Enhanced UVC Responsivity of Heteroepitaxial α-Ga2O3 Photodetector with Ultra-Thin HfO2 Interlayer

Abstract

1. Introduction

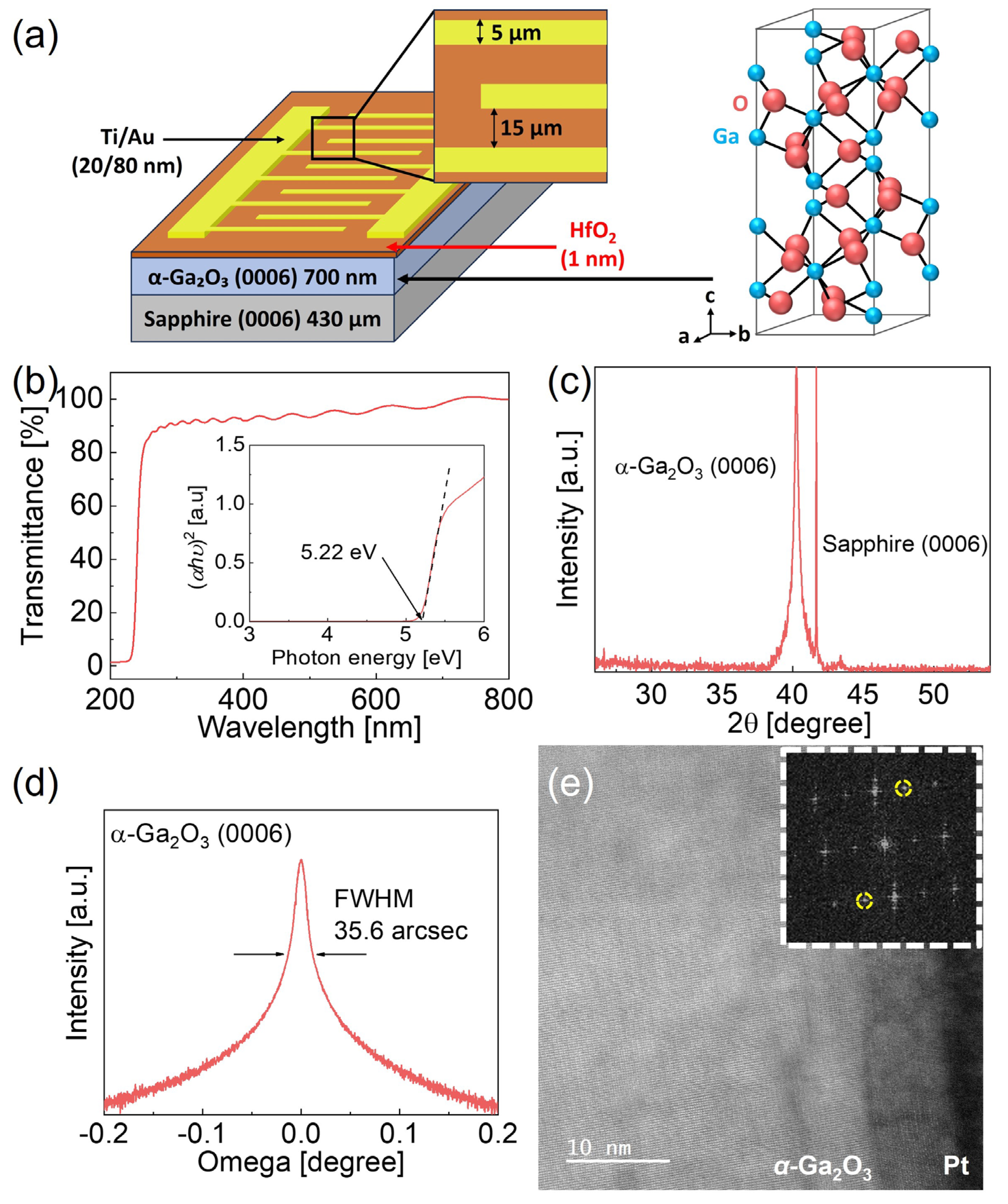

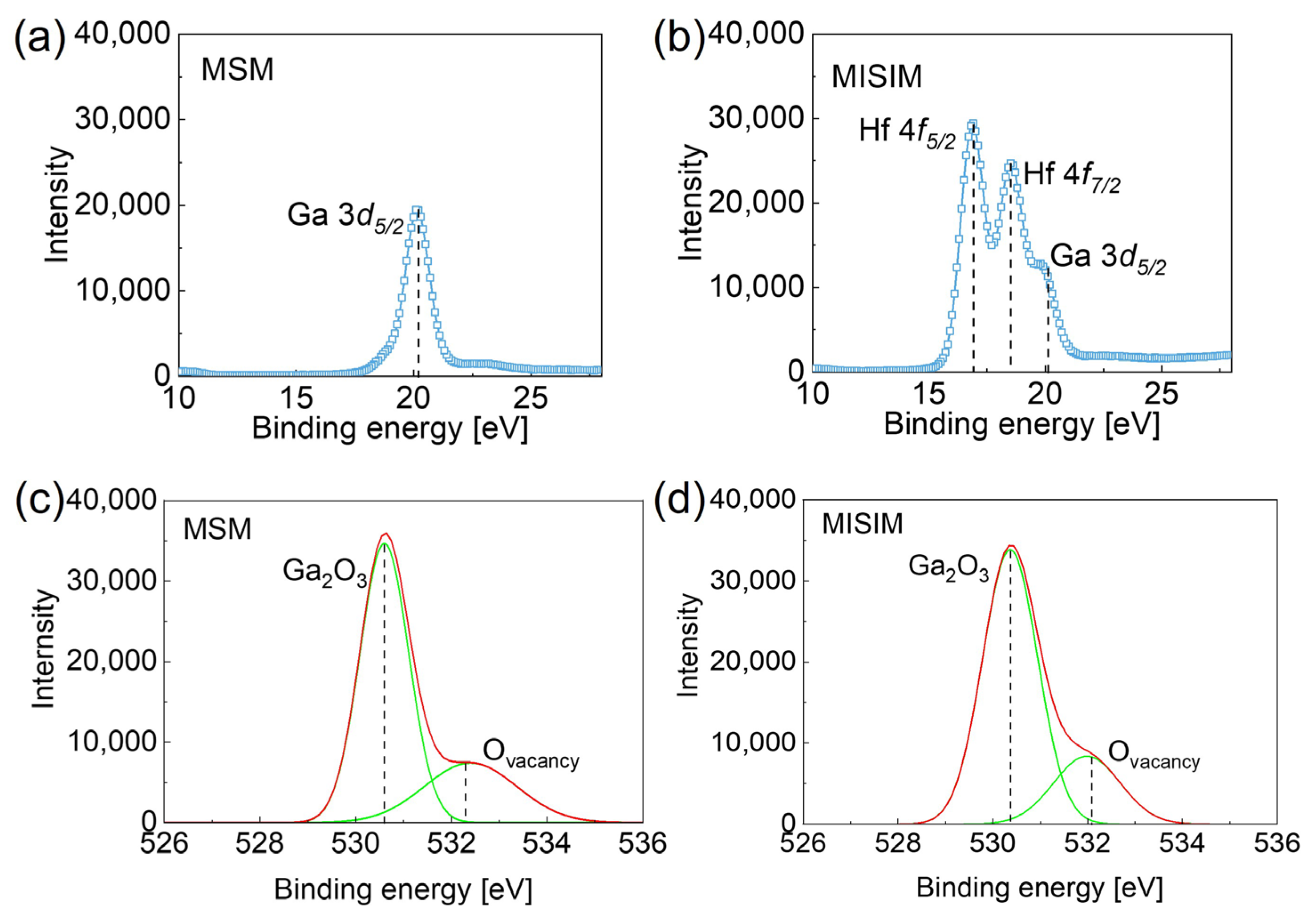

2. Experimental Section

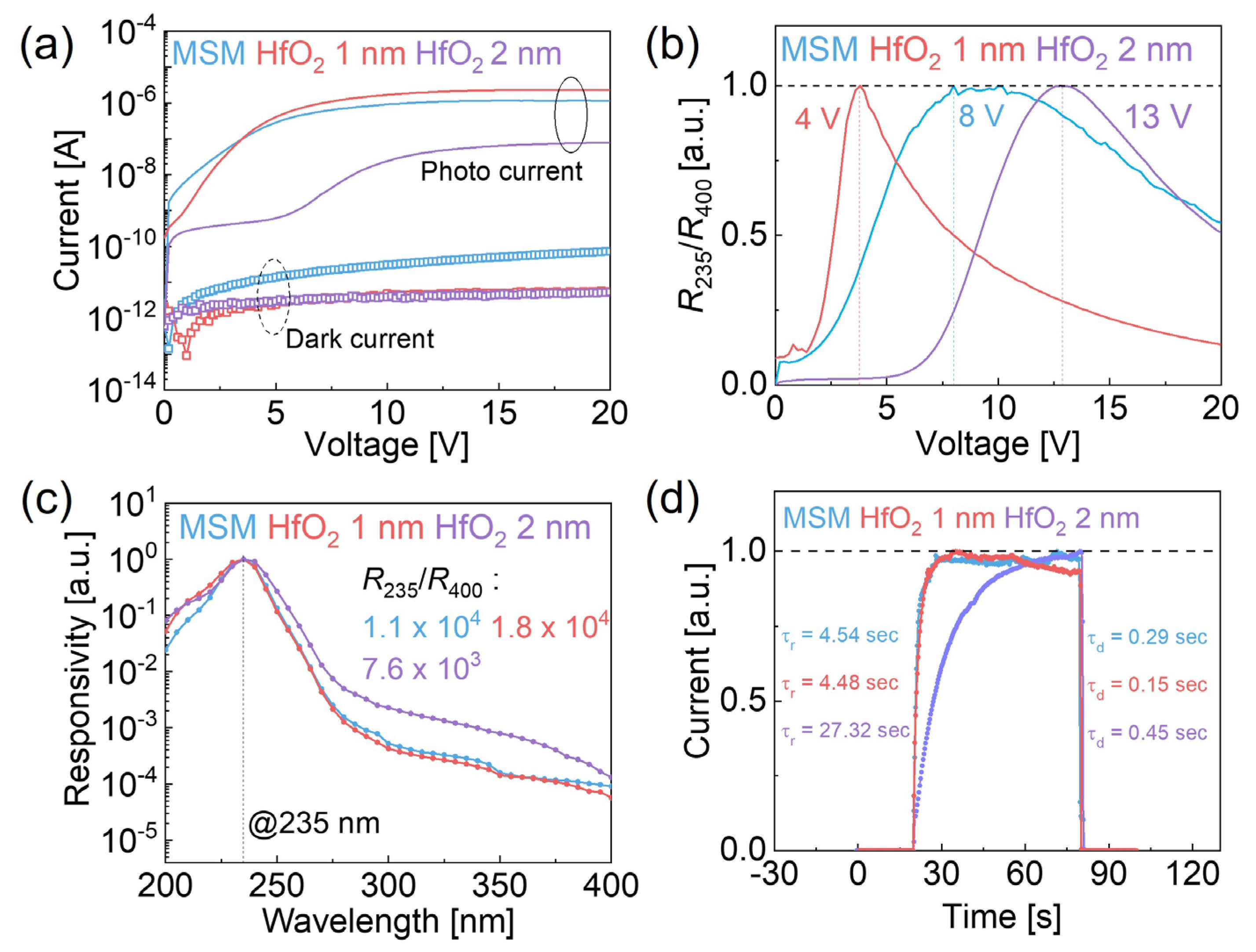

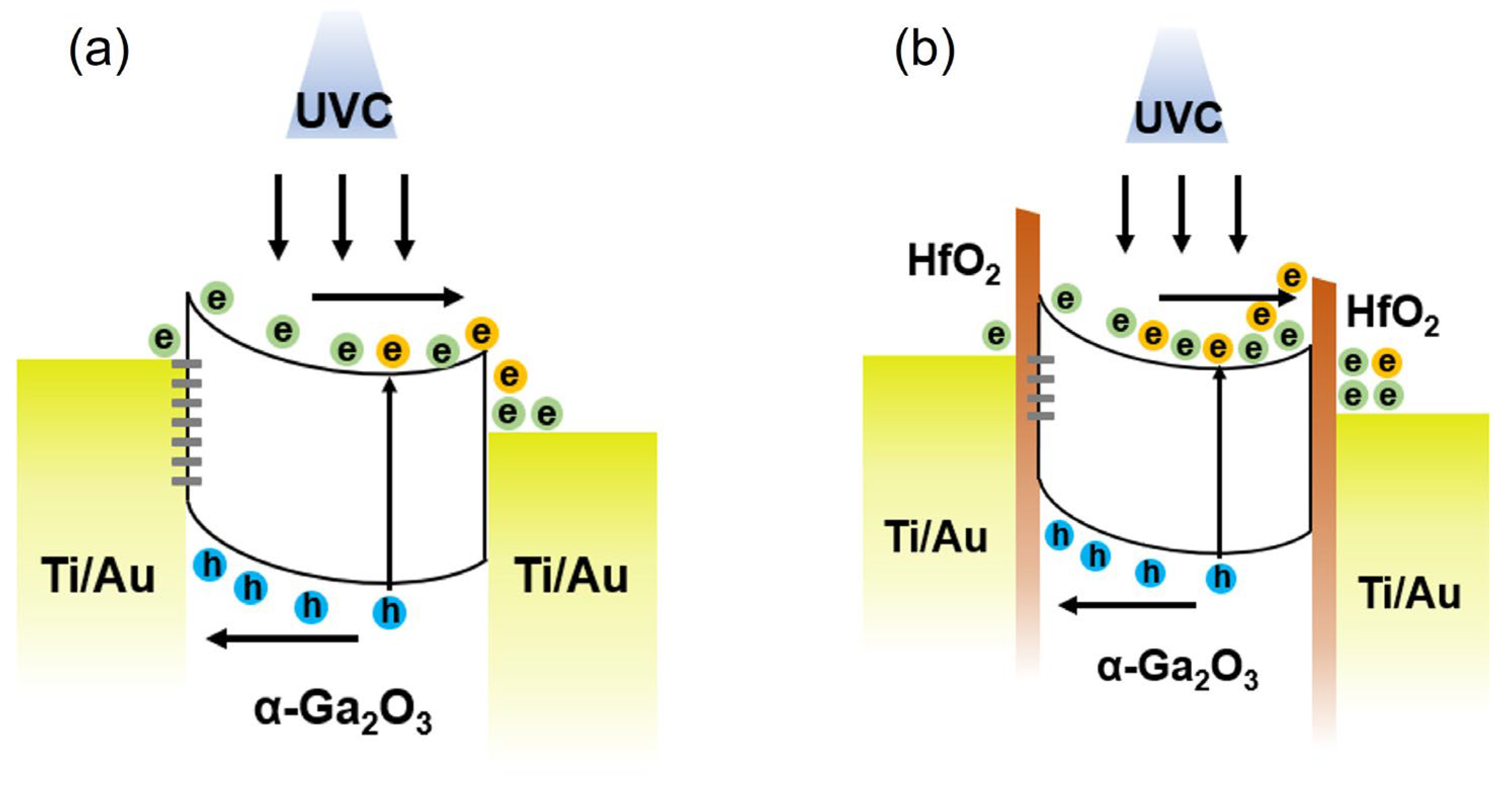

