Abstract

The apparel industry plays a critical role in the global economy but continues to face persistent challenges related to fit accuracy, overproduction, inefficiencies, and limited digital integration. These issues are particularly evident in made-to-measure (MtM) manufacturing, where manual processes, fragmented digital tools, and weak data continuity hinder scalability and sustainability. This study aims to identify the key barriers to MtM 4.0 adoption and propose a digitally integrated workflow capable of supporting efficient, sustainable, and customer-centric apparel production. A systematic review of Industry 4.0 technologies and MtM practices is conducted to structure the problem and derive the requirements for a next-generation workflow. Based on these insights, a three-stage MtM 4.0 workflow (connecting design, product development, and production) is developed and operationalized in a functional prototype, MtM Lusitano 4.0. The prototype integrates a web configurator, a rule-based pattern engine, and ERP/MES connectivity, enabling full digital continuity from customer input to shop-floor execution. Results from industrial deployment confirm functional improvements, including increased measurement accuracy, reduced manual interventions, and stable production release flows. The study concludes that the proposed MtM 4.0 workflow strengthens operational efficiency, supports sustainability goals, and provides a structured pathway for digital transformation in the apparel sector.

1. Introduction

Industry 4.0 (I4.0) marks a new stage in the industrial revolution, driven by innovative technologies [1,2]. The apparel sector views this transformation as essential to its future and is increasingly engaged in exploring its adoption. The integration of emerging and advanced technologies will help companies to achieve sustainability and a market competitive advantage [3]. This sector is usually recognized as a crucial industry, and it is one of the utmost valuable economic sectors [4], since it produces what people want to wear every day or on a specific occasion [5].

An apparel product, from concept to customer, encompasses the entire clothing and fashion industry, including garment manufacturing, yarn and fabric production, and fiber development [6,7]. As a result, the process typically involves three major stages: apparel design, manufacturing, and retailing [5]. These stages are increasingly dependent on technological innovation, with Industry 4.0 technologies (e.g., the Internet of Things (IoT), artificial intelligence (AI), collaborative robotics, smart sensors, big data analytics, virtual and augmented reality, and additive manufacturing (3D printing)) playing a central role in modernizing and integrating operations [8,9]. These technologies support process innovation by enabling real-time data acquisition, advanced analytics, automation of repetitive or labor-intensive tasks, immersive digital prototyping, and on-demand production. Such innovation is crucial to deliver products that meet the evolving needs of consumers [7,8]. While the apparel industry traditionally relied on standardized mass production, driven by trends and forecasted demand, consumer expectations have shifted toward greater variety, immediacy, and personalized offerings [10]. Accordingly, the integration of I4.0 concepts is increasingly recognized as a pathway to achieving higher flexibility, efficiency, and responsiveness in apparel value chains [9].

However, despite the growing relevance of digitalization, there are still difficulties in understanding how to effectively operationalize this integration across clothing manufacturing processes. The literature highlights challenge in planning assembly lines responding to consumers’ increasing demand for differentiation and personalization and adopting advanced technologies at scale [10,11]. Implementing mass customization in apparel production remains complex because different digital technologies affect product type, performance, and quality in distinct ways [10,12]. For example, AI- and big-data-driven pattern optimization can enhance fit accuracy, whereas smart sensors and IoT systems improve process stability and quality control by reducing measurement or stitching deviations. Conversely, low levels of automation or limited digital integration often lead to variability in product quality, longer lead times, and higher operational costs. Product quality is also economically influenced by factors such as material utilization efficiency, rework frequency, defect rates, and the level of manual expertise required during design and production [12]. Although mass customization offers higher perceived value for consumers, the apparel industry remains largely low-tech (particularly in the design phase) where empirical validation is limited, and product-platform design methods still require further development to support ergonomic variation, size adaptability, and reliable fit across diverse body types [12]. Made-to-measure (MtM) is a production method that emphasizes the individual customization in contemporary fashion design [13]. This approach helps reduce overproduction by better aligning production with actual demand [14]. However, it is complex and time-consuming for workers such as managers and operators in assembly lines [15]. Therefore, the integration of advanced technologies can streamline operations and strengthen business models built around MtM and on-demand manufacturing [14]. Indeed, the success of the MtM approach depends on its precision [16]. For example, it is still difficult to define the consumer’s personalized style, fit, and colors [7]. The consumer’s specific body proportions are difficult to consider for the specific definition of the garment. Overall, there are challenges related to the application and the use of advanced technologies in the apparel industry, especially with the MtM approach.

