Abstract

The textile and clothing industry generates much pollution and consumes a large amount of resources. Improper uses and disposal of clothing products make the problems much more severe. Fast fashion products shorten the valid lifecycle and generate more waste than regular clothing products. Considering the features of fashion products, a system of a rent-based closed-loop supply chain is developed to improve the sustainability of fashion products. The supply chain processes (fashion design and manufacturing, laundry, logistics and disposal), the operations management issues (inventory management, closed-loop logistics, human-clothing matching, booking system and the rental pricing) and the sustainability promotion aspects (customization, responsive system, culture and policy aspects) are investigated by devising sustainable strategies. The rationalities of the developed system and strategies are reviewed and elucidated in detail. The results may contribute to building sustainable closed-loop fashion supply chains, the related information systems and operational and managerial mechanisms.

1. Introduction

Today, clothing is labeled as beautiful decoration, individuation, fashion and artistic. The springing up of textile and clothing industries brings rapid development to clothing products, which inevitably causes serious pollution. The used clothing may be resold, reused and donated, and most of it is finally discarded [1]. Textiles in municipal solid waste are found mainly in the form of discarded clothing, although other sources include furniture, carpets, tires, footwear and nondurable goods, such as sheets and towels. Moreover, in the many and long processes of clothing manufacturing, the environment is heavily polluted and many resources are wasted. Textile recycling is a method of reusing or reprocessing used clothing, fibrous material and clothing scraps from the manufacturing process. As an intuitive and sustainable strategy, reusing the clothing can reduce manufacturing pollution and resource consumption. However, consumers have different opinions and behaviors regarding clothing disposal, recycling and remanufacturing.

Industrialization and fast fashion trends make the clothing pollution problem much more severe. Although some fashion products can be recycled by waste clothing bins or donated to charity shops, the manufacturing, sales, distribution and use phases have generated much pollution. Therefore, optimal disposal methods cannot relieve the pollution too much. The fashion and textile industry should seek novel and good approaches to achieve sustainability. Much research has been conducted to improve the sustainability in material production and usage, manufacturing processes, transportation and warehousing, selling and services. However, fast fashion makes these situations worse, because each piece of clothing is fashionable; thus, it is used only for a short term. Many fashion clothing products are just used several times, then stored in chests, and finally, most are discarded as garbage. Fast fashion products improve life quality, but meanwhile, they produce waste and pollution.

Based on the features of fast fashion products, this work develops a rent-based system for improving the sustainability of the products. Fast fashion products usually have shorter lifecycles than regular clothing products; the costs of these products then are relatively higher; the fashion in one city may be transferred to other cities in a fashion cycle. When the fashion products are consumed by rental services, these features can be utilized to improve sustainability. Based on these considerations, this work develops a sustainable rent-based closed-loop supply chain for fashion products. The sustainability and the strategies to improve the sustainability of the supply chain are investigated. However, our developed supply chain system is workable on the premise that consumers can accept fast fashion products that are rented cyclically. This premise should be inspected in real life by empirical studies. In this work, this is stated with respect to the following reasons. First, financial leasing and equipment leasing have been a tendency in industries. As an efficient financial means, leasing becomes important for many companies to expand their markets, which becomes the background of product leasing. Second, many products, including furniture, computers and other products that can be temporarily used, also have been rented. Third, many special types of clothing products have been supported by rental markets. In China, wedding apparel, performance costumes and other formal or informal dresses have been widely leased by many specialized fashion companies. Although this evidence is not fully revealed in the literature, their prevalence motivates this work.

Compared to the studies on the fashion and textile industry, supply chain design and sustainable fashion products, this study contributes to the literature in the following aspects. First, two closed-loop supply chains are proposed for fashion products in the regular retailing channel mode and the rent-based mode. Rental services comprise the primary contribution, and all schemes are developed by considering the business mode based on rental services. Second, the activities in the rent-based closed-loop supply chain are compared with the regular retailing channel mode, based on some strategies that have been researched for sustainable fashion retailing [2]. Moreover, sustainable operational strategies are devised for these activities. Further, the managerial implications for improving sustainability are examined and discussed. The key scholarly feature of this work involves a system of a rental-based closed-loop supply chain and a framework of research aspects. Based on these, special business modes, consumer behaviors and sustainability values can be further examined. Practitioners can use the results to design business innovation methods and operations management schemes. To our knowledge, few publications have elucidated these aspects systematically.

In the rest of the paper, the studies related to the fashion supply chain and rental services are reviewed first in Section 2. Then, after a system of a rent-based closed-loop supply chain is developed, the sustainable strategies are investigated and discussed at three levels, namely supply chain processes, operations management issues and sustainability promotion strategies, in Section 3, Section 4 and Section 5, respectively. The final conclusions are made in Section 6.

2. Related Studies

2.1. Supply Chain of Fashion Products and Its Sustainability

This section reviews the fashion supply chain, the environmental and social impacts of the clothing industry and, based on these, we focus on the sustainability issue.

Clothing products are a basic need for humans. With consumers’ increasing concerns over the environmental pollution caused by clothing products, the traditional clothing industry, with simple, standardized designs, is challenged, which leads to reforming the fashion industry and the fashion supply chains [3]. Compared with the traditional clothing industry, the fashionable clothing industry aims to attract consumers into stores as frequently as possible to increase the frequency by which they purchase fashionable styles [4]. Developing fashionable products requires shortened market cycles, more fashion seasons, highly flexible manufacturing and design capabilities and blending trendy clothing raw material and supplies in very short lead times [5].

Many innovative strategies in the clothing sector are proposed for “fast fashion” [4]. Fashion product companies have to deal with a very competitive environment and respond to consumers, who become ever more demanding. To stay competitive, companies rely on sophisticated information and logistics systems and, especially, accurate and reliable forecasting systems [6]. Jørgensen and Jensen [7] proposed different forecasting models that produce more accurate and more reliable sales forecasts for sales in the clothing industry by using advanced methods, such as fuzzy logic, neural networks and data mining. Retailers started focusing on expanding their product ranges with updated products and faster responsiveness to new fashion from fashion shows. Bhardwaj and Fairhurst [4] described multi-season clothing markets, which put pressure on suppliers to deliver fashion products in smaller batches with reduced lead times. Retailers, like Zara and Hennes and Mauritz, have changed their strategies towards the faster adoption of the latest fashions from fashion shows and introduced interpretations of the new designs to stores within three to five weeks to attract consumers.

Recently, fashion products have experienced a rapid development, whereas the fast fashion industry also has negative impacts on the environment and society, due to the short life cycles of the products. To respond to these increasing environmental and social problems, fast fashion companies have started to adopt sustainable strategies and practices [8]. The fast fashion industry is widespread across developing and developed countries. Due to the economic, social and environmental problems, companies increasingly focus on the sustainability of fashion products throughout their supply chains. Turker and Altuntas [8] examined the current situation of sustainable supply chain management in the fast fashion industry by analyzing reports from nine companies. This revealed that these companies focus significantly on supplier compliance, employing further monitoring and auditing activities to prevent production problems, improving overall supply chain performance and sustainability criteria for their suppliers.

The textile and clothing sector involves a kind of lengthy and complicated supply chain, which is responsible for the significant amount of carbon footprint creation and is a chief source of emissions of greenhouse gases [9]. Production, transportation, usage, consumption and disposal of textile products pose a threat to the size of the carbon footprint. To trim down the carbon footprint in each phase of a textile product’s life cycle, one possible way is to recycle the textile process waste and also the end-of-life textile products. Muthu et al. [9] investigated the possibilities, barriers and challenges to recycling textile waste materials with case studies. Muthu et al. [9] found that recycling of process waste would contribute to the direct reduction of the carbon footprint. Recycling end-of-life fashion products involves many barriers and challenges. Designers should consider “ecological design” in the design phase to address most of the difficulties faced by recycling the end-of-life textile products, which will help to reduce the carbon footprint of the textile products. Choi [10] analytically examined the impacts brought by the carbon footprint tax on fashion supply chain systems

The fashionable clothing industry itself suffers from environmental and social burdens. Ramos et al. [11] addressed the economic, environmental and social aspects of reverse logistics systems. The environmental and social components should be considered by the clothing industry. The use of fibers, such as cotton, wool and synthetics, has a direct, significant environmental impact; cotton and wool production requires large quantities of water and pesticides, whereas synthetic fibers are extracted from non-renewable resources and require considerable energy to produce. The production processes, and in particular, the phases of dyeing, drying and finishing, use intensive chemical products and natural resources and generate a high environmental impact [12]. Jørgensen and Jensen [7] analyzed environmental impacts from the production and consumption of clothing in Denmark based on business case studies. The companies impose environmental restrictions on suppliers in newly industrialized countries to different degrees. Some fashion companies recently launched the eco-labelling strategy, because they see a need to show environmental commitment publicly. The globalization of the fashion industry requires moving the products from low-labor-cost countries to consumers in Europe and the U.S., with the consequent environmental impacts of transportation. Due to the time pressure on fast fashion orders, the fashion supply chain under globalization deduces heavy environmental burdens by increased transportation mileage and CO2 emissions. Increased time pressure on the order cycles of the fast fashion industry results in employee abuse and other unethical working practices at manufacturing sites [5].

