Abstract

The severe hot temperature and high traffic loadings in the Kingdom of Saudi Arabia (KSA) are causing distress in flexible pavements within a few years of service. Secondly, the conventional bitumen extracted from Saudi oil refineries have a performance grade of 64-10 (PG 64-10), which does not meet the SuperPave performance grade requirement for most of the KSA’s regions. In order to improve the performance grade of bitumen, different percentages of municipal wastes (plastic and crumb rubber) were used as bitumen additives. The performance of bitumen at low, intermediate, and high temperatures was evaluated. This is important as the waste production is rising significantly due to the fast urbanization and high population growth in the KSA. Particularly, when there are very few ways of recycling these wastes (municipal, as well as industrial), which in fact have great impact on the environment. High-density polyethylene (HDP), low-density polyethylene (LDP), and crumb rubber (CR) with 5%, 10%, and 15% by weight of bitumen, were mixed with the base bitumen (PG 64-10). Rotational viscometer (RV), dynamic shear rheometer (DSR), and bending beam rheometer (BBR) were used to evaluate the viscosity, rutting, fatigue, and low-temperature behavior of base and modified binders. The test results indicated that the rutting (permanent deformation) and fatigue resistance were significantly improved in modified binders due to the improvement in the visco-elastic properties.

1. Introduction

Owing to the rapid urbanization and population increase, the production of municipal waste is rising significantly in the KSA. Currently, most of the municipal waste (such as glasses, low- and high-density polyethylene, and crumb rubber, etc.) is just being disposed into open landfills. This act is not only dangerous to human health but also to the living environment. Consequently, serious attention is required in the use of these wastes. The simple solution to this problem is that this sheer waste should be recycled. The most practical way of recycling is to use it in both road and building constructions.

There are many applications of bitumen/asphalt as a building material, especially used in the construction of flexible pavements. The bitumen exhibits complex behavior due to its visco-elastic characteristics. On one hand, it behaves like a viscous fluid when subjected to high temperature and slow moving loads. On the other hand, it acts like solid elastic when subjected to fast moving traffic or at low temperatures [1,2].

Furthermore, owing to the severe hot climate and rapid growth in traffic, the flexible pavements in the KSA are failing prematurely during the initial period of service. Similarly, using base bitumen of PG 64-10 (which is the only bitumen available in KSA), without modifying, leads to flexible pavement distresses in terms of rutting, fatigue, and low-temperature cracks.

Different modifiers/additives are being used to improve the performance of bitumen under different conditions. These modifiers/additives include polyethylene, rubbers, styrene butadiene styrene (SBS), styrene butadiene rubber (SBR), ethylene vinyl acetate (EVA), locolust, and EE-2, etc. [3,4,5,6,7]. Since few of the asphalts are resistant to rutting (due to high temperature and heavy loading) and low-temperature cracking without using proper modifiers, this motivated us to modify the base asphalt with particles of nano-TiO2, nano-ZnO, nano-CaCO3, SBS, and SBR.

The previous studies revealed that physical and chemical reaction of polymers with asphalt were significantly important in the modification process. Low- and high-temperature properties of modified asphalt were improved considerably. Moreover, the nano-CaCO3 was available in abundance and was less expensive as compared to other nano-polymers [8,9,10,11,12]. In addition to these modifiers, various other polymers, such as SBS, EVA, and polypropylenes, have been used in asphalt modifications and the temperature susceptibility was decreased significantly in modified binders [13,14,15,16,17].

Recently, KSA is facing a large challenge in terms of management of its solid waste. According to the recent estimates of 2015, KSA is producing more than 15 million tons of municipal waste each year, while this figure was 12.1 million tons per year back in 2007 [18]. Owing to the absence of recycling techniques in the KSA, a major portion of these wastes are being dumped into open landfills [18,19]. Similarly, informal sectors extract papers, plastics, metals etc. from these wastes and recycle it at a very slow rate that is only around 10%–15% of the total production in the KSA.

Moreover, a recent study, conducted on solid waste management for Jeddah city, found that papers (21%), plastics (13%), metals (6%), glasses (4%), wood (1%), organics (48%), and others (7%) were extracted from the municipal wastes alone [20]. Furthermore, a rapid increase in the usage of vehicles was also one of the major causes in the production of such wastes. As a result, over 30 million waste tires were found in the KSA (SIPA, 2013) [21].

