Abstract

The catalytic tetranuclear manganese-calcium-oxo cluster in the photosynthetic reaction center, photosystem II, provides an excellent blueprint for light-driven water oxidation in nature. The water oxidation reaction has attracted intense interest due to its potential as a renewable, clean, and environmentally benign source of energy production. Inspired by the oxygen-evolving complex of photosystem II, a large of number of highly innovative synthetic bio-inspired molecular catalysts are being developed that incorporate relatively cheap and abundant metals such as Mn, Fe, Co, Ni, and Cu, as well as Ru and Ir, in their design. In this review, we briefly discuss the historic milestones that have been achieved in the development of transition metal catalysts and focus on a detailed description of recent progress in the field.

Keywords:

water oxidation reaction; transition metal catalysts; ruthenium; iridium; manganese; iron; cobalt; copper; nickel 1. Introduction

1.1. Solar Water Oxidation in Nature

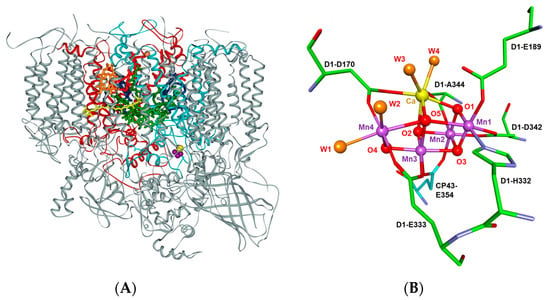

Sunlight is an abundant, green, sustainable, and renewable source of energy, however, the photochemical conversion and storage of solar energy has been a challenge [1]. Nature uses photosynthesis to convert solar energy into chemical energy through light-driven water oxidation and atmospheric CO2 fixation [1,2,3,4,5,6,7,8,9]. Water oxidation, one of the most energetically demanding reactions in nature, takes place in the multi-subunit membrane protein complex, photosystem II (PSII) (Figure 1A), in plants and cyanobacteria. The structure of PSII has been determined through X-ray diffraction [10,11,12,13] and femtosecond X-ray free electron lasers (XFEL) [14,15,16,17]. Photosystem II is comprised of a core of heterodimeric polypeptides, D1 and D2, surrounded by ~20 polypeptide subunits [14], within which there are more than 1300 water molecules [10]. The waters are mostly located at the stromal and lumenal surfaces, as is commonly encountered in transmembrane proteins [10].

Figure 1.

(A) The multi-subunit membrane protein complex, photosystem II (PSII), as observed in the 1.9 Å resolution X-ray crystal structure and (B) the tetranuclear manganese-calcium-oxo (Mn4CaO5) catalytic cluster in the oxygen-evolving complex (OEC) of PSII [10]. The manganese (Mn1–Mn4), O2− (O1–O5), and Ca2+ ions are depicted as purple, red, and yellow spheres, respectively. The oxygen atoms of the four water-derived ligands that are coordinated to the Mn4CaO5 cluster, W1–W4, are shown in orange, where W1 and W2 are coordinated to the dangling Mn ion, Mn4, and W3, and W4 are ligands to the Ca2+ ion. The amino acid residues that are coordinated to the metal ions of the Mn4Ca-oxo cluster in the OEC are also shown.

Photosystem II utilizes visible light to convert water into dioxygen at the catalytic tetranuclear manganese-calcium-oxo (Mn4Ca-oxo) cluster in the oxygen-evolving complex (OEC). The Mn4Ca-oxo cluster in the OEC has a distorted cubane-like structure with three manganese (Mn1–Mn3), one calcium, and four oxygen (O1–O3 and O5) atoms and a ‘dangling’ manganese atom (Mn4) that is linked to the cubane through di-μ-oxo linkages to the O atoms, O5 and O4 (numbering of the atoms is shown in Figure 1B) [10]. In addition to the μ-oxo-bridged oxygen atoms, the Mn4 and Ca ions are coordinated by the water-derived ligands, W1, W2 and W3, W4 [10,14,18,19], respectively, as well as one imidazole and six carboxylate ligands that are derived from the amino acid residues in the D1 and CP43 polypeptides of PSII (Figure 1B) [10,11,12,14]. The Mn4Ca-oxo cluster in the OEC is surrounded by additional amino acid residues and structured water molecules that form an extensive network of hydrogen bonds with the ligands of the Mn4Ca-oxo cluster and are thought to facilitate substrate water delivery, electron transfer, and proton egress during the water oxidation reaction [20].

The water oxidation reaction of PSII proceeds through the formation of five charge-storage or S-states (S0–S4) in the Kok S-state cycle [21], where the formation of each S-state intermediate is initiated by the absorption of a photon and the transfer of an electron (or electron and proton) [21,22,23,24]. This results in the accumulation of oxidizing equivalents at the Mn4Ca-oxo cluster, which leads to the O–O bond formation in the transient higher-oxidation state S4 intermediate. The conversion of two molecules of water into dioxygen entails the transfer of four electrons and the release of four protons, hence, the removal of electron(s) and the release of proton(s) proceeds in a coordinated fashion through proton-coupled electron transfer (PCET) reactions [25,26,27]. This prevents an overall buildup of charge through redox leveling in the OEC [28,29]. The release of protons is proposed to follow the pattern 1, 0, 1, 1, and 1 in the S0 to S1, S1 to S2, S2 to S3, and S3 to S0 via transient S4 states, respectively [30]. Photosynthetic water oxidation efficiently catalyzes the conversion of water into dioxygen with a TON of ~106 and a TOF of ~600 s−1 [4,31]. Hence, the low over-potential and high efficiency of the OEC is a promising blueprint for the development of artificial bio-inspired catalysts for water splitting that can generate clean and renewable energy from sunlight [32,33,34,35].

The challenges in designing efficient artificial catalysts stem from the complexity of the water oxidation reaction, which requires the transfer of four electrons and four protons during the catalytic cycle [7,36,37]. This is a major bottleneck, as an effective catalyst would have to accommodate successive charge storage states and participate in PCET reactions during water oxidation [4,23,29,38]. Furthermore, water oxidation is energetically demanding, requiring at least 113.5 kcal/mol (equivalent to a redox potential of 1.23 V vs. normal hydrogen electrode (NHE)) to drive the reaction [39,40]. Thus, artificial water oxidation would require the presence of a strong oxidant. Finally, an efficient catalyst would need to have a mechanism for the binding of substrate water as well as egress of protons during the water oxidation reaction. The catalytic Mn4Ca-oxo cluster of PSII is coordinated by seven amino acid residues (D1-Asp170, D1-Glu189, D1-Glu333, D1-Asp342, D1-Ala344, CP43-Glu354, and D1-Ala344) (Figure 1B) [10,12,13] that form an extensive hydrogen-bond network with other amino acid residues and structured water molecules that facilitate the delivery of substrate water and the egress of protons in the OEC [12]. It is challenging to replicate the unique environment of the catalytic site of PSII in an artificial catalyst.

1.2. Synthetic Water Oxidation Catalysts

The water oxidation reaction of PSII has been of intense interest as it serves as a blueprint for the development of active and robust synthetic water oxidation catalysts that mimic the OEC of PSII [32,33,34,35,41,42]. The dioxygen produced is released to atmosphere, whereas the electrons and protons from water oxidation may be used to generate economically useful dihydrogen and organic molecules [1,43,44].

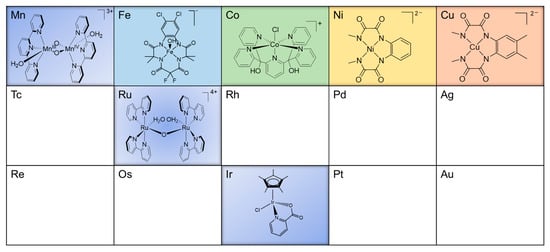

Synthetic catalysts for artificial water oxidation (WOC) can be classified into two groups, namely, molecular catalysts and bulk semiconductors. Although semiconductor surfaces (e.g., metals oxides) are easy to synthesize and recover and have displayed reasonable stability for the water oxidation reaction [45,46,47], they are generally vulnerable to harsh reaction conditions (such as low or high pH), often lack structural reproducibility, and are hard to characterize through physical and chemical methods [48]. Since the synthesis of the first well-defined molecular WOC [49], the development of such catalysts has been the subject of extensive research and the strategies that were previously employed in the field can be useful to improve the design of WOC. Amongst the current WOCs, Ru-based catalysts have received extensive attention [4,37,50,51,52], some of which have displayed high catalytic activity [53,54,55]. However, there is also an interest in developing earth-abundant, cost-effective catalysts comprised of first-row (3d) transition metals, such as manganese, iron, cobalt, copper, and nickel. In this review, we describe molecular water oxidation catalysts that are based on 3d (Mn, Fe, Co, Cu, Ni), 4d (Ru), and 5d (Ir) transition metals (Figure 2), with an emphasis on the progress in the field over the past five years. The examples discussed in this review highlight the role of ligand design in the stability, solubility, and catalytic activity of molecular WOC. We refer the reader to previous and thorough review articles [7,56,57,58,59,60] for catalytic systems that were developed prior to this period.

Figure 2.

The 3d (Mn, Fe, Co, Ni, and Cu), 4d (Ru), and 5d (Ir) metals in the periodic table that have been incorporated in the design of synthetic bio-inspired molecular catalysts for water oxidation. Key examples of the catalysts that have been developed for each metal are also shown.

2. Ruthenium-Based Molecular Catalysts

2.1. Dinuclear Ruthenium Catalysts

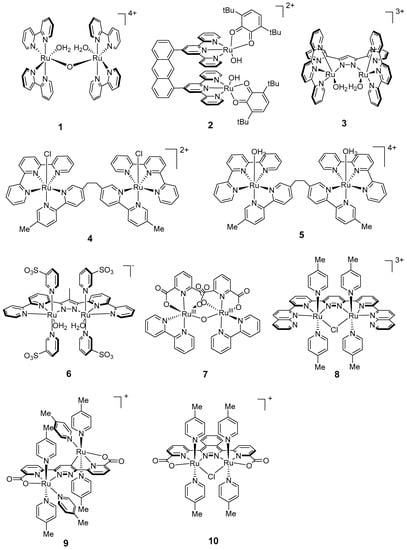

The ruthenium-based dinuclear molecular catalyst for water oxidation, known as the “blue dimer”, [(H2O)RuIII(bipy)2(μ-O)RuIII(bipy)2(H2O)]4+ (1) (Figure 3), was first reported by Meyer and coworkers in 1982 [49]. This complex is comprised of a RuIII dimer, where the metal ions are linked by a μ-oxo bridge. Each RuIII ion is coordinated by two bipyridine (bipy) ligands that provide an open coordination site to accommodate a water ligand. The blue dimer displayed a turnover number (TON) and turnover frequency (TOF) of 13.2 and 0.0042 s−1, respectively, for the chemical oxidation of water using [Ce(NO3)6][(NH4)2] (CAN) as a sacrificial oxidant (Table 1) [61,62]. CAN provides a sufficient oxidation potential to oxidize the investigated catalysts at approximately 1.75 V vs. NHE (pH 0.9) [60,63]. The mechanism of water oxidation by complex 1 was investigated by kinetic measurements in combination with isotope replacement studies to determine the kinetic isotope effect, which suggested that the reaction predominantly proceeded through a water nucleophilic attack (WNA) mechanism with the formation of a high-valent intermediate, [(O)RuV(μ-O)RuV(O)]4+, where uncoordinated water molecules attack the RuV=O group of the intermediate. However, the results were unable to exclude the possibility of intramolecular or bimolecular pathways in the reaction [64,65,66,67]. The moderately low catalytic performance of complex 1 was attributed to the anation of an active intermediate, in which the [(O)RuV(μ-O)RuV(O)]4+ cation coordinated an anion forming the species, [(bipy)2(H2O)RuIV(μ-O)RuIII(X)(bipy)2]4+ (where, X = ClO4−, CF3SO3− and NO3−), which resulted in the deactivation of the system [68].

