Assessment of Crystalline Materials for Solid State Lighting Applications: Beyond the Rare Earth Elements

Abstract

1. Introduction

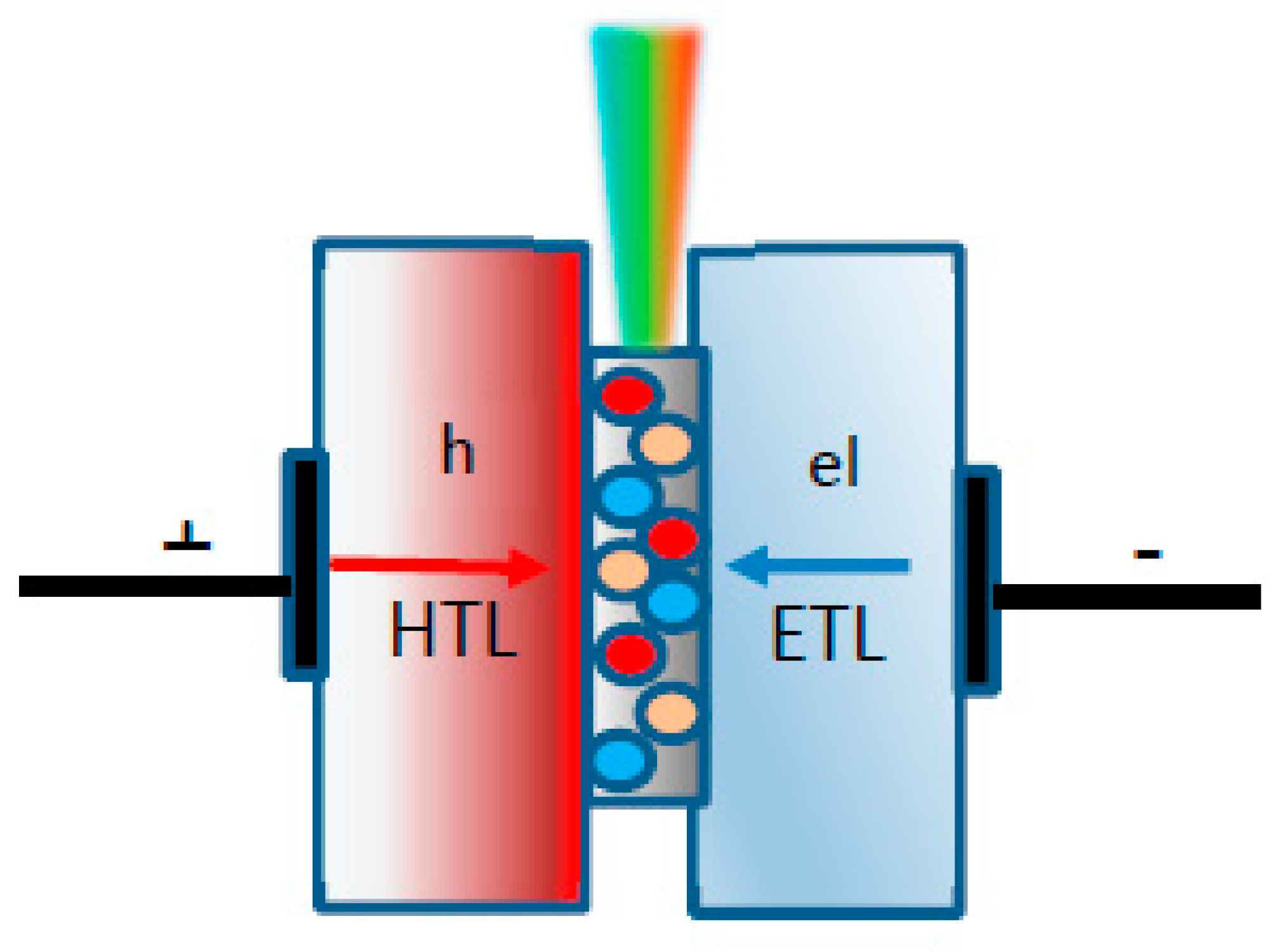

2. Session 1: The Electroluminescent Pumping Devices

3. Session 2: Properties of the Phosphor

4. Session 3: Rare-Earth-Based Phosphors

5. Session 4: Criticisms of Rare-Earth

6. Session 5: Beyond Rare-Earth Elements in White LED

7. Conclusions and Perspectives

Funding

Conflicts of Interest

References

- Cangeloso, S. LED Lighting: A Primer to Lighting the Future; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2012; ISBN 9781449334765. [Google Scholar]

- Humphreys, C.J. Solid-State Lighting. MRS Bull. 2008, 33, 459–470. [Google Scholar] [CrossRef]

- Zissis, G. Energy Consumption and Environmental and Economic Impact of Lighting: The Current Situation. In Handbook of Advanced Lighting Technology; Springer Science and Business Media LLC: Berlin, Germany, 2016; pp. 1–13. [Google Scholar]

