3D Printed MEMS Technology—Recent Developments and Applications

Abstract

1. Introduction

2. Typical 3D Printing Techniques

3. 3D Printed Microfluidic Devices

3.1. General Remarks on Toxicity of Materials for Biotechnological Applications

3.2. Photolithography

3.3. Two-Photon and Multi-Photon Polymerization

3.4. Inkjet 3D Printing

3.5. Metal Additive Manufacturing

3.6. Preparing Molds by 3D Printing Methods

3.7. Combining 3D Printing with Other Technologies

4. 3D-Printed Microelectromechanical Systems (MEMS) Sensors

4.1. Chemical Sensors

4.2. Physical Sensors

5. 3D-Printed MEMS Actuators

5.1. Switches

5.2. Vibration Actuator

5.3. Aeronautics and Astronautics

5.4. Nanopositioning

5.5. Macro-Positioning

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tanaka, M. An industrial and applied review of new MEMS devices features. Microelectron. Eng. 2007, 84, 1341–1344. [Google Scholar] [CrossRef]

- Nguyen, C.T.-C. Frequency-selective MEMS for miniaturized low-power communication devices. IEEE Trans. Microw. Theory Tech. 1999, 47, 1486–1503. [Google Scholar] [CrossRef]

- Kahn, H.; Tayebi, N.; Ballarini, R.; Mullen, R.L.; Heuer, A.H. Fracture toughness of polysilicon MEMS devices. Sens. Actuators A Phys. 2000, 82, 274–280. [Google Scholar] [CrossRef]

- Duffy, D.C.; McDonald, J.C.; Schueller, O.J.A.; Whitesides, G.M. Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal. Chem. 1998, 70, 4974–4984. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.-J.; Rodger, D.C.; Meng, E.M.; Humayun, M.S.; Tai, Y.-C. Surface-micromachined Parylene dual valves for on-chip unpowered microflow regulation. J. Microelectromech. Syst. 2007, 16, 223–231. [Google Scholar] [CrossRef]

- Fan, Z.F.; Engel, J.M.; Chen, J.; Liu, C. Parylene surface-micromachined membranes for sensor applications. J. Microelectromech. Syst. 2004, 13, 484–490. [Google Scholar] [CrossRef]

- Chronis, N.; Lee, L.P. Electrothermally activated SU-8 microgripper for single cell manipulation in solution. J. Microelectromech. Syst. 2005, 14, 857–863. [Google Scholar] [CrossRef]

- Ben-Ner, A.; Siemsen, E. Decentralization and localization of production: The organizational and economic consequences of additive manufacturing (3D printing). Calif. Manag. Rev. 2017, 59, 5–23. [Google Scholar] [CrossRef]

- Duarte, L.C.; Chagas, C.; Ribeiro, L.E.B.; Coltro Tomazelli, W.K. 3D printing of microfluidic devices with embedded sensing electrodes for generating and measuring the size of microdroplets based on contactless conductivity detection. Sens. Actuators B Chem. 2017, 251, 427–432. [Google Scholar] [CrossRef]

- Noorani, R. Rapid Prototyping: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kozior, T.; Blachowicz, T.; Ehrmann, A. Adhesion of 3D printing on textile fabrics—Inspiration from and for other research areas. J. Eng. Fibers Fabrics 2020. submitted. [Google Scholar] [CrossRef]

- Korger, M.; Bergschneider, J.; Lutz, M.; Mahltig, B.; Finsterbusch, K.; Rabe, M. Possible applications of 3D printing technology on textile substrates. IOP Conf. Ser. Mater. Sci. Eng. 2016, 141, 012011. [Google Scholar] [CrossRef]

- Unger, L.; Scheideler, M.; Meyer, P.; Harland, J.; Görzen, A.; Wortmann, M.; Dreyer, A.; Ehrmann, A. Increasing Adhesion of 3D Printing on Textile Fabrics by Polymer Coating. Tekstilec 2018, 61, 265–271. [Google Scholar] [CrossRef]

- Jung, H.; Kim, C.J.; Kong, S.H. An optimized MEMS-based electrolytic tilt sensor. Sens. Actuators A Phys. 2007, 139, 23–30. [Google Scholar] [CrossRef]

- Schröder, H.; Obermeier, E.; Horn, A.; Wachutka, G.K.M. Convex corner undercutting of {100} silicon in anisotropic KOH etching: The new step-flow model of 3-D structuring and first simulation results. J. Microelectromech. Syst. 2001, 10, 88–97. [Google Scholar] [CrossRef]