Studies of the blue dimer were followed by the synthesis and characterization of a series of dinuclear ruthenium complexes with a variety of ligands bridging the ruthenium ions, such as pyrazole [69,70], pyridazine [71,72], and phthalazine [73]. Tanaka et al. (2001) reported a dinuclear complex, [RuII2(OH)2(3,6-tBu2qui)2(btpyan)]2+ (2) (where 3,6-tBu2qui = 3,6-di-tert-butyl-1,2-benzoquinone), that featured a novel ligand, 1,8-bis(2,2′:6′,2′′-terpyridyl)anthracene (btpyan), to bridge the two ruthenium ions [74]. Complex 2 was capable of electrochemical water oxidation with a TON of 21 in the presence of water in 1,1,1-triflurorethanol and displayed a TON of 33,500 on the surface of an indium tin oxide (ITO) electrode [74]. Subsequently, Llobet and coworkers (2004) demonstrated that the complex [(H2O)RuII(terpy)2(μ-bpp)RuII(terpy)2(H2O)]3+ (3) (where, terpy = 2,2′:6′,2′′-terpyridine) with the bridging ligand, 3,5-bis(2-pyridyl)pyrazolate (bpp−) displayed improved catalytic activity with a TON of 512 and a TOF of 0.014 s−1 for chemical water oxidation using CAN as a sacrificial oxidant [69]. The presence of the btpyan and bpp− bridging ligands in the complexes 2 and 3, respectively, offered alternatives to the previous strategy of μ-oxo-bridged dinuclear ruthenium complexes [4], which is unique as there are very few dinuclear ruthenium complexes that have been shown to be catalytically active in the absence of bridging μ-oxo ions.

This was followed by the development of two dinuclear ruthenium complexes [{RuII(terpy)Cl}2(μ-L)]2+ (4) and [{RuII(terpy)(H2O)}2(μ-L)]4+ (5) (where, L = bis[5-(5′-methyl-2,2′-bipyridinyl)]ethane) by Sakai and coworkers (2009) [75] that displayed activity for chemical water oxidation with TONs of 75 and 106, respectively, using CAN as an oxidant. It was found that the activities of complexes 4 and 5 were much higher than that of the μ-O bridged complex 1. More importantly, an induction time of 2–3 h was observed for complex 4. However, the initial rate of O2 formation for complex 5, the aqua species, did not show an induction period for oxygen formation, implying that the aqua (instead of the chloro) species was active during the catalysis of the water oxidation reaction [75]. Subsequently, Llobet and coworkers (2014) developed a powerful and oxidatively rugged complex, [{RuII(py-SO3)2(H2O)}2(μ-Mebbp)]− (6) (where, HMebbp = 2,4-bis(bipyridin)-3-methyl-pyrazole and py-SO3 = pyridine-3-sulfonate), with a pyrazolate-based equatorial ligand that featured a TON of 22.6 and a TOF of 0.068 s−1 for chemical water oxidation using CAN as an oxidant [70]. In complex 6, Mebbp− is a bis(tridentate) monoanionic ligand that was designed to act as a bridging scaffold that placed the two ruthenium ions in close proximity. The Mebbp− ligand appeared to induce subtle geometric variations on the relative disposition of the active Ru–OHX groups that regulated the O–O bond formation pathway and influenced the mechanism toward WNA. This was in contrast to the intermolecular bimolecular (I2M) mechanism that was suggested for analogous complexes with 3,5-bis(2-pyridyl)pyrazolato dinucleating, Hbpp−, ligand due to the strategic disposition and encumbrance of the terpy ligands [57,69,76,77]. This study demonstrated that subtle variations in ligand design could be used to regulate the O−O bond formation pathway of the water oxidation reaction. Additionally, the tridentate dianionic meridional pyridyl-2,6-dicarboxylato (pdc2−) ligand was used to generate a dinuclear ruthenium complex 7. Although complex 7 was not a catalyst for water oxidation, it was shown to act as a precursor for a ruthenium-aqua mononuclear complex, [RuII(pdc-κ3-N1O2)(bipy)(H2O)] (31) (where, pdc = pyridyl-2,6-dicarboxylato and bipy = 2,2′-bipyridine), that was an active water oxidation catalyst with low overpotential of 240 mV at pH 1 and a TOF of 0.2 s−1 [78].

Further improvements in the design of dinuclear ruthenium catalysts included the incorporation of a rigid polypyridyl equatorial ligand in [RuII2(μ-L)(μ-Cl)(pic)4]3+ (8) (where L = 6-di-(6′-[1″,8″-naphthyrid-2″-yl]-pyridin-2′-yl)pyrazine and pic = 4-picoline), which improved the catalytic performance for chemical water oxidation using CAN as a sacrificial oxidant at pH 1 with a TON and TOF of 538 [50,79] and 0.046 s−1, respectively [50,71]. During this time, biophysical studies of PSII indicated that the presence of negatively-charged carboxylate ligands in the vicinity of the OEC likely improve the stability of the high-valent manganese intermediates by lowering the oxidation potential of the catalytic Mn4Ca-oxo cluster [45,50,72,80]. This led to the incorporation of carboxylate ligands in the design of dinuclear ruthenium complexes [72,73]. While the dinuclear ruthenium complexes containing neutral ligands displayed high oxidation potentials, which required the use of strong chemical oxidants, such as CeIV for catalytic water oxidation, it was thought that the redox potentials of these complexes could be decreased by ligand modification. The presence of negatively-charged ligands could lower the oxidation potential of the complexes and stabilize the higher oxidation states of the metal ions [72]. In principle, this could present the possibility of driving the water oxidation reaction by a mild oxidant. Using this strategy, Sun and coworkers prepared a dinuclear ruthenium catalyst with a negatively charged dicarboxylate ligand. The complex [Ru(pic)3(μ-cppd)Ru(pic)3]+ (9) (where, H2cppd = 3,6-bis-(6′-carboxypyrid-2′-yl)-pyridazine) yielded a TON and TOF of 4700 and 0.28 s−1, respectively, for chemical water oxidation using CAN as an oxidant [50,73]. Moreover, the complex [Ru(pic)2(μ-Cl)(μ-cpptz)Ru(pic)2]+ (10) (where, H2cpptz = 1,4-bis(6′-COOH-pyrid-2′-yl)phthalazine) displayed improved catalytic activity under identical conditions with a TON of 10,400 and a TOF of 1.2 s−1 [73]. Both complex 9 and 10 provided direct evidence of the benefit of introducing carboxylate functionalities in the equatorial ligand framework of dinuclear ruthenium catalysts. In 2021, Meyerstein and coworkers reported a dinuclear ruthenium carbonate complex, Na3[Ru2(µ-CO3)4], that is electrochemically active for water oxidation with a TOF of 0.10 s−1 under pH-neutral conditions and 1.48 s−1 in bicarbonate media (pH 8.3) [81].

Figure 3.

Chemical structures of recent dinuclear ruthenium catalysts 1–10 for water oxidation: [(H2O)RuIII(bipy)2(μ-O)RuIII(bipy)2(H2O)]4+ (1, bipy = 2,2′-bipyridine) [49]; [RuII2(OH)2(3,6-tBu2qui)2(btpyan)]2+ (2, btpyan = 1,8-bis(2,2′:6′,2″-terpyridyl)anthracene, 3,6-tBu2qui = 3,6-di-tert-butyl-1,2-benzoquinone) [74]; [(H2O)RuII(terpy)2(μ-bpp)RuII(terpy)2(H2O)]3+ (3, bpp = 3,5-bis(2-pyridyl)pyrazolate, terpy = 2,2′:6′,2″-terpyridine) [69]; [{RuII(terpy)Cl}2(μ-L)]2+ (4, L = bis[5-(5′-methyl-2,2′-bipyridinyl)]ethane) [75]; [{RuII(terpy)(H2O)}2(μ-L)]4+ (5, L = bis[5-(5′-methyl-2,2′-bipyridinyl)]ethane) [75]; [{RuII(py-SO3)2(H2O)}2(μ-Mebbp)]− (6, Mebbp = 2,4-bis(bipyridin)-3-methyl-pyrazole) [70]; [{RuIII(pdc-κ3-N1O2)(bipy)}2(μ-O)] (7, pdc = 2,6-pyridinedicarboxylato, bipy= 2,2′-bipyridine) [78]; [RuII2(μ-L)(μ-Cl)(pic)4]3+ (8, L = 6-di-(6′-[1″,8″-naphthyrid-2″-yl]-pyridin-2′-yl)pyrazine, pic = 4-picoline) [71]; [Ru(pic)3(μ-cppd)Ru(pic)3]+ (9, ccpd = 3,6-bis-(6′-carboxypyrid-2′-yl)-pyridazine) [72]; [Ru(pic)2(μ-Cl)(μ-cpptz)Ru(pic)2]+ (10, cpptz = 1,4-bis-(6′-carboxypyrid-2′-yl)-phthalazine) [73].

Table 1.

Select catalytic parameters and experimental conditions for dinuclear ruthenium catalysts 1–10, which are active in water oxidation. Electrochemical and chemical water oxidation using CAN are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TOF values that are not listed in this table are not available in literature.

Table 1.

Select catalytic parameters and experimental conditions for dinuclear ruthenium catalysts 1–10, which are active in water oxidation. Electrochemical and chemical water oxidation using CAN are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TOF values that are not listed in this table are not available in literature.

| Binuclear Ru Complex | TON | TOF (s−1) | Experimental Conditions | Reference |

|---|---|---|---|---|

| 1 | 13.2 | 0.0042 | chem WO | [49,61,62] |

| 2 | 21 | - | electrochem WO | [74] |

| 3 | 512 | 0.014 | chem WO | [69] |

| 4 | 75 | - | chem WO | [75] |

| 5 | 106 | - | chem WO | [75] |

| 6 | 22.6 | 0.068 | chem WO | [70] |

| 7 | inactive | inactive | electrochem WO | [78] |

| 8 | 538 | 0.046 | chem WO | [50,71,79] |

| 9 | 4700 | 0.28 | chem WO | [72,73] |

| 10 | 10,400 | 1.2 | chem WO | [73] |

2.2. Mononuclear Ruthenium Catalysts

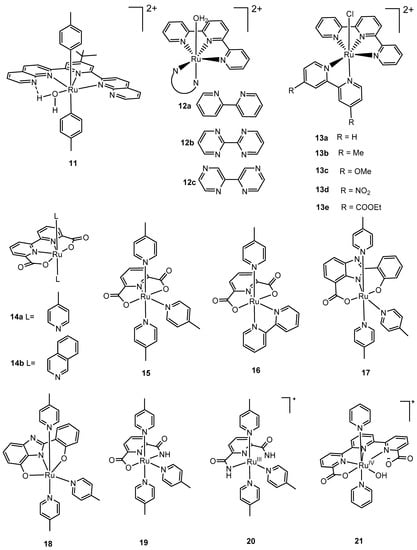

The success of the blue dimer [49] in catalyzing water oxidation and the lower catalytic activity of mononuclear ruthenium complexes in early studies [61] led to the assumption that multinuclear catalysts were required for the successful conversion of water to dioxygen. However, the design of a series of mononuclear ruthenium complexes that were catalytically active for water oxidation challenged this hypothesis [71]. The ease of the chemical syntheses led to a shift towards the design of effective mononuclear ruthenium catalysts for water oxidation. The complex [(ntp)(pic)2Ru(H2O)]2+ (11) (where, ntp = 2,6-di(1,8-naphthyridin-2-yl)-4-tert-butylpyridine) (Figure 4), reported by Thummel and coworkers, displayed catalytic activity for water oxidation (Table 2) and paved the way for the development of mononuclear ruthenium complexes for water oxidation. Subsequently, a study by Meyer and coworkers on the mononuclear ruthenium complexes [Ru(terpy)(bpm)(OH2)]2+ (12b) and [Ru(terpy)(bpz)(OH2)]2+ (12c) (where, bpm = 2,2′-bipyrimidine; bpz = 2,2′-bipyrazine) demonstrated conclusively that a single Ru site is sufficient for catalytic water oxidation [82,83]. A large number of monomeric ruthenium complexes for water oxidation have been reported since the initial findings by Thummel, Meyer and coworkers. The mononuclear ruthenium catalysts that have been reported in the literature can broadly be divided into two classes based on the equatorial and axial ligands that were employed in the respective syntheses.