- Withnall, R.; Silver, J. Physics of Light Emission from Rare-Earth Doped Phosphors. In Handbook of Visual Display Technology; Springer Science and Business Media LLC: Berlin, Germany, 2012; pp. 1019–1028. [Google Scholar]

- Ganguli, R.; Cook, U.R. Rare earths: A review of the landscape. MRS Energy Sustain. 2018, 5, 5. [Google Scholar] [CrossRef]

- Janotti, A.; Van De Walle, C.G. Fundamentals of zinc oxide as a semiconductor. Rep. Prog. Phys. 2009, 72, 126501. [Google Scholar] [CrossRef]

- Lima, S.; Cremona, M.; Davolos, M.R.; Legnani, C.; Quirino, W. Electroluminescence of zinc oxide thin-films prepared via polymeric precursor and via sol–gel methods. Thin Solid Films 2007, 516, 165–169. [Google Scholar] [CrossRef]

- Rahman, F. Zinc oxide light-emitting diodes: A review. Opt. Eng. 2019, 58, 010901. [Google Scholar] [CrossRef]

- Fan, J.; Sreekanth, K.; Xie, Z.; Chang, S.; Rao, K.V. p-Type ZnO materials: Theory, growth, properties and devices. Prog. Mater. Sci. 2013, 58, 874–985. [Google Scholar] [CrossRef]

- Baltakesmez, A.; Tekmen, S.; Köç, P.; Tüzemen, S.; Meral, K.; Onganer, Y. UV-visible detector and LED based n-ZnO/p-Si heterojunction formed by electrodeposition. AIP Adv. 2013, 3, 032125. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Xu, H.; Liu, W.; Zhang, C.; Wang, C.; Wang, Z.; Ma, J.; Liu, Y. Color-Tunable ZnO/GaN Heterojunction LEDs Achieved by Coupling with Ag Nanowire Surface Plasmons. ACS Appl. Mater. Interfaces 2018, 10, 15812–15819. [Google Scholar] [CrossRef]

- Ding, M.; Guo, Z.; Zhou, L.; Fang, X.; Zhang, L.; Zeng, L.; Xie, L.; Zhao, H. One-Dimensional Zinc Oxide Nanomaterials for Application in High-Performance Advanced Optoelectronic Devices. Crystals 2018, 8, 223. [Google Scholar] [CrossRef]

- Ohta, H.; Orita, M.; Hirano, M.; Hosono, H. Fabrication and characterization of ultraviolet-emitting diodes composed of transparent p-n heterojunction, p-SrCu2O2 and n-ZnO. J. Appl. Phys. 2001, 89, 5720–5725. [Google Scholar] [CrossRef]

- Deng, R.; Yao, B.; Li, Y.; Xu, Y.; Li, J.; Li, B.; Zhang, Z.; Zhang, L.; Zhao, H.; Shen, D. Ultraviolet electroluminescence from n-ZnO/p-NiO heterojunction light-emitting diode. J. Lumin. 2013, 134, 240–243. [Google Scholar] [CrossRef]

- Schrier, J.; Demchenko, D.O.; Wang, L.-W.; Alivisatos, A.P.; Wang, L.-Y.; Alivisatos, A.P. Optical Properties of ZnO/ZnS and ZnO/ZnTe Heterostructures for Photovoltaic Applications. Nano Lett. 2007, 7, 2377–2382. [Google Scholar] [CrossRef] [PubMed]

- Ievskaya, Y.; Hoye, R.L.Z.; Sadhanala, A.; Musselman, K.; MacManus-Driscoll, J. Fabrication of ZnO/Cu2O heterojunctions in atmospheric conditions: Improved interface quality and solar cell performance. Sol. Energy Mater. Sol. Cells 2015, 135, 43–48. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, J.; Zhang, B.; Du, G.; Xia, X.; Yin, W.; Zhang, S.; Wang, H.; Zhao, L.; Dong, X. Dominant ultraviolet electroluminescence from p-ZnO:As/n-SiC(6H) heterojunction light-emitting diodes. Appl. Phys. Lett. 2012, 100, 101112. [Google Scholar] [CrossRef]

- Ohta, H.; Mizoguchi, H.; Hirano, M.; Narushima, S.; Kamiya, T.; Hosono, H. Fabrication and characterization of heteroepitaxial p-n junction diode composed of wide-gap oxide semiconductors p-ZnRh2O4/n-ZnO. Appl. Phys. Lett. 2003, 82, 823–825. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, D.; Geng, H. Heterojunctions Based on II-VI Compound Semiconductor One-Dimensional Nanostructures and Their Optoelectronic Applications. Crystals 2017, 7, 307. [Google Scholar] [CrossRef]

