Advances in Flame Retardant Poly(Lactic Acid)

Abstract

1. Introduction

2. Current Trends in Flame-Retardant PLA

2.1. Metal Oxide Fillers

2.2. Phosphorus-Based Fillers

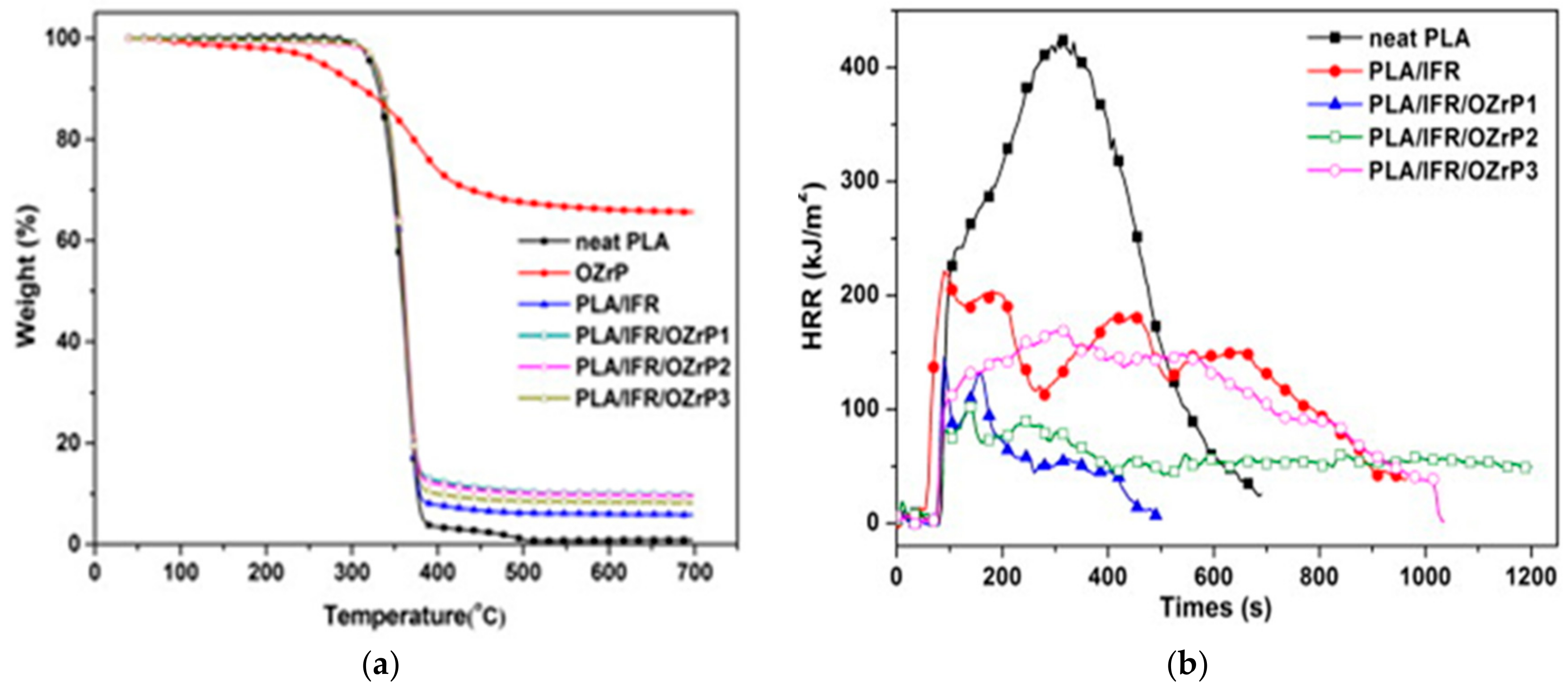

2.3. 2D Fillers

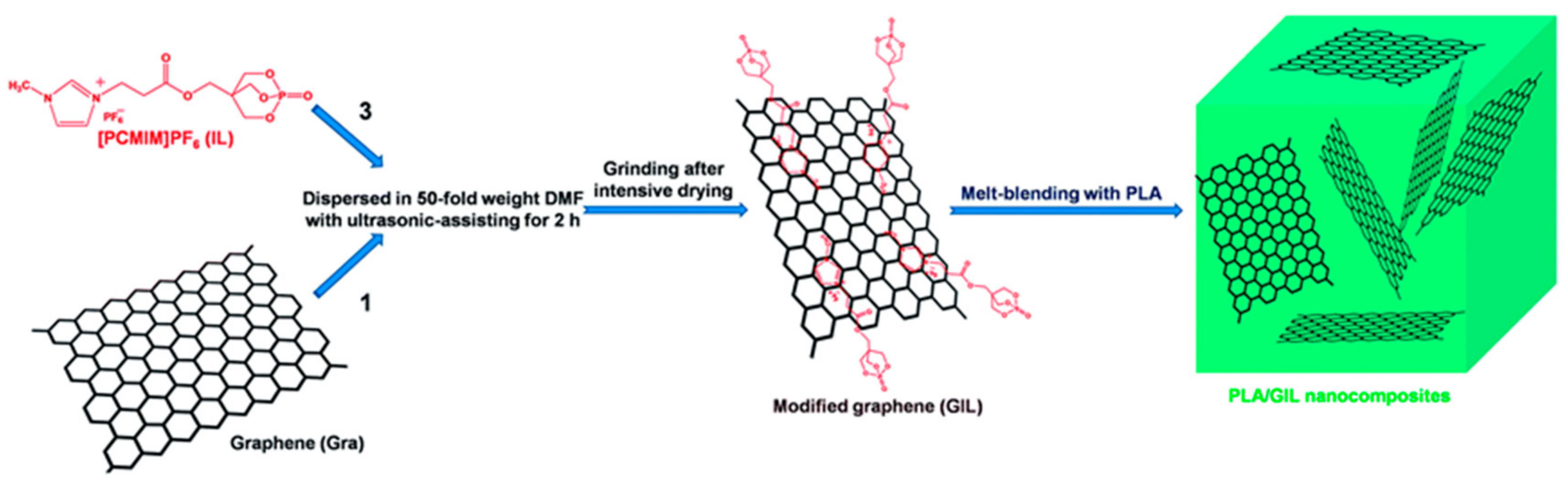

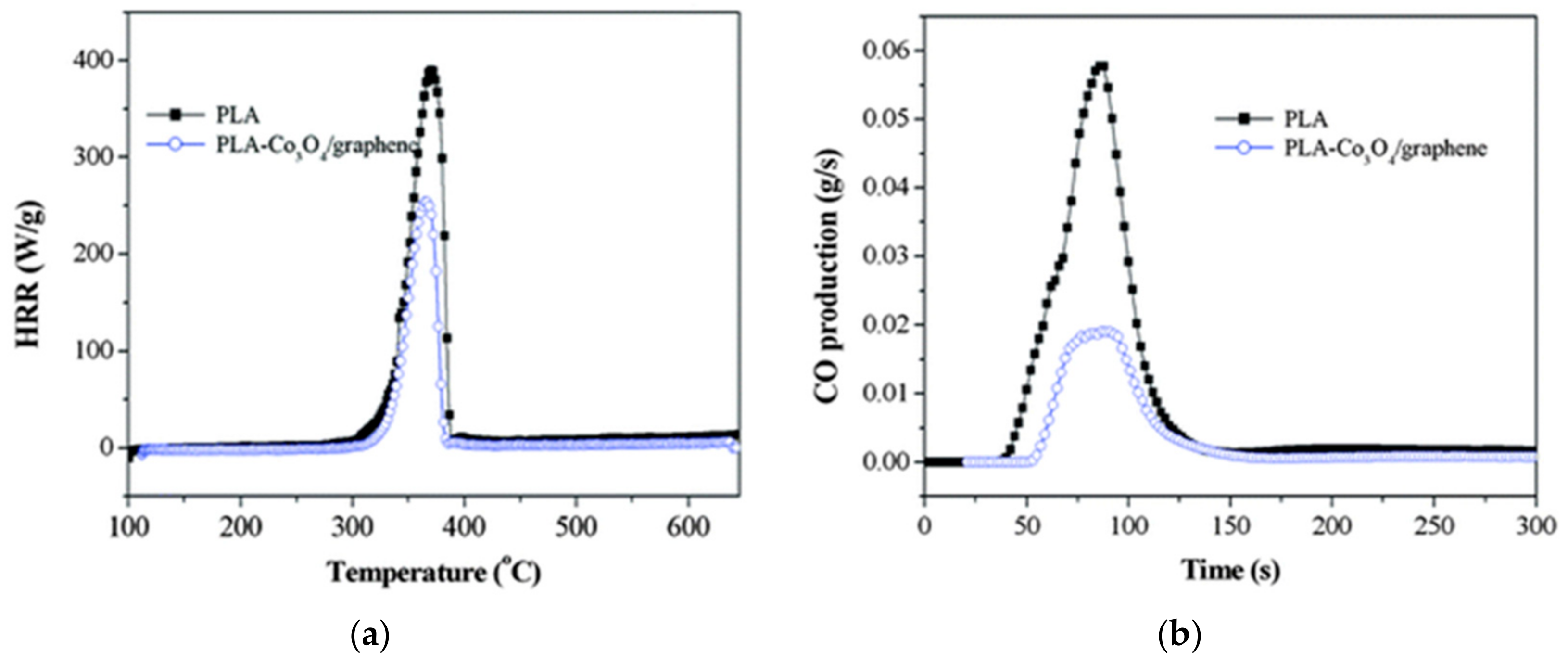

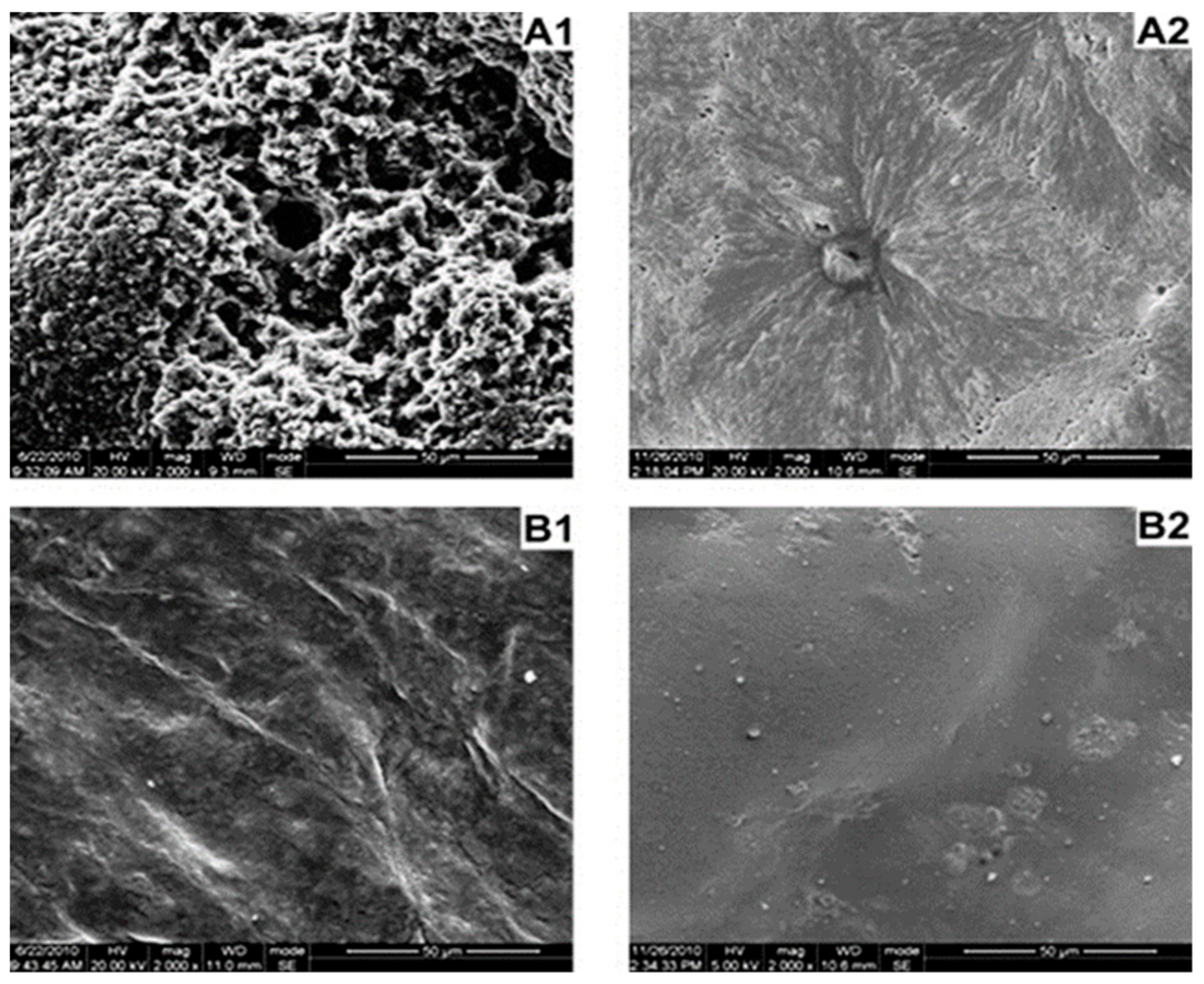

2.3.1. Graphene