Berlinguette and coworkers investigated a series of structurally related mononuclear ruthenium catalysts that were formulated as [Ru(terpy)(L)(OH2)]2+ (where, L = 2,2′-bipyridine (bipy) (12a), 4,4′-dimethoxy-2,2′-bipyridine (bipy-OMe), and 4,4′-dicarboxy-2,2′-bipyridine (bipy-COOH)) [84]. The goal of this study was to determine the effect of the electronic density at the active site on the catalytic performance while holding the balance of the structure at parity. The effects of the systematic modification of the substituent groups on the bipy ligand of the complex indicated that while the presence of electron-withdrawing groups (EWG), such as –Cl and –COOH, suppressed the rate of the reaction, kobs, and enhanced the catalytic TON, the installation of electron-donating groups (EDG), such as –OMe, accelerated the catalytic rate while decreasing the stability of the catalyst [85]. The observation of a reverse relationship between the rate of the reaction and the TON was similar to prior observations by Thummel and coworkers [86]. However, a study by Berlinguette and coworkers suggested that chemical water oxidation driven by CeIV as an oxidant led to reaction pathways that diverged from the prevailing “acid-base” mechanism for single-site catalysts. The catalysts displayed complicated pathways that involved the incorporation of O atoms from different sources [87,88].

Thummel and coworkers (2008) assessed a series of chloro-coordinated mononuclear ruthenium complexes using terpy, bipy, and related derivatives as ligands that demonstrated high catalytic activity for water oxidation [86]. These studies demonstrated that the presence of an EDG led to an increase in the rate of the reaction with a decrease in the TON, whereas an EWG yielded a higher TON with a decrease in the rate [86]. The parent complex [RuII(terpy)(bipy)(Cl)]+ (13a) in this study was shown to be catalytically active for water oxidation with a TON of 390 using CAN as an oxidant, and it was suggested that the mechanism for complex 13a involved a seven-coordinate intermediate retaining the Ru–Cl bond [86]. However, in contrast to these observations, Sakai and coworkers demonstrated that complex 13a was inactive in the presence of NaCl in solution. This was thought to be due to a dominant shift of the substitution equilibrium, [RuII(terpy)(bipy)Cl]+ + Solv ⇌ [RuII(terpy)(bipy)(Solv)]2+ + Cl−, towards the reactant. Moreover, since the oxygen evolution as a function of time suggested that the chloro species was inactive, the real catalyst responsible for dioxygen evolution was inferred to be the aqua species, [RuII(terpy)(bipy)(Solv)]2+, in solution. This suggested that the conversion of the [Ru(terpy)(bipy)Cl]+ complex (13a) to the [Ru(terpy)(bipy)(H2O)]2+ species (12a) may have been involved in the mechanism [75].

Although several studies have proposed a tentative mechanism for water oxidation involving seven-coordinate ruthenium intermediates [82,86,89], it was not possible to isolate and characterize these proposed complexes. This left an open question as to the interaction of water molecules with ruthenium in mononuclear catalysts. The use of negatively charged ligands was thought to be an appropriate means to capture high-valent ruthenium intermediates as they can stabilize higher oxidation states. Given the enhanced catalytic performance of dinuclear ruthenium complexes (9) and (10) with a dicarboxylato ligand where the introduction of negatively charged ligands dramatically lowered the oxidation potential of RuII to RuIII [72,73], equatorial backbone ligands with terminating carboxylato groups were also introduced in the design of mononuclear ruthenium complexes. The synthesis of a mononuclear ruthenium complex, [Ru(bda)(pic)2] (14a) (where, bda2− = 2,2′-bipyridine-6,6′-dicarboxylate), was shown to stabilize a possible seven-coordinate RuIV dimeric intermediate with a proposed [HOHOH]− bridging ligand [90]. This supported the hypothesis that the O–O bond formation could arise from the coupling of two RuIV=O units, termed as the “interaction between two metal oxo units” or the intermolecular bimolecular (I2M) pathway for water oxidation.

Subsequently, two mononuclear ruthenium complexes, [RuII(pdc)(pic)3] (15) and [RuII(pdc)(bipy)(pic)] (16) (where, H2pdc = 2,6-pyridinedicarboxylic acid), were investigated for their catalytic activity in chemical water oxidation [91]. Complex 15 displayed a TON of 553 and a TOF of 0.23 s−1, which was better than complex 16, which had a TON of 17 and a TOF of 7.2 × 10−3 s−1 at pH 1 for chemical water oxidation in the presence of CeIV ions [91]. Although both 15 and 16 employed tridentate equatorial backbone ligands containing negatively charged biscarboxylato groups, they were not as catalytically active as [Ru(bda)(pic)2] (14a) [53], which displayed a TON of 2000 and a TOF of 41 s−1 under similar reaction conditions. Upon closer examination, the tetradentate equatorial backbone with two axial picoline ligands in complex 14a formed a highly distorted octahedral configuration with an “open coordination site” (O–Ru–O angle of 123°) that greatly facilitated the access of an aqua ligand [50,90]. The isolation of a RuIV dimeric intermediate with a [HOHOH]− bridging ligand from water oxidation catalyzed by complex 14a suggested that radical coupling of Ru=O units led to O–O bond formation [90]. As a result of this finding, isoquinolines were employed as axial ligands to facilitate the non-covalent attraction between them and lower the barrier of interaction for the Ru=O units. This strategy succeeded as the complex [Ru(bda)(isq)2] (14b) (where, isq = isoquinoline) and led to a TON of 8369 and a TOF of 303 s−1 [53].

The studies involving mononuclear ruthenium catalysts described thus far required a powerful sacrificial oxidant, CAN, for chemical water oxidation. In principle, it should be possible to use a light-absorbing photosensitizer to conduct sustainable light-driven water oxidation. As described by Åkermark and coworkers [92], a major obstacle that is frequently encountered in light-driven water oxidation is the mismatch between the relatively high redox potential at which a catalyst assumes its active state and the lower potential attainable with a photosensitizer. One way to decrease the redox potential of the active catalyst is to involve PCET, which is a fundamental process that is employed in nature by the OEC of PSII [25,27]. It involves the simultaneous transfer of an electron and a proton, which has a profound effect on the energetics of the water oxidation reaction. As mentioned in the Introduction section, PCET allows for redox leveling at the catalytic site, which is a prerequisite for carrying out the four-electron water oxidation reaction. Additionally, another means of altering the redox potential of the active catalyst is to coordinate electron-donating and redox-active ligands to the metal centers, which would influence the balance between efficiency and stability of the water oxidation catalysts [92]. Thus, Åkermark and coworkers demonstrated that the introduction of imidazole and phenol motifs, in combination with carboxylate groups, facilitated PCET and the formation of high-valent metal–oxo catalytic intermediates at low potentials. This strategy was implemented by the development of two mononuclear ruthenium complexes, [RuIII(L)(pic)3] (where, L = 2-(2-hydroxyphenyl)-1H-benzimidazole-7-carboxylate (17) and L = 2-(2-hydroxyphenyl)-1H-benzimidazol-7-ol (18)), which contained negative equatorial backbone ligands comprised of imidazole and phenol motifs with a carboxylate group [92]. By using the imidazole motif, it was possible to introduce a combined redox and proton-transfer mediator, a highly active and essential element, into the mononuclear ruthenium catalysts. Complex 17, with a single carboxylate and phenol moiety, displayed a TON of up to 4000 and a TOF of 7.4 s−1 with [Ru(bipy)3]3+ as an oxidant for chemical water oxidation, and a postulated [RuV=O]n+ intermediate of 18 was characterized by high-resolution mass spectrometry [92]. Moreover, to evaluate the possibility of performing light-driven water oxidation under homogeneous, neutral conditions at pH 7.2, the authors employed a three-component system consisting of complex 17 or 18, a photosensitizer ([Ru(bipy)3]2+ or [Ru(bipy)2(deeb)]2+ (where, deeb = 4,4′-di(ethoxycarbonyl)-2,2′-bipyridine)), and a sacrificial electron acceptor (Na2S2O8). Successful evolution of dioxygen was detected upon visible-light illumination of this system. The [Ru(bipy)3]2+ photosensitizer displayed a low TON of approx. 20, whereas, replacing [Ru(bipy)3]2+ (E [RuIII/RuII] = 1.26 V vs. NHE) with the more strongly oxidizing photosensitizer [Ru(bipy)2(deeb)]2+ (E [RuIII/RuII] = 1.4 V vs. NHE) yielded a significantly higher TON of ~200 [92]. Similarly, [Ru(bda)(pic)2] (14a), [RuII(pdc)(pic)3] (15) and [RuII(pdc)(bipy)(pic)] (16) also demonstrated moderate catalytic performance for photochemical water oxidation using [Ru(bipy)3]2+ or [Ru(bipy)2(dcb)]2+ (dcb = 4,4′-dicarboxyethyl-2,2′-bipyridine) as a photosensitizer and [Co(NH3)5Cl]Cl2, or Na2S2O8 as a sacrificial electron acceptor [91,93].

The design of a mononuclear ruthenium complex with a carboxylate-amide motif, [RuII(HL)(pic)3] (19) (where, L = 6-carbamoylpicolinic acid), was also shown to catalyze water oxidation (TON of 280 and TOF of 1.16 s−1) at a neutral pH of 7.2 using [Ru(bipy)3]3+ as a mild chemical oxidant [94]. This complex was similar to [RuII(pdc)(pic)3] (15), with the difference that one of the carboxylate ligands was replaced by an amide group. The crystal structure of complex 19 revealed a RuIII ion due to the strong electron-donating ability of the 6-carbamoylpicolinic acid ligand. The presence of the carboxylate-amide ligand in 19 lowered the redox potential of the complex to an extent where catalytic water oxidation could take place under neutral conditions with the mild [Ru(bipy)3]3+ oxidant [94]. In comparison with the mononuclear ruthenium complex, 19, catalysts based on neutral nitrogen containing heterocyclic ligands were generally not compatible with the mild oxidant, [Ru(bipy)3]3+. This study once again highlighted the importance of incorporating anionic backbone ligands to decrease the redox potential of ruthenium catalysts.

The above results led to the design of the complex [RuIII(H2pdca)(pic)3]+ (20) (where, H4pdca = 2,6-pyridine-dicarboxamide), which was also shown to catalyze water oxidation at a low redox potential using [Ru(bipy)3]3+ at pH 7.2 with a TON of 400 and a TOF of 1.6 s−1 [95]. The improvement of the catalytic activity in terms of TOF was attributed to the presence of a flexible equatorial backbone ligand. This was followed by the synthesis of a seven-coordinate mononuclear ruthenium complex, [RuIV(OH)(tda-κ-N3O)(py)2]+ (21) (where, tda2− = 2,2′:6′,2″-terpyridine-6,6″-dicarboxylate) that was found to be an active and robust catalyst with a maximum TOF (TOFmax) of 50,000 s−1 at pH 10 using a foot-of-wave analysis (FOWA) [54]. Based on density functional theory (DFT) calculations, it was proposed that the carboxylate moiety in the dianionic ligand, tda2−, stabilized seven-coordinate intermediates in the high-valent oxidation state of the catalyst. Moreover, the dangling carboxylate group was a putative hydrogen-bonding site that could function as a proton acceptor and hence favor WNA. This could lower the free energy of the activation and lead to O–O bond formation [54]. To our best knowledge, the catalytic activity of complex 21 is the highest that has been reported in literature, albeit it uses FOWA.

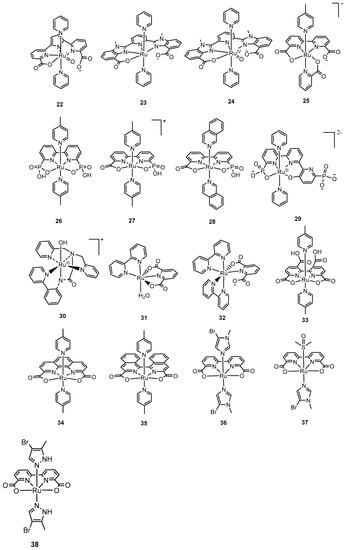

The trianionic mononuclear ruthenium complex, [RuV(O)(t5a-κ-N2O)(py)2] (22) (where, t5a3− = 2,5-bis(6-carboxylatopyridin-2-yl)pyrrol-1-ide and py = pyridine), was demonstrated to be an efficient catalyst with a TOFmax of 9400 s−1 at pH 7 via the FOWA [96]. In this case, the highly anionic nature of the backbone could reduce the redox potential of the RuIV/RuV couple, and the flexibility of the carboxylate moiety could facilitate intramolecular proton transfer to facilitate O–O bond formation through WNA. However, unlike complex 21, which required the formation of a seven-coordinate RuV=O intermediate during water oxidation, complex 22 was not thought to require a seven-coordinate intermediate for O–O formation. This was due to the geometrical distortion of 12° and increased anionic nature of 22 in comparison with 21 (Table 3) [51,96]. The ligands tda2− and t5a3− were shown to be flexible, adaptive, multidentate, and equatorial and were thus termed as “FAME ligands” [51]. We would like to refer the readers to a recent review article that is focused on ruthenium-based molecular catalysts with the ability to achieve seven-coordinate intermediates and unprecedented activity [51].

