Synergistic Mechanisms Underlie the Peroxide and Coagent Improvement of Natural-Rubber-Toughened Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Mechanical Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Blend Preparation

2.2.2. Gel Fraction Measurement

2.2.3. Rheological Characterization

2.2.4. Scanning Electron Microscopy (SEM)

2.2.5. Mechanical Characterization

2.2.6. Thermogravimetric Analysis (TGA)

2.2.7. Differential Scanning Calorimetry (DSC)

2.2.8. X-ray Diffraction (XRD)

2.2.9. Fourier Transform Infrared Spectroscopy (FTIR)

2.2.10. Proton Nuclear Magnetic Resonance (1H NMR) Spectroscopy

3. Results and Discussion

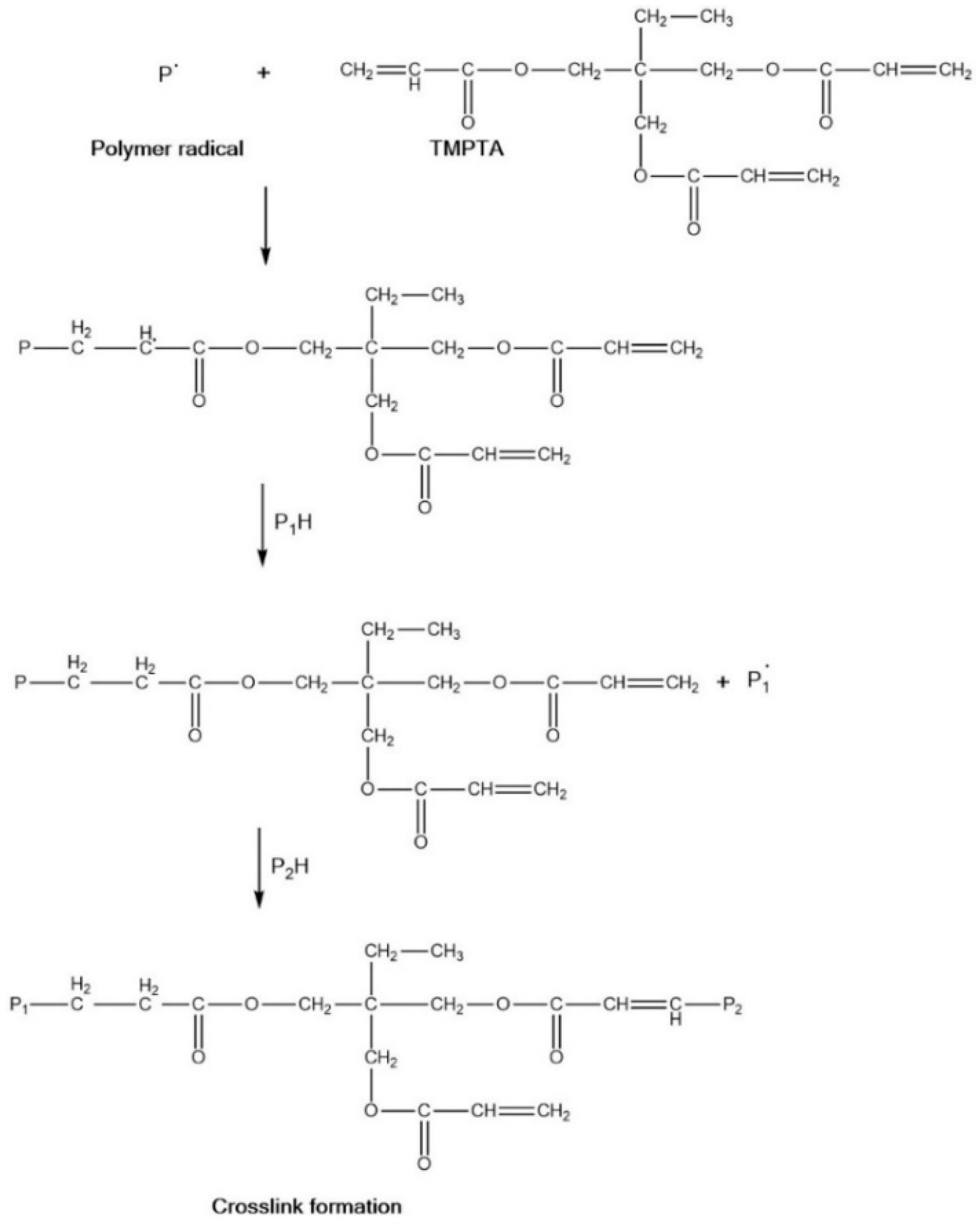

3.1. Crosslink Formation during Reactive Blending

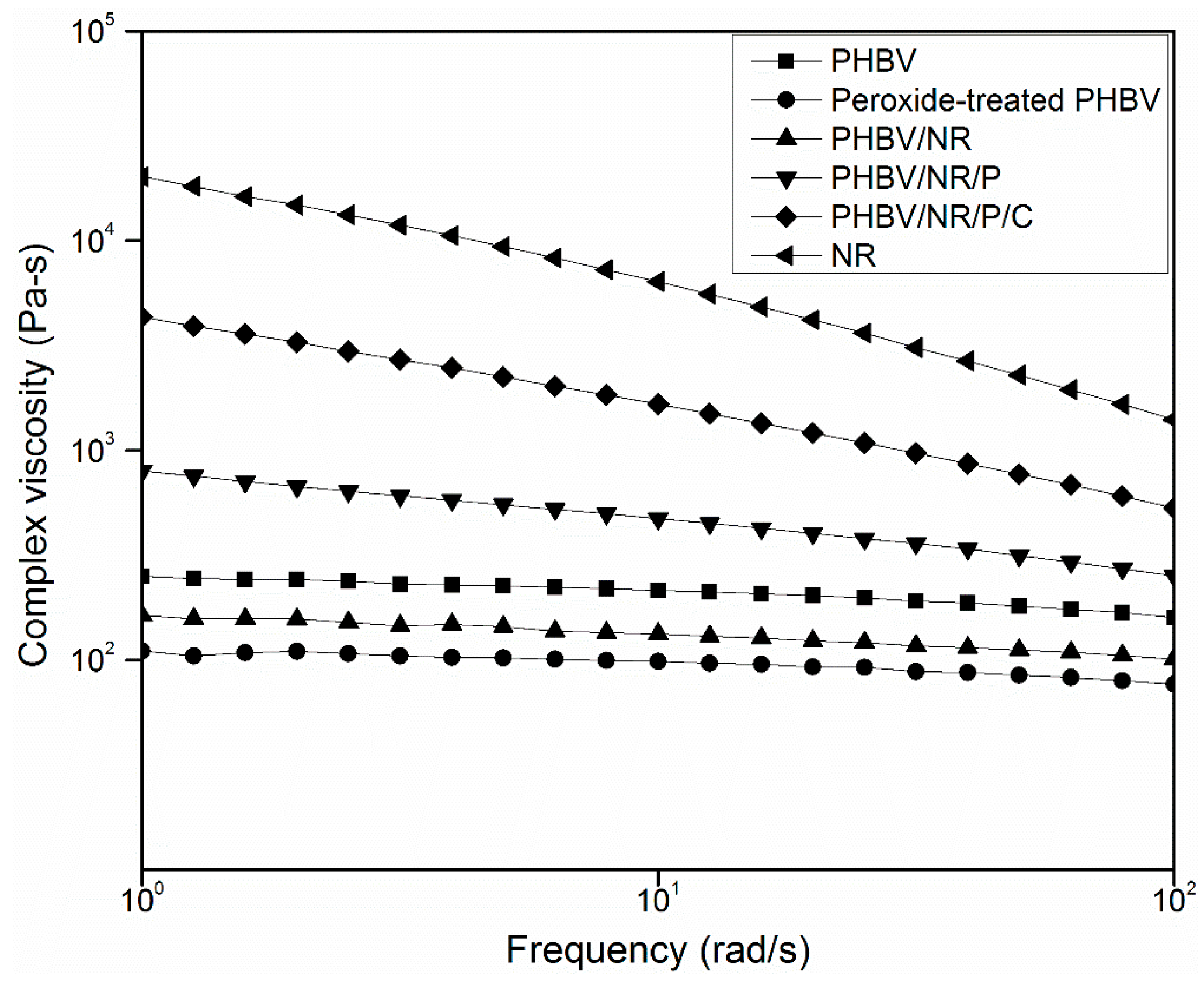

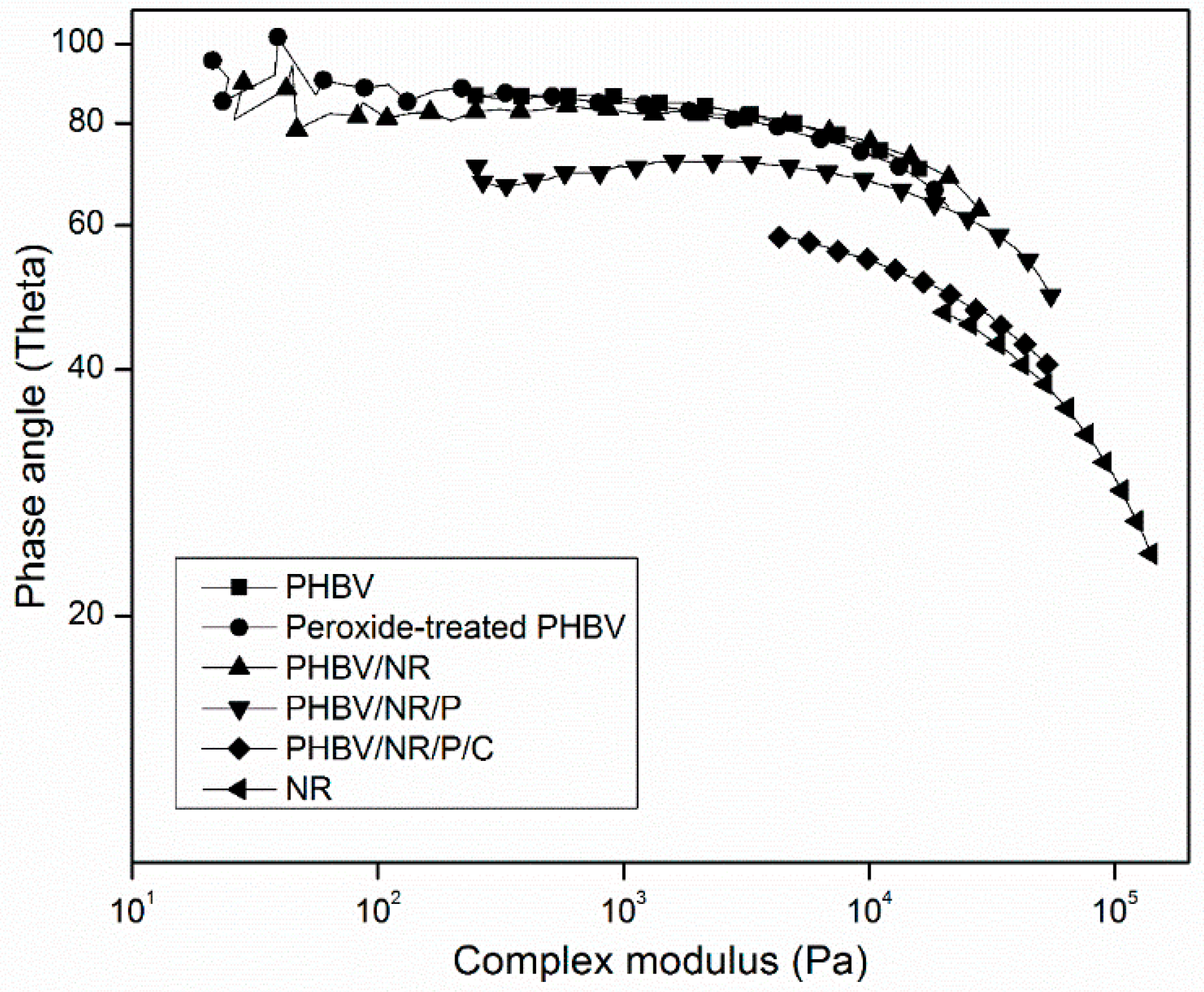

3.2. Rheological Properties

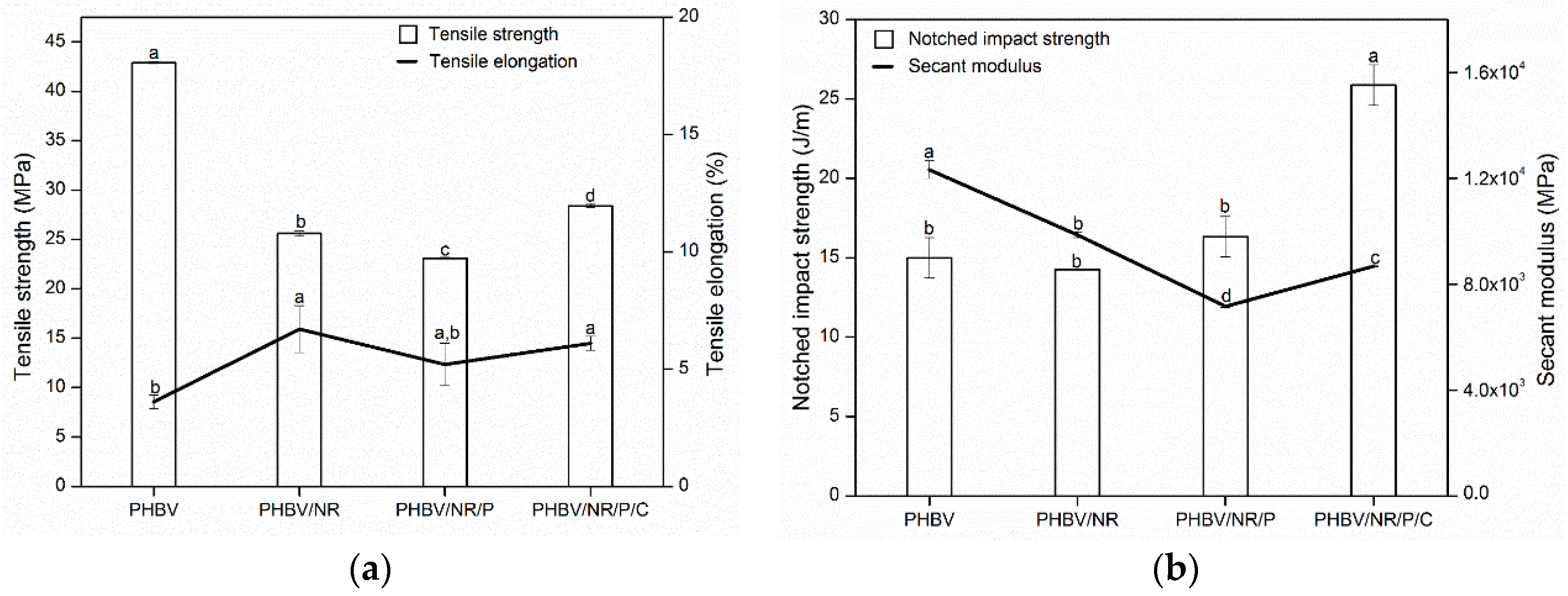

3.3. Mechanical Properties

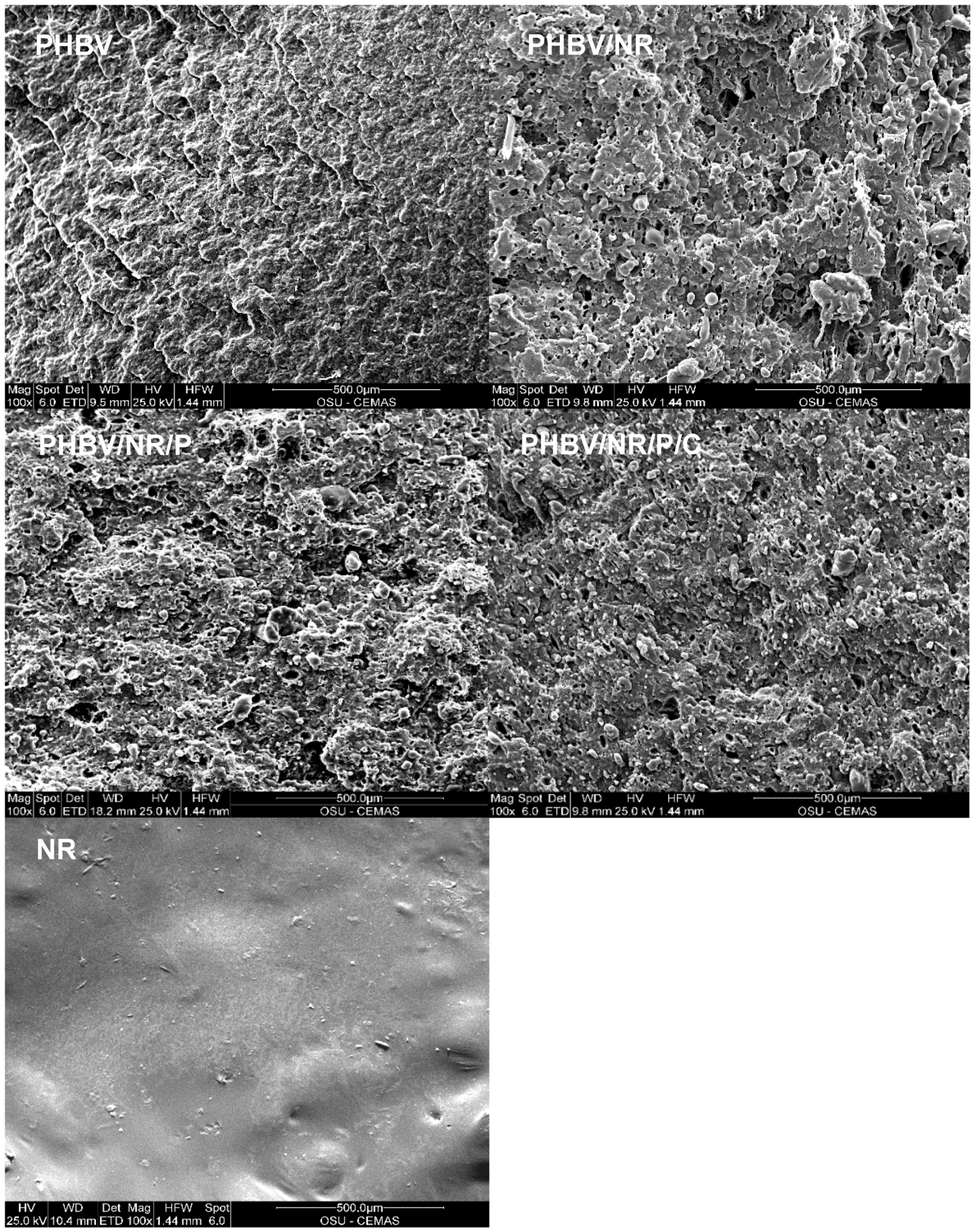

3.4. Morphology

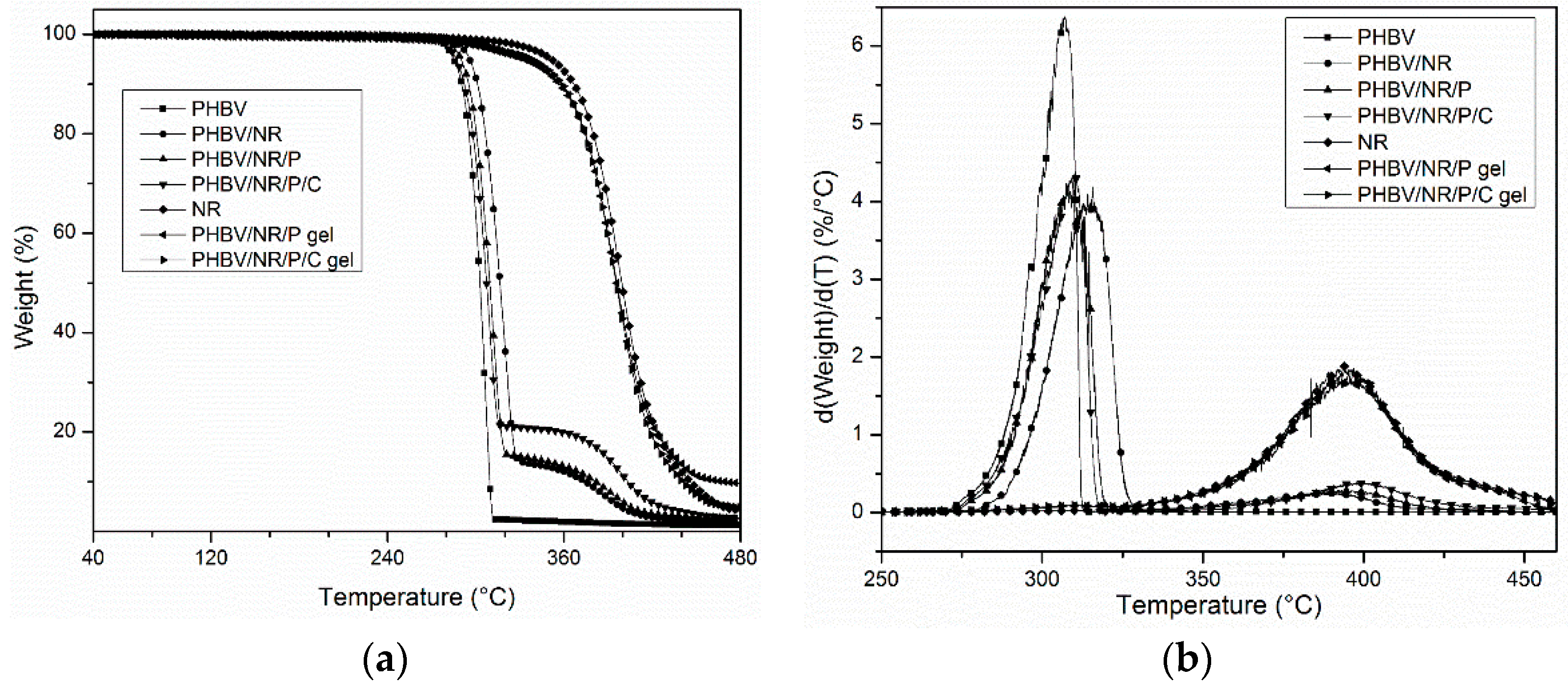

3.5. Thermal Properties

3.6. Crystallization Properties

3.6.1. DSC

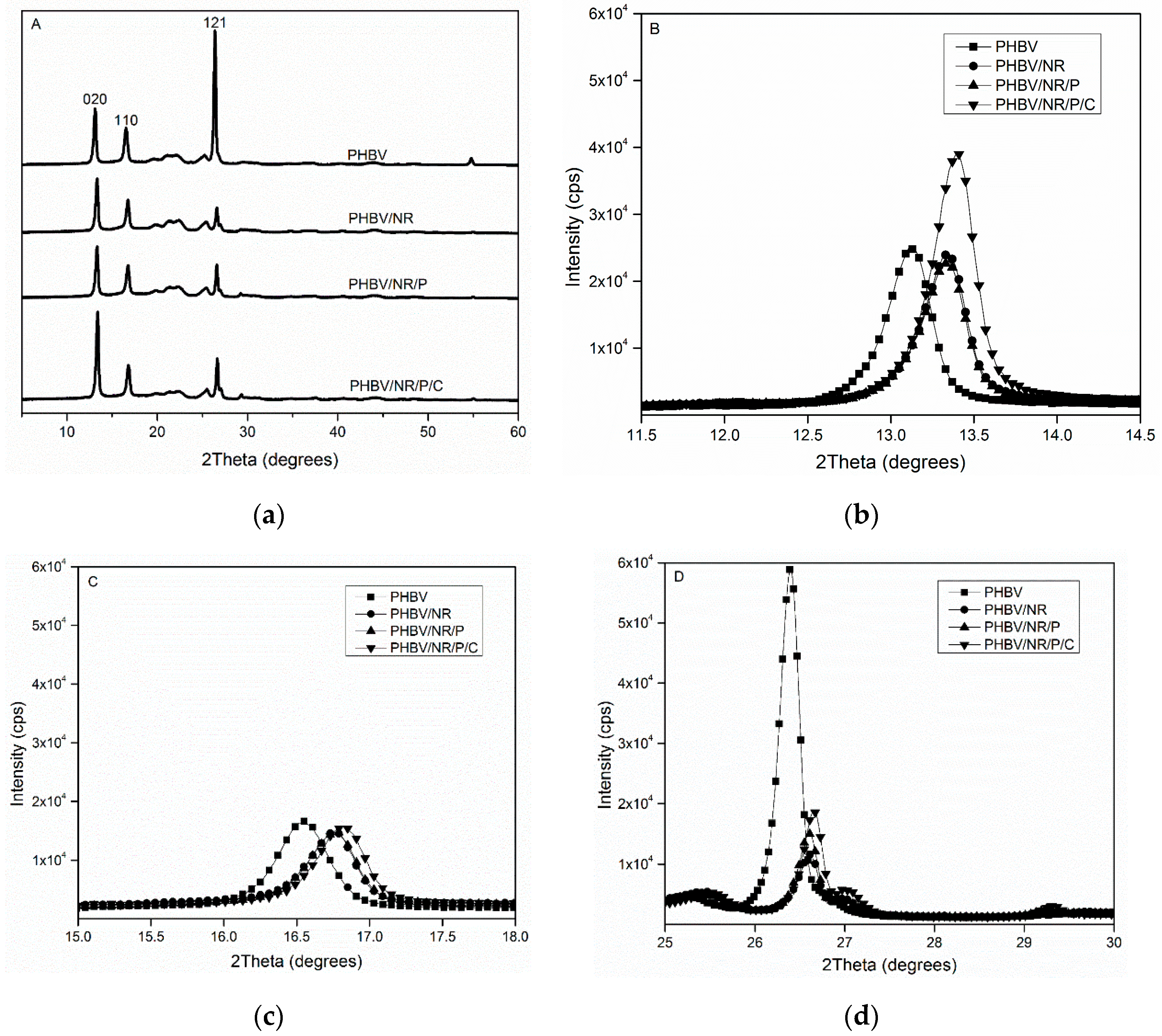

3.6.2. XRD

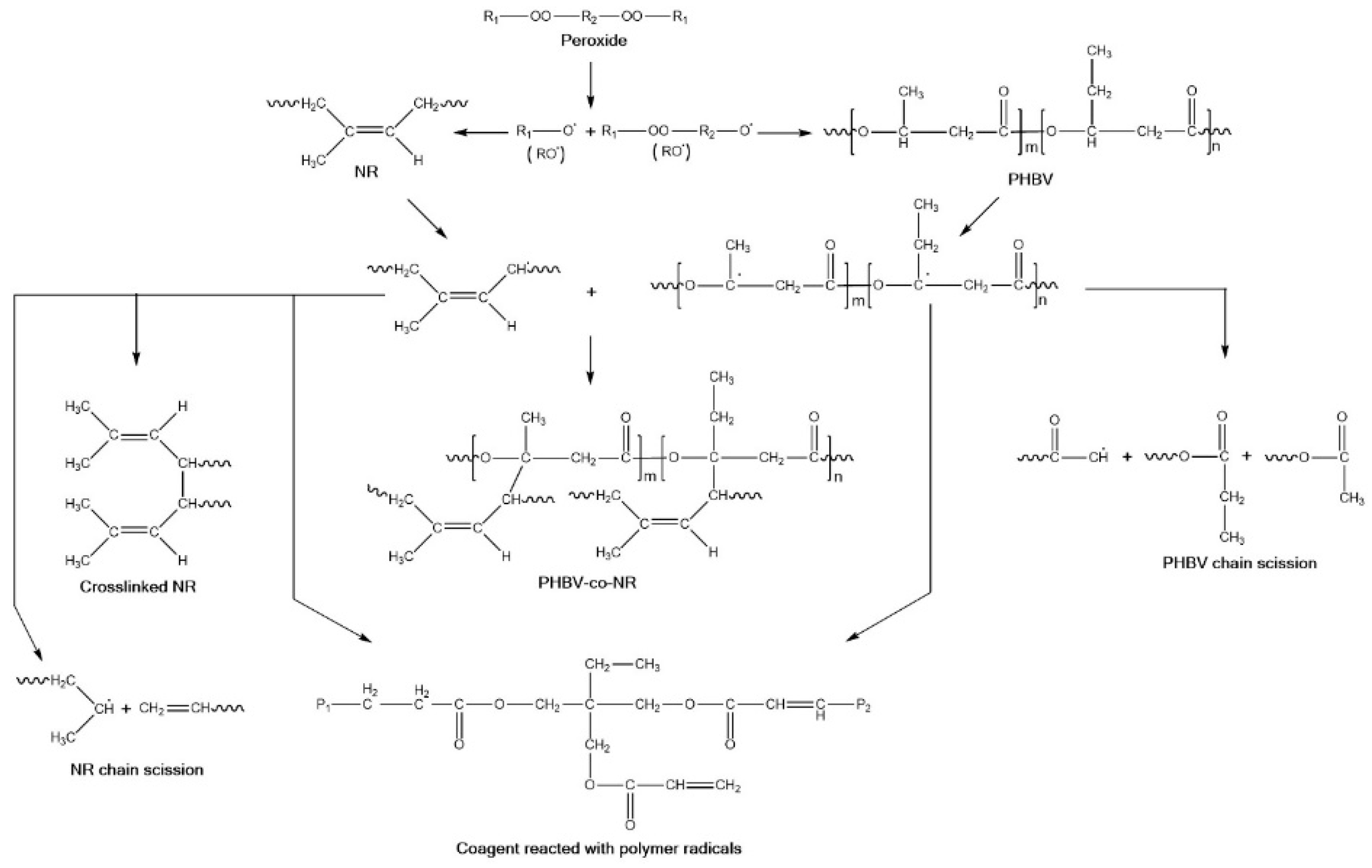