The addition of different stages/forms of bleaching clay (which is used to clarify vegetable oil in food industries) wastes in binder and hot mix asphalt considerably affect the rheological properties of the binder, stiffness of the mix, and interaction with bitumen at intermediate and high temperatures [22]. Therefore, this study was performed to find possible alternatives that could improve the performance of bitumen’s grades from PG 64-10 to higher grades and then optimizing the bitumen and modifying with municipal wastes (LDP, HDP, and CR). As a result of that, modifying the base bitumen with different percentages of LDP, HDP, and CR would enhance resistance of asphalt against rutting and cracking. It would also help in recycling these municipal wastes to reduce environmental pollution. The Ministry of Transportation (MOT) had recommended the use of different polymers in asphalt modification in order to improve its performance against high temperatures and heavy loadings [23].

2. Materials and Methods

2.1. Materials

The base binder of Performance Grade PG 64-10 was used in this study, as obtained from a local Saudi refinery. Crumb rubber (CR), high-density polyethylene (HDP), and low-density polyethylene (LDP) with 5%, 10%, and 15% by weight of bitumen were used as bitumen additives. The LDP, HDP, and crumb rubber were procured from local recycling factories (size range from 1–4 mm). The crumb rubber was obtained from the wastage of tires, and was grinded using a traditional mechanical grinder. After grinding, sieving was performed to obtain fine material (pass through sieve #100). This process was done to achieve the uniformity during the mixing of CR in bitumen. Then, the powdered crumb rubber was blended in molten asphalt using a high-speed laboratory mixer.

Similarly, both the polymers (LDP and HDP) were blended with molten asphalt at a temperature of 20–30 °C higher than the respective melting point of the polymers (the melting point of LDP is 110 °C, and 126 °C for HDP) with a high-speed laboratory mixer [24]. Then the binders were mixed at a speed of 1000 rpm for 20 min (speed and time was obtained by optimizing the value of “G*/Sin Phase angle”). It is worth mentioning that the tests were conducted on binders only, and, hence, the wet process of polymer modification was used during the modification.

The physical properties of materials used in this study are given in Table 1.

Table 1.

Characteristics of bitumen, LDP, and HDP.

2.2. Methods

The grade of bitumen was determined at King Faisal University Highway laboratory using specified ASTM standards (D7175-08, D2872-04, D6521-08, and D6648-08) for SuperPave binder testing [25,26,27,28].

A laboratory shear mixer was used to mix different percentages (5%, 10%, and 15%) of CR, HDP, and LDP with base bitumen. The viscosities of controlled bitumen and modified bitumen (with CR, HDP, and LDP) were determined using a rotational viscometer (RV) at 135 °C and 165 °C at a spindle speed of 20 rpm. The rheological properties at high and intermediate temperatures were determined using a dynamic shear rheometer (DSR). A bending beam rheometer (BBR) was used to evaluate the properties of the binder at low temperatures. Tests were performed on controlled bitumen samples and modified bitumen samples (with CR, HDP, and LDP replaced at 5%, 10%, and 15% by weight of bitumen).

3. Results and Discussion

3.1. Viscosity

A rotational viscometer was used to determine the viscosity of binders used in this study. All of the tests were conducted following the standard conditions of temperature (135 °C) and spindle rotation (20 rpm) as per ASTM D4402 [29]. According to the Strategic Highway Research Program (SHRP) specifications, the viscosity shall not increase 3 Pa·s for proper handling and pumping under the required temperature conditions [30].

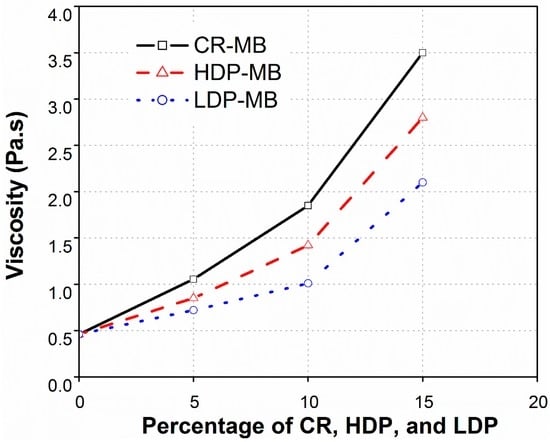

It is clear from the Figure 1 that the viscosity of binders increased with increasing percentages of LDP, HDP, and CR.

Figure 1.