- Pandy, A.; Landsberge, L.M.; Kahrizi, P.M. Mask-Under-Etch Experiments of Si{110} in TMAH. In Proceedings of the 1999 IEEE Canadian Conference on Electrical and Computer Engineering, Edmonton, AB, Canada, 9–12 May 1999; pp. 1621–1626. [Google Scholar]

- Eliyahu, D.; Gileadi, E.; Galun, E.; Eliaz, N. Atomic force microscope-based meniscus-confined three-dimensional electrodeposition. Adv. Mater. Technol. 2020, 5, 1900827. [Google Scholar] [CrossRef]

- Nouri-Goushki, M.; Mirzaali, M.J.; Angeloni, L.; Fan, D.; Minneboo, M.; Ghatkesar, M.K.; Staufer, U.; Fratila-Apachitei, L.E.; Zadpoor, A.A. 3D printing of large areaas of highly ordered submicron patterns for modulating cell behavior. ACS Appl. Mater. Interfaces 2020, 12, 200–208. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the surface texture and mechanical properties of FDM printed samples after thermal and chemical treatment. Strojniški Vestnik J. Mech. Eng. 2020, 66, 105–113. [Google Scholar]

- Moroni, L.; Boland, T.; Burdick, J.A.; de Maria, C.; Derby, B.; Forgacs, G.; Groll, J.; Li, Q.; Malda, J.; Mironov, V.A.; et al. Biofabrication: A guide to technology and terminology. Trends Biotechnol. 2018, 36, 384–402. [Google Scholar] [CrossRef]

- Tan, K.H.; Chua, C.K.; Leong, K.F.; Cheah, C.M.; Gui, W.S.; Tan, W.S.; Wiria, F.E. Selective laser sintering of biocompaticle polymers for applications in tissue engineering. Bio-Med. Mater. Eng. 2005, 15, 113–124. [Google Scholar]

- Zhou, W.Y.; Lee, S.H.; Wang, M.; Cheung, W.L.; Ip, W.Y. Selective laser sintering of porous tissue engineering scaffolds from poly(L-lactide)/carbonated hydroxyapatite nanocomposite microspheres. J. Mater. Sci. Mater. Med. 2008, 19, 2535–2540. [Google Scholar] [CrossRef]

- Moroni, L.; de Wijn, J.R.; van Blitterswijk, C.A. 3D fiber-deposited scaffolds for tissue engineering: Influence of pores geometry and architecture on dynamic mechanical properties. Biomaterials 2006, 27, 974–985. [Google Scholar] [CrossRef]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. Engineering hydrogels for biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J.; Abdulla, R.; Parker, B.; Samanipour, R.; Ghosh, S.; Kim, K.Y. A simple and high-resolution stereolithography-based 3D bioprinting system using visible light crosslinkable bioinks. Biofabrication 2015, 7, 045009. [Google Scholar] [CrossRef] [PubMed]

- Pearre, B.W.; Michas, C.; Tsang, J.-M.; Gardner, T.J.; Otchy, T.M. Fast micron-scale 3D printing with a resonant-scanning two-photon microscope. Addit. Manuf. 2019, 30, 100887. [Google Scholar] [CrossRef]

- Kumi, G.; Yanez, C.; Belfield, K.D.; Fourkas, J.T. High-speed multiphoton absorption polymerization: Fabrication of microfluidic channels with arbitrary cross-sections and high aspect ratios. Lab Chip 2010, 8, 1057–1060. [Google Scholar] [CrossRef] [PubMed]

- Straub, M.; Gu, M. Near-infrared photonic crystals with higher-order bandgaps generated by two-photon photopolymerization. Opt. Lett. 2002, 27, 1824–1826. [Google Scholar] [CrossRef]

- Thiel, M.; Fischer, J.; von Freymann, G.; Wegener, M. Direct laser writing of three-dimensional submicron structures using a continuous-wave laser at 532 nm. Appl. Phys. Lett. 2010, 97, 221102. [Google Scholar] [CrossRef]

- Kampker, A.; Triebs, J.; Kawollek, S.; Ayvaz, P.; Beyer, T. Direct polymer additive tooling—Effect of additive manufactured polymer tools on part material properties for injection moulding. Rapid Prototyp. J. 2019, 25, 1575–1584. [Google Scholar] [CrossRef]

- Zander, N.E.; Park, J.H.; Boelter, Z.R.; Gillan, M.A. Recycled cellulose polypropylene composite feedstocks for material extrusion additive manufacturing. ACS Omega 2019, 4, 13879–13888. [Google Scholar] [CrossRef]

- Maniere, C.; Kerbart, G.; Harnois, C.; Marinel, S. Modeling sintering anisotropy in ceramic stereolithography of silica. Acta Mater. 2020, 182, 163–171. [Google Scholar] [CrossRef]