2.3.2. Clays

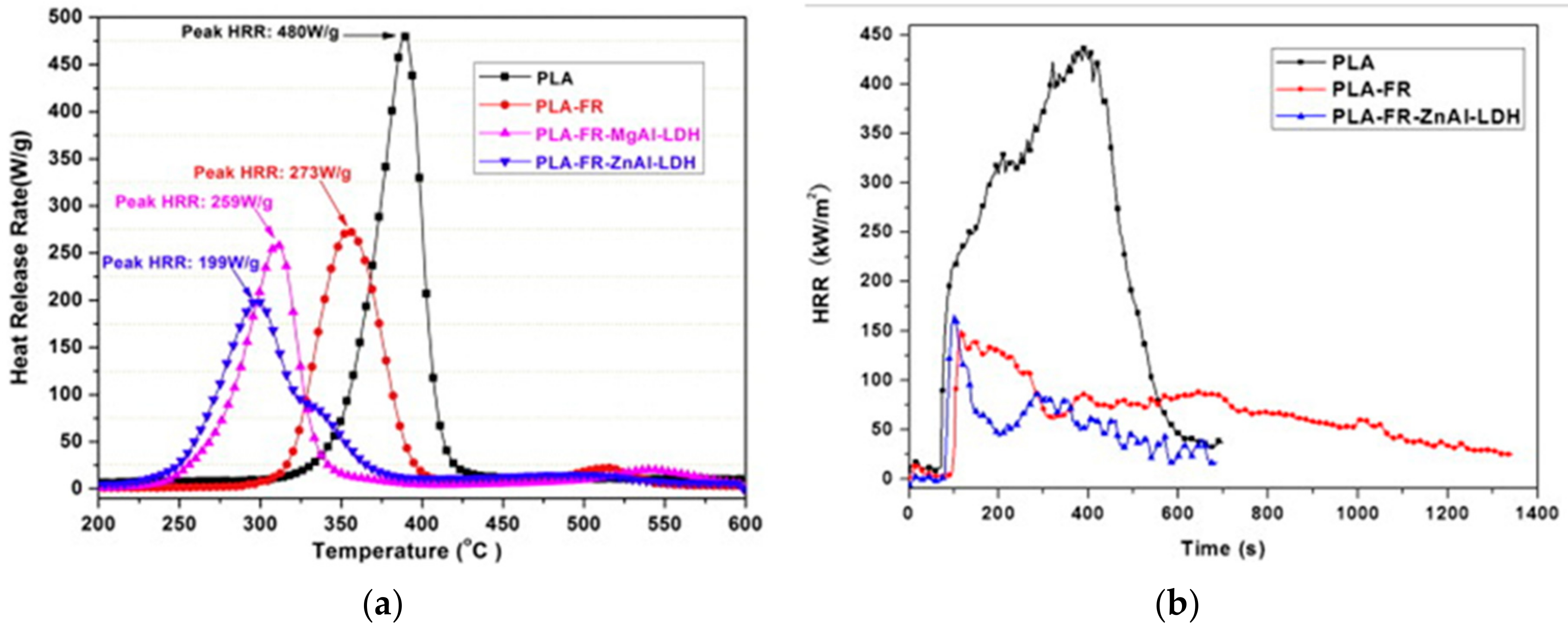

2.3.3. Layered Double Hydroxides (LDH)

2.4. 1D Fillers

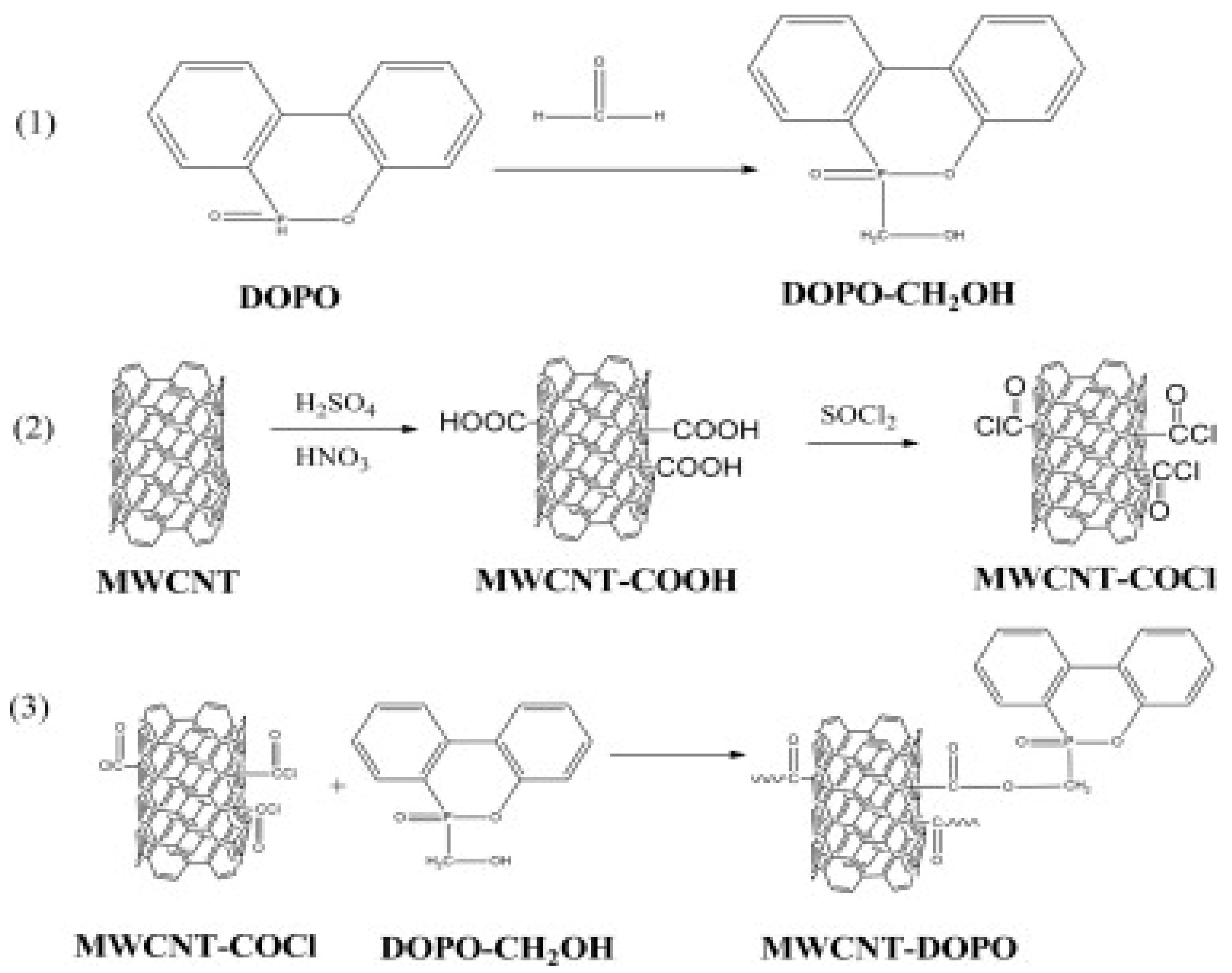

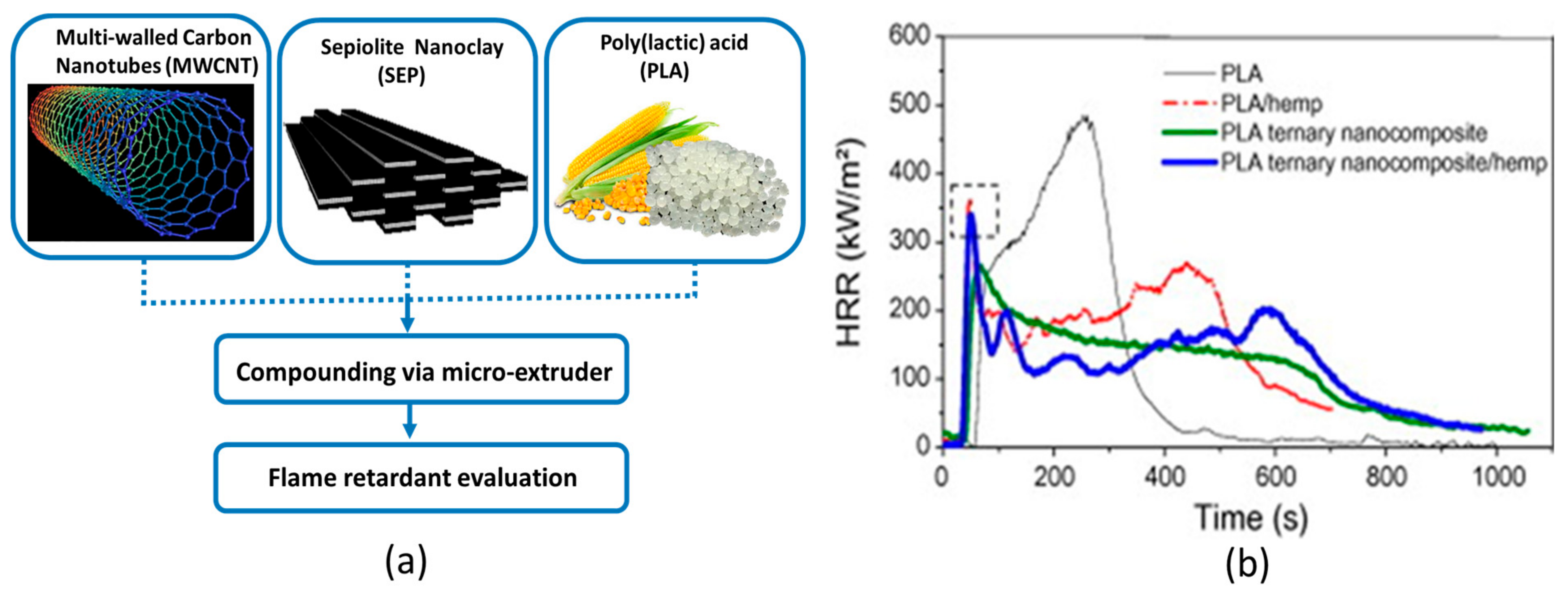

Carbon Nanotubes

2.5. Polymer Molecules

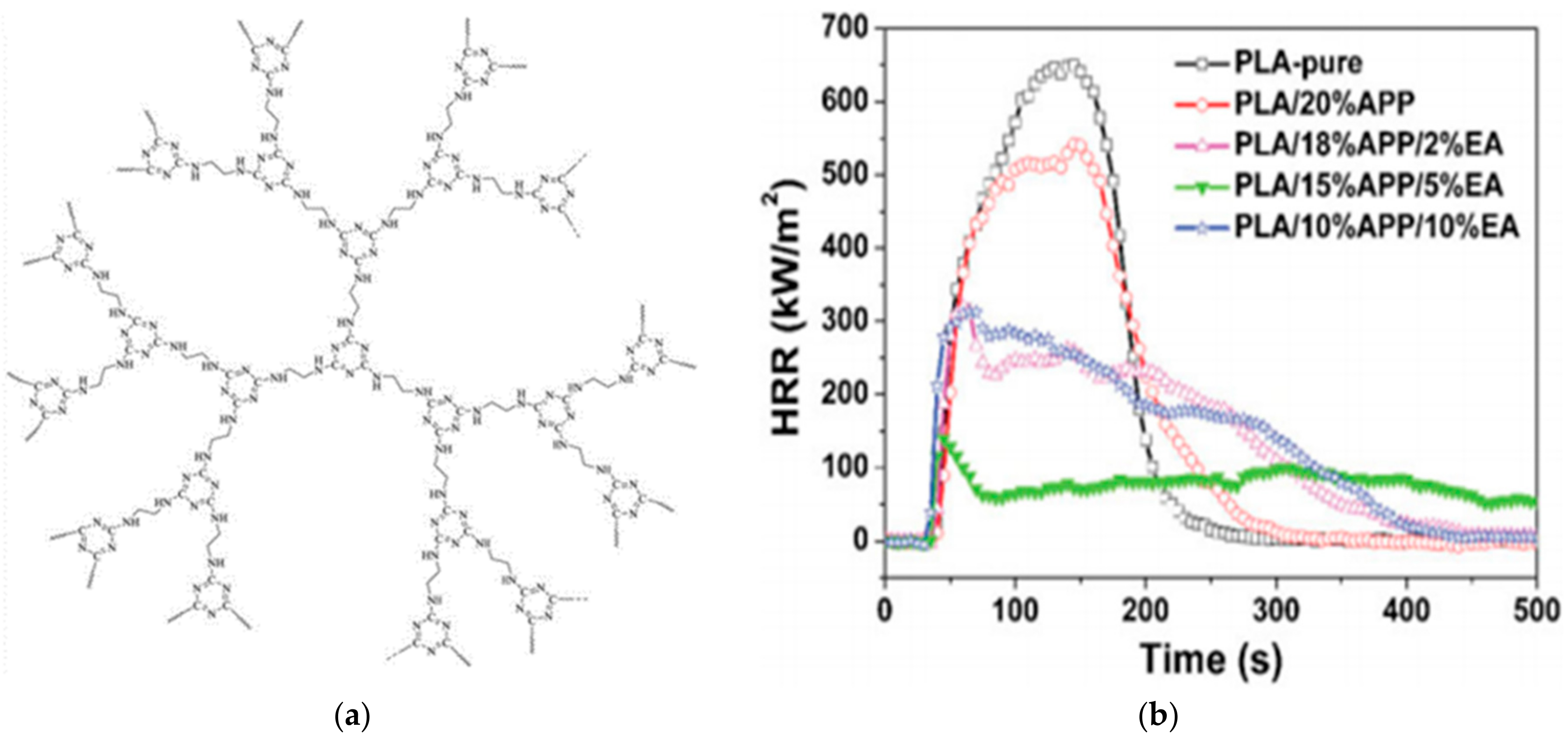

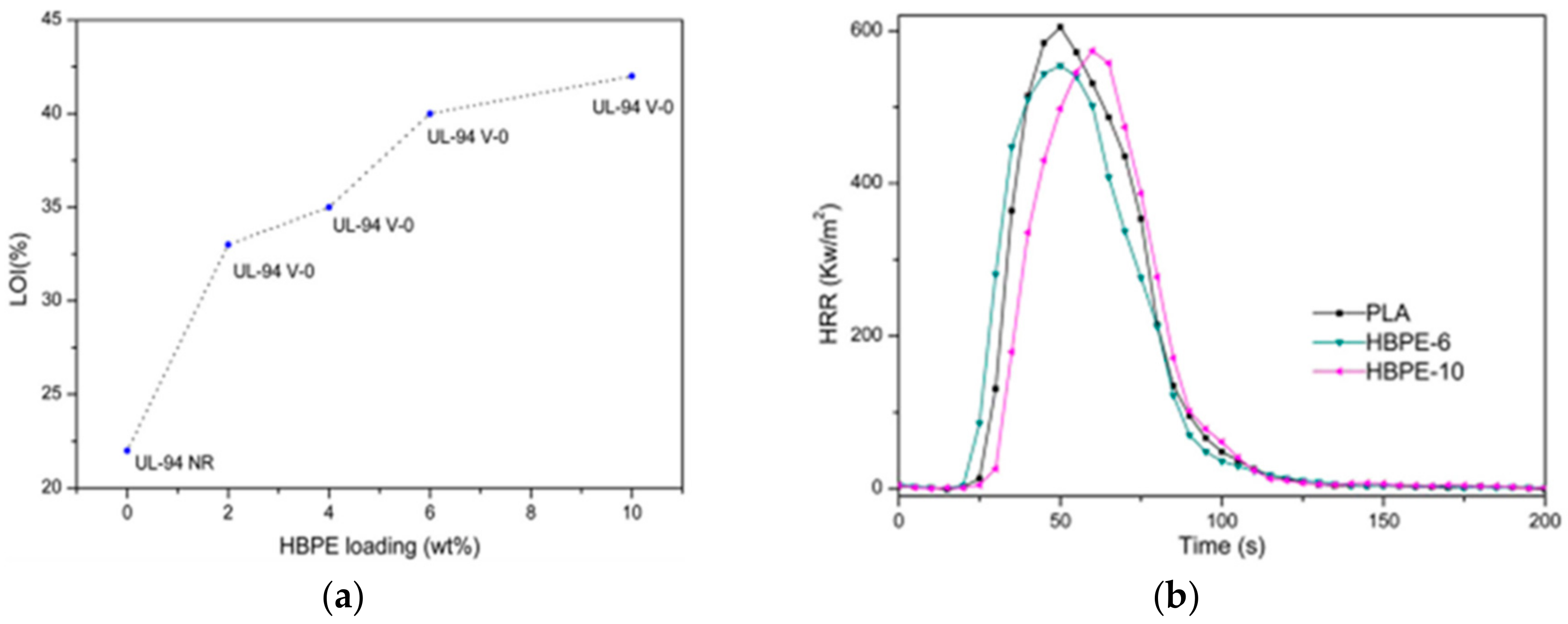

Hyperbranched Polymers

3. Conclusions and Future Prospects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Johansson, C.; Bras, J.; Mondragon, I.; Nechita, P.; Plackett, D.; Simon, P.; Svetec, D.G.; Virtanen, S.; Baschetti, M.G.; Breen, C.; et al. Renewable fibers and bio-based materials for packaging applications—A review of recent developments. BioResources 2012, 7, 2506–2552. [Google Scholar] [CrossRef]