Despite growing attention to digital transformation in the apparel sector, existing studies often remain fragmented, focusing either on individual technologies or on broad strategic implications. Few works address in detail how I4.0 can be effectively integrated into MtM systems, where customization, fit, and sustainability create unique implementation challenges. This gap highlights the need for a structured analysis of the barriers specific to MtM 4.0 and for practical guidance to support its adoption. In this study, transitioning towards MtM 4.0 refers to the progressive adoption of digitally integrated processes (linking configuration, pattern engineering, and production execution) to enable higher precision, responsiveness, and traceability in customized apparel manufacturing. This transition is directly influenced by factors such as measurement accuracy, pattern-to-production consistency, defect and rework levels, material utilization, and lead-time variability, all of which affect both product quality and economic performance.

Accordingly, the objectives of this study are twofold: (i) to identify and systematize the main barriers hindering the successful integration of I4.0 in the apparel industry, with particular emphasis on MtM production methods (the identified barriers are broadly applicable across most apparel segments, as they result from technological fragmentation, low digital maturity, and integration gaps that affect both customized and ready-to-wear processes); (ii) to propose a conceptual workflow that can guide companies in transitioning towards MtM 4.0. To address these objectives, the paper is guided by the following research questions: RQ1—what are the key technological, organizational, and operational barriers to adopting Industry 4.0 in MtM apparel manufacturing? RQ2—how can the challenges to overcome these barriers be structured into a practical workflow that supports managers and researchers in designing MtM 4.0 systems?

This study contributes to the literature by bridging the gap between conceptual discussions of Industry 4.0 and the practical realities of MtM manufacturing. Academically, it systematizes adoption barriers and advances understanding of customization-oriented digital transformation. Practically, it offers a workflow that managers can use as a roadmap to support decision-making, improve operational efficiency, and foster sustainable and consumer-centric apparel production. In addition, the study presents MtM Lusitano 4.0 app, an operational MtM 4.0 prototype that demonstrates the feasibility of implementing this workflow in an industrial context, translating customization principles into real digital capabilities and traceable production execution.

2. Apparel Industry and Made-to-Measure in Industry 4.0 Context

2.1. Apparel Industry Specifics

The apparel industry is usually recognized as a crucial industry for income generation on a global scale [4]. It also represents a large economic activity in the world. This industry is considered to have a complex and extended value chain which can be identified by different companies: (i) fiber manufacturers (raw material supplier); (ii) textile manufacturers; (iii) apparel makers, and (iv) retailers [5,6,7]. As highlighted in the literature, these companies have different attitudes relative to innovation. Fiber manufacturers take into consideration the inclusion of natural fibers and innovative bio-based synthetics in the production of fibers and consider producing recyclable or biodegradable materials [6]. Textile manufacturers are innovating in the precision of cutting, dyeing, and yarning processes to reduce waste in their processes [7]. Apparel maker innovation trends are focusing on the process of apparel design and on the process of apparel assembly—activities such as cutting, sewing, finishing, and packing [5,17]. Achieving a balance between product quality and production cost (an ongoing challenge for producers, distributors, and consumers) depends increasingly on process efficiency, material optimization, and digital integration rather than solely on labor or sourcing costs [8,9].

These companies are spread across different countries and different regions, but the brand-name apparel companies in European and American countries control the fashion trends, the brands, and the distribution channels [18]. These companies’ strategy is centered on offering high-quality products through frequent collections tailored to consumer needs, all at moderately low prices [19]. This strategy is outlined as being highly market-oriented, in a consumer-driven economy, and often based on a ready-to-wear model [20].

Despite the fact that this strategy favors efficiency and cost control, consumers increasingly demand personalized products [8,9] involving the processing of variations in body shapes and sizes; this is difficult to address within standardized systems [17]. Even under recessionary or unstable economic conditions, these personalization trends remain relevant, as MtM 4.0 reduces overproduction and inventory levels, minimizes fabric waste, and improves fit accuracy (factors that directly lower operational costs and strengthen economic resilience). In fact, meeting these personalization expectations requires individualized garments with selected fabrics, styles, and unique measurements tailored to each customer’s need [13,17]. Existing research has primarily examined comfort and garment fit, but less attention has been paid to the way that fit influences the consumer’s body image, which is also a significant purchasing criterion [10]. Indeed, garment fit is the relationship between the consumer’s body and the garment, and its evaluation is a process that should include physical, functional, and visual criteria [21].