- Tan, P.F.; Shen, F.; Li, B.; Zhou, K. A thermo-metallurgical-mechanical model for selective laser melting of Ti6Al4V. Mater. Des. 2019, 168, 107642. [Google Scholar] [CrossRef]

- de Araujo Filho, W.D.; Morales, R.E.M.; Schneider, F.K.; de Araujo, L.M.P. Microfluidics device manufacturing using the technique of 3D printing. In Proceedings of the ASME 12th International Conference on Nanochannels, Microchannels, and Minichannels 2014, Chicago, IL, USA, 3–7 August 2014; p. V001T15A002. [Google Scholar]

- Leary, J.F.; Key, J.; Vidi, P.A.; Cooper, C.L.; Kole, A.; Reece, L.M.; Lelievre, S.A. Human organ-on-a-chip BioMEMS devices for testing new diagnostic and therapeutic strategies. Proc. SPIE 2013, 8615, 86150A. [Google Scholar]

- Lifton, V.A.; Lifton, G.; Simon, S. Options for additive rapid prototyping methods (3D printing) in MEMS technology. Rapid Prototyp. J. 2014, 20, 403–412. [Google Scholar] [CrossRef]

- Zhu, F.; Skommer, J.; Friedrich, T.; Kaslin, J.; Wlodkowic, D. 3D printed polymers toxicity profiling—A caution for biodevice applications. Proc. SPIE 2015, 9668, 96680Z. [Google Scholar]

- Beckwith, A.L.; Borenstein, J.T.; Velasquez-Garcia, L.F. Monolithic, 3D-printed microfluidic platform for recapitulation of dynamic tumor microenvironments. J. Microelectromech. Syst. 2018, 27, 1009–1022. [Google Scholar] [CrossRef]

- Fuad, N.M.; Carve, M.; Kaslin, J.; Wlodkowic, D. Characterization of 3D-Printed Moulds for Soft Lithography of Millifluidic Devices. Micromachines 2018, 9, 116. [Google Scholar] [CrossRef]

- Sun, Z.M.; Velasquez-Garcia, L.F. Monolithic FFF-Printed, Biocompatible, Biodegradable, Dielectric-Conductive Microsystems. J. Microelectromech. Syst. 2017, 26, 1356–1370. [Google Scholar] [CrossRef]

- Carve, M.; Wlodkowic, D. 3D-Printed Chips: Compatibility of Additive Manufacturing Photopolymeric Substrata with Biological Applications. Micromachines 2018, 9, 91. [Google Scholar] [CrossRef]

- Araujo Filho, W.D.; Araujo, L.M.P.; Mauricio, C.R.M. 3D printing techniques in the manufacture of microfluidic devices for generation of microbubbles. SCIOL Biomed. 2019, 3, 143–151. [Google Scholar]

- Jia, Y.; Su, C.; He, M.G.; Liu, K.; Sun, H.; Lin, Q. Isothermal titration calorimetry in a 3D-printed microdevice. Biomed. Microdev. 2019, 21, 96. [Google Scholar] [CrossRef]

- Emons, M.; Obata, K.; Binhammer, T.; Ovsianikov, A.; Chichkov, B.N.; Morgner, U. Two-photon polymerization technique with sub-50 nm resolution by sub-10 fs laser pulses. Opt. Mater. Express 2012, 7, 942–947. [Google Scholar] [CrossRef]

- Nguyen, A.K.; Narayan, R.J. Two-photon polymerization for biological applications. Mater. Today 2017, 6, 314–322. [Google Scholar] [CrossRef]

- Kübler, S.M.; Xia, C.; Sharma, R.; Digaum, J.L.; Martinez, N.P.; Valle, C.L.; Rumpf, R.C. Fabrication of Functional Nanophotonic Devices by Multi-Photon Lithography. Proc. SPIE 2019, 10915, 1091502. [Google Scholar]

- Jui, C.-W.; Trappey, A.J.C.; Fu, C.-C. Discover Patent Landscape of Two-photon Polymerization Technology for the Production of 3D Nano-structure Using Claim-based Approach. Recent Patents Nanotechnol. 2018, 12, 218–230. [Google Scholar] [CrossRef] [PubMed]

- Walczak, R.; Kawa, B.; Adamski, K. Inkjet 3D printed microfluidic device for growing seed root and stalk mechanical characterization. Sens. Actuators A Phys. 2019, 297, 111557. [Google Scholar] [CrossRef]