- Irimia-Vladu, M. “Green” electronics: Biodegradable and biocompatible materials and devices for a sustainable future. Chem. Soc. Rev. 2014, 43, 588–610. [Google Scholar] [CrossRef] [PubMed]

- Madanhire, I.; Mbohwa, C. Mitigating Environmental Impact of Petroleum Lubricants; Springer: Berlin, Germany, 2016. [Google Scholar]

- Carus, M. Bio-Based Polymers Worldwide: Ongoing Growth Despite Difficult Market Environment; Nova-Institut GmbH: Hürth, Germany, 2017; pp. 1–4. [Google Scholar]

- Ikada, Y.; Tsuji, H. Biodegradable polyesters for medical and ecological applications. Macromol. Rapid Commun. 2000, 21, 117–132. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Vink, E.T.; Rabago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of life cycle assessment to NatureWorks™ polylactide (PLA) production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Bourbigot, S.; Fontaine, G. Flame retardancy of polylactide: An overview. Polym. Chem. 2010, 1, 1413–1422. [Google Scholar] [CrossRef]

- Reti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability properties of intumescent PLA including starch and lignin. Polym. Adv. Technol. 2008, 19, 628–635. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Yang, J.; Hu, Y. The effect of different organic modified montmorillonites (OMMTs) on the thermal properties and flammability of PLA/MCAPP/lignin systems. J. Appl. Polym. Sci. 2013, 127, 4967–4973. [Google Scholar] [CrossRef]

- Gu, L.; Qiu, J.; Yao, Y.; Sakai, E.; Yang, L. Functionalized MWCNTs modified flame retardant PLA nanocomposites and cold rolling process for improving mechanical properties. Compos. Sci. Technol. 2018, 161, 39–49. [Google Scholar] [CrossRef]

- Shaw, S. Halogenated flame retardants: Do the fire safety benefits justify the risks? Rev. Environ. Health 2010, 25, 261–306. [Google Scholar] [CrossRef] [PubMed]

- Alaee, M.; Arias, P.; Sjödin, A.; Bergman, Å. An overview of commercially used brominated flame retardants, their applications, their use patterns in different countries/regions and possible modes of release. Environ. Int. 2003, 29, 683–689. [Google Scholar] [CrossRef]

- Darnerud, P.O. Toxic effects of brominated flame retardants in man and in wildlife. Environ. Int. 2003, 29, 841–853. [Google Scholar] [CrossRef]

- Altarawneh, M.; Dlugogorski, B.Z. Formation of polybrominated dibenzofurans from polybrominated biphenyls. Chemosphere 2015, 119, 1048–1053. [Google Scholar] [CrossRef] [PubMed]

- Altarawneh, M.; Dlugogorski, B.Z. A mechanistic and kinetic study on the formation of PBDD/Fs from PBDEs. Environ.l Sci. Technol. 2013, 47, 5118–5127. [Google Scholar] [CrossRef] [PubMed]

- La Guardia, M.J.; Schreder, E.D.; Uding, N.; Hale, R.C. Human Indoor Exposure to Airborne Halogenated Flame Retardants: Influence of Airborne Particle Size. Int. J. Environ. Res. Public Health 2017, 14, 507. [Google Scholar] [CrossRef] [PubMed]

- Legler, J.; Brouwer, A. Are brominated flame retardants endocrine disruptors? Environ. Int. 2003, 29, 879–885. [Google Scholar] [CrossRef]

- Khalil, A.; Parker, M.; Brown, S.E.; Cevik, S.E.; Guo, L.W.; Jensen, J.; Olmsted, A.; Portman, D.; Wu, H.; Suvorov, A. Perinatal exposure to 2,2′,4′4′-Tetrabromodiphenyl ether induces testicular toxicity in adult rats. Toxicology 2017, 15, 21–30. [Google Scholar] [CrossRef] [PubMed]

- Okoro, H.K.; Ige, J.O.; Iyiola, O.A.; Pandey, S.; Lawal, I.A.; Zvinowanda, C.; Ngila, C.J. Comprehensive reviews on adverse health effects of human exposure to endocrine-disrupting chemicals. Fresenius Environ. Bull. 2017, 26, 4623–4636. [Google Scholar]

- Liu, M.; Yin, H.; Chen, X.; Yang, J.; Liang, Y.; Zhang, J.; Yang, F.; Deng, Y.; Lu, S. Preliminary ecotoxicity hazard evaluation of DOPO-HQ as a potential alternative to halogenated flame retardants. Chemosphere 2018, 193, 126–133. [Google Scholar] [CrossRef] [PubMed]

- Tawiah, B.; Yu, B.; Cheung, W.Y.; Chan, S.Y.; Yang, W.; Fei, B. Synthesis and application of synergistic azo-boron-BPA/polydopamine as efficient flame retardant for poly (lactic acid). Polym. Degrad. Stab. 2018, 152, 64–74. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R Rep. 2017, 117 (Suppl. C), 1–25. [Google Scholar] [CrossRef]

- Wu, N.; Yang, R. Effects of metal oxides on intumescent flame-retardant polypropylene. Polym. Adv. Technol. 2011, 22, 495–501. [Google Scholar] [CrossRef]

- Hornsby, P.R.; Watson, C.L. A study of the mechanism of flame retardance and smoke suppression in polymers filled with magnesium hydroxide. Polym. Degrad. Stab. 1990, 30, 73–87. [Google Scholar] [CrossRef]

- Joel, J. Global Flame Retardant Chemicals Market Set for Rapid Growth, To Reach Around USD 10.0 Billion by 2020. Available online: http://www.marketresearchstore.com/news/global-flame-retardant-chemicals-market-set-for-rapid-123 (accessed on 10 November 2017).

- Li, N.; Xia, Y.; Mao, Z.; Wang, L.; Guan, Y.; Zheng, A. Influence of antimony oxide on flammability of polypropylene/intumescent flame retardant system. Polym. Degrad. Stab. 2012, 97, 1737–1744. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Kandola, B.K.; Davies, P.J.; Zhang, S.; Padbury, S.A. Developments in flame retardant textiles—A review. Polym. Degrad. Stab. 2005, 88, 3–12. [Google Scholar] [CrossRef]

- Sato, H.; Kondo, K.; Tsuge, S.; Ohtani, H.; Sato, N. Mechanisms of thermal degradation of a polyester flame-retarded with antimony oxide/brominated polycarbonate studied by temperature-programmed analytical pyrolysis. Polym. Degrad. Stab. 1998, 62, 41–48. [Google Scholar] [CrossRef]

- Nishida, H.; Fan, Y.; Mori, T.; Oyagi, N.; Shirai, Y.; Endo, T. Feedstock recycling of flame-resisting poly (lactic acid)/aluminum hydroxide composite to l,l-lactide. Ind. Eng. Chem. Res. 2005, 44, 1433–1437. [Google Scholar] [CrossRef]

- Yanagisawa, T.; Kiuchi, Y.; Iji, M. Enhanced flame retardancy of polylactic acid with aluminum tri-hydroxide and phenolic resins. Kobunshi Ronbunshu 2009, 66, 49–54. [Google Scholar] [CrossRef]

- Woo, Y.; Cho, D. Effect of aluminum trihydroxide on flame retardancy and dynamic mechanical and tensile properties of kenaf/poly(lactic acid) green composites. Adv. Compos. Mater. 2013, 22, 451–464. [Google Scholar] [CrossRef]

- Weil, E.D. Phosphorus-based flame retardants. In Flame—Retardant Polymeric Materials; Lewin, M., Atlas, S.M., Pearce, E.M., Eds.; Springer: Boston, MA, USA, 1978; Volume 2, pp. 103–131. [Google Scholar]

- Levchik, S.V.; Weil, E.D. A review of recent progress in phosphorus-based flame retardants. J. Fire Sci. 2006, 24, 345–364. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.V.; Ravey, M.; Zhu, W. A survey of recent progress in phosphorus-based flame retardants and some mode of action studies. Phosphorus Sulfur Silicon Relat. Elem. 1999, 144, 17–20. [Google Scholar] [CrossRef]

- Schartel, B. Phosphorus-based flame retardancy mechanisms—Old hat or a starting point for future development? Materials 2010, 3, 4710–4745. [Google Scholar] [CrossRef] [PubMed]