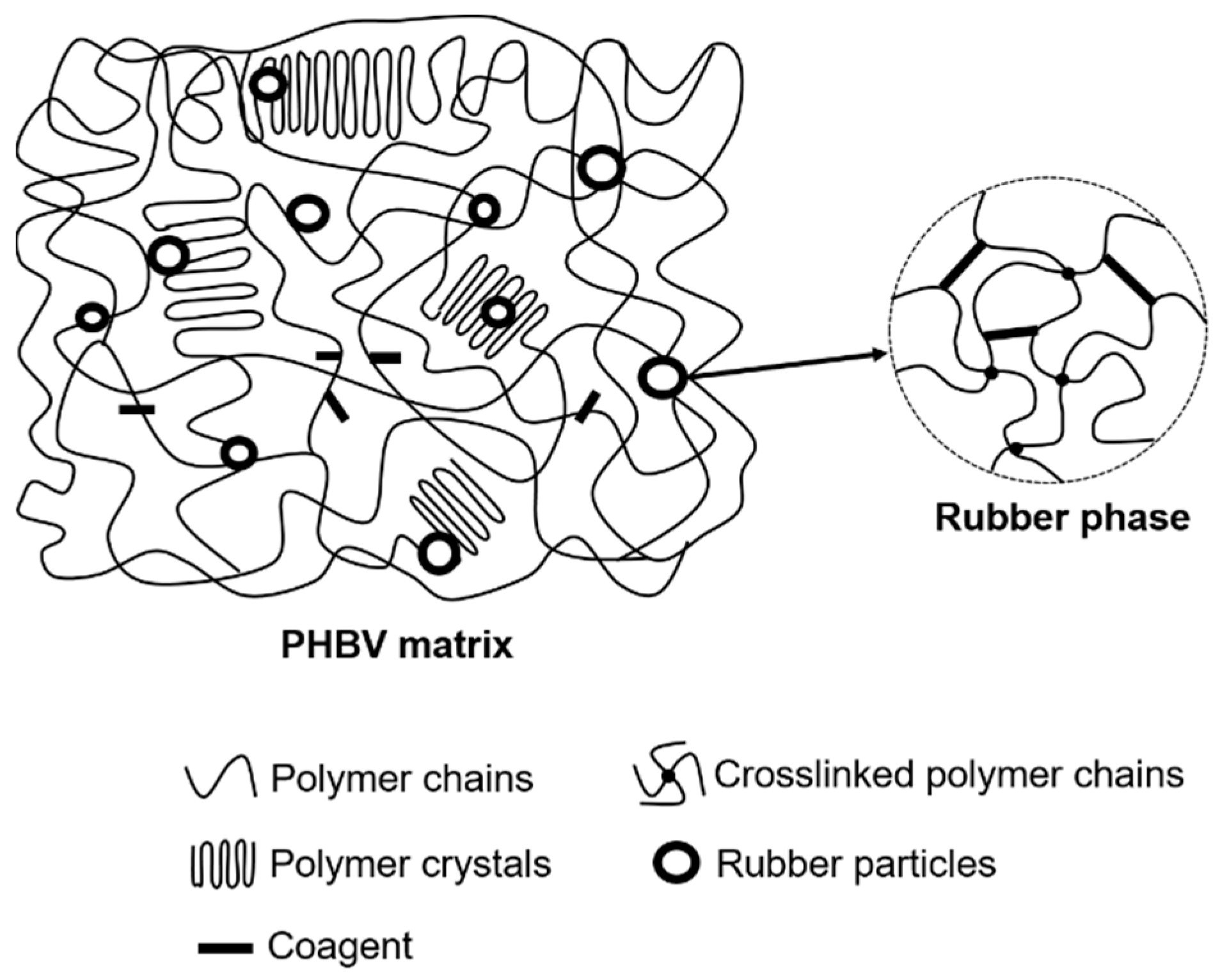

3.7. Reaction Mechanism

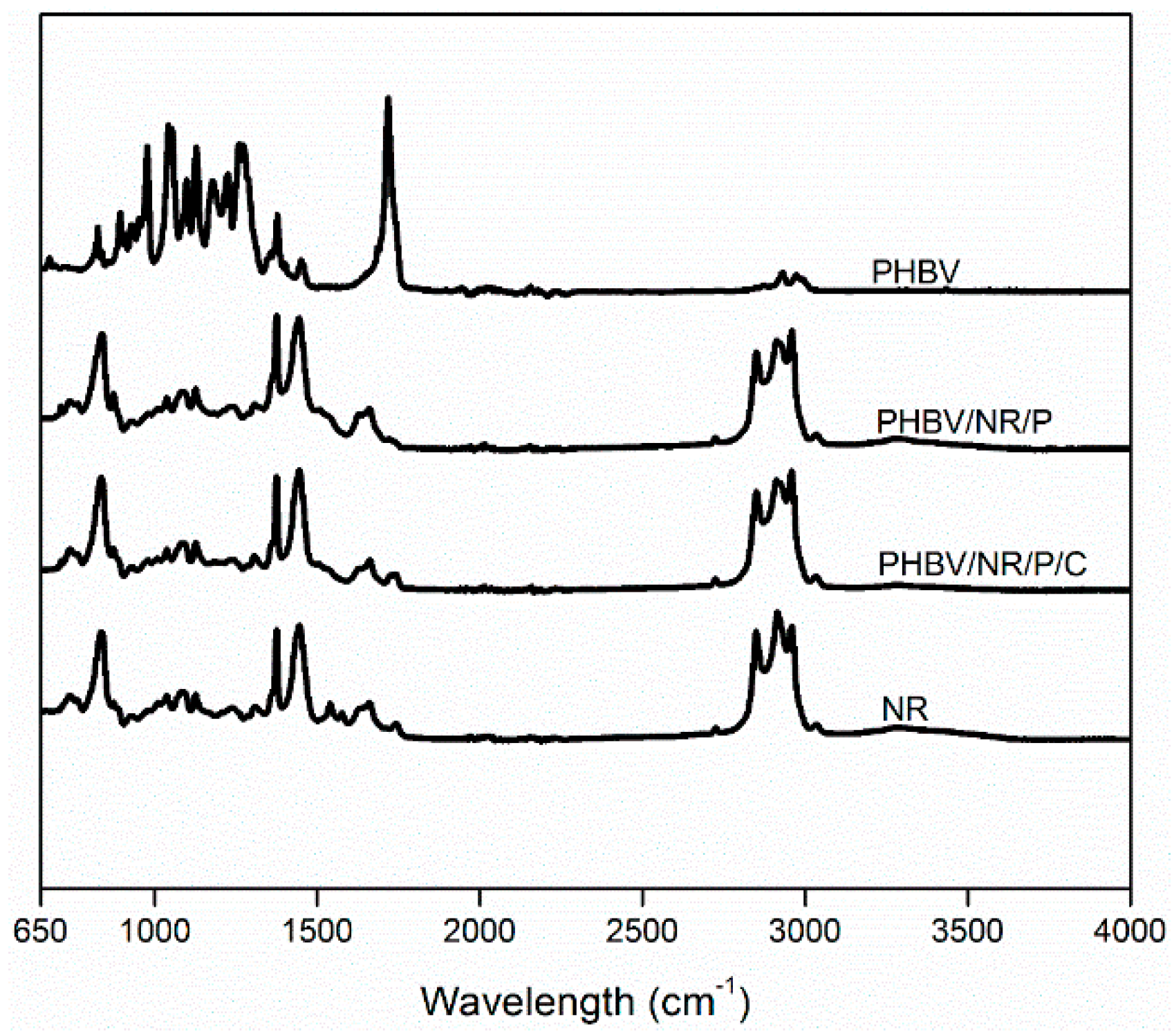

3.7.1. FTIR

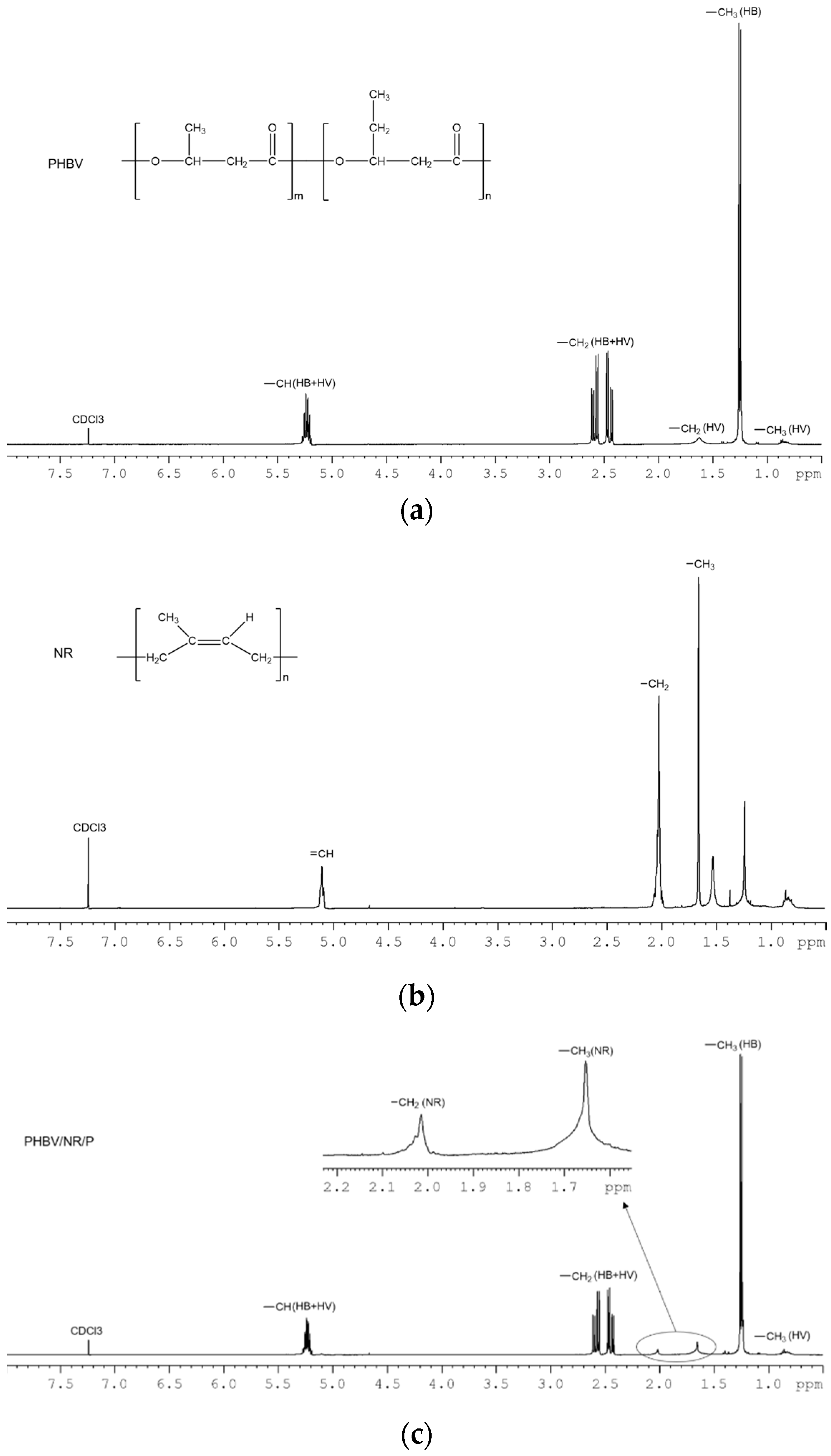

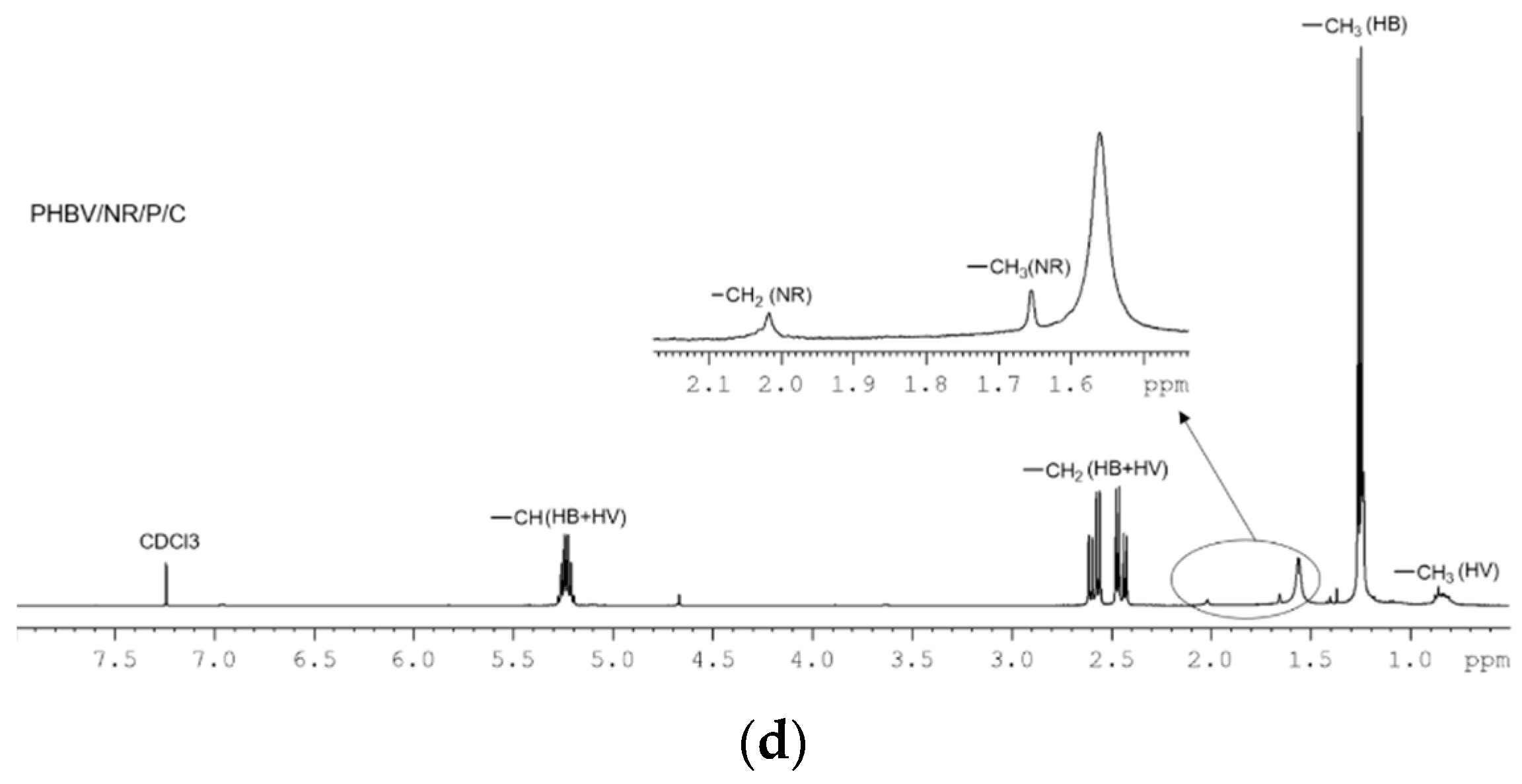

3.7.2. NMR

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alavi, S.; Thomas, S.; Sandeep, K.; Kalarikkal, N.; Varghese, J.; Yaragalla, S. Polymers for Packaging Applications; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Jendrossek, D.; Schirmer, A.; Schlegel, H. Biodegradation of polyhydroxyalkanoic acids. Appl. Microbiol. Biotechnol. 1996, 46, 451–463. [Google Scholar] [CrossRef]

