Abstract

The effect of heating method employed for drying and calcination during the synthesis of 1 wt% Pt/Al2O3 catalyst was investigated. Conventional heating (CH) in resistive oven and microwave heating (MW) in single mode were applied, and the Pt dispersion and Brunauer-Emmett-Teller (BET) surface area were measured to characterize the samples. It was evidenced that the fast and homogeneous heating offered by the microwave heating led to higher Pt dispersion. However, this benefit was only achieved when the subsequent calcination was performed in a conventional oven. The aging in microwave oven of conventionally prepared—as well as MW-prepared—catalysts demonstrated the great ability of microwave irradiation to accelerate platinum sintering. After 1 h at 800 °C under microwave, catalysts showed a dispersion of 5%. Therefore, microwave treatment should be considered for accelerated catalyst aging but should be avoided as a calcination technique for the synthesis of highly dispersed Pt/Al2O3.

1. Introduction

A common method to prepare supported noble metal catalyst is wet impregnation. It consists in impregnating a porous metal oxide, with a high surface area, with a solution of noble metal precursor. The solvent is then evaporated by a slow drying step while the remaining compounds from the metal complex are decomposed by high temperature calcination. These two steps are crucial for the resulting metal distribution and metal particle size. Drying is a complex process in which the solvent is transferred from the pores to the liquid-gas interface, where it evaporates. The diffusion of solvent from the inside to the outside of the support particle induces the transport of the dissolved metal towards the exterior of the support particles, where it becomes more concentrated, especially when the metal adsorption on the support is weak [1,2]. If the metal cannot diffuse back inward in the last stage of the drying process, the formation of larger particles located within the outer layer of the catalyst particle in a “egg-white” or “egg-shell” configuration occurs. Exposure to high temperature during calcination brings about metallic particles mobility and coalescence, which also results in the formation of large particles. To control the metal deposition uniformity and the metal particle size it is necessary to limit the transport phenomena observed during drying in a conventional furnace based on resistive heating, also called Joule heating. With this aim, other ways of drying impregnated catalysts have been used such as spray drying [3] and freeze-drying [4,5], yielding high initial dispersion. The specificity of microwave heating is its homogeneity. It has been shown that microwave drying leads to a more uniform distribution of metal particles than regular oven drying in the case of Ni/Al2O3 catalyst [2,6,7]. These results were explained by the unique volumetric heating provided by microwaves. Microwave heating is also appreciated in zeolite synthesis [8,9,10,11] due to shorter time required, energy saving and narrower particle size distribution. In ceramics science, microwave (MW) sintering can lead to higher material density at lower temperature or after a shorter time than conventional oven sintering [12,13].

Although the impact of microwave treatment during catalyst preparation has been addressed, little is known on the effect of microwave-assisted drying and calcination on the resulting particle size. Moreover, the studies reporting on the effect of microwaves on metal distribution employed household multimode pulsed microwave ovens which limit the electromagnetic field intensity and does not allow temperature measurement. In the present study, microwave-assisted synthesis of 1 wt% Pt/Al2O3, widely used in automotive catalysis to carry out oxidation reactions, was performed. The impact of microwave drying and calcination on the resulting platinum dispersion was compared with conventional drying and calcination.

2. Materials and Methods

2.1. Catalyst Preparation

Platinum was deposited by incipient wetness method onto a pre-calcined γ-Al2O3 support to obtain a Pt content of 1 wt%. Pt(NO3)2 (Sigma-Aldrich, St. Louis, MO, USA) precursor was used and diluted in deionized water to obtain an aqueous solution, the volume of which corresponded to the pore volume of the support. The samples were then dried either in a conventional oven at 110 °C overnight or in a microwave oven at 210 °C for 15 min (see the description of the set-up below). The MW drying temperature was chosen for practical reasons as it was the temperature reached by bare alumina irradiated with the minimum controlled power allowed by the generator (60 W). The drying time was determined by MW drying of wetted alumina. 15 min appeared sufficient to evaporate all water from the alumina pores, which was controlled by weighing the alumina after drying. A short drying time was sought to study solely the drying stage and limit the catalyst exposure to MW. Calcination of dried samples was carried out at 600 °C for 2 h and 30 min in conventional and MW oven, respectively. Similarly, the MW calcination duration was determined during a calcination test and kept as short as possible to limit unnecessary aging. The color change of the catalyst indicated the decomposition of nitrate and the oxidation of platinum. The usual calcination was conducted under air flow in a vertical tubular quartz reactor surrounded by a furnace. Aging was performed in the same MW oven at 700 and 800 °C. The catalysts were maintained at these respective temperatures for 1 h.