Viscosity of controlled and CR-, HDP-, and LDP-modified binders at 135 °C.

The viscosity of binders has a significant impact on the workability (handling and pumping during mixing and placing) of asphalt mixes, as well as on the energy consumption during the mixing process. The 15% CR-MB exceeded the maximum limit of viscosity and, therefore, required more energy for its mixing. A significant increased viscosity of 15% CR resulted in a less workable modified asphalt mix. To overcome such workability problems, SASOBIT® (Fischer-Tropsch wax) can be added to CR-MB to reduce the viscosity of the modified asphalt. In addition, the mixing temperature of hot mix asphalt can also be reduced up to 30 °C with the addition of SASOBIT® [31].

3.2. Measurement of Elasticity of LDP-, HDP-, and CR-Modified Binders

The behavior of asphalt depends on the temperature as well as on the loading time due to its visco-elastic nature. Dynamic shear rheometers (DSR) were used to evaluate the effect of both the temperature and the loading time on asphalt binders. The rheological properties (complex modulus and phase angle) at intermediate to high temperatures can also be measured using DSR.

In this study, the controlled asphalt and modified asphalt with LDP, HDP, and CR (5%, 10%, and 15%) by weight of bitumen were tested using DSR following the standard conditions of the SuperPave binder tests [30]. All of the tests were conducted at a frequency of 1.59 Hz and different temperatures, such as 46, 52, 58, 64, 70, 76, and 82 °C, which corresponded to the SuperPave performance grade testing specifications.

The complex modulus (G*) and phase angle (δ) are the basic parameters measured by DSR. Complex modulus was used to evaluate the binder resistance to deformation and the amounts of recoverable and non-recoverable deformation were calculated using the measured values of the phase angle [32].

Phase angle also inversely related to elasticity of binders; the greater the value of the phase angle means a less elastic binder and, thus, more susceptible to deformation. Similarly, the lesser the value of the phase angle indicates that the binder is more elastic and less susceptible to deformation. On the other hand, a high value of complex modulus (G*) indicates that the binder shows more resistance against deformation when subjected to different loading and temperature conditions. Keeping in mind the hot climate of the Kingdom during the summer, tests on DSR were conducted considering high temperatures reaching up to 82 °C.

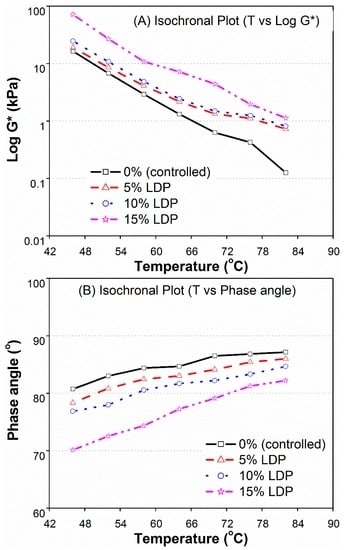

3.2.1. LDP Modified Binders

Relationships between temperature vs. complex modulus (G*) and temperature vs. phase angle (δ) are presented in Figure 2A,B for LDP-modified bitumen. It can be seen from the isochronal plot (Figure 2A) that the increase in percentage of LDP results in the improved value of G* as compared to the controlled bitumen, even at the highest temperature.

Figure 2.

Relationship between temperature vs. complex modulus (A) and phase angle (B) for LDP-modified bitumen.

The binder modified with 15% LDP by weight of bitumen showed maximum value of complex modulus (G*), which is 2–7 times of the controlled bitumen, when tested at 46, 52, 58, 64, 70, 76, and 82 °C temperatures and, hence, less susceptible to deformation. Similarly, LDP-modified binder showed improved performance at all of the test temperatures in terms of the decline in the phase angle (δ) and, hence, the elasticity of the LDP-modified binder increased as compared to the controlled bitumen.

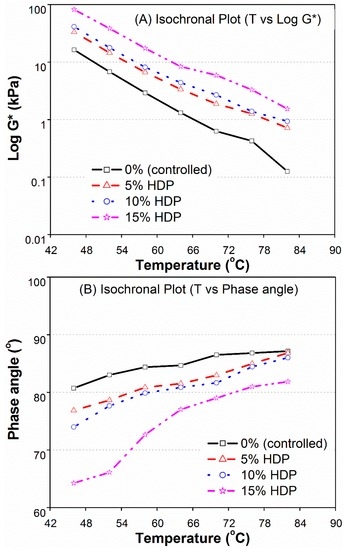

3.2.2. HDP Modified Binders

Relationships between temperature vs. complex modulus (G*) and temperature vs. phase angle (δ) are presented in Figure 3A,B for HDP-modified bitumen. It can be seen from the isochronal plot (Figure 2A) that the HDP-modified binder shows improved value of G* as compared to the controlled bitumen even at the highest temperature.