Based on the above considerations, Llobet and coworkers developed the complex, [RuII(mcbp)(py)2] (23) (where, mcbp2− = 2,6-bis(1-methyl-4-(carboxylate)-benzimidazol-2-yl)pyridine), which also contained flexible anionic carboxylate ligands [97]. The active species, [RuIV(O)(mcbp)(py)2] (24), was generated by the controlled potential electrolysis (CPE) of complex 23 and displayed improved activity for water oxidation with TOFmax of 40,000 s−1 at pH 9 [97]. Additionally, the complex [Ru(bda)(pic)(pyC)] (25) (where, pyC = 2-pyridinecarboxylate), with a similar backbone as the bda family of ligands (e.g., complex 14) but with carboxylate groups on the axial pyridine rather than equatorial backbone ligands, has also been reported in the literature. Complex 25 contained a dangling carboxylate ligand similar to complex 21, which was suggested to facilitate a WNA pathway [98]. However, the catalytic performance of complex 25 was low with a TOFmax of 0.63–0.74 s−1 measured via FOWA at pH 7, which was ascribed to its geometric features [98]. Unlike complex 14 and the parent complex 21, [RuII(tda-κ-N3O)(py)2], which were shown to have a distorted octahedral geometry with a large O–Ru–O angle of 123° (or an O–Ru–N angle of 125°), complex 25 displayed a near perfect octahedral geometry with an O–Ru–O angle of 93.72° [51,90,98].

Subsequently, Concepcion and coworkers incorporated phosphate ligands in a bipyridine backbone to generate complexes such as [RuII(bpaH2)(pic)2]+ (26) (where, bpaH4 = 2,2′-bipyridine-6,6′-diphosphonic acid), [RuIII(bpHc)(pic)2]+ (27), and [RuII(bpHc)(isq)2] (28) (where, bpH2cH = 2,2′-bipyridine-6-phosphonic acid- 6′-carboxylic acid) [99,100]. Complex 28, with a carboxylate-phosphonate moiety, exhibited the highest activity among these complexes, with a TOF of 107 s−1 under acidic conditions and using CAN as an oxidant. However, the incorporation of a diphosphonate ligand in complex 26 drastically decreased the activity to 0.65 s−1 [100]. The complex, [RuIII(tPaO-κ-N2OPOC)(py)2]2− (29) (where, tPaO5− = 3-(hydroxo-[2,2′:6′,2″-terpyridine]-6,6″-diyl)bis(phosphonate)), was derived from a seven-coordinate H4tPa-based ruthenium complex, [RuIV(H2tPa-κ-N3O2)(py)2]2+ (where, H4tPa = 2,2′:6′,2′′-terpyridine-6,6′′-diphosphonic acid), under neutral and basic conditions, where an exogenous OH− ion from the solvent was coordinated to the complex [RuIV(H2tPa-κ-N3O2)(py)2]2+. This led to the formation of the six-coordinate complex [RuIV(OH)(tPa-κ-N2O)(py)2]− or [RuIV(O)(HtPa-κ-N2O)(py)2]−. In this case, it was proposed that the RuV=O intermediate undergoes intramolecular oxygen atom insertion into the CH bond of a non-coordinated pyridyl ring to generate the catalytically active complex 29 with a TOFmax of 16,000 s−1, measured via FOWA at pH 7.2 [101]. Most recently, there was an interesting complex, [(LN5−)RuIII–OH]+ (30), with a redox-active electron-rich polypyridyl ligand that was reported for electrochemical catalytic water oxidation at neutral pH [102]. Complex 30 was generated from [(LN5−)RuIII–Cl] by an oxidative-induced ligand exchange at neutral pH, and this species was electrochemically oxidized to form the active intermediate [(LN5−)+•RuIV=O]2+, with a surprisingly low overpotential of 183 mV for O–O formation through a WNA pathway [102]. In this case, ligand oxidation was proposed to lower overpotential (1.0 V vs. NHE), which was supported by DFT calculations [102].

There is a family of mononuclear ruthenium complexes, [RuII(pdc-κ3-N1O2)(bipy)(H2O)] (31) and [RuII(pdc-κ2-N1O1)(bipy)2] (32), containing the tridentate dianionic meridional pyridyl-2,6-dicarboxylato (pdc2−) ligand that have been studied for their electrochemical activity towards water oxidation [78,103]. Complex 31 has been shown to electrochemically catalyze water oxidation with a low overpotential of 240 mV under acidic conditions (pH of 1), due to the presence of two carboxylate groups on the pdc2− ligand. The complex 32 was shown to generate a RuIV intermediate, [RuIV(O)(pdc-κ2-N1O1)(bipy)2], upon the addition of CeIV ions in solution and a WNA mechanism was proposed for O–O bond formation [103]. Complex 32 was studied electrochemically with a TOF of 3400 s−1, and the high-valent RuIV=O involved in the catalytic cycle had a seven-coordinate intermediate with a dangling carboxylate group, which could facilitate O–O bond formation by intramolecular proton transfer and thus decrease the activation energy [103]. In 2021, Ahlquist et al. reported a mononuclear catalyst, [Ru(bnda)(pic)2] (33) (where, H2bnda = 2,2′-bi(nicotinic acid)-6,6′-dicarboxylic acid), to investigate the effect of steric hindrance and hydrophilicity of the bda backbone [104]. The comparison of the parent backbone of complex 14 and [Ru(pda)(pic)2] (34) (where, pda2− = 1,10-phenanthroline-2,9-dicarboxylate, pic = 4-picoline) and [Ru(biqa)(pic)2] (35) (where, biqa2− = (1,1′-biisoquinoline)-3,3′-dicarboxylate) indicated a switching of the mechanism of O–O bond formation between the WNA and I2M pathway [104]. Based on experimental studies, catalyst 33 undergoes I2M, whereas complexes 34 and 35 follow the WNA pathway, although DFT calculations of complexes 33–35 have indicated that I2M is a more favorable pathway. This difference may be due to failure to consider solvation effects and the collision of RuV=O species in the DFT calculations [104].

The modification of the axial ligands to enhance the catalytic performance of mononuclear ruthenium complexes was explored by Sun and coworkers. They designed the complexes, [Ru(bda)(Im)2] (36) (where, Im = imidazole) and [Ru(bda)(Im)(DMSO)] (37) (where, DMSO = dimethylsulfoxide) [105,106], which contained both imidazole and DMSO as axial ligands. Complex 36, with two axial imidazole ligands, yielded a TON of 1150 and a TOF of 4.5 s−1 for chemical water oxidation [105]. In contrast, the complex [Ru(bda)(Im)(DMSO)] (37), which contained an imidazole and DMSO axial ligand, exhibited better stability and improved catalytic activity with a TON of 4050 and a TOF of up to 176.5 s−1 [105]. Detailed mechanistic investigations of the catalytic water oxidation reaction using kinetics, electrochemistry, high-resolution mass spectrometry, and density functional theory (DFT) calculations suggested the in situ formation of a RuII complex with an accessible seventh coordination site. The measured catalytic activity and kinetics revealed the influence of the axial ligands on the catalytic activity, where the increase of catalytic activity for complex 37 with an axial imidazole and DMSO ligands was attributed to the unhindered coupling between terminal oxygen atoms [105]. The catalytic activity of mononuclear ruthenium complexes was shown to be further enhanced with a TON of 6200 and TOF of 506 s−1 by employing two bromo substituted pyrazole-based axial ligands, [RuII(bda)(L)2] (38) (where bda2− = 2,2′-bypyridine-6,6′-dicarboxylate and L = 4-Br-3-methyl pyrazole). The enhanced catalytic activity of 38 was ascribed to the high hydrophobicity of the complex, which tended to favor dimerization and, hence, facilitate the I2M reaction pathway [48,106]. Complexes 36–38 presented the possibility of simultaneously observing the effects of the axial and equatorial ligand modifications. However, the modification of the equatorial backbone ligand, bda2−, used in these catalysts has not been fully explored to date. This is most likely due to the challenges that are involved in the synthesis of substituted bda2− backbone ligands [50]. This is an avenue that could lead to further improvements of the catalytic performance as the introduction of substituents on the bda2− backbone has been shown to influence the mechanistic pathways of mononuclear catalysts [50].

Table 2.

Selected catalytic parameters and experimental conditions for Ru catalysts 11–38 in water oxidation. Electrochemical and chemical water oxidation using [Ce(NO3)6][(NH4)2] (CAN) are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TON or TOF values that are not listed in this table are unavailable in literature *.

Table 2.

Selected catalytic parameters and experimental conditions for Ru catalysts 11–38 in water oxidation. Electrochemical and chemical water oxidation using [Ce(NO3)6][(NH4)2] (CAN) are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TON or TOF values that are not listed in this table are unavailable in literature *.

| Ru Complex | TON | TOF (s−1) | Experimental Conditions | Reference |

|---|---|---|---|---|

| 11 | 260 | 0.014 | chem WO | [50,71,86] |

| 12a | 320 | 0.0296 | chem WO | [85] |

| 13a | 390 | - | chem WO | [86] |

| 13b | 190 | - | chem WO | [86] |

| 13c | 110 | - | chem WO | [86] |

| 13d | 260 | - | chem WO | [86] |

| 13e | 570 | - | chem WO | [86] |

| 14a | 2000 | 41 | chem WO | [53] |

| 14b | 8360 | 303 | chem WO | [53] |

| 15 | 553 | 0.23 | chem WO | [91] |

| 16 | 17 | 7.2 × 10−3 | chem WO | [91] |

| 17 | 4000 | 7.4 | chem WO (w/[Ru(bipy)3]3+) | [92] |

| 18 | 180 | 0.3 | chem WO (w/[Ru(bipy)3]3+) | [92] |

| 19 | 280 | 1.16 | chem WO (w/[Ru(bipy)3]3+) | [94] |

| 20 | 400 | 1.6 | chem WO (w/[Ru(bipy)3]3+) | [95] |

| 23 | n.a | - | inactive | [97] |

| 26 | 5.0 | 0.65 | chem WO | [100] |

| 27 | 3.8 | 58 | chem WO | [100] |

| 28 | 3.8 | 107 | chem WO | [100] |

| 30 | 21 | - | electrochem WO | [102] |

| 31 | 1.2 | 0.2 | chem WO | [78] |

| 32 | n.a | 3400 | electrochemWO | [103] |

| 33 | 480 | 10 | chem WO | [104] |

| 34 | 310 | 0.102 | chem WO | [107] |

| 35 | 87 | 0.63 | chem WO | [108] |

| 36 | 1150 | 4.5 | chem WO | [105] |

| 37 | 4050 | 176.5 | chem WO | [105] |

| 38 | 6200 | 506 | chem WO | [106] |

* Foot of wave analysis (FOWA) was used to calculate the catalytic parameters of the following complexes: 21: TON 2.7 × 107, TOF 50,000 s−1 [54]; 22: TOF 9400 s−1 [96]; 24: TON 4 × 106, TOF 40,000 s−1 [97]; 25: TON 587, TOF 0.63–0.74 s−1 [98]; 29: TON 4.2 × 107, TOF 16,000 s−1 [101].

Figure 4.