2.2. Microwave Set-Up

The apparatus used was a Sairem microwave oven (Neyron, France), equipped with a 2.45 GHz cavity magnetron, a 2-kW generator and a single-mode microwave applicator (Figure S1). In this study, the transverse electric mode (TE105) was used in order to heat the sample by direct interaction between the matter and the electric field. The microwaves produced were in resonance within a standard WR340 rectangular waveguide. The generated power spanned from 60 to 2000 W. The catalyst was contained in a low-absorption alumina crucible (height = 14 mm, Ø = 25 mm) surrounded by an in-house made SiC ring acting as susceptor and a sample holder and thermal insulation made of fibrous alumina as described in previous studies [14]. The sample holder was placed in a chamber where the intensity of the electromagnetic field could be fine-tuned. This system allows to reach high temperature rapidly and with low input power due to the resonance phenomenon. The temperature was monitored by a pyrometer placed above the sample and pointing down to the sample. Two pyrometers with various temperature range were used: 60–400 °C and 350–2000 °C. The pyrometers were calibrated with conventional furnace and the emissivity used was 0.8, corresponding to alumina. Preliminary tests were performed on alumina or wet alumina to determine the power settings required to heat the sample at a steady desired temperature.

2.3. Pt Dispersion Measurement

The platinum dispersion was measured by chemisorption of probe molecules on an ASAP2020 (Micromeritics, Norcross, GA, USA). Ca. 400 mg of catalyst was used to get sufficient available metal to perform reliable measurement. After in situ oxidation (30 min at 350 °C in air) and subsequent reduction (2 h at 450 °C in H2), the sample was evacuated, and stepwise CO adsorption was performed at 35 °C to obtain an isotherm of the adsorbed quantity from 1 to 400 mmHg. The adsorption was repeated after evacuation to quantify the amount of physisorbed CO. The difference of both isotherms is a constant line, the value of which corresponds to the quantity of chemisorbed CO. An example of CO adsorption isotherm is provided in Figure S2. The stoichiometry of CO adsorption on Pt was set to 1 although the presence of bridged CO adsorbates would decrease the CO:Pt ratio and lead to underestimation of the dispersion. H2–O2 titration was also employed to validate the CO chemisorption results. The same instrument was used, and the pretreatment protocol was identical as for CO chemisorption. The amount of H2 consumed by both reaction with oxygen adsorbed on platinum and dissociative adsorption of H2 on platinum was obtained by extrapolation of the isotherm at P = 0.

2.4. Surface Area Measurements

The surface area of the materials was measured by physisorption of N2 at 77 K with a Micromeritics Tristar apparatus (Norcross, GA, USA). The catalysts were previously degassed for 4 h at 250 °C. The surface area was calculated according to the BET method.

3. Results

To study the impact of microwave thermal treatment on Pt dispersion, a set of 1 wt% Pt/Al2O3 samples was prepared with different combinations of drying and calcination methods. Table 1 summarizes the synthesis conditions of each sample, as well as their aging treatment.

Table 1.

Summary of 1 wt% Pt/Al2O3 samples synthesized.

Some samples were entirely prepared with the help of a conventional oven, operating under gas flow, where the heat was transferred to the sample via the surrounding atmosphere. Those samples were then aged under microwave radiation at various temperatures in order to study the effect of microwaves on already prepared catalysts. It should be noted that the normal aging time of 1 h, used at 700 and 800 °C, was reduced to 30 min in the case of the aging at 600 °C to reproduce the same treatment as the microwave-assisted calcination. One singular sample was dried under microwave and calcined in conventional oven to investigate the effect of MW drying. Additional catalysts were both dried, calcined and, when applicable, aged in MW oven. This addresses the effect of MW calcination and allows to compare the impact of MW aging on MW-prepared and conventionally prepared 1 wt% Pt/Al2O3 catalysts.