- Gao, Z.; Lu, L.; Xue, X.; Li, J.; Zhao, L.; Ahmad, D.; Li, H. Comparative Study of ZnO Nanostructures Grown on Variously Orientated GaN and AlxGa1−xN: The Role of Polarization, and Surface Pits. Crystals 2019, 9, 663. [Google Scholar] [CrossRef]

- Borysiewicz, M.A. ZnO as a Functional Material, a Review. Crystals 2019, 9, 505. [Google Scholar] [CrossRef]

- Katayama, K.; Matsubara, H.; Nakanishi, F.; Nakamura, T.; Doi, H.; Saegusa, A.; Mitsui, T.; Matsuoka, T.; Irikura, M.; Takebe, T.; et al. ZnSe-based white LEDs. J. Cryst. Growth 2000, 214, 1064–1070. [Google Scholar] [CrossRef]

- Fuchs, F.; Soltamov, V.A.; Väth, S.; Baranov, P.G.; Mokhov, E.N.; Astakhov, G.V.; Dyakonov, V. Silicon carbide light-emitting diode as a prospective room temperature source for single photons. Sci. Rep. 2013, 3, 1637. [Google Scholar] [CrossRef]

- Lin, K.; Xing, J.; Na Quan, L.; De Arquer, F.P.G.; Gong, X.; Lu, J.; Xie, L.; Zhao, W.; Zhang, D.; Yan, C.; et al. Perovskite light-emitting diodes with external quantum efficiency exceeding 20 per cent. Nature 2018, 562, 245–248. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.-K.; Liu, Q.; Yang, D.-W.; Liang, Y.-C.; Sui, L.-Z.; Wei, J.-Y.; Xue, G.-W.; Zhao, W.-B.; Wu, X.-Y.; Dong, L.; et al. Water-induced MAPbBr3@PbBr(OH) with enhanced luminescence and stability. Light Sci. Appl. 2020, 9, 44. [Google Scholar] [CrossRef] [PubMed]

- Luo, D.; Chen, Q.; Qiu, Y.; Zhang, M.; Liu, B. Device Engineering for All-Inorganic Perovskite Light-Emitting Diodes. Nanomaterials 2019, 9, 1007. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.-C.; Tien, C.-H.; Tseng, Z.-L.; Dong, Y.-S.; Yang, S. Influence of PMMA on All-Inorganic Halide Perovskite CsPbBr3; Quantum Dots Combined with Polymer Matrix. Materials 2019, 12, 985. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Li, Z.; Kong, L.; Zhu, N.; Shan, A.; Li, L. Enhancing the Stability of CH3NH3PbBr3 Quantum Dots by Embedding in Silica Spheres Derived from Tetramethyl Orthosilicate in “Waterless” Toluene. J. Am. Chem. Soc. 2016, 138, 5749–5752. [Google Scholar] [CrossRef] [PubMed]

- Kim, A.; Lee, H.; Kwon, H.-C.; Jung, H.S.; Park, N.-G.; Jeong, S.; Moon, J. Fully solution-processed transparent electrodes based on silver nanowire composites for perovskite solar cells. Nanoscale 2016, 8, 6308–6316. [Google Scholar] [CrossRef]

- Cheng, G.; Liu, Y.; Chen, T.; Chen, W.; Fang, Z.; Zhang, J.; Ding, L.; Li, X.; Shi, T.; Xiao, Z. Efficient All-Inorganic Perovskite Light-Emitting Diodes with Improved Operation Stability. ACS Appl. Mater. Interfaces 2020, 12, 18084–18090. [Google Scholar] [CrossRef]

- Smet, P.F.; Parmentier, A.B.; Poelman, D. Selecting Conversion Phosphors for White Light-Emitting Diodes. J. Electrochem. Soc. 2011, 158, R37. [Google Scholar] [CrossRef]

- Choudhury, A.K.R. Principles of Colour and Appearance Measurement; Elsevier: Amsterdam, The Netherlands, 2014; Volume 2, ISBN 9781782423881. [Google Scholar]

- Guo, X.; Houser, K. A review of colour rendering indices and their application to commercial light sources. Light Res. Technol. 2004, 36, 183–197. [Google Scholar] [CrossRef]

- Lisitsyn, V.; Tulegenova, A.; Polisadova, E.; Lipatov, E.; Vaganov, V.; Lisitsyna, L.; Ju, Y. Nanodefects in YAG:Ce-Based Phosphor Microcrystals. Crystals 2019, 9, 476. [Google Scholar] [CrossRef]

- Ricci, P.C.; Salis, M.; Corpino, R.; Carbonaro, C.M.; Fortin, E.; Anedda, A. A kinetics model for Tb3+ recombinations in low doped Tb: Lu1.8Y0.2SiO5 crystals. J. Appl. Phys. 2010, 108, 043512. [Google Scholar] [CrossRef]

