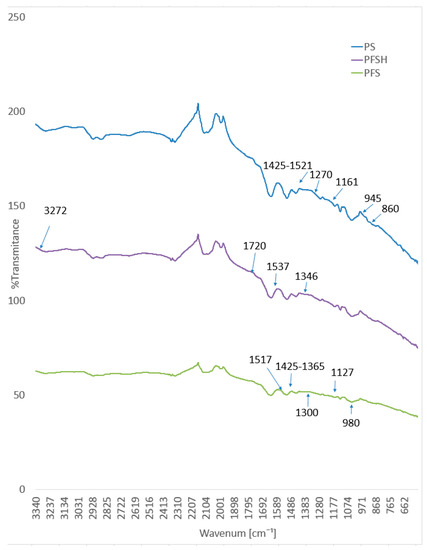

FTIR-ATR infrared spectra of plasma treated samples: dyed with Clevios F ET and coated with Clevios S V3 (PFS) and Clevios F ET/Clevios S V3 + 3 wt.% Tubicoat fixing agent HT are shown in Figure 17. As described in our previous study [66], FTIR-ATR spectra of the wool surface after plasma treatment showed a decrease in aliphatic hydrocarbons (C–C, C–H), oxidation of –S–S–, an increase in the number of amino groups -N-H₂. This means that the N₂ plasma-treatment wool fabric samples have a more reactive and hydrophilic surface, resulting in better absorption of the PEDOT:PSS polymer [67].

Figure 17.

ATR infrared spectra of the wool samples PS, PFS, and PFSH.

All of the peaks from the wool fiber covered with PEDOT:PSS were nearly identical to the pure film of PEDOT:PSS dispersion (Figure 17). The principal peaks of the sample (PS) absorption were located at 1161 cm−1 (sulfonic acid group of PSS), 1065–945 cm−1 (C–O–C stretching), 945 cm−1 and 860 cm−1 (C–S stretching), and 1270 cm−1 (C=C and C–C stretching of the quinoidal structure of PEDOT) [64]. Specific wavelengths of specific PEDOT:PSS absorption peaks were found in Clevios F ET and Clevios S V3 spectra. Peaks at 1127 cm−1 (sulfonic acid group) and 1425 cm−1 (corresponding to the C=C and C–C stretching vibrations coming from the thiophene ring) were also found, showing that the PEDOT:PSS was successfully interpolated on the surface of the wool fabric (Figure 17). Similar PEDOT:PSS peaks were found by Mingwei Tian et al. on cotton fabric surfaces at 1517 cm−1 and 1300 cm−1 [35]. Similar spectra to Figure 16 are found on sample PFSH near 3272 cm−1 and 1537 cm−1, 1346 cm−1 wavelength range. These results, when combined with the signal at 1720 cm−1, which represents the stretching vibrations of the C=O, may indicate that there are still a few unreacted O–H molecules in the polymer and a small amount of aldehyde that is not yet involved in the cross-linking of melamine resin [44,45,63] (Figure 17).

4. Conclusions

The SEM images show that after plasma treatment dyeing with Clevios F ET and coating with Clevios S V3 3 wt.% Tubicoat fixing agent HT composition, the resulting coating is more rigid and evenly coated on the reverse side of the fabric. This may have improved rubbing and washing resistance. Using only coating with Clevios S V3, the surface coating is visible only on the surface. After plasma treatment, dyeing, and coating with PEDOT:PSS commercial products named Clevious, the linear resistivity was almost halved compared to coating with Clevios S V3 alone. The functional groups introduced onto the surface after N2 gas plasma treatment, and Tubicoat fixing agent HT of wool fabric were characterized by FTIR-ATR spectroscopy. The results of color difference measurement show that N2 plasma treatment and melamine formaldehyde Tubicoat fixing agent HT increased the resistance of PEDOT:PSS coated samples to washing and rubbing, and more intense color and electrical conductivity retaining were received.