The manufacturing system that ensures these personalized solutions is MtM: it satisfies the consumers’ needs by creating custom-designed products based on specific measurements, preferences, and specifications [13]. These evaluations depend on factors such as body scan precision, rule-based pattern generation, material characteristics, sewing accuracy, and customer-defined requirements, which jointly determine whether a garment is perceived as high or low quality. In the design phase, three essential specifications must occur: fit, ergonomics and/or functionality, and image/esthetical design [10,12]. Indeed, a design personalization system must allow consumers to quickly evaluate garments [22]. Additionally, other specifications can be considered, for example, the impact of the garment product on the environment. Consumers are more eco-aware and are willing to pay more for eco-friendly products [3,23].

These needs and trends have a major role in shaping the growth of innovation in every individual attitude, technology, processes, or product [23]. Therefore, more and more, this industry must have a high level of innovation to develop a consumer-technology product in order to deliver the best products on time, achieve the potential value of advanced technologies, and maintain long-term sustainability [3,7,20,24].

Although MtM systems do not allow for traditional mass production, they can still deliver cost reductions and efficiency gains through several other mechanisms. In MtM 4.0, these benefits arise primarily from process efficiency: automated configuration and rule-based pattern generation reduce manual data entry, minimize communication errors, and avoid rework, which together lower operational costs while improving fit accuracy and customer-perceived quality. By aligning production more closely with actual demand, MtM minimizes overproduction and excess inventory (key sources of waste in conventional ready-to-wear models) [14]. Improved garment fit further reduces returns and unsold stock, boosting operational efficiency [15]. Additionally, digital tools (e.g., body scanning, pattern adjustment, and virtual simulation) streamline design and fitting processes, cutting time and labor required for customization [16,17].

More recent studies provide further evidence: Bao et al. [8] showed that novel production line designs can significantly increase efficiency and flexibility in garment manufacturing, which is particularly beneficial for smaller, personalized orders, and Glogar et al. [9] demonstrated that integrating lean manufacturing with I4.0 technologies in fashion helps reduce waste, improve productivity, and bring sustainability benefits without relying on high-volume scale.

Consequently, while the unit cost of MtM garments may remain above that of large-scale mass-produced items, the overall system can still realize cost savings and efficiency improvements across the value chain through reductions in waste, returns, overstock, and non-value-adding activities. Moreover, MtM promotes sustainability via collaborative customization. This means that a smart product requires smart design and smart manufacturing—and thus, understanding how advanced I4.0 technologies can positively impact MtM implementation, as well as what barriers the sector faces, is essential [8,9,14,16].

2.2. Industry 4.0 in Apparel Industry

I4.0 is considered as a model where new forms of production and consumption will intensely transform all major industrial and manufacturing systems [20,25]. It integrates manufacturing system operations with communication, information, and intelligence technologies [26]. Cyber-physical systems (CPSs) meet today’s dynamic production challenges [3,27]. According to these authors, CPSs are based on key technologies (cloud computing, radio-frequency identification (RFID), big data, and Internet of Things (IoT)) [2,28] that enhance the efficiency of the entire industry. Indeed, I4.0 can be differentiated based on its key technologies [29].

Bai et al. [26] stated that I4.0 technologies are considered and grouped into two distinct areas: physical and digital technologies. These technologies seek to overcome the challenges of global competition, volatile markets, technology communication, and information and intelligence [26]. Marshall et al. [30] stated that I4.0 technologies enable large-scale personalization, foster sustainability throughout the supply chain, and enhance efficiency across design, manufacturing, and distribution.

In their systematic literature review, Deepthi and Bansal [25] identified the IoT as the most widely adopted I4.0 technology in the apparel sector, followed by RFID, additive manufacturing, augmented/virtual reality (AR/VR), and AI. They also noted that research on additive manufacturing and AI remains comparatively scarce. Complementing this perspective, Falani et al. [31], through a multi-case study, highlighted system integration and big data as the most relevant technologies driving adoption. From a sustainability standpoint, Bai et al. [26] emphasized that drones represent one of the most sustainable I4.0 solutions in the industry.

