Abstract

Oil palm is an important economic crop that is widely cultivated, especially in Southeast Asia. Thailand is one of the world’s largest producers and exporters of palm oil. Efficient management of oil palm plantations is crucial for increasing yields and minimizing agricultural losses. This study aimed to develop a smart oil palm plantation and production management system. This system utilizes Internet of Things (IoT) technology and an integrated supervised machine learning model utilizing regression analysis to monitor and control agricultural equipment within the plantation. MySQL database was used for management of sensor data. Python (version 3.9.6) programming and Google Map API were used for data analysis, spatial analysis and data visualization suite in the system. The results showed that the data from the sensors are displayed in real-time, allowing plantation managers to monitor conditions remotely and make informed adjustments as needed. The system also includes data analysis and data visualization tools for decision-making regarding production management. The model attained an accuracy of over 95%, which reflects its reliability in performing the specified prediction task. The system serves as a support tool for automating soil quality monitoring, fertilization, and field maintenance in oil palm plantations. This enhances productivity, reduces operational costs, and improves yield planning.

1. Introduction

Oil palm is a significant economic crop that is widely cultivated, particularly in Southeast Asia, notably in Indonesia and Malaysia, which are the world’s largest palm oil producers. Thailand is also one of the countries that cultivates oil palm in many areas nationwide [1,2]. This crop plays a significant role in Thailand’s agricultural sector, as it is a high-value cash crop that consistently generates export income. At present, Thailand ranks among the world’s leading producers and exporters of palm oil. Thai palm oil products are exported to key markets around the world and show a steady growth trend, particularly during periods of palm oil price volatility. Palm oil exports, therefore, play a crucial role in promoting the country’s economy and ensuring stability for its agricultural sector [3]. Oil palm yields are influenced by multiple factors, particularly environmental changes and climate variability [4]. Research indicates that the global average temperature has increased by more than 1 °C in comparison to pre-industrial levels. Furthermore, recent years indicate an approach toward an increase of 1.5 °C in warming, which has impacted agricultural areas in many countries, including those involved in oil palm production [5,6]. An increase in temperature by 1–4 °C may reduce yields by 10–40%; specifically, a 2 °C rise could result in yield reductions of up to 30% [4,7,8]. In addition, insufficient humidity in oil palm plantations can lead to nutrient deficiencies [9,10]. Rainfall also plays a crucial role: if dry spells last longer than two months, the Oil Extraction Rate (OER) will decline in the following 11 months, while excessive rainfall may reduce Fresh Fruit Bunch (FFB) yields and delay harvesting [11]. These findings highlight that climate change, in multiple dimensions, can significantly impact oil palm yields.

The application of Information Technology (IT) in agriculture, such as the Internet of Things (IoT) and agricultural data analytics, plays a crucial role in the development of smart farming. Systems have been developed that use sensors to collect data for analysis and display of crop information, as well as to control the operation of various devices [12]. At the same time, tractor tracking systems that integrate Geographic Information System (GIS), Global Positioning System (GPS), and wireless networks enable farmers to monitor the location and operation of tractors in real-time [13]. Previous research has indicated that farm management should incorporate these technologies to enhance efficiency, reduce costs, and create opportunities to increase yield and profit [14]. With advances in Information and Communication Technology (ICT), IoT and sensors now play a key role in linking and exchanging data between devices in real-time. IoT is not merely a traditional computer network but an embedded system that expands its capabilities as more devices are connected [15]. Moreover, IoT can be integrated with other technologies, such as Wireless Sensor Networks (WSN), to transmit data seamlessly and enable further utilization [16].

In addition, machine learning has become increasingly important in smart agriculture, as it can process massive amounts of agricultural data collected from IoT and sensors. Machine learning also helps in identifying patterns, predicting yields, detecting plant diseases, and optimizing resource usage, leading to more accurate and data-driven decision-making. When integrated with IoT and WSN, machine learning not only enhances automation but also transforms raw data into deep insights that significantly improve productivity and sustainability in modern agriculture [1].

Previous works that have implemented machine learning and IoT are focused primarily on plant management, addressing plant growth monitoring and assessment without extending coverage to yield prediction, soil analysis, disease detection, or resource optimization [17,18]. Another study broadened this scope by integrating plant management with crop and yield management, enabling data-driven productivity forecasting [19]. In contrast, the others emphasized disease, weed, and water management, underscoring the importance of mitigating crop health risks and ensuring efficient resource utilization [20], and also concentrate exclusively on crop and yield management through machine-learning-based forecasting techniques [21,22].

Meanwhile, efficient management of oil palm plantations is a key factor in increasing yields and reducing agricultural losses. Monitoring environmental conditions such as temperature, humidity, soil moisture, light intensity, and soil nutrients is essential for making appropriate cultivation decisions. In addition, tracking the harvesting process and analyzing factors affecting productivity can help farmers plan plantation management more accurately. Therefore, this research aims to develop an intelligent oil palm plantation management system that integrates environmental monitoring, nutrient management, and harvest tracking to support cultivation decision-making and enhance production efficiency sustainably. The main contributions of our research can be described as follows:

- Intelligent systems are developed for managing and monitoring crops within cultivation areas, with a particular focus on oil palms. The approach integrates IoT, microcontrollers, and the Maps API with machine learning, enabling data-driven analysis and predictive capabilities to support efficient decision-making in crop management.

- We propose a comprehensive framework that integrates plant management, crop and yield management, soil management, and water management, offering a multi-dimensional solution for oil palm plantations.

- This integrated approach enables real-time monitoring of plantation conditions, supports data-driven decision-making, and facilitates the optimization of critical agricultural processes.

- Our development comprises a station system and a web-based application designed to support managing a smart oil palm plantation.

The content in the following sections of this article is as follows: Section 2 provides details on the design and development of the station system and web application; Section 3 presents the results in the form of the application; Section 4 discusses the research findings; and lastly, Section 5 concludes the article with a summary of the research and future work.

2. Related Work

Recent research on the adoption of IoT and machine learning technologies in oil palm agriculture demonstrates varying scopes and levels of implementation across different management aspects. There are seven features to classify the use of machine learning and IoT-based applications in agriculture [23], i.e., plant management, crop and yield management, soil management, disease management, weed management, water management, and animal tracking. Table 1 presents a comparison of previous studies in these aspects.

Table 1.

Comparison of previous work using IoT and machine learning in oil palm agriculture.

Mahendran et al. [17] and Abouelmagd et al. [18] focus primarily on plant management, addressing plant growth monitoring and assessment without extending coverage to yield prediction, soil analysis, disease detection, or resource optimization. Machine learning and Internet of Things (IoT) technologies were used to detect nutritional deficiencies in oil palm trees, enabling a consistent supply of high-quality palm oil to meet increasing global demand [17]. Their findings indicate that further exploration of integrated machine learning, IoT, and deep learning approaches is warranted to achieve accurate, early detection of nutrient deficiencies in oil palm cultivation. Additionally, the results indicated that the integration of ML and IoT can enhance the efficiency of biodiesel production, providing a scalable and reliable solution for sustainable energy development [18].

