Abstract

The continuous oligomerization of glycerol for the formation of polyglycerol was carried out for the first time under microwave activation. In the presence of potassium carbonate, we studied the ease of handling, effects of temperature, flow rate and residence time of an inexpensive homogeneous commercial catalyst. The main linear and branched-chain diglycerol and triglycerol regioisomers were characterized and the quantification of the different isomers was realized. Successive cyclic mode processes followed by short distance distillation allowed the mixture to be enriched with glycerol ethers and thus to obtain a mixture of diglycerol (50.2 wt%), triglycerol (22.1 wt%), tetraglycerol (9.5 wt%), and pentaglycerol (4.3 wt%).

1. Introduction

Considering the programmed decrease in oil resources, the concept of biorefinery is of great interest to the chemical industry, which sees it as a new path of development [1,2,3,4,5]. In particular, the use of vegetable oils is a promising alternative to meet future challenges [6,7,8]. Among the oilseed chemicals, glycerol is an outstanding example with great potential for conversion into valuable products. Glycerol, propan-1,2,3-triol, is a polyol having two identical primary OHs in position 1 and 3, respectively and a secondary OH. The three hydroxyl groups have similar pKa and, therefore, close reactivity. Several chemical modifications obtained by oxidation, hydrogenolysis, etherification, esterification, dehydration and oligomerisation of glycerol have led to the production of various value-added chemicals. These glycerol derivatives have specific applications in the polymer, agrochemical and pharmaceutical industries [9,10,11,12,13].

In order to create sustainable processes in green chemistry and engineering, alternative intensification processes such as continuous flow [14,15] and microwave [16,17,18,19,20] have been explored. Among these, microwave-assisted continuous organic synthesis [21,22] as a hybrid technology offers significant processing advantages over traditional chemistry using a batch reactor. The main improvements related to continuous flow are the control of the temperature and reaction media, the choice of wider experimental parameters, scale-up, energy efficiency, reduced waste, improved safety of persons and infrastructure as well as the possibility to use heterogeneous catalysts and the possibility to perform multi-step synthesis, among others. The present work focuses on the efficient oligomerization of glycerol in a continuous microwave flow process.

2. Results and Discussion

Oligomerization of glycerol has been widely described through the use of different basic or acidic, homogeneous or heterogeneous catalysts. Continuing our previous work, K2CO3 as a homogeneous basic catalyst and glycerol (PG1) were chosen as this protocol can easily be carried out continuously. Oligomerization was carried out using a continuous microwave intensification process using commercial equipment (Sairem). For this study, the main linear and branched-chain diglycerol and triglycerol regioisomers were characterized in accordance with our previous works [7,18]. A brief temperature study (200 °C–238 °C) with a constant flow of 1.0 mL min−1 showed that a temperature lower than 230 °C did not permit an efficient conversion of glycerol (<2%) and 238 °C was the higher temperature allowed by the equipment (see Supplementary Materials Table S1 and Figures S2–S6 for nuclear magnetic resonance (NMR) spectra).

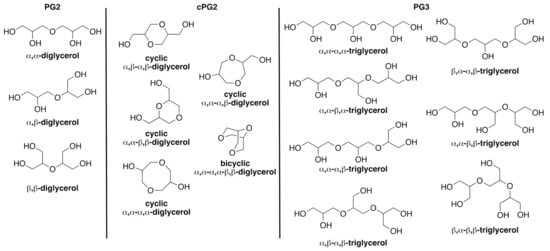

Based on these results, and in order to minimize the cyclic oligomer formation (cPG2) due to long irradiation times, variation of the flow (0.25–1.0 mL min−1) was studied at 238 °C (below 0.2 mL min−1, temperature cannot be well controlled because of heat accumulation in an irradiation cell) (Table 1). Significant oligomerization is observed, particularly at low flow (0.25 F1.0 mL min−1), with formation of many regiosisomers (PG2 and PG3) and cyclic products (cPG2). However, the conversion of glycerol (PG1) remains low because of a small reaction volume (20 mL against 54 mL total volume). However, the longer the residence time the better the glycerol (PG1) conversion and the higher the yields of diglycerol (PG2), triglycerol (PG3) and tetraglycerol (PG4). With a reaction time four times longer, glycerol (PG1) conversion and diglycerol (PG2) yield are increased from 16% to 41% and from 12% to 22%, respectively. Obviously, mixtures of dimer, trimer and tetramer include the corresponding regioisomers (PG2: α,α-diglycerol, α,β-diglycerol, β,β-diglycerol; PG3: α,α-α,α-diglycerol, α,α-β,α-diglycerol, α,α-α,β-diglycerol, α,β-α,β-diglycerol, β,α-α,β-diglycerol, α,α-β,β-diglycerol, β,α-β,β-diglycerol) (Figure 1).