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sang, L.; Liao, M.; Sumiya, M. A Comprehensive Review of Semiconductor Ultraviolet Photodetectors: From Thin Film to One-Dimensional Nanostructures. Sensors 2013, 13, 10482–10518. [Google Scholar] [CrossRef]

- Blumenschein, N.; Paskova, T.; Muth, J.F. Effect of Growth Pressure on PLD-Deposited Gallium Oxide Thin Films for Deep-UV Photodetectors. Phys. Status Solidi (A) Appl. Mater. Sci. 2019, 216, 1900098. [Google Scholar] [CrossRef]

- Tak, B.R.; Garg, M.; Dewan, S.; Torres-Castanedo, C.G.; Li, K.H.; Gupta, V.; Li, X.; Singh, R. High-Temperature Photocurrent Mechanism of β-Ga2O3 Based Metal-Semiconductor-Metal Solar-Blind Photodetectors. J. Appl. Phys. 2019, 125, 144501. [Google Scholar] [CrossRef]

- Wei, T.C.; Tsai, D.S.; Ravadgar, P.; Ke, J.J.; Tsai, M.L.; Lien, D.H.; Huang, C.Y.; Horng, R.H.; He, J.H. See-through Ga2O3 Solar-Blind Photodetectors for Use in Harsh Environments. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 112–117. [Google Scholar] [CrossRef]