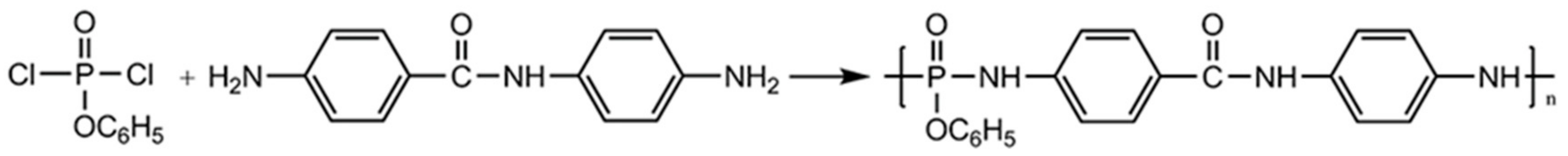

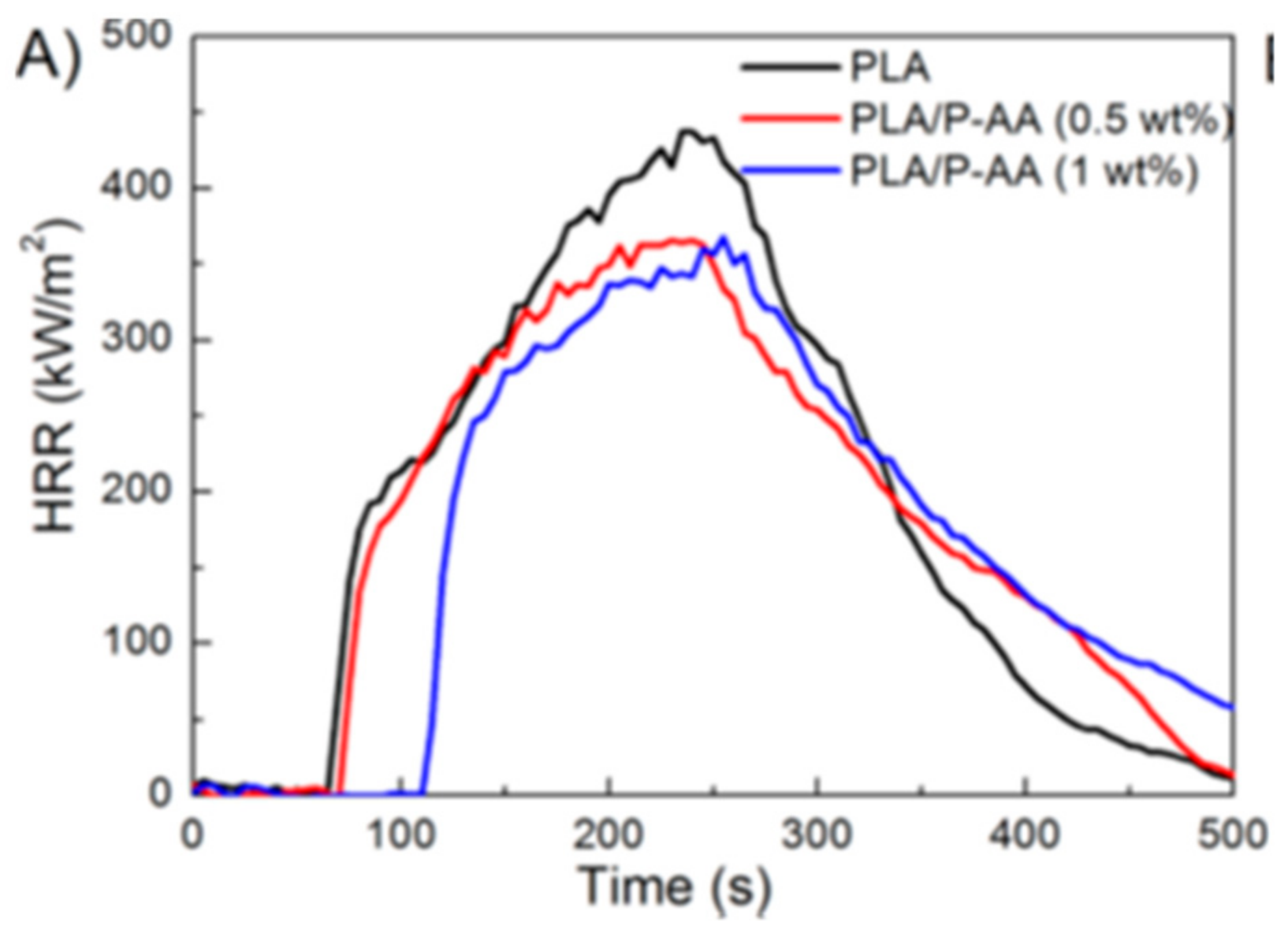

- Shi, X.; Liao, F.; Ju, Y.; Dai, X.; Cao, Y.; Li, J.; Wang, X. Improving the flame retardance and melt dripping of poly (lactic acid) with a novel polymeric flame retardant of high thermal stability. Fire Mater. 2017, 41, 362–374. [Google Scholar] [CrossRef]

- Dasari, A.; Yu, Z.Z.; Cai, G.P.; Mai, Y.W. Recent developments in the fire retardancy of polymeric materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Song, L.; Xuan, S.; Wang, X.; Hu, Y. Flame retardancy and thermal degradation behaviors of phosphate in combination with POSS in polylactide composites. Thermochim. Acta 2012, 527, 1–7. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Hu, Y. Modification of lignin and its application as char agent in intumescent flame-retardant poly(lactic acid). Polym. Eng. Sci. 2012, 52, 2620–2626. [Google Scholar] [CrossRef]

- Muriel Rakotomalala, E.S.; Hörold, S.; Bio-Based and Flame Retardant. Clariant Featured Article on Bio-Based Materials and Flame Retardant. 2011. Available online: https://www.clariant.com/~/media/Files/Business-Units/Additives/Additives-_-Flame Retardants/Article_FR.pdf (accessed on 24 August 2017).

- Zhao, X.; Guerrero, F.R.; Llorca, J.; Wang, D.Y. New Superefficiently Flame-Retardant Bioplastic Poly (lactic acid): Flammability, Thermal Decomposition Behavior, and Tensile Properties. ACS Sustain. Chem. Eng. 2015, 4, 202–209. [Google Scholar] [CrossRef]

- Li, S.; Deng, L.; Xu, C.; Wu, Q.; Wang, Z. Making a Supertough Flame-Retardant Polylactide Composite through Reactive Blending with Ethylene-Acrylic Ester-Glycidyl Methacrylate Terpolymer and Addition of Aluminum Hypophosphite. ACS Omega 2017, 2, 1886–1895. [Google Scholar] [CrossRef]

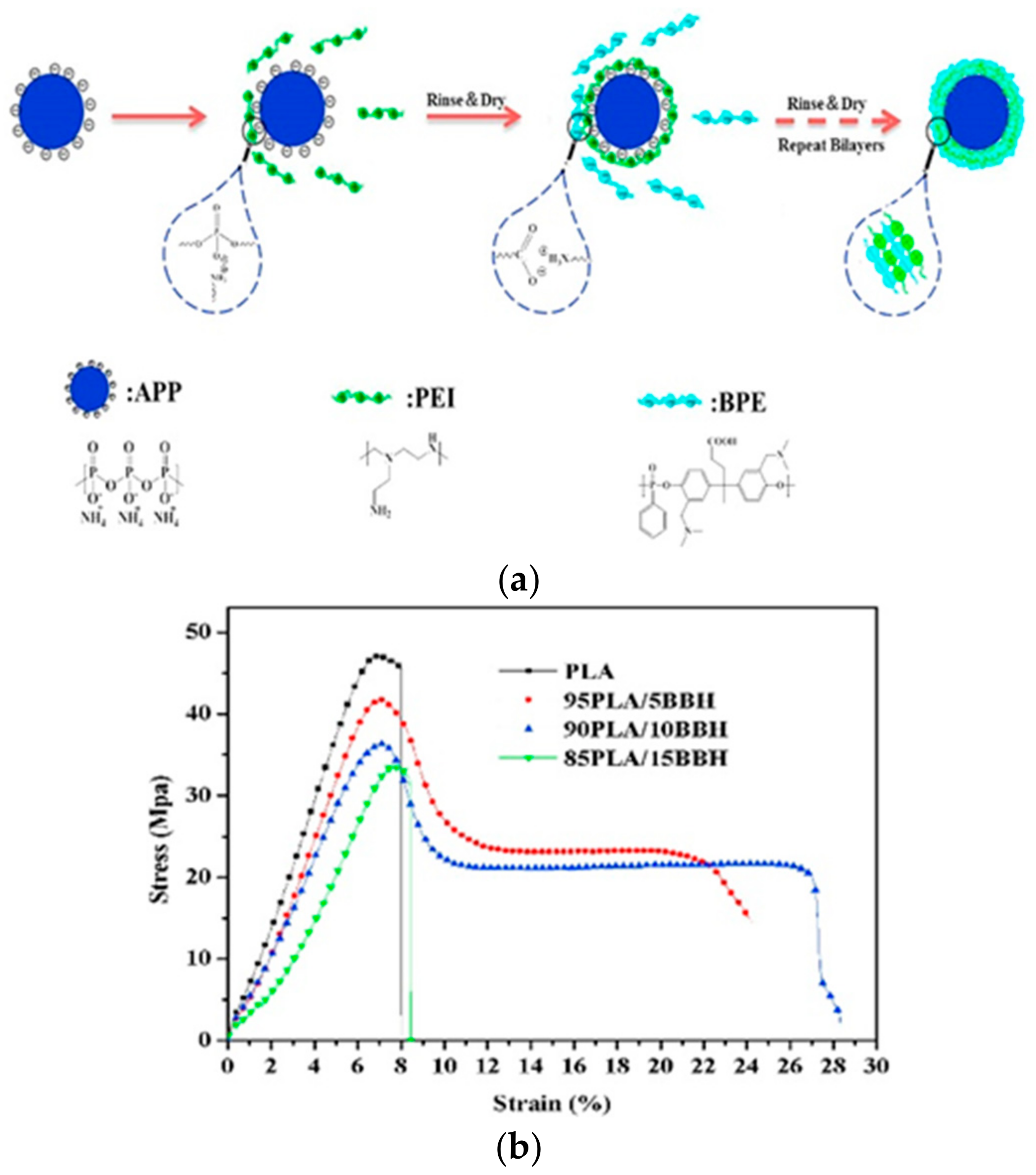

- Jing, J.; Zhang, Y.; Tang, X.; Zhou, Y.; Li, X.; Kandola, B.K.; Fang, Z. Layer by layer deposition of polyethyleneimine and bio-based polyphosphate on ammonium polyphosphate: A novel hybrid for simultaneously improving the flame retardancy and toughness of polylactic acid. Polymer 2017, 108 (Suppl. C), 361–371. [Google Scholar] [CrossRef]

- Yang, W.; Yang, W.J.; Tawiah, B.; Zhang, Y.; Wang, L.L.; Zhu, S.E.; Chen, T.B.Y.; Yuen, A.C.Y.; Yu, B.; Liu, Y.F.; et al. Synthesis of anhydrous manganese hypophosphite microtubes for simultaneous flame retardant and mechanical enhancement on poly (lactic acid). Compos. Sci. Technol. 2018, 164, 44–50. [Google Scholar] [CrossRef]

- Cheng, X.W.; Guan, J.P.; Tang, R.C.; Liu, K.Q. Improvement of flame retardancy of poly (lactic acid) nonwoven fabric with a phosphorus-containing flame retardant. J. Ind. Text. 2016, 46, 914–928. [Google Scholar] [CrossRef]

- Tang, G.; Wang, X.; Xing, W.; Zhang, P.; Wang, B.; Hong, N.; Yang, W.; Hu, Y.; Song, L. Thermal degradation and flame retardance of biobased polylactide composites based on aluminum hypophosphite. Ind. Eng. Chem. Res. 2012, 51, 12009–12016. [Google Scholar] [CrossRef]

- Wei, L.L.; Wang, D.Y.; Chen, H.B.; Chen, L.; Wang, X.L.; Wang, Y.Z. Effect of a phosphorus-containing flame retardant on the thermal properties and ease of ignition of poly (lactic acid). Polym. Degrad. Stab. 2011, 96, 1557–1561. [Google Scholar] [CrossRef]