Figure 3.

Relationship between temperature vs. complex modulus (A) and phase angle (B) for HDP-modified bitumen.

The binder modified with 15% HDP by weight of bitumen showed an increased value of complex modulus (G*) from 4–11 times of the controlled bitumen when tested at 46, 52, 58, 64, 70, 76, and 82 °C temperatures and, hence, less susceptible to deformation. Moreover, bitumen modified with 5% and 10% HDP showed better results as compared to the controlled bitumen. Similarly, HDP-modified binder showed improved performance at all of the test temperatures in terms of the decline in the phase angle (δ) and, hence, the elasticity of the HDP-modified binder increased as compared to the controlled bitumen.

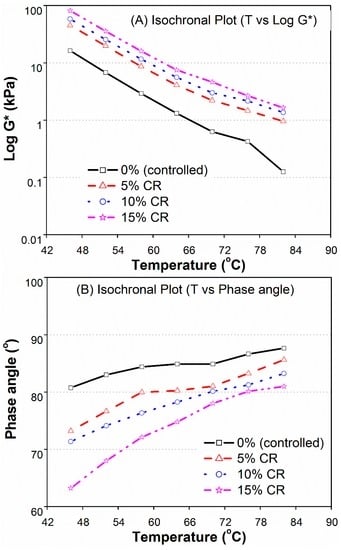

3.2.3. CR Modified Binders

Relationships between temperature vs. complex modulus (G*) and temperature vs. phase angle (δ) are presented in Figure 4A,B for CR-modified bitumen. It can be seen from the isochronal plot (Figure 2A) that the CR-modified binder shows improved value of G* as compared to controlled bitumen even at the highest temperature.

Figure 4.

Relationship between temperature vs. complex modulus (A) and phase angle (B) for CR-modified bitumen.

The binder modified with 15% CR by weight of bitumen showed an increased value of complex modulus (G*) from 4–12 times of controlled bitumen when tested at 46, 52, 58, 64, 70, 76, and 82 °C temperatures and, hence, less susceptible to deformation. Moreover, bitumen modified with 5% and 10% CR showed better results as compared to controlled bitumen. Similarly, CR-modified binder showed improved performance at all of the test temperatures in terms of the decline in the phase angle (δ) and, hence, the elasticity of the CR-modified binder increased as compared to the controlled bitumen samples.

3.3. Rutting Susceptibility of Modified Binders

The rutting parameter (G*/Sinδ) is determined from two basic factors (G* and δ) as obtained from the DSR test results discussed in previous sections. According to the SuperPave specifications, the rutting parameter (G*/Sinδ) must be minimized to 1.00 kPa for the original binder in order to reduce rutting (permanent deformation) in asphalt pavements.

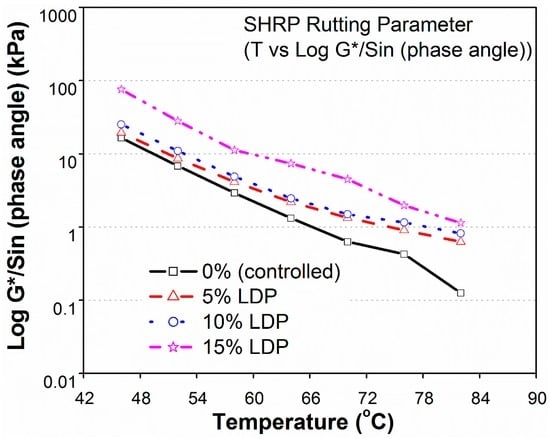

3.3.1. LDP-MB

Figure 5 shows the relationship between temperature and rutting parameter (G*/Sinδ) for LDP-modified bitumen (LDP-MB). It can be concluded from the results that the increase in percentage of LDP causes the increase in binder resistance to rutting (permanent deformation). Furthermore, it was observed that at a temperature of 64 °C and below, the LDP-MB as well as the controlled binder meets the SuperPave minimum requirement (G*/Sinδ > 1 kPa).