- Storck, J.-L.; Böttjer, R.; Vahle, D.; Brockhagen, B.; Grothe, T.; Dietz, K.-J.; Rattenholl, A.; Gudermann, F.; Ehrmann, A. Seed germination and seedling growth on knitted fabrics as new substrates for hydroponic systems. Horticulturae 2019, 5, 73. [Google Scholar] [CrossRef]

- Huang, X.L.; Bauder, T.; Do, T.; Suen, H.; Boss, C.; Kwon, P.; Yeom, J. A Binder Jet Printed, Stainless Steel Preconcentrator as an In-Line Injector of Volatile Organic Compounds. Sensors 2019, 19, 2748. [Google Scholar] [CrossRef]

- Dinh, T.; Phan, H.P.; Kashaninejad, N.; Nguyen, T.K.; Dao, D.V.; Nguyen, N.T. An On-Chip SiC MEMS Device with Integrated Heating, Sensing, and Microfluidic Cooling Systems. Adv. Mater. Interfaces 2018, 5, 1800764. [Google Scholar] [CrossRef]

- Adamski, K.; Kawa, B.; Walczak, R. Inkjet 3D printed Venturi Microflowmeter. In Proceedings of the 2018 XV International Scientific Conference on Optoelectronic and Electronic Sensors (COE), Warsaw, Poland, 17–20 June 2018. [Google Scholar]

- Villegas, M.; Cetinic, Z.; Shakeri, A.; Didar, T.F. Fabricating smooth PDMS microfluidic channels from low-resolution 3D printed molds using an omniphobic lubricant-infused coating. Anal. Chim. Acta 2018, 1000, 248–255. [Google Scholar] [CrossRef]

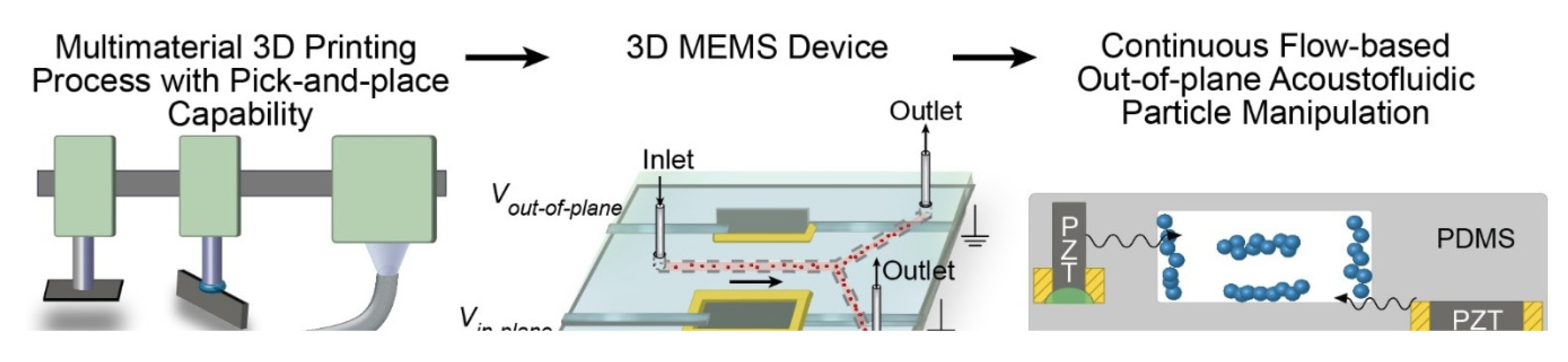

- Cesewski, E.; Haring, A.P.; Tong, Y.X.; Singh, M.; Thakur, R.; Laheri, S.; Read, K.A.; Powell, M.D.; Oestreich, K.J.; Johnson, B.N. Additive manufacturing of three-dimensional (3D) microfluidic-based microelectromechanical systems (MEMS) for acoustofluidic applications. Lab Chip 2018, 18, 2087–2098. [Google Scholar] [CrossRef]

- Tamura, T.; Suzuki, T. Seamless fabrication technique for micro to millimeter structures by combining 3D printing and photolithography. Jpn. J. Appl. Phys. 2019, 58, SDDL10. [Google Scholar] [CrossRef]

- Thapa, S.; Borquist, E.; Weiss, L. Thermal energy recovery via integrated small scale boiler and superheater. Energy 2018, 142, 765–772. [Google Scholar] [CrossRef]

- Feldmann, M.; Waldschik, A.; Büttgenbach, S. Technology and application of electro-depositable photo resists to create uniform coatings needed for complex 3D micro actuators and sensors. Microsyst. Technol. Micro Nanosyst. Inf. Storage Process. Syst. 2007, 13, 557–562. [Google Scholar] [CrossRef]

