Abstract

The Internet of Things (IoT) is transforming industrial operations, particularly under Industry 4.0, by enabling real-time connectivity and automation. Accurate indoor localization is critical for warehouse management, where GPS-based solutions are ineffective due to signal obstruction. This paper presents a smart indoor positioning system (IPS) integrating Ultra-Wideband (UWB) sensors with Long Short-Term Memory (LSTM) neural networks and Kalman filtering, employing a tailored data fusion sequence and parameter optimization for real-time object tracking. The system was deployed in a 54 m2 warehouse section on forklifts equipped with UWB modules and QR scanners. Experimental evaluation considered accuracy, reliability, and noise resilience in cluttered industrial conditions. Results, validated with RMSE, MAE, and standard deviation, demonstrate that the hybrid Kalman–LSTM model improves localization accuracy by up to 4% over baseline methods, outperforming conventional sensor fusion approaches. Comparative analysis with standard benchmarks highlights the system’s robustness under interference and its scalability for larger warehouse operations. These findings confirm that combining temporal pattern learning with advanced sensor fusion significantly enhances tracking precision. This research contributes a reproducible and adaptable framework for intelligent warehouse management, offering practical benefits aligned with Industry 4.0 objectives.

1. Introduction

The Internet of Things (IoT) continues to transform industrial operations by enabling seamless interconnection of physical devices and intelligent data exchange [,,,,,,]. Within industrial contexts, the Industrial Internet of Things (IIoT) is driving the evolution of warehouse management, a critical component of smart manufacturing and Industry 4.0 [,]. Accurate real-time tracking of mobile assets in warehouses is essential for enhancing inventory visibility, minimizing manual errors, and supporting automated, data-driven decision-making [,].

Traditional GPS-based localization is ineffective indoors due to signal attenuation and interference, prompting the adoption of alternative technologies such as Ultra-Wideband (UWB), Bluetooth Low Energy (BLE), Wi-Fi, and Radio-Frequency Identification (RFID), each offering distinct trade-offs in accuracy, reliability, and cost [,,,]. Despite these advances, existing indoor positioning systems often face challenges related to noise, occlusion, and limited scalability, particularly in dynamic warehouse environments [,].

To address these limitations, this study proposes a hybrid indoor localization system that integrates UWB sensing with Long Short-Term Memory (LSTM) neural networks and Kalman filtering, employing a tailored data fusion sequence and parameter optimization to achieve high-precision, real-time tracking. The system was deployed and evaluated in a 54 m2 warehouse section, with forklifts equipped with UWB modules and QR scanners. Performance assessment included tracking accuracy, noise resilience, and statistical validation using RMSE, MAE, and standard deviation.

This research contributes to the advancement of smart warehouse management by delivering a scalable, adaptable, and robust localization solution that aligns with Industry 4.0 principles of automation, efficiency, and intelligent data-driven operations. The proposed framework demonstrates practical viability and offers a foundation for further development of IoT-enabled indoor tracking systems in industrial environments.

2. Literature Review

2.1. The Internet of Things and Industrial Automation

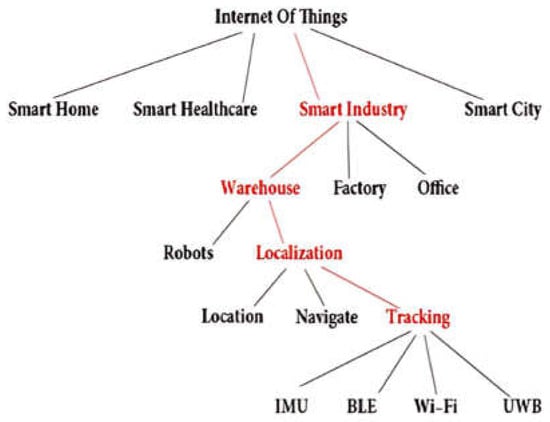

IoT has evolved significantly since the late 1990s, integrating technologies such as RFID, wireless sensor networks, smart devices, and cloud computing to enable real-time data exchange between physical and digital systems [,,]. This convergence supports applications in smart homes, healthcare, agriculture, transportation, and industrial automation. IIoT, a specialized branch of IoT, facilitates predictive maintenance, process optimization, and enhanced supply chain transparency [,]. Warehouse management systems (WMS) benefit from real-time visibility of inventory and mobile equipment [,,,]. Figure 1 demonstrates an overview of industrial automation.

Figure 1.

IoT and Industrial Automation Overview.