Figure 5.

Effect of temperature and percentage of LDP on rutting parameter of LDP-MB

However, at 70 °C the bitumen modified with 5%, 10%, and 15% LDP meets the minimum requirements, while controlled bitumen does not meet the minimum requirements at temperatures above 64 °C. At a temperature of 76 °C the 5% LDP-MB does not meet the minimum SuperPave requirements for rutting resistance. Moreover, the 15% LDP-MB exceeded the limiting value of rutting parameter at the highest temperature of 82 °C, while the controlled as well as other modified bitumen has failed at this temperature.

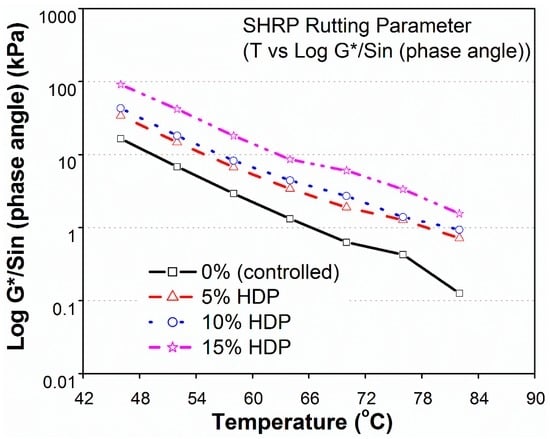

3.3.2. HDP-MB

Figure 6 presents the relationship between the temperature and the rutting parameter (G*/Sinδ) for HDP-modified bitumen (HDP-MB). It can be concluded from the results that with an increasing percentage of HDP, the binder resistance to rutting (permanent deformation) has also increased. At temperatures 64 °C and below, both HDP-MB and the controlled binder meet the SuperPave minimum requirements (G*/Sinδ > 1 kPa).

Figure 6.

Effect of temperature and percentage of HDP on rutting parameter of HDP-MB.

However, at 70 °C and 76 °C temperatures the bitumen modified with 5%, 10%, and 15% HDP meets the minimum requirements, while the controlled bitumen does not meet the minimum requirements above 64 °C. Moreover, the 15% HDP-MB exceeds the limiting value of rutting parameter at the highest temperature of 82 °C, while the controlled, as well as other modified bitumen, failed at this temperature to meet the minimum criteria.

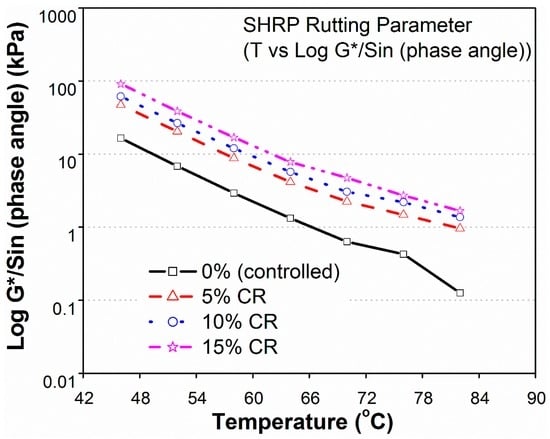

3.3.3. CR-MB

Figure 7 presents the relationship between the temperature and the rutting parameter (G*/Sinδ) for CR-modified bitumen (CR-MB). It can be concluded from the results that with an increasing percentage of CR, the binder resistance to rutting (permanent deformation) has also increased. At temperatures 64 °C and below, both CR-MB and the controlled binder meets the SuperPave minimum requirements (G*/Sinδ > 1 kPa).

Figure 7.

Effect of temperature and percentage of CR on rutting parameter of CR-MB.

However, at 70 °C and 76 °C temperatures the bitumen modified with 5%, 10%, and 15% CR meets the minimum requirements, while the controlled bitumen does not meet the minimum requirements above 64 °C. Moreover, 10% and 15% CR-MB exceed the limiting value of the rutting parameter at the highest temperature of 82 °C, while the controlled bitumen and other modified bitumen has failed at this temperature.