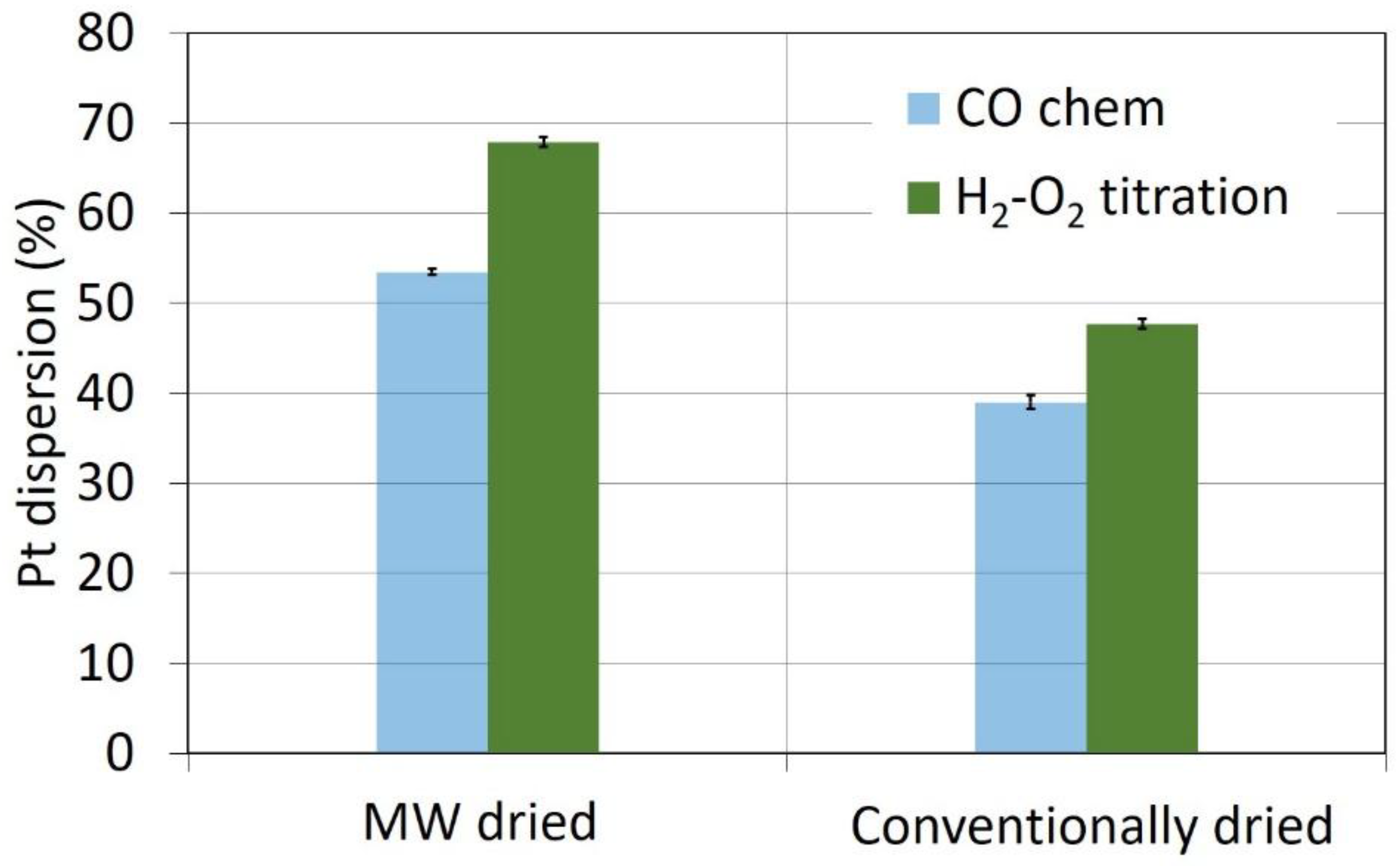

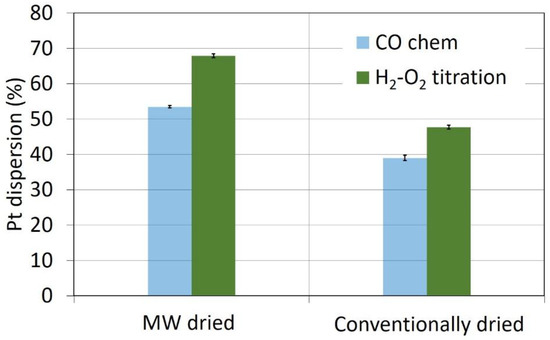

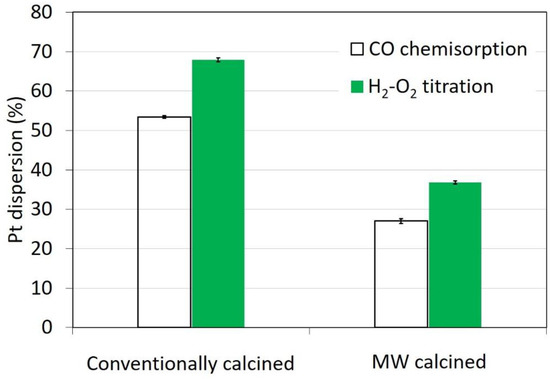

3.1. Effect of Microwave Drying

The dispersion presented by the two fresh catalysts calcined in usual oven and dried in a different way is shown in Figure 1. It can be seen that both CO chemisorption and H2–O2 titration reveal higher Pt dispersion for the MW-dried sample. H2–O2 titration gave consistently higher dispersion values than CO chemisorption which can be attributed to the underestimation of the dispersion measured by CO chemisorption due to the chosen CO:Pt adsorption stoichiometric ratio. In addition, both samples had similar BET surface area (147 m2/g), as reported in Table 2. In light of this result, one can conclude that MW drying yields higher platinum dispersion than conventional resistive drying.

