Study on the Low-Damage Material Removal Mechanism of Silicon Carbide Ceramics Under Longitudinal–Torsional Ultrasonic Grinding Conditions

Abstract

1. Introduction

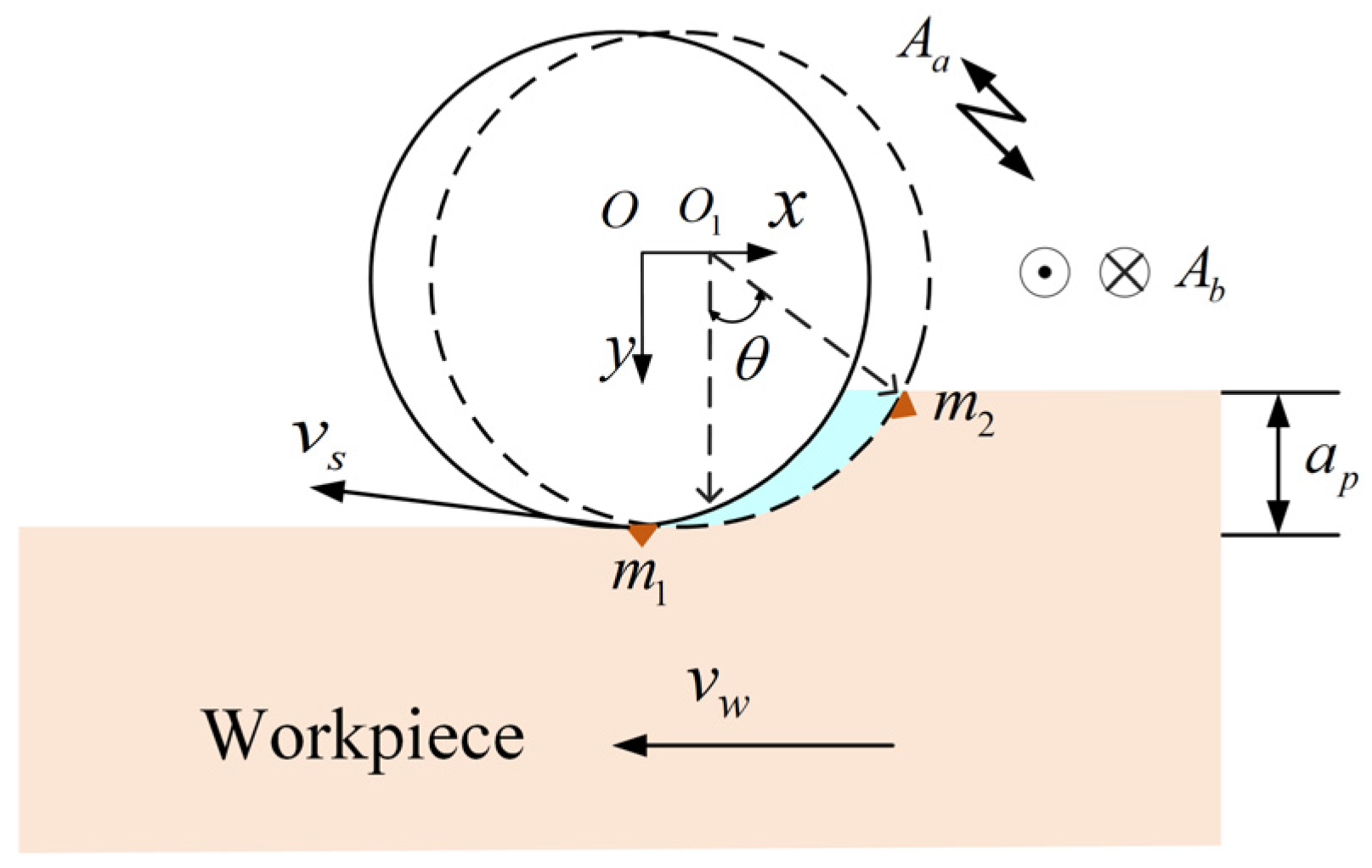

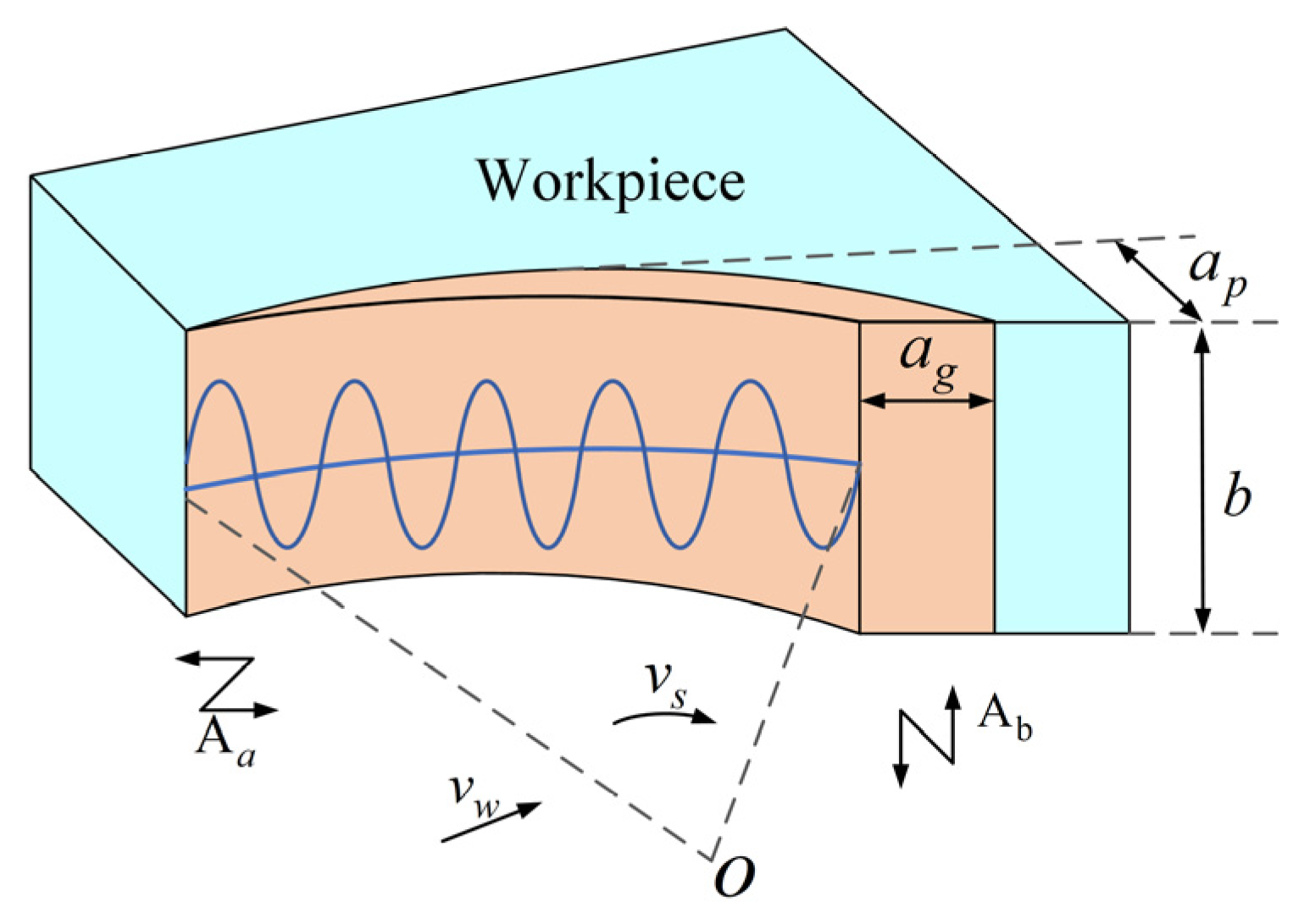

2. Modeling the Critical Cutting Depth of SiC Under LTUVG Conditions

3. LTUS Test

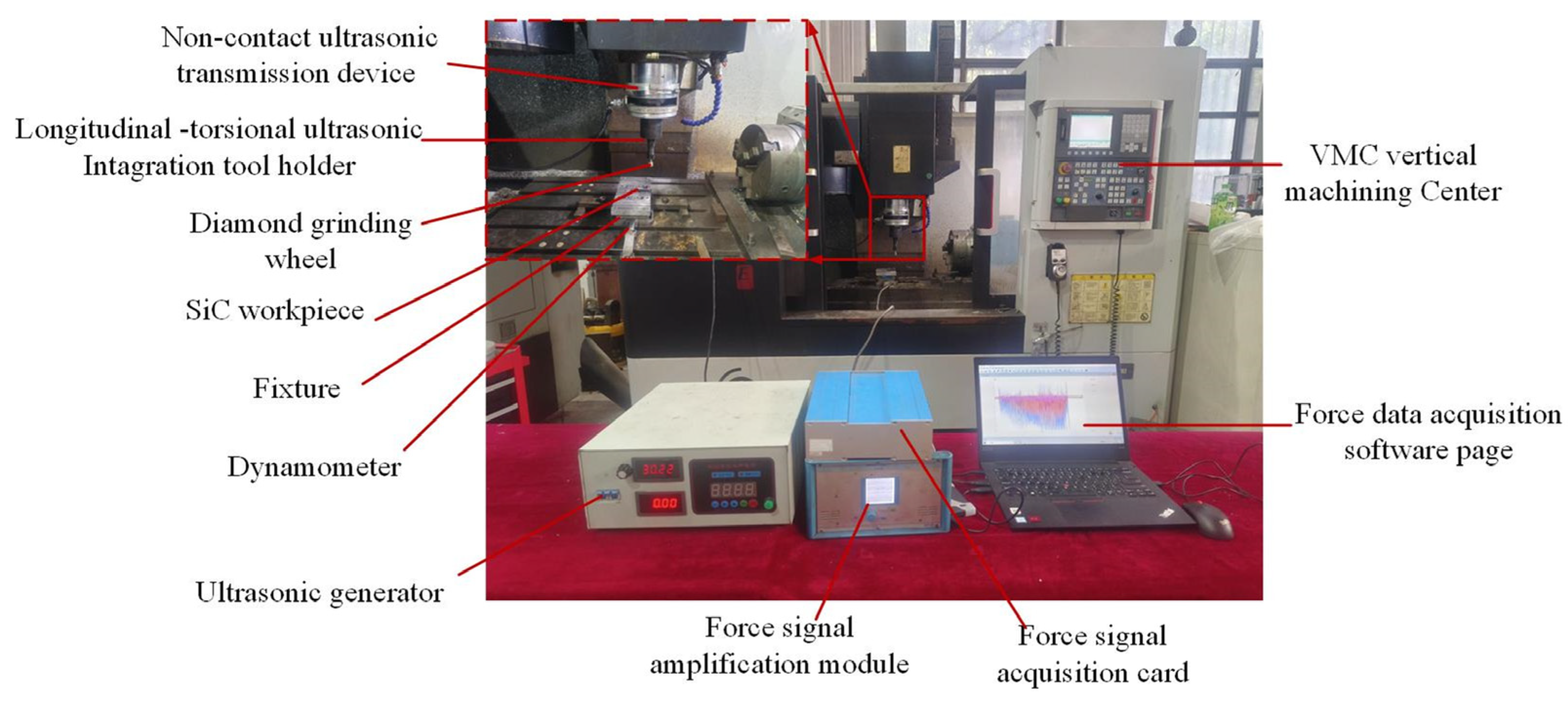

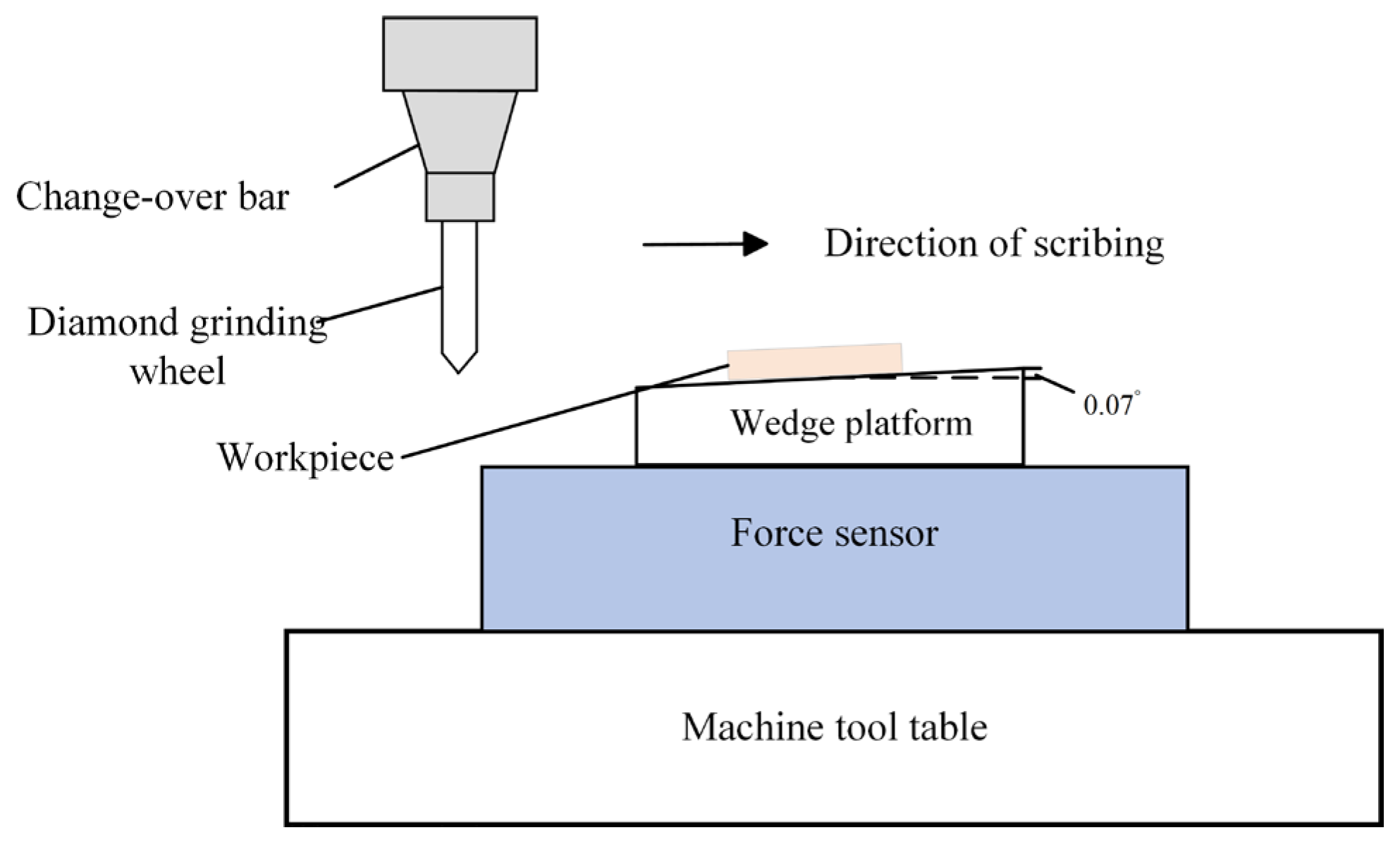

3.1. Construction of Test Platforms

3.2. Experimental Design

3.3. Experimental Results and Analysis

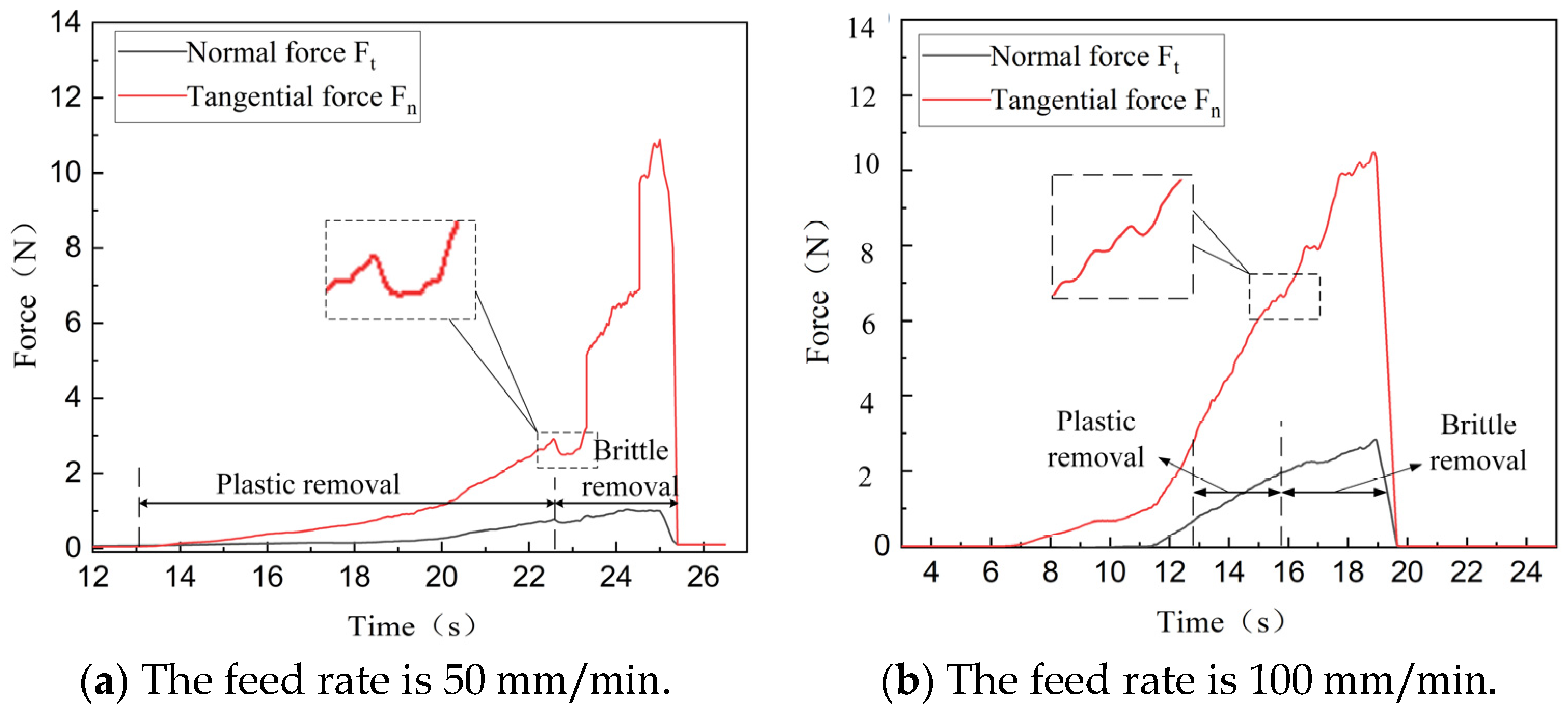

3.3.1. Effect of Scratching Speed on Scratching Force

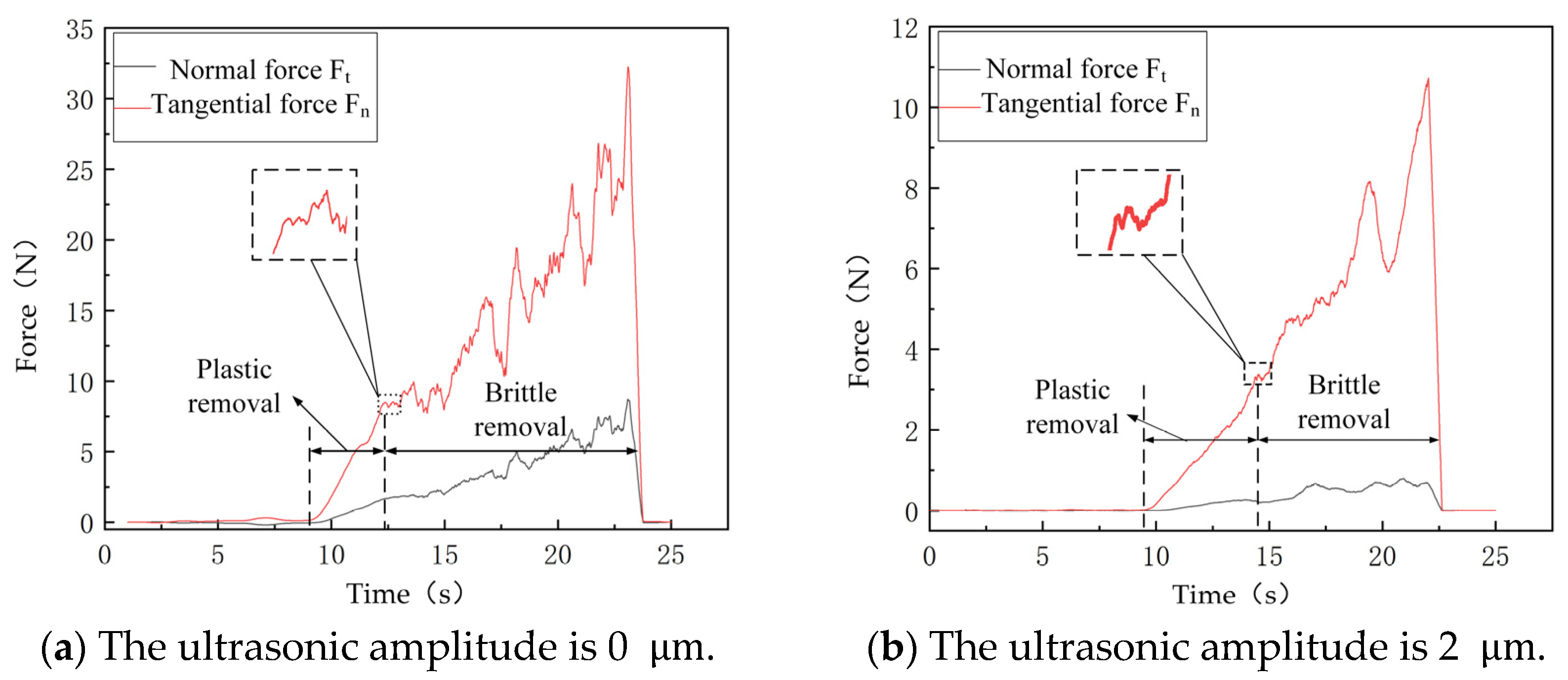