2.2. Challenges in Indoor Localization

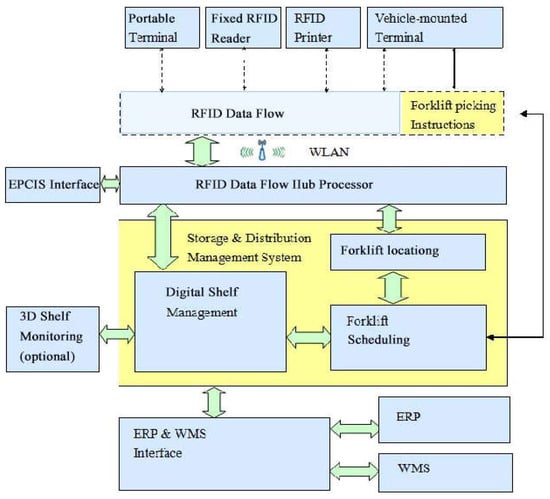

GPS performance deteriorates indoors due to signal blockage and multipath effects, prompting the use of BLE, Wi-Fi, RFID, and UWB [,,,]. UWB, in particular, offers high localization accuracy (sub-meter precision) and robustness to interference [,]. Prior studies demonstrate hybrid systems combining UWB and Kalman filtering for precise forklift tracking [,]. BLE and Wi-Fi provide cost-effective alternatives but face limitations in obstacle-rich warehouse environments [,]. Figure 2 below demonstrates indoor localization.

Figure 2.

Indoor Localization.

2.3. Machine Learning in Indoor Localization

Machine learning techniques enhance localization accuracy by processing sensor data under complex environmental conditions. Kalman filters provide noise reduction and smooth positional estimates but struggle with nonlinear motion [,,,]. LSTM neural networks capture temporal patterns in sequential data, learning from historical sensor measurements and adapting to fluctuating signal environments [,]. Hybrid methods, such as Kalman-LSTM architectures, combine noise reduction and temporal learning, improving localization in cluttered environments [,]. Figure 3 below shows machine learning in indoor localization. Hybrid methods machine learning in indoor localization is demonstrated in Figure 4.

Figure 3.

Machine Learning in Indoor Localization.

Figure 4.

Hybrid Methods Machine Learning in Indoor Localization.

2.4. Deep Learning for Sequential Data: From CNN to RNN and LSTM

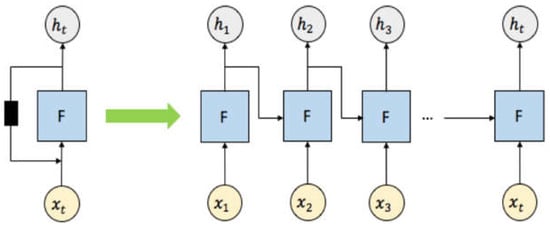

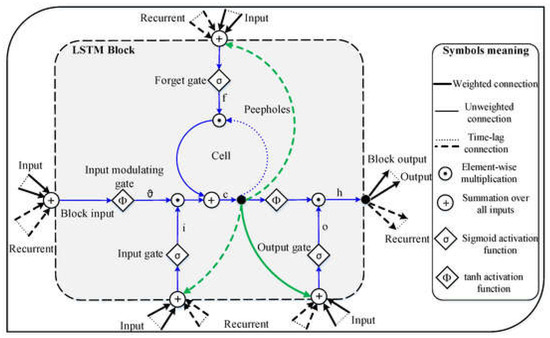

Deep learning networks, particularly RNNs and LSTMs, are effective for time-dependent data like positional tracking []. LSTM networks overcome the vanishing gradient problem, retaining long-term dependencies through memory cells and gated structures: input, forget, output, and modulation gates [,]. This makes them ideal for trajectory prediction in dynamic warehouse environments. Figure 5 below shows vanilla RNN sequential operation overview.

Figure 5.

Vanilla RNN Sequential Operation Overview.

2.5. Research Gap and Contribution

Existing IPS solutions often fail under real-world warehouse conditions due to interference, occlusion, and unpredictable forklift motion [,]. Most studies rely on controlled environments, failing to capture operational complexities. This research addresses these gaps by implementing a UWB-Kalman-LSTM hybrid system in an active warehouse, achieving improved accuracy, noise resilience, and real-time adaptability [,,,,].

3. Proposed Method

This section outlines the techniques, system architecture, and implementation strategy for the proposed indoor localization system, designed to support real-time object tracking in smart warehouse environments.