Figure 1.

Comparison of Pt dispersion of samples conventionally dried (110 °C overnight) and dried by microwave irradiation (210 °C, 15 min). The dispersion was measured by CO chemisorption and H2–O2 titration. Both samples were calcined in conventional furnace.

Table 2.

BET surface area of all prepared samples.

The higher dispersion measured on MW-dried catalyst can be attributed to the higher drying temperature (210 °C vs. 110 °C) or to a specific effect of microwave irradiation and uniform heating. Vallee and Conner investigated the sorption and sorption selectivity of various compounds on an oxide surface under MW irradiation [15,16]. They found that adsorption of compounds depends on the properties of the adsorbates, the adsorbents and the surface of adsorption. Desorption of compounds with high permittivity, which reflects the ability to absorb microwave energy, was much greater under MW heating than in the conventional oven. In the case of a mixture, this property leads to the possibility of selective heating and selective adsorption/desorption depending on the compounds’ permittivity [16,17]. Since water has a significantly higher permittivity than Pt, water desorption is enhanced in favor of Pt adsorption under MW irradiation. In addition, the fast and intense evaporation of the solvent due to MW heating provokes deposition of the solute in situ [18] leading to the high platinum dispersion measured. The higher dispersion measured after a fast drying indicates either that the diffusion of platinum is extremely slow [19] or its interaction with the surface is strong [18]. As reported by Bond et al. [20], microwave drying of a Ni/Al2O3 catalyst after wet impregnation leads to a more homogeneous metal distribution and shorter time than conventional drying, which is in line with our results.