- Zinn, M.; Witholt, B.; Egli, T. Occurrence, synthesis and medical application of bacterial polyhydroxyalkanoate. Adv. Drug Deliv. Rev. 2001, 53, 5–21. [Google Scholar] [CrossRef]

- Poli, A.; Di Donato, P.; Abbamondi, G.R.; Nicolaus, B. Synthesis, production, and biotechnological applications of exopolysaccharides and polyhydroxyalkanoates by archaea. Archaea 2011, 2011, 693253. [Google Scholar] [CrossRef] [PubMed]

- Biron, M. Industrial Applications of Renewable Plastics: Environmental, Technological, and Economic Advances; William Andrew: New York, NY, USA, 2016. [Google Scholar]

- Roy, I.; Visakh, P. Polyhydroxyalkanoate (PHA) Based Blends, Composites and Nanocomposites; Royal Society of Chemistry: New York, NY, USA, 2014; Volume 30. [Google Scholar]

- Yu, H.; Yan, C.; Yao, J. Fully biodegradable food packaging materials based on functionalized cellulose nanocrystals/poly (3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites. RSC Adv. 2014, 4, 59792–59802. [Google Scholar] [CrossRef]

- Modi, S.; Koelling, K.; Vodovotz, Y. Assessment of PHB with varying hydroxyvalerate content for potential packaging applications. Eur. Polym. J. 2011, 47, 179–186. [Google Scholar] [CrossRef]