- Li, J.; Tang, Y.; Tang, Y.; Ding, X.; Yuan, D.; Yu, B. Study on Scattering and Absorption Properties of Quantum-Dot-Converted Elements for Light-Emitting Diodes Using Finite-Difference Time-Domain Method. Materials 2017, 10, 1264. [Google Scholar] [CrossRef] [PubMed]

- Armetta, F.; Saladino, M.L.; Giordano, C.; Defilippi, C.; Marciniak, L.; Hreniak, D.; Caponetti, E. Non-conventional Ce:YAG nanostructures via urea complexes. Sci. Rep. 2019, 9, 3368. [Google Scholar] [CrossRef] [PubMed]

- Gang, S.-R.; Kim, D.; Kim, S.-M.; Hwang, N.; Lee, K.-C. Improvement in the moisture stability of CaS:Eu phosphor applied in light-emitting diodes by titania surface coating. Microelectron. Reliab. 2012, 52, 2174–2179. [Google Scholar] [CrossRef]

- Xia, Q.; Batentschuk, M.; Osvet, A.; Winnacker, A.; Schneider, J. Quantum yield of Eu2+ emission in (Ca1−xSrx)S:Eu light emitting diode converter at 20–420 K. Radiat. Meas. 2010, 45, 350–352. [Google Scholar] [CrossRef]

- Lempicki, A.; Berman, E.; Wojtowicz, A.; Balcerzyk, M.; Boatner, L.A. Cerium-doped orthophosphates: New promising scintillators. IEEE Trans. Nucl. Sci. 1993, 40, 384–387. [Google Scholar] [CrossRef]

- Rooh, G.; Kim, H.J.; Park, H.; Kim, S.; Jiang, H. Cerium-Doped Cs2NaGdCl6Cs2NaGdCl6 Scintillator for X-Ray and γ-Ray Detection. IEEE Trans. Nucl. Sci. 2013, 61, 397–401. [Google Scholar] [CrossRef]

- Ricci, P.C.; Carbonaro, C.M.; Casu, A.; Cannas, C.; Corpino, R.; Stagi, L.; Anedda, A. Optical and structural characterization of cerium doped LYSO sol–gel polycrystal films: Potential application as scintillator panel for X-ray imaging. J. Mater. Chem. 2011, 21, 7771. [Google Scholar] [CrossRef][Green Version]

- Baccaro, S.; Blaẑek, K.; De Notaristefani, F.; Maly, P.; Mares, J.; Pani, R.; Pellegrini, R.; Soluri, A. Scintillation properties of YAP:Ce. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 1995, 361, 209–215. [Google Scholar] [CrossRef]

- Chiriu, D.; Stagi, L.; Ricci, P.C.; Corpino, R.; Ricci, P.C. Energy transfer mechanism between Ce and Tb ions in sol–gel synthesized YSO crystals. Mater. Chem. Phys. 2016, 171, 201–207. [Google Scholar] [CrossRef]

- Thomas, K.; Alexander, D.; Sisira, S.; Gopi, S.; Biju, P.; Unnikrishnan, N.V.; Joseph, C. Energy transfer driven tunable emission of Tb/Eu co-doped lanthanum molybdate nanophosphors. Opt. Mater. 2018, 80, 37–46. [Google Scholar] [CrossRef]

- Chiriu, D.; Stagi, L.; Carbonaro, C.; Corpino, R.; Casula, M.; Ricci, P.C. Towards the development of new phosphors with reduced content of rare earth elements: Structural and optical characterization of Ce:Tb: Al2SiO5. Mater. Res. Bull. 2016, 77, 15–22. [Google Scholar] [CrossRef]

- Silveira, W.S.; Nascimento, P.A.; Silva, A.J.; Rezende, M.V.S. Luminescent properties and energy transfer mechanism from Tb3+ to Eu3+ doped in Y3Al5O12 phosphors. J. Alloy. Compd. 2020, 822, 153651. [Google Scholar] [CrossRef]

- Wojtowicz, A. Physics of Solid-State Laser Materials. Acta Phys. Pol. A 1991, 80, 193–205. [Google Scholar] [CrossRef]

- Tucureanu, V.; Matei, A.; Mihalache, I.; Danila, M.; Popescu, M.C.; Bita, B. Synthesis and characterization of YAG:Ce,Gd and YAG:Ce,Gd/PMMA nanocomposites for optoelectronic applications. J. Mater. Sci. 2014, 50, 1883–1890. [Google Scholar] [CrossRef]

- Anedda, A.; Carbonaro, C.; Chiriu, D.; Ricci, P.C.; Aburish-Hmidat, M.; Guerini, M.; Lorrai, P.; Fortin, E. Compositional Tuning of Photoluminescence Properties in Nd-Doped YAG–YSGG Mixed Structures. IEEE J. Quantum Electron. 2006, 42, 563–569. [Google Scholar] [CrossRef]