Khan et al. [19] broaden this scope by integrating plant management with crop and yield management, enabling data-driven productivity forecasting. They developed an application to predict oil palm yield using weather and soil moisture data. The most influential features contributing to the prediction were identified as rainfall, cloud amount, number of rain days, wind speed, and root zone soil wetness. The study concluded that the proposed machine learning workflow provides a robust and flexible solution for oil palm yield prediction, highlighting the significance of automated model and feature selection.

In contrast, Ramasenderan et al. [20] emphasize disease, weed, and water management, underscoring the importance of mitigating crop health risks and ensuring efficient resource utilization. The system monitors environmental conditions via sensors and generates recommendations for irrigation scheduling, pest management, and tree health maintenance. By analyzing historical data and weather patterns, the AI system is capable of predicting future trends to support informed decision-making.

Other studies, including those by Anggala and Sutabri [21] and Mamun [22], concentrate exclusively on crop and yield management through machine-learning-based forecasting techniques. An IoT-based smart farming system was developed that leverages machine learning to enhance operational efficiency, optimize resource utilization, and increase crop yields [22]. By analyzing the large volumes of data generated by IoT devices, the system enables farmers to make informed decisions, predict trends, and manage their farms proactively.

Unlike the aforementioned studies, the proposed study introduces a more comprehensive framework that integrates plant management, crop and yield management, soil management, and water management, offering a multi-dimensional solution for oil palm plantations. This integrated approach enables real-time monitoring of plantation conditions, supports data-driven decision-making, and facilitates the optimization of critical agricultural processes. By combining multiple management dimensions within a single framework, the system addresses key limitations of existing precision agriculture methods, such as fragmented monitoring, inefficient resource utilization, and delayed response to environmental changes. Consequently, the proposed framework provides a scalable, adaptive, and holistic solution that enhances productivity, sustainability, and operational efficiency in oil palm cultivation.

3. Materials and Methods

3.1. Process Overview

The process overview for this study presents the development of a smart management station for oil palm plantations and yield. This system utilizes IoT technology to monitor and control agricultural equipment within the plantation using a multi-station IoT architecture. The deployment consisted of one main station acting as the centralized node responsible for data aggregation, environmental monitoring, system control, and database synchronization, together with four sub-stations distributed across the plantation to monitor microclimatic and soil conditions. The experimental site is an oil palm plantation (9.088042, 99.351098), covering approximately 4350 m2. Data collection was conducted over two separate periods—November to December 2024 and March to April 2025, capturing both short-term temporal variability and different seasonal patterns of temperature, humidity, light intensity, soil conditions, and nutrient levels in soil. Furthermore, there is an integrated automated GIS-based visualization provided. This enables operators to create optimized planting plans, aiming to reduce production costs and increase the efficiency of investment.

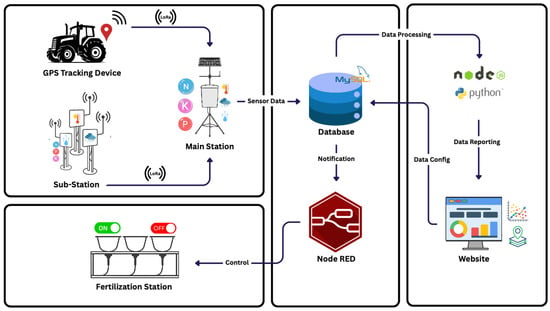

Figure 1 presents the structural design of this research system, developed to enhance the management of oil palm plantations using IoT and GIS technologies. Environmental parameters include air temperature and humidity, soil temperature and moisture, light intensity, rainfall, and nutrient levels in the soil (NPK), which were collected by the main station and sub-stations. The sub-stations transmitted data to the main station via LoRa signals. GPS devices mounted on harvesting vehicles capture precise geospatial yield location data. The main station also performed environmental monitoring, data aggregation, and forwarded the data to the MySQL database through MQTT over Wi-Fi. The database schema supports multi-parameter environmental records, georeferenced harvest data, and system control logs, enabling comprehensive spatial-temporal analysis. The system incorporates machine learning-based predictive models, which includes correlation-based feature assessment, multiple linear regression modeling, time-series estimation of soil moisture and nutrient variation, and time-series yield forecasting. These models operate on both historical and real-time sensor streams to identify influential environmental factors, generate short-term predictive insights and actionable recommendations, including irrigation scheduling, nutrient application, and harvest planning tailored to specific plantation zones. A web-based interface, integrated with GIS mapping, provides real-time spatial visualization, decision-support dashboards, and remote system control functionalities, allowing users to operate irrigation and fertilization systems in both automatic and manual modes. This integrated workflow ensures that the machine learning component is embedded directly within the data acquisition–processing–control loop, enabling actionable and data-driven plantation management.

Figure 1.

The process overview for implementing the smart oil palm management system.

3.2. Smart Oil Palm Plantation Management Station

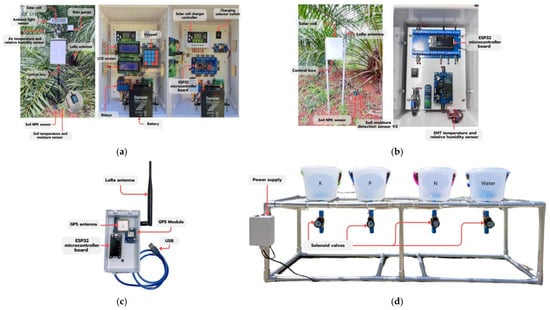

The oil palm plantation management station (Figure 2) is designed as a primary unit (main station) to monitor and manage environmental conditions within the plantation using an integrated system of sensors and automated controls. It operates by collecting real-time data on essential factors like soil temperature and moisture, air temperature and relative humidity, rainfall, ambient light, and nutrient levels, through various sensors strategically placed throughout the plantation. Data acquisition from both the main station and the four sub-stations was configured to read once every two minutes. Each sub-station transmitted data to the main station using a LoRa communication module operating in the 868–915 MHz band. The Received Signal Strength Indicator (RSSI) averaged −92.4 dBm (Decibel-milliwatt) over the deployment range of 5–50 m, despite realistic field obstructions such as oil palm trunks and tall grasses. After receiving the sensor packets, the main station processed and forwarded the data to a cloud-based MySQL (version 5.5) database via MQTT with Wi-Fi. Moreover, the station provides automated irrigation and fertilization based on these readings, ensuring that the oil palm trees receive optimal water and nutrients. The software architecture consists of three layers: (i) an embedded systems layer responsible for reading data from sensors and sending or receiving data via LoRa signals, (ii) the gateway layer for communication between the main station and the database system via the Node-RED (version 3.1.8) platform using the MQTT protocol, and (iii) a web application layer built using Python and Node.js (version v22.14.0) for real time graphical rendering. It displays data in real time via a user friendly website interface, enabling plantation managers to monitor conditions remotely and make informed adjustments as needed.

Figure 2.

Structure of the smart oil palm management system: (a) Main station; (b) Sub-station; (c) GPS Tracking Device; and (d) Fertilization Station (N: Nitrogen, P: Phosphorus, K: Potassium).