3.3.2. Effects of Ultrasonic Amplitude on the Scratching Force

3.3.3. Morphological Analysis of the Scratched Surface of Silicon Carbide Ceramic

4. Conclusions

- (1)

- According the kinematic characteristics of LTUVG, LTUV can increase the cutting arc length of single abrasive particle and reduce the maximum unaltered cutting thickness of SiC, and the maximum unaltered cutting thickness decreases with the increase in grinding speed, ultrasonic amplitude, and the cutting arc length and increases with the grinding depth and feed rate.

- (2)

- Based on the critical depth of SiC under LTUVG, LTUV greatly improves the strain rate, dynamic fracture toughness, and critical depth; as a result, the plastic removal area increased, and the critical depth increased with the grinding speed, ultrasonic amplitude, and the strain rate of SiC and decreased with the increase in grinding depth and feed rate.

- (3)

- In terms of the LTUS tests of SiC, it can be seen that LTUV significantly reduces the scratching force and changes the removal method, and the brittle removal of normal scratching can cause severe damage on both sides of the groove and the large pits on the machined surface; however, ultrasonic scratching expands the plastic removal on the machined surface, there are no obvious pits on the scratched surface, and the quality is significantly improved.

- (4)

- Future research should mainly focus on the interactions between multiple abrasive particles and the energy transfer characteristics during LTUVG to explore the material removal mechanism of SiC ceramics, which could provide a theoretical basis for the ultraprecise machining of brittle–hard material.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, Z.; Wen, X.; Wan, W.; Liu, F. Precision grinding technology of silicon carbide (sic) ceramics by longitudinal torsional ultrasonic vibrations. Materials 2023, 16, 5572. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Su, H.; He, J.; Qian, N. The effect of torsional vibration in longitudinal-torsional coupled ultrasonic vibration-assisted grinding of silicon carbide ceramics. Materials 2021, 14, 688. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Wang, K.; Zakharov, O.; Cui, H. Damage evolution mechanism and low-damage grinding technology of silicon carbide ceramics. Int. J. Extreme Manuf. 2025, 7, 36. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F. Material removal mode and friction behaviour of rb-sic ceramics during scratching at elevated temperatures. J. Eur. Ceram. Soc. 2019, 39, 3534–3545. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, X.; Du, J.; Rao, X. Study on ultrasonic-assisted scratching and mirror grinding of silicon carbide based on truncated coarse diamond wheel. Precis. Eng. 2025, 93, 587–603. [Google Scholar] [CrossRef]

- Qiao, G.; Yi, S.; Zheng, W.; Zhou, M. Material removal behavior and crack-inhibiting effect in ultrasonic vibration-assisted scratching of silicon nitride ceramics. Ceram. Int. 2022, 48, 4341–4351. [Google Scholar] [CrossRef]

- Cao, J.; Wu, Y.; Lu, D.; Fujimoto, M. Material removal behavior in ultrasonic-assisted scratching of sic ceramics with a single diamond tool. Int. J. Mach. Tools Manuf. 2014, 79, 49–61. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.; Meng, B.; Liu, L. Material removal mechanism and grinding force modelling of ultrasonic vibration assisted grinding for sic ceramics. Ceram. Int. 2017, 43, 2981–2993. [Google Scholar] [CrossRef]