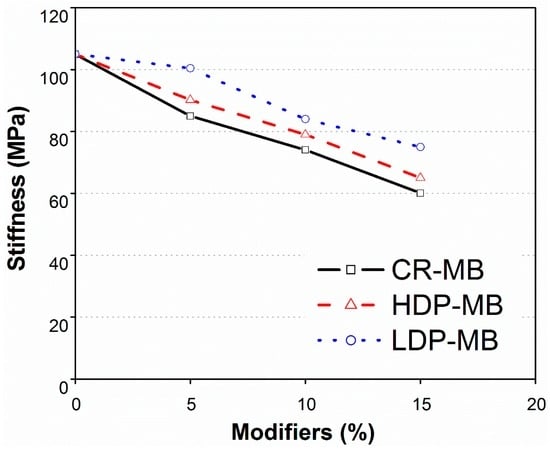

3.4. Creep Stiffness of Modified Binders

Bending beam rheometer (BBR) was developed by SHRP to evaluate the rheological properties of binders at low temperatures. The binder behaved as an elastic solid at the lowest pavement temperature and, hence, BBR was used to evaluate the performance of modified binder at a temperature of −10 °C (selected based on the temperature zoning for Saudi Arabia) [33].

Furthermore, the tests were performed on the base binder and on the modified binders, which were aged in a rolling thin film oven (RTFO) and pressure aging vessel (PAV) prior to the test. From Figure 8, it can be concluded that the stiffness of binders is decreasing with an increase in the percentage of modifiers. This clearly reflects improvement in binder resistance against low temperature cracks. The stiffness of CR, HDP, and LDP modified binder at 60 s (AASHTO M320) are within the range of the SuperPave specifications.

Figure 8.

Stiffness of CR, HDP, and LDP modified binders at −10 °C.

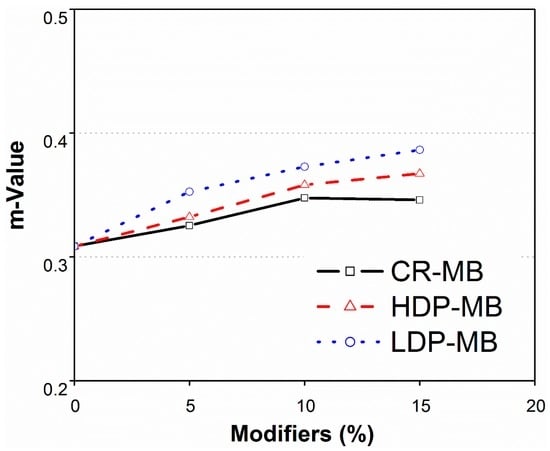

The rate of change in stiffness is measured by m-value, which is the slope of the stiffness curve. According to SuperPave specifications, the m-value will be greater or equal to 0.300 under 60 s loading time. As shown in Figure 9, the m-values of all binders lie within the range. Currently, the authors have focused on conventional DSR tests in this study. However, further research will be conducted in the future using multiple stress creep recovery (MSCR) to study the rutting phenomena of modified bitumen with MSCR tests.

Figure 9.

Rate of change in creep stiffness (m-value) at −10 °C for CR, HDP, and LDP modified binders.

4. Conclusions

The rheological properties of the base binder and the binder modified with municipal wastes (CR, HDP, and LDP) were determined using RV, DSR, and BBR. The base binder (PG 64-10) did not satisfy the SuperPave specifications in most of the KSA regions, where maximum average seven days pavement temperature reached up to 76 °C during the summer season. In this study, different municipal wastes (LDP, HDP, and CR) were used to evaluate the rheological properties of modified bitumen at high temperature, as well as to improve the grade of traditional bitumen. Application of these municipal wastes in road construction would reduce environmental issues by avoiding dumping them into open spaces. Based on the results of this study, the following main conclusions were drawn:

- Binder modified with CR, HDP, and LDP showed significant improvement of viscosity. However, viscosity of 15% CR-MB exceeded the SuperPave specifications, which could affect the workability of the asphalt mix during its mixing and placing. To overcome this problem, SASOBIT® could be added to CR-MB to reduce this exceeded viscosity.

- Increased percentages of CR, HDP, and LDP had significant effects on the visco-elastic properties of the modified binders. The modified binders showed improved elasticity as compared to base bitumen due to increase in the complex modulus (G*) and the decline in phase angle (δ) values. The increase in G* for LDE, HDP, and CR were 2–7, 4–11,and 4–12 times, respectively, as compared to controlled bitumen for temperatures 46, 52, 58, 64, 70, 76, and 82 °C.

- The base binder (PG 64-10) was found to be more susceptible to rutting at temperatures above 64 °C.