3.1. Review of Indoor Positioning Techniques

IPS alternatives for GPS include BLE, Wi-Fi, RFID, UWB, and IMUs, compared in Table 1 for accuracy, range, and cost [,,]. UWB is preferred for sub-meter precision; IMUs provide motion data but require sensor fusion; BLE and Wi-Fi are prone to signal fluctuation [,]. Table 1 displays a comparison of Indoor Localization Technologies.

Table 1.

Comparison of Indoor Localization Technologies.

3.2. Inertial Navigation System (INS)

An Inertial Navigation System (INS) estimates acceleration, velocity, and position using an Inertial Measurement Unit (IMU) comprising an accelerometer, gyroscope, and magnetometer. Given an initial position, the system continuously tracks motion based on sensor data but suffers from cumulative drift errors over time, especially indoors where GPS is unavailable. To enhance accuracy and reliability, sensor fusion techniques integrating IMUs with complementary technologies such as UWB, Wi-Fi, Bluetooth, or RFID are used to estimate initial positions and mitigate drift errors []. The following table provides a comparative overview of these supporting technologies. Table 2. Displays a Comparison of Accuracy and Coverage of Sensors.

Table 2.

Comparison of Accuracy and Coverage of Sensors.

3.3. Algorithmic Framework: Kalman Filter and LSTM

The system’s localization accuracy relies on two core algorithms: the Kalman Filter and the LSTM Neural Network. The Kalman Filter performs signal smoothing and noise reduction by blending sensor inputs with prior estimates, ensuring real-time accuracy. The LSTM, a recurrent deep learning model, learns temporal dependencies in time-series data to enhance localization precision. In this hybrid approach, the Kalman Filter first processes raw UWB signals to reduce noise, and the refined outputs are then fed into the LSTM for final position prediction, combining real-time responsiveness with temporal learning [,,].

3.4. System Architecture and Design

Hardware Components: UWB modules, IMU sensors, ceiling anchors, QR scanners, server node [,].

Software Stack: Python, version 3.13 leveraging libraries for LSTM and data processing [,].

System Workflow:

- Forklifts are equipped with UWB tags and QR code scanners.

- UWB signals are captured by fixed anchors across the warehouse.

- Kalman filter reduces noise in raw UWB measurements.

- LSTM model predicts object trajectories for enhanced temporal accuracy.

- The system visualizes and logs positions in real-time for warehouse management.

Figure 6 below displays internal architecture of an LSTM block.

Figure 6.

Internal Architecture of an LSTM Block.