- Kaur, D.; Kumar, M. A Strategic Review on Gallium Oxide Based Deep-Ultraviolet Photodetectors: Recent Progress and Future Prospects. Adv. Opt. Mater. 2021, 9, 2002160. [Google Scholar] [CrossRef]

- Yam, J.C.S.; Kwok, A.K.H. Ultraviolet Light and Ocular Diseases. Int. Ophthalmol. 2014, 34, 383–400. [Google Scholar] [CrossRef]

- Narayanan, D.L.; Saladi, R.N.; Fox, J.L. Ultraviolet Radiation and Skin Cancer. Int. J. Dermatol. 2010, 49, 978–986. [Google Scholar] [CrossRef]

- Yang, C.; Liang, H.; Zhang, Z.; Xia, X.; Tao, P.; Chen, Y.; Zhang, H.; Shen, R.; Luo, Y.; Du, G. Self-Powered SBD Solar-Blind Photodetector Fabricated on the Single Crystal of β-Ga2O3. RSC Adv 2018, 8, 6341–6345. [Google Scholar] [CrossRef]

- Alema, F.; Hertog, B.; Mukhopadhyay, P.; Zhang, Y.; Mauze, A.; Osinsky, A.; Schoenfeld, W.V.; Speck, J.S.; Vogt, T. Solar Blind Schottky Photodiode Based on an MOCVD-Grown Homoepitaxial β-Ga2O3 Thin Film. APL Mater. 2019, 7, 022527. [Google Scholar] [CrossRef]

- Singh Pratiyush, A.; Krishnamoorthy, S.; Vishnu Solanke, S.; Xia, Z.; Muralidharan, R.; Rajan, S.; Nath, D.N. High Responsivity in Molecular Beam Epitaxy Grown β-Ga2O3 Metal Semiconductor Metal Solar Blind Deep-UV Photodetector. Appl. Phys. Lett. 2017, 110, 221107. [Google Scholar] [CrossRef]

- Li, Z.; An, Z.; Xu, Y.; Cheng, Y.; Cheng, Y.; Chen, D.; Feng, Q.; Xu, S.; Zhang, J.; Zhang, C.; et al. Improving the Production of High-Performance Solar-Blind β-Ga2O3 Photodetectors by Controlling the Growth Pressure. J. Mater. Sci. 2019, 54, 10335–10345. [Google Scholar] [CrossRef]

- Chu, S.Y.; Shen, M.X.; Yeh, T.H.; Chen, C.H.; Lee, C.T.; Lee, H.Y. Investigation of Ga2O3-Based Deep Ultraviolet Photodetectors Using Plasma-Enhanced Atomic Layer Deposition System. Sensors 2020, 20, 6159. [Google Scholar] [CrossRef]

- Pearton, S.J.; Yang, J.; Cary, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A Review of Ga2O3 Materials, Processing, and Devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, W. A Review of Ga2O3 Deep-Ultraviolet Metal-Semiconductor Schottky Photodiodes. J. Phys. D Appl. Phys. 2023, 56, 093002. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, W.; Zhang, J.; Zhang, T.; Chen, L.; Wang, L.; Zhang, Y.; Cao, Y.; Ji, L.; Ye, J. Directional Carrier Transport in Micrometer-Thick Gallium Oxide Films for High-Performance Deep-Ultraviolet Photodetection. ACS Appl. Mater. Interfaces 2023, 15, 10868–10876. [Google Scholar] [CrossRef] [PubMed]

- Sheoran, H.; Fang, S.; Liang, F.; Huang, Z.; Kaushik, S.; Manikanthababu, N.; Zhao, X.; Sun, H.; Singh, R.; Long, S. High Performance of Zero-Power-Consumption MOCVD-Grown β-Ga2O3-Based Solar-Blind Photodetectors with Ultralow Dark Current and High-Temperature Functionalities. ACS Appl. Mater. Interfaces 2022, 14, 52096–52107. [Google Scholar] [CrossRef] [PubMed]

- Muazzam, U.U.; Chavan, P.; Raghavan, S.; Muralidharan, R.; Nath, D.N. Optical Properties of Mist CVD Grown α-Ga2O3. IEEE Photonics Technol. Lett. 2020, 32, 422–425. [Google Scholar] [CrossRef]