Author Contributions

Conceptualization, J.P. and A.S.; methodology, J.P.; software, A.S.; validation, J.P. and A.S.; formal analysis, J.P., A.S. and V.R.; investigation, J.P.; resources, A.A.; data curation, J.P. and A.S.; writing—original draft preparation, J.P.; writing—review and editing, J.P., S.V.-Ž., V.R. and A.S.; visualization, J.P.; supervision, A.S. and S.V.-Ž., V.R.; project administration, A.A. and J.P.; funding acquisition, A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Van Langenhove, L.; Puers, R.; Matthys, D. Intelligent textiles for protection. In Textiles for Protection; Woodhead Publishing in Textiles: Cambridge, UK, 2005; pp. 176–195. [Google Scholar]

- Cherenack, K.; Van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- Van Langenhove, L. Smart textiles for protection: An overview. In Smart Textiles for Protection; Woodhead Publishing in Textiles: Cambridge, UK, 2013; pp. 3–33. [Google Scholar]

- Koncar, V. Introduction to smart textiles and their applications. In Smart Textiles and Their Applications; Woodhead Publishing Series in Textiles: Cambridge, UK, 2016; pp. 1–8. [Google Scholar]

- Kongahage, D.; Foroughi, J. Actuator materials: Review on recent advances and future outlook for smart textiles. Fibers 2019, 7, 21. [Google Scholar] [CrossRef]

- Köhler, A.R. Challenges for eco-design of emerging technologies: The case of electronic textiles. Mater. Des. 2013, 51, 51–60. [Google Scholar] [CrossRef]

- Shawl, R.K.; Long, B.R.; Werner, D.H.; Gavrin, A. The Characterization of Conductive Textile Materials Intended for Radio Frequency Applications. IEEE Antennas Propag. Mag. 2007, 49, 28–40. [Google Scholar] [CrossRef]

- El Gharbi, M.; Fernández-García, R.; Ahyoud, S.; Gil, I. A review of flexible wearable antenna sensors: Design, fabrication methods, and applications. Materials 2020, 13, 3781. [Google Scholar] [CrossRef]

- Huang, J.; Virji, S.; Weiller, B.H.; Kaner, R.B. Polyaniline nanofibers: Facile synthesis and chemical sensors. J. Am. Chem. Soc. 2003, 125, 314–315. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T. Conductive polymer-based sensors for biomedical applications. Biosens. Bioelectron. 2011, 26, 1825–1832. [Google Scholar] [CrossRef]

- Devaux, E.; Aubry, C.; Campagne, C.; Rochery, M. PLA/carbon nanotubes multifilament yarns for relative humidity textile sensor. J. Eng. Fibers Fabr. 2011, 6, 155892501100600302. [Google Scholar] [CrossRef]

- Wang, J.; Lu, C.; Zhang, K. Textile-Based Strain Sensor for Human Motion Detection. Energy Environ. Mater. 2020, 3, 80–100. [Google Scholar] [CrossRef]

- Bayram, Y.; Zhou, Y.; Shim, B.S.; Xu, S.; Zhu, J.; Kotov, N.; Volakis, J.L. E-Textile Conductors and Polymer Composites for Conformal Lightweight Antennas. IEEE Trans. Antennas Propag. 2010, 58, 2732–2736. [Google Scholar] [CrossRef]

- Hu, L.; Pasta, M.; La Mantia, F.; Cui, L.; Jeong, S.; Deshazer, H.D.; Choi, J.W.; Han, S.M.; Cui, Y. Stretchable, Porous, and Conductive Energy Textiles. Nano Lett. 2010, 10, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Meng, J.; Zhang, J.; Chen, X.; Du, M.; Chen, Y.; Hou, C.; Wang, J.; Ju, A.; Wang, X.; et al. Three-Dimensional Hierarchically Porous Graphene Fiber-Shaped Supercapacitors with High Specific Capacitance and Rate Capability. ACS Appl. Mater. Interfaces 2019, 11, 25205–25217. [Google Scholar] [CrossRef]

- Xu, Q.; Lu, C.; Sun, S.; Zhang, K. Electrochemical properties of PEDOT:PSS/V2O5 hybrid fiber based supercapacitors. J. Phys. Chem. Solids 2019, 129, 234–241. [Google Scholar] [CrossRef]

- Krifa, M. Electrically conductive textile materials—Application in flexible sensors and antennas. Textiles 2021, 1, 239–257. [Google Scholar] [CrossRef]

- Cheng, K.B.; Ueng, T.H.; Dixon, G. Electrostatic Discharge Properties of Stainless Steel/Polyester Woven Fabrics. Text. Res. J. 2001, 71, 732–738. [Google Scholar] [CrossRef]

- Hebeish, A.A.; El-Gamal, M.A.; Said, T.S.; El-Hady, R.A.A. Major factors affecting the performance of ESD-protective fabrics. J. Text. Inst. 2010, 101, 389–398. [Google Scholar] [CrossRef]

- Zhang, X. 2—Antistatic and conductive textiles. In Functional Textiles for Improved Performance, Protection and Health; Pan, N., Sun, G., Eds.; Woodhead Publishing: Cambridge, UK, 2011; pp. 27–44. [Google Scholar]

- Electrostatic Discharge Association ESD Association Advisory for Electrostatic Discharge Terminology-Glossary. ESD ADV1.0–2009. Available online: www.esda.org/assets/Documents/c23d92d4ab/Fundamentals-of-ESD-Part-1-An-Introduction-to-ESD.pdf (accessed on 25 April 2023).