3.2.1. Ethical and Sustainability Considerations

To ensure responsible deployment of IoT technologies in oil palm plantation monitoring, this study adopts essential ethical and sustainability practices. The IoT sensors collect only non-personal environmental and agronomic data (e.g., soil moisture, temperature, humidity), ensuring that no identifiable information about farmers or workers is recorded. All transmitted data are encrypted and handled under a data-minimization policy to maintain privacy and prevent unauthorized access. From a sustainability perspective, the sensing devices operate on low-power hardware to reduce energy consumption and extend device lifespan in field conditions. Proper maintenance and responsible disposal of electronic components are also emphasized to minimize environmental impact. These measures support the ethical, secure, and sustainable use of IoT devices in oil palm plantation management.

3.2.2. Main Station

This is the central processing hub where sensor data are collected, analyzed, and used to control irrigation and fertilization systems. The station sends automated commands to regulate water and nutrient supply, optimizing plantation health and yield. The station in the oil palm plantation is equipped to assess soil quality and environmental conditions on its own, utilizing the high-precision SHT20 I2C sensor (Sensirion Holding AG, Zurich, Switzerland) to measure soil temperature and moisture (accuracy: ± 3%, ± 0.3 °C), SHT20 I2C for air temperature and relative humidity (accuracy: ± 3%RH, ± 0.3 °C), WH-SP-RG Rain Gauge, TEMT6000 (Vishay Semiconductors, Malvern, PA, USA) for ambient light, and RS485 Soil NPK Sensor, Model PR-3000-TR-NPK-N01 ((Shandong Renke Measurement & Control Technology Co., Ltd., Shandong, China), (accuracy ± 2%). Data from these sensors are processed by the LILYGO LoRa32 868 Mhz ESP32 microcontroller board (Shenzhen Xinyuan Electronic Technology Co., Ltd., Shenzhen, China) and displayed both on a 20 × 4 LCD screen and also using data from the sub-stations. The main station can operate in two modes: automatic and manual. Users can configure operating conditions either through a control keypad at the main station or remotely via the website, which allows adjustments to both the main monitoring station and the fertilizer station settings. Additionally, the station supports two battery charging methods for reliable operating power: solar energy through 6 V, 1.67 A, 10 W solar cells with dimensions of 230 × 340 mm2 or 220 VAC power converted to 12 VDC to ensure stable voltage for all electronic components within the control box, as shown in Figure 2a.

The main station is powered by a hybrid energy supply consisting of a 12 V 5.5 Ah battery charged either by a 10 W solar panel or, when available, by a 220 VAC-to-12 VDC power converter. The integrated electronics of the main station consume approximately 0.17 A at 5 V (equivalent to 71 mA at 12 V), and after accounting for the 10–20% conversion loss inherent in the DC-to-DC step-down process, a fully charged 12 V 5.5 Ah battery can sustain continuous station operation for around 65.7 h, or approximately 2.7 days under stable 5 V supply conditions. The dual power design was selected to ensure operational reliability in diverse agricultural environments. Solar power is essential for remote plantation zones where grid electricity is not accessible, while the AC power option supports deployment in semi-rural areas where electrical infrastructure is available, enabling uninterrupted operation during prolonged periods of low solar irradiation. The hybrid configuration therefore improves power availability, reduces operational downtime, and ensures consistent data logging throughout the monitoring period.

3.2.3. Sub-Stations

These units, placed throughout the plantation, extend monitoring into remote areas and work in sync with the main station for accurate and consistent environmental data across the plantation. Each sub-station is equipped with embedded sensors for soil and environmental monitoring, utilizing the high-precision SHT20 I2C sensor to measure soil temperature and moisture (accuracy: ±3%RH, ±0.3 °C), SHT20 I2C for air temperature and relative humidity (accuracy: ±3%RH, ±0.3 °C), WH-SP-RG Rain Gauge, TEMT6000 for ambient light, and RS485 Soil NPK Sensor, Model PR-3000-TR-NPK-N01, (accuracy ±2%). Data from these sensors are processed by the LILYGO LoRa32 868 Mhz ESP32 microcontroller board and displayed both on a 20 × 4 LCD screen and through a dedicated web application as shown in Figure 2a. These data are transmitted via a LoRa antenna using the MQTT protocol over a Wi-Fi connection and are stored in a centralized database for further analysis. Soil moisture levels are monitored utilizing the Soil moisture detection sensor V2, while soil nutrient content, specifically for Nitrogen (N), Phosphorus (P), and Potassium (K), is measured using the RS485 Soil NPK Sensor, Model PR-3000-TR-NPK-N01, with a measurement accuracy of ±2%. This sensor configuration enables accurate and reliable monitoring of both soil moisture and nutrient levels, supporting optimal soil management practices. Environmental conditions are monitored using DHT22 temperature and relative humidity sensor (Aosong Electronics, Guangzhou, China) (accuracy: ±2%RH, ±0.2 °C) installed outside the control box. Data from all sensors are processed by the LILYGO LoRa32 868 MHz ESP32 microcontroller, which consolidates and sends them to the main station via a LoRa antenna using the MQTT protocol over a Wi-Fi connection. The sub-station is sustainably powered by a 5.5 V, 400 mA, 2.2 W solar cell (160 × 92 mm2) mounted on the control box, connected to a lithium battery charging module that stabilizes voltage before storing energy in a 12 VDC battery. A DC-to-DC voltage regulator converts 12 VDC from the battery to 5 VDC, ensuring reliable power for all sub-station electronics, as illustrated in Figure 2b.

3.2.4. GPS Tracking Devices

Installed on vehicles and harvesting equipment, the GPS Tracking Device records positional data and tracks harvest activities, providing real-time location and status information to enhance resource allocation and planning. A GY-NEO-7M GPS module integrated with a LoRa32 868 MHz ESP32 microcontroller reads location coordinates and transmits data to the main station via LoRa antenna. These data are sent to a website using the MQTT protocol over Wi-Fi, displaying the harvester’s location on a satellite map (Figure 2c).

3.2.5. Fertilization Station

This station automates nutrient delivery to plants by calculating the precise amount of fertilizer needed based on soil data from sensors. It dynamically adjusts nutrient supply to minimize waste and support optimal growth. The station controls four solenoid valves: Channel 1 for water tank, Channel 2 for N tank, Channel 3 for P tank, and Channel 4 for K tank. These valves are operated via relays based on commands from a microcontroller in the main station as shown in Figure 2d. The system processes data from sensors and can be controlled through the buttons on a keypad or a dashboard on a website.