Sustainability issues are particularly vital to the fashion supply chain, because of current fierce competition, intensive resource use and penurious labor conditions in some regions [12]. The fast changing fashions and low price strategies encourage clothing consumption among young women, resulting in many unused fashion products and waste. Fashion products are often discarded while still having a potential lifetime. Farrant et al. [13] assessed that the net environmental benefits are created by the disposal of used clothing. Apparently, reusing fashion products is beneficial to avoid the production of new clothes. Many charitable organizations therefore collect used clothing products and resell them as second-hand clothes [13]. Reusing clothes actually results in a decrease of the environmental burden of the life cycle of clothing. In the literature on the environmental burden of clothing, most of focuses solely on the energy consumption aspects and pays little attention to the potential benefits of used clothing. It was found that clothes reuse can significantly contribute to reducing the environmental burden of clothing.

The fashion supply chain and its effects on sustainability are well studied in the literature. Primarily the materials, production and logistics aspects are focused on, although the sustainability issue is increasingly of concern for researchers. Moreover, the short lifetime of fashion products indeed makes the sustainability problem more marked than general products. This study focuses on rental service for fashion products and its effects on sustainability.

2.2. Rental Service

Rental service has become a popular option, mostly because it does not require substantial upfront costs, and regular maintenance is often handled by the lessor. Here, the term, rental service, refers to the service provided to manage the leasing process of fashion products in the perspective of supply chain management. Kuo [14] took the office copy machine as an example to propose a maintenance service based on rental services. The provided service includes maintenance, recycling, reverse logistics and final waste disposal. Degl’ Innocenti and Girardone [15] provided evidence on the cost advantages of leasing companies by focusing on ownership structures and diversification strategies. The results suggested that cost efficiency and economies of scale have decreased significantly over the period analyzed. Diversification strategies are crucial in determining the cost effectiveness of leasing firms. Nonetheless, smaller, independent and less diversified leasing firms appear to benefit from high economies of scale and great technological advancements. Degl’ Innocenti and Girardone [15] examined the ownership, diversification and cost advantages based on the evidence from the Italian leasing industry.

Car rental companies, as popular rental services providers, are well studied. You and Hsieh [16] addressed the problems of fleet size and vehicle transfer for car rental companies with multiple branches. The problem is formulated as a constrained mixed-integer programming model considering dynamic demands and solved by a hybrid heuristic approach. The proposed model is applied to the analysis of a car rental company in Taiwan. Guerriero and Olivito [17] considered the application of revenue management techniques in the context of the car rental industry. In particular, Guerriero and Olivito [17] presented a dynamic programming formulation for the problem of assigning cars of several categories to consumers, with rental requests arising dynamically and randomly with time.

However, rental service is not always better than procurement. The total system cost was found to be better in the procurement model than the rental model, because the consumers will use the product carefully, since they think the products are their own property. Liu et al. [18] used a benefit-cost analysis tool to evaluate the impacts of combined tax breaks from depreciation and interest paid on home-equity loans in a rental service on competitiveness under different purchase options for a solar photovoltaic system in California. Liu et al. [18] suggested that the additional tax breaks from depreciation in conjunction with those from interest paid on home-equity loans can make purchasing more competitive.

The consumer behaviors in rental systems are increasingly of concern. Kuo [14] constructed a rental system in a reverse logistics environment based on the product service system (PSS) theory. This system includes the complete management of product examination, maintenance, upgrading, products recycling and final waste disposal. Due to different procurement processes of PSS, the procurement of new products and the rental products are analyzed. Guerriero and Olivito [17] addressed a rental scenario where the rental service can start and end at different locations. In the devised framework, the logistics operator decided whether to accept or reject a rental request. Primal and dual acceptance policies are developed, and their effectiveness is assessed based on an extensive computational phase. Zentner et al. [19] addressed the question of rental patterns affected by consumer behaviors, how consumption patterns for popular and “long-tail” products change when consumers move from brick-and-mortar stores to Internet markets. The consumer-level panel data obtained from a national video rental chain are used for the study. As suggested by the results, a significant amount of products are sold online due to the direct influence of the channel on consumer behavior, not just due to the consumers who decide to use the Internet channel or the types of products that consumers decide to purchase online.

As one type of product service system, renting instead of purchasing may reduce consumers’ worries about uncertainties, especially for expensive new products. By leasing a solar power system, consumers can get electricity without actually owning it for more than 20 years, and the risk due to uncertainties is thus shared by the service providers and consumers. If market installation increases due to leasing, it may be a good example of product service system implementation in the renewable energy area [20]. Although solar power systems are considered as one of the most promising renewable energy sources, some uncertain factors, as well as the high cost could be barriers that create consumer resistance. Leasing instead of purchasing, as one type of product service system, could be an option to reduce consumer concern with respect to such issues. Shih and Chou [20] focused on consumer concerns about uncertainty and willingness to pay for leasing solar power systems. People that are concerned with sustainability tend to pay more for a shorter lease time.

On the contribution of rental services to sustainability, chemical leasing business models are labeled as a corporate social responsibility initiative to improve occupational health and safety and to strengthen the ability of companies to protect the environment from the adverse effects of the chemicals they apply. Chemical leasing is a service-oriented business mode that shifts the focus from increasing the sales volume of chemicals towards a value-added approach. Recent pilot projects have shown the economic benefits of introducing chemical leasing business models in a broad range of sectors. Moser et al. [21] argued that the fundamental economic and ecological considerations are not enough under the corporate social responsibility initiative. The organization’s responsibility for the impact of its business activities on the environment should be focused on the stakeholders. Bassamboo et al. [22] studied a rental system where a fixed number of heterogeneous users rent one at a time from a collection of reusable products. The transient behavior following the introduction of a new product that is desired by all of the users is investigated.

In the promotion aspects of cost reduction and consumer differentiation of satisfaction, rental service has emerged as an important business mode widely used in various industries. In fact, rental service involves resource intensive utilization, such that the energy, waste and material can be used under control. For fashion products with short life cycles, through rental services, sustainability can be improved through various processes and materials in the fashion supply chain. Inspired by the rental practices in the markets related to the clothing industry and the above literature on the fashion supply chain and rental services, we try to formulate a system for a rent-based fashion supply chain by considering sustainability. The conceptual model, operations management issues and the sustainability promotion strategies are developed and examined by reviewing the related literature.