- Wang, S.; Song, C.; Chen, G.; Guo, T.; Liu, J.; Zhang, B.; Takeuchi, S. Characteristics and biodegradation properties of poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/organophilic montmorillonite (PHBV/OMMT) nanocomposite. Polym. Degrad. Stab. 2005, 87, 69–76. [Google Scholar] [CrossRef]

- Pilla, S. Handbook of Bioplastics and Biocomposites Engineering Applications; John Wiley & Sons: New York, NY, USA, 2011; Volume 81. [Google Scholar]

- Li, J.; Lai, M.; Liu, J. Effect of poly (propylene carbonate) on the crystallization and melting behavior of poly (β-hydroxybutyrate-co-β-hydroxyvalerate). J. Appl. Polym. Sci. 2004, 92, 2514–2521. [Google Scholar] [CrossRef]

- Choi, J.S.; Park, W.H. Effect of biodegradable plasticizers on thermal and mechanical properties of poly (3-hydroxybutyrate). Polym. Test. 2004, 23, 455–460. [Google Scholar] [CrossRef]

- Qian, J.; Zhu, L.; Zhang, J.; Whitehouse, R.S. Comparison of different nucleating agents on crystallization of poly (3-hydroxybutyrate-co-3-hydroxyvalerates). J. Polym. Sci. Part B Polym. Phys. 2007, 45, 1564–1577. [Google Scholar] [CrossRef]

- Yu, H.-y.; Qin, Z.-y.; Zhe, Z. Cellulose nanocrystals as green fillers to improve crystallization and hydrophilic property of poly (3-hydroxybutyrate-co-3-hydroxyvalerate). Prog. Nat. Sci. Mater. Int. 2011, 21, 478–484. [Google Scholar] [CrossRef]

- Avella, M.; Martuscelli, E.; Raimo, M. Review Properties of blends and composites based on poly (3-hydroxy) butyrate (PHB) and poly (3-hydroxybutyrate-hydroxyvalerate)(PHBV) copolymers. J. Mater. Sci. 2000, 35, 523–545. [Google Scholar] [CrossRef]

- Baillie, C.; Jayasinghe, R. Green composites: Towards a sustainable future? In Green Composites, 2nd ed.; Elsevier: New York, NY, USA, 2017; pp. 1–5. [Google Scholar]

- Walker, I.; Collyer, A. Rubber toughening mechanisms in polymeric materials. In Rubber Toughened Engineering Plastics; Springer: New York, NY, USA, 1994; pp. 29–56. [Google Scholar]

- Liang, J.; Li, R. Rubber toughening in polypropylene: A review. J. Appl. Polym. Sci. 2000, 77, 409–417. [Google Scholar] [CrossRef]

- Bucknall, C.; Karpodinis, A.; Zhang, X. A model for particle cavitation in rubber-toughened plastics. J. Mater. Sci. 1994, 29, 3377–3383. [Google Scholar] [CrossRef]

- Muratoglu, O.; Argon, A.; Cohen, R.; Weinberg, M. Toughening mechanism of rubber-modified polyamides. Polymer 1995, 36, 921–930. [Google Scholar] [CrossRef]

- Van Dommelen, J.; Brekelmans, W.; Baaijens, F. Micromechanical modeling of particle-toughening of polymers by locally induced anisotropy. Mech. Mater. 2003, 35, 845–863. [Google Scholar] [CrossRef]

- Bartczak, Z.; Argon, A.S.; Cohen, R.E.; Weinberg, M. Toughness mechanism in semi-crystalline polymer blends: II. High-density polyethylene toughened with calcium carbonate filler particles. Polymer 1999, 40, 2347–2365. [Google Scholar] [CrossRef]

- Zhang, B.; Bian, X.; Xiang, S.; Li, G.; Chen, X. Synthesis of PLLA-based block copolymers for improving melt strength and toughness of PLLA by in situ reactive blending. Polym. Degrad. Stab. 2017, 136, 58–70. [Google Scholar] [CrossRef]

- Zhang, N.; Lu, X. Morphology and properties of super-toughened bio-based poly (lactic acid)/poly (ethylene-co-vinyl acetate) blends by peroxide-induced dynamic vulcanization and interfacial compatibilization. Polym. Test. 2016, 56, 354–363. [Google Scholar] [CrossRef]

- Zeng, J.-B.; Li, K.-A.; Du, A.-K. Compatibilization strategies in poly (lactic acid)-based blends. RSC Adv. 2015, 5, 32546–32565. [Google Scholar] [CrossRef]

- Shonaike, G.O.; Simon, G.P. Polymer Blends and Alloys; CRC Press: New York, NY, USA, 1999; Volume 52. [Google Scholar]

- Zhang, Z.; Zhao, X.; Wang, S.; Zhang, J.; Zhang, W. Inducing a network structure of rubber phase: An effective approach to toughen polymer without sacrificing stiffness. RSC Adv. 2014, 4, 60617–60625. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, D.; Xu, C. Dynamically vulcanized biobased polylactide/natural rubber blend material with continuous cross-linked rubber phase. ACS Appl. Mater. Interfaces 2014, 6, 3811–3816. [Google Scholar] [CrossRef] [PubMed]

- Babu, R.R.; Singha, N.K.; Naskar, K. Dynamically vulcanized blends of polypropylene and ethylene octene copolymer: Influence of various coagents on thermal and rheological characteristics. J. Appl. Polym. Sci. 2010, 117, 1578–1590. [Google Scholar] [CrossRef]

- Luo, S.; Cao, J.; McDonald, A.G. Interfacial improvements in a green biopolymer alloy of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and lignin via in situ reactive extrusion. ACS Sustain. Chem. Eng. 2016, 4, 3465–3476. [Google Scholar] [CrossRef]

- Ma, P.; Hristova-Bogaerds, D.G.; Lemstra, P.J.; Zhang, Y.; Wang, S. Toughening of PHBV/PBS and PHB/PBS Blends via In situ Compatibilization Using Dicumyl Peroxide as a Free-Radical Grafting Initiator. Macromol. Mater. Eng. 2012, 297, 402–410. [Google Scholar] [CrossRef]

- Henning, S.K.; Costin, R. Fundamentals of Curing Elastomers with Peroxides and Coagents I: Coagent Structure-Property Relationships. In Proceedings of the 167th Technical Meeting of the Rubber Division, San Antonio, TX, USA, 16–18 May 2005; American Chemical Society: Washington, DC, USA, 2005; pp. 16–18. [Google Scholar]

- Wan, C. Reactive Modification of Polyesters and Their Blends; ProQuest: Ann Arbor, MI, USA, 2004. [Google Scholar]

- Zhao, X. Toughen PHBV Bioplastics with Natural Rubber to Broaden Their Packaging Applications. Ph.D. Dissertation, The Ohio State University, Columbus, OH, USA, 2018. [Google Scholar]

- Zhao, X.; Venoor, V.; Koelling, K.; Cornish, K.; Vodovotz, Y. Bio-based blends from poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and natural rubber for packaging applications. J. Appl. Polym. Sci. 2018, 47334. [Google Scholar] [CrossRef]

- Do, I.; Yoon, L.; Kim, B.; Jeong, H. Effect of viscosity ratio and peroxide/coagent treatment in PP/EPR/PE ternary blends. Eur. Polym. J. 1996, 32, 1387–1393. [Google Scholar] [CrossRef]

- Babu, R.R.; Singha, N.K.; Naskar, K. Dynamically vulcanized blends of polypropylene and ethylene octene copolymer: Influence of various coagents on mechanical and morphological characteristics. J. Appl. Polym. Sci. 2009, 113, 3207–3221. [Google Scholar] [CrossRef]

- Modi, S.J.; Cornish, K.; Koelling, K.; Vodovotz, Y. Fabrication and improved performance of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) for packaging by addition of high molecular weight natural rubber. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Modi, S.; Koelling, K.; Vodovotz, Y. Assessing the mechanical, phase inversion, and rheological properties of poly-[(R)-3-hydroxybutyrate-co-(R)-3-hydroxyvalerate](PHBV) blended with poly-(l-lactic acid)(PLA). Eur. Polym. J. 2013, 49, 3681–3690. [Google Scholar] [CrossRef]

- Modi, S.; Koelling, K.; Vodovotz, Y. Miscibility of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) with high molecular weight poly (lactic acid) blends determined by thermal analysis. J. Appl. Polym. Sci. 2012, 124, 3074–3081. [Google Scholar] [CrossRef]

- Kuntanoo, K.; Promkotra, S.; Kaewkannetra, P. Biodegradation of polyhydroxybutyrate-co-hydroxyvalerate (PHBV) blended with natural rubber in soil environment. Int. Sci. Index. 2013, 7, 12. [Google Scholar]

- McNally, T.; McShane, P.; Nally, G.; Murphy, W.; Cook, M.; Miller, A. Rheology, phase morphology, mechanical, impact and thermal properties of polypropylene/metallocene catalysed ethylene 1-octene copolymer blends. Polymer 2002, 43, 3785–3793. [Google Scholar] [CrossRef]

- Yin, B.; Zhao, Y.; Yang, W.; Pan, M.-m.; Yang, M.-b. Polycarbonate/liquid crystalline polymer blend: Crystallization of polycarbonate. Polymer 2006, 47, 8237–8240. [Google Scholar] [CrossRef]

- Buonerba, A.; Cuomo, C.; Speranza, V.; Grassi, A. Crystalline syndiotactic polystyrene as reinforcing agent of cis-1, 4-polybutadiene rubber. Macromolecules 2009, 43, 367–374. [Google Scholar] [CrossRef]