A broader analysis of the literature (Table 1) indicates a heterogeneous landscape of technology implementation. IoT emerges as the most consistently reported enabler, reflecting its role in real-time monitoring of production lines, supply chain traceability, and data-driven decision-making within each company or its direct supply chain partners. Big data and analytics, often linked with IoT, are also widely mentioned as essential for handling the large volumes of information generated across design, manufacturing, and retail stages. In contrast, technologies such as blockchain and digital twins appear less frequently, suggesting that they are still at an exploratory or early adoption stage in this industry. Similarly, although additive manufacturing and AI are recognized for their potential to support personalization and design innovation, their limited presence in the literature confirms the observation of Deepthi and Bansal [25] that these fields remain underdeveloped. Finally, more unconventional technologies (e.g., drones, nanotechnology, and QR codes) are rarely reported but are increasingly being discussed for their sustainability and logistics potential.

Table 1.

I4.0 Technologies with potential to be applied in the apparel industry.

Taken together, the evidence shows that while the apparel industry has embraced certain core I4.0 technologies such as IoT, big data, and system integration, the adoption of more advanced or disruptive tools remains fragmented and uneven. This unevenness highlights a critical research and practice gap: technologies with the greatest promise for enabling customization, precision, and sustainability (e.g., AI, additive manufacturing, digital twins) are precisely those least developed in this context. Understanding and addressing this imbalance is therefore central to accelerating the transition towards MtM 4.0. This gap is noted to contextualize technological maturity in the sector, not to evaluate financial return mechanisms.

The integration of I4.0 in the apparel sector extends beyond the mere application of advanced technologies; it represents a systemic transformation of production and value creation models. The literature identifies multiple benefits associated with I4.0 adoption in apparel companies, including more efficient factory operations, enhanced global value chain integration, waste reduction, and decreased physical effort for workers in textile and clothing production [8,9,34,35]. Additional advantages include the availability of advanced business management tools, the promotion of sustainable manufacturing, accelerated innovation, reduced inventory levels, and data-driven decision-making processes. Complementing these outcomes, several defining characteristics of I4.0 in this industry have been reported, such as sustainability, seamless data exchange through networked systems, real-time automation, and the integration of lean manufacturing principles. Other recurrent features are improvements in product and service quality, greater transparency across operations, enhanced adaptability and responsiveness to market dynamics, advanced digitalization, and the capacity to deliver rapid and personalized customization of products and services [3,7,18,26].

Digitalization has been a main driver of change all through the supply chain [18]. Bandara and Senanayake [11] mentioned that manufacturers use real-time data of their sewing assembly lines for monitoring of performance indicators. Hidayatno et al. [29] considered several technologies and provide examples of what can possibly be achieved. For example, the application of AI in knitting processes has been shown to reduce waste by up to 80% through the use of computer-controlled knitting technologies. Similarly, robotics can support automated pattern making, cutting, sewing, and yarn weaving with precise tension control, thereby reducing manual effort and increasing accuracy through the use of virtual stitching software [29]. Also, Monteiro et al. [33] mentioned that AR/VR allows the creation of virtual scenarios, reducing waste, and that additive manufacturing is widely used to make accessories, such as necklaces, earrings, or bracelets, which reduces acquisition costs. In the apparel design process and product development process, several complexities are identified when defining shape, assembly rules, and functional details of real tailored garments [36].

The success of the MtM approach depends largely on precision (i.e., technical accuracy of measurements, pattern derivation, and garment assembly) [16], and several technologies have been introduced to improve system performance. Product platform design and optimization methods have been proposed [12]; however, only a few existing approaches simultaneously integrate aspects such as fit, ergonomics, and body image, as well as production, inventory, and sales considerations [10,12,22]. Advances in data analytics and machine learning offer opportunities to develop data-driven personalization services and enhance consumer experience [10].

To support personalization, virtual try-on systems allow users to evaluate three-dimensional (3D) garment models in real time [22]. Likewise, 3D body scanning plays an important role in obtaining accurate measurements for apparel customization [17]. The integration of 3D laser scanning with CAD software has been applied to virtual design and fit testing [15], and commercial CAD tools such as Gerber AccuMark, Lectra, and Assyst are widely used in MtM. Nevertheless, these tools remain complex and time-consuming, requiring specialized expertise to adjust patterns according to individual measurements [17].

Recent progress in AI and visualization technologies is also noteworthy. Deng et al. [13] demonstrated the generation of high-quality virtual garment images that accurately reflect input drawings and fabrics, thereby improving design efficiency and reuse rates. Consequently, personalized design is increasingly being developed in AR/VR environments [22]. Digital avatars—created through 3D scanning and integrated with CAD—enable the assessment of garment fit and its impact on body image [10]. Experimental studies show that such avatars can provide richer product information than conventional e-catalogs [10,22].