3. The Sustainable Closed-Loop Fashion Supply Chain

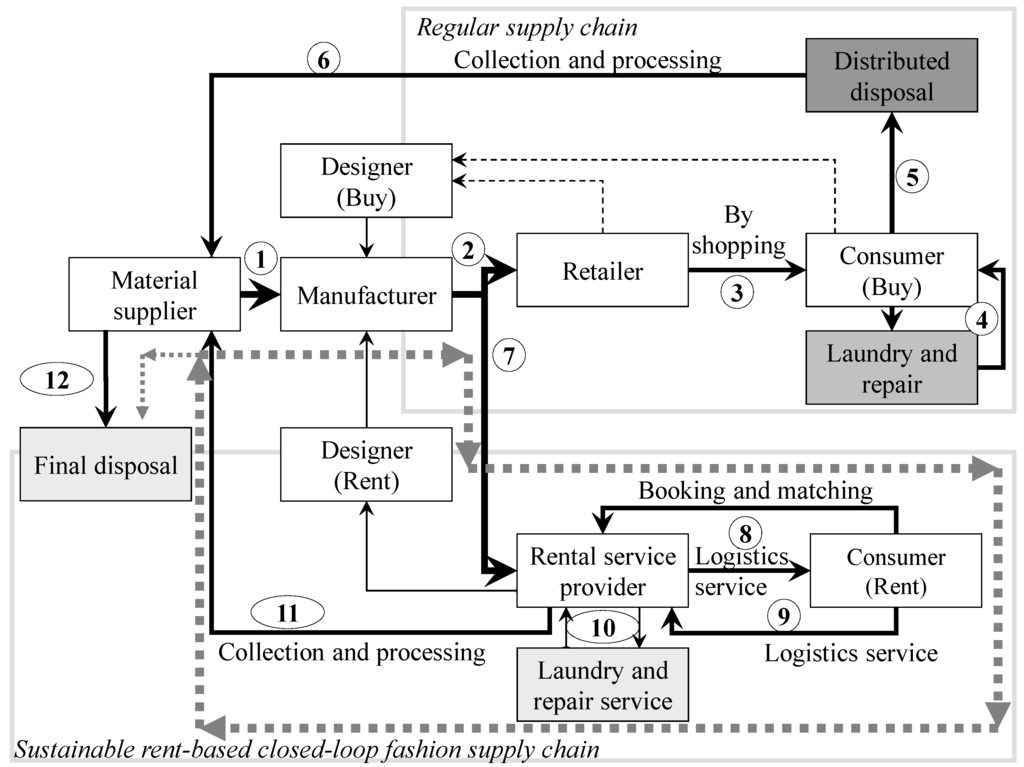

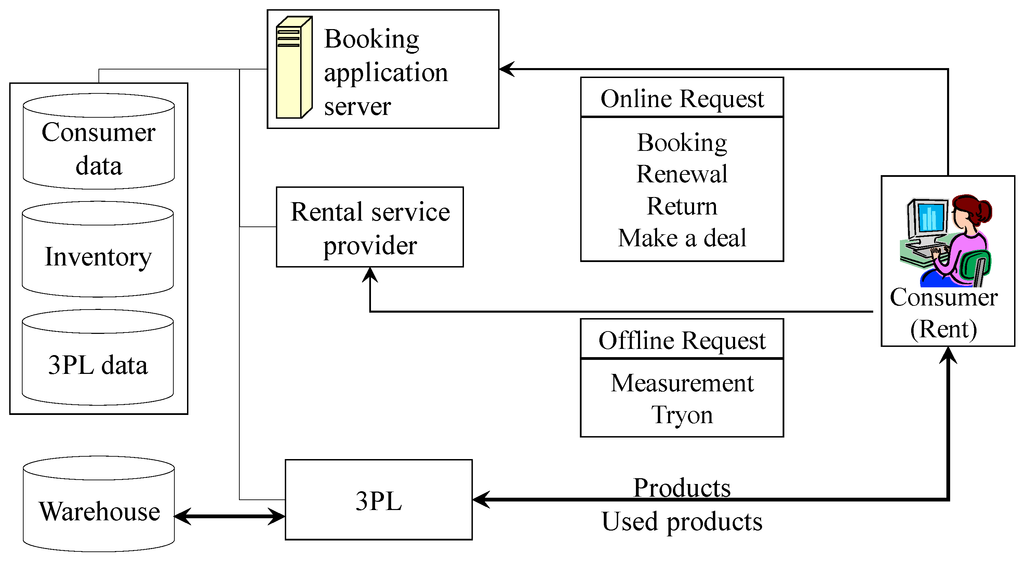

The main contribution of this study involves the design of a sustainable closed-loop supply chain for fashion products. Considering fashionable clothing products, a system of a sustainable rent-based closed-loop supply chain is presented in Figure 1. In the figure, eight types of stakeholders and four important processes are involved.

Figure 1.

A system of a sustainable rent-based closed-loop supply chain.

The rent-based closed-loop supply chain is described as follows. The fashion products used by rental services are manufactured according to the designs. The designs must be based on the careful investigation of the markets. The details of the fashion system include garment sizes, materials, colors and patterns, which should be perfectly researched by using data from the target market. Some consumers may become designers after they experience the buying and rental services. They may have different judgments on the fashion trends and consumer perceptions. The products are distributed to consumers by two channels: traditional sales by retails and rental services. From the traditional retailer channel, the consumers buy fashion products from the retailers and wash the products in use or dispose of the products by themselves in a distributed manner. Some of the disposals may be collected and reused by the material suppliers. Through the rental service channel, consumers book the fashion products by online or offline approaches. The matched products are used by the consumers, and then, they are sent to the rental service providers by logistics services. The laundry and repair processes are handled by the rental service providers themselves or outsourcing. Anyway, the products will be collected and treated in batches periodically. The laundry and repair process includes washing, disinfection and repair. Most products will be used again by the rental services. Some out-of-date or worn-out products will be sent to the material suppliers for further reuse engineering processes. By retailing and especially rental services, the data of consumer buying and rental behavior can be collected for forecasting fashion trends. Actually, the rental service could have a stronger fashion discovery capability than retailing, because the consumers may communicate with the rental service providers with higher frequencies.

Closed-loop supply chain and logistics systems are well studied in the literature [22,23]. Notably, the term “closed-loop” means a high degree of utilizing the resources in a loop. Therefore, final disposal is usually a necessary process in such systems. Indeed, many rent-based business modes have shown the figures for the closed-loop supply chain, e.g., rental systems of cars, furniture and computers. However, the nature of fast fashion may increase the feasibility of designing a sustainable supply chain, which will be elucidated in the following subsections. In this work, we study the sustainable rent-based closed-loop supply chain by introducing a conceptual model and developing operations and management strategies by reviewing related literature. The sustainability of the supply chain is examined in the following aspects: resource consumption, labor and power usage, operations scales and difficulties. They are discussed in the five processes that promote the sustainability of the fashion supply chain (the laundering, logistics, disposal, design and manufacturing in Section 3.1 to Section 3.5) and five management issues (Section 4).

3.1. Sustainable Laundry

Water is used in large quantities in (distributed) laundries, which, at present, produce relatively high quantities of wastewater [24] in the retailing channel in Figure 1. Fijan et al. [25] presented research on how to optimize a laundering program to reduce the wastewater burden, thus achieving a more sustainable laundering procedure. A green surgical textile program was investigated, and the first step of optimization was performed based on the results of measuring certain parameters in the water taken from individual chambers. The wastewater volumes were reduced after optimization of the program, although effluent treatment plants for water reuse remain necessary. An experimental laundering procedure with a high dosage of sodium hypochlorite was also conducted in order to observe a correlation between measured values of active chlorine and conductivity. Following this study, laundries in the rental service can search for opportunities to improve sustainability. In the rental services, general laundering procedures can be even more effective, sustainable and environmentally friendly if the measures in Table 1 are taken.

Conclusively, the business mode based on rental service can generate many opportunities to improve the sustainability of laundry operations in the fashion supply chain by controlling the operations, chemicals, recycling and reusing of water and saving energy.

Table 1.

Green laundry procedures for washing of products in the rental service.

| No. | Aspects | Sustainable methods and reasons | Literature |

|---|---|---|---|

| 1 | Control | Through information technology, the conductivity with the possibility of regulating the dosage of sodium hypochlorite can be monitored, and thus, overdosing can be avoided. The damage to water can be reduced. | Fijan et al. [25] |

| 2 | Chemicals | The laundering procedure can be optimized by minimizing the consumption of all cleaning mixtures, thus reducing the biochemical oxygen demand (BOD5), chemical oxygen demand (COD) and suspended and sediment substances. | Järvi and Paloviita [26] |

| 3 | Recycling and reuse | Using water recycling and reuse devices is possible for processing batches of laundry, although this requires major investments in effluent treatment plants. | Mainali et al. [27] |

| 4 | Energy saving | The energy from the hot water after the main washing can be used via a heat exchanger for heating fresh rinsing water. | Fijan et al. [25] |

3.2. Green Logistics

With respect to the environmental pollution, transportation is the most visible aspect of the supply chain. Transportation CO2 emissions amount to some 14% of the total emissions, both at the global and EU level [28]. Transportation is also a main source of NOx, SO2 and PM (particulate matter or fine dust) emissions. Piecyk and McKinnon [29] studied the most relevant factors for CO2 emissions in road transport: structural factors influencing modal split, commercial factors influencing load factors, operational factors, functional factors and final external factors influencing the carbon intensity of fuel. Dekker et al. [28] examined four choices with respect to transportation, which are supported by operations research models, namely mode choice (or modal split), use of intermodal transport, equipment choice and fuel choice.

The storage of products also has an environmental impact. Inventory holding costs play a large part in supply chain design, as the more storage is centralized, the less the storage costs. Harris et al. [30] evaluated a multi-objective facility location problem for large instances that considers robust solutions where financial costs and CO2 emissions are minimized simultaneously under the consideration of flexibility at the tactical consumer allocation level. The robustness of the solutions over a period of time with the focus on large data instances is examined.

Based on Figure 1, Table 2 presents the logistics activities (12 transportation terms and six inventory activities) labeled in Figure 1. First, almost all activities of the rent-based closed-loop supply chain, except for the inventory activity of customers, are performed in centralized or scaled ways. Second, the inventory activity of customers is not identified as a centralized or scaled activity, because the inventory can be believed to be managed by the rental service providers. The products are in use by customers and as inventory at rental service providers. Third, five logistics activities (transportation Activities 3, 4, 5 and 6 and the inventory activity of customers) of the regular fashion product supply chain are not performed in a centralized manner, and four of them (except for 6) are not performed in a scaled manner.

It seems that the rental service mode would impose greater effects on the environment by transportation activities, considering transportation distances and emissions. Fortunately, as presented in Table 2, in the rent-based supply chain, more activities are scaled such that they can be more fully controlled to increase sustainability. We may just consider that the transportation Activities 8 and 9 (Figure 1) have negative impacts. Actually, these activities are usually outsourced to general third-party logistics (3PL), which indeed minimizes the impact. In other activities, the centralized and scaled processes of the rental service contribute to the savings of transport power, energy and pollution.

Table 2.

The logistics activities of the sustainable closed-loop supply chain. 3PL, third-party logistics.

| Activity description | B/R | C? | S? | |

|---|---|---|---|---|

| Transport | (1) material supply | BR | Y | Y |

| (2) product distribution from manufacturer to retailer | B | Y | Y | |

| (3) customers travel to retailers | B | N | N | |

| (4) laundry and repair (buy) | B | N | N | |

| (5) products disposal | B | N | N | |

| (6) collection of discards | B | N | Y | |

| (7) distribution from manufacturer to rental service providers | R | Y | Y | |

| (8) distribution from rental service providers to customers (by 3PL) | R | Y | Y | |

| (9) collection from customers to rental service providers (by 3PL) | R | Y | Y | |

| (10) laundry and repair (rent) | R | Y | Y | |

| (11) final recycling | R | Y | Y | |

| (12) final disposal | BR | Y | Y | |

| Inventory | material supplier | BR | Y | Y |

| manufacturer | BR | Y | Y | |

| retailer | B | Y | Y | |

| rental service provider | R | Y | Y | |

| customer (buy) | B | N | N | |

| customer (rent) | R | - | - |

Notes: B = regular supply chain (buy); R = rent-based closed-loop supply chain; C? = the activities are performed at distributed customers or not; S? = the activities are performed in a large-scale batch or for almost each customer.