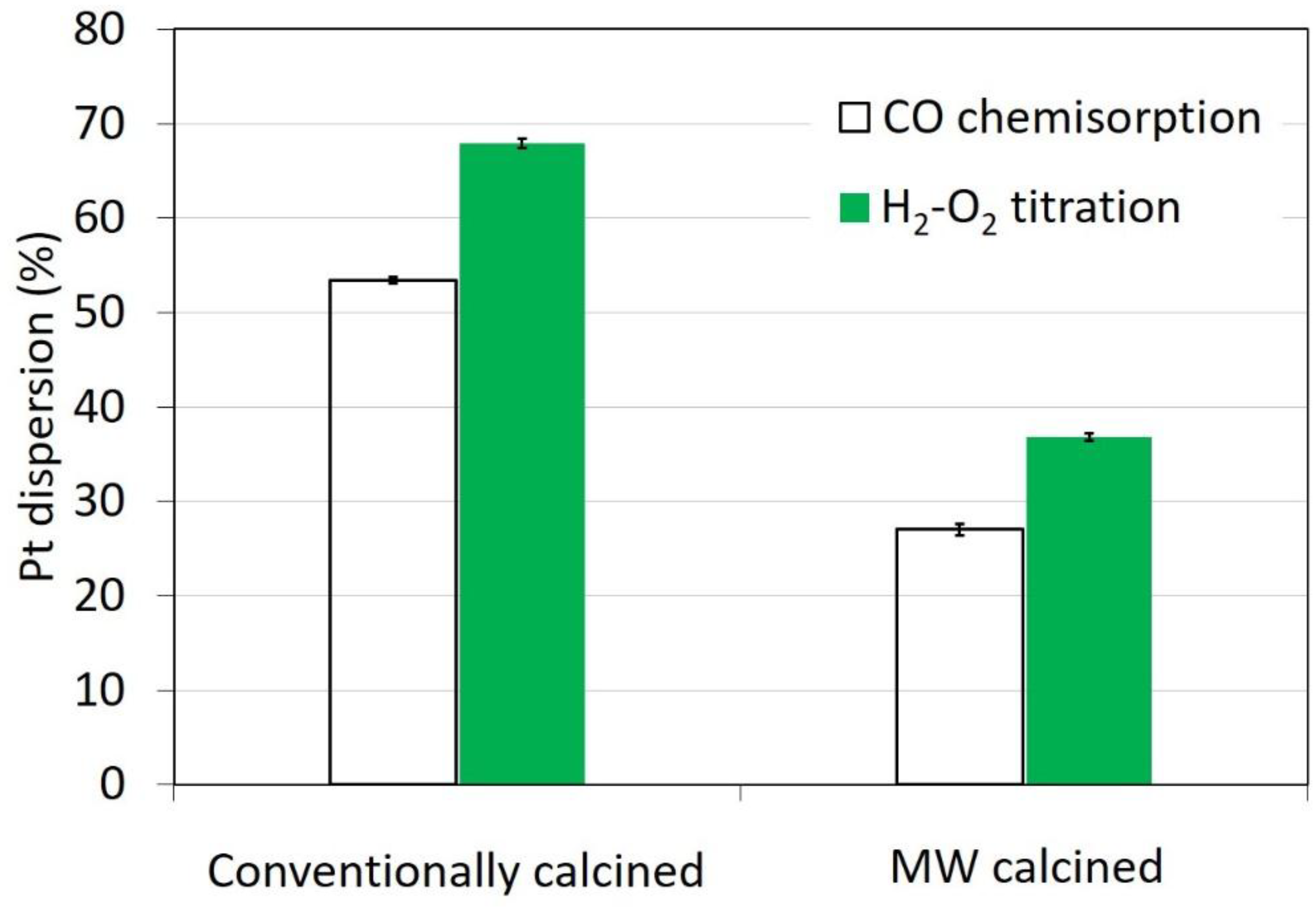

3.2. Effect of Microwave Calcination

After impregnation and drying, a calcination step is necessary to decompose the counterions or ligands of the metal precursor. It consists in a thermal treatment beyond the decomposition temperature of the precursor for a sufficient time. However, care must be taken of metal migration and aggregation due to high temperature. The use of microwave to perform this step was compared to the resistive heating. In Figure 2, the effect of the calcination method can be compared on samples dried with MW. It is clear that MW calcination is detrimental for platinum dispersion despite the shorter time of exposure to 600 °C. During MW calcination, the catalyst lost near 30% of available platinum sites. This result is found for both dispersion measurement techniques. As the H2 titration stoichiometry is known (H/Ptsurface = 1), the amount of Pt surface atoms can be inferred for each catalyst and subsequently the CO chemisorption stoichiometry can be assessed. Our results show consistently a CO/Pt ratio in the range 0.71–0.79 for all samples, regardless of the dispersion or preparation method. This stoichiometry corresponds to a ratio of linearly bonded CO and bridged CO of around 1. The BET surface area was not decreased by MW aging (151 m2/g for the sample both dried and calcined by MW in Table 2). MW heating presents therefore the ability to rapidly sinter Pt at relatively low temperature. This implies great mobility of Pt nanoparticles on alumina surface during MW irradiation. It could be due to a specific effect of the electromagnetic field on metallic particles and on their interaction with the support [21], which enhances their mobility. Local hot spots in the catalyst bed are difficult to detect but are likely to occur [22,23] and would cause platinum sintering. The elucidation of the enhanced sintering mechanism will require further study.

Figure 2.

Comparison of Pt dispersion of samples conventionally calcined (600 °C, 2 h) and calcined by microwave irradiation (600 °C, 30 min). The dispersion was measured by CO chemisorption and H2–O2 titration. Both samples were dried by microwave irradiation.