- Tseghai, G.B.; Mengistie, D.A.; Malengier, B.; Fante, K.A.; Van Langenhove, L. PEDOT: PSS-based conductive textiles and their applications. Sensors 2020, 20, 1881. [Google Scholar] [CrossRef]

- Rubeziene, V.; Baltusnikaite-Guzaitiene, J.; Abraitiene, A.; Sankauskaite, A.; Ragulis, P.; Santos, G.; Pimenta, J. Development and investigation of PEDOT: PSS composition coated fabrics intended for microwave shielding and absorption. Polymer 2021, 13, 1191. [Google Scholar] [CrossRef]

- Guo, Y.; Otley, M.T.; Li, M.; Zhang, X.; Sinha, S.K.; Treich, G.M.; Sotzing, G.A. PEDOT: PSS “wires” printed on textile for wearable electronics. ACS Appl. Mater. Interfaces 2016, 8, 26998–27005. [Google Scholar] [CrossRef]

- Lund, A.; van der Velden, N.M.; Persson, N.K.; Hamedi, M.M.; Müller, C. Electrically conducting fibres for e-textiles: An open playground for conjugated polymers and carbon nanomaterials. Mater. Sci. Eng. R Rep. 2018, 126, 1–29. [Google Scholar] [CrossRef]

- Kaynak, A. Conductive polymer coatings. In Active Coatings for Smart Textiles; Hu, J., Ed.; Woodhead: Sydney, Australia, 2016; Volume 176, pp. 113–136. [Google Scholar]

- Ding, Y.; Invernale, M.A.; Sotzing, G.A. Conductivity trends of PEDOT-PSS impregnated fabric and the effect of conductivity on electrochromic textile. ACS Appl. Mater. Interfaces 2010, 2, 1588–1593. [Google Scholar] [CrossRef] [PubMed]

- Otley, M.T.; Alamer, F.A.; Guo, Y.; Santana, J.; Eren, E.; Li, M.; Lombardi, J.; Sotzing, G.A. Phase segregation of PEDOT: PSS on textile to produce materials of >10 A mm−2 current carrying capacity. Macromol. Mater. Eng. 2017, 302, 1600348. [Google Scholar] [CrossRef]

- Elschner, A.; Loevenich, W.; Eiling, A.; Bayley, J. ITO Alternative: Solution Deposited Clevios TM PEDOT: PSS for Transparent Conductive Applications. Heraeus Trade Artic. 2012. Available online: https://www.yumpu.com/en/document/read/10545247/english-cleviostm-conductive-transparent-and-flexible-polymers (accessed on 20 April 2023).

- Alhashmi Alamer, F.; Althagafy, K.; Alsalmi, O.; Aldeih, A.; Alotaiby, H.; Althebaiti, M.; Alnefaie, M.A. Review on PEDOT: PSS-Based Conductive Fabric. ACS Omega 2022, 7, 35371–35386. [Google Scholar] [CrossRef] [PubMed]

- Ryan, J.D.; Mengistie, D.A.; Gabrielsson, R.; Lund, A.; Müller, C. Machine-washable PEDOT: PSS dyed silk yarns for electronic textiles. ACS Appl. Mater. Interfaces 2017, 9, 9045–9050. [Google Scholar] [CrossRef] [PubMed]

- Ankhili, A.; Tao, X.; Cochrane, C.; Koncar, V.; Coulon, D.; Tarlet, J.M. Ambulatory evaluation of ECG signals obtained using washable textile-based electrodes made with chemically modified PEDOT: PSS. Sensors 2019, 19, 416. [Google Scholar] [CrossRef]

- Tao, X.; Huang, T.H.; Shen, C.L.; Ko, Y.C.; Jou, G.T.; Koncar, V. Bluetooth Low Energy-Based Washable Wearable Activity Motion and Electrocardiogram Textronic Monitoring and Communicating System. Adv. Mater. Technol. 2018, 3, 1700309. [Google Scholar] [CrossRef]