- Yuan, X.Y.; Wang, D.Y.; Chen, L.; Wang, X.L.; Wang, Y.Z. Inherent flame retardation of bio-based poly (lactic acid) by incorporating phosphorus linked pendent group into the backbone. Polym. Degrad. Stab. 2011, 96, 1669–1675. [Google Scholar] [CrossRef]

- Jing, J.; Zhang, Y.; Fang, Z. Diphenolic acid based biphosphate on the properties of polylactic acid: Synthesis, fire behavior, and flame retardant mechanism. Polymer 2017, 108, 29–37. [Google Scholar] [CrossRef]

- Yemisci, F.; Yesil, S.; Aytac, A. Improvement of the flame retardancy of plasticized poly (lactic acid) by means of phosphorus-based flame retardant fillers. Fire Mater. 2017, 41, 964–972. [Google Scholar] [CrossRef]

- Cao, H.; Zhang, Y.; Li, X.; Wang, F.; Zhang, X. Effects of treated waste silicon rubber on properties of poly (lactic acid)/ammonium polyphosphate composites. J. Appl. Polym. Sci. 2017, 134, 45231. [Google Scholar] [CrossRef]

- Zhao, X.; Gao, S.; Liu, G. A THEIC-based polyphosphate melamine intumescent flame retardant and its flame retardancy properties for polylactide. J. Anal. Appl. Pyrolysis 2016, 122 (Suppl. C), 24–34. [Google Scholar] [CrossRef]

- Chen, C.; Gu, X.; Jin, X.; Sun, J.; Zhang, S. The effect of chitosan on the flammability and thermal stability of polylactic acid/ammonium polyphosphate biocomposites. Carbohydr. Polym. 2017, 157 (Suppl. C), 1586–1593. [Google Scholar] [CrossRef] [PubMed]

- Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Fierro, V.; Celzard, A. PLA with an intumescent system containing lignin and ammonium polyphosphate for flame retardant textile. Polymers 2016, 8, 331. [Google Scholar] [CrossRef]

- Feng, C.; Liang, M.; Jiang, J.; Huang, J.; Liu, H. Flame retardant properties and mechanism of an efficient intumescent flame retardant PLA composites. Polym. Adv. Technol. 2016, 27, 693–700. [Google Scholar] [CrossRef]

- Feng, C.; Liang, M.; Zhang, Y.; Jiang, J.; Huang, J.; Liu, H. Synergistic effect of lanthanum oxide on the flame retardant properties and mechanism of an intumescent flame retardant PLA composites. J. Anal. Appl. Pyrolysis 2016, 122 (Suppl. C), 241–248. [Google Scholar] [CrossRef]

- Fox, D.M.; Lee, J.; Citro, C.J.; Novy, M. Flame retarded poly (lactic acid) using POSS-modified cellulose. 1. Thermal and combustion properties of intumescing composites. Polym. Degrad. Stab. 2013, 98, 590–596. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xuan, S.; Xing, W.; Bai, Z.; Lu, H. Flame retardancy and thermal degradation of intumescent flame retardant poly (lactic acid)/starch biocomposites. Ind. Eng. Chem. Res. 2010, 50, 713–720. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Aguedo, M.; Richel, A.; Brohez, S.; Delvosalle, C.; Dubois, P. Phosphorus and nitrogen derivatization as efficient route for improvement of lignin flame retardant action in PLA. Eur. Polym. J. 2016, 84 (Suppl. C), 652–667. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Khelifa, F.; Rose, G.; Brohez, S.; Delvosalle, C.; Dubois, P. Cellulose/phosphorus combinations for sustainable fire retarded polylactide. Eur. Polym. J. 2016, 74 (Suppl. C), 218–228. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Bonaccorso, F.; Fal’Ko, V.; Novoselov, K.S.; Roche, S.; Bøggild, P.; Borini, S.; Koppens, F.H.; Palermo, V.; Pugno, N.; et al. Science and technology roadmap for graphene, related two-dimensional crystals, and hybrid systems. Nanoscale 2015, 7, 4598–4810. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Sakthivel, T.; Seal, S. Recent development in 2D materials beyond graphene. Prog. Mater. Sci. 2015, 73, 44–126. [Google Scholar] [CrossRef]

- Tong, X.Z.; Song, F.; Li, M.Q.; Wang, X.L.; Chin, I.J.; Wang, Y.Z. Fabrication of graphene/polylactide nanocomposites with improved properties. Compos. Sci. Technol. 2013, 88 (Suppl. C), 33–38. [Google Scholar] [CrossRef]

- Ōya, A.; Marsh, H. Phenomena of catalytic graphitization. J. Mater. Sci. 1982, 17, 309–322. [Google Scholar] [CrossRef]

- Gui, H.; Xu, P.; Hu, Y.; Wang, J.; Yang, X.; Bahader, A.; Ding, Y. Synergistic effect of graphene and an ionic liquid containing phosphonium on the thermal stability and flame retardancy of polylactide. RSC Adv. 2015, 5, 27814–27822. [Google Scholar] [CrossRef]

- Moon, I.K.; Lee, J.; Ruoff, R.S.; Lee, H. Reduced graphene oxide by chemical graphitization. Nat. Commun. 2010, 1, 73. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.D.; Bai, Z.M.; Tang, G.; Song, L.; Stec, A.A.; Hull, T.R.; Zhan, J.; Hu, Y. Fabrication of Ce-doped MnO2 decorated graphene sheets for fire safety applications of epoxy composites: Flame retardancy, smoke suppression, and mechanism. J. Mater. Chem. A 2014, 2, 17341–17351. [Google Scholar] [CrossRef]

- Wang, X.; Song, L.; Yang, H.; Xing, W.; Lu, H.; Hu, Y. Cobalt oxide/graphene composite for highly efficient CO oxidation and its application in reducing the fire hazards of aliphatic polyesters. J. Mater. Chem. 2012, 22, 3426–3431. [Google Scholar] [CrossRef]

- Valapa, R.B.; Pugazhenthi, G.; Katiyar, V. Effect of graphene content on the properties of poly (lactic acid) nanocomposites. RSC Adv. 2015, 5, 28410–28423. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C. Polymer/layered silicate (clay) nanocomposites: An overview of flame retardancy. Prog. Polym. Sci. 2010, 35, 902–958. [Google Scholar] [CrossRef]

- Morgan, A.B. Flame retarded polymer-layered silicate nanocomposites: A review of commercial and open literature systems. Polym. Adv. Technol. 2006, 17, 206–217. [Google Scholar] [CrossRef]

- Porter, D.; Metcalfe, E.; Thomas, M. Nanocomposite fire retardants—A review. Fire Mater. 2000, 24, 45–52. [Google Scholar] [CrossRef]

- Paul, M.A.; Alexandre, M.; Degée, P.; Henrist, C.; Rulmont, A.; Dubois, P. New nanocomposite materials based on plasticized poly (l-lactide) and organo-modified montmorillonites: Thermal and morphological study. Polymer 2003, 44, 443–450. [Google Scholar] [CrossRef]

- Shibata, M.; Someya, Y.; Orihara, M.; Miyoshi, M. Thermal and mechanical properties of plasticized poly (l-lactide) nanocomposites with organo-modified montmorillonites. J. Appl. Polym. Sci. 2006, 99, 2594–2602. [Google Scholar] [CrossRef]

- Pluta, M. Morphology, and properties of polylactide modified by thermal treatment, filling with layered silicates and plasticization. Polymer 2004, 45, 8239–8251. [Google Scholar] [CrossRef]

- Li, S.; Yuan, H.; Yu, T.; Yuan, W.; Ren, J. Flame-retardancy and anti-dripping effects of intumescent flame retardant incorporating montmorillonite on poly (lactic acid). Polym. Adv. Technol. 2009, 20, 1114–1120. [Google Scholar] [CrossRef]

- Solarski, S.; Ferreira, M.; Devaux, E.; Fontaine, G.; Bachelet, P.; Bourbigot, S.; Delobel, R.; Coszach, P.; Murariu, M.; Da Silva Ferreira, A.; et al. Designing polylactide/clay nanocomposites for textile applications: Effect of processing conditions, spinning, and characterization. J. Appl. Polym. Sci. 2008, 109, 841–851. [Google Scholar] [CrossRef]

- Fukushima, K.; Murariu, M.; Camino, G.; Dubois, P. Effect of expanded graphite/layered-silicate clay on thermal, mechanical and fire retardant properties of poly (lactic acid). Polym. Degrad. Stab. 2010, 95, 1063–1076. [Google Scholar] [CrossRef]

- Chiang, M.-F.; Wu, T.-M. Synthesis, and characterization of biodegradable poly (l-lactide)/layered double hydroxide nanocomposites. Compos. Sci. Technol. 2010, 70, 110–115. [Google Scholar] [CrossRef]

- Liu, X.Q.; Wang, D.Y.; Wang, X.L.; Chen, L.; Wang, Y.Z. Synthesis of organo-modified α-zirconium phosphate and its effect on the flame retardancy of IFR poly (lactic acid) systems. Polym. Degrad. Stab. 2011, 96, 771–777. [Google Scholar] [CrossRef]

- Khan, A.I.; O’Hare, D. Intercalation chemistry of layered double hydroxides: Recent developments and applications. J. Mater. Chem. 2002, 12, 3191–3198. [Google Scholar] [CrossRef]

- Radha, A.; Kamath, P.V.; Shivakumara, C. Mechanism of the anion exchange reactions of the layered double hydroxides (LDHs) of Ca and Mg with Al. Solid State Sci. 2005, 7, 1180–1187. [Google Scholar] [CrossRef]

- Xu, Z.P.; Lu, G.Q. Hydrothermal synthesis of layered double hydroxides (LDHs) from mixed MgO and Al2O3: LDH formation mechanism. Chem. Mater. 2005, 17, 1055–1062. [Google Scholar] [CrossRef]

- Wang, D.Y.; Leuteritz, A.; Wang, Y.Z.; Wagenknecht, U.; Heinrich, G. Preparation and burning behaviors of flame retarding biodegradable poly (lactic acid) nanocomposite based on zinc aluminum layered double hydroxide. Polym. Degrad. Stab. 2010, 95, 2474–2480. [Google Scholar] [CrossRef]