3.2.6. Workflow Diagram of the Smart Oil Palm Management System

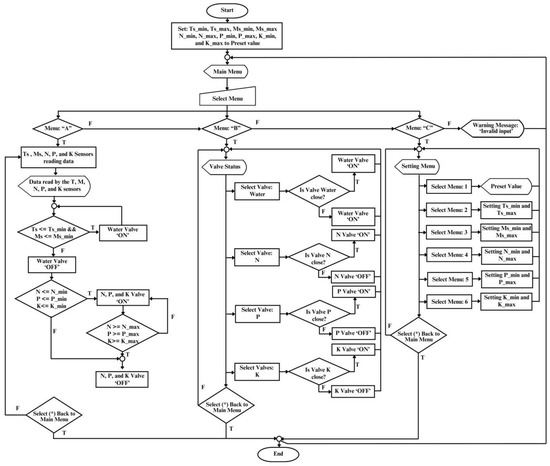

The system initiates with the configuration of standard parameters for key variables, including temperature (Ts_min and Ts_max), soil moisture (Ms_min and Ms_max), and soil nutrient content levels (N_min, N_max, P_min, P_max, K_min, and K_max). The main interface offers three operational modes: (i) Menu A enables the real-time acquisition and analysis of sensor data while autonomously controlling solenoid valves. Water valves are activated when Ts or Ms values fall below their lower thresholds, and nutrient valves are independently triggered when N, P, or K levels drop below their designated minimum thresholds, with each valve shut off once the relevant upper limit is exceeded. (ii) Menu B provides real-time monitoring and manual valve control, allowing users to fine-tune system performance. (iii) Menu C allows parameter customization in response to local environmental conditions or agronomic requirements as illustrated in Figure 3. Through these functionalities, the system ensures precise, efficient, and sustainable management of water and nutrient resources, minimizing input wastage and enhancing yield outcomes. The integration of Figure 1 and Figure 3 clearly demonstrates the interconnection between the system’s architecture and workflow, where database-driven analytics, IoT-enabled monitoring, and user interactions collectively transform raw sensor data into evidence-based management strategies for oil palm plantations.

Figure 3.

Smart oil palm management system flowchart (*: return to the main menu).

3.3. Web Application

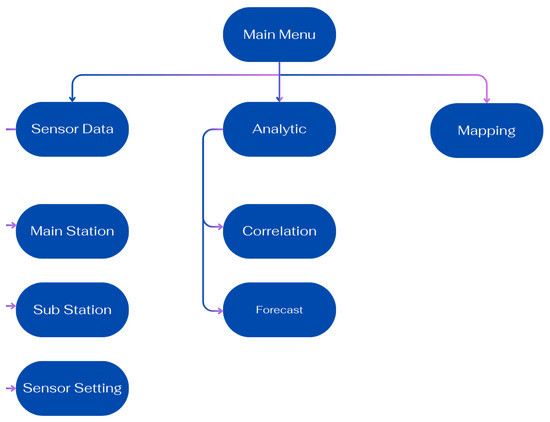

The diagram in Figure 4 presents the structural hierarchy of a website application, starting from the Main Menu. It is divided into three main sections: sensor data, analytics, and mapping. This website was developed using Node.js for both the Front-end and Back-end, along with Node-RED for the User Interface (UI) components and the Google Maps API for mapping functionalities. Additionally, this research utilizes MySQL for storing the data used in the study. Below is a breakdown of the key elements.

Figure 4.

Website Architecture.

3.3.1. Technologies Used

- Python (version 3.9.6): A high-level programming language that is widely popular for system development and data analysis;

- Node.js (version 22.14.0): A runtime for executing JavaScript on the server side;

- Node-RED (version 3.1.8): A platform for building IoT applications and automation systems;

- Google Maps API (version 2.20.6): Used for mapping features and displaying location-based data;

- MySQL (version 5.5): Database management system for smart oil palm management.

3.3.2. Website Features and Functionality

- Correlation Analysis Page: (1) Allows users to select two variables from dropdown menus. (2) Calculates the Correlation Coefficient (r) to measure the strength and direction of the relationship between variables. (3) Displays R-squared (R2), indicating how well the data are fit by the model. And (4) A scatter plot with a regression line is generated for data visualization.

- Linear Regression Analysis Page: (1) Users select an independent variable (X) and a dependent variable (Y). (2) The system performs Linear Regression to determine the relationship. (3) Display outputs (Correlation Coefficient (r) measures the strength of association; R2 shows the percentage of variation explained by the model). (4) Displays a scatter plot with a regression line.

- Mapping Page: (1) Uses Google Maps API to visualize location data. Users can access environmental data such as air temperature, air humidity, soil temperature, soil humidity, light intensity, rainfall, soil nutrient (Nitrogen, Phosphorus, and Potassium) levels, and distance from the main station. When a time period is selected, the system displays the estimated values in the area as points on the map and the estimates are graded to color shades.

3.3.3. Data Processing

- Data Input: (1) Users select variables for correlation or regression. (2) Location data are imported from KML files for mapping.

- Data Processing (Backend—Node.js): (1) Performs correlation and regression calculations, and (2) retrieves and formats location data.

- Data Visualization (Frontend—React): (1) Uses Ant Design for form components. (2) Displays scatter plots using a charting library. (3) Integrates Google Maps API for location-based analysis.

3.3.4. Data Analysis

Correlation and Linear Regression analysis are statistical tools used to study the relationships between variables. Both methods aim to help us understand how changes in one variable affect another. These methods have the following details [17].

- Correlation analysis: A statistical technique used to measure and describe the strength and direction of the relationship between two variables, with correlation values ranging from −1 to +1. A correlation of +1 indicates a perfect positive relationship, −1 indicates a perfect negative relationship, and 0 indicates no linear relationship. Common methods for correlation analysis include Pearson’s correlation, which is used for linear relationships, and Spearman’s rank correlation, which is used for monotonic relationships.

- Linear Regression analysis: A statistical technique used to study the relationship between an independent variable and a dependent variable by creating a linear equation that can predict the value of the dependent variable from the independent variable. The resulting equation is of the form , where represents the value of the dependent variable; is the y-intercept; is the coefficient (slope) that indicates the rate of change in the dependent variable when the independent variable changes.

R2 or coefficient of determination is used to measure the relationship between an independent variable and a dependent variable in linear regression analysis. It indicates how well our model explains the variability of the data, with values ranging from 0 to 1. If R2 = 1, the model explains all the data, while R2 = 0 means that the model cannot explain any of the data. In the analysis of the relationship between two variables, R2 can be used to assess how meaningful and strong the correlation or relationship between the variables is. This value can be calculated using the following formula [24,25]:

where is the actual value of the dependent variable at each data point; is the predicted value from the model; is the mean of the actual values; is the number of data points.

3.3.5. Machine Learning

In this study, a total of 10,700 records were utilized for model development. To ensure a rigorous evaluation framework, the dataset was divided into 80% for training and 20% for testing. A supervised machine learning approach was employed, which included both regression and forecasting models. Linear Regression served as the baseline estimator, while Support Vector Regression (SVR) and Random Forest Regression (RFR) were incorporated to account for nonlinear dynamics and complex feature interactions, thereby improving predictive performance.

All models were trained using standardized preprocessing procedures, including feature scaling, missing-data imputation, and outlier assessment. The performance of the models was evaluated on an independent testing set and supplemented by 10-fold cross-validation for the machine learning models. Predictive accuracy and model generalizability were assessed using Root Mean Squared Error (RMSE), Mean Absolute Error (MAE) and the Coefficient of Determination (R2).

3.3.6. Mapping

Mapping in agriculture refers to the use of maps or spatial technology to collect and display data related to agricultural areas, such as soil moisture, temperature, biodiversity, or soil quality. Mapping helps farmers visualize and analyze environmental data in agricultural areas more clearly, enabling better decision-making in resource management, such as water usage, crop rotation, or pest control. Additionally, mapping helps in monitoring long-term environmental changes, allowing farmers to adapt to evolving conditions. It also contributes to improving production efficiency and ensuring the sustainability of natural resources [26].