3.5. Deployment Scenario

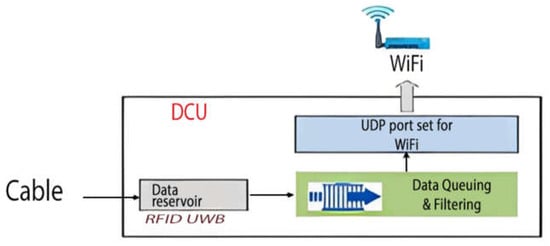

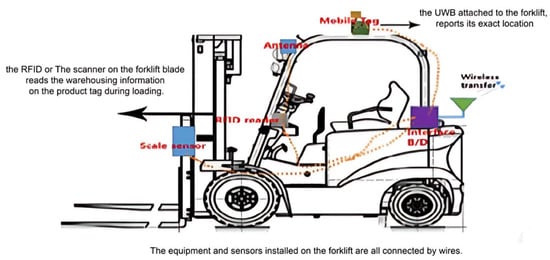

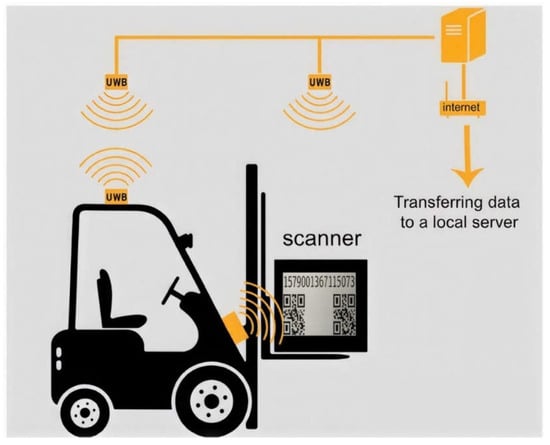

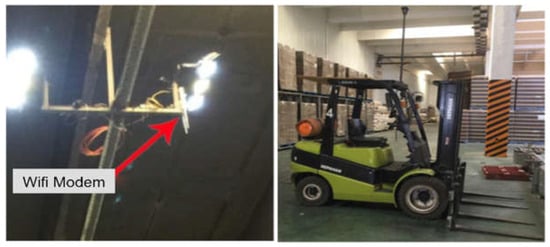

The hybrid system was deployed in a 54 m2 industrial warehouse section containing racks, forklifts, and moving pallets, with typical metallic structures causing multipath effects [,,]. Forklifts were equipped with UWB modules, while anchors were mounted at fixed heights on the ceiling to enable real-time positioning. Each product was labeled with a unique QR code scanned during loading, with data immediately transmitted to the server. This setup allowed continuous monitoring of both forklift movements and precise product locations during loading and unloading. The following figures illustrate the implementation environment. included typical metallic structures causing multipath effects [,,]. Figure 7, Figure 8 and Figure 9 reveal relevant pictorials.

Figure 7.

Real-Time Warehouse Position Tracking System Using UWB.

Figure 8.

Warehouse Area Used for System Implementation and UWB Anchors Installed on the Warehouse Ceiling.

Figure 9.

WiFi Modem and Forklift.

As can be seen in the figure above, in order to obtain the position of the forklift, a number of UWB anchors have been installed in the environment at certain heights with the aim of proper coverage.

4. Experimental Evaluation

To validate the proposed UWB–LSTM–Kalman hybrid localization system, extensive experiments were conducted in a 54 m2 industrial warehouse environment. The evaluation focused on three main aspects: localization accuracy, noise resilience, and real-time performance under dynamic operational conditions. The forklift was equipped with a UWB module and IMU sensors, while multiple anchors were mounted on the ceiling to provide triangulation. QR code scanners recorded the identity and location of products during loading and unloading activities.

4.1. Experimental Setup

- Hardware Configuration: The system consisted of six UWB anchors, a high-precision IMU, and a QR scanner mounted on the forklift. The UWB modules operated in the 3–7 GHz band with TOA (Time-of-Arrival) measurement for precise localization.

- Data Collection: Positional data were recorded continuously at 10 Hz and transmitted to a central server for processing. Each experiment consisted of 20 trials covering different routes, speeds (0.5–2 m/s), and load configurations.

Evaluation Metrics:

- ○

- Mean Absolute Error (MAE): Average deviation of predicted forklift positions from ground-truth coordinates.

- ○

- Root Mean Square Error (RMSE): Quantifies the variance of errors.

- ○

- Noise Resilience: Performance under signal interference simulated by metal obstacles and Wi-Fi traffic.

- ○

- Processing Latency: Time from data acquisition to position prediction.

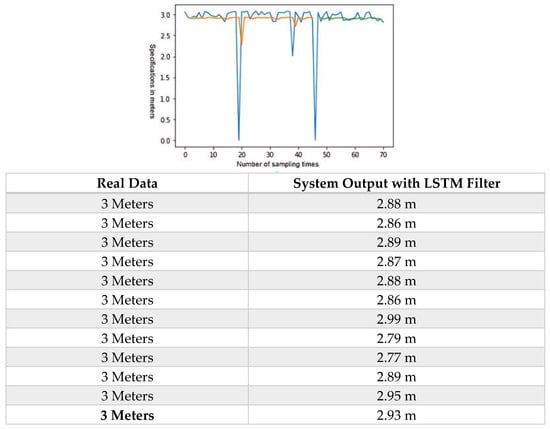

4.2. LSTM-Only Performance

The LSTM model was first applied to raw UWB and IMU data. Results showed that the network learned sequential motion patterns effectively, reducing the MAE from 0.14 m (raw Kalman filter output) to 0.11 m. RMSE improved by 12% compared to baseline Kalman filtering. The model demonstrated robustness against transient signal noise; however, abrupt changes in motion (e.g., sharp turns or acceleration) occasionally caused prediction overshoot. Figure 10 shows LSTM-enhanced forklift position output.

Figure 10.

LSTM-Enhanced Forklift Position Output Analysis.