- Shang, M.; Fan, J.; Lian, H.; Zhang, Y.; Geng, D.; Lin, J. A Double Substitution of Mg2+–Si4+/Ge4+ for Al(1)3+–Al(2)3+ in Ce3+-Doped Garnet Phosphor for White LEDs. Inorg. Chem. 2014, 53, 7748–7755. [Google Scholar] [CrossRef]

- Xia, Q.; Batentschuk, M.; Osvet, A.; Richter, P.R.; Häder, D.-P.; Schneider, J.; Wondraczek, L.; Winnacker, A.; Brabec, C.J. Red-emitting Ca1−xSrxS:Eu2+ Phosphors as Light Converters for Plant-growth Applications. In Proceedings of the Materials Research Society Symposium, Boston, MA, USA, 28 November–2 December 2011; Cambridge University Press (CUP): Cambridge, UK, 2011; Volume 1342, pp. 67–72. [Google Scholar]

- Cho, Y.-S.; Huh, Y.-D. Cathodoluminescence Properties of Red-Emitting Sr1−xCaxS:Eu Phosphors. Bull. Korean Chem. Soc. 2016, 37, 991–996. [Google Scholar] [CrossRef]

- Piao, X.; Horikawa, T.; Hanzawa, H.; Machida, K.-I. Characterization and luminescence properties of Sr2Si5N8:Eu2+ phosphor for white light-emitting-diode illumination. Appl. Phys. Lett. 2006, 88, 161908. [Google Scholar] [CrossRef]

- Hoerder, G.J.; Seibald, M.; Baumann, D.; Schröder, T.; Peschke, S.; Schmid, P.C.; Tyborski, T.; Pust, P.; Stoll, I.; Bergler, M.; et al. Sr[Li2Al2O2N2]:Eu2+-A high performance red phosphor to brighten the future. Nat. Commun. 2019, 10, 1824. [Google Scholar] [CrossRef]

- Sijbom, H.F.; Verstraete, R.; Joos, J.J.; Poelman, D.; Smet, P.F. K2SiF6:Mn4+ as a red phosphor for displays and warm-white LEDs: A review of properties and perspectives. Opt. Mater. Express 2017, 7, 3332. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, L.; Zhou, T.; Sun, B.; Wang, Y.; Kang, J.; Gao, P.; Huang, J.; Selim, F.A.; Wong, C.-P.; et al. High recorded color rendering index in single Ce,(Pr,Mn):YAG transparent ceramics for high-power white LEDs/LDs. J. Mater. Chem. C 2020, 8, 4329–4337. [Google Scholar] [CrossRef]

- Pust, P.; Weiler, V.; Hecht, C.; Tücks, A.; Wochnik, A.S.; Henß, A.-K.; Wiechert, D.; Scheu, C.; Schmidt, P.J.; Schnick, W. Narrow-band red-emitting Sr[LiAl3N4]:Eu2+ as a next-generation LED-phosphor material. Nat. Mater. 2014, 13, 891–896. [Google Scholar] [CrossRef]

- Lee, B.; Lee, S.; Jeong, H.G.; Sohn, K.-S. Solid-State Combinatorial Screening of (Sr,Ca,Ba,Mg)2Si5N8:Eu2+ Phosphors. ACS Comb. Sci. 2011, 13, 154–158. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Lin, C.-C.; Yeh, C.-W.; Liu, R.-S. Light Converting Inorganic Phosphors for White Light-Emitting Diodes. Materials 2010, 3, 2172–2195. [Google Scholar] [CrossRef]

- Lakshmanan, A. Luminescence and Display Phosphors: Phenomena and Applications; Nova Publishers: Hauppauge, NY, USA, 2008; ISBN 9781614701972. [Google Scholar]

- Leano, J.L., Jr.; Fang, M.-H.; Liu, R.-S. Critical Review—Narrow-Band Emission of Nitride Phosphors for Light-Emitting Diodes: Perspectives and Opportunities. ECS J. Solid State Sci. Technol. 2017, 7, R3111–R3133. [Google Scholar] [CrossRef]

- Xie, R.-J.; Hirosaki, N.; Li, Y.; Takeda, T. Rare-Earth Activated Nitride Phosphors: Synthesis, Luminescence and Applications. Materials 2010, 3, 3777–3793. [Google Scholar] [CrossRef]

- Huang, C.-H.; Chen, T.-M. Ca9La(PO4)7:Eu2+,Mn2+: An emission-tunable phosphor through efficient energy transfer for white light-emitting diodes. Opt. Express 2010, 18, 5089–5099. [Google Scholar] [CrossRef]

- Li, K.; Shang, M.; Geng, D.; Lian, H.; Zhang, Y.; Fan, J.; Lin, J. Synthesis, Luminescence, and Energy-Transfer Properties of β-Na2Ca4(PO4)2(SiO4):A (A = Eu2+, Dy3+, Ce3+/Tb3+) Phosphors. Inorg. Chem. 2014, 53, 6743–6751. [Google Scholar] [CrossRef]