3.3. Green Disposal

Textile disposal is an increasing problem in the world. During 1995, the denim industry generated more than 70 million kilos of scrap in landfills in the USA; unrecovered textile waste contributed to approximately 4.5% of U.S. landfills; in the U.K., there are annually more than 100 million tons of waste resulting from households and commerce [1]. Fast fashion retailing is leading consumers towards an increased rate of purchasing and the trend to keep clothing for an ever shorter time, which results in a cost in clothing disposal. Bianchi and Birtwistle [1] empirically explored two methods of sustainable clothing disposal behavior: donating to charities and giving away to family and friends. The results show that consumer recycling behavior is a strong and direct driver to donate to charity. In addition, consumer awareness of environment protection and consumer age affect donating behavior. Using survey questionnaires, Joung and Park-Poaps [31] investigated four different clothing disposal options (resale, donation, reusing and discarding) and examined five motivational factors (environmental, economic, charity concerns, convenience concerns and information unavailability). The influences of attitudes on the environment and subjective norms of family and friends on clothing disposal behaviors also were examined. The results indicated that resale and donation behaviors were explained by environmental concerns and that reuse and resale behaviors were explained by economic concerns. Charity concerns motivated donation behaviors, and convenience motivated discarding behaviors. In industrialized countries, donation bins located across the country and charity shops are set for clothing disposal. Once collected, the textiles are sorted and sent to those in need in the community or sold through shops to generate capital to fund social problems.

Waste disposal is examined and studied. Pek and Jamal [32] estimated the nonmarket values for a number of waste disposal technologies to identify an improved waste disposal management strategy. Implicit prices for environmental attributes, such as psychological fear, land use, air pollution and river water quality, were estimated. Based on a rapid impact assessment matrix (RIAM) assessment for municipal solid waste disposal options in Varanasi, India, Phillips and Mondal [33] applied a mathematical model of sustainability to determine whether the options are potentially sustainable or unsustainable and, if deemed as sustainable, to determine the level and nature of the sustainability. There are many different approaches for waste disposal. With respect to the options of municipal waste disposal evaluated by Mondal et al. [34] for Varanasi, five approaches were examined: open dumping, sanitary landfill, biomethanation, gasification and incineration. However, the above research and methods do not handle the disposal of clothing products completely.

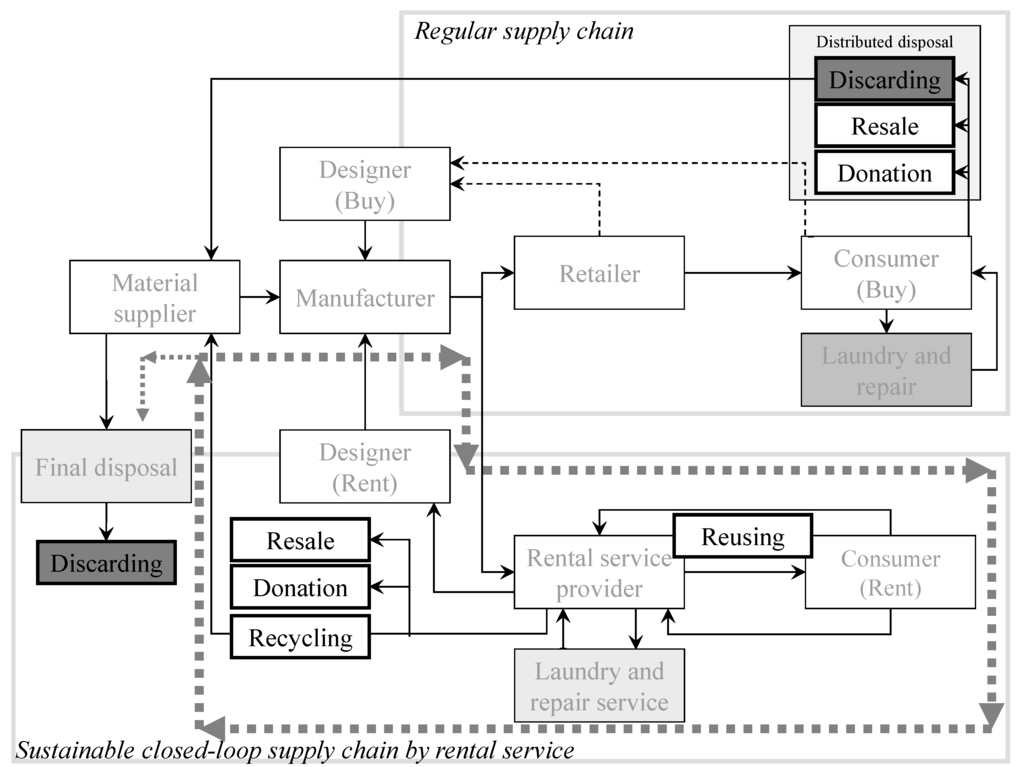

Figure 2 presents the five disposal options [31] in the supply chain: resale, donation, reusing, recycling and discarding. In the regular supply chain, the used fashion products may be disposed by donation, resale and discarding. As studied by Joung and Park-Poaps [31] and Bianchi and Birtwistle [1], the diverse consumer behaviors play important roles in the disposal. In developing countries, when the donation bins and charity shops are not well set, the convenience concerns may result in the disposal behavior. However, the rent-based supply chain instinctively serves for reusing the products, although finally, the products are discarded in batches under good control. The rental service itself is a way of reusing, and the final recycling is also an extension of reusing. In the aspects shown in Table 2, the rent-based supply chain provides the feasibility of scaled disposal, such that the sustainability modes and technologies can be efficiently used with low costs.

3.4. Sustainable Design

Today consumers are becoming more aware of the need to protect the environment, and companies promote their goods or services with eco-labels. The terms, “environmentally” and “friendly” (also eco-friendly, nature friendly and green), refer to goods and services, laws, guidelines and policies claiming to inflict minimal or no harm on the environment. Clothing is an integral part of our lives, and green or environmental concerns have started to draw more and more attention in the textile and clothing sector. According to Cervellon and Wernerfelt [35], in sustainable and ecological sectors, the supply chain is of utmost concern for consumers, as most benefits derived from eco-purchasing are linked to the green and ethical credentials of the supply chain. In particular, in the eco-fashion sector, purchasing motivations are based on health (such as allergy prevention) and the contribution to the welfare of society (such as reduced pollution, fair treatment of workers or no fur/leather use). Consequently, consumers pay for an adherence to certain codes of conduct in addition to the purchase of a fashion piece. Eryuruk [36] analyzed how green the textile and clothing industry is with respect to the product lifecycle, from raw material through the design, production and logistics up to disposal, in order to indicate important points and parameters for greening the industry. Moon et al. [37] developed guidelines for the design and production of sustainable energy-saving fashion products. Theoretically, our work demonstrates a systematic and logistical procedure for the identification of energy factors for sustainable fashion and the development of feasible and practical scenarios for design and production.

Figure 2.

The disposal options of fashion product supply chains.

The short life span of textiles and especially fashion products is one of the main problems in the current industrial system based on planned obsolescence. Niinimäki and Hassi [38] presented design strategies that focus on extending product life spans through better intrinsic quality and lifetime guarantees, product satisfaction and product attachment. Moreover, Niinimäki and Hassi [38] explained how services might extend the product life span. Three strategies are discussed as follows:

- (1)

- Long lifetime guarantee and product satisfaction: Mont [39] asserted that manufacturers could hold new opportunities to increase the intrinsic product quality and durability. However, the life span of the product, as well as the quality of textiles and garments are difficult to evaluate at the point of purchasing. Therefore, maintenance quality is critical. At this point, rental service is a better choice.

- (2)

- Product attachment and emotionally satisfying design: The products are meaningful to the user over a long period of time, and thus, they are not easily disposable. This often means a unique design process or co-creation with the user. By rental services, preference and emotion can feedback efficiently. Two typical processes are involved: customization, semi-finished products and modular structures; co-creation and open source design.

- (3)

- Services: Product-service systems emphasize systems thinking and drive companies to focus on consumer needs. A “zero emission society” consumer should invest in services and purchase functions instead of products. In this type of society, all materials should be automatically returned to the producer after the use phase, and this creates environmental value for the whole system. Consumer satisfaction is at the center of attention in a service economy, and it can be implemented by offering good product performance through services that do not increase waste streams. Today, designers are able to create individual and unique looks by using digital technologies that enable placing the consumer’s attachments, emotions and wishes at the center of the design process, securing a deep product relationship with consumers and increasing the likelihood of a long life span of the product. Products aimed for long-term use have to be made with high quality. The quality of products is directly linked with their durability. Longer product life spans can also be achieved through services, such as upgrading or updating, repairing or product modification systems or services. These services extend the enjoyable use time of the product, as well as postpone the psychological obsolescence that consumers themselves feel about the product.

The above literature mentioned or indicated the aspects of possible strategies for sustainable product design and services (as listed in the first two columns in Table 3). Based on these aspects, Table 3 summarizes some sustainable design strategies for fashion products, especially by considering the roles of rental services. Although some of these strategies are also suitable for a general fast fashion supply chain, for the purpose of producing a holistic view, they are all presented in Table 3.