Despite these advances, important limitations remain. As Dove [37] highlights, technological progress in body scanning and virtual fitting rooms often addresses only the final fitting of mass-produced garments, without resolving the fundamental challenges of clothing sizing. Waist measurement, for instance, has been persistently problematic [17,37]. Furthermore, the vast diversity of apparel designs makes it impractical to predefine adjustment rules for all cases [16]. Even so, researchers increasingly recognize AI as a transformative catalyst for enabling true individual customization [5,13].

Taken together, these developments show that while MtM has strong potential, significant technical and operational challenges remain, with implications not only for garment design but also for supply chain management [18]. These unresolved issues highlight the need to systematically identify and address the barriers that hinder the effective implementation of MtM within the broader Industry 4.0 paradigm, which is the focus of the following section.

3. Barriers and Challenges of the Apparel Industry for the Future

Over the years, the apparel industry has undergone significant changes over time [24]. This industry needs updating, and therefore, to keep up with the innovations that arise from the I4.0 paradigm is a big challenge [30]. Through their work, Falani et al. [31] identified that investment in new technologies is a huge challenge. In this way, several barriers are identified by various authors as being related to I4.0 (Table 2). Mim et al. [34] considered that “people in the textile and apparel sectors must develop forward-thinking leadership skills while considering technology and innovation”. Indeed, this industry faces challenges such as efficiency, sustainability, and rapid response to consumers’ dynamic requirements, as well as product quality and regulatory compliance, which are required for its survival [3].

Table 2.

Barriers in the apparel industry in I4.0.

The integration of technology enhances efficiency and customization, engaging consumers through digital and physical products that are individually customized [14]. According to Guo and Istook [17], the “MtM method has not changed too much since it was developed. Improvements could be made to make the process easier.” For example, garment design and manufacturing can be improved in terms of quality and efficiency through the application of AI in material selection, to improve production tasks, and in garment quality control [13]. So, particular challenges can be identified with the deployment of MtM system implementation related to I4.0 (Table 3). The design phase is the most crucial for this system, where it is central to have software for the development of garments associated with the shopping experience on online platforms and considering personalized body image, fit, and ergonomics/functionality [10,12]. For these to operate properly, it is necessary to have digital knowledge to work with new technologies and thus put these issues into practice [14].

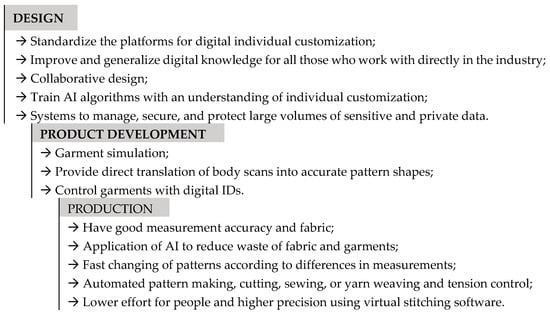

Table 3.

Challenges of MTM 4.0.

4. Conceptual Framework: A Workflow for MtM 4.0

Hillaire and Bayard [36] proposed a workflow of the apparel process from design to production in a 3D digital model. The suggested workflow presents the sequence of steps from design to product development, finishing in production, and establishes a set of rules to create a process that would produce a customized garment with zero defects.

Based on the identified challenges of integration with I4.0, a workflow is proposed. Figure 1 presents the proposed workflow as a roadmap for improvement of MtM in I4.0. It presents the actions to be taken into account in each of the three steps: design, product development, and production.

Figure 1.

Proposed workflow for improvement of MtM in I4.0.

The integration of standardized platforms for digital individual customization can enhance design processes, ensuring accessibility to digital knowledge for all involved. Collaborative design methodologies, supported by AI algorithms trained in individual customization, enable precision-driven personalization. Advanced systems should be implemented to manage, secure, and protect vast amounts of sensitive data. In product development, garment simulation facilitates the direct translation of body scans into accurate pattern shapes, optimizing fit and design. Digital IDs provide precise garment control throughout the production cycle. High measurement accuracy and fabric assessment are prioritized, with AI-driven solutions minimizing material waste. Rapid pattern modifications adapt to varying measurements, enhancing efficiency. Automated pattern making, cutting, sewing, and yarn weaving ensure seamless production with real-time tension control. Virtual stitching software reduces manual effort while increasing precision, redefining garment manufacturing standards.