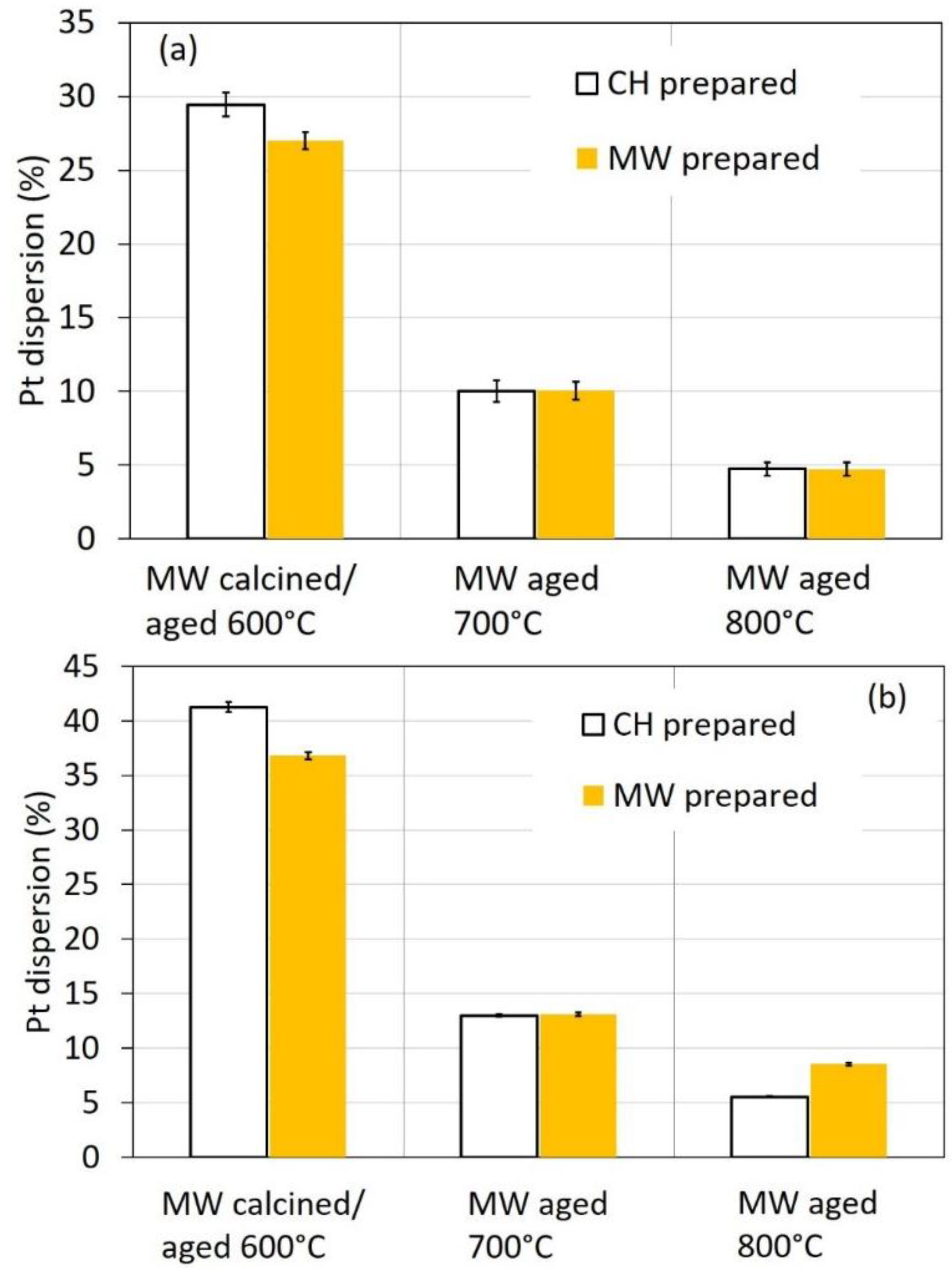

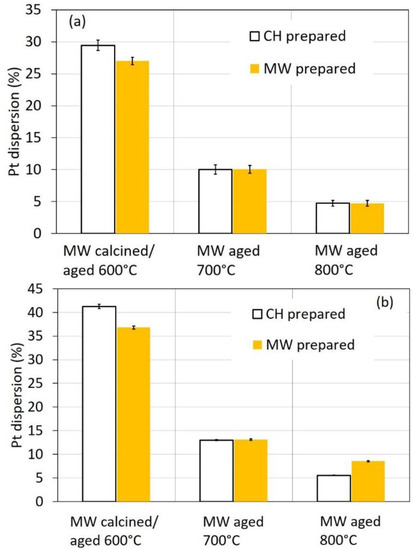

3.3. Effect of Microwave Aging

In practical applications, catalysts are often subjected to high temperatures or thermal treatment that leads to morphological changes which are often studied in the laboratory. However, this leads to noble metal sintering and/or loss of surface area due to support phase changes. Thermal and chemical aging is often simulated in the laboratory to elucidate these mechanisms and evaluate the impact of aging conditions on catalytic activity [4,24,25]. Here, we attempted to use MW irradiation to provoke accelerated aging of Pt/Al2O3. Alumina has very low dielectric constant (9) and dielectric loss (0.0063) at 25 °C [26] which makes this material transparent to MW. However, these electrical parameters increase with temperature and impurities in the material [27]. As a metal, Pt reflects MW and can induce arcing. However, the dielectric parameters are temperature dependent and a SiC susceptor was used in our experiment to ignite the temperature raise. Unlike for drying, where water filled the alumina pores, and for calcination, where nitrate species could absorb and convert MW into heat, Pt/Al2O3 was the sole medium to interact with the MW during aging. Ca. 1 g of sample was used for aging and the temperature was reached, in all cases, in less than 20 min. Firstly, at the temperatures tested, it was noted that alumina easily generated heat from MW absorption and consequently little extra input power was needed to increase the temperature from 700 to 800 °C. Secondly, arcing was not observed during MW aging due to the susceptor presence. High temperature MW treatment of Pt/Al2O3 was therefore successfully performed. The dispersion measured after MW aging of MW and CH prepared catalysts is depicted in Figure 3. It should be noted that the CH-prepared sample, MW-aged 30 min at 600 °C, was previously CH-calcined for 2 h at 600 °C, while the MW-prepared sample was only MW-calcined for 30 min at 600 °C. The CH sample has therefore been exposed to 600 °C for a longer time (2.5 h) than the MW sample (0.5 h) and yet presents a slightly greater dispersion. This highlights the strong effect of MW calcination at 600 °C on Pt dispersion.