Table 3.

Possible strategies for sustainable fashion product design in rental service.

| Aspect | Sustainable design strategy | Role of rental service |

|---|---|---|

| Material choice | Choose sustainable materials | Cater to specific consumers with sustainable purposes |

| Design art and special types of fashion products with reusable non-fabric material | Customization for special purposes | |

| Attach the carbon footprint information and guide the consumer’s sustainable preference | The information can be updated by the rental service | |

| Pattern design | Reusable design by using parts | The fashionable parts can be easily found by the rental service |

| Easy dissembling design for reuse and recycling | Short-term rental decreases the demand for a firm pattern structure | |

| Express the environmental and sustainable themes | The consumer’s preferences can be affected by services | |

| Advertising | Positive figures of sustainability can be used | Rental service itself indicates a sustainable consumption behavior |

| Service | The sustainable design can be extended by services such that the consumer can experience the sustainable products directly under instructions; new emotional value and environmental value can be created | The rental service with sales and logistics helps to introduce the sustainable designs to consumers |

3.5. Sustainable Manufacture

In the context of the fashion product lifecycle, the concept of sustainability can be seen in terms of three stages: manufacturing, utilization and disposal. Issues, such as the supply of raw materials, the production of final products, application of chemical treatments and/or processes of operational and logistical activities are involved in the manufacturing stage. In general, sustainability-oriented materials include organic fibers, naturally-colored fibers and recyclable fibers [40]. From the perspective of sustainability, sustainable processes require a minimum of resources or effort to accomplish. Furthermore, chemicals, such as dyestuffs, resins, softening agents, washing detergents and many others, used in fashion product materials, cause serious pollution problems [41]. A green-oriented firm aims to design and produce products that can minimize the negative impact on the environment by giving special attention to the waste, carbon emissions and energy used in each of these three stages [42].

A sustainable society cannot be realized without more efficient approaches and technologies, which must be partially provided by manufacturing. Sustainable manufacturing [43] (based on environmental conscious manufacturing) is broad in scope. A lot of sustainable manufacturing research has focused on product development and end-of-life management. Niinimäki and Hassi [38] presented a set of design and manufacturing strategies for the textile and clothing industry that could reduce the environmental impact of textile and clothing production and consumption. However, these presented strategies will not directly lead to sustainable practices, as the system is not yet ready for radical change. Smith and Ball [44] developed guidelines for material, energy-and-waste process flow modelling to support the pursuit of sustainable manufacturing. In the context of sustainable manufacturing, Ball et al. [45] examined the concept of zero carbon manufacturing as a constituent element of sustainable manufacturing, which focused on the tactical and operational levels of an organization. Zero carbon manufacturing takes the perspective of the manufacturer and seeks to improve the environmental performance of their system by understanding the process flows within it.

The above studies examine the energy and carbon emissions problems primarily for the manufacturing stage. Moon et al. [37] identified the major energy factors of a sustainable fashion product along different stages of its life (see Table 4). The first group of energy factors involves the use of materials; the second group relates to the design of a garment and involves style construction and other design elements; the third group connects to the control of operational activities along the supply chain; that is, manufacturing, distribution, trading and retailing.

In the closed-loop fashion supply chain in Figure 1, compared with the other processes, the rental service imposes little effect on the manufacturing stage (Table 4). However, the rental service may change the scale of manufacturing and the consumption modes. At the manufacturing scale, the reusing and recycling scales are enlarged. Through frequent and efficient face-to-face sales and logistics services, sustainable materials, designing and manufacturing technologies can be reported to the consumers; thus, the rental service can guide sustainable consumption. The utilization and disposal stages are different because of increased scales in the rent-based supply chain (Figure 1).

4. Operations Management Issues

Section 3 described five important processes in the closed-loop fashion supply chain, while this section focuses on the operational and managerial issues in promoting the sustainability of the supply chain.

Table 4.

Energy factors of sustainable fashion (Table 1 in Moon et al. [37]).

| Energy factor | Stages of fashion product lifecycle | ||

|---|---|---|---|

| Manufacturing stage | Utilization stage | Disposal stage | |

| Use of materials |

|

|

|

| Style design of the products |

|

|

|

| Control of operational activities |

|

|

|

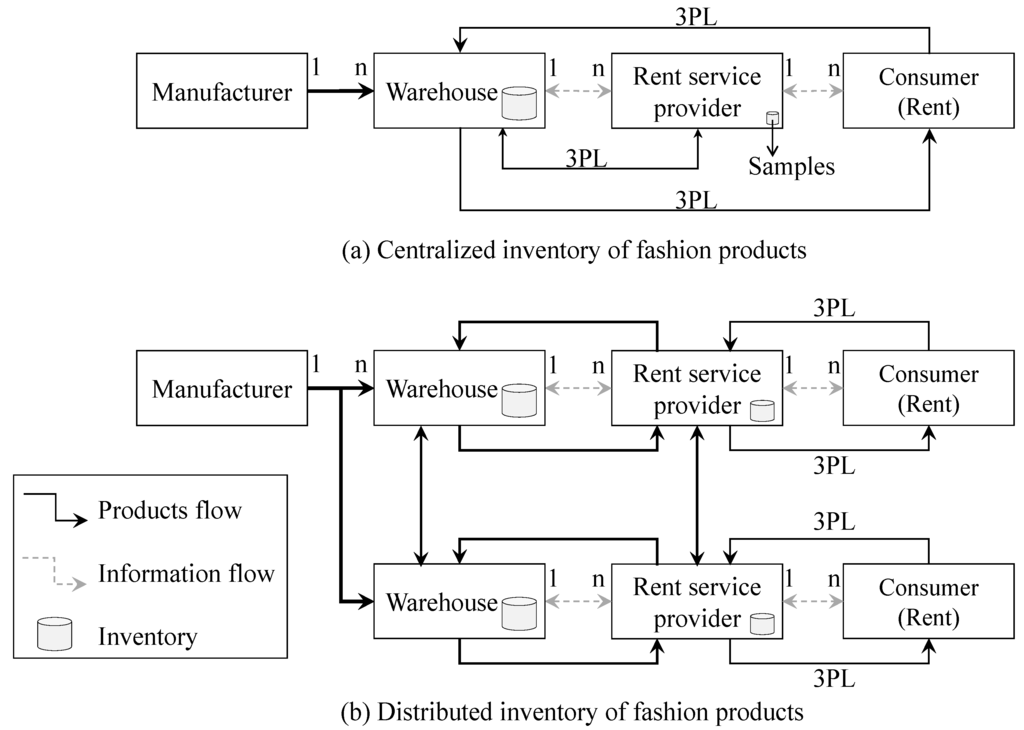

4.1. Centralize vs. Distributed Inventory Management

In practice, fast fashion products are directly distributed to retailers, and the inventories are shared by transshipment. However, according to the life spans of the products and responsiveness of the logistics systems, the products may also be stored and distributed through warehouses. For example, the Lifeng 3PL logistics company manages many warehouses for clothing brands. The contributions of centralized and distributed inventory management to cost and risk minimization are not identical, which depends on the application scenarios. Schmitt et al. [46] examined the expected costs and cost variances of the system in centralized and decentralized inventory systems. When demand is deterministic and supply may be disrupted, using a decentralized inventory design can reduce cost variance through the risk diversification effect. Schmitt et al. [46] also investigated the risk-diversification effect, in which the expected cost is the same in the centralized and decentralized systems, but the cost variance is smaller in the decentralized system. Ehrenthal et al. [47] provided insights into the impact of incorporating demand seasonality in a retail replenishment system. By the decrease of non-stationary demand in inventory management, retailers can reduce inventory holding, handling and stock-out cost substantially. Cost savings are higher for fast-moving items with higher demand variability and a lower case pack size. Yet, in some cases, considering demand seasonality can lead to an increase in costs.

This study does not make a decision on the use of centralized or distributed inventory management. In Figure 3, the centralized and distributed inventory flows of fashion products are presented. Notably, the disposal flows are not included in the figure. In the centralized one (Figure 3a), the products are distributed from the manufacturer to the warehouses. Each warehouse should serve for at least one rental service provider. However, only some typical samples are distributed from the warehouse to the rental service providers. After the consumers determine their rent plans by trying the samples with the help of the servicers, the warehouse will distribute the product to the consumers by 3PL. Inversely, the used products after the rent period will be collected by 3PL from the consumers to the warehouse. In Figure 3, only the warehouses manage the big inventories.

The distributed one (Figure 3b) depicts more complex logistics flows. The products are generally not distributed from warehouses to consumers, but through rent service providers to consumers. Therefore, rental service providers also manage rather big inventories. Further, to share the inventory, logistics transshipment may occur among the warehouses and rental service providers.

Comparing the two modes, the following differences are observed. In the centralized one, the inventories are centrally managed, such that they can be efficiently utilized; consumers cannot take the products directly home after ordering them at the rental service providers; small product packages are directly distributed to or collected from consumers by the 3PL, and thus, seemly more transportation costs, energy and impacts on the environment are involved. In the distributed one, the consumer can experience the product at the rent sites, and satisfaction may be improved, whereas the online booking system may degrade this superiority; scaled transportation between warehouses and rental service providers can be performed; however, the inventory management becomes complex.