- Liang, J.; Devakumar, B.; Sun, L.; Wang, S.; Sun, Q.; Huang, X.; Balaji, D. Full-visible-spectrum lighting enabled by an excellent cyan-emitting garnet phosphor. J. Mater. Chem. C 2020, 8, 4934–4943. [Google Scholar] [CrossRef]

- Dewulf, J.; De Matos, C.T.; Baranzelli, C.; Ciupagea, C.; Dias, P.; Kayam, Y.; Pavel, C.; Peirò, L.T.; Tzimas, E.; Vidal-legaz, B.; et al. Methodology for establishing the EU list of Critical Raw Materials. Publ. Off. Eur. Union 2017, 1–25. [Google Scholar] [CrossRef]

- Filho, W.L. An Analysis of the Environmental Impacts of the Exploitation of Rare Earth Metals. In Rare Earths Industry; Elsevier BV: Amsterdam, The Netherlands, 2016; pp. 269–277. [Google Scholar]

- Ali, S. Social and Environmental Impact of the Rare Earth Industries. Resources 2014, 3, 123–134. [Google Scholar] [CrossRef]

- Jowitt, S.M.; Werner, T.T.; Weng, Z.; Mudd, G.M. Recycling of the rare earth elements. Curr. Opin. Green Sustain. Chem. 2018, 13, 1–7. [Google Scholar] [CrossRef]

- Ricci, P.C.; Murgia, M.; Ricci, P.C.; Sgariotto, S.; Stagi, L.; Corpino, R.; Chiriu, D.; Grilli, M.L. New life of recycled rare earth-oxides powders for lighting applications. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 329, p. 012002. [Google Scholar]

- Bae, W.K.; Lim, J.; Lee, N.; Park, M.; Lee, H.; Kwak, J.; Char, K.; Lee, C.; Lee, S. R/G/B/Natural White Light Thin Colloidal Quantum Dot-Based Light-Emitting Devices. Adv. Mater. 2014, 26, 6387–6393. [Google Scholar] [CrossRef]

- Lee, K.-H.; Han, C.-Y.; Kang, H.-D.; Ko, H.; Lee, C.; Lee, J.; Myoung, N.; Yim, S.-Y.; Yang, H. Highly Efficient, Color-Reproducible Full-Color Electroluminescent Devices Based on Red/Green/Blue Quantum Dot-Mixed Multilayer. ACS Nano 2015, 9, 10941–10949. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Su, Q.; Chen, S. Recent progress in the device architecture of white quantum-dot light-emitting diodes. J. Inf. Disp. 2019, 20, 169–180. [Google Scholar] [CrossRef]

- Sadeghi, S.; Kumar, B.G.; Melikov, R.; Aria, M.M.; Jalali, H.B.; Nizamoglu, S. Quantum dot white LEDs with high luminous efficiency. Optics 2018, 5, 793–802. [Google Scholar] [CrossRef]

- Kim, H.; Lee, W.; Moon, H.; Kim, S.J.; Chung, H.K.; Chae, H. Interlayer doping with p-type dopant for charge balance in indium phosphide (InP)-based quantum dot light-emitting diodes. Opt. Express 2019, 27, A1287–A1296. [Google Scholar] [CrossRef]

- Lim, J.; Park, M.; Bae, W.K.; Lee, N.; Lee, S.; Lee, C.; Char, K. Highly Efficient Cadmium-Free Quantum Dot Light-Emitting Diodes Enabled by the Direct Formation of Excitons within InP@ZnSeS Quantum Dots. ACS Nano 2013, 7, 9019–9026. [Google Scholar] [CrossRef]

- Mura, S.; Ludmerczki, R.; Stagi, L.; Garroni, S.; Carbonaro, C.M.; Ricci, P.C.; Casula, M.F.; Malfatti, L.; Innocenzi, P. Integrating sol-gel and carbon dots chemistry for the fabrication of fluorescent hybrid organic-inorganic films. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Carbonaro, C.M.; Chiriu, D.; Stagi, L.; Casula, M.F.; Thakkar, S.V.; Malfatti, L.; Suzuki, K.; Ricci, P.C.; Corpino, R. Carbon Dots in Water and Mesoporous Matrix: Chasing the Origin of their Photoluminescence. J. Phys. Chem. C 2018, 122, 25638–25650. [Google Scholar] [CrossRef]

- Zholobak, N.; Popov, A.; Shcherbakov, A.B.; Popova, N.R.; Guzyk, M.M.; Антoнoвич, В.; Yegorova, A.V.; Scrypynets, Y.V.; Leonenko, I.; Baranchikov, A.; et al. Facile fabrication of luminescent organic dots by thermolysis of citric acid in urea melt, and their use for cell staining and polyelectrolyte microcapsule labelling. Beilstein J. Nanotechnol. 2016, 7, 1905–1917. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Wei, M.; Zheng, Z.; Huang, X.; Song, X.; Qiu, S.; Yang, X.; Liu, X.; Qiu, J.; Dong, G. Full-Color Chemically Modulated g-C3N4 for White-Light-Emitting Device. Adv. Opt. Mater. 2019, 7, 1–11. [Google Scholar] [CrossRef]