Google Maps API is a set of tools provided by Google that allows access to and utilization of Google Maps data in applications or websites. It enables developers to display maps, add address search tools, place coordinates, show travel routes, and conduct spatial data analyses [27]. This functionality can be effectively applied in the agricultural sector to support mapping activities. With the Google Maps API, farmers can identify the locations of their agricultural plots, display environmental data such as soil moisture, rainfall levels, or temperature in specific areas, and plan their cultivation and land management more efficiently. Additionally, it can be used to monitor environmental changes and assist in resource allocation decisions to ensure optimal use, ultimately enhancing the efficiency and sustainability of agricultural practices [28,29,30,31].

4. Results and Discussions

4.1. Main Manu or Home Page

Based on the design and development of a web application for oil palm plantation management using Ant Design (version 5.20.6), React (version 18.3.1), Node.js, and the Google Maps (version 2.20.6) API, when a user accesses the system, they are directed to the home page or main interface. On this page, there are three primary menu options available: (1) Sensor Data, (2) Analytic, and (3) Mapping. These options are presented on the main screen, as illustrated in Figure 5.

Figure 5.

Main Menu.

4.2. Sensor Data Pages

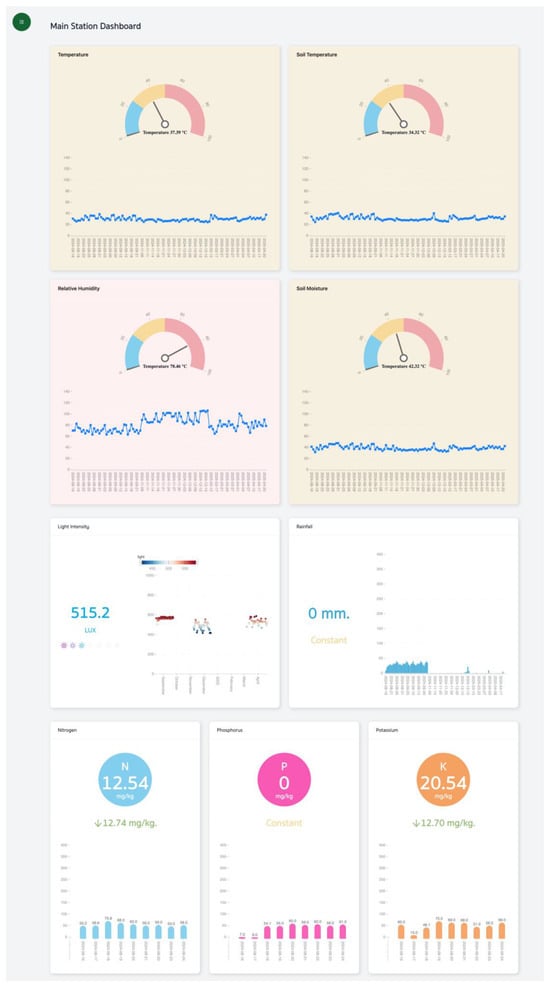

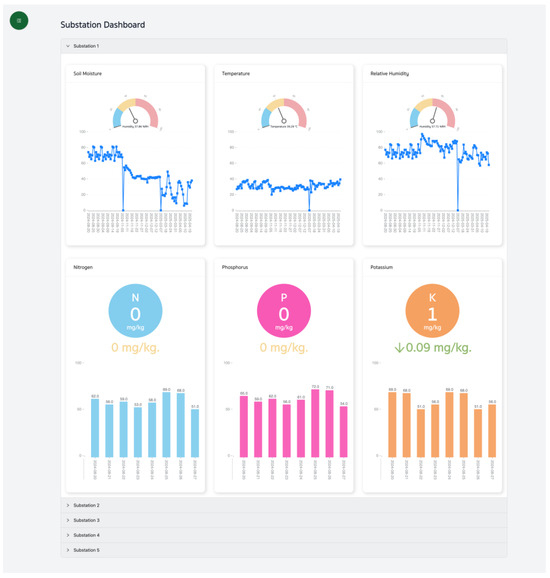

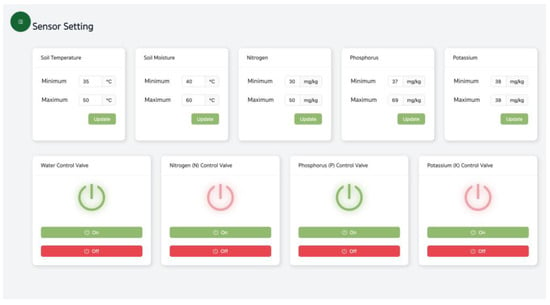

This section deals with collecting, viewing, or configuring sensor data. The system is divided into three main components: the Main Station (Figure 6), the Sub Station (Figure 7), and the Sensor Setting (Figure 8). Detailed explanations of each component are provided in Section 4.2.1, Section 4.2.2 and Section 4.2.3.

Figure 6.

Main Station Dashboard.

Figure 7.

Substation Dashboard.

Figure 8.

Sensor Setting Dashboard.

4.2.1. Main Station Sensor Monitoring Dashboard

This page presents the Main Station Dashboard for a sensor monitoring system. It provides semi-real-time and historical data visualization for various environmental parameters (Figure 6). The key components of the Main Station are described in detail as follows:

- Temperature: Displays current temperature using a gauge and shows historical trends in a line chart;

- Soil Temperature: Gauge visualization for soil temperature and line chart tracking fluctuations over time;

- Relative Humidity: Current humidity level displayed on a gauge, with historical trends visualized through a time-series graph;

- Soil Moisture: Gauge representing soil moisture levels and line chart depicting changes;

- Light Intensity: Value displayed in LUX and a scatter plot visualizing intensity variation;

- Rainfall: Current rainfall level in mm and bar chart tracking rainfall patterns;

- Soil Nutrients: Nitrogen (N), Phosphorus (P), and Potassium (K) each nutrient has a circular display with historical values in bar charts.

4.2.2. Substation Sensor Monitoring Dashboard

Substation selection (Dropdown) allows users to switch between multiple substations (Substation 1, Substation 2, etc.) as shown in Figure 7. The key components of each Substation are described in detail as follows.

- Soil Moisture: Displays current soil moisture using a gauge and shows historical trends in a line chart;

- Temperature: Displays current soil moisture temperature using a gauge and shows historical trends in a line chart;

- Relative Humidity: Humidity level shown on a gauge and historical trend via a time series graph;

- Soil Nutrients: Nitrogen (N), Phosphorus (P), and Potassium (K). Each nutrient has trends in number and arrow. circular display with historical values in bar charts.

4.2.3. Sensor Setting

This Sensor Setting dashboard (Figure 8) allows users to configure sensor thresholds and control valves for an automated monitoring system. The key components of the Sensor Setting are described in detail as follows:

- Sensor Threshold Settings (Top Section): Users can set minimum and maximum values for various parameters, namely for Soil Temperature, Soil Moisture, Nitrogen (N), Phosphorus (P), and Potassium (K). Each setting has an Update button to apply changes;

- Control Valves (Bottom Section): Users can turn ON or OFF control mechanisms for Water Control Valve, Nitrogen Control Valve, Phosphorus Control Valve, Potassium Control Valve (Currently OFF). Color indicators show Red (OFF) or Green (ON).