- Tao, X.; Koncar, V.; Huang, T.-H.; Shen, C.-L.; Ko, Y.-C.; Jou, G.-T. How to Make Reliable, Washable, and Wearable Textronic Devices. Sensors 2017, 17, 673. [Google Scholar] [CrossRef]

- Tian, M.; Hu, X.; Qu, L.; Zhu, S.; Sun, Y.; Han, G. Versatile and ductile cotton fabric achieved via layer-by-layer self-assembly by consecutive adsorption of graphene doped PEDOT: PSS and chitosan. Carbon 2016, 96, 1166–1174. [Google Scholar] [CrossRef]

- Jang, Y.; Park, Y.D.; Lim, J.A.; Lee, H.S.; Lee, W.H.; Cho, K. Patterning the organic electrodes of all-organic thin film transistors with a simple spray printing technique. Appl. Phys. Lett. 2006, 89, 183501. [Google Scholar] [CrossRef]

- Kale, K.H.; Desai, A.N. Atmospheric pressure plasma treatment of textiles using non-polymerising gases. Indian J. Fibre Text. Res. 2011, 36, 289–299. [Google Scholar]

- Haji, A. Natural dyeing of wool with henna and yarrow enhanced by plasma treatment and optimized with response sur-face methodology. J. Text. Inst. 2020, 111, 467–475. [Google Scholar] [CrossRef]

- Udakhe, J.; Honade, S.; Shrivastava, N. Plasma induced physicochemical changes and reactive dyeing of wool fabrics. J. Mater. 2015, 2015, 620370. [Google Scholar] [CrossRef]

- Mori, M.; Inagaki, N. Relationship between anti-felting properties and physicochemical properties of wool treated with low-temperature plasma. Res. J. Text. Appar. 2006, 10, 33–45. [Google Scholar] [CrossRef]

- Varnaitė-Žuravliova, S.; Sankauskaitė, A.; Stygienė, L.; Krauledas, S.; Bekampienė, P.; Milčienė, I. The investigation of barrier and comfort properties of multifunctional coated conductive knitted fabrics. J. Ind. Text. 2016, 45, 585–610. [Google Scholar] [CrossRef]

- Dorieh, A.; Pour, M.F.; Movahed, S.G.; Pizzi, A.; Selakjani, P.P.; Kiamahalleh, M.V.; Aghaei, R. A review of recent progress in melamine-formaldehyde resin based nanocomposites as coating materials. Prog. Org. Coat. 2022, 165, 106768. [Google Scholar] [CrossRef]

- Manasoglu, G.; Kanik, M.; Yildirim, K. Effect of fixation conditions on yellowing behavior of cellulose powder–coated fabrics. J. Eng. Fibers Fabr. 2019, 14, 1558925019829049. [Google Scholar] [CrossRef]

- Merline, D.J.; Vukusic, S.; Abdala, A.A. Melamine formaldehyde: Curing studies and reaction mechanism. Polym. J. 2013, 45, 413–419. [Google Scholar] [CrossRef]

- Funda, S.; Ohki, T.; Liu, Q.; Hossain, J.; Ishimaru, Y.; Ueno, K.; Shirai, H. Correlation between the fine structure of spin-coated PEDOT: PSS and the photovoltaic performance of organic/crystalline-silicon heterojunction solar cells. J. Appl. Phys. 2016, 120, 033103. [Google Scholar] [CrossRef]

- Mantione, D.; Del Agua, I.; Schaafsma, W.; ElMahmoudy, M.; Uguz, I.; Sanchez-Sanchez, A.; Mecerreyes, D. Low-temperature cross-linking of PEDOT: PSS films using divinylsulfone. ACS Appl. Mater. Interfaces 2017, 9, 18254–18262. [Google Scholar] [CrossRef]

- ISO 13688:2012; Protective Clothing—General Requirements. ISO—International Organization for Standardization: Geneva, Switzerland, 2012.

- LST EN ISO 105-C06:2010; Textiles—Tests for Colour Fastness—Part C06: Colour Fastness to Domestic and Commercial Laundering (ISO 105-C06:2010). Lithuanian Standards Board: Vilnius, Lithuania, 2010.

- LST EN ISO 139:2006; Textiles—Standard Atmospheres for Conditioning and Testing (ISO 139:2005). Lithuanian Standards Board: Vilnius, Lithuania, 2006.

- LST EN ISO 105-X12:2016; Textiles—Tests for Colour Fastness—Part X12: Colour Fastness to Rubbing (ISO 105-X12:2016). Lithuanian Standards Board: Vilnius, Lithuania, 2016.