- Son, H.; Choi, Y.-J.; Hwang, J.; Jeon, D.-W. Influence of Post-Annealing on Properties of α-Ga2O3 Epilayer Grown by Halide Vapor Phase Epitaxy. ECS J. Solid State Sci. Technol. 2019, 8, Q3024–Q3027. [Google Scholar] [CrossRef]

- Bae, J.; Park, J.H.; Jeon, D.W.; Kim, J. Self-Powered Solar-Blind α-Ga2O3 Thin-Film UV-C Photodiode Grown by Halide Vapor-Phase Epitaxy. APL Mater. 2021, 9, 101108. [Google Scholar] [CrossRef]

- Leach, J.H.; Udwary, K.; Rumsey, J.; Dodson, G.; Splawn, H.; Evans, K.R. Halide Vapor Phase Epitaxial Growth of β-Ga2O3 and α-Ga2O3 Films. APL Mater. 2019, 7, 022504. [Google Scholar] [CrossRef]

- Lee, M.; Yang, M.; Lee, H.Y.; Lee, H.U.; Lee, H.; Son, H.; Kim, U.J. The Growth of HVPE α-Ga2O3 Crystals and Its Solar-Blind UV Photodetector Applications. Mater. Sci. Semicond. Process. 2021, 123, 105565. [Google Scholar] [CrossRef]

- Kim, S.; Yoon, Y.; Seo, D.; Park, J.H.; Jeon, D.W.; Hwang, W.S.; Shin, M. Alpha-Phase Gallium Oxide-Based UVC Photodetector with High Sensitivity and Visible Blindness. APL Mater. 2023, 11, 061107. [Google Scholar] [CrossRef]

- Oshima, T.; Okuno, T.; Arai, N.; Suzuki, N.; Hino, H.; Fujita, S. Flame Detection by a β-Ga2O3-Based Sensor. Jpn. J. Appl. Phys. 2009, 48, 011605. [Google Scholar] [CrossRef]

- Kaneko, K.; Fujita, S.; Shinohe, T.; Tanaka, K. Progress in α-Ga2O3 for Practical Device Applications. Jpn. J. Appl. Phys. 2023, 62, SF0803. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.W.; Kim, H.Y.; Jeon, D.W.; Cho, S.B.; Park, J.H. A Pre-Reaction Suppressing Strategy for α-Ga2O3 Halide Vapor Pressure Epitaxy Using Asymmetric Precursor Gas Flow. CrystEngComm 2022, 24, 3049–3056. [Google Scholar] [CrossRef]

- Son, H.; Choi, Y.; Hong, S.-K.; Park, J.-H.; Jeon, D.-W. Reduction of dislocations in α-Ga2O3 epilayers grown by halide vapor-phase epitaxy on a conical frustum-patterned sapphire substrate. IUCrJ 2021, 8, 462–467. [Google Scholar] [CrossRef]

- Feng, Z.; Feng, Q.; Zhang, J.; Zhang, C.; Zhou, H.; Li, X.; Huang, L.; Xu, L.; Hu, Y.; Zhao, S.; et al. Band Alignments of SiO2 and HfO2 Dielectrics with (AlxGa1-x)2O3 Film (0≤x≤0.53) Grown on Ga2O3 Buffer Layer on Sapphire. J. Alloys Compd. 2018, 745, 292–298. [Google Scholar] [CrossRef]

- Barreca, D.; Milanov, A.; Fischer, R.A.; Devi, A.; Tondello, E. Hafnium Oxide Thin Film Grown by ALD: An XPS Study. Surf. Sci. Spectra 2007, 14, 34–40. [Google Scholar] [CrossRef]

- Wang, J.; Ji, X.; Yan, Z.; Qi, S.; Liu, X.; Zhong, A.; Li, P. The Role of oxygen vacancies in Ga2O3-Based Solar-Blind Photodetectors. J. Alloys Compd. 2024, 970, 172448. [Google Scholar] [CrossRef]

- Wang, H.; Tang, C.; Yang, W.; Zhao, J.; Liu, L.; Mu, J.; Zhang, Y.; Zeng, C. Recrystallization Behavior, Oxygen Vacancy and Photoluminescence Performance of Sputter-Deposited Ga2O3 Films via High-Vacuum in Situ Annealing. Ceram. Int. 2022, 48, 3481–3488. [Google Scholar] [CrossRef]