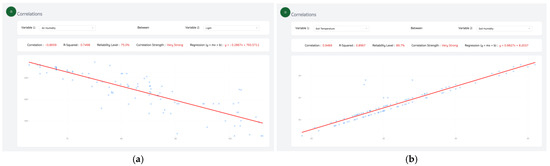

4.3. Data Analytics Page

This section is used for data analysis, which includes the Correlation and Linear Regression Analysis pages as illustrated in Figure 9. The details of each page are described in Section 4.3.1 and Section 4.3.2.

Figure 9.

Data Analytics Pages show (a) Correlation; and (b) Linear Regression.

4.3.1. Correlation Analysis

The Correlation Analysis Page (Figure 9a) allows users to analyze relationships between two environmental variables. Users can select different environmental variables (e.g., Temperature, Soil Temperature, Relative Humidity, Soil Moisture, Light Intensity, Rainfall, Soil Nutrients) to compare their relationship by calculating:

- Correlation Coefficient (r)—Measures the strength and direction of the relationship;

- R2 Value—Indicates how well one variable explains the variation in another;

- Scatter Plot & Trend Line—A visual representation of the relationship.

4.3.2. Linear Regression Analysis

The Linear Regression Analysis Page is designed to analyze the relationship between an independent variable (predictor) and a dependent variable (outcome). It provides statistical outputs such as correlation, R-squared, and a scatter plot with a fitted regression line, as shown in Figure 9b.

4.3.3. Model Performance

The model performance results indicated that the Linear Regression model achieved the best overall performance, with the lowest RMSE of 1.96, the lowest MAE of 1.56 and the highest R2 value of 0.95. This confirms its strong ability to model IoT sensor data for accurate predictions in oil palm plantations. However, both SVR and RFR showed comparatively lower performance (SVR: RMSE = 2.15, MAE = 1.75, R2 = 0.94; RFR: RMSE = 2.16, MAE = 1.73, R2 = 0.94).

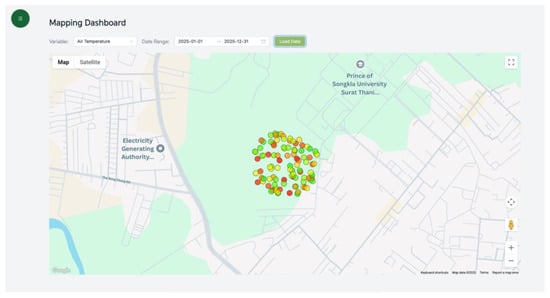

4.4. Mapping Page

Mapping Page (Figure 10) is an interactive web-based GIS tool designed to visualize sensor data collected from various locations. The system utilizes the Google Maps API to provide a dynamic map interface with base layers (Map & Satellite). It directly plots location-based data points representing estimated environmental values.

Figure 10.

Sensor Measurements Displayed on the Geographic Map.

Users can select specific time periods to view data on

- airTemp (Air Temperature);

- airHumi (Air Humidity);

- soilTemp (Soil Temperature);

- soilHumi (Soil Humidity);

- lightValue (Light Intensity);

- rainValue (Rainfall);

- nitroValue (Nitrogen level in soil);

- phosValue (Phosphorus level in soil);

- potoValue (Potassium level in soil);

- Distance (Possibly the distance from a reference point).

Each data point is plotted on the map and color-graded to reflect the intensity or concentration of the corresponding environmental factor. When users click on a data point, a pop-up window provides detailed sensor readings and contextual information, such as the distance from the main station.

4.5. Discussion

The main issue in oil palm management today is the lack of sufficient and accurate data regarding the environment and soil conditions in oil palm plantations. This leads to incorrect and less efficient decision-making in resource management of fertilizer, water, and harvesting. Moreover, monitoring and controlling factors like temperature, soil moisture, or nutrient levels in the soil are difficult to achieve at the desired level. This can result in crop loss or inappropriate use of resources. Therefore, developing an intelligent system to enhance the management of oil palm plantations efficiently is essential [32]. In this research, a smart oil palm management system has been developed using IoT technology, microcontrollers, and the Google Maps API to support plantation management.

IoT technology plays a crucial role in oil palm management by enhancing the efficiency of cultivation and harvesting through sensor systems and real-time data analysis. Sensors can measure soil moisture, weather conditions, and nutrient levels, allowing precise adjustments to irrigation and fertilization. This helps reduce costs and environmental impact. The data collected from IoT also enable farm managers to make more informed decisions, leading to more accurate and sustainable oil palm plantation management [33,34]. In previous research, IoT technology has been applied in various aspects of oil palm plantation management, including soil monitoring, water management, fertilization, and more [35,36,37,38]. Our system utilizes IoT technology combined with microcontrollers and the Google Maps API to manage oil palm plantations by integrating data from various sensors, such as soil moisture, weather conditions, and nutrient levels. This allows for precise and efficient adjustments in irrigation and fertilization, and enables monitoring the oil palm harvesting process.

The findings of this study indicate that the integration of LoRa technology into smart oil palm management systems facilitates reliable, long-range, and low-power transmission of sensor data across the plantation. This capability significantly enhances management efficiency and contributes to a reduction in operational costs. These results corroborate the observations of Ruslan et al. [35], who reported the efficacy of LoRa-based communication for the transmission of agronomic data in oil palm plantations, particularly in expansive and remote areas. When compared to previous studies, these findings further reinforce the advantages of sensor-based agricultural monitoring. Muangprathub et al. [12] highlighted that sensor networks enhance real-time data acquisition and support automated control processes, while Swain et al. [14] emphasized that the integration of digital technologies into farm management can lead to cost reductions and improved decision-making. This study extends prior findings by demonstrating that the combination of sensor networks and LoRa communication not only retains these benefits, but also enhances system scalability and field coverage, rendering it particularly suitable for large and remote plantation environments. Collectively, the results align with and build upon existing research, providing robust evidence for the effectiveness of LoRa-enabled smart agriculture systems.

A web application was developed to display data from all sensors at the oil palm plantation management station installed at the plantation. This allows users to monitor temperature, soil temperature, relative humidity, soil moisture, light intensity, rainfall, and soil nutrients. Users can also control irrigation and the application of various minerals to the plantation. Our web application includes correlation and Linear Regression analysis, presented in a scatter plot format. Additionally, users can view sensor data via the Google Maps interface, including air temperature, air humidity, soil temperature, soil moisture, light intensity, rainfall; and nitrogen, phosphorus, and potassium levels in the soil; and the distance.