Selected mononuclear ruthenium complexes 11–38 for water oxidation: [(ntp)(pic)2Ru(H2O)]2+ (11, ntp = 2,6-di (1,8-naphthyridin-2-yl)-4-tert-butylpyridine, pic = 4-picoline) [71,86]; Ru(terpy)(bipy)(OH2)]2+ (12a, bipy = 2,2′-bipyridine) [85], [Ru(terpy)(bpm)(OH2)]2+ (12b, terpy = 2,2′:6′,2″-terpyridine, bpm = 2,2′-bipyrimidine) [82]; [Ru(terpy)(bpz)(OH2)]2+ (12c, terpy = 2,2′:6′,2″-terpyridine, bpz = 2,2′-bipyrazine) [82]; [Ru(terpy)(bipy)(Cl)]+ (13a, terpy = 2,2′:6′,2″-terpyridine, bipy = 2,2′-bipyridine); [Ru(terpy)(dmbipy)(Cl)]+ (13b, dmbipy = 4,4′-dimethyl-2,2′-bipyridine); [Ru(terpy)(dmxbipy)(Cl)]+ (13c, dmxbipy = 4,4′-dimethoxy-2,2′-bipyridine); [Ru(terpy)(dnbipy)(Cl)]+ (13d, dnbipy = 4,4′-dinitro-2,2′-bipyridine); [Ru(terpy)(dedcbipy)(Cl)]+ (13e, dedcbipy = diethyl-2,2′-bipyridine-4,4′-dicarboxylate) [86]; [Ru(bda)(pic)2] (14a, bda = 2,2′-bipyridine-6,6′-dicarboxylate, pic = 4-picoline); [Ru(bda)(isq)2] (14b, isq = isoquinoline) [53]; [Ru(pdc)(pic)3] (15, pdc = 2,6-pyridinedicarboxylate, pic = 4-picoline) [91]; [Ru(pdc)(bipy)(pic)] (16, pdc = 2,6-pyridinedicarboxylate, bipy = 2,2′-bipyridine, pic = 4-picoline) [91], [RuIII(L)(pic)3] (17, L = 2-(2-hydroxyphenyl)-1H-benzimidazole-7-carboxylate; 18, L = 2-(2-hydroxyphenyl)-1H-benzimidazol-7-ol) [92]; [Ru(HL)(pic)3] (19, L = 6-carbamoylpicolinic acid) [94]; [RuIII(H2pdca)(pic)3]+ (20, H4pdca = 2,6-pyridine-dicarboxamide) [95]; [RuIV(OH)(tda-κ-N3O(py)2]+ (21, tda = 2,2′:6′,2″-terpyridine-6,6″-dicarboxylate, py = pyridine) [54]; {RuV(O)(t5a-κ-N2O)(py)2} (22, t5a = 2,5-bis(6-carboxylatopyridin-2-yl)pyrrol-1-ide, py = pyridine) [96]; [Ru(mcbp)(py)2] (23, mcbp = 2,6-bis(1-methyl-4-(carboxylate)-benzimidazol-2-yl)pyridine, py = pyridine); [RuIV(O)(mcbp)(py)2] (24) [97]; [Ru(bda)(pic)(pyC)] (25, bda = 2,2′-bipyridine-6,6′-dicarboxylate, pic = 4-picoline, pyC = 2-pyridinecarboxylate) [98]; Ru(bpaH2)(pic)2] (26, bpaH2 = 2,2′-bipyridine-6,6′-diphosphonate, pic = 4-picoline); [RuIII(bpHc)(pic)2]+ (27, bpH2cH = 2,2′-bipyridine-6-phosphonic acid- 6′-carboxylic acid); [RuII(bpHc)(isq)2] (28, isq = isoquinoline) [100]; [RuIII(tPaO-κ-N2OPOC)(py)2]2− (29, tPaO = 3-(hydroxo-[2,2′:6′,2″-terpyridine]-6,6”-diyl)bis(phosphonate) [101]; [(LN5−)RuIII-OH]+ (30, L = 2-(bis-pyridin-2-ylmethyl-amino)-N-(2-pyridin-2-yl-phenyl)-acetamide) [102]; [Ru(pdc-κ3-N1O2)(bipy)(H2O)] (31, pdc = pyridyl-2,6-dicarboxylato, bipy = 2,2′-bipyridine) [78]; and [Ru(pdc-κ2-N1O1)(bipy)2] (32, pdc = pyridyl-2,6-dicarboxylato, bipy = 2,2′-bipyridine) [103]; [Ru(bnda)(pic)2] (33, bnda = 2,2′-bi(nicotinic acid)-6,6′-dicarboxylate) [104], [Ru(pda)(pic)2] (34, pda = 1,10-phenanthroline-2,9-dicarboxylate, pic = 4-picoline) [107]; [Ru(biqa)(pic)2] (35, biqa = (1,1′-biisoquinoline)-3,3′-dicarboxylate) [108]; [Ru(bda)(Im)2] (36, bda = 2,2′-bipyridine-6,6′-dicarboxylate, Im = imidazole); [Ru(bda)(Im)(DMSO)] (37, DMSO = dimethylsulfoxide) [105]; [Ru(bda)(L)2] (38, bda = 2,2′-bypyridine-6,6′-dicarboxylate, L = 4-Br-3-methyl pyrazole) [106].

Table 3.

Comparison of complexes 21 and 22 that contain similar backbone ligands.

Table 3.

Comparison of complexes 21 and 22 that contain similar backbone ligands.

| Ru Complex | CCN Angle for Free Backbone Ligand | CCN Angle for Complex (ave.) * | Coordination Number | Activation Energy | Redox Potential (RuIV/RuIII, RuV=O/RuIV=O) |

|---|---|---|---|---|---|

| 21 (tda) | 120° | 113.9° | 7 | M11-L, 19.5 kcal/mol | 1.1 V, 1.43 V |

| 22 (t5a) | 126° | 111.5° | 6 | M06-L, 14.2 kcal/mol | 0.55 V, 1.41 V |

* The CCN angle for complex (ave.) determined from structural data available from the Cambridge Structural Database (CSD).

3. Iridium Catalysts

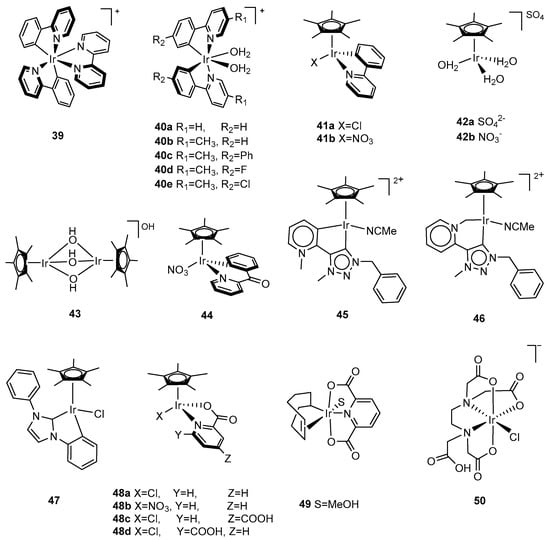

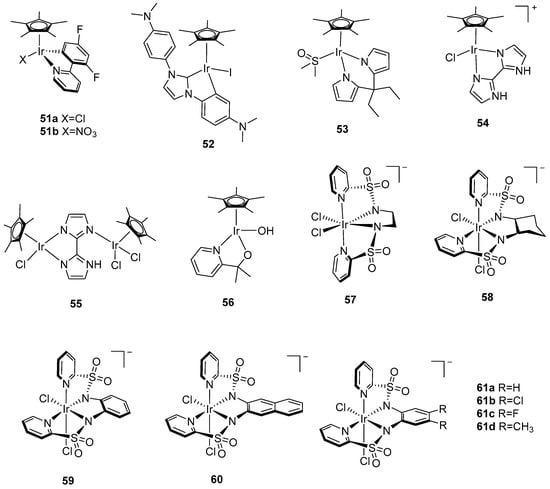

Iridium-based homogeneous catalysts were not reported in the literature until 2008. Below, we briefly review the research in this area that has been summarized elsewhere through 2015 [7]. In 2008, Bernhard et al. studied bis-aqua iridium complexes (Figure 5, 40a–40e) with cyclometalating ligands and a surrogate catalyst, [IrIII(ppy)2(bipy)]+ (39) (where, bipy = 2,2′-bipyridine, ppy = 2-phenylpyridine), without coordinated aqua ligands [109]. One of the complexes (40d) achieved a TON of 2760 after a week in CeIV solution (Table 4), while the investigation of catalytic activity of the surrogate catalyst displayed no oxygen evolution. This finding suggested that open coordination sites (for water ligands) were necessary for catalysis [109]. In 2009, Crabtree and coworkers developed precatalysts based on iridium with pentamethylcyclopentadienyl (Cp*) and 2-phenylpyrimidine (or ppy) ligands [110]. The precursor, [IrIII(Cp*)(ppy)(Cl)] (41a), catalyzed water oxidation driven by CeIV with a TOF of 54 min−1, which was considered the most active catalyst at that time [110]. The [IrV(Cp*)(O)(ppy)]+ species was proposed as a possible intermediate in agreement with electronic structure calculations by DFT [110]. The following year, Crabtree and coworkers developed iridium half-sandwich complexes, such as Cp*Ir(N-C)X, [Cp*Ir(N-N)X]X, and [CpIr(N-N)X]X (where, X = Cl, I or NO3−), as precatalysts for water oxidation, which have been reviewed in the literature [7].

In this review, we highlight that the tris-aqua [Cp*Ir(H2O)3]SO4 (42a) and dimeric [(Cp*Ir)(µ-OH)3(IrCp*)]OH (43) complexes exhibited TOFs of up to 20 min−1 and 25 min−1 on a per-iridium basis, respectively, with CeIV as the primary oxidant at pH 0.89 [111]. DFT calculations indicated that an O–O bond was formed by the intermolecular attack of water to an iridium oxo ligand, and proton transfer to the oxo group was assisted by an additional water molecule [111]. A parallel study on a tris-aqua complex, [Cp*Ir(H2O)3](NO3)2 (42b), was conducted by MacChioni and coworkers, which highlighted that both the synthetic ease to the tris-aqua complex, [Cp*Ir(H2O)3](NO3)2 (42b), as well as the high activity with TOFs up to 15.7 min−1 with long-term activity [112]. Another complex, [Cp*Ir(bzpy)NO3] (44) (where, bzpy = 2-benzoylpyridine), with NO3− as a ligand to impart water solubility, was examined with a TON of 1250 and a TOF of 8.46 min−1, as measured by UV-Vis under CAN [112,113]. The value increased to 12.7 min−1 when the oxygen evolution was measured by a Clark electrode [113] and up to 31 min−1 by probing different catalyst concentrations [114].

Iridium complexes with a carbene-type ligand were developed by Bernhard and coworkers in 2010 and two resulting complexes, 45 and 46, exhibited excellent stability with TONs of 10,000 and 8350 within 5 days, respectively [115]. In 2011, Crabtree and coworkers incorporated an N-heterocyclic carbene (NHC) ligand and Cp* to form the complex [Cp*Ir(NHC)Cl] (47) as a precatalyst that displayed moderate activity with a TOF of 8 min−1 driven by CAN and a TOF of 12–16 min−1 with sodium periodate (at pH 5); deactivation of the precatalyst was ascribed to the low pH in CeIV solution under the former conditions [116]. As incorporation of a carboxylate moiety into ligands on ruthenium proved to be an effective strategy to improve catalytic activity (vide supra), MacChioni and coworkers developed a series of iridium complexes, 48a–48d and 49, as precatalysts for water oxidation [114]. The complexes 48a and 48b exhibited impressive performances with TOFs of 287 min−1 and 277 min−1 under optimized conditions with CeIV as sacrificial oxidant, respectively, whereas complex 49, bearing a dicarboxylate moiety, turned out to be the least active [114]. Complex 48d, with a pendant –COOH moiety, featured the lowest potential and exhibited a TOF of 17 min−1 [114]. In 2012, MacChioni and coworkers developed the precatalyst [IrCl(Hedta)]Na (50) with monoprotonated ethylenediaminetetraacetic acid (edta) with a goal to replace Cp* as it slowly degraded in harsh acidic oxidative conditions [117]. The Hedta ligand is easy to synthesize and can stabilize metal ions in high oxidation states [117]. The complex (50) exhibited excellent stability with a TON up to 12,000, whereas it showed only moderate TOFs of 5.4 to 7.3 min−1 [117]. An interesting finding was the neutral complex [Ir(H2O)(Hedta)], which catalyzed water oxidation with a TOF of 2.6 min−1. It was suggested that the complex [IrCl(Hedta)]− underwent ligand exchange with water to generate [Ir(H2O)(Hedta)] for water oxidation [117]. In 2014, MacChioni et al. developed Cp*-based precatalysts 41b, 51a, 51b, 52, 53, 54, and 55, some with strongly electron-donating amido ligands. These complexes showed stabilities through TONs > 500 for all the precatalysts examined. The complexes [Cp*Ir(bimH2)Cl]Cl (54) (where, bimH2 = 2,2′-bismidazole) and [Cp*IrCl(μ2-κ2-κ1-bimH)IrCl2Cp*] (55) displayed high catalytic activities with TOFs of 26 min−1 and 58 min−1, respectively, as measured by a Clark electrode. Complex 52, bearing an NHC ligand, showed a TOF of 7 min−1 from UV-Vis data [118], which agreed well with analogous complex [Cp*Ir(NHC)Cl] (47) with a TOF of 8 min−1 reported by Crabtree et al. [116]. Although an NHC ligand can effectively stabilize high-valent iridium (IV), as evidenced by the EPR observations [116], Cp*Ir precatalysts incorporating the NHC ligand did not display high catalytic activity.