- The SHRP rutting parameter (G*/Sinδ) was improved significantly in modified binders at higher temperatures. Binders modified with 5%–15% of HDP and CR, and 10%–15% of LDP, satisfied the minimum requirements of SuperPave rutting criteria, at temperatures of 70 and 76 °C. Moreover, the performance grade of base binder (PG 64-10) was improved to PG 76-10 for HDP and CR modifications, and up to PG 70-10 for 10%–15% LDP.

- Binder modified with 15% LDP and HDP exceeded the minimum SuperPave rutting criteria at the highest temperature (82 °C) and, hence, the performance grade rose to PG 82-10. Consequently, bitumen modified with 15% LDP, HDP, and CR could satisfactorily be used in road construction throughout KSA.

- An inverse relationship was observed between creep stiffness and the binder resistance against low temperature cracks. Increased dosage of modifiers results in a decrease of the stiffness value and, hence, offered more resistance to low temperature cracks in asphalt pavements.

Acknowledgments

The Deanship of Scientific Research (DSR) at King Faisal University (KFU) through DSR “sixteenth annual research project # 160172” supported this work. The authors wish to express their gratitude for the financial support that has made this study possible.

Author Contributions

Muhammad Nasir Amin and Muhammad Imran Khan designed the research. Muhammad Imran Khan performed the experiments. Muhammad Nasir Amin, and Muhammad Imran Khan analyzed the experimental results. Muhammad Nasir Amin, Muhammad Imran Khan and Muhammad Umair Saleem wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| PG | Performance Grade |

| HDP | High-Density Polyethylene |

| LDP | Low-Density Polyethylene |

| CR | Crumb Rubber |

| RV | Rotational Viscometer |

| DSR | Dynamic Shear Rheometer |

| BBR | Bending Beam Rheometer |

| SBS | Styrene Butadiene Styrene |

| SBR | Styrene Butadiene Rubber |

| EVA | Ethylene Vinyl Acetate |

| G* | Complex Modulus |

| δ | Phase angle |

| cP | Centipoise |

| rpm | Revolution per minute |

| SHRP | Strategic Highway Research Program |

| CR-MB | Crumb Rubber—Modified Bitumen |

| LDP-MB | Low-Density Polyethylene—Modified Bitumen |

| HDP-MB | High-Density Polyethylene—Modified Bitumen |

| kPa | Kilo-Pascal |

| RTFO | Rolling Thin Film Oven |

| PAV | Pressure Aging Vessel |

| MSCR | Multiple Stress Creep Recovery |

| Pa·s | Pascal second |

References

- Masad, E.; Huang, C.; Airey, G.; Muliana, A. Nonlinear viscoelastic analysis of unaged and aged asphalt binders. Constr. Build. Mater. 2008, 22, 2170–2179. [Google Scholar] [CrossRef]

- Airey, G. Rheological evaluation of ethylene vinyl acetate polymer modified bitumen. Constr. Build. Mater. 2002, 16, 473–487. [Google Scholar] [CrossRef]

- Ait-Kadi, A.; Brahimi, H.; Bousmina, M. Polymer blends for enhanced asphalt binders. Polym. Eng. Sci. 1996, 36, 1724–1733. [Google Scholar] [CrossRef]

- Blanco, R.; Rodríguez, R.; García-Garduño, M.; Castaño, V.M. Rheological properties of styrene-butadiene copolymer-reinforced asphalt. J. Appl. Polym. Sci. 1996, 61, 1493–1501. [Google Scholar] [CrossRef]

- Hesp, S.A.; Woodhams, R.T. Asphalt–polyolefin emulsion breakdown. Colloid Polym. Sci. 1991, 269, 825–834. [Google Scholar] [CrossRef]

- Newman, J.K. Dynamic shear rheological properties of polymer-modified asphalt binders. J. Elast. Plast. 1998, 30, 245–263. [Google Scholar]

- Yousefi, A.A. Polyethylene dispersions in bitumen: The effects of the polymer structural parameters. J. Appl. Polym. Sci. 2003, 90, 3183–3190. [Google Scholar] [CrossRef]

- Zhang, H.L.; Su, M.; Zhao, S.F.; Zhang, Y.P.; Zhang, Z.P. High and low temperature properties of Nano-particles/polymer modified asphalt. Constr. Build. Mater. 2016, 114, 323–332. [Google Scholar] [CrossRef]