Our research is highly beneficial and could have a significant impact on the development of the agricultural sector, especially in the management of oil palm plantations. The intelligent system developed can enhance the efficiency of resource utilization, enabling farmers to make accurate decisions based on varying environmental and soil conditions. This results in reduced production costs and increased sustainable yields. Additionally, it helps minimize unnecessary resource waste and ensures effective monitoring and management of oil palm plantations without the need to be physically present at all times. As a result, farmers gain more time for planning and can manage their plantations more effectively. The previous studies [17,18] indicated that the integration of machine learning, IoT-based sensing, and deep learning techniques offers significant potential for the accurate and timely detection of nutrient deficiencies in oil palm cultivation. This aligns closely with the results of this study, which demonstrate that combining high-resolution environmental data with machine learning models enhances predictive accuracy and supports more informed management decisions.

The proposed system offers several significant advantages aimed at enhancing the management efficiency of oil palm plantations. By integrating environmental data with predictive modeling, this system improves the precision of managerial decisions and facilitates a more effective allocation of agricultural inputs, resulting in measurable reductions in production costs. However, several limitations merit consideration. The reliability of system performance relies on regular maintenance, accurate calibration, and organized data management. The performance of the system is also contingent upon the continuity and reliability of sensor data. This reliability can be compromised by hardware malfunctions, environmental interferences, or connectivity challenges, particularly in regions characterized by dense canopy cover or complex terrain. Concerns regarding data governance, ownership, and privacy highlight the necessity for strong cybersecurity measures and effective regulatory frameworks.

5. Conclusions and Future Work

This research developed an intelligent oil palm plantation management system that integrates IoT technology, microcontrollers, and the Google Maps API. The system can monitor environmental conditions such as temperature, soil temperature, relative humidity, soil moisture, light intensity, rainfall, and soil nutrients (specifically Nitrogen, Phosphorus, and Potassium), while also supporting nutrient management and harvest process tracking. Data analysis using correlation and Linear Regression reveals relationships among the variables, with model performance evaluated using the coefficient of determination R2. The results indicate that the system can enhance decision-making efficacy in plantation management, improve operational efficiency by optimizing resource use, and demonstrate practical effectiveness in real plantation conditions. Although this study focused specifically on oil palm, the approach can be adapted to other crops in the future, and additional technologies may further improve the system’s performance.

For future work, the research needs some improvements to develop holistic decision-support systems and predictive analytics across multiple agricultural dimensions. Advanced deep learning architectures, adaptive sensor fusion techniques, and spatial-temporal modeling could be explored to enhance the accuracy of early detection, especially for disease and weed management [20]. Additionally, large-scale field deployments and longitudinal evaluation studies are necessary to validate the system’s robustness under varying environmental conditions. Finally, incorporating economic, environmental, and social sustainability metrics may provide a more practical basis for adoption among plantation stakeholders. Collaborative research involving agronomists, data scientists, and industry practitioners is also recommended to ensure real-world applicability and scalability.

Author Contributions

Conceptualization, S.K., K.P. and S.P.; methodology, S.K., K.P., S.P., N.S. and W.P.; software, S.K., K.P., S.P., N.S. and W.P.; validation, S.K., K.P. and S.P.; formal analysis, S.K., W.P. and N.S.; investigation, S.K., K.P. and S.P.; resources, S.K., K.P. and S.P.; data curation, W.P. and N.S.; writing—original draft preparation, S.K., K.P., S.P., N.S. and W.P.; writing—review and editing, S.K.; visualization, S.K. and N.S.; supervision, S.K., K.P. and S.P.; project administration, S.K.; funding acquisition, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by National Science, Research and Innovation Fund (NSRF) and Prince of Songkla University (Grant No. SIT6701363S).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in this article. Can contact the corresponding author for query further information.

Acknowledgments

The authors thank Seppo J. Karrila for constructive comments on the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zaki, M.A.M.; Ooi, J.; Ng, W.P.Q.; How, B.S.; Lam, H.L.; Foo, D.C.; Lim, C.H. Impact of industry 4.0 technologies on the oil palm industry: A literature review. Smart Agric. Technol. 2025, 10, 100685. [Google Scholar] [CrossRef]

- Intamano, P.; Gheewala, S.H.; Musikavong, C. Ecological footprint of bio-based diesel under climate change conditions toward sustainable palm oil industry and alternative energy development in Thailand. Sustain. Prod. Consum. 2024, 46, 82–95. [Google Scholar] [CrossRef]

- Leng, K.Y.; Tamilwanan, N. Thailand’s palm oil: Evolving from domestic smallholder centrism to sustainable exports. In Governing the Palm Oil Industry: Perspectives from Southeast Asia and Latin America, 1st ed.; O’Reilly, P., Varkkey, H., Eds.; Routledge: London, UK, 2024; pp. 99–130. [Google Scholar]

- Sarkar, M.S.K.; Begum, R.A.; Pereira, J.J. Impacts of climate change on oil palm production in Malaysia. Environ. Sci. Pollut. Res. 2020, 27, 9760–9770. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2023: Synthesis Report. Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2023. Available online: https://www.ipcc.ch/report/ar6/syr/ (accessed on 1 October 2025).

- Allen, M.R.; Dube, O.P.; Solecki, W.; Aragón-Durand, F.; Cramer, W.; Humphreys, S.; Kainuma, M.; Kala, J.; Mahowald, N.; Mulugetta, Y.; et al. Framing and context. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Masson-Delmotte, V., Zhai, P., Pörtner, H.O., Roberts, O., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2018. [Google Scholar]

- Ahmed, A.; Mohd, Y.B.I.; Abdullah, A.M. Oil palm in the face of climate change: A review of recommendations. IOP Conf. Ser. Earth Environ. Sci. 2021, 646, 012065. [Google Scholar]

- Paterson, R.R.M.; Lima, N. Climate change affecting oil palm agronomy, and oil palm cultivation increasing climate change, require amelioration. Ecol. Evol. 2018, 8, 452–461. [Google Scholar] [CrossRef]

- Teh, C.B.S. Availability, use, and removal of oil palm biomass in Indonesia. Rep. Prep. Int. Counc. Clean Transp. 2016, 2, 1–39. [Google Scholar]

- Shafiq, K.M. The Effect of Rainfall Distribution to Production of Oil Palm in Different Location. 2017. Available online: https://ir.uitm.edu.my/id/eprint/24332/ (accessed on 1 October 2025).

- Abubakar, A.; Ishak, M.Y.; Makmom, A.A. Impacts of and adaptation to climate change on the oil palm in Malaysia: A systematic review. Environ. Sci. Pollut. Res. Int. 2021, 28, 54339–54361. [Google Scholar] [CrossRef]

- Muangprathub, J.; Boonnam, N.; Kajornkasirat, S.; Lekbangpong, N.; Wanichsombat, A.; Nillaor, P. IoT and agriculture data analysis for smart farm. Comput. Electron. Agric. 2019, 156, 467–474. [Google Scholar] [CrossRef]

- Watthanawisuth, N.; Tongrod, N.; Kerdcharoen, T.; Tuantranont, A. Real-time monitoring of GPS-tracking tractor based on ZigBee multi-hop mesh network. In Proceedings of the ECTI-CON2010: The 2010 ECTI International Confernce on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Chiang Mai, Thailand, 19–21 May 2010; IEEE: New York, NY, USA, 2010; pp. 580–583. [Google Scholar]