Figure 3.

The management modes of the centralized and distributed inventory of fashion products.

4.2. Closed-Loop Logistics Services

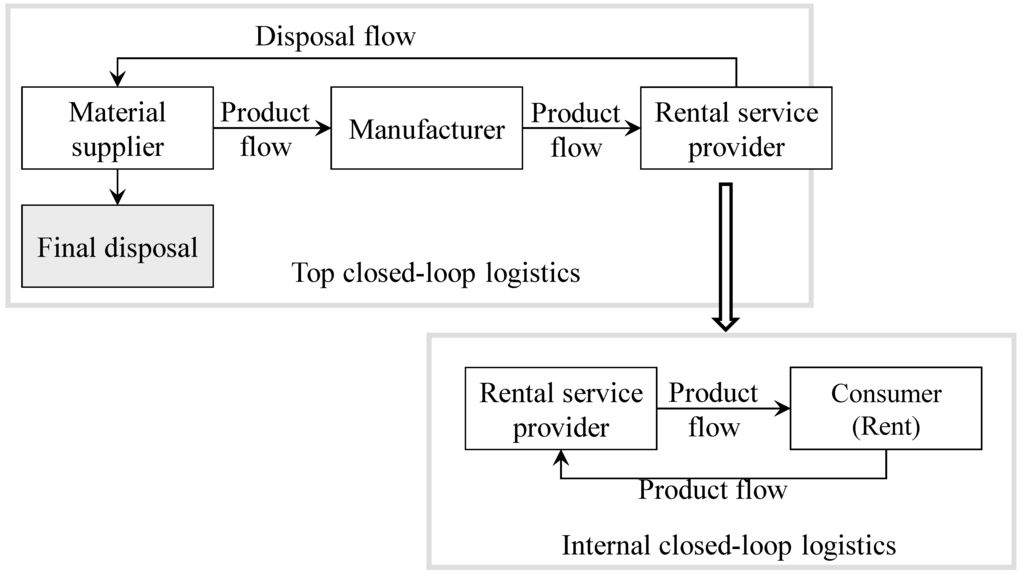

Due to the problem of global warming, green supply chain management and closed-loop logistics have drawn the attention of researchers. Wang and Hsu [23] formulated a cyclic logistics network problem into a generalized closed-loop model by the integration of forward and reverse logistics. Ferrucci and Bock [48] introduced the dynamic pickup and delivery problem with real-time control (DPDPRC) for providing urgent real-world transportation services to consumers. Specifically, the DPDPRC considers intra-day transportation services of express courier service companies and integrates real-world aspects that are crucial for a practical application. These two studies presented closed-loop logistics at two levels, the closed-loop logistics system or supply chain design and the closed-loop transportation chain design.

These two levels of closed-loop logistics are also presented in this study. The devised model is in Figure 1: two big closed-loop logistics (one for the regular fashion supply chain and another for the rent-based closed-loop fashion supply chain) and a small, but frequently used internal closed-loop logistics in the rent-based supply chain.

In the top closed-loop logistics (Figure 4), some detailed transportation and transshipment links are not depicted. In this loop, the forward flows are products, whereas the reverse flows are used products. Because the used products come from the rental service providers after cleaning and treatment, they are safe and can be transported together by containers with the forward flows. An exception is the flow to the final disposal. Nevertheless, this kind of flow usually can be compacted and efficiently transported. The internal closed-loop logistics when performed by a vehicle fleet can be formulated as a vehicle routing problem with pickup and delivery. The vehicle spaces can be utilized by the forward and reverse product flows simultaneously. Based on the above descriptions and analysis, the logistics can be put into sustainable closed-loop logistics practices.

Figure 4.

A system of a sustainable rent-based closed-loop supply chain.

4.3. Human-Clothing Matching Method

Mass customization producers must rely on agility to respond to personalized demands in a timely fashion; besides, the use of lean principles becomes mandatory to provide affordable customization [49]. Da Silveira et al. [50] identified four steps in generating and processing mass customization orders, namely (1) building the product catalog; (2) configuring consumer orders; (3) transferring orders to manufacturing and (4) manufacturing customized orders. The state-of-the-art research on these activities has experienced significant development in the literature, mostly motivated by the popularization of e-commerce and the growing use of the Internet to shorten distances between supply chain actors. Measuring human bodies and generating size systems are the important tasks involved. These tasks are initially discussed for mass customization in the literature, and they are also critical for the rental service.

Table 5 presents three papers considering human-clothing matching problems. Inspired by these results, the features of the rent-based fashion supply chain are considered, and thus, the possible applications and extensions are proposed in the table. The inspirations in the last column (Table 5) are presented for the purpose of improving the rental service quality by reducing the try-on times. These inspirations are also effective for general apparel retailing practices. The human-clothing matching models help to improve the efficacy of rental services when many fashion products are available for the consumers.

Table 5.

Inspirations of human-clothing matching methods for the rent-based supply chain.

| Literature | Method | Inspirations |

|---|---|---|

| Cho et al. [51] | Cho et al. [51] proposed a cross-sectional line model at regular intervals. This model is easy for controlling body shape and also for calculating length and perimeters. The consumers can modify the body model to match their own body shape during Internet or catalogue shopping; it can also enable apparel manufacturers to communicate with their consumers by describing the body model to fit on the screen while in the ordering process. |

|

| Hu et al. [52] | Hu et al. [52] studied the problem of clothing uniform assignment (CUA) with garment size fitting constraints and propose an immune co-evolutionary algorithm to search optimal assignments of uniform garments to employees. Multi-size fitting measures are proposed based on multi-attribute decision making. |

|

| Ding et al. [53] | Ding et al. [53] used the multi-criteria decision making (MCDM) model to solve the large-scale fit garment matching problem with the constraints of size satisfaction. The concepts, including “ideal garment” and “loose garment”, are used to model the consumer request. Two affinity measures (dominance and distance affinities) represent the similarity of antibody to antibody and that of antibody to antigen. The proposed method provides a key tool for a garment store sale system or online garment order system to support accurate garment size matching. |

|

4.4. Booking System under Uncertainty

Booking, as a strategy to cope with uncertainty, is usually coupled with revenue management. Revenue management enhances the revenues of a company by means of demand-management decisions. Romero Morales and Wang [54] examined the performance of the state-of-the-art data mining methods when applied to a booking-based revenue management system considering cancellation rate forecasting. The set of relevant variables to describe cancellation behavior is very different in different stages of the booking horizon. Bendoly [55] studied the real-time feedback and booking behavior in the hospitality industry considering the balance between imperfect judgment and imperfect prescription. The results suggest implications for the practical use of continuous feedback. Shylo et al. [56] presented an optimization framework for batch scheduling within a block booking system that maximizes the expected utilization of operating room resources subject to a set of probabilistic capacity constraints. These studies focus on the uncertainty treatment of booking in revenue management.

The booking system in rental services can also be used to diminish the effects of demand uncertainty on the utilization ratios of products. Especially, because of the nature of fast fashion, the turnover ratio or the rent times are important indices for improving the profitability of the products. Figure 5 presents the information and product flows in the booking system. Through the booking system, a consumer can submit four types of online requests to the rental service provider: booking, renewal of a booking order, the return of a used product and making a deal by e-commerce. Initially, a consumer may not in fact complete the booking request just by online means. She or he should go to the rental service provider to measure her or his body and try on the products. These offline activities will generate the consumer’s body data that may be repeatedly used in the future booking request. The booking uncertainty can be mediated by a pricing strategy that is elucidated in the next subsection.

Figure 5.

The booking system.

4.5. Competitive Rental Pricing Problem

Pricing is well studied in the context of supply chain management, even in the textile and fashion industry. Motivated by the issues of supply chain channels in the fashion product industry, especially in the clothing industry, Li et al. [57] considered optimal pricing and order policies in two supply chain channel modes: the centralized channel mode and the decentralized channel mode. In both modes, the new product orders (production) and pricing and off-season product discount sales with random market demands are considered, especially the off-season product returns and processing under the closed-loop channel situation. Some research has also been carried out on the periodic pricing problem with product returns [58]. Usually, two-period models are used to study the market competition between new and remanufactured products to find the optimal equilibrium sale price.

The pricing problem in the rent-based supply chain is also studied in the context of revenue management. By considering the dynamics of uncertain rental demand and return processes, Tang and Deo [59] presented a base model for analyzing the impact of rental duration on the stocking level, the rental price and the retailer’s profit. The base model is extended to address the issue of competition in rental duration and rental price.

These studies contribute to the pricing problem for the fashion products in the devised rental service. The competition of the rental pricing problem occurs with the following features. First, the rental products should be competitive with the new products on sale. However, because the rental products generally are used for a short term, the competitive advantages should be further measured. Second, the rental products should not activate price competition with the products that are regularly sold. Rent and retailing aim at different markets. Third, in the rental pricing problem, the sales and logistics services should be incorporated into the model, as well as the green, environment and social values of using sustainable fashion products. These features should be considered in the pricing models by extending the pioneering studies on pricing.