- Farahani, R.D.; Chizari, K.; Therriault, D. Three-dimensional printing of freeform helical microstructures: A review. Nanoscale 2014, 6, 10470–10485. [Google Scholar] [CrossRef]

- Bauer, R.; Stewart, G.; Johnstone, W.; Boyd, E.; Lengden, M. 3D-printed miniature gas cell for photoacoustic spectroscopy of trace gases. Opt. Lett. 2014, 39, 4796–4799. [Google Scholar] [CrossRef]

- Vincent, T.A.; Gardner, J.W. A low cost MEMS based NDIR system for the monitoring of carbon dioxide in breath analysis at ppm levels. Sens. Actuators B Chem. 2016, 236, 954–964. [Google Scholar] [CrossRef]

- Ilke, M.; Bauer, R.; Lengden, M. Performance of a 3D Printed Photoacoustic Sensor for Gas Detection in Mid-Infrared. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October–1 November 2017; pp. 1482–1484. [Google Scholar]

- Valyrakis, M.; Pavlovskis, E.; Alexakis, A. Designing a “smart pebble” for sediment transport monitoring. In Proceedings of the 36th IAHR World Congress: Deltas of the Future and What Happens Upstream, The Hague, The Netherlands, 28 June–3 July 2015; pp. 2843–2850. [Google Scholar]

- Shen, Z.Y.; Kottapalli, A.G.P.; Subramaniam, V.; Miao, J.M.; Asadnia, M.; Triantafyllou, M. Biomimetic Flow Sensors for Biomedical Flow Sensing in Intravenous Tubes. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October–3 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–3. [Google Scholar]

- Raoufi, M.A.; Moshizi, S.A.; Razmjou, A.; Wu, S.Y.; Warkiani, M.E.; Asadnia, M. Development of a Biomimetic Semicircular Canal With MEMS Sensors to Restore Balance. IEEE Sens. J. 2019, 19, 11675–11686. [Google Scholar] [CrossRef]

- Kwon, H.B.; Yoo, S.J.; Hong, U.S.; Kim, K.; Han, J.; Kim, M.K.; Kang, D.H.; Hwang, J.; Kim, Y.J. MEMS-based condensation particle growth chip for optically measuring the airborne nanoparticle concentration. Lab Chip 2019, 19, 1471–1483. [Google Scholar] [CrossRef]

- Krysztof, M.; Grzebyk, T.; Gorecka-Drzazga, A.; Adamski, K.; Dziuban, J. Electron optics column for a new MEMS-type transmission electron microscope. Bull. Pol. Acad. Sci. Tech. Sci. 2018, 66, 133–137. [Google Scholar]

- Das, S.K.; Baptist, J.R.; Sahasrabuddhe, R.; Lee, W.H.; Popa, D.O. Package Analysis of 3D-Printed Piezo-Resistive Strain Gauge Sensors. Proc. SPIE 2016, 9859, 985905. [Google Scholar]

- Baptist, J.R.; Zhang, R.S.; Wie, D.M.; Saadatzi, M.N.; Popa, D.O. Fabrication of strain gauge based sensors for tactile skins. Proc. SPIE 2017, 10216, 102160F. [Google Scholar]

- Yang, Z.W.; Yu, H.B.; Zhou, P.L.; Wang, J.Y.; Liu, L.Q. Fabrication of Three-dimensional Conductive Structures Using Direct Ink Writing. In Proceedings of the 2017 IEEE 7th Annual International Conference on Cyber Technology in Automation, Control, and Intelligent Systems (CYBER), Honolulu, HI, USA, 1 July–4 August 2017; pp. 1562–1565. [Google Scholar]

- Kusano, Y.; Segovia-Fernandez, J.; Sonmezoglu, S.; Amirtharajah, R.; Horsley, D.A. Frequency selective MEMS microphone based on a bioinspired spiral-shaped acoustic resonator. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Kaohsiung, Taiwan, 18–22 June 2017; pp. 71–74. [Google Scholar]

- Tiller, B.; Reid, A.; Zhu, B.T.; Guerreiro, J.; Domingo-Roca, R.; Jackson, J.C.; Windmill, J.F.C. Piezoelectric microphone via a digital light processing 3D printing process. Mater. Des. 2019, 165, 107593. [Google Scholar] [CrossRef]

- Watanabe, K.; Kinoshita, M.; Mine, T.; Morishita, M.; Fujisaki, K.; Matsui, R.; Sagawa, M.; Machida, S.; Oba, H.; Sugiyama, Y.; et al. Plasma ion-beam 3D printing: A novel method for rapid fabrication of customized MEMS sensors. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 459–462. [Google Scholar]