- Bledowski, M.; Wang, L.; Ramakrishnan, A.; Khavryuchenko, O.V.; Khavryuchenko, V.D.; Ricci, P.C.; Strunk, J.; Cremer, T.; Kolbeck, C.; Beranek, R. Visible-light photocurrent response of TiO2–polyheptazine hybrids: Evidence for interfacial charge-transfer absorption. Phys. Chem. Chem. Phys. 2011, 13, 21511–21519. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Liao, C.-Z.; Kong, L.; Wu, D.; Liu, Y.; Lee, P.-H.; Shih, K. Facile synthesis of highly reactive and stable Fe-doped g-C3N4 composites for peroxymonosulfate activation: A novel nonradical oxidation process. J. Hazard. Mater. 2018, 354, 63–71. [Google Scholar] [CrossRef]

- Sun, J.; Phatake, R.; Azoulay, A.; Peng, G.; Han, C.; Barrio, J.; Xu, J.; Wang, X.; Shalom, M. Covalent Functionalization of Carbon Nitride Frameworks through Cross-Coupling Reactions. Chem. A Eur. J. 2018, 24, 14921–14927. [Google Scholar] [CrossRef]

- Thorat, N.; Yadav, A.; Yadav, M.; Gupta, S.; Varma, R.; Pillai, S.; Fernandes, R.; Patel, M.; Patel, N. Ag loaded B-doped-g C3N4 nanosheet with efficient properties for photocatalysis. J. Environ. Manag. 2019, 247, 57–66. [Google Scholar] [CrossRef]

- Wang, X.; Chen, X.; Thomas, A.; Fu, X.; Antonietti, M. Metal-Containing Carbon Nitride Compounds: A New Functional Organic-Metal Hybrid Material. Adv. Mater. 2009, 21, 1609–1612. [Google Scholar] [CrossRef]

- Montoya, A.T.; Gillan, E.G. Photocatalytic Carbon Nitride Materials with Nanoscale Features Synthesized from the Rapid and Low-Temperature Decomposition of Trichloromelamine. ACS Appl. Nano Mater. 2018, 1, 5944–5956. [Google Scholar] [CrossRef]

- Stagi, L.; Chiriu, D.; Ricci, P.C.; Corpino, R.; Ricci, P.C. Structural and optical properties of carbon nitride polymorphs. Diam. Relat. Mater. 2016, 68, 84–92. [Google Scholar] [CrossRef]

- Porcu, S.; Roppolo, I.; Salaun, M.; Sarais, G.; Barbarossa, S.; Casula, M.F.; Carbonaro, C.M.; Ricci, P.C. Come to light: Detailed analysis of thermally treated Phenyl modified Carbon Nitride Polymorphs for bright phosphors in lighting applications. Appl. Surf. Sci. 2020, 504, 144330. [Google Scholar] [CrossRef]

- Wang, Y.; He, J.; Chen, H.; Chen, J.; Zhu, R.; Ma, P.; Towers, A.; Lin, Y.; Gesquiere, A.J.; Wu, S.-T.; et al. Ultrastable, Highly Luminescent Organic-Inorganic Perovskite-Polymer Composite Films. Adv. Mater. 2016, 28, 10710–10717. [Google Scholar] [CrossRef] [PubMed]

- Luridiana, A.; Pretta, G.; Chiriu, D.; Ricci, P.C.; Corpino, R.; Secci, F.; Frongia, A.; Stagi, L.; Ricci, P.C. A facile strategy for new organic white LED hybrid devices: Design, features and engineering. RSC Adv. 2016, 6, 22111–22120. [Google Scholar] [CrossRef]

- Ricci, P.C.; Laidani, N.; Chiriu, D.; Salis, M.; Carbonaro, C.; Corpino, R. ALD growth of metal oxide on carbon nitride polymorphs. Appl. Surf. Sci. 2018, 456, 83–94. [Google Scholar] [CrossRef]

- Qiao, Y.; Li, W.; Bao, J.; Zheng, Y.; Feng, L.; Ma, Y.; Yang, K.; Wu, A.; Bai, H.; Yang, Y. Controlled synthesis and luminescence properties of core-shell-shell structured SiO2@AIPA-S-Si-Eu@SiO2 and SiO2@AIPA-S-Si-Eu-phen@SiO2 nanocomposites. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Sosa, J.D.; Bennett, T.F.; Nelms, K.; Liu, B.; Tovar, R.C.; Liu, Y. Metal–Organic Framework Hybrid Materials and Their Applications. Crystals 2018, 8, 325. [Google Scholar] [CrossRef]