Table 1.

Microwave-assisted continuous oligomerization of glycerol with peristaltic pump (gas chromatography (GC) analysis) 1.

Figure 1.

Linear/branched isomers of diglycerol (PG2) and triglycerol (PG3) and cyclic isomers of diglycerol (cPG2).

In order to increase the residence time while keeping the same equipment and specially the same reactor, the reaction mixture was re-injected to simulate a system with reactors in serial mode. These results suggest that while residence time controls glycerol conversion (Table 1), flow influences the distribution of oligomers with high flow favoring glycerol dimers over larger oligomers (Table 2).

Table 2.

Microwave-assisted continuous oligomerization of glycerol with peristaltic pump in serial mode (GC analysis) 1.

To extend the result obtained in serial mode and to obtain better selectivity of the dimer (PG2), the process was used in cyclic mode (Figure 2). In these experimental conditions, there is no steady state as the composition of the solution changes at any time. Due to the variation in volume in our system (loss of water during the reaction), it is not possible to quantify the cycles. Therefore, only the reaction time was taken as a parameter to study the evolution of the composition of the solution during the reaction cycles (Table 3). With a flow rate of 0.5 mL min−1, the modification of the oligomer distribution is confirmed and a better selectivity of the dimer PG2 (26.4% after 250 min vs. 12.3% after 50 min) has been obtained for a higher glycerol conversion. However, higher glycerol (PG1) conversion and higher diglycerol (PG2) formation as well leads to increased trimer (PG3) and tetramer (PG4) formation. The application of this method without microwave activation was carried out using the same experimental protocol using conventional heating (Table 3, entry 5). PG2 selectivity (59%) was better using microwave technology than that (34%) using conventional heating. Many works have described the thermal and kinetic phenomena (thermal microwave effect) or the selective interaction of the electromagnetic field with specific molecular entities (specific or non-thermal microwave effect). The reality is that when in all the comparison experiments between microwave heating and conventional heating applying the exact same adequately measured reaction temperature profiles we have never found any effect that ultimately could not be rationalized by a purely bulk temperature phenomenon. Incorrect temperature measurement is the only valid reason when such effects have been claimed [23,24].

Figure 2.

Cyclic microwave-assisted continuous oligomerization of glycerol in a gram scale.

Table 3.

Microwave-assisted continuous oligomerization of glycerol with peristaltic pump in cyclic mode (GC analysis) 1.

In order to obtain a mixture of oligomers with a minimum amount of glycerol (PG1) and a maximum amount of diglycerol (PG2), short path evaporation has been explored using the 2 L Short Path Distillation Kit manufactured by Lab1st (Shanghai, China). The entire kit consists a magnetic stirring heating mantle (2 L), glassware kit for short path distillation, chilling circulator, vacuum pump (2.0 L s−1). Starting from the crude mixture of glycerol derivatives, this promising separation technique was used at 150 °C under 0.1 mbar (Table 4). A new oligomerization was undertaken starting with a sample obtained after 250 min of reaction at 238 °C and 0.5 mL min−1 with similar ratio of isomers (Table 4, entry 1 and Table 3, entry 4). Glycerol (PG1) and cyclic dimer (cPG2) were completely evaporated and no trace was detected in the residual fraction (Table 4, entry 3). Furthermore, an oligoglycerol enriched mixture containing 50% diglycerol (PG2) was obtained.

Table 4.

Fractionation of the glycerol derivatives from optimized glycerol oligomerization via short path evaporation (GC analysis).

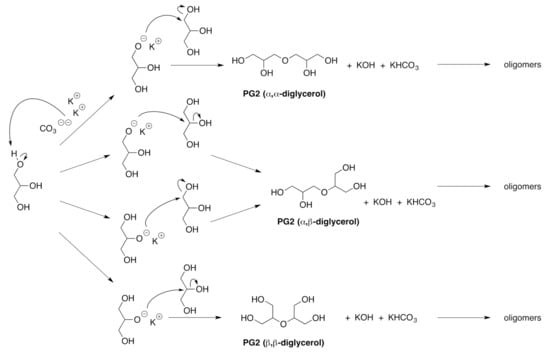

The reaction of glycerol with basic homogeneous K2CO3 followed a SN2 type route. The direct regioselective nucleophile attack of CO32− to the the primary or the secondary hydroxyl group of glycerol form the corresponding glycerolate. This anion attack to a carbon atom of a second glycerol with simultaneous split off of KOH result in a mixture of K2CO3, KHCO3 and KOH having different activities (Scheme 1). The kinetics of the reaction in homogeneous phase and the order reaction in the presence of basic carbonate was reported [25,26]. The authors mentioned that the oligomerization obeys a first-order kinetics with consecutive conversion of diglycerols to higher oligoglycerols.