- Carli, L.N.; Daitx, T.S.; Soares, G.V.; Crespo, J.S.; Mauler, R.S. The effects of silane coupling agents on the properties of PHBV/halloysite nanocomposites. Appl. Clay Sci. 2014, 87, 311–319. [Google Scholar] [CrossRef]

- Yei, D.-R.; Kuo, S.-W.; Su, Y.-C.; Chang, F.-C. Enhanced thermal properties of PS nanocomposites formed from inorganic POSS-treated montmorillonite. Polymer 2004, 45, 2633–2640. [Google Scholar] [CrossRef]

- Thayer, T.A.; Bagby, M.D.; Moore, R.N.; DeAngelis, R.J. X-ray diffraction of nitinol orthodontic arch wires. Am. J. Orthod. Dentofac. Orthop. 1995, 107, 604–612. [Google Scholar] [CrossRef]

- Uvarov, V.; Popov, I. Metrological characterization of X-ray diffraction methods at different acquisition geometries for determination of crystallite size in nano-scale materials. Mater. Charact. 2013, 85, 111–123. [Google Scholar] [CrossRef]

- Li, S.D.; Yu, H.P.; Peng, Z.; Zhu, C.S.; Li, P.S. Study on thermal degradation of sol and gel of natural rubber. J. Appl. Polym. Sci. 2000, 75, 1339–1344. [Google Scholar] [CrossRef]

- Moad, G. The synthesis of polyolefin graft copolymers by reactive extrusion. Prog. Polym. Sci. 1999, 24, 81–142. [Google Scholar] [CrossRef]

- Immirzi, B.; Malinconico, M.; Orsello, G.; Portofino, S.; Volpe, M. Blends of biodegradable polyesters by reactive blending: Preparation, characterisation and properties. J. Mater. Sci. 1999, 34, 1625–1639. [Google Scholar] [CrossRef]

- Thitithammawong, A.; Nakason, C.; Sahakaro, K.; Noordermeer, J. Effect of different types of peroxides on rheological, mechanical, and morphological properties of thermoplastic vulcanizates based on natural rubber/polypropylene blends. Polym. Test. 2007, 26, 537–546. [Google Scholar] [CrossRef]

- Bhowmick, A.K.; Stephens, H. Handbook of Elastomers; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Utara, S.; Boochathum, P. Novel dynamic vulcanization of polyethylene and ozonolysed natural rubber blends: Effect of curing system and blending ratio. J. Appl. Polym. Sci. 2011, 120, 2606–2614. [Google Scholar] [CrossRef]

- Yan, D.; Wang, W.-J.; Zhu, S. Effect of long chain branching on rheological properties of metallocene polyethylene. Polymer 1999, 40, 1737–1744. [Google Scholar] [CrossRef]

- Dluzneski, P.R. Peroxide vulcanization of elastomers. Rubber Chem. Technol. 2001, 74, 451–492. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G. Accelerated weathering studies on the bioplastic, poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym. Degrad. Stab. 2016, 126, 93–100. [Google Scholar] [CrossRef]

- D’Haene, P.; Remsen, E.E.; Asrar, J. Preparation and characterization of a branched bacterial polyester. Macromolecules 1999, 32, 5229–5235. [Google Scholar] [CrossRef]

- Liu, Q.-S.; Zhu, M.-F.; Wu, W.-H.; Qin, Z.-Y. Reducing the formation of six-membered ring ester during thermal degradation of biodegradable PHBV to enhance its thermal stability. Polym. Degrad. Stab. 2009, 94, 18–24. [Google Scholar] [CrossRef]

- Nanda, M.R.; Misra, M.; Mohanty, A.K. The Effects of Process Engineering on the Performance of PLA and PHBV Blends. Macromol. Mater. Eng. 2011, 296, 719–728. [Google Scholar] [CrossRef]

- Du, M.; Guo, B.; Jia, D. Thermal stability and flame retardant effects of halloysite nanotubes on poly(propylene). Eur. Polym. J. 2006, 42, 1362–1369. [Google Scholar] [CrossRef]

- Kim, B.; Do, I. Effect of viscosity ratio, rubber composition, and peroxide/coagent treatment in PP/EPR blends. J. Appl. Polym. Sci. 1996, 61, 439–447. [Google Scholar] [CrossRef]

- Pötschke, P.; Abdel-Goad, M.; Alig, I.; Dudkin, S.; Lellinger, D. Rheological and dielectrical characterization of melt mixed polycarbonate-multiwalled carbon nanotube composites. Polymer 2004, 45, 8863–8870. [Google Scholar] [CrossRef]

- Yeganeh, J.K.; Goharpey, F.; Foudazi, R. Can only rheology be used to determine the phase separation mechanism in dynamically asymmetric polymer blends (PS/PVME)? RSC Adv. 2012, 2, 8116–8127. [Google Scholar] [CrossRef]

- Dawidziuk, K. Peroxide-Initiated Modification of Polylactic Acid (PLA) and Poly (3-Hydroxyalkanoates)(PHAs) in the Presence of Allylic and Acrylic Coagents. Master Thesis, Queen’s University, Kingston, ON, Canada, 2018. [Google Scholar]

- Khan, I.; Poh, B. Natural rubber-based pressure-sensitive adhesives: A review. J. Polym. Environ. 2011, 19, 793. [Google Scholar] [CrossRef]

- Kasatochkin, V.; Lukin, B. The Molecular Structure and Properties of Rubber. Rubber Chem. Technol. 1952, 25, 12–14. [Google Scholar] [CrossRef]

- Fakhru’l-Razi, A.; Atieh, M.A.; Girun, N.; Chuah, T.G.; El-Sadig, M.; Biak, D.R.A. Effect of multi-wall carbon nanotubes on the mechanical properties of natural rubber. Compos. Struct. 2006, 75, 496–500. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Cassagnau, P.; Lopez-Manchado, M.A. Structure and properties of polylactide/natural rubber blends. Mater. Chem. Phys. 2011, 129, 823–831. [Google Scholar] [CrossRef]

- Yoon, L.K.; Choi, C.H.; Kim, B.K. Reactive extrusion of PP/natural rubber blends. J. Appl. Polym. Sci. 1995, 56, 239–246. [Google Scholar] [CrossRef]

- Akbari, A.; Jawaid, M.; Hassan, A.; Balakrishnan, H. Epoxidized natural rubber toughened polylactic acid/talc composites: Mechanical, thermal, and morphological properties. J. Compos. Mater. 2014, 48, 769–781. [Google Scholar] [CrossRef]

- Wang, X.-H.; Zhang, H.-X.; Wang, Z.-G.; Jiang, B.-Z. Toughening of poly (butylene terephthalate) with epoxidized ethylene propylene diene rubber. Polymer 1997, 38, 1569–1572. [Google Scholar] [CrossRef]

- Yuan, D.; Xu, C.; Chen, Z.; Chen, Y. Crosslinked bicontinuous biobased polylactide/natural rubber materials: Super toughness, “net-like”-structure of NR phase and excellent interfacial adhesion. Polym. Test. 2014, 38, 73–80. [Google Scholar] [CrossRef]

- Haneefa, A.; Bindu, P.; Aravind, I.; Thomas, S. Studies on tensile and flexural properties of short banana/glass hybrid fiber reinforced polystyrene composites. J. Compos. Mater. 2008, 42, 1471–1489. [Google Scholar] [CrossRef]

- Sun, Y.-J.; Willemse, R.J.; Liu, T.; Baker, W.E. In situ compatibilization of polyolefin and polystyrene using Friedel—Crafts alkylation through reactive extrusion. Polymer 1998, 39, 2201–2208. [Google Scholar] [CrossRef]

- Crompton, T.R. Physical Testing of Plastics; Smithers Rapra: Shrewsbury, UK, 2012. [Google Scholar]

- Prospector, U.L. Polystyrene (PS) Typical Properties Generic PS (GPPS). Available online: https://plastics.ulprospector.com/generics/43/c/t/polystyrene-ps-properties-processing/sp/2 (accessed on 22 March 2019).

- Database, P.P. General Purpose Polystyrene (GPPS). Available online: http://polymerdatabase.com/Commercial%20Polymers/PS.html (accessed on 22 March 2019).