5. Discussions

Beyond the operations and management issues investigated in the Section 3 and Section 4, a more primitive problem is faced: how can the market accept the sustainable rental fashion products and the corresponding consumption style of wearing them? Three sustainability promotion strategies are discussed for adding value to and guiding the consumers’ perceptions to such sustainable products and business modes. However, this work does not examine the consumers’ receptiveness of the rental service of fast fashion products by empirical studies. Therefore, this work is based on the hypothesis that the market exists.

5.1. Fast fashion Customization and Design

Three strategies are discussed for speeding fast fashion customization design.

- (1)

- Interactive co-design with consumers: Watcharapanyawong et al. [60] presented a framework, aiming to develop mass customization for the textile and apparel industries. The developed model considers consumers’ needs at industrial levels. Hu et al. [61] developed interactive co-design models and algorithms for garment pattern design. By the similar methods above, consumers can anticipate the creation process of sustainable fashion products.

- (2)

- Mass customization by new technologies and optimization methods: In mass customization, the parts are produced in advance, and the assembling processes are started after the consumers post her or his orders. In the fast fashion industry, the difficulty of such a customization method is increased by the nature of flexible fashion designs. New sewing and optimization techniques can be applied [62].

- (3)

- Fast redistribution among regions: This involves the observation of Chinese cities that can be classified into about four levels of awareness of fashion trends. The fashion products will prevail from the first-level cities (e.g., Shanghai) to the second-level cities (e.g., Qingdao), then to the third-level cities (e.g., Jiaozhou) and, finally, to the country towns. Therefore, the fashion products can be redistributed to the lower level cities following this route.

5.2. Responsive System for Fashionable Products

Fashion itself is full of uncertainty. Forecasting has been studied for fashion sales and inventory [63], although the results are usually meaningless in practice. To cope with the fast fashion feature, a practical way is to respond to it fast and efficiently. Four aspects for a fast response to fast fashion are discussed as follows.

- (1)

- Information system integrating various stakeholders: Ngai et al. [64] provided a comprehensive review of research articles related to the application of decision support and intelligent systems in the textile and apparel supply chains. The information system has the following functions contributing to a fast response. The booking orders, consumer preferences, market status and fast fashion trends can be spread through information flows fast. The system management universal data can be used as a data source for mining fashion trends and consumer behaviors. These results contribute to the design of fashionable products and adjust sales promotion strategies.

- (2)

- Booking requirement management: As studied above, booking can reduce the demand uncertainty and product costs. It also contributes to efficient scheduling of products and other resources (e.g., logistics capability). The uncertainty management and optimization modules play important roles in the responsive system.

- (3)

- Consumer management: Body measurement and invalid try-ons may reduce the value experience of rental products. Efficient measurement and the later memory mechanisms (that recorded the measurement results as historical data) help to reduce the measurement difficulty. Therefore, a size database should be built and shared among all rental service providers. According to the consumers’ sizes, concise and accurate human-clothing matching can filter the candidate fashion products for recommendation.

- (4)

- Fast logistics server for shortening the waiting time: Through logistics services, the fashion products are sent to and collected from the consumers. Moreover, this is also a way to serve the consumers face to face, which can increase the value experience.

5.3. Sustainable Disposition for Fashionable Products

The attitudes toward fashion product disposal modes reflect those to rental fashion products to a certain extent. By investigating clothing value-expressive symbolism and consumption empirically through national culture and socio-demographic covariates, Millan et al. [65] indicated that significant differences regard consumer interests in clothing, preference for utilitarian, self-expressive and hedonic meanings of clothing artifacts, preference for well-known clothing brands, brand loyalty and the importance of clothing attributes. Armstrong et al. [66] examined sustainable product-service systems for clothing by exploring consumer perceptions of consumption alternatives. To guide the demands for rental fashion products, two strategies are discussed below.

- (1)

- Tracking the carbon footprint for activating social responsibility: Tracking the carbon footprint may be a way for assessing each fashion product by information technologies and systems. Although a lower carbon footprint [10] is advocated for the industry, the fashion products labeled with carbon footprint values are not prevailing in the market.

- (2)

- Pricing strategies and political guidelines. As analyzed in Section 3 and Section 4, rental fashion products contribute to sustainability, while changing consumption behaviors. Although the pricing option can be used to expand the market by decreasing profits, political guidelines considering the environment and social values should be carried out to support the development of financial and political support.

6. Conclusions

This work developed a system of a sustainable rent-based closed-loop supply chain for fashion products. The rental service is introduced especially to shape the regular supply chain based on the traditional retailing channel and to improve the sustainability by three levels of processes, operations and promotion strategies. Despite the contribution of this work to the literature, it has limitations that require further investigation. This work developed a system and elucidated the components and strategies of the system by a review. The validities and efficiencies of this are not further proven by numerical or empirical studies. As for future study directions, additional data will be collected from the textile and fashion industries to study the acceptance situations of the rent-based fashion supply chain. Second, the consumer behaviors and the social psychology that play important roles in the application of rent-based sustainable business modes will be examined by empirical studies. Third, based on the sustainable strategies investigated or discussed at three levels, the involved operations optimization and management problems, e.g., the booking, pricing and routing problems, will be studied. In the context of the sustainable closed-loop fashion supply chain, these directions have additional distinct features. In summary, aiming at the sustainability of fashion products, this work systematically characterizes a specific supply chain and its components in operations, management and promotion by strategy designs, based on a review. Most importantly, many new problems for the devised sustainable closed-loop fashion supply chain are proposed for future study.

Acknowledgments

This study is partially supported by the National Nature Science of China (71101088, 71171129, 71390521, 71471109), the National Nature Science of Jiangsu (09KJA520001), the Science Foundation of Ministry of Education of China and Shanghai (20113121120002, 14YZ100, 20123121110004, 13SG48, 09YJA630072) and the Science and Technology Commission of Shanghai (12ZR1412800, 12510501600).

Author Contributions

Zhi-Hua Hu has worked in the textile and fashion industry for several years and started the research of this work. The principle framework of this study was created by Zhi-Hua Hu, and the research was organized and finished by Zhi-Hua Hu. However, because this work involves the review of many papers and investigations into the industry, the three coauthors devoted much effort to these tasks. Qing Li (a postgraduate student) and Yan-Feng Wang (a PhD candidate student) worked on the reviewing work more than Zhi-Hua Hu and Xian-Juan Chen (a postgraduate student), while Chen devoted much to the writing and proofing of the paper. All authors have read and approved the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bianchi, C.; Birtwistle, G. Consumer clothing disposal behaviour: A comparative study. Int. J. Consum. Stud. 2012, 36, 335–341. [Google Scholar] [CrossRef]

- Choi, T.-M.; Chiu, C.-H. Mean-downside-risk and mean-variance newsvendor models: Implications for sustainable fashion retailing. Int. J. Prod. Econ. 2012, 135, 552–560. [Google Scholar] [CrossRef]

- Barnes, L.; Lea-Greenwood, G.; Doyle, S.A.; Moore, C.M.; Morgan, L. Supplier management in fast moving fashion retailing. J. Fash. Mark. Manag. 2006, 10, 272–281. [Google Scholar]

- Bhardwaj, V.; Fairhurst, A. Fast fashion: Response to changes in the fashion industry. Int. Rev. Retail Distrib. Consum. Res. 2010, 20, 165–173. [Google Scholar] [CrossRef]

- Barnes, L.; Lea-Greenwood, G.; Barnes, L.; Lea-Greenwood, G. Fast fashioning the supply chain: Shaping the research agenda. J. Fash. Mark. Manag. 2006, 10, 259–271. [Google Scholar]

- Choi, T.-M.; Hui, C.-L.; Liu, N.; Ng, S.-F.; Yu, Y. Fast fashion sales forecasting with limited data and time. Decis. Support Syst. 2014, 59, 84–92. [Google Scholar] [CrossRef]

- Jørgensen, M.S.; Jensen, C.L. The shaping of environmental impacts from danish production and consumption of clothing. Ecol. Econ. 2012, 83, 164–173. [Google Scholar] [CrossRef]

- Turker, D.; Altuntas, C. Sustainable supply chain management in the fast fashion industry: An analysis of corporate reports. Eur. Manag. J. 2014, 32, 837–849. [Google Scholar] [CrossRef]

- Muthu, S.; Li, Y.; Hu, J.; Ze, L. Carbon footprint reduction in the textile process chain: Recycling of textile materials. Fibers Polym. 2012, 13, 1065–1070. [Google Scholar] [CrossRef]

- Choi, T.-M. Carbon footprint tax on fashion supply chain systems. Int. J. Adv. Manuf. Technol. 2013, 68, 835–847. [Google Scholar] [CrossRef]

- Ramos, T.R.P.; Gomes, M.I.; Barbosa-Póvoa, A.P. Planning a sustainable reverse logistics system: Balancing costs with environmental and social concerns. Omega 2014, 48, 60–74. [Google Scholar] [CrossRef]

- De Brito, M.P.; Carbone, V.; Blanquart, C.M. Towards a sustainable fashion retail supply chain in Europe: Organisation and performance. Int. J. Prod. Econ. 2008, 114, 534–553. [Google Scholar] [CrossRef]

- Farrant, L.; Olsen, S.; Wangel, A. Environmental benefits from reusing clothes. Int. J. Life Cycle Assess. 2010, 15, 726–736. [Google Scholar] [CrossRef]