In contrast to conventional PLM/CAD/MES workflows (typically optimized for standardized ready-to-wear processes and not for individualized production), the proposed model embeds personalization logic, automated pattern derivation, and traceable execution in a unified chain [16,17,36]. Existing I4.0 apparel frameworks also tend to focus on enabling technologies in isolation, such as IoT, simulation, or digital monitoring, without addressing the end-to-end digitalization requirements specific to MtM workflows [25,26]. In detail, our workflow integrates three improvements critical for MtM 4.0 implementation. First, it incorporates precision technologies (AI-driven fit estimation, measurement-to-pattern translation, and simulation accuracy issues raised in Section 2 and Section 3), which are not addressed in existing frameworks. Second, it embeds system-level digital continuity that links configuration, parametric patterning, and production execution through ERP/MES integration, overcoming the interoperability gap identified in the literature. Third, it explicitly incorporates sustainability and traceability mechanisms, responding to industry expectations for circularity and demand-driven production. Therefore, the proposed workflow extends prior MtM and digital design models by systematizing the technological, organizational, and sustainability-oriented requirements necessary for a fully operational MtM 4.0 system.

Overall, following this workflow towards an MtM production system will have positive impact in sustainability, personalization, and operational excellence in the apparel industry.

5. MtM Lusitano 4.0—An Innovative Solution for the Apparel Industry

The barriers, challenges, and technology gaps identified in Section 2 and Section 3—particularly those related to platform integration, precision in pattern generation, and interoperability across the supply chain—highlight the need for practical implementations of MtM solutions within the I4.0 paradigm. The conceptual workflow proposed in Section 4 defines a structured roadmap to enable smart design, product development, and production. Building on this foundation, the MtM Lusitano 4.0 app emerges as an applied research outcome that aims to operationalize these principles in the Portuguese apparel sector.

5.1. Context and Motivation

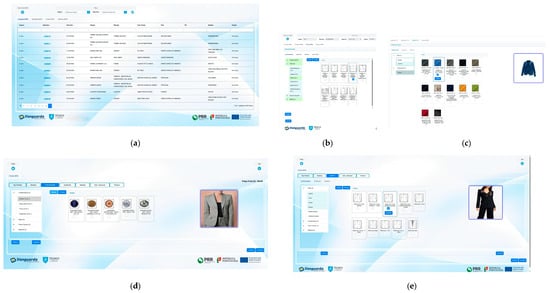

Development of the MtM Lusitano 4.0 app (Figure 2) is integrated in the national industrial mobilizing agenda “Projeto Lusitano”, which focuses on strengthening high-value textile production through digitalization and automation. Responding to the increasing demand for personalized and sustainable products (see Section 2), this module leverages MtM as a strategic differentiator—reducing overproduction, minimizing waste, and fostering competitiveness among Portuguese manufacturers, including SMEs that face several I4.0 adoption barriers (as highlighted in Table 2).

Figure 2.

Digital navigation structure of the MtM Lusitano 4.0 app, with the visualization and configuration interface enabling interactive selection of garment components, styles, and fabrics, combined with 3D preview generation to support precise personalization and consumer decision-makingshowing (a) the production job listing and workflow execution interface supporting traceability and operator guidance in personalized apparel manufacturing; (b) The Customization (“Customização”) Menu of a MTM Request (“Pedido MTM”), with the deployment of the Style (“Estilo”) with several places of the Buttons (“Botões na frente”) to choose; (c) The Customization (“Customização”) Menu of a MTM Request (“Pedido MTM”), with the deployment of the Components-Fabric (“Componentes—Tecido”) with the possibility to see the Details (“Detalhes”); (d,e) The Customization (“Customização”) Menu of a MTM Request (“Pedido MTM”), with the deployment of the Characteristics (“Características”) with several types of Front Pockets (“Bolsos”).

The examples illustrated in Figure 2 and Figure 3 correspond to real usage scenarios implemented in an operating textile–apparel company participating in the Lusitano Agenda. These interfaces reflect the actual execution of the proposed workflow, where customer configuration, parametric pattern derivation, and ERP/MES integration were tested in a production environment. As such, the MtM Lusitano 4.0 app constitutes a concrete operational demonstration of how the three-stage workflow can be applied in industry.

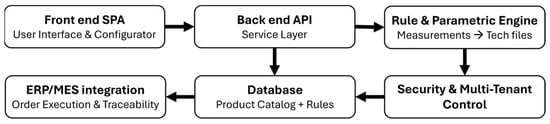

Figure 3.

Functional architecture of the MtM Lusitano 4.0 app, highlighting the integration between the web-based configuration interface, the back end with database and rule/parametric engine, and the interoperability layer with ERP/MES/PLM systems to ensure full digital continuity across the value chain.