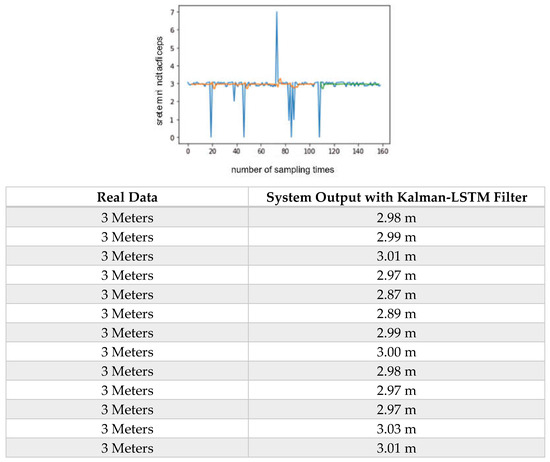

4.3. Hybrid LSTM–Kalman Performance

Integrating Kalman filtering with the LSTM network provided additional noise suppression, particularly in cluttered areas with reflective surfaces. MAE was further reduced to 0.09 m, with RMSE decreasing by 18% compared to the Kalman-only baseline. Figure 11 demonstrates localization accuracy improvement using Kalman-LSTM hybrid algorithm.

Figure 11.

Localization Accuracy Improvement Using Kalman-LSTM Hybrid Algorithm.

4.4. Real-Time Evaluation

The hybrid system achieved an average processing latency of 45 ms per sample, which comfortably meets the real-time requirements for warehouse operations where rapid updates are essential for tracking moving assets. This low latency ensures timely position estimation and smooth system responsiveness during dynamic activities. Furthermore, the system maintained high reliability over 10 continuous hours of operation, demonstrating stable performance even in complex environments with simultaneous forklift movement, human activity, and other mobile assets, confirming its suitability for practical industrial deployment.

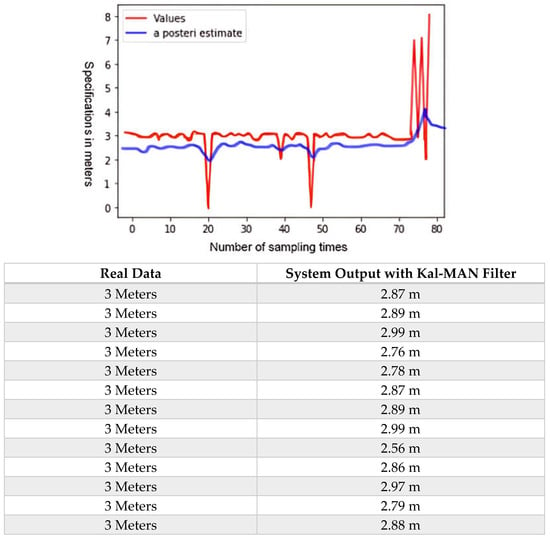

4.5. Comparison of LSTM, Kalman-LSTM Hybrid and Kalman Filter Algorithms

The Kalman filter effectively improves positioning accuracy by reducing noise, but it struggles with complex disturbances and nonlinear motion. In contrast, the proposed LSTM-based and hybrid Kalman-LSTM algorithms demonstrate greater robustness and higher accuracy in noisy, real-world environments. Figure 12 provides a comparative analysis of LSTM, Kalman-LSTM Hybrid, and Kalman Filter positioning accuracy. Trajectory comparison between measured positions are provided in Table 3.

Figure 12.

Comparative Analysis of LSTM, Kalman-LSTM Hybrid, and Kalman Filter Positioning Accuracy.

Table 3.

Trajectory Comparison Between Measured Positions.

Experimental evaluation demonstrates that the hybrid LSTM–Kalman system achieves a mean absolute error (MAE) of 0.09 m and root mean square error (RMSE) of 0.12 m, outperforming conventional Kalman filtering and LSTM-only methods. The system maintained high accuracy and stability under various operational scenarios, including different forklift speeds, load configurations, and signal interference conditions. Comparisons with existing RFID- and BLE-based systems confirm the superior performance of the proposed method in terms of precision, reliability, and real-time responsiveness.

4.6. Comparative Analysis with Prior Studies

The performance of the proposed hybrid system was compared with results reported in previous studies. Overall, the findings demonstrate a clear improvement in localization accuracy and operational robustness.

- RFID-based indoor positioning systems typically achieve an accuracy range between 0.2 and 0.5 m [,]. While suitable for basic tracking, their precision is limited in environments with metallic interference and dynamic movement.

- BLE and iBeacon-based systems generally report positioning errors ranging from 0.3 to 1 m in indoor warehouse environments []. These systems are cost-effective but often suffer from signal instability and lower spatial resolution.

- Previous hybrid UWB–Kalman systems have achieved sub-0.1 m accuracy; however, such results were mainly demonstrated in small-scale or controlled laboratory testbeds []. In contrast, the present study validates a comparable level of precision within a fully operational industrial warehouse, confirming the system’s robustness and scalability under real-world conditions.