- Jang, S.; Song, S.; Lim, J.H.; Kim, H.S.; Phan, B.T.; Ha, K.-T.; Park, S.; Park, K.H. Application of Various Metal-Organic Frameworks (MOFs) as Catalysts for Air and Water Pollution Environmental Remediation. Catalysis 2020, 10, 195. [Google Scholar] [CrossRef]

- Yu, X.; Wang, L.; Cohen, S. Photocatalytic metal–organic frameworks for organic transformations. Cryst. Eng. Comm. 2017, 19, 4126–4136. [Google Scholar] [CrossRef]

- Mendiratta, S.; Lee, C.-H.; Lee, S.-Y.; Kao, Y.-C.; Chang, B.-C.; Lo, Y.-H.; Lu, K.-L. Structural Characteristics and Non-Linear Optical Behaviour of a 2-Hydroxynicotinate-Containing Zinc-Based Metal-Organic Framework. Molcules 2015, 20, 8941–8951. [Google Scholar] [CrossRef] [PubMed]

- Zhan, X.-Q.; Yu, X.-Y.; Tsai, F.-C.; Ma, N.; Liu, H.-L.; Han, Y.; Xie, L.; Jiang, T.; Shi, D.; Xiong, Y. Magnetic MOF for AO7 Removal and Targeted Delivery. Crystals 2018, 8, 250. [Google Scholar] [CrossRef]

- Cho, Y.J.; Yook, K.S.; Lee, J.Y. Cool and warm hybrid white organic light-emitting diode with blue delayed fluorescent emitter both as blue emitter and triplet host. Sci. Rep. 2015, 5, 7859. [Google Scholar] [CrossRef] [PubMed]

- Mondal, T.; Mondal, S.; Bose, S.; Sengupta, D.; Ghorai, U.K.; Saha, S.K. Pure white light emission from a rare earth-free intrinsic metal–organic framework and its application in a WLED. J. Mater. Chem. C 2018, 6, 614–621. [Google Scholar] [CrossRef]

- He, H.; Sun, F.; Borjigin, T.; Zhao, N.; Zhu, G. Tunable colors and white-light emission based on a microporous luminescent Zn(ii)-MOF. Dalton Trans. 2014, 43, 3716. [Google Scholar] [CrossRef]

- Cui, Y.; Song, T.; Yu, J.; Yang, Y.; Wang, Z.; Qian, G. Dye Encapsulated Metal-Organic Framework for Warm-White LED with High Color-Rendering Index. Adv. Funct. Mater. 2015, 25, 4796–4802. [Google Scholar] [CrossRef]

- Xuan, W.; Zhu, C.; Liu, Y.; Cui, Y. Mesoporous metal–organic framework materials. Chem. Soc. Rev. 2012, 41, 1677–1695. [Google Scholar] [CrossRef]

- Sun, C.-Y.; Wang, X.-L.; Zhang, X.; Qin, C.; Li, P.; Su, Z.; Zhu, N.-X.; Shan, G.-G.; Shao, K.-Z.; Wu, H.; et al. Efficient and tunable white-light emission of metal–organic frameworks by iridium-complex encapsulation. Nat. Commun. 2013, 4, 2717. [Google Scholar] [CrossRef] [PubMed]

| Semiconductor Material | Emission Wavelength (nm) |

|---|---|

| GaAs | 850–940 |

| GaAsP | 630–660 |

| GaAsP | 605–620 |

| GaAsP:N | 585–595 |

| AlGaP | 550–570 |

| SiC | 430–505 |

| GaInN | 430–460 |

| 2017 Critical Raw Materials List | |||

|---|---|---|---|

| Antimony | Fluorspar | LREEs | Phsphorus |

| Baryte | Gallium | Magnesium | Scandium |

| Beryllium | Germanium | Natural graphite | Silicon metal |

| Bismuth | Hafnium | Natural rubber | Tantalum |

| Borate | Helium | Niobium | Tungsten |

| Cobalt | HREEs | PGMs | Vanadium |

| Coking coal | Indium | Phosphate rock | - |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricci, P.C. Assessment of Crystalline Materials for Solid State Lighting Applications: Beyond the Rare Earth Elements. Crystals 2020, 10, 559. https://doi.org/10.3390/cryst10070559

Ricci PC. Assessment of Crystalline Materials for Solid State Lighting Applications: Beyond the Rare Earth Elements. Crystals. 2020; 10(7):559. https://doi.org/10.3390/cryst10070559

Chicago/Turabian StyleRicci, Pier Carlo. 2020. "Assessment of Crystalline Materials for Solid State Lighting Applications: Beyond the Rare Earth Elements" Crystals 10, no. 7: 559. https://doi.org/10.3390/cryst10070559

APA StyleRicci, P. C. (2020). Assessment of Crystalline Materials for Solid State Lighting Applications: Beyond the Rare Earth Elements. Crystals, 10(7), 559. https://doi.org/10.3390/cryst10070559