Scheme 1.

Mechanism pathway for the oligomerization of glycerol in the presence of K2CO3.

3. Experimental

3.1. Reagents

Glycerol (99% purity) was purchased from Fisher. Potassium carbonate (98% purity) and bis(trimethylsilyl)acetamide (BSA, 98.5% purity) were purchased from Acros. All materials were used without further purification. Distilled H2O was used for oligomerization. For analysis, pure α,α-diglycerol, α,α-α,α-triglycerol and linear tetraglycerol were produced from commercially available reagent in accordance with literature [27]. A 2.45 GHz microwave equipment, Miniflow 200SS manufactured by Sairem SAS (Decines-Charpieu, France) was used with a Watson Marlow 520 peristaltic pump (Watson-Marlow Fluid Technology Group, Cornwall, UK).

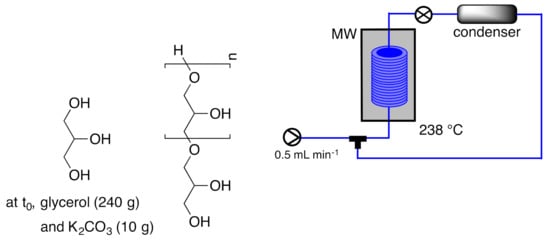

3.2. Microwave-Assisted Continuous Oligomerization of Glycerol

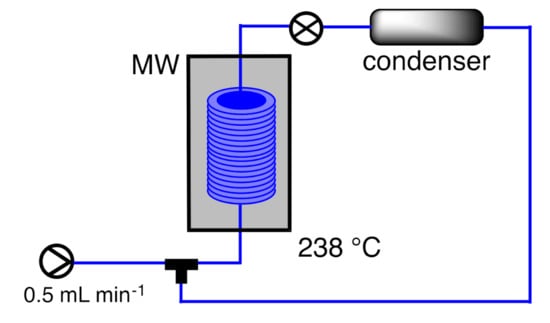

A mixture of glycerol (PG1, 240 g; 2.61 mol) and potassium carbonate (10.0 g, 72.4 mmol) were magnetically stirred (1000 rpm) at 50 °C until complete dissolution of potassium carbonate in a 250 mL glass beaker. The resulting homogeneous phase was pumped at a 0.5 mL min−1 flow using a peristaltic pump (0.1–50 mL min−1), into the coiled reactor (54 mL) including an irradiation cell (diameter 4.5 mm, 20 mL) at 238 °C (Figure 3). Peristaltic pipes volume can be neglected (1 mm diameter).

Figure 3.

Microwave-assisted continuous flow oligomerization of glycerol.

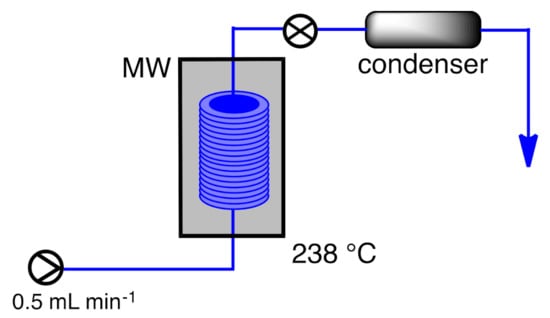

In cyclic continuous flow process, the reactor output was collected from the beginning of the experiment in the same reactor used to feed the system (Figure 4). After 250 min, the reactor output was collected. Whatever the process used, GC analysis using the calibration curve permitted the yields of glycerol oligomers to be determined (Figures S7–S11).

Figure 4.

Microwave-assisted cyclic continuous flow oligomerization of glycerol.