5. Discussion

The experimental results confirm that integrating UWB sensing with LSTM-based temporal learning and Kalman filtering significantly improves real-time localization accuracy and operational robustness in industrial environments. Beyond technical performance, the findings also highlight key practical considerations related to cost, deployment, and long-term maintenance relevant to industrial applications.

5.1. Impact of Hybrid Filtering

The hybrid filtering approach demonstrated that while the Kalman filter effectively suppresses sensor noise, the LSTM network captures dynamic motion trends, resulting in smoother and more reliable trajectories. This synergy reduced prediction errors by approximately 4% compared to conventional Kalman-only systems. From an industrial perspective, such accuracy improvements directly translate into reduced downtime caused by tracking errors, leading to higher throughput efficiency in logistics and manufacturing settings.

5.2. Environmental Challenges

Warehouse environments typically involve reflective metallic structures, product occlusions, and dynamic movement of forklifts and workers. The hybrid system maintained high accuracy under these challenging conditions, confirming the robustness of UWB as a primary sensing modality. This resilience reduces the frequency of recalibration or sensor repositioning, lowering maintenance overhead and improving system reliability in continuous 24/7 operations.

5.3. Comparison with Traditional Methods

In contrast to RFID or Wi-Fi-based indoor positioning systems, the proposed UWB–LSTM–Kalman approach achieves sub-meter accuracy in near real-time without the need for dense infrastructure. Although UWB anchors have a higher initial cost than passive RFID tags, their lower density requirements and extended operational lifespan reduce the total cost of ownership over time. Furthermore, the integration of QR codes for product-level tracking adds value with minimal investment, enhancing traceability during inventory handling without requiring additional sensing hardware.

5.4. Industrial and Practical Implications

From an operational standpoint, the hybrid localization framework offers several tangible benefits for industrial stakeholders:

- Operational Efficiency: Real-time location tracking of forklifts and inventory supports optimized route planning, reducing idle time and traffic congestion.

- Cost Efficiency: The system minimizes manual inventory audits and losses due to misplaced items, providing measurable savings in labor and time.

- System Integration: Compatibility with warehouse management systems enables predictive analytics for demand forecasting and preventive maintenance scheduling.

- Maintenance Considerations: UWB sensors and anchors require limited recalibration once installed, and the modular design allows for incremental upgrades without halting warehouse operations. Regular software-based recalibration, rather than hardware replacement, further reduces lifecycle maintenance costs.

5.5. Limitations

While the system performed effectively in a medium-sized warehouse, scaling to large or multi-floor facilities may necessitate strategic optimization of anchor placement and network synchronization. Moreover, LSTM training depends on the availability of sufficient motion data to capture diverse operational patterns. Future enhancements could integrate additional sensors such as LiDAR or visual SLAM for redundancy, particularly in environments with frequent layout changes or electromagnetic interference.

6. Conclusions

This study presents a robust hybrid localization system for real-time warehouse management that integrates UWB sensing, LSTM neural networks, and Kalman filtering. The proposed approach effectively overcomes major challenges in indoor positioning, such as multipath interference, dynamic motion, and sensor noise common in industrial settings. Experimental results show that the hybrid LSTM–Kalman system outperforms conventional Kalman and LSTM-only models, achieving high accuracy (MAE 0.09 m, RMSE 0.12 m) and stable performance under diverse operational conditions. Compared with RFID- and BLE-based systems, it delivers superior precision, reliability, and real-time responsiveness, confirming its suitability for smart warehouse applications.

The integration of QR code-based product tracking further enhances operational intelligence by enabling automated identification, monitoring, and inventory management, thus supporting route optimization, congestion reduction, and error minimization in warehouse workflows. This work contributes to the Industrial IoT domain by demonstrating how data-driven algorithms, combined with robust sensing technologies, can significantly enhance operational efficiency in smart warehouses. Moreover, the findings highlight the scalability of the hybrid UWB–LSTM–Kalman framework for larger, multi-floor, and highly dynamic industrial environments.

From a practical perspective, this system can be viewed as an enabling technology for modern logistics operations. In simple terms, it helps warehouse managers and staff know exactly where every item and vehicle is at any moment, reducing search time, preventing misplaced goods, and improving workflow safety and efficiency. The system can also integrate with existing warehouse management platforms with minimal additional infrastructure, making it a cost-effective and easily maintainable solution for real-world industrial use.

Future research directions include integrating additional sensing modalities such as LiDAR or computer vision to improve accuracy and robustness, scaling the system for large-scale industrial complexes, and leveraging predictive analytics for proactive maintenance and operational optimization.