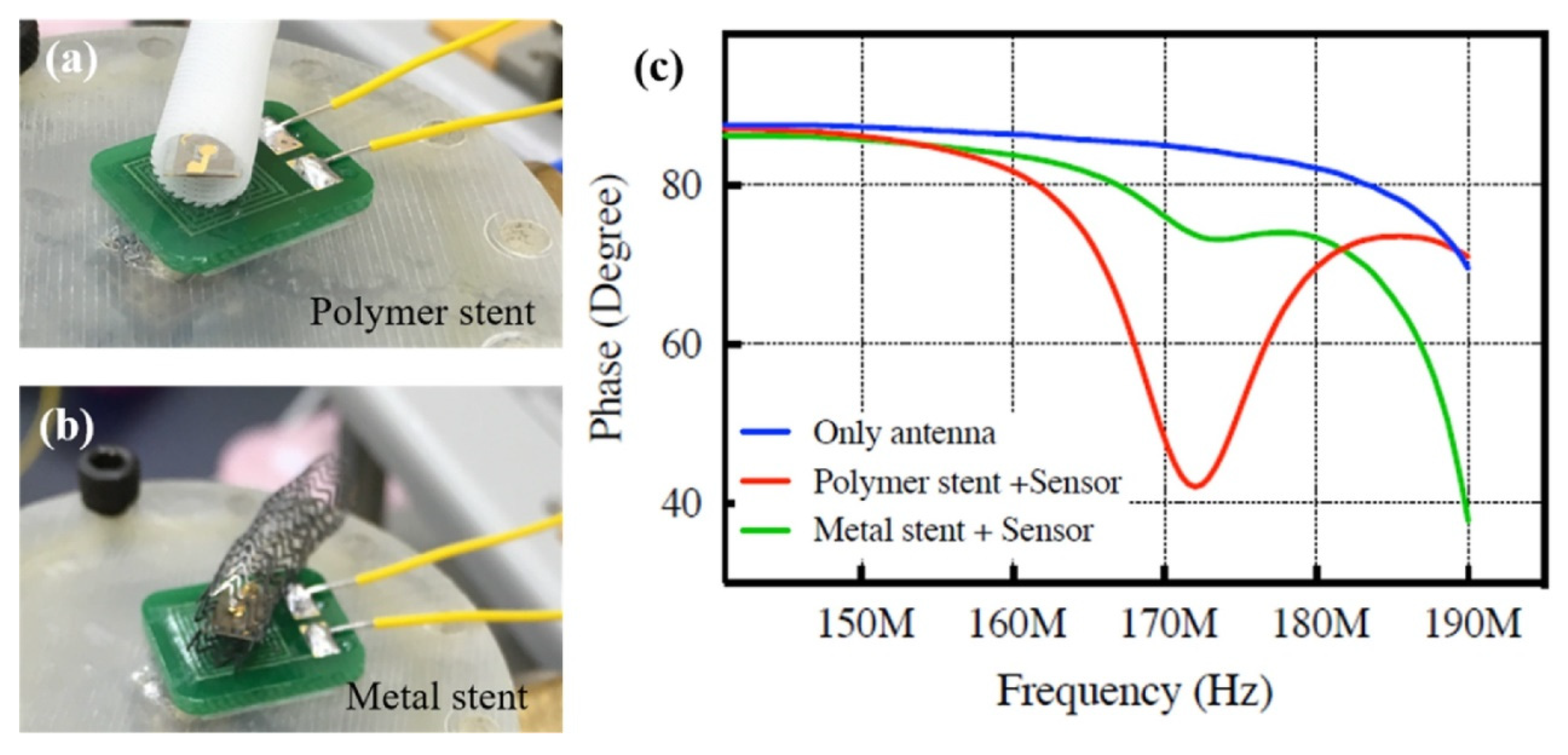

- Park, J.S.; Kim, J.-K.; Kim, D.-S.; Shanmugasundaram, A.; Park, S.A.; Kang, S.; Kim, S.-H.; Jeong, M.H.; Lee, D.-W. Wireless pressure sensor integrated with a 3D printed polymer stent for smart health monitoring. Sens. Actuators B Chem. 2019, 280, 201–209. [Google Scholar] [CrossRef]

- Wang, Y.J.; Gao, L.B.; Fan, S.F.; Zhou, W.Z.; Li, X.; Lu, Y. 3D printed micro-mechanical device (MMD) for in situ tensile testing of micro/nanowires. Extrem. Mech. Lett. 2019, 33, 100575. [Google Scholar] [CrossRef]