- Rehab, A.; Salahuddin, N. Nanocomposite materials based on polyurethane intercalated into montmorillonite clay. Mater. Sci. Eng. A 2005, 399, 368–376. [Google Scholar] [CrossRef]

- Yu, J.Y.; Feng, P.C.; Zhang, H.L. Effect of organo-montmorillonite on aging properties of asphalt. Constr. Build. Mater. 2009, 23, 2636–2640. [Google Scholar] [CrossRef]

- Yu, J.; Wang, L.; Zeng, X. Effect of montmorillonite on properties of styrene–butadiene–styrene copolymer modified bitumen. Polym. Eng. Sci. 2007, 47, 1289–1295. [Google Scholar] [CrossRef]

- Fang, C.; Yu, R.; Zhang, Y. Combined modification of asphalt with polyethylene packaging waste and organophilic montmorillonite. Polym. Test. 2012, 31, 276–281. [Google Scholar] [CrossRef]

- Perez, L.A.; Martinez, B.F.; Gallegos, C.; Gonzalez, O.; Munoz, M.; Santamaria, A. Influence of the processing conditions on the rheological behaviour of polymer-modified bitumen. Fuel 2003, 82, 1339–1348. [Google Scholar]

- Lu, X.; Isacsson, U. Modification of road bitumen with thermoplastic polymers. Polym. Test. 2001, 20, 77–86. [Google Scholar] [CrossRef]

- Gonzalez, O.; Pena, J.; Munoz, M.; Santamaria, A.; Perez, L.A.; Martinez, B.F. Rheological techniques as a tool to analyze polymer-bitumen interactions: Bitumen modified with polyethylene and polyethylene-based blends. Energy Fuel 2002, 16, 1256–1263. [Google Scholar] [CrossRef]

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Habib, N.; Kamaruddin, Z.; Napiah, M.; Tan, M. Rheological properties of polyethylene and polypropylene modified bitumen. Int. J. Civ. Environ. Eng. 2011, 3, 96–100. [Google Scholar]

- Khan, M.S.M.; Zakariya, K. Biodegradable waste to biogas: Renewable energy option for the Kingdom of Saudi Arabia. Int. J. Innov. Appl. Stud. 2013, 4, 101–113. [Google Scholar]

- Kosseva, M.R. Chapter 3 Processing of Food Wastes. Adv. Food Nutr. Res. 2009, 58, 57–136. [Google Scholar] [PubMed]

- Hakamil, B.A.; El-Sayed, S.A.S. Household Solid Waste Composition and Management in Jeddah City, Saudi Arabia: A planning model. Int. Res. J. Environ. Sci. 2015, 4, 1–10. [Google Scholar]

- Saudi Industrial Property Authority. Report on waste tires in KSA. 2013. Available online: http://www.modon.gov.sa/en/pages/default.aspx (accessed on 3 March 2016). [Google Scholar]

- Francesco, M.; Cesare, S.; Valeria, V.; Claudio, L.; Giulio, D. Rheological characterization of bituminous mastics containing waste bleaching clays. In Proceedings of the 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials, Ancona, Italy, 7–9 October 2015; Volume 11, pp. 595–606.

- Ministry of Transport, Saudi Arabia. Available online: http://www.mot.gov.sa/ (accessed on 20 February 2014).

- Farhat, M.A.; Asi, I.M.; Wahhab, H.A.; Al-Dubabe, I.A. Characterization of Polymer Modified Gulf Asphalts. Pet. Sci. Technol. 1999, 17, 125–145. [Google Scholar]

- ASTM D7175-08. Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D2872-04. Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test); American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D6521-08. Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV); American Society for Testing and Materials: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM D6648-08. Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR); American Society for Testing and Materials: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM D4402. Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Asphalt Institute. SP-1 Superpave Performance Graded Asphalt Binder Specification and Testing; Asphalt Institute: Lexington, KY, USA, 2003. [Google Scholar]

- Gui, J.Z.; Ping, G. Workability of Sasobit Warm Mixture Asphalt. Energy Procedia 2012, 16, 1230–1236. [Google Scholar]

- Uddin, W. Viscoelastic characterization of polymer modified asphalt binders of pavement applications. Appl. Rheol. 2003, 13, 191–199. [Google Scholar]

- Wahab, H.A.; Asi, I.M.; Ibrahim, A.D.; Alit, M.F. Development of performance-based bitumen specifications for the Gulf countries. Constr. Build. Mater. 1997, 11, 15–22. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).