- Liu, G.-C.; He, Y.-S.; Zeng, J.-B.; Xu, Y.; Wang, Y.-Z. In situ formed crosslinked polyurethane toughened polylactide. Polym. Chem. 2014, 5, 2530–2539. [Google Scholar] [CrossRef]

- Santos, R.J.d.; Agostini, D.L.d.S.; Cabrera, F.C.; Reis, E.A.P.d.; Ruiz, M.R.; Budemberg, E.R.; Teixeira, S.R.; Job, A.E. Sugarcane bagasse ash: New filler to natural rubber composite. Polímeros 2014, 24, 646–653. [Google Scholar] [CrossRef]

- Chuan, L.S.; Siang, L.G. Cure and Physical Characterizations of Natural Rubber Blended with Recycled Latex-Foam-Waste. Am. J. Eng. Res. (AJER) 2017, 6, 141–148. [Google Scholar]

- Joseph, R.; George, K.; Francis, D.J. Scanning electron microscopy examination of the fracture surface of NR/SBR and NR/BR blends. Int. J. Polym. Mater. 1988, 12, 111–123. [Google Scholar] [CrossRef]

- Wu, S. Control of intrinsic brittleness and toughness of polymers and blends by chemical structure: A review. Polym. Int. 1992, 29, 229–247. [Google Scholar] [CrossRef]

- Deblieck, R.A.; Van Beek, D.; Remerie, K.; Ward, I.M. Failure mechanisms in polyolefines: The role of crazing, shear yielding and the entanglement network. Polymer 2011, 52, 2979–2990. [Google Scholar] [CrossRef]

- Wu, S. A generalized criterion for rubber toughening: The critical matrix ligament thickness. J. Appl. Polym. Sci. 1988, 35, 549–561. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, K.; Xu, C.; Chen, Y. Supertoughened biobased poly (lactic acid)–epoxidized natural rubber thermoplastic vulcanizates: Fabrication, co-continuous phase structure, interfacial in situ compatibilization, and toughening mechanism. J. Phys. Chem. B 2015, 119, 12138–12146. [Google Scholar] [CrossRef] [PubMed]

- D’orazio, L.; Greco, R.; Mancarella, C.; Martuscelli, E.; Ragosta, G.; Silvesrte, C. Effect of the addition of ethylene-propylene random copolymers on the properties of high-density polyethylene/isotactic polypropylene blends: Part 1—Morphology and impact behavior of molded samples. Polym. Eng. Sci. 1982, 22, 536–544. [Google Scholar] [CrossRef]

- He, J.D.; Cheung, M.K.; Yu, P.H.; Chen, G.Q. Thermal analyses of poly (3-hydroxybutyrate), poly (3-hydroxybutyrate-co-3-hydroxyvalerate), and poly (3-hydroxybutyrate-co-3-hydroxyhexanoate). J. Appl. Polym. Sci. 2001, 82, 90–98. [Google Scholar] [CrossRef]

- George, S.; Varughese, K.T.; Thomas, S. Thermal and crystallisation behaviour of isotactic polypropylene/nitrile rubber blends. Polymer 2000, 41, 5485–5503. [Google Scholar] [CrossRef]

- Halimatuddahliana; Ismail, H. The effect of dynamic vulcanization on the properties of polypropylene/ethylene-propylene diene terpolymer/natural rubber (PP/EPDM/NR) ternary blend. Polym.-Plast. Technol. Eng. 2008, 48, 34–41. [Google Scholar] [CrossRef]

- Bartczak, Z.; Argon, A.S.; Cohen, R.E.; Weinberg, M. Toughness mechanism in semi-crystalline polymer blends: I. High-density polyethylene toughened with rubbers. Polymer 1999, 40, 2331–2346. [Google Scholar] [CrossRef]

- Noda, I.; Satkowski, M.M.; Dowrey, A.E.; Marcott, C. Polymer alloys of Nodax copolymers and poly (lactic acid). Macromol. Biosci. 2004, 4, 269–275. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S. Microstructural characterisation of geopolymers synthesised from kaolinite/stilbite mixtures using XRD, MAS-NMR, SEM/EDX, TEM/EDX, and HREM. Cem. Concr. Res. 2002, 32, 1705–1716. [Google Scholar] [CrossRef]

- Kunioka, M.; Tamaki, A.; Doi, Y. Crystalline and thermal properties of bacterial copolyesters: Poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and poly (3-hydroxybutyrate-co-4-hydroxybutyrate). Macromolecules 1989, 22, 694–697. [Google Scholar] [CrossRef]

- Bai, H.; Huang, C.; Xiu, H.; Zhang, Q.; Fu, Q. Enhancing mechanical performance of polylactide by tailoring crystal morphology and lamellae orientation with the aid of nucleating agent. Polymer 2014, 55, 6924–6934. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z. Impact behaviour of polypropylene filled with multi-walled carbon nanotubes. Eur. Polym. J. 2007, 43, 3197–3207. [Google Scholar] [CrossRef]

- Bai, H.; Wang, Y.; Song, B.; Han, L. Synergistic toughening effects of nucleating agent and ethylene–octene copolymer on polypropylene. J. Appl. Polym. Sci. 2008, 108, 3270–3280. [Google Scholar] [CrossRef]

- Hudson, S.; Smith, C.; Kaplan, D. Biopolymers from Renewable Resources; Springer Science and Business Media: New York, NY, USA, 1998; pp. 96–118. [Google Scholar]

- Chen, Y.; Chen, K.; Wang, Y.; Xu, C. Biobased heat-triggered shape-memory polymers based on polylactide/epoxidized natural rubber blend system fabricated via peroxide-induced dynamic vulcanization: Co-continuous phase structure, shape memory behavior, and interfacial compatibilization. Ind. Eng. Chem. Res. 2015, 54, 8723–8731. [Google Scholar] [CrossRef]

- Rolere, S.; Liengprayoon, S.; Vaysse, L.; Sainte-Beuve, J.; Bonfils, F. Investigating natural rubber composition with Fourier Transform Infrared (FT-IR) spectroscopy: A rapid and non-destructive method to determine both protein and lipid contents simultaneously. Polym. Test. 2015, 43, 83–93. [Google Scholar] [CrossRef]

- Bousfield, G. Effect of Chain Extension on Rheology and Tensile Properties of PHB and PHB-PLA Blends; École Polytechnique de Montréal: Montréal, QC, Canada, 2014. [Google Scholar]

- Dehkordi, M.H. Air Quality in the Museum Environment: Exemplary Investigations on Air Pollutants in Berlin, Tehran und Mumbai Museums; Hochschule für Bildende Künste: Dresden, Germany, 2015. [Google Scholar]

- Tanaka, Y. Structural characterization of natural polyisoprenes: Solve the mystery of natural rubber based on structural study. Rubber Chem. Technol. 2001, 74, 355–375. [Google Scholar] [CrossRef]

- Chutamas, M.; Sunthornvarabhas, J.; Sriroth, K.R. Evaluation of Gamma Radiation on NR/PHBV Blends. Appl. Mech. Mater. 2013, 300–301, 1325–1329. [Google Scholar] [CrossRef]

- Chutamas, M.; Sunthornvarabhas, J.; Hyun, J.K.; Klanarong, S. Improving Mechanical Properties of Poly-β-Hydroxybutyrate-co-β-Hydroxyvalerate by Blending with Natural Rubber and Epoxidized Natural Rubber. Adv. Mater. Res. 2014, 983, 179–182. [Google Scholar] [CrossRef]

| Heaters | Temperatures (°C) |

|---|---|

| 1 (Below hopper) | 180 |

| 2 | 175 |

| 3 | 175 |

| 4 | 170 |

| 5 | 170 |

| 6 | 160 |

| 7 | 160 |

| 8 | 155 |

| 9 | 150 |

| 10 (Die) | 145 |

| Sample | PHBV/NR (wt/wt) | Peroxide (wt %) | Coagent (wt %) |

|---|---|---|---|

| PHBV | 100:0 | 0 | 0 |

| PHBV/NR | 85:15 | 0 | 0 |

| PHBV/NR/P | 85:15 | 0.45 | 0 |

| PHBV/NR/P/C | 85:15 | 0.45 | 0.63 |

| Samples | Pristine PHBV | Pristine NR | Extruded NR * | PHBV/NR | PHBV/NR/P | PHBV/NR/P/C |

|---|---|---|---|---|---|---|

| Gel (wt %) | 0 | 1.56 ± 0.04 | 3.91 ± 0.02 | 0 | 6.0 ± 0.71 | 13.0 ± 0.35 |

| Sample | Tm (°C) | Tc(peak) (°C) | Tg(NR) (°C) | Tg(PHBV) (°C) | Tp (°C) | Xc (%) |

|---|---|---|---|---|---|---|

| PHBV | 172.0 ± 0.04 | 120.8 ± 0.17 | - | 5.6 ± 0.30 | 299.4 ± 0.93 | 74.7 ± 0.02 |

| PHBV/NR | 171.9 ± 0.56 | 119.4 ± 0.59 | −64.5 ± 0.52 | 6.0 ± 0.30 | 313.7 ± 1.49 | 61.6 ± 0.02 |

| PHBV/NR/P | 171.7 ± 0.26 | 117.2 ± 0.30 | −65.2 ± 0.41 | 6.2 ± 0.30 | 309.5 ± 2.74 | 58.8 ± 0.02 |

| PHBV/NR/P/C | 169.8 ± 0.54 | 116.8 ± 0.33 | −65.8 ± 0.54 | 4.3 ± 0.30 | 308.7 ± 1.63 | 56.8 ± 0.02 |

| NR | - | - | −66.8 ± 0.08 | - | 394.7 ± 1.16 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Cornish, K.; Vodovotz, Y. Synergistic Mechanisms Underlie the Peroxide and Coagent Improvement of Natural-Rubber-Toughened Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Mechanical Performance. Polymers 2019, 11, 565. https://doi.org/10.3390/polym11030565

Zhao X, Cornish K, Vodovotz Y. Synergistic Mechanisms Underlie the Peroxide and Coagent Improvement of Natural-Rubber-Toughened Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Mechanical Performance. Polymers. 2019; 11(3):565. https://doi.org/10.3390/polym11030565

Chicago/Turabian StyleZhao, Xiaoying, Katrina Cornish, and Yael Vodovotz. 2019. "Synergistic Mechanisms Underlie the Peroxide and Coagent Improvement of Natural-Rubber-Toughened Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Mechanical Performance" Polymers 11, no. 3: 565. https://doi.org/10.3390/polym11030565

APA StyleZhao, X., Cornish, K., & Vodovotz, Y. (2019). Synergistic Mechanisms Underlie the Peroxide and Coagent Improvement of Natural-Rubber-Toughened Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Mechanical Performance. Polymers, 11(3), 565. https://doi.org/10.3390/polym11030565