Figure 3.

Platinum dispersion of various MW-aged Pt/Al2O3 catalysts (30 min at 600 °C and 1 h at 700 and 800 °C). (a) CO chemisorption and (b) H2–O2 titration results.

The BET surface area of Pt/Al2O3 decreased moderately due to microwave aging. It dropped from 147 to 138 m2/g and from 151 to 137 m2/g after 1 h at 800 °C (Table 2) for the conventionally prepared catalyst and the microwave prepared catalyst, respectively. This indicates that γ-alumina phase transition was not promoted by the microwave treatment. It also illustrates that microwaves specifically affect the metal nanoparticles, which could be a way to reach optimum particle size without altering the pore structure and specific surface area of the support.

4. Conclusions

The utilization of microwave heating during the synthesis of Pt/Al2O3 catalyst was investigated and compared to conventional heating (CH), with focus on resulting platinum dispersion. Higher dispersion was obtained when drying of the impregnated alumina was performed under microwave irradiation than under conventional heating. However, this result was only obtained when subsequent calcination was done in a conventional oven. Indeed, MW calcination led to lower dispersion after both MW and CH drying. Aging at 700 and 800 °C under microwave irradiation was also studied and the results revealed platinum sintering on both MW- and CH-prepared catalysts. A 1 h exposure to 700 °C yielded a dispersion of ca. 10% while at 800 °C, the dispersion dropped to ca. 5%, which is a very low value based on the initial dispersion and the rather short aging time. Microwaves are capable of accelerating Pt sintering. The BET surface area, however, was moderately affected by microwaves.

Supplementary Materials

The following are available online at http://www.mdpi.com/2073-4344/8/9/348/s1, Figure S1: Description of the single-mode microwave apparatus (Sairem). Figure S2: Example of a typical CO adsorption isotherm: 1st isotherm corresponds to both physisorbed and chemisorbed CO, 2nd isotherm, measured after evacuation, corresponds to physisorbed CO and the difference corresponds, therefore, to the amount of chemisorbed CO.

Author Contributions

X.A. conceived and performed the experiments, acquired funding, analyzed the data and wrote the original draft. A.T. provided the microwave equipment and expertise in microwave irradiation, performed the microwave experiments and reviewed and edited the draft.

Funding

This research received no external funding.

Acknowledgments

The Norges teknisk-naturvitenskapelige universitet (NTNU) is gratefully acknowledged for financial support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Van Den Berg, G.H.; Rijnten, H.T. The Impregnation and Drying Step in Catalyst Manufacturing. Stud. Surf. Sci. Catal. 1979, 3, 265–277. [Google Scholar]

- Lekhal, A.; Glasser, B.J.; Khinast, J.G. Impact of drying on the catalyst profile in supported impregnation catalysts. Chem. Eng. Sci. 2001, 56, 4473–4487. [Google Scholar] [CrossRef]

- Santiago, M.; Restuccia, A.; Gramm, F.; Pérez-Ramírez, J. Spray deposition method for the synthesis of supported catalysts with superior metal dispersion. Microporous Mesoporous Mater. 2011, 146, 76–81. [Google Scholar] [CrossRef]

- Auvray, X.; Pingel, T.; Olsson, E.; Olsson, L. The effect gas composition during thermal aging on the dispersion and NO oxidation activity over Pt/Al2O3 catalysts. Appl. Catal. B 2013, 129, 517–527. [Google Scholar] [CrossRef]

- Eggenhuisen, T.M.; Munnik, P.; Talsma, H.; de Jongh, P.E.; de Jong, K.P. Freeze-drying for controlled nanoparticle distribution in Co/SiO2 Fischer–Tropsch catalysts. J. Catal. 2013, 297, 306–313. [Google Scholar] [CrossRef]

- Liu, X.; Khinast, J.G.; Glasser, B.J. Drying of supported catalysts for low melting point precursors: Impact of metal loading and drying methods on the metal distribution. Chem. Eng. Sci. 2012, 79, 187–199. [Google Scholar] [CrossRef]

- Vergunst, T.; Kapteijn, F.; Moulijn, J.A. Monolithic catalysts—Non-uniform active phase distribution by impregnation. Appl. Catal. A 2001, 213, 179–187. [Google Scholar] [CrossRef]

- Choi, K.Y.; Tompsett, G.; Conner, W.C. Microwave assisted synthesis of silicalite–Power delivery and energy consumption. Green Chem. 2008, 10, 1313–1317. [Google Scholar] [CrossRef]

- Tompsett, G.A.; Conner, W.C.; Yngvesson, K.S. Microwave synthesis of nanoporous materials. Chem. Phys. Chem. 2006, 7, 296–319. [Google Scholar] [CrossRef] [PubMed]