Compared with traditional MtM workflows (often dependent on manual pattern adjustments, isolated CAD systems, and fragmented configuration tools) MtM Lusitano 4.0 delivers a unified digital chain that connects customer input directly to production execution. This integration reduces reliance on expert knowledge, enhances pattern accuracy, and eliminates common discontinuities in data and process flow. As such, the prototype demonstrates how an MtM 4.0 system can advance beyond existing digital frameworks in terms of automation, precision, and overall process coherence.

5.2. Functional Architecture and Innovation

This implementation directly responds to the technological, organizational, and operational barriers identified in Section 2, Section 3 and Section 4 by translating the proposed MtM 4.0 workflow into concrete functional modules that improve fit accuracy, reduce manual intervention, and ensure digital continuity across configuration, pattern engineering, and production execution. The solution adopts a cloud-based, modular, and fully web-native architecture designed to align with the digital foundations described in Section 4 (Figure 3):

- Front end: responsive single-page application providing garment configuration, visual feedback (2D/3D), and production tracking.

- Back end: API REST/GraphQL enabling multi-tenant management of product rules, materials, variants, and workflow logic.

- Parametric rule engine: core component translating customer measurements and stylistic selections into automatically generated technical files (BOMs, routing instructions).

- Integration layer: connectors for synchronizing data with ERP/MES/PLM systems, ensuring traceability across design–planning–manufacturing flow.

- Scalability and security:cloud infrastructure with isolated multi-tenant data domains and authentication via OAuth2/SSO.

This architecture directly addresses interoperability constraints and digital knowledge limitations reported in Section 3 (Table 3). The platform incorporates several capabilities to overcome current technological bottlenecks in MtM, enabling personalization at scale while reducing non-value-added activities. In Table 4, a comparison is made of MtM Lusitano 4.0 app features and challenges and needs identified (Section 2.2, Table 3).

Table 4.

MtM Lusitano 4.0 features alignment with identified barriers/challenges.

The purpose of the prototype is not to replicate or replace commercial CAD capabilities but to integrate MtM configuration, rule-based patterning, and ERP/MES execution in a continuous chain—functionalities not jointly supported by AccuMark, Lectra, or Assyst.

5.3. Operational Impact and Sustainability Performance

The MtM Lusitano 4.0 app is designed to generate measurable improvements across both operational efficiency and environmental sustainability, reflecting the benefits associated with I4.0 adoption described in Section 2.2. By digitally linking product configuration to production execution, the platform shortens time-to-order and increases responsiveness to customer demand. The automatic generation of technical files and optimized production routing contributes to higher production accuracy and reduces rework and return rates, improving overall productivity and resource utilization. In addition, fabric waste is minimized through MtM’s demand-driven manufacturing logic, as garments are produced only after customer specification, directly addressing overproduction and inventory inefficiencies that currently affect the apparel sector (Section 2 and Section 3).

Sustainability performance is further strengthened by the capacity to adapt patterns and measurements with precision, supporting size accuracy and thereby reducing the environmental impact associated with disposal of poorly fitting garments. The traceability enabled by ERP/MES integration enhances accountability throughout the product life cycle, paving the way for circular practices such as material recirculation and extended product responsibility, in line with evolving sustainability expectations from both consumers and regulators. Altogether, MtM Lusitano 4.0 app operationalizes the objectives of the workflow proposed in Section 4—delivering an intelligent MtM system aligned with ecological efficiency, customization at scale, and continuous improvement under the I4.0 paradigm.

While existing MtM workflows often rely on manual pattern adjustment, independent CAD tools, or disconnected configuration platforms, MtM Lusitano 4.0 directly operationalizes the improvements proposed in Section 4. By implementing an end-to-end digital chain (from customer input to shop-floor execution), the system reduces dependency on expert knowledge, improves pattern accuracy, and resolves long-standing traceability and integration limitations. Although full quantitative performance assessment (e.g., cycle time reduction, waste reduction, operator time) is still being conducted as part of the ongoing industrial deployment, the prototype has already been validated with real production orders. Observations from these deployment tests confirm functional improvements such as higher measurement accuracy, fewer manual adjustments, and more stable production release sequences, supporting the expected positive impacts highlighted in the workflow. Sustainability performance is further strengthened through the capacity to adapt patterns and measurements with high precision, improving size accuracy and reducing environmental impacts associated with returns and disposal of poorly fitting garments. The digital traceability enabled by ERP/MES integration enhances accountability throughout the product life cycle, facilitating circular practices such as material recirculation and extended product responsibility in alignment with emerging sustainability expectations. Altogether, MtM Lusitano 4.0 serves as empirical evidence of how an MtM 4.0 workflow surpasses traditional digital frameworks in precision, automation, sustainability, and interoperability, fully operationalizing the objectives of the proposed workflow and delivering an intelligent MtM system aligned with ecological efficiency, customization at scale, and continuous improvement under the I4.0 paradigm.