- Lee, Y.; Han, J.; Choi, B.; Yoon, J.; Park, J.; Kim, Y.; Lee, J.; Kim, D.H.; Kim, D.M.; Lim, M.; et al. Three-dimensionally printed micro-electromechanical switches. ACS Appl. Mater. Interfaces 2018, 10, 15841–15846. [Google Scholar] [CrossRef]

- Xie, X.; Zaitsev, Y.; Velasquez-Garcia, L.F.; Teller, S.J.; Livermore, C. Scalable, MEMS-enabled, vibrational tactile actuators for high resolution tactile displays. J. Micromech. Microeng. 2014, 24, 125014. [Google Scholar] [CrossRef]

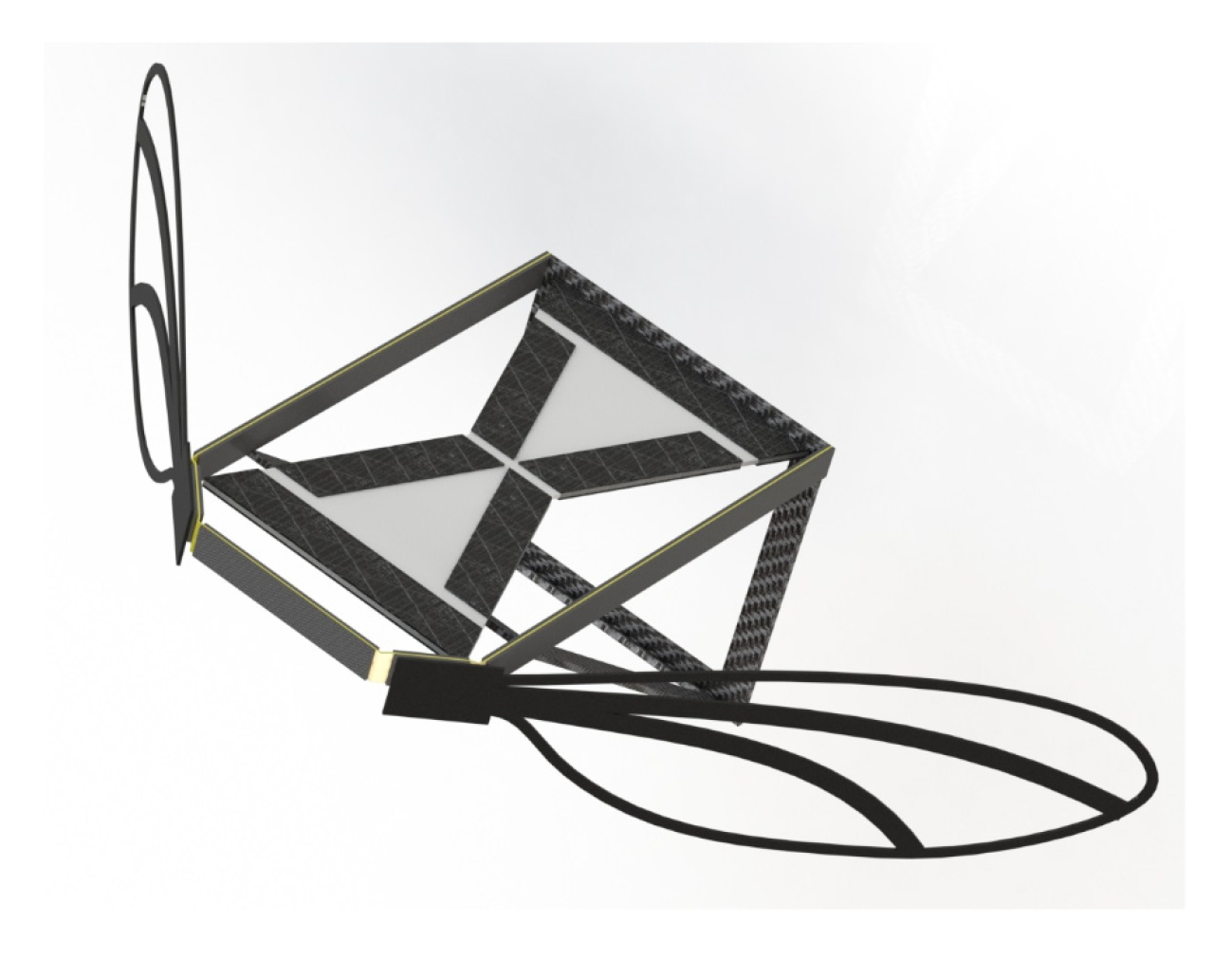

- Joshi, N.; Köhler, E.; Enoksson, P. MEMS based micro aerial vehicles. J. Phys. Conf. Ser. 2016, 757, 012035. [Google Scholar] [CrossRef]