- Shan, X.; Song, L.; Xing, W.; Hu, Y.; Lo, S. Effect of nickel-containing layered double hydroxides and cyclophosphazene compound on the thermal stability and flame retardancy of poly (lactic acid). Ind. Eng. Chem. Res. 2012, 51, 13037–13045. [Google Scholar] [CrossRef]

- Jin, X.; Gu, X.; Chen, C.; Tang, W.; Li, H.; Liu, X.; Bourbigot, S.; Zhang, Z.; Sun, J.; Zhang, S. The fire performance of polylactic acid containing a novel intumescent flame retardant and intercalated layered double hydroxides. J. Mater. Sci. 2017, 52, 12235–12250. [Google Scholar] [CrossRef]

- Xueying, S.; Yuan, H.; Haiqun, C.; Xiongjun, Y. Study on Thermal Property, Flame Retardancy and Mechanism of Poly (lactic acid)/Intumescent Flame Retardant/NiAl Layer Double Hydroxide Nanocomposites. Sci. Adv. Mater. 2015, 7, 1848–1857. [Google Scholar] [CrossRef]

- Ding, P.; Kang, B.; Zhang, J.; Yang, J.; Song, N.; Tang, S.; Shi, L. Phosphorus-containing flame retardant modified layered double hydroxides and their applications on polylactide film with good transparency. J. Colloid Interface Sci. 2015, 440 (Suppl. C), 46–52. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-Y.; Shih, Y.-F. Flame-retardant recycled bamboo chopstick fiber-reinforced poly (lactic acid) green composites via multifunctional additive system. J. Taiwan Inst. Chem. Eng. 2016, 65 (Suppl. C), 452–458. [Google Scholar] [CrossRef]

- Shabanian, M.; Hajibeygi, M.; Hedayati, K.; Khaleghi, M.; Khonakdar, H.A. New ternary PLA/organoclay-hydrogel nanocomposites: Design, preparation, and study on thermal, combustion and mechanical properties. Mater. Des. 2016, 110 (Suppl. C), 811–820. [Google Scholar] [CrossRef]

- Chow, W.S.; Teoh, E.L. Flexible and flame-resistant poly (lactic acid)/organomontmorillonite nanocomposites. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Ye, L.; Ren, J.; Cai, S.Y.; Wang, Z.G.; Li, J.B. Poly (lactic acid) nanocomposites with improved flame retardancy and impact strength by combining phosphinates and organoclay. Chin. J. Polym. Sci. 2016, 34, 785–796. [Google Scholar] [CrossRef]

- Cheng, K.C.; Yu, C.B.; Guo, W.; Wang, S.F.; Chuang, T.H.; Lin, Y.H. Thermal properties and flammability of polylactide nanocomposites with aluminum trihydrate and organoclay. Carbohydr. Polym. 2012, 87, 1119–1123. [Google Scholar] [CrossRef]

- Murariu, M.; Bonnaud, L.; Yoann, P.; Fontaine, G.; Bourbigot, S.; Dubois, P. New trends in polylactide (PLA)-based materials: “Green” PLA–Calcium sulfate (nano) composites tailored with flame retardant properties. Polym. Degrad. Stab. 2010, 95, 374–381. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Peijs, T. Multiwalled carbon nanotubes and sepiolite nanoclays as flame retardants for polylactide and its natural fiber reinforced composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 954–963. [Google Scholar] [CrossRef]

- Kim, F.S.; Ren, G.; Jenekhe, S.A. One-dimensional nanostructures of π-conjugated molecular systems: Assembly, properties, and applications from photovoltaics, sensors, and nanophotonics to nanoelectronics. Chem. Mater. 2010, 23, 682–732. [Google Scholar] [CrossRef]

- Zhai, T.; Fang, X.; Li, L.; Bando, Y.; Golberg, D. One-dimensional CdS nanostructures: Synthesis, properties, and applications. Nanoscale 2010, 2, 168–187. [Google Scholar] [CrossRef] [PubMed]

- Sang, L.; Liao, M.; Sumiya, M. A comprehensive review of semiconductor ultraviolet photodetectors: From a thin film to one-dimensional nanostructures. Sensors 2013, 13, 10482–10518. [Google Scholar] [CrossRef] [PubMed]

- Yoon, H.; Jang, J. Conducting-polymer nanomaterials for high-performance sensor applications: Issues and challenges. Adv. Funct. Mater. 2009, 19, 1567–1576. [Google Scholar] [CrossRef]

- Peng, S.; Li, L.; Hu, Y.; Srinivasan, M.; Cheng, F.; Chen, J.; Ramakrishna, S. Fabrication of spinel one-dimensional architectures by single-spinneret electrospinning for energy storage applications. ACS Nano 2015, 9, 1945–1954. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wong, C.K.; Yuan, C.A.; Zhang, G. Nanowire-based gas sensors. Sens. Actuators B Chem. 2013, 177, 178–195. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, G.; Zhang, J.; Zhang, L. Shape-controlled growth of one-dimensional Sb2O3 nanomaterials. Nanotechnology 2004, 15, 762. [Google Scholar] [CrossRef]

- Beyer, G. Carbon nanotubes as flame retardants for polymers. Fire Mater. 2002, 26, 291–293. [Google Scholar] [CrossRef]

- Schartel, B.; Pötschke, P.; Knoll, U.; Abdel-Goad, M. Fire behavior of polyamide 6/multiwall carbon nanotube nanocomposites. Eur. Polym. J. 2005, 41, 1061–1070. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Grulke, E.; Hilding, J.; Groth, K.; Harris, R.; Butler, K.; Shields, J.; Kharchenko, S.; Douglas, J. Thermal and flammability properties of polypropylene/carbon nanotube nanocomposites. Polymer 2004, 45, 4227–4239. [Google Scholar] [CrossRef]

- Wu, Q.; Zhu, W.; Zhang, C.; Liang, Z.; Wang, B. Study of fire retardant behavior of carbon nanotube membranes and carbon nanofiber paper in carbon fiber reinforced epoxy composites. Carbon 2010, 48, 1799–1806. [Google Scholar] [CrossRef]

- Liu, T.; Phang, I.Y.; Shen, L.; Chow, S.Y.; Zhang, W.D. Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 2004, 37, 7214–7222. [Google Scholar] [CrossRef]

- Wang, L.; He, X.; Wilkie, C.A. The utility of nanocomposites in fire retardancy. Materials 2010, 3, 4580–4606. [Google Scholar] [CrossRef] [PubMed]

- Bourbigot, S.; Fontaine, G.; Gallos, A.; Bellayer, S. Reactive extrusion of PLA and of PLA/carbon nanotubes nanocomposite: Processing, characterization and flame retardancy. Polym. Adv. Technol. 2011, 22, 30–37. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Functionalized multi-walled carbon nanotube for improving the flame retardancy of ramie/poly (lactic acid) composite. Compos. Sci. Technol. 2014, 104, 26–33. [Google Scholar] [CrossRef]

- Hu, Y.; Xu, P.; Gui, H.; Wang, X.; Ding, Y. Effect of imidazolium phosphate and multiwalled carbon nanotubes on thermal stability and flame retardancy of polylactide. Compos. Part A Appl. Sci. Manuf. 2015, 77, 147–153. [Google Scholar] [CrossRef]

- Täuber, K.; Marsico, F.; Wurm, F.R.; Schartel, B. Hyperbranched poly (phosphoester) as flame retardants for technical and high-performance polymers. Polym. Chem. 2014, 5, 7042–7053. [Google Scholar] [CrossRef]

- Tao, K.; Li, J.; Xu, L.; Zhao, X.; Xue, L.; Fan, X.; Yan, Q. A novel phosphazene cyclomatrix network polymer: Design, synthesis, and application in flame retardant polylactide. Polym. Degrad. Stab. 2011, 96, 1248–1254. [Google Scholar] [CrossRef]

- Zang, L.; Wagner, S.; Ciesielski, M.; Müller, P.; Döring, M. Novel star-shaped and hyperbranched phosphorus-containing flame retardants in epoxy resins. Polym. Adv. Technol. 2011, 22, 1182–1191. [Google Scholar] [CrossRef]

- Cheng, K.C.; Chang, S.C.; Lin, Y.H.; Wang, C.C. Mechanical and flame retardant properties of polylactide composites with hyperbranched polymers. Compos. Sci. Technol. 2015, 118, 186–192. [Google Scholar] [CrossRef]

- Chen, Y.; Mao, X.; Qian, L.; Yang, C. Flammability and anti-dripping behaviors of polylactide composite containing hyperbranched triazine compound. Integr. Ferroelectr. 2016, 172, 10–24. [Google Scholar] [CrossRef]

- Ke, C.H.; Li, J.; Fang, K.Y.; Zhu, Q.L.; Zhu, J.; Yan, Q.; Wang, Y.Z. Synergistic effect between a novel hyperbranched charring agent and ammonium polyphosphate on the flame retardant and anti-dripping properties of polylactide. Polym. Degrad. Stab. 2010, 95, 763–770. [Google Scholar] [CrossRef]