Molecular iridium catalysts experienced noteworthy progress in 2015 when Brudvig, Crabtree, Schmuttenmaer and coworkers developed an inactive molecular iridium catalyst, [Cp*Ir(pyalc)OH] (56), that dimerized in NaIO4 solution to generate a highly active system once bound to an oxide surface. The so-called het-WOC (56-het) can electrochemically catalyze water oxidation with low overpotential (η = 14 mV) and a high TOF (7.9 s−1) and stability, with a TON of 106 [119]. This het-WOC is different from a benchmark IrO2 nanomaterial (60–100 nm) that required 580 mV to reach an oxygen evolution rate of 6.6 s−1 per electroactive iridium atom [119].

Bernhard and coworkers developed a series of iridium(III) complexes in 2016 [120,121] and 2017 [120,121] with tetradentate bis(pyridine-2-sulfonamide) (bpsa) chelates (57–59) to form resilient wrap-around ligand environments; this structure provides a strong electron-donating environment to stabilize positively-charged iridium intermediates. These catalysts (57–59) exhibited good stability with TONs up to 3540, whereas the best initial TOF of these catalysts was 7.5 × 10−3 s−1 [120]. Through the modification of the linker moiety to tune the electronic structures of complexes 60 and 61a–61d, complex 60 exhibited good catalytic activity with a TON of 13,840 and a TOF of 1.38 × 10−2 s−1; the complex [IrIII(bpsa-Ph)(Cl)2]− (61a) achieved an even higher TON of 16200 and a TOF 3.90 × 10−2 s−1 with CeIV as oxidant at pH 1 [121]. (Please note that complex 59 and 61a are the same; due to different experimental conditions reported, the TON and TOF data reported in reference [121] is larger than that reported in reference [120]). Electrochemical quartz-crystal microbalance studies were employed to distinguish the heterogenous WOCs from homogenous catalysts; dynamic light scattering (DLS) experiments ruled out IrOx particles for catalytic activity in CeIV-driven water oxidation [120,121]. More recently, Bonchio et al. [122] reported the first light-driven water oxidation catalyst, an IrIV,IV2(pyalc)2 μ-oxo-dimer (where, pyalc = 2-(2′-pyridyl)-2-propanoate) called ‘Ir-blue’, synthesized by reacting inactive complex [Cp*Ir(pyalc)OH] (56) with excess sodium periodate [123]. The catalytic activity of the dimer depended on the light intensity and can reach up to a TON of 32 and TOF of 9.7 × 10−2 s−1 per iridium center under standard photochemical water oxidation conditions, e.g., Ru(bipy)32+ as a photosensitizer and Na2S2O8 as sacrificial electron acceptor [122].

Figure 5.

Chemical structures of iridium catalysts 39–61 for water oxidation: [IrIII(ppy)2(bipy)]+ (39, ppy = 2-phenylpyridine, bipy = 2,2′-bipyridine) [109]; [Ir(ppy)2(H2O)2]+ (40a, ppy = 2-phenylpyridine); [Ir(5-R1,4′-R2,2- phenylpyridine)2(H2O)2]+ (40b, R1 = CH3, R2=H; 40c, R1 = CH3, R2 = Ph; 40d, R1 = CH3, R2 = F; 40e, R1 = CH3, R2 = Cl) [109]; [IrIII(Cp*)(ppy)(Cl)] (41a, Cp* = pentamethylcyclopentadienyl, ppy = 2-phenylpyridine); [IrIII(Cp*)(ppy)(NO3)] (41b, Cp* = pentamethylcyclopentadienyl, ppy = 2-phenylpyridine) [110]; [Cp*Ir(H2O)3]SO4 (42a, Cp* = pentamethylcyclopentadienyl) [111]; [Cp*Ir(H2O)3](NO3)2 (42b, Cp* = pentamethylcyclopentadienyl) [112]; [(Cp*Ir)(µ-OH)3(IrCp*)]OH (43, Cp* = pentamethylcyclopentadienyl) [111]; [Cp*Ir(bzpy)NO3] (44, bzpy = 2-benzoylpyridine) [112], [Cp*Ir(MeCN)(L)]2+ (45, L = 2-(1-benzyl-1H-1,2,3-triazol-4-yl)pyridine, carbon-bound); (46, L = 2-(1-benzyl-1H-1,2,3-triazol-4-yl)pyridine, nitrogen-bound) [115]; [Cp*Ir(κ2C2,C2′-NHC)Cl] (47, κ2C2,C2′-NHC = κ2C2,C2′-1,3-diphenylimidazol-2-ylidene) [116]; [Cp*Ir(κ2-N,O)X] (48a, κ2-N,O = 2-pyridinecarboxylate, X = Cl; 48b, κ2-N,O = 2-pyridinecarboxylate, X = NO3; 48c, κ2-N,O = 4-carboxy-2-pyridinecarboxylate, X = Cl; 48d, κ2-N,O = 6-carboxy-2-pyridinecarboxylate, X = Cl); [Ir(κ3-N,O,O)(1-κ-4,5-η2-C8H13)(MeOH)] (49, κ3-N,O,O = 2,6-pyridinedicarboxylate) [114], [IrCl(Hedta)]¯ (50, Hedta = monoprotonated ethylenediaminetetraacetic acid) [117]; [Cp*Ir(2′,4′-F2-ppy)Cl] (51a, 2′,4′-F2-ppy = 2′,4′-difluoro-2-phenylpyridine); [Cp*Ir(2′,4′-F2-ppy)(NO3)] (51b, 2′,4′-F2-ppy = 2′,4′-difluoro-2-phenylpyridine); [Cp*Ir(κ2-C2,C2′-NHC)I] (52, κ2-C2,C2′-NHC = κ2-C2,C2′-1,3-bis(4-(N,N-dimethylamino)phenyl)-imidazol-2-ylidene); [Cp*Ir(bpyr)(DMSO)] (53, bpyr = bis-diethyl-pyrrole, DMSO = dimethylsulfoxide); [Cp*Ir(bimH2)Cl]Cl (54, bimH2 = 2,2′-bisimidazole); [Cp*IrCl(μ2-κ2-κ1-bimH)IrCl2Cp*] (55, bimH = 2,2′-bisimidazole) [118], [Cp*Ir(pyalc)OH] (56, pyalc = 2-(2′pyridyl)-2-propanolate) [119], [Ir(bpsa-en)Cl2]− (57, bpsa-en = N,N’-(ethane-1,2-diyl)bis(pyridine-2-sulfonamide); [Ir(bpsa-Cy)Cl2]− (58, bpsa-Cy = N,N’-((1R,2R)-cyclohexane-1,2-diyl)bis-(pyridine-2-sulfonamide)); [Ir(bpsa-Ph)Cl2]− (59, bpsa-Ph = N,N’-(phenylene-1,2-diyl)bis(pyridine-2-sulfonamide)) [120]; [Ir(bpsa-NPTH)Cl2]− (60, bpsa-NPTH = N,N’-(naphthalene-2,3-diyl)bis(pyridine-2-sulfonamide)) [121], [Ir(bpsa-Ph)Cl2]− (61a, bpsa-Ph = N,N’-(phenylene-1,2-diyl)bis(pyridine-2-sulfonamide)); [Ir(bpsa-PhdCl)Cl2]− (61b, bpsa-PhdCl = N,N’-(4,5-dichloro-phenylene-1,2-diyl)bis(pyridine-2-sulfonamide)); [Ir(bpsa-PhdF)Cl2]− (61c, bpsa-PhdF = N,N’-(4,5-difluoro-phenylene-1,2-diyl)bis(pyridine-2-sulfonamide)); [Ir(bpsa-PhdMe)Cl2]− (61d, bpsa-PhdMe = N,N’-(4,5-dimethyl-phenylene-1,2-diyl)bis(pyridine-2-sulfonamide)) [121].

Table 4.

Selected catalytic parameters and experimental conditions for Ir catalysts 39–61 for water oxidation. Electrochemical and chemical water oxidation using CAN are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TON or TOF values that are not listed in this table are unavailable in literature.

Table 4.

Selected catalytic parameters and experimental conditions for Ir catalysts 39–61 for water oxidation. Electrochemical and chemical water oxidation using CAN are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TON or TOF values that are not listed in this table are unavailable in literature.

| Ir Complex | TON | TOF | Condition | References |

|---|---|---|---|---|

| 39 | 0 | 0 s−1 | chem WO | [109] |

| 40a | 2490 | - | chem WO | [109] |

| 40b | 2270 | - | chem WO | [109] |

| 40d | 2760 | - | chem WO | [109] |

| 41a | n.a | 54, 4.68 min−1 | chem WO | [110,112] |

| 41b | >500 | 14 min−1 | chem WO | [118] |

| 42a | - | 20 min−1 | chem WO | [111] |

| 42b | - | 15.7 min−1 | chem WO | [112] |

| 43 | - | 25 min−1 | chem WO | [111] |

| 44 | 1250 | 8.4, 8.46, 12.7, 31 min−1 | chem WO | [112,113,114] |

| 45 | 10,000 | 314 h−1 | chem WO | [115] |

| 46 | 8350 | - | chem WO | [115] |

| 47 | - | 8 min−1 | chem WO | [116] |

| 48a | 1200 | 287 min−1 | chem WO | [114] |

| 48b | 2000 | 277 min−1 | chem WO | [114] |

| 48c | 750 | 23 min−1 | chem WO | [114] |

| 48d | 1300 | 17 min−1 | chem WO | [114] |

| 49 | 500 | 5 min−1 | chem WO | [114] |

| 50 | 12,000 | 5.4–7.3 min−1 | chem WO | [117] |

| 51b | 500 | 11 min−1 | chem WO | [118] |

| 52 | n.a | 7 min−1 | chem WO | [118] |

| 53 | 500 | 11 min−1 | chem WO | [118] |

| 54 | 500 | 26 min−1 | chem WO | [118] |

| 55 | 500 | 58 min−1 | chem WO | [118] |

| 56 het * | 106 | 7.9 s−1 | electrochem WO | [119] |

| 57 | 245 | 9.07 × 10−4 s−1 | chem WO | [120] |

| 58 | 2000 | 3.55 × 10−3 s−1 | chem WO | [120] |

| 59 | 3540 | 3.55 × 10−3 s−1 | chem WO | [120] |

| 60 | 13,840 | 1.38 × 10−2 s−1 | chem WO | [121] |

| 61a | 16,200 | 3.90 × 10−2 s−1 | chem WO | [121] |

| 61b | 15,860 | 3.24 × 10−2 s−1 | chem WO | [121] |

| 61c | 13,210 | 1.69 × 10−2 s−1 | chem WO | [121] |

| 61d | 14,700 | 2.13 × 10−2 s−1 | chem WO | [121] |

* 56 het is abbreviated from ‘56-heterogenous catalyst’, generated from a dimer of 56 bound to the surface of nanoITO suspended on a fluorine-doped tin oxide (FTO) coated glass slide.

4. Catalysts Based on First Row Transition Metals

First-row transition metals have been attracting research attention in the design of efficient molecular catalysts for water oxidation due to their abundance and low cost. However, the development of water oxidation catalysts based on first-row transition metals is relatively limited by virtue of being substitutionally labile, which indicates that ligands coordinated to these metals can exchange with water and/or solvents [4]. In many cases, initial precursor complexes decompose to catalytically active metal oxide particle precipitates. Therefore, studies on water oxidation catalysts based on first-row transition metals should be carefully evaluated to rule out the formation of corresponding metal oxide particles responsible for catalyzing water oxidation. To overcome these challenges, ligands need to be structurally engineered with high metal ion affinity (even in aqueous media) to permit access to and stabilize elevated oxidation states.