3.3. Gas Chromatography Analysis

Gas chromatography analyses were performed on a PerkinElmer gas chromatography (Autosystem XL GC) (Perkin Elmer, Waltham, MA, USA) with the following parameters: an Altech AT HT column, temperature of the detector at 300 °C, temperature of the injector at 340 °C, and a nitrogen constant flow of 1 mL min−1. The column was heated at 150 °C for 2 min, and then warmed to 350 °C with a temperature gradient of 15 °C min−1 before being held at that temperature for 4.67 min. Before injection, each sample was derivatized using the following protocol. Addition of bis(trimethylsilyl)acetamide (BSA) (0.5 mL) to a sample (40 mg) was realized and the mixture was heated at 50 °C for 30 min. Then 1 mL of ethyl acetate was added to the solution, and 1 mL of the resulting solution was injected in the gas chromatography column. Glycerol, linear diglycerol, triglycerol and tetraglycerol were used as standard samples. The identification of other products was based on previous works by De Meulenaer et al. [28].

4. Conclusions

Microwave-assisted continuous oligomerization of glycerol was developed in cyclic mode using commercial equipment (Sairem). Glycerol conversion is controlled by the residence time, the continuous flow has an impact on the distribution of oligomers, with smaller oligomers being obtained for higher flow. The optimized conditions (glycerol (240 g, 2.61 mol), K2CO3 (10.0 g, 72.4 mmol) at 238 °C for 250 min, 0.5 mL min−1) afforded a glycerol conversion of 45% and a diglycerol selectivity higher than 54%. After purification by short-distance evaporation, a 50% enriched dimer mixture is obtained without a trace of glycerol and cyclic diglycerol. Further research with a larger reactor and higher power would allow more selective enriched oligoglycerol mixtures to be obtained.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4344/11/2/166/s1.

Author Contributions

R.N. and F.A.A. conceived and designed the experiments; R.N. and F.A.A. performed the experiments; R.N. and N.G. analyzed the data; C.L. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Researchers Supporting Project Number (RSP-2020/259) King Saud University, Riyadh, Saudi.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was funded by the Researchers Supporting Project Number (RSP-2020/259) King Saud University, Riyadh, Saudi.

Conflicts of Interest

The authors declare no competing financial interest.

References

- Figueroa-Diaz, A.B.; Carlos-Hernandeez, S.; Diaz-Jimenez, L. Crude glycerol/guishe based catalysts for biodiesel production: Conforming a guishe biorefinery. Catalysts 2021, 11, 3. [Google Scholar] [CrossRef]

- Checa, M.; Nogales-Delgado, S.; Montes, V.; Encinar, J.M. Recent advances in glycerol catalytic valorization: A review. Catalysts 2020, 10, 1279. [Google Scholar] [CrossRef]

- Esteban, J.; Yustos, P.; Ladero, M. Catalytic processes from biomass-derived hexoses and pentoses: A recent literature overview. Catalysts 2018, 8, 637. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, D.; Padron, D.R.; Len, C. Recent advances in catalytic hydrogenation of furfural. Catalysts 2019, 9, 796. [Google Scholar] [CrossRef]

- Manzoli, M.; Menegazzo, F.; Signoretto, M.; Marchese, D. Biomass derived chemicals: Furfural oxidative esterification to methyl-2-furoate over gold catalysts. Catalysts 2016, 6, 107. [Google Scholar] [CrossRef]

- Aitlaalim, A.; Ouanji, F.; Benzaouak, A.; El Mahi, M.; Lotfi, E.M.; Kacimi, M.; Liotta, L.F. Utilization of waste grooved Razor shel (GRS) as a catalyst in biodiesel production from refined and waste cooking oils. Catalysts 2020, 10, 703. [Google Scholar] [CrossRef]

- Galy, N.; Nguyen, R.; Blach, P.; Sambou, S.; Luart, D.; Len, C. Glycerol oligomerization in continuous flow reactor. J. Ind. Eng. Chem. 2017, 51, 312–318. [Google Scholar] [CrossRef]

- Len, C.; Delbecq, F.; Corpas, C.C.; Ramos, E.R. Continuous flow conversion of glycerol into chemicals: An overview. Synthesis 2018, 50, 723–740. [Google Scholar] [CrossRef]

- Galy, N.; Nguyen, R.; Yalgin, H.; Thiebault, N.; Luart, D.; Len, C. Glycerol in subcritical and supercritical solvents. J. Chem. Technol. Biotechnol. 2017, 92, 14–26. [Google Scholar] [CrossRef]

- Gu, Y.; Jerome, F. Glycerol as a sustainable solvent for green chemistry. Green Chem. 2010, 12, 1127–1138. [Google Scholar] [CrossRef]