- Zhang, K.; Yin, Z.; Dai, C.; Miao, Q. Material removal mechanism of sic ceramics by elliptic ultrasonic vibration-assisted grinding using single grain. Ceram. Int. 2023, 49, 10041–10055. [Google Scholar] [CrossRef]

- Yuan, D.; Zhang, D. Modeling and Experimental Study Forces of Silicon Carbide Ceramics by Longitudinal-Torsional Ultrasonic Grinding. Int. J. Trend Res. Dev. 2025, 12, 2394–9333. [Google Scholar]

- Sun, J.; Li, C.; Zhou, Z.; Liu, B. Material removal mechanism and force modeling in ultrasonic vibration-assisted micro-grinding biological bone. Chin. J. Mech. Eng. 2023, 36, 25. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, L. Analytical grinding force prediction with random abrasive grains of grinding wheels. Int. J. Mech. Sci. 2023, 250, 11. [Google Scholar] [CrossRef]

- Cheng, G. Research on Detection of Dynamic Effective Abrasive Grains of Grinding Wheel and Its Influence on Machined Surface of Engineering Ceramics. Master’s Thesis, Huaqiao University, Xiamen, China, 2021. [Google Scholar]

- Wu, C.; Li, B.; Liang, S.Y. A critical energy model for brittle-ductile transition in grinding considering wheel speed and chip thickness effects. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1372–1380. [Google Scholar] [CrossRef]

- Ding, Z.; Li, B.; Liang, S.Y. Maraging steel phase transformation in high strain rate grinding. Int. J. Adv. Manuf. Technol. 2015, 80, 711–718. [Google Scholar] [CrossRef]

- Hecker, R.L.; Liang, S.Y.; Wu, X.J.; Xia, P. Grinding force and power modeling based on chip thickness analysis. Int. J. Adv. Manuf. Technol. 2007, 33, 449–459. [Google Scholar] [CrossRef]

- Gao, X.; An, W.; Wang, L.; Chen, B.; Xu, W.; Feng, Q.; Li, Q.; Yuan, S. Study on the critical conditions for ductile-brittle transition in ultrasonic-assisted grinding of SiC particle-reinforced Al-MMCs. Ceram. Int. 2024, 50, 52742–52760. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Hardness (G Pa) | Fracture Toughness (MPa·m1/2) | Elastic Modulus (G Pa) | Poisson’s Ratio |

|---|---|---|---|---|---|

| SiC | 3560 | 33 | 5 | 410 | 0.14 |

| Group Number | Feed Rate mm/min | Ultrasonic Amplitude () |

|---|---|---|

| B1 | 50 | 4 |

| B2 | 100 | 4 |

| B3 | 150 | 4 |

| B4 | 200 | 4 |

| B5 | 100 | 0 |

| B6 | 100 | 2 |

| B7 | 100 | 4 |

| B8 | 100 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Ma, Z.; Yan, Y.; Yuan, D.; Wang, Y. Study on the Low-Damage Material Removal Mechanism of Silicon Carbide Ceramics Under Longitudinal–Torsional Ultrasonic Grinding Conditions. Micromachines 2025, 16, 1048. https://doi.org/10.3390/mi16091048

Liu J, Ma Z, Yan Y, Yuan D, Wang Y. Study on the Low-Damage Material Removal Mechanism of Silicon Carbide Ceramics Under Longitudinal–Torsional Ultrasonic Grinding Conditions. Micromachines. 2025; 16(9):1048. https://doi.org/10.3390/mi16091048

Chicago/Turabian StyleLiu, Junli, Zhenqi Ma, Yanyan Yan, Dengke Yuan, and Yifan Wang. 2025. "Study on the Low-Damage Material Removal Mechanism of Silicon Carbide Ceramics Under Longitudinal–Torsional Ultrasonic Grinding Conditions" Micromachines 16, no. 9: 1048. https://doi.org/10.3390/mi16091048

APA StyleLiu, J., Ma, Z., Yan, Y., Yuan, D., & Wang, Y. (2025). Study on the Low-Damage Material Removal Mechanism of Silicon Carbide Ceramics Under Longitudinal–Torsional Ultrasonic Grinding Conditions. Micromachines, 16(9), 1048. https://doi.org/10.3390/mi16091048