- Swain, K.C.; Singha, C. Mapping of agriculture farms using GPS and GIS technique for precision farming. Int. J. Agric. Eng. 2018, 11, 269–275. [Google Scholar] [CrossRef]

- Mazhar, R.; Awais, A.; Anand, P.; Seungmin, R. Urban planning and building smart cities based on the Internet of Things using Big Data analytics. Comput. Netw. 2016, 101, 63–80. [Google Scholar]

- Adame, T.; Bel, A.; Carreras, A.; Melia-Segui, J.; Oliver, M.; Pous, R. CUIDATS: An RFID–WSN hybrid monitoring system for smart health care environments. Future Gener. Comput. Syst. 2018, 78, 602–615. [Google Scholar] [CrossRef]

- Mahendran, R.; Tadiboina, S.N.; Thrinath, B.V.S.; Gadgil, A.A.; Madem, S.; Srivastava, Y. Application of Machine Learning and Internet of Things for Identification of Nutrient Deficiencies in Oil Palm. In Proceedings of the International Conferences on Contemporary Computing and Informatics, Uttar Pradesh, India, 14–16 December 2022; pp. 2024–2028. [Google Scholar] [CrossRef]

- Abouelmagd, L.M.; Askr, H.; Darwish, A.; Hassanien, A.E. An Intelligent and Optimized System for Predicting Sustainable Biodiesel Production Using IoT-Based Palm-Oil Trees. BioEnergy Res. 2025, 18, 111. [Google Scholar] [CrossRef]

- Khan, N.; Kamaruddin, M.A.; Sheikh, U.U.; Nawawi, M.; Yusup, Y.; Bakht, M.P.; Noor, N.M. Prediction of Oil Palm Yield Using Machine Learning in the Perspective of Fluctuating Weather and Soil Moisture Conditions: Evaluation of a Generic Workflow. Plants 2022, 13, 1697. [Google Scholar] [CrossRef]

- Ramasenderan, N.; Thiruchelvam, V.; Sivathasan, R.; Ravinchandra, K.; Yahya, A.; Sivanesan, S. Enhancing palm tree oil production through an automated sensory system and IoT monitoring on the Blynk platform. AIP Conf. Proc. 2024, 3161, 020163. [Google Scholar] [CrossRef]

- Anggala, R.; Sutabri, T. Penggunaan Machine Learning untuk Pelayanan Monitoring Kegiatan Pemanenan Kelapa Sawit pada Perusahaan PT BKI SSB. J. Mhs. Kreat. 2024, 2, 57–60. [Google Scholar] [CrossRef]

- Al Mamun, M. IoT-Based Agriculture and Smart Farming: Machine Learning Applications: A Commentary. Deleted J. 2024, 2, 000110. [Google Scholar] [CrossRef]

- Maduranga, M.W.P.; Abeysekera, R. Machine learning applications in iot based agriculture and smart farming: A review. Int. J. Eng. Appl. Sci. Technol. 2020, 4, 24–27. [Google Scholar] [CrossRef]

- Navarro, D.; Foxcroft, D. Correlation and linear regression. In Learning Statistics with Jamovi: A Tutorial for Beginners in Statistical Analysis; Navarro, D., Foxcroft, D., Eds.; Open Book Publishers (OBP): Cambridge, UK, 2025; pp. 255–294. [Google Scholar]

- Chicco, D.; Warrens, M.J.; Jurman, G. The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef]

- Khan, M.R.; Crabbe, R.A.; Malik, N.A.; O’Meara, L. Applications of geospatial technologies for precision agriculture. In Precision Agriculture: Evolution, Insights and Emerging Trends; Zaman, Q., Ed.; Academic Press: Cambridge, MA, USA, 2023; pp. 71–83. [Google Scholar]

- Yousif, A.N.; Ibrahim, H.M. Online Destinations Map using Google Maps API Based on the Private Database. Int. J. Inf. Technol. Comput. Eng. 2023, 3, 35–39. [Google Scholar] [CrossRef]

- Shrivastava, P.; Tewari, V.K.; Gupta, C.; Singh, G. IoT and radio telemetry based wireless engine control and real-time position tracking system for an agricultural tractor. Discov. Internet Things 2023, 3, 6. [Google Scholar] [CrossRef]

- Bayano-Tejero, S.; Márquez-García, F.; Sarri, D.; Sola-Guirado, R.R. Olive yield monitor for small farms based on an instrumented trailer to collect big bags from the ground. Precis. Agric. 2024, 25, 412–429. [Google Scholar] [CrossRef]

- Hitimana, E.; Kuradusenge, M.; Sinayobye, O.J.; Ufitinema, C.; Mukamugema, J.; Murangira, T.; Masabo, E.; Rwibasira, P.; Ingabire, D.A.; Niyonzima, S.; et al. Revolutionizing Coffee Farming: A Mobile App with GPS-Enabled Reporting for Rapid and Accurate On-Site Detection of Coffee Leaf Diseases Using Integrated Deep Learning. Software 2024, 3, 146–168. [Google Scholar] [CrossRef]

- MIT, J.M.J.; Macolado, J.G.; Soberano, K.T.; Librel, N.G., Jr. Agri Demo Farm Mapping with Geoferencing. GASJAHSS 2024, 2, 307–314. [Google Scholar]

- Seminar, K.B.; Imantho, H.; Sudradjat; Yahya, S.; Munir, S.; Kaliana, I.; Mei Haryadi, F.; Noor Baroroh, A.; Supriyanto; Handoyo, G.C.; et al. PreciPalm: An Intelligent System for Calculating Macronutrient Status and Fertilizer Recommendations for Oil Palm on Mineral Soils Based on a Precision Agriculture Approach. Sci. World J. 2024, 2024, 788726. [Google Scholar] [CrossRef]

- Chalvantharan, A.; Lim, C.H.; Ng, D.K.S. Economic Feasibility and Water Footprint Analysis for Smart Irrigation Systems in Palm Oil Industry. Sustainability 2023, 15, 8069. [Google Scholar] [CrossRef]

- Abubakar, A.; Ishak, M.Y. Exploring the intersection of digitalization and sustainability in oil palm production: Challenges, opportunities, and future research agenda. Environ. Sci. Pollut. Res. 2024, 31, 50036–50055. [Google Scholar] [CrossRef]

- Ruslan, A.A.; Salleh, S.M.; Hatta, S.F.W.M.; Sajak, A.A.B. IoT Soil Monitoring based on LoRa Module for Oil Palm Plantation. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 215–220. [Google Scholar] [CrossRef]

- Torasa, C.; Sermsri, N. Development of Water Management System Used IoT in Oil Palm Plantations. Int. J. Emerg. Technol. Adv. Eng. 2023, 13, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Daud, M.; Zulfikar, M.Y.; Hasibuan, A.; Isa, M. Prototype of Automatic Watering and Fertilizing System for Oil Palm Seeds Based on Internet of Things. AJEEET 2023, 3, 1–9. [Google Scholar] [CrossRef]

- Azhar, I.N.; Idris, A.; Wisnujati, N.S.; Sulong, S.M.; Rahindra, H.A. IoT Based Smart Palm Oil Seed Segregator using RGB Color Sensor. J. Adv. Res. Appl. Mech. 2024, 118, 40–53. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).