- Brar, T.; France, P.; Smirniotis, P.G. Control of Crystal Size and Distribution of Zeolite A. Ind. Eng. Chem. Res. 2001, 40, 1133–1139. [Google Scholar] [CrossRef]

- Gharibeh, M.; Tompsett, G.A.; Conner, W.C. Microwave reaction enhancement: The rapid synthesis of SAPO-11 molecular sieves. Top. Catal. 2008, 49, 157–166. [Google Scholar] [CrossRef]

- Xie, Z.; Yang, J.; Huang, Y. Densification and grain growth of alumina by microwave processing. Mater. Lett. 1998, 37, 215–220. [Google Scholar] [CrossRef]

- Presenda, Á.; Salvador, M.D.; Penaranda-Foix, F.L.; Catalá-Civera, J.M.; Pallone, E.; Ferreira, J.; Borrell, A. Effects of microwave sintering in aging resistance of zirconia-based ceramics. Chem. Eng. Process. 2017, 122, 404–412. [Google Scholar] [CrossRef]

- Heuguet, R.; Marinel, S.; Thuault, A.; Badev, A. Effects of the Susceptor Dielectric Properties on the Microwave Sintering of Alumina. J. Am. Ceram. Soc. 2013, 96, 3728–3736. [Google Scholar] [CrossRef]

- Vallee, S.J.; Conner, W.C. Microwaves and Sorption on Oxides: A Surface Temperature Investigation. J. Phys. Chem. B 2006, 110, 15459–15470. [Google Scholar] [CrossRef] [PubMed]

- Vallee, S.J.; Conner, W.C. Effects of microwaves and microwave frequency on the selectivity of sorption for binary mixtures on oxides. J. Phys. Chem. C 2008, 112, 15483–15489. [Google Scholar] [CrossRef]

- Jobic, H.; Santander, J.E.; Conner, W.C.; Wittaker, G.; Giriat, G.; Harrison, A.; Ollivier, J.; Auerbach, S.M. Experimental evidence of selective heating of molecules adsorbed in nanopores under microwave radiation. Phys. Rev. Lett. 2011, 106, 157401. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-Y.; Aris, R. The Distribution of Active ingredients in Supported Catalysts Prepared by Impregnation. Catal. Rev. Sci. Eng. 1985, 27, 207–340. [Google Scholar] [CrossRef]

- Nelmark, A.V.; Kheifez, L.I.; Fenelonov, V.B. Theory of Preparation of Supported Catalysts. Ind. Eng. Chem. Prod. Res. Dev. 1981, 20, 439–450. [Google Scholar] [CrossRef]

- Bond, G.; Moyes, R.B.; Pollington, S.D.; Whan, D.A. The Advantageous use of Microwave Radiation in the Preparation of Supported Nickel Catalysts. Stud. Surf. Sci. Catal. 1993, 75, 1805–1808. [Google Scholar]

- Olevsky, E.A.; Maximenko, A.L.; Grigoryev, E.G. Ponderomotive effects during contact formation in microwave sintering. Modell. Simul. Mater. Sci. Eng. 2013, 21, 055022. [Google Scholar] [CrossRef]

- Stuerga, D.; Gaillard, P. Microwave heating as a new way to induce localized enhancements of reaction rate. Non-isothermal and heterogeneous kinetics. Tetrahedron 1996, 52, 5505–5510. [Google Scholar] [CrossRef]

- Zhang, X.; Hayward, D.O.; Mingos, D.M.P. Microwave dielectric heating behavior of supported MoS2 and Pt catalysts. Ind. Eng. Chem. Res. 2001, 40, 2810–2817. [Google Scholar] [CrossRef]

- Auvray, X.P.; Olsson, L. Sulfur dioxide exposure: A way to improve the oxidation catalyst performance. Ind. Eng. Chem. Res. 2013, 52, 14556–14566. [Google Scholar] [CrossRef]

- Mihai, O.; Fathali, A.; Auvray, X.; Olsson, L. DME, propane and CO: The oxidation, steam reforming and WGS over Pt/Al2O3. The effect of aging and presence of water. Appl. Catal. B 2014, 160–161, 480–491. [Google Scholar] [CrossRef]

- Durka, T.; van Gerven, T.; Stankiewicz, A. Microwaves in heterogeneous gas-phase catalysis: Experimental and numerical approaches. Chem. Eng. Technol. 2009, 32, 1301–1312. [Google Scholar] [CrossRef]

- Atlas, L.M.; Nagao, H.; Nakamura, H.H. Control of Dielectric Constant and Loss in Alumina Ceramics. J. Am. Ceram. Soc. 1962, 45, 464–471. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).