- LST EN ISO 105-A01:2010; Textiles—Tests for Colour Fastness—Part A01: General Principles of Testing (ISO 105-A01:2010). Lithuanian Standards Board: Vilnius, Lithuania, 2010.

- LST EN ISO 105-A02:1993; Textiles. Tests for Colour Fastness. Part A02: Grey Scale for Assessing Change in Colour (ISO 105-A02:1993). Lithuanian Standards Board: Vilnius, Lithuania, 1993.

- LST EN ISO 105-J03:2010; Textiles—Tests for Colour Fastness—Part J03: Calculation of Colour Differences (ISO 105-J03:2009). Lithuanian Standards Board: Vilnius, Lithuania, 2010.

- LST EN ISO 16812:2019; Petroleum, Petrochemical and Natural Gas Industries—Shell-and-Tube Heat Exchangers (ISO 16812:2019). Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- Alemu, D.; Wei, H.Y.; Ho, K.C.; Chu, C.W. Highly conductive PEDOT: PSS electrode by simple film treatment with methanol for ITO-free polymer solar cells. Energy Environ. Sci. 2012, 5, 9662–9671. [Google Scholar] [CrossRef]

- Kim, B.; Koncar, V.; Devaux, E.; Dufour, C.; Viallier, P. Electrical and morphological properties of PP and PET conductive polymer fibers. Synth. Met. 2004, 146, 167–174. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, P.; Zhang, L.; Zhong, Y.; Sui, X.; Wang, B.; Mao, Z. High-performance textile electrodes for wearable electronics obtained by an improved in situ polymerization method. Chem. Eng. J. 2019, 361, 897–907. [Google Scholar] [CrossRef]

- Kumpikaitė, E.; Varnaitė-Žuravliova, S.; Tautkutė-Stankuvienė, I.; Laureckienė, G. Comparison of mechanical and end-use properties of grey and dyed cellulose and cellulose/protein woven fabrics. Materials 2021, 14, 2860. [Google Scholar] [CrossRef] [PubMed]

- Åkerfeldt, M.; Strååt, M.; Walkenström, P. Electrically conductive textile coating with a PEDOT-PSS dispersion and a polyurethane binder. Text. Res. J. 2013, 83, 618–627. [Google Scholar] [CrossRef]

- Zhou, X.; Rajeev, A.; Subramanian, A.; Li, Y.; Rossetti, N.; Natale, G.; Cicoira, F. Self-healing, stretchable, and highly adhesive hydrogels for epidermal patch electrodes. Acta Biomater. 2022, 139, 296–306. [Google Scholar] [CrossRef]

- Xu, Y.; Patsis, P.A.; Hauser, S.; Voigt, D.; Rothe, R.; Günther, M.; Zhang, Y. Cytocompatible, injectable, and electroconductive soft adhesives with hybrid covalent/noncovalent dynamic network. Adv. Sci. 2019, 6, 1802077. [Google Scholar] [CrossRef]

- Panigrahy, S.; Kandasubramanian, B. Polymeric thermoelectric PEDOT: PSS & composites: Synthesis, progress, and applications. Eur. Polym. J. 2020, 132, 109726. [Google Scholar]

- Bumbac, M.; Zaharescu, T.; Nicolescu, C.M. Thermal and radiation stability of alkyd based coatings used as insulators in the electrical rotating machines. J. Sci. Arts 2017, 1, 119–130. [Google Scholar]

- Chang, H.C.; Sun, T.; Sultana, N.; Lim, M.M.; Khan, T.H.; Ismail, A.F. Conductive PEDOT: PSS coated polylactide (PLA) and poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) electrospun membranes: Fabrication and characterization. Mater. Sci. Eng. C 2016, 61, 396–410. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, X.; Luo, S.; Li, S. Preparation and property analysis of melamine formaldehyde foam. Adv. Mater. Phys. Chem. 2012, 2, 63–67. [Google Scholar] [CrossRef]

- Petkevičiūtė, J.; Sankauskaitė, A.; Jasulaitienė, V.; Varnaitė-Žuravliova, S.; Abraitienė, A. Impact of Low-Pressure Plasma Treatment of Wool Fabric for Dyeing with PEDOT: PSS. Materials 2022, 15, 4797. [Google Scholar] [CrossRef] [PubMed]

- Kan, C.W.; Chan, K.; Yuen, C.W.M. Surface characterization of low temperature plasma treated wool fiber-the effect of the nature of gas. Fibers Polym. 2004, 5, 52–58. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).