In summary, the proposed hybrid localization system offers a highly accurate, reliable, and practical solution for indoor positioning, delivering tangible operational benefits and paving the way for next-generation Industrial IoT applications.

Author Contributions

Conceptualization, B.M., N.R. and J.R.; methodology, B.M. and J.R.; software, J.R.; validation, B.M., J.R. and N.R.; formal analysis, J.R. and N.R.; investigation, B.M.; resources, B.M.; data curation, B.M., N.R. and J.R.; writing—original draft preparation, N.R. and J.R.; writing, review and editing, N.R.; visualization, B.M.; supervision, N.R. and J.R.; project administration, N.R. and J.R.; funding acquisition, None. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Farahzadi, A.; Shams, P.; Rezazadeh, J.; Farahbakhsh, R. Middleware technologies for cloud of things: A survey. Digit. Commun. Netw. 2018, 4, 176–188. [Google Scholar] [CrossRef]

- Chóliz, J.; Eguizabal, M.; Hernández-Solana, Á.; Valdovinos, A. Comparison of Algorithms for UWB Indoor Location and Tracking Systems. In Proceedings of the 2011 IEEE 73rd Vehicular Technology Conference, Budapest, Hungary, 15–18 May 2011. [Google Scholar]

- Eslami, E.; Razi, N.; Lonbani, M.; Rezazadeh, J. Unveiling IoT Customer Behaviour: Segmentation and Insights for Enhanced IoT-CRM Strategies: A Real Case Study. Sensors 2024, 24, 1050. [Google Scholar] [CrossRef] [PubMed]

- Shah, S.H.; Yaqoob, I. A survey: Internet of Things (IOT) technologies, applications and challenges. In Proceedings of the 2016 IEEE Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 21–24 August 2016; pp. 381–385. [Google Scholar]

- Ahmed, E.; Yaqoob, I.; Gani, A.; Imran, M.; Guizani, M. Internet-of-things-based smart environments: State of the art, taxonomy, and open research challenges. IEEE Wirel. Commun. 2016, 23, 10–16. [Google Scholar] [CrossRef]

- Lee, C.K.M.; Zhang, S.Z.; Ng, K.K.H. Development of an industrial Internet of things suite for smart factory towards re-industrialization. Adv. Manuf. 2017, 5, 335–343. [Google Scholar] [CrossRef]

- Qiuping, W.; Shunbing, Z.; Chunquan, D. Study on Key Technologies of Internet of Things Perceiving Mine. Procedia Eng. 2011, 26, 2326–2333. [Google Scholar] [CrossRef]

- Li, Y.; Hou, M.; Liu, H.; Liu, Y. Towards a theoretical framework of strategic decision, supporting capability and information sharing under the context of Internet of Things. Inf. Technol. Manag. 2012, 13, 205–216. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, J.; Lee, H.; Moon, K. IoT-based data transmitting system using a UWB and RFID system in smart warehouse. In Proceedings of the 2017 Ninth International Conference on Ubiquitous and Future Networks (ICUFN), Milan, Italy, 4–7 July 2017. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, M.; Yang, C.; Fang, J.; Huang, G.Q. Distributed and collaborative proactive tandem location tracking of vehicle products for warehouse operations. Comput. Ind. Eng. 2018, 125, 637–648. [Google Scholar] [CrossRef]

- Lim, A.; Zhang, K. A Robust RFID-Based Method for Precise Indoor Positioning. In Proceedings of the 19th International Conference on Industrial, Engineering and Other Applications of Applied Intelligent Systems, IEA/AIE 2006, Annecy, France, 27–30 June 2006; Lecture Notes in Computer Science. pp. 1189–1199. [Google Scholar] [CrossRef]

- Li, M.; Gu, S.; Chen, G.; Zhu, Z. A RFID-based Intelligent Warehouse Management System Design and Implementation. In Proceedings of the 2011 IEEE 8th International Conference on E-Business Engineering, Beijing, China, 19–21 October 2011. [Google Scholar] [CrossRef]

- Kollmeyer, C. Explaining Deindustrialization: How Affluence, Productivity Growth, and Globalization Diminish Manufacturing Employment. Am. J. Sociol. 2009, 114, 1644–1674. [Google Scholar] [CrossRef]