4.1. Manganese Catalysts

With manganese present in the natural OEC, synthetic complexes based on manganese have attracted significant scientific interest over the years. In early studies, Brudvig, Crabtree and coworkers had proposed that the dimanganese di-μ-oxo complex, [MnIII,IV2 (μ-O)2(bipy)4][ClO4]3, was active in chemical water oxidation [124,125]. Although numerous synthetic models containing Mn have been constructed in the past 30 years [126], only a few of the complexes have demonstrated catalytic activity for water oxidation [127,128]. The first synthetic functional Mn cubane model, Mn4O4(O2P(Ph)2)6, was synthesized in 1997 [129]. This complex, as well as the Mn4O4((MePh)2PO2)6 catalyst reported by Dismukes and coworkers [130,131], can release dioxygen with UV light absorption in the gas phase as shown in Equation (2):

These two functional cuboidal clusters release dioxygen (concomitant with ligand dissociation) when excited under photochemical conditions. It has been proposed that an intramolecular two-electron charge transfer weakened Mn–O bonds and considerable distortion of the complex resulted in loss of the phosphinate bridge [130,131]. The distortion of core bonds allowed for the oxygen atoms to move in close proximity to form a peroxy intermediate, thereby lowering the activation barrier for dioxygen formation [130,131]. Subsequently, a synthetic Mn4Ca cluster featuring high structural resemblance to the natural OEC was found to be inactive in water oxidation [132].

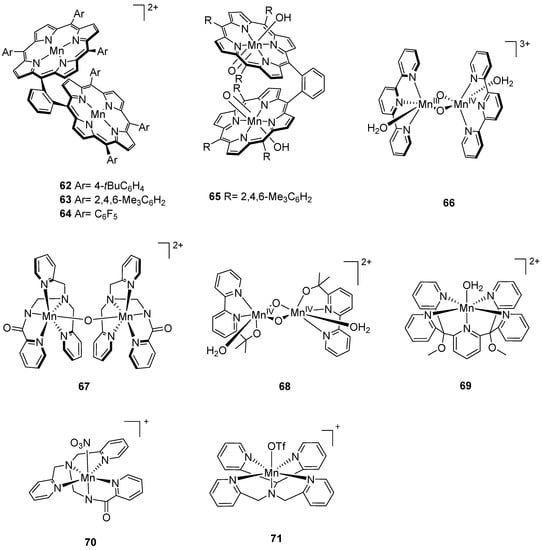

In 1994, a chelating bis-porphyrin model was used to form stable catalytic complexes, 62, 63, and 64 (Figure 6). Complex 64 showed the highest activity at high potentials (1.8–2.0 V vs. Ag/Ag+) with a TON of up to 9.2 in acetonitrile containing [nBu4N][OH] [133] (Table 5). The key intermediate involved in water oxidation, a dinuclear MnV=O (65) (Figure 6), was characterized by spectroscopic methods; however, the mechanism of O–O bond formation was inconclusive as there were two pathways to form an O–O bond: either by the attack of external water on the H2O—MnV=O group or by the coupling two MnV=O units in the dimer [134].

The earliest Mn complexes that were found to be active in light-driven water oxidation were coordinated to a dianionic tetradentate N2O2 Schiff base ligand, of which the complex [{MnIII(salpd)(H2O)}2][CIO4]2 (where, salpd = propane-l,3-diylbis(salicylideneiminate) was found to be the most active [128]. The rate of dioxygen evolution was independent of solvent, however, it depended on the concentration of the manganese complex (and quinone) as well as the pH of the reaction mixture [128]. The modification of the electronic properties of the ligand generated an active complex under irradiation and in the presence of p-benzoquinone, although the activity was not as good as the parent complex, [{MnIII(salpd)(H2O)}2](CIO4)2 [135]. Water photolysis occurred when an aqueous solution of a salen-based dimer, [MnIII(3,5,Cl-salen)(H2O)2]2(ClO4)2 (where, 3,5,Cl-salen = N,N’-3,5-dichloro(salicylidene)-1,2-diaminoethane), was irradiated under visible light together with bulk p-benzoquinone [136]. X-ray diffraction presented the possibility of hydrogen bonding interactions in the system [136]. Another functional model in this context employed the negatively charged pentadentate ligand, N-methyl-N’-carboxymethyl-N,N’-bis(2-pyridylmethyl)ethane-1,2-diamine (mcbpen−), which can catalyze water oxidation driven by tert-butylhydrogenperoxide (TBHP) or CeIV [137]. The evolution of dioxygen using CeIV (pH 1) was in lower yields compared to TBHP (pH 4.75), as the pH of CeIV is very low and does not favor the formation of high-valent oxo-bridged Mn intermediates [137]. Unlike the case of [MnIII/IV2(μ-O)2(terpy)2(H2O)2](NO3)3·6H2O, which generated dioxygen under sodium hypochlorite and oxone (with ultimate decomposition to permanganate) [138,139], the complex [MnII2(mcbpen)2(H2O)2](ClO4)2 was not shown to produce permanganate as a product of water oxidation catalysis with either TBHP or CeIV as oxidant [137].

In 1999, Brudvig and coworkers synthesized a functional model, [MnIII,IV2(µ-O)2(terpy)2(H2O)2](NO3)3 (66), for water oxidation with a TOF of 0.67 s−1 [138,139]. The success of the model encouraged the group to develop a series of complexes with the general formula, [MnIII,IV2(µ-O)2(L)2(X)2]3+ (L = terpy, terpy derivatives and X = labile ligand), with their catalytic performance assayed in situ and in pure solution with oxone as the oxidant [140]. The parent catalyst with terpy, 66, exhibited the best catalytic performance and the in situ solution showed relatively higher catalytic rate than that of corresponding pure complex, which was ascribed to additional oxone solution [140]. An 18O isotope labeling experiment was carried out to study the mechanism of water oxidation by the complex with oxone as an oxidant due to the fast exchange of oxygen in hypochlorite. It was proposed that O–O bond formation involved the attack of water (or oxone) on a MnV=O intermediate. Other functional μ-oxo-bridged dinuclear models included [Mn(PaPy3)(μ-O)(PaPy3)Mn]2+ (67), reported by Brudvig and coworkers in 2013 with a TOF of 13.9 × 10−3 s−1 using oxone as an oxidant [141], and the recent complex, [Mn(bipyalk)(H2O)(µ-O)]2(OTf)2 (68), reported by Crabtree, Brudvig and coworkers that achieved a TOF of 5.5 × 10−3 s−1 with oxone as an oxidant [142]. Additionally, three functional mononuclear manganese complexes, 69–71, were developed by Brudvig and coworkers in 2013 [141]. The catalytic performance of these complexes was examined with oxone as an oxidant. Complex 69 did not show evolution of dioxygen, however, complexes 70 and 71 displayed a TOF of 9.9 × 10−3 s−1 and 3.4 × 10−3 s−1, respectively, under the same conditions, highlighting the role that the anionic N-donor carboxamido ligand in complex 70 played in stabilizing high-valent intermediate(s) [141].

Table 5.

Selected catalytic parameters and experimental conditions for Mn catalysts 62–71 for water oxidation. Electrochemical and chemical water oxidation are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TON or TOF values that are not listed in this table are unavailable in literature.

Table 5.

Selected catalytic parameters and experimental conditions for Mn catalysts 62–71 for water oxidation. Electrochemical and chemical water oxidation are abbreviated as ‘electrochem WO’ and ‘chem WO’, respectively. The TON or TOF values that are not listed in this table are unavailable in literature.

| Mn complex | TON | TOF | Condition | References |

|---|---|---|---|---|

| 62 | - | 0.04 min−1 | electrochem WO | [133] |

| 63 | - | 0.05 min−1 | electrochem WO | [133] |

| 64 | 9.2 | 0.11 min−1 | electrochem WO | [133] |

| 65 | - | - | chem WO w/m-CPBA | [134] |

| 66 | >50 | 0.67 s−1 | chem WO w/oxone | [139,143] |

| 67 | - | 13.9 × 10−3 s−1 | chem WO w/oxone | [141] |

| 68 | - | 5.5 × 10−3 s−1 | chem WO w/oxone | [142] |

| 69 | inactive | inactive | chem WO w/oxone | [141] |

| 70 | - | 9.9 × 10−3 s−1 | chem WO w/oxone | [141] |

| 71 | - | 3.4 × 10−3 s−1 | chem WO w/oxone | [141] |

Figure 6.

Chemical structures of selected manganese catalysts 62–71 for water oxidation: [Mn2(μ-o-xyl)(tBuPP)2]2+ (62, tBuPP = 5,l0,15,20-tetrakis(4-tert-butylphenyl)-21H,23H-porphin) [133]; [Mn2(μ-o-xyl)(TMP)2]2+ (63, TMP = 5,l0,15,20-tetrakis(2,4,6-trimethylphenyl)-21H,23H-porphin) [133]; [Mn2(μ-o-xyl)(PFPP)2]2+ (64, PFPP = 5,l0,15,20-tetrakis(pentafluorophenyl)-21H,23H-porphin) [133]; [MnV2(μ-o-xyl)(TMP)2(OH)2(O)2]2+ (65, TMP = 5,l0,15,20-tetrakis(2,4,6-trimethylphenyl)-21H,23H-porphin) [134]; [MnIII/IV2(µ-O)2(terpy)2(H2O)2]3+ (66, terpy = 2,2′:6′,2”-terpyridine) [138,139]; [Mn((PaPy3)(μ-O)(PaPy3)Mn]2+ (67, PaPy3H = N,N-bis(2-pyridylmethyl)-amine-N-ethyl-2-pyridine-2-carboxamide) [141]; [MnIV(bipyalk)2(H2O)2(µ-O)2]2+ (68, bipyalk = 2-([2,2′-bipyridin])-6-yl)propan-2-olate) [142]; [Mn(PY5)(OH2)]2+ (69, PY5 = 2,6-bis(bis(2-pyridyl)methoxymethane)- pyridine) [141]; [Mn(PaPy3)(NO3)]+ (70, PaPy3H = N,N-bis(2-pyridylmethyl)-amine-N-ethyl-2-pyridine-2-carboxamide) [141]; [Mn(N4Py)OTf]+ (71, N4Py = N,N-bis(2-pyridyl- methyl)-N-bis(2-pyridyl)methylamine) [141].

4.2. Iron Catalysts

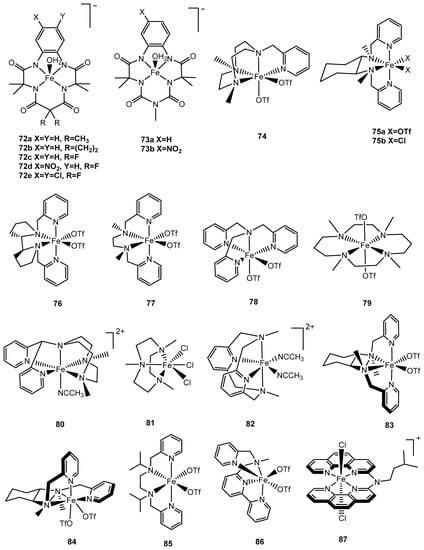

The development of iron-based complexes for water oxidation started in 2010 when Bernhard and Collins and coworkers employed tetraanionic tetraamido macrocyclic ligands (TAML), given this ligand type was known to effectively stabilize high oxidation states of transition metals and were robust against oxidation [144]. Fe-TAMLs will catalyze the evolution of dioxygen from water; complex 72e (Figure 7) exhibited the best catalytic activity with a TOF of 1.3 s−1 and a TON of 16 using CAN as an oxidant at pH 0.7 [144,145]. The catalytic activity of Fe-TAMLs increase from 72a to 72e (Figure 7), with complex 72a the least stable showing no dioxygen evolution [145]. Another Fe-TAML complex (73a) with a methylamino bridging group (—NMe) was reported in 2014 by Dhar and coworkers with an improved TON of 220, whereas the TOF of the complex decreased to 0.67 s−1 with the photosensitizer [Ru(bipy)3]2+ and Na2S2O8 as the sacrificial oxidant [146]. This complex, 73a, was found to catalyze WO driven under chemical conditions by CAN with a TON of 10 and a TOF of 0.03 s−1; the lower performance was ascribed to demetalation at pH 1. To improve the stability of Fe-TAMLs in acidic solution, a nitro group (—NO2) was introduced to further optimize catalytic performance [146]. This modification to 73b showed a slight improvement with a TON of 17 and a TOF of 0.06 s−1 compared to complex 73a under chemical WO with CeIV as an oxidant. Under photochemical WO conditions, 73a exhibited better activity than 73b with a TON of 60 and a TOF of 0.21 s−1. Supported by characterization data from techniques such as electron paramagnetic resonance (EPR), ultraviolet–visible spectroscopy (UV-Vis), and high-resolution mass spectrometry (HRMS), it was proposed that a high-valent FeV=O intermediate was generated during photochemical irradiation. Likewise, O–O bond formation was said to involve a nucleophilic attack by water at FeV=O to generate a FeIII-hydroperoxo intermediate, which then oxidized to release dioxygen and regenerate the original FeIII-TAML aqua complex [146].