- Khandekar, P.; Biswas, K.; Kothari, D.; Muthurajan, H. Nano Mechanical Properties of Ceramic Polymer Composite Micro Thruster Developed Using 3D Printing Technology. Adv. Sci. Lett. 2018, 24, 5884–5890. [Google Scholar] [CrossRef]

- Fiaz, H.S.; Settle, C.R.; Hoshino, K. Metal additive manufacturing for microelectromechanical systems: Titanium alloy (Ti-6Al-4V)-based nanopositioning flexure fabricated by electron beam melting. Sens. Actuators A Phys. 2016, 249, 284–293. [Google Scholar] [CrossRef]

- Bernasconi, R.; Credi, C.; Tironi, M.; Levi, M.; Magagnin, L. Electroless metallization of stereolithographic photocurable resins for 3D printing of functional microdevices. J. Electrochem. Soc. 2017, 164, B3059–B3066. [Google Scholar] [CrossRef]

- Taylor, A.P.; Cuervo, C.V.; Arnold, D.P.; Velasquez-Garcia, L.F. Fully 3D-Printed, Monolithic, Mini Magnetic Actuators for Low-Cost, Compact Systems. J. Microelectromech. Syst. 2019, 28, 481–493. [Google Scholar] [CrossRef]

- Fogel, O.; Winter, S.; Benjamin, E.; Krylov, S.; Kotler, Z.; Zalevsky, Z. 3D printing of functional metallic microstructures and its implementation in electrothermal actuators. Addit. Manuf. 2018, 21, 307–311. [Google Scholar] [CrossRef]

- Ertugrul, I.; Akkus, N.; Yuce, H. Fabrication of MEMS-based electrothermal microactuators with additive manufacturing technologies. Mater. Tehnol. 2019, 53, 665–670. [Google Scholar] [CrossRef]

- Han, D.; Gu, H.R.; Kim, J.W.; Yokota, S. A bio-inspired 3D-printed hybrid finger with integrated ECF (electro-conjugate fluid) micropumps. Sens. Actuators A Phys. 2017, 257, 47–57. [Google Scholar] [CrossRef]

| Technology | Min. Feature Size | Material | Ref. |

|---|---|---|---|

| Selective laser sintering | <400 µm | Div. Polymers | [21,22] |

| Fused deposition modeling | 200 µm | Diverse polymers | [23] |

| Robot dispensing | 200 µm | Hydrogels | [24] |

| Stereolithography | 30–70 µm | Photosensitive polymers | [25] |

| 3D inkjet printing | 28 µm | Photoresist | [24] |

| Resonant direct laser writing | 1–4 µm | IP-Dip photoresist | [26] |

| Multiphoton absorption polymerization | 1 µm | SU8 photoresist | [27] |

| Two-photon polymerization | 0.28–1.5 µm | Photoresists | [28] |

| Direct laser writing | 0.085–1.5 µm | Photoresists | [29] |

| Technology | Possible Applications |

|---|---|

| Fused deposition modeling | Dielectric-conductive systems, switches |

| Micro-stereolithography | In situ tensile tests of micro- or nanowires, electrothermal microactuator |

| Stereolithography | Microfluidic devices, conductive parts, molds, cantilevers, magnetic actuators |

| 3D inkjet printing | Microfluidic devices, Venturi microflowmeter, conductive structures, strain gauge sensors |

| Multiphoton absorption polymerization | Microfluidic devices, photonic crystals, nanophotonic devices |

| Two-photon polymerization | Microfluidic devices, electrothermal microactuator |

| Binder jet printing | Microfluidic devices, in-line injection of volatile organic compounds |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blachowicz, T.; Ehrmann, A. 3D Printed MEMS Technology—Recent Developments and Applications. Micromachines 2020, 11, 434. https://doi.org/10.3390/mi11040434

Blachowicz T, Ehrmann A. 3D Printed MEMS Technology—Recent Developments and Applications. Micromachines. 2020; 11(4):434. https://doi.org/10.3390/mi11040434

Chicago/Turabian StyleBlachowicz, Tomasz, and Andrea Ehrmann. 2020. "3D Printed MEMS Technology—Recent Developments and Applications" Micromachines 11, no. 4: 434. https://doi.org/10.3390/mi11040434

APA StyleBlachowicz, T., & Ehrmann, A. (2020). 3D Printed MEMS Technology—Recent Developments and Applications. Micromachines, 11(4), 434. https://doi.org/10.3390/mi11040434