- Yuan, L.; Li, S.; Song, G.; Sun, X.W.; Zhang, X. Solution-Processed Amorphous Gallium Oxide Gate Dielectric for Low-Voltage Operation Oxide Thin Film Transistors. J. Mater. Sci. Mater. Electron. 2021, 32, 8347–8353. [Google Scholar] [CrossRef]

- Seol, J.H.; Kang, S.B.; Lee, C.J.; Won, C.H.; Park, H.; Lee, J.H.; Hahm, S.H. Graphene/Al2O3/AlGaN/GaN Schottky MISIM Diode for Sensing Double UV Bands. IEEE Sens. J. 2016, 16, 6903–6907. [Google Scholar] [CrossRef]

- Chang, C.Y.; Huang, Y.W.; Lin, Y.J.; Liao, J.Y.; Lin, J.S.; Li, Y.M.; Chen, C.Y.; Sheu, J.T.; Pan, F.M. Photoconductive Properties of Polycrystalline Selenium Based Lateral MISIM Photodetectors of High Quantum Efficiency Using Different Dielectrics as the Charge Blocking Layer. J. Mater. Sci. Mater. Electron. 2019, 30, 12956–12965. [Google Scholar] [CrossRef]

- Zhang, C.; Tian, C.; Wei, S.; Cai, Z.; Long, H.; Zhang, J.; Hong, R.; Yang, W. High-Performance β-GaO MISIM Solar-Blind Photodetectors With an Interfacial AlN Layer. IEEE Photonics Technol. Lett. 2024, 36, 593–596. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Ranga, P.; Saleh, M.; Roy, S.; Scarpulla, M.A.; Lynn, K.G.; Krishnamoorthy, S. Schottky Barrier Height Engineering in β-Ga2O3 Using SiO2 Interlayer Dielectric. IEEE J. Electron Devices Soc. 2020, 8, 286–294. [Google Scholar] [CrossRef]

- Song, S.; Kim, S.H.; Kim, S.G.; Han, K.H.; Kim, H.J.; Yu, H.Y. Effective Schottky Barrier Height and Interface Trap Density Reduction Engineering Using 2-Dimensional Reduced Graphene Oxide Interlayer for Metal-Interlayer-Semiconductor Contact Structure. J. Alloys Compd. 2023, 937, 168327. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Kumar, A.; Durante, O.; Sessa, A.; Faella, E.; Viscardi, L.; Intonti, K.; Giubileo, F.; Martucciello, N.; Romano, P.; et al. Temperature-dependent photoconductivity in two-dimensional MoS2 transistors. Mater. Today Nano 2023, 24, 100382. [Google Scholar] [CrossRef]

- Qiu, M.; Jia, Z.; Yang, M.; Nishimura, K.; Lin, C.-T.; Jiang, N.; Yuan, Q. High Detectivity Solar Blind Photodetector Based on Mechanical Exfoliated Hexagonal Boron Nitride Films. Nanotechnology 2023, 34, 285204. [Google Scholar] [CrossRef]

- Sang, L.W.; Liao, M.Y.; Koide, Y.; Sumiya, M. High-temperature ultraviolet detection based on InGaN Schottky photodiodes. Appl. Phys. Lett. 2011, 99, 031115:1–031115:3. [Google Scholar] [CrossRef]

- Khan, T.; Kandar, S.; Ali, S.; Singh, P.; Horng, R.-H.; Singh, R. Selective UV Sensing for Energy-Efficient UV-A Artificial Synapses Using a ZnO/ZnGa2O4 Heterojunction Diode. Small 2025, 21, 2500098. [Google Scholar] [CrossRef]

- Yang, H.; Cheng, T.-H.; Xin, Q.; Liu, Y.; Feng, H.Y.; Luo, F.; Mu, W.; Jia, Z.; Tao, X. Efficient Suppression of Persistent Photoconductivity in β-Ga2O3-Based Photodetectors with Square Nanopore Arrays. ACS Appl. Mater. Interfaces 2023, 15, 32522–32532. [Google Scholar] [CrossRef]