- Shit, R.C.; Sharma, S.; Puthal, D.; Zomaya, A.Y. Location of Things (LoT): A Review and Taxonomy of Sensors Localization in IoT Infrastructure. IEEE Commun. Surv. Tutor. 2018, 20, 2028–2061. [Google Scholar] [CrossRef]

- Kodali, R.K.; Jain, V.; Bose, S.; Boppana, L. IoT based smart security and home automation system. In Proceedings of the 2016 International Conference on Computing, Communication and Automation (ICCCA), Greater Noida, India, 29–30 April 2016. [Google Scholar] [CrossRef]

- Alsheikh, M.A.; Lin, S.; Niyato, D.; Tan, H.-P. Machine Learning in Wireless Sensor Networks: Algorithms, Strategies, and Applications. IEEE Commun. Surv. Tutor. 2014, 16, 1996–2018. [Google Scholar] [CrossRef]

- Zhao, Z.; Fang, J.; Huang, G.Q.; Zhang, M. iBeacon enabled indoor positioning for warehouse management. In Proceedings of the 2016 4th International Symposium on Computational and Business Intelligence (ISCBI), Olten, Switzerland, 5–7 September 2016. [Google Scholar] [CrossRef]

- Martínez-Barberá, H.; Herrero-Perez, D. Autonomous navigation of an automated guided vehicle in industrial environments. Robot. Comput.-Integr. Manuf. 2010, 26, 296–311. [Google Scholar] [CrossRef]

- Chow, H.K.; Choy, K.L.; Lee, W.B.; Lau, K.C. Design of a RFID case-based resource management system for warehouse operations. Expert Syst. Appl. 2006, 30, 561–576. [Google Scholar] [CrossRef]

- Michel, J.F.; Millner, H.; Vossiek, M. A novell wireless forklift positioning system for indoor and outdoor use. In Proceedings of the 2008 5th Workshop on Positioning, Navigation and Communication, Hannover, Germany, 27 March 2008. [Google Scholar] [CrossRef]

- Chernyshev, M.; Baig, Z.; Bello, O.; Zeadally, S. Internet of Things (IoT): Research, Simulators, and Testbeds. IEEE Internet Things J. 2018, 5, 1637–1647. [Google Scholar] [CrossRef]

- Özgür, Ç.; Alias, C.; Noche, B. Comparing sensor-based and camera-based approaches to recognizing the occupancy status of the load handling device of forklift trucks. In Logistics Journal: Proceedings; Wissenschaftliche Gesellschaft für Technische Logistik e.V.: Hamburg, Germany, 2016. [Google Scholar]

- Sattarian, M.; Rezazadeh, J.; Farahbakhsh, R.; Bagheri, A. Indoor navigation systems based on data mining techniques in internet of things: A survey. Wirel. Netw. 2019, 25, 1385–1402. [Google Scholar] [CrossRef]

- Godrich, H.; Petropulu, A.P.; Poor, H.V. Power Allocation Strategies for Target Localization in Distributed Multiple-Radar Architectures. IEEE Trans. Signal Process. 2011, 59, 3226–3240. [Google Scholar] [CrossRef]

- Greff, K.; Srivastava, R.K.; Koutnik, J.; Steunebrink, B.R.; Schmidhuber, J. LSTM: A Search Space Odyssey. IEEE Trans. Neural Netw. Learn. Syst. 2017, 28, 2222–2232. [Google Scholar] [CrossRef] [PubMed]

- Karimi, A.; Razi, N.; Rezazadeh, J. An IoT Healthcare System Based on Fog Computing and Data Mining: A Diabetic Use Case. Appl. Sci. 2024, 14, 7924. [Google Scholar] [CrossRef]

- Khodamoradi, F.; Rezazadeh, J.; Ayoade, J. Accurate Indoor Localization with IoT Devices and Advanced Fingerprinting Methods. Algorithms 2024, 17, 544. [Google Scholar] [CrossRef]

- Poulose, A.; Eyobu, O.S.; Han, D.S. An Indoor Position-Estimation Algorithm Using Smartphone IMU Sensor Data. IEEE Access 2019, 7, 11165–11177. [Google Scholar] [CrossRef]

- Farahsari, P.S.; Farahzadi, A.; Rezazadeh, J.; Bagheri, A. A Survey on Indoor Positioning Systems for IoT-Based Applications. IEEE Internet Things J. 2022, 9, 7680–7699. [Google Scholar] [CrossRef]

- Ding, B.; Chen, L.; Chen, D.; Yuan, H. Application of RTLS in Warehouse Management Based on RFID and Wi-Fi. In Proceedings of the 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–14 October 2008. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).