- Katryniok, B.; Paul, S.; Dumeignil, F. Recent developments in the field of catalytic dehydration of glycerol to acrolein. ACS Catal. 2013, 3, 1819–1834. [Google Scholar] [CrossRef]

- Jerome, F.; Pouilloux, Y.; Barrault, J. Rational design of solid catalyst for the selective use of glycerol as a natural organic building block. ChemSusChem 2018, 1, 586–613. [Google Scholar] [CrossRef] [PubMed]

- Kansy, D.; Bosowska, K.; Czaja, K.; Poliwoda, A. The formation of glycerol oligomers with two new types of end groups in the presence of a homogeneous alkaline catalyst. Polymers 2019, 11, 144. [Google Scholar] [CrossRef] [PubMed]

- Wiles, C.; Watts, P. Continuous process technology: A tool for sustainable production. Green Chem. 2014, 16, 55–62. [Google Scholar] [CrossRef]

- Vaccaro, L.; Lanari, D.; Marrochi, A.; Strappaveccia, G. Flow approaches towards sustainability. Green Chem. 2014, 16, 3680–3704. [Google Scholar] [CrossRef]

- Liu, J.; Hou, Q.; Ju, M.; Ji, P.; Sun, Q.; Li, W. Biomass pyrolysis technology by catalytic fast pyrolysis, catalytic co-pyrolysis and microwave-assisted pyrolysis: A review. Catalysts 2020, 10, 742. [Google Scholar] [CrossRef]

- Klosowski, G.; Mikulski, D.; Lewandowska, N. Microwave-assisted degradation of biomass with the use of acid catalysis. Catalysts 2020, 10, 641. [Google Scholar] [CrossRef]

- Nguyen, R.; Galy, N.; Len, C. A Simple and Efficient Process for Large Scale Glycerol Oligomerization by Microwave Irradiation. Catalysts 2017, 7, 123. [Google Scholar] [CrossRef]

- Bookong, P.; Ruchirawat, S.; Boonyarattanakalin, S. Optimization of microwave-assisted etherification of glycerol to polyglycerol by sodium carbonate as catalyst. Chem. Eng. J. 2015, 275, 253–261. [Google Scholar] [CrossRef]

- Iaych, K.; Dumarcay, S.; Fredon, E.; Gerardin, C.; Lemor, A.; Gerardin, P. Microwave-assisted synthesis of polyglycerol from glycerol carbonate. J. Appl. Polym. Sci. 2011, 120, 2354–2360. [Google Scholar] [CrossRef]

- Saggadi, H.; Polaert, I.; Luart, D.; Len, C.; Estel, L. Microwaves under pressure for the continuous production of quinoline from glycerol. Catal. Today 2015, 255, 66–74. [Google Scholar] [CrossRef]

- Polaert, I.; Estel, L.; Luart, D.; Len, C.; Delmotte, M. A new and original microwave continuous reactor under high pressure for future chemistry. AIChE J. 2017, 63, 192–199. [Google Scholar] [CrossRef]

- Dudley, G.B.; Stiegman, A.E. Changing perspectives on the strategic use of microwave heating in organic synthesis. Chem. Rec. 2018, 18, 381. [Google Scholar] [CrossRef] [PubMed]

- Kappe, C.O. My twenty years in microwave chemistry: From kitchen ovens to microwaves that aren’t microwaves. Chem. Rec. 2019, 19, 15–39. [Google Scholar] [CrossRef] [PubMed]

- Richter, M.; Krisnandi, Y.K.; Eckelt, R.; Martin, A. Homogeneously catalyzed batch reactor glycerol etherification by CsHCO3. Catal. Commun. 2008, 9, 2112–2116. [Google Scholar] [CrossRef]

- Martin, A.; Richter, M. Oligomerization of glycerol—A critical review. Eur. J. Lipid Sci. Technol. 2011, 113, 100–117. [Google Scholar] [CrossRef]

- Cassel, S.; Debaig, C.; Benvegnu, T.; Chaimbault, P.; Lafosse, M.; Plusquellec, D.; Rollin, P. Original Synthesis of Linear, Branched and Cyclic Oligoglycerol Standards. Eur. J. Org. Chem. 2001, 2001, 875–896. [Google Scholar] [CrossRef]

- De Meuleaer, B.; Vanhoutte, B.; Huyghebaert, A. Development of chromatographic method for the determination of degree of polymerization of polyglycerol and polyglycerol fatty acid esters. Chromatographia 2000, 51, 44–52. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).