- Sui, Y.; Liang, H.; Huo, W.; Zhan, X.; Zhu, T.; Mei, Z. Flexible UV Detectors Based on In-Situ Hydrogen Doped Amorphous Ga2O3 with High Photo-to-Dark Current Ratio. Mater. Futures 2024, 3, 015701. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, H.; Hou, X.; Han, K.; Zhong, W.; Feng, X.; Zhan, H.; Liu, W.; Zhao, X.; Gao, N.; et al. Crystal-Phase Engineering of ε-Ga2O3 for High-Performance Deep UV Photodetectors via MOCVD. Sci. China Mater. 2025, 68, 1174–1183. [Google Scholar] [CrossRef]

- Fei, Z.; Chen, Z.; Chen, W.; Chen, S.; Wu, Z.; Lu, X.; Wang, G.; Liang, J.; Pei, Y. ε-Ga2O3 thin films grown by metal-organic chemical vapor deposition and its application as solar-blind photodetectors. J. Alloys Compd. 2022, 925, 166632. [Google Scholar] [CrossRef]

| Phase | Grown | Detection | PDCR | Responsivity | Dark Current | Ref |

|---|---|---|---|---|---|---|

| Alpha | HVPE | 235 nm | 8.7 × 103 (@20 V) | 1.38 A/W (@8 V) | 73 pA (@20 V) | This work (w/o) |

| Alpha | HVPE | 235 nm | 7.3 × 104 (@20 V) | 0.68 A/W (@4 V) | 5.5 pA (@20 V) | This work (1 nm) |

| Alpha | HVPE | 235 nm | 5.2 × 102 (@20 V) | 0.17 A/W (@13 V) | 5.2 pA (@20 V) | This work (2 nm) |

| Beta | PLD | 254 nm | 14 (@10 V) | 30.45 A/W (@10 V) | 4.2 nA | [2] |

| Beta | PLD | 255 nm | 7.1 × 103 (@10 V) | 0.74 A/W (@10 V) | 0.32 nA | [3] |

| Beta | MBE | 236 nm | 103 (@20 V) | 1.5 A/W (@4 V) | 4 nA (@20 V) | [10] |

| Beta | RF sputtering | 254 nm | 105 | 303 A/W | 10 pA (@20 V) | [11] |

| Amorphous | Sputtering | 254 nm | 2.6 × 107 (@5 V) | 3.2 × 104 A/W (@ 5V) | 51 pA (@5 V) | [42] |

| Epsilon | MOCVD | 254 nm | 2.4 × 107 | 639 A/W (@10 V) | 4.6 pA | [43] |

| Epsilon | MOCVD | 252 nm | 1.0 × 103 (@15 V) | 0.38 A/W (@15 V) | 20 nA (@15 V) | [44] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, S.; Oh, S.; Lee, G.; Kim, Y.; Kim, S.; Park, J.-H.; Shin, M.; Jeon, D.-W.; Yoo, G. Enhanced UVC Responsivity of Heteroepitaxial α-Ga2O3 Photodetector with Ultra-Thin HfO2 Interlayer. Micromachines 2025, 16, 836. https://doi.org/10.3390/mi16070836

Yoon S, Oh S, Lee G, Kim Y, Kim S, Park J-H, Shin M, Jeon D-W, Yoo G. Enhanced UVC Responsivity of Heteroepitaxial α-Ga2O3 Photodetector with Ultra-Thin HfO2 Interlayer. Micromachines. 2025; 16(7):836. https://doi.org/10.3390/mi16070836

Chicago/Turabian StyleYoon, SiSung, SeungYoon Oh, GyuHyung Lee, YongKi Kim, SunJae Kim, Ji-Hyeon Park, MyungHun Shin, Dae-Woo Jeon, and GeonWook Yoo. 2025. "Enhanced UVC Responsivity of Heteroepitaxial α-Ga2O3 Photodetector with Ultra-Thin HfO2 Interlayer" Micromachines 16, no. 7: 836. https://doi.org/10.3390/mi16070836

APA StyleYoon, S., Oh, S., Lee, G., Kim, Y., Kim, S., Park, J.-H., Shin, M., Jeon, D.-W., & Yoo, G. (2025). Enhanced UVC Responsivity of Heteroepitaxial α-Ga2O3 Photodetector with Ultra-Thin HfO2 Interlayer. Micromachines, 16(7), 836. https://doi.org/10.3390/mi16070836