- Kuo, T. Simulation of purchase or rental decision-making based on product service system. Int. J. Adv. Manuf. Technol. 2011, 52, 1239–1249. [Google Scholar] [CrossRef]

- Degl’Innocenti, M.; Girardone, C. Ownership, diversification and cost advantages: Evidence from the Italian leasing industry. J. Int. Financ. Mark. Inst. Money 2012, 22, 879–896. [Google Scholar] [CrossRef]

- You, P.-S.; Hsieh, Y.-C. A study on the vehicle size and transfer policy for car rental problems. Transp. Res. Part E Logist. Transp. Rev. 2014, 64, 110–121. [Google Scholar] [CrossRef]

- Guerriero, F.; Olivito, F. Revenue Models and Policies for the Car Rental Industry. J. Math. Model. Algor. 2014, 13, 247–282. [Google Scholar] [CrossRef]

- Liu, X.; O’Rear, E.G.; Tyner, W.E.; Pekny, J.F. Purchasing vs. leasing: A benefit-cost analysis of residential solar PV panel use in California. Renew. Energy 2014, 66, 770–774. [Google Scholar] [CrossRef]

- Zentner, A.; Smith, M.; Kaya, C. How Video Rental Patterns Change as Consumers Move Online. Manag. Sci. 2013, 59, 2622–2634. [Google Scholar] [CrossRef]

- Shih, L.H.; Chou, T.Y. Customer concerns about uncertainty and willingness to pay in leasing solar power systems. Int. J. Environ. Sci. Technol. 2011, 8, 523–532. [Google Scholar] [CrossRef]

- Moser, F.; Jakl, T.; Joas, R.; Dondi, F. Chemical Leasing business models and corporate social responsibility. Environ. Sci. Pollut. Res. 2014. [Google Scholar] [CrossRef]

- Bassamboo, A.; Kumar, S.; Randhawa, R.S. Dynamics of New Product Introduction in Closed Rental Systems. Oper. Res. 2009, 57, 1347–1359. [Google Scholar] [CrossRef]

- Wang, H.-F.; Hsu, H.-W. A closed-loop logistic model with a spanning-tree based genetic algorithm. Comput. Oper. Res. 2010, 37, 376–389. [Google Scholar] [CrossRef]

- Šostar-Turk, S.; Petrinić, I.; Simonič, M. Laundry wastewater treatment using coagulation and membrane filtration. Resour. Conserv. Recycl. 2005, 44, 185–196. [Google Scholar] [CrossRef]

- Fijan, S.; Fijan, R.; Šostar-Turk, S. Implementing sustainable laundering procedures for textiles in a commercial laundry and thus decreasing wastewater burden. J. Clean. Prod. 2008, 16, 1258–1263. [Google Scholar] [CrossRef]

- Järvi, P.; Paloviita, A. Product related information for sustainable use of laundry detergents in finnish households. J. Clean. Prod. 2007, 15, 681–689. [Google Scholar] [CrossRef]

- Mainali, B.; Pham, T.T.; Ngo, H.H.; Guo, W.; Listowski, A.; O’Halloran, K.; Miechel, C.; Muthukaruppan, M.; Johnston, R. Introduction and feasibility assessment of laundry use of recycled water in dual reticulation systems in Australia. Sci. Total Environ. 2014, 470–471, 34–43. [Google Scholar] [CrossRef] [PubMed]

- Dekker, R.; Bloemhof, J.; Mallidis, I. Operations research for green logistics–an overview of aspects, issues, contributions and challenges. Eur. J. Oper. Res. 2012, 219, 671–679. [Google Scholar] [CrossRef]

- Piecyk, M.I.; McKinnon, A.C. Forecasting the carbon footprint of road freight transport in 2020. Int. J. Prod. Econ. 2010, 128, 31–42. [Google Scholar] [CrossRef]

- Harris, I.; Mumford, C.L.; Naim, M.M. A hybrid multi-objective approach to capacitated facility location with flexible store allocation for green logistics modeling. Transp. Res. Part E Logist. Transp. Rev. 2014, 66, 1–22. [Google Scholar] [CrossRef]

- Joung, H.-M.; Park-Poaps, H. Factors motivating and influencing clothing disposal behaviours. Int. J. Consum. Stud. 2013, 37, 105–111. [Google Scholar] [CrossRef]

- Pek, C.-K.; Jamal, O. A choice experiment analysis for solid waste disposal option: A case study in malaysia. J. Environ. Manag. 2011, 92, 2993–3001. [Google Scholar] [CrossRef]

- Phillips, J.; Mondal, M.K. Determining the sustainability of options for municipal solid waste disposal in varanasi, india. Sustain. Cities Soc. 2014, 10, 11–21. [Google Scholar] [CrossRef]

- Mondal, M.K.; Rashmi; Dasgupta, B.V. Eia of municipal solid waste disposal site in varanasi using riam analysis. Resour. Conserv. Recycl. 2010, 54, 541–546. [Google Scholar] [CrossRef]

- Choi, T.M.; Lo, C.K.Y.; Wong, C.W.Y.; Yee, R.W.Y.; Cervellon, M.C.; Wernerfelt, A.S. Knowledge sharing among green fashion communities online. J. Fash. Mark. Manag. Int. J. 2012, 16, 176–192. [Google Scholar]

- Eryuruk, S.H. Greening of the textile and clothing industry. Fibres Text. East. Eur. 2012, 95, 22–27. [Google Scholar]

- Moon, K.K.-L.; Youn, C.; Chang, J.M.T.; Yeung, A.W.-H. Product design scenarios for energy saving: A case study of fashion apparel. Int. J. Prod. Econ. 2013, 146, 392–401. [Google Scholar] [CrossRef]

- Niinimäki, K.; Hassi, L. Emerging design strategies in sustainable production and consumption of textiles and clothing. J. Clean. Prod. 2011, 19, 1876–1883. [Google Scholar]

- Mont, O. Clarifying the concept of product-service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Caniato, F.; Caridi, M.; Crippa, L.; Moretto, A. Environmental sustainability in fashion supply chains: An exploratory case based research. Int. J. Prod. Econ. 2012, 135, 659–670. [Google Scholar] [CrossRef]

- Lo, C.K.Y.; Yeung, A.C.L.; Cheng, T.C.E. The impact of environmental management systems on financial performance in fashion and textiles industries. Int. J. Prod. Econ. 2012, 135, 561–567. [Google Scholar] [CrossRef]

- Green, K.; Morton, B.; New, S. Green purchasing and supply policies: Do they improve companies’ environmental performance? Supply Chain Manag. Int. J. 1998, 3, 89–95. [Google Scholar]

- Rahimifard, S.; Clegg, A.J. Aspects of sustainable design and manufacture. Int. J. Prod. Res. 2007, 45, 4013–4019. [Google Scholar] [CrossRef]

- Smith, L.; Ball, P. Steps towards sustainable manufacturing through modelling material, energy and waste flows. Int. J. Prod. Econ. 2012, 140, 227–238. [Google Scholar] [CrossRef]

- Ball, P.D.; Evans, S.; Levers, A.; Ellison, D. Zero carbon manufacturing facility—towards integrating material, energy, and waste process flows. J. Eng. Manuf. 2009, 223, 1085–1096. [Google Scholar] [CrossRef]

- Schmitt, A.J.; Sun, S.A.; Snyder, L.V.; Shen, Z.-J.M. Centralization versus decentralization: Risk pooling, risk diversification, and supply chain disruptions. Omega 2014. [Google Scholar] [CrossRef]

- Ehrenthal, J.C.F.; Honhon, D.; van Woensel, T. Demand seasonality in retail inventory management. Eur. J. Oper. Res. 2014, 238, 527–539. [Google Scholar] [CrossRef]

- Ferrucci, F.; Bock, S. Real-time control of express pickup and delivery processes in a dynamic environment. Transp. Res. Part B 2014, 63, 1–14. [Google Scholar] [CrossRef]

- Fogliatto, F.S.; da Silveira, G.J.C.; Borenstein, D. The mass customization decade: An updated review of the literature. Source Doc. Int. J. Prod. Econ. 2012, 138, 14–25. [Google Scholar] [CrossRef]

- Da Silveira, G.; Borenstein, D.; Fogliatto, F.S. Mass customization: Literature review and research directions. Int. J. Prod. Econ. 2001, 72, 1–13. [Google Scholar]

- Cho, Y.; Okada, N.; Park, H.; Takatera, M.; Inui, S.; Shimizu, Y. An interactive body model for individual pattern making. Int. J. Cloth. Sci. Technol. 2005, 17, 91–99. [Google Scholar] [CrossRef]

- Hu, Z.-H.; Yu, X.-K.; Sheng, Z.-H. An immune co-evolutionary algorithm based approach for problems related to clothing uniform assignment. Int. J. Cloth. Sci. Technol. 2013, 25, 70–82. [Google Scholar] [CrossRef]

- Ding, Y.-S.; Hu, Z.-H.; Zhang, W.-B. Multi-criteria decision making approach based on immune co-evolutionary algorithm with application to garment matching problem. Expert Syst. Appl. 2011, 38, 10377–10388. [Google Scholar] [CrossRef]

- Romero Morales, D.; Wang, J. Forecasting cancellation rates for services booking revenue management using data mining. Eur. J. Oper. Res. 2010, 202, 554–562. [Google Scholar]