- Li, Z.; Wei, P.; Yang, Y.; Yan, Y.; Shi, D. Synthesis of a hyperbranched poly (phosphamide ester) oligomer and its high-effective flame retardancy and accelerated nucleation effect in polylactide composites. Polym. Degrad. Stab. 2014, 110, 104–112. [Google Scholar] [CrossRef]

| PLA Type/Brand and Supplier | Main FR Component | FR Loading wt % | LOI% | UL94 | Cone Calorimetry Parameters (CCP) | TGA | Ref. | |

|---|---|---|---|---|---|---|---|---|

| PHRR Reduction % | T5% | Residue %/Max. T (°C) | ||||||

| PLA nonwoven fabric from Shenzhen Shengdefu Cellulon Co. Ltd., China. | cyclic phosphonate ester | - | 35 | - | 7 (A) | 207.2 | - | [46] |

| PLA (4032D) by Nature Works | Aluminum hypophosphite (AHP) | 30 | 29.5 | V-0 | 48.2 (C) | 332 | 22.4 | [47] |

| (700 °C), Air | ||||||||

| PLA (4032D) (Mw 206,583 g/mo) by Nature Works | phosphorus-containing polymer or oligomer | 13.32 | 23.0 | V-2 | 4.7 (C) | 415 | 40.9 | [48] |

| (700 °C), Air | ||||||||

| PLA from NatureWorks Ltd. | Organophophorus flame retardant | 30 | 32 | V-0 | - | 250 | 3.1 | [49] |

| (700 °C) | ||||||||

| N2 | ||||||||

| PLA (3052D) by Nature Works | Diphenolic biphosphate | 16 | 27.4 | V-0 | 19.62 (C) | 342 | 7.51 | [50] |

| (700 °C), Air | ||||||||

| PLA (2002D) by NatureWorks | Poly(ethylene glycol) (PEG), Ammonium polyphosphate, boron phosphate, and tri-phenyl phosphate | 32 | 32.4 | V-0 | - | 295 | 2.8 | [51] |

| (700 °C), Air | ||||||||

| PLA (4032D) by NatureWorks | Silicone rubber composites and ammonium polyphosphate | 20 | 29.2 | V-0 | 42.1(C) | 323 | 2.78 | [52] |

| (700 °C), Air | ||||||||

| PLA (2002D) by Natureworks | Tris(2-hydroxyethyl) isocyanurate polyphosphate melamine (TPM) | 25 | 36.5 | V-0 | 68 (C) | 265 | 30.6 | [53] |

| (700 °C), Air | ||||||||

| PLA (3052D) by NatureWorks | Chitosan with ammonium polyphosphate (APP) | 7 | 33.1 | V-0 | 17.4 (C) | - | 4.1 | [54] |

| (700 °C), Air | ||||||||

| PLA grade (6202D) by NatureWorks | Lignin and ammonium polyphosphate (AP) | 20 | - | V-0 | 32.3 (B) | 320 | 14.3 | [55] |

| (700 °C), Air | ||||||||

| Polylactide by NatureWorks | Charring agent (CNCA-DA) containing triazine and benzene rings and APP | 30 | 45.6 | V-0 | 10 (C) | 310 | 29.3 | [56] |

| (700 °C), Air | ||||||||

| PLA by NatureWorks | Lanthanum oxide (La2O3), Ammonium polyphosphate((APP), an Oligomeric charring agent with triazine (CNCA-DA) | 24 | 42.7 | V-0 | 27 (C) | 316 | 4.2 | [57] |

| (700 °C), Air | ||||||||

| PLA (2002D from Cargill,) | POSS-modified nanofibrillated cellulose (PNFC), Ammonium polyphosphate (APP) | 15 | - | - | 45 (C**) | - | - | [58] |

| PLA resin (4032D) by NatureWorks | Microencapsulated ammonium polyphosphate (APP) and melamine (2:1), Starch | 30 | 41 | V-0 | 76 (C) | 25 | 22.2 | [59] |

| (600 °C),Air | ||||||||

| PLA resin (3051D) by NatureWorks | Phosphorus modified lignin {kraft lignin (P-K), organsolv lignin (P-O) | P-K 20 | - | V-0 | 23 (C) | - | 15 | [60] |

| 13 | ||||||||

| P-O 20 | - | V-0 | 33 (C) | (700 °C) Air | ||||

| PLA from NatureWorks supplied by Cargill | Starch, lignin, ammonium polyphosphate | 40 | 32 | V-0 | 50 (C) | - | - | [9] |

| PLA resin (3051D) by NatureWorks | Phosphorus, Microcrystalline and nano-crystalline cellulose (P-MCC &P-NCC), aluminum phytate (Al-PA) | P-MCC 20, | - | V-0 | 8 (C*) | - | - | [61] |

| P-NCC 20 | V-2 | 35 (C*) | - | - | ||||

| Al-PA, P-MCC 20 | - | V-2 | 38 (C*) | - | - | |||

| PLA Type/Brand and Supplier | Main FR Chemical Component | Total FR Loading/(LDH) % | LOI% | UL-94 | Cone Calorimetry Parameters | TGA | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|

| PHRR Reduction % | TSR(m2/m2/Heat Flux (KWm2) | T-5% | Residue %/Max. T (°C) | ||||||

| PLA (3052D) by NatureWo-rks | Diethylenetriaminepenta-(methylenephosp-honic) acid with melamine, and phytic acid modified LDH | 15/(3) | 38.9 | V-0 | 63 (C) | 0.81 | 300 | 10.66 | [87] |

| (700 °C) | |||||||||

| 35 | N2 | ||||||||

| PLA (2002D) by Polymer UNIC Technology (Suzhou) Co., Ltd. | NiAl LDH, Silane coated APP, pentaerythritol phosphate (PEPA), Corn starch, Poly(butylene succinate) | 35/(2.5) | 30 | V-0 | 21 (C) | - | 315 | 17.3 | [88] |

| (700 °C) | |||||||||

| 35 | N2 | ||||||||

| PLA (REVODE201) from Hisun biomaterials Co., Ltd. (Zhejiang, China | NiAl-LDH modified 2-carboxylethyl-phenyl-phosphinic acid | 10/(10) | - | - | 37 (A) | - | - | - | [89] |

| 35 | |||||||||

| PLA (model 2002D) UNIC Technology Co., Ltd. | NiFe, NiAl, and NiCr LDH-SDS Hexaphenoxycycl-otriphosphazene (HPCP) | 10/(2) | 29 | V-0 | - | - | - | 7.2 | [86] |

| (700 °C) | |||||||||

| N2 | |||||||||

| PLA Biomer L9000 from Biomer, Krailling, Germany | Zn-Al-LDH, ammonium polyphosphate pentaerythritol and melamine cyanurate | 23/(2) | - | - | 59 (C) | - | - | - | [85] |

| 35 | |||||||||

| PLA (2003D) Nature-Works LLC | nano-clay, recycled bamboo chopstick fiber APP and expandable graphite (EG) | 27/(6) | - | V-0 | - | - | 377.8 | 21.88 | [90] |

| (850 °C) | |||||||||

| N2 | |||||||||

| PLA (4042D) Natureworks | Hydrogel-organoclay | 6/(3) | - | - | MCC | 17.1 | 325 | 3.66 | [91] |

| (800) | |||||||||

| 28 | N2 | ||||||||

| PLA, (Mw = 150,000) Tong-Jie-Liang Biomaterial Co. Ltd. | Organically modified montmorillonite (OMMT) and aluminium diethylphosphinate (AlPi) | 20/(5) | 28 | V-0 | 26.2 (C*) | - | 328 | 4.87 | [92] |

| (700 °C) | |||||||||

| 35 | N2 | ||||||||

| PLA, (Ingeo 3051D) from NatureWorks, USA | OMMT, isopropylated triaryl phosphate ester | 35/(5) | - | V-0 | - | - | 258.4 | 4.75 | [93] |

| (600) | |||||||||

| N2 | |||||||||

| PLA (2002D) by NatureWo-rks | OMMT, Aluminum trihydrate (ATH, H-42M grade) | 50/(5) | 42 | V-0 | 65 (c***) | - | 320 | - | [94] |

| (650) | |||||||||

| 50 | Air | ||||||||

| PLA, (4032D) by Nature Works | Alpha-zirconium phosphate (α-ZrP) | (10) | 26.5 | V-0 | 42 (C***) | - | 316 | 14.3 | [80] |

| (700 °C) | |||||||||

| 35 | N2 | ||||||||

| PLA, Galastic by Galactic S.A. | Organo-modified layered silicates (OMLS) | 43/(3) | - | - | 42 (C) | - | 354 | - | [95] |

| 35 | (600) Air | ||||||||

| PLA (Biopearls) from Jongboom Holding B.V (Netherlands) | Sepiolite nanoclay and multi-wall nanotubes (MCWNT) | 20/(10) | - | - | 58 (C*) | - | 336 | N2 | [96] |

| 13 | |||||||||

| (1000 °C), Air | |||||||||

| 35 | N2 | ||||||||

| PLA (4032D) by Nature-Works | Ionic liquid containing phosphonium and surface-functionalized graphene (GIL). | 6/(4) | - | - | 40 (C***) | - | 331.4 | 9 | [66] |

| (800 °C) | |||||||||

| 35 | N2 | ||||||||

| PLA Cargill Dow Inc. (America) | Tricobalt tetraoxide-functionalized graphene composites (CO3O4/graphene) | 1 | - | - | 40 (C**) | - | - | - | [69] |

| (700 °C) | |||||||||

| 35 | N2 | ||||||||

| PLA by Galactic S.A. | Poly(ethyleneglycol) 1000 (PEG 1000) and montmorillonite, organo-modified | 20/(3) | - | - | - | - | - | - | [74] |

| (600 °C) | |||||||||

| N2 | |||||||||

| PLA from Dow–Cargill, Inc. | Organomodified particles of clay, unmodified particles of clay, plasticizer—Poly(ethylene glycol) | 20/(3) | - | - | - | - | - | - | [76] |

| (600 °C) | |||||||||

| Air | |||||||||

| Tong-Jie-Liang Biomaterial Co. Ltd. (China) | Organically modified montmorillonite (O-MMT) | 20/(5) | 27.5 | V-0 | - | - | 277 | 24.9 | [77] |

| (700 °C) | |||||||||

| Air | |||||||||

| PLA Galastic, by Galactic S.A | Organomodified bentonite (Bentone® 104-B104) | 10 | - | - | 46 (B) | - | - | - | [78] |

| (600 °C) | |||||||||

| 35 | N2 | ||||||||

| PLA (4032D) NatureWorks | Expanded graphite and organically modified montmorillonite | 12/(3) | - | - | - | 352 | - | [79] | |

| (800 °C) | |||||||||

| N2 | |||||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tawiah, B.; Yu, B.; Fei, B. Advances in Flame Retardant Poly(Lactic Acid). Polymers 2018, 10, 876. https://doi.org/10.3390/polym10080876

Tawiah B, Yu B, Fei B. Advances in Flame Retardant Poly(Lactic Acid). Polymers. 2018; 10(8):876. https://doi.org/10.3390/polym10080876

Chicago/Turabian StyleTawiah, Benjamin, Bin Yu, and Bin Fei. 2018. "Advances in Flame Retardant Poly(Lactic Acid)" Polymers 10, no. 8: 876. https://doi.org/10.3390/polym10080876

APA StyleTawiah, B., Yu, B., & Fei, B. (2018). Advances in Flame Retardant Poly(Lactic Acid). Polymers, 10(8), 876. https://doi.org/10.3390/polym10080876