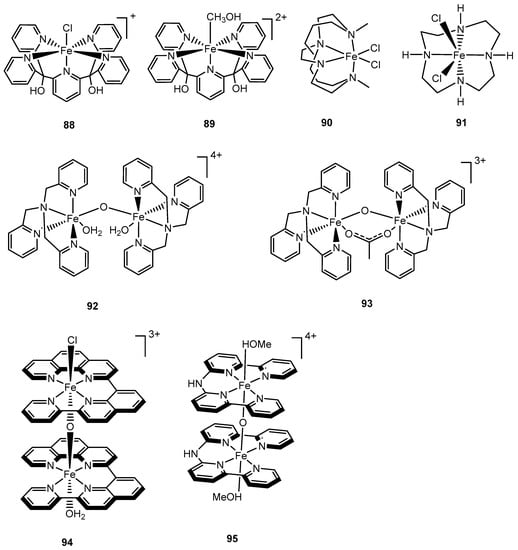

A systematic study of iron complexes for water oxidation was reported by Lloret-Fillol and Costas et al. in 2011 [147]. Neutral tetradentate organic ligands were employed to form complexes 74–80 (Figure 7), and their catalytic performances are listed in Table 6. To compare other metals with the same Me2Pytacn ligand (where, Me2Pytacn = 1-(2′-pyridylmethyl)-4,7-dimethyl-1,4,7-triazacyclononane), complexes [M(OTf)2(Me2Pytacn)] (M = Ni, Co, Mn) were synthesized and it was found that these metal complexes were inactive for water oxidation, whereas complex 74, featuring Fe, was highly active with a TON of 70 and a TOF of 0.12 s−1 using CAN as the oxidant [147]. A structural feature shared among complexes 74–78 is that they exhibit two cis labile coordination sites, which could serve as a rationale in the design of iron-based catalysts for WO. In support of this, amongst complexes 74–80, the latter two (79 and 80) are inactive; 79 features two trans labile ligands, and complex 80 has only one available (solvated) coordination site. An isotope labeling experiment involving complex 74 confirmed water (as opposed to NaIO4) as the oxygen source for dioxygen and a kinetic study showed FeIV=O to be an intermediate (resting state) as characterized by UV-Vis and electrospray ionization mass spectrometry (ESI-MS). The mechanism was suggested to involve the oxidation of FeIV=O to form FeV=O, which undergoes attack by water to form FeIII-hydroperoxide required for O–O bond formation. FeIII-hydroperoxide will then undergo further oxidation by CeIV to form FeIV-hydroperoxide, which catalyzes the release of dioxygen [147]. DFT and time-dependent DFT calculations [148] were employed to study the catalytic cycle driven by CeIV. A more energetically favorable pathway was suggested by evoking the +IV oxidation state for all on-cycle intermediates. In 2014, Sun and coworkers explored 11 iron-based complexes, all of which featured 2 cis labile coordination sites. In addition, carboxylate or ethanolate moieties were incorporated into the design of iron-based catalysts although these modifications were not found to be as effective as similar designs for ruthenium-based catalysts for WO [149]. Dinuclear complexes structurally mimicking the ‘blue dimer’ (vide supra) were found to be inactive toward WO [149]. Only 2 complexes out of the 11 that were examined, 81 and 82, catalyzed WO to generate dioxygen with a moderate catalytic performance, with a TOF of 0.1 s−1 for complex 82 [149]. This study also ruled out the presence of nanoparticulate iron oxide in the system, which can be responsible for WO [149].

In 2015, two other aminopyridyl iron complexes, 83 and 84, were reported by Costas and Lloret-Fillol and coworkers to be topological isomers that achieved TONs of 160 and 380, respectively, and TOFs of 0.16 s−1 and 0.28 s−1, respectively [150]. The mechanism of dioxygen evolution was proposed to involve an iron-oxo-cerium intermediate, O=FeIV–O–CeIV, which was characterized by UV-Vis, cryospray high-resolution mass spectrometry (CSI-HRMS), and resonance Raman spectroscopy [150]. A different mechanism based on the formation of an iron–oxo–cerium adduct was proposed for complex 83 in water oxidation, and this heteronuclear dinuclear species was experimentally characterized [150]. Two iron-based complexes, 85 and 86, with different tetraazadentate ligands were reported by Thapper and coworkers in 2016 [151]. These two complexes leveraged a design wherein labile ligands are oriented in a cis conformation. Complexes 85 and 86 catalyze WO with TONs of 14 and 2 and TOFs of 0.18 s−1 and 2 × 10−3 s−1, respectively, using CeIV as oxidant [151].

Thummel et al. reported an interesting FeIII(dpa) complex, 87, with a square planar tetradentate polypyridyl ligand featuring two labile trans ligands that evolves dioxygen with a TOF of 0.23 s−1 driven by CeIV [152]. Another two mononuclear polypyridyl iron-based complexes with the pyridine-2,6-diylbis[di(pyridin-2-yl)methanol] (Py5OH) ligand were developed by Thapper and coworkers in 2016 [153]. The only difference between complexes 88 and 89 is that the axial chloride ligand in 88 was replaced by a methanol ligand in 89; both are catalytically active under acidic CeIV/[Ru(bipy)3]3+-driven chemistry, however, their activity depends on specific conditions for WO. For instance, complex 88 exhibited better catalytic performance than complex 89 under neutral pH with [Ru(bipy)3]3+as an oxidant for WO (TOF of 2.2 s−1 vs. 0.9s−1); however, the opposite results were observed when acidic conditions were employed. Additionally, the axial chloride ligand played a role in stabilizing catalyst 88 relative to 89, which degraded at a higher pH (10.5 vs. 9.5) [153]. Dynamic light scattering experiments were employed to examine the integrity of the complexes; no iron oxide (nano)particles were found in these systems, yet these particles were detected when the pH achieved ≥9 [153].

Complexes 79, 81, 90, and 91 are representatives of iron catalysts containing secondary or tertiary amino ligands. The first two complexes were discussed earlier in this section. In 2015, Lau et al. reported that complex 90 with a cyclam ligand exhibited catalytic activity toward WO when NaIO4 was used as oxidant, with TONs up to 1030 [154]. In the same year, Zhan and coworkers reported the first water-soluble iron-cyclen complex (91) for electrochemical WO with a TOF up to 65 s−1 [155]. However, the result from this study was proven to be incorrect due to the formation of iron oxide particulates, which were shown by Najafpour et al. to be responsible for WO [156].

Impressive progress in iron-based catalysts for water oxidation was made in 2016 when Kawata and Masaoka and coworkers reported that a penta-nuclear iron catalyst achieved a TON of 107 and a TOF of 1900 s−1 under electrochemical water oxidation [157]. Intramolecular O–O bond formation was proposed as the mechanism that involved two iron-oxo moieties [157]. The dinuclear iron complexes, 92–95, have also been developed and examined. Complex 92, reported in 2014 by Najafpour and coworkers, can catalyze water oxidation with a TOF of 0.72 s−1 in the presence of CeIV, whereas the catalytic activity of complex 93, reported by Ding and Ma and coworkers, exhibited a TON of 2380 and a TOF of 2.2 s−1 using oxone as an oxidant [158,159]. Related bis(μ-O) complexes, 94 and 95, were investigated for water oxidation. In the presence of CeIV, 94 showed reasonable activity with a TOF of 2.2 s−1 [152], while electrocatalytic water oxidation was achieved with complex 95 with a TOF of 1.2 s−1 [160].

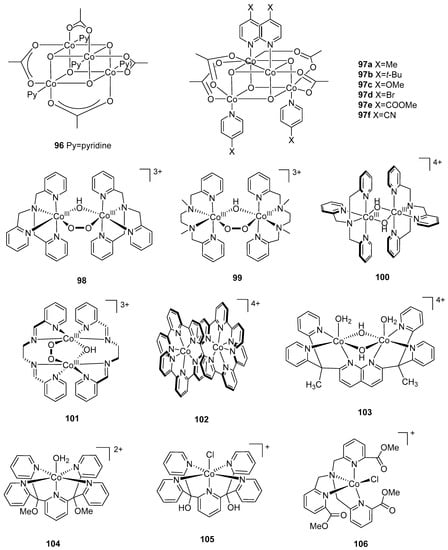

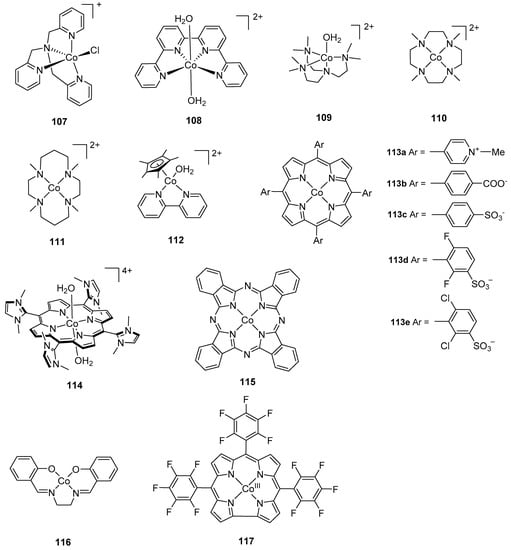

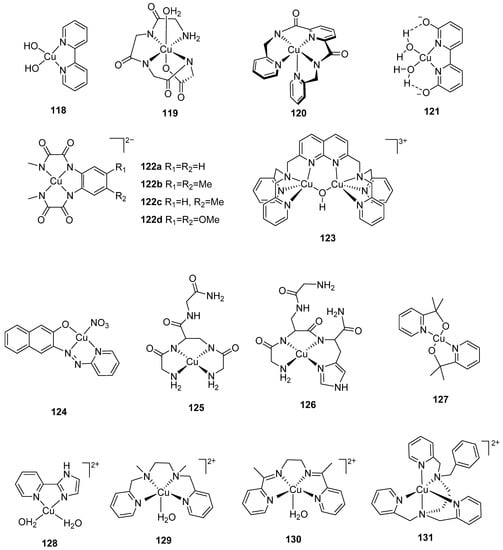

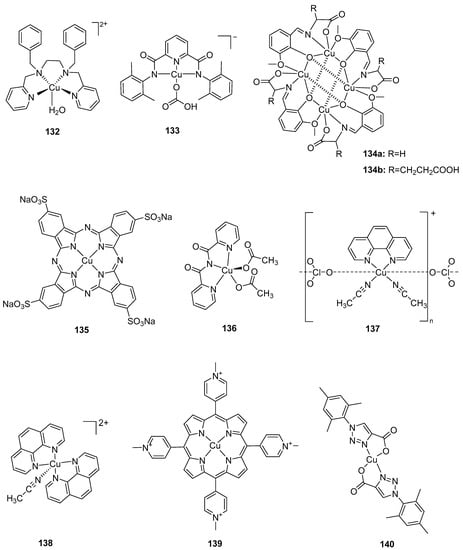

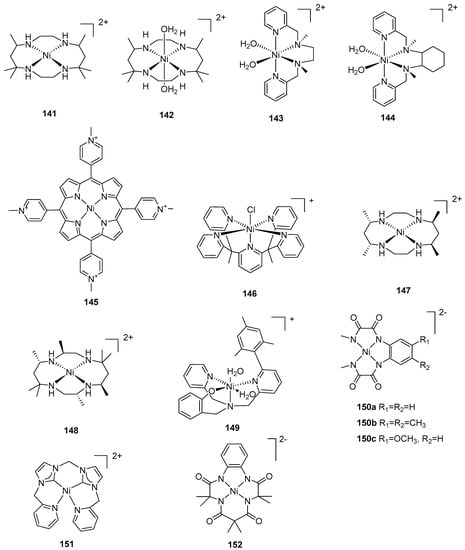

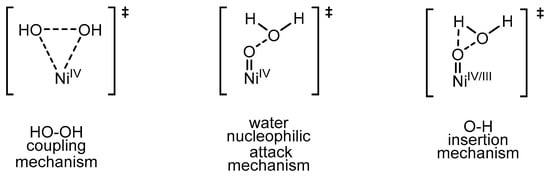

Table 6.