6. Conclusions

The structured literature review demonstrated that MtM adoption is constrained by technological fragmentation across CAD/PLM–MES–ERP systems, insufficient automation of body-to-pattern transformation, high implementation effort for parametric modelling, data security and privacy concerns, and a persistent skills gap in digital and analytics competencies. These findings, as an answer to RQ1, reinforce that MtM demands not only digitalization but coordinated process redesign supported by secure and interoperable infrastructures.

A three-stage workflow (design → product development → production) is proposed, connecting personalization decisions to shop-floor execution in a traceable and waste-minimizing manner. Validated through the MtM Lusitano 4.0 prototype (which integrates a web-based configurator, a parametric rule engine, and ERP/MES connectors), the workflow demonstrates measurable operational and sustainability improvements, including reduced rework and material waste, improved measurement accuracy, and demand-driven production release. Compared with existing MtM and digital process models, the proposed workflow introduces three distinctive advances: (i) a fully integrated digital chain ensuring continuity between design, product development, and production; (ii) the incorporation of precision-oriented technologies such as AI, simulation tools, and digital IDs that directly address the technological and organizational gaps identified in Section 2 and Section 3; and (iii) an operational implementation that shows how these elements collectively reduce waste, improve fit accuracy, and enable scalable personalization. These improvements are not present in current frameworks, which typically treat customization, simulation, and production planning as fragmented processes. Collectively, the results confirm that aligning product configuration with automated technical file generation and traceable production execution enhances operational efficiency, minimizes overproduction and returns, and strengthens sustainability outcomes. The work consolidates fragmented evidence on I4.0 adoption in apparel, clarifies MtM-specific constraints (e.g., measurement, CAD/simulation, integration), and advances a structured workflow that researchers can use as a reference model for MtM 4.0 studies.

The evaluation is constrained by limited quantitative evidence (KPIs such as lead time, fabric yield, return rates) and a lack of longitudinal assessment and of full life cycle or social sustainability analysis.

Future research will focus on completing the quantitative assessment of operational and sustainability indicators as the industrial pilot progresses, enabling a full impact evaluation of the workflow. In addition, although the prototype was initially validated within a single apparel category, its rule-based engine and configuration architecture were intentionally designed to be category-agnostic. Upcoming validation cycles will therefore extend testing to multiple product types (such as formal, casual, and sportswear), allowing a broader assessment of generalizability and strengthening the evidence for applicability across diverse apparel scenarios. Beyond multi-category validation, future work will also advance through multi-site pilots with pre/post quantitative metrics, controlled comparisons against conventional MtM workflows, and comprehensive life cycle and techno-economic assessments. Further methodological developments will explore the integration of digital twins for fit and simulation, standardized data models for enhanced interoperability, and advanced AI techniques to support pattern adjustment and demand-driven production planning. Finally, human-centric evaluations (addressing operator workload, skill development, and consumer body image perception), together with comparative benchmarking of performance and integration efficiency against commercial CAD systems, will provide the complementary empirical evidence required to consolidate the full maturity of the proposed MtM 4.0 framework.

In sum, the paper offers an evidence-based roadmap and a working implementation toward sustainable, consumer-centric MtM 4.0, while outlining the empirical work required to validate and scale these results across diverse apparel contexts.

Author Contributions

Conceptualization, P.P., S.D. and V.C.-M.; Methodology, P.P., S.D. and V.C.-M.; Software, P.S. and P.P.; Validation, P.P. and S.D.; Formal analysis, P.P. and S.D.; Investigation, P.P. and S.D.; Resources, P.S.; Data curation, P.P., S.D. and P.S.; Writing—original draft, P.P. and S.D.; Writing—review & editing, P.P. and S.D.; Supervision, P.P.; Funding acquisition, P.P. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge Fundação para a Ciê ncia e a Tecnologia (FCT) for its financial support via LAETA (project: https://doi.org/10.54499/UID/50022/2025, accessed on 3 September 2025). This work has been supported by the European Union under NextGenerationEU, through a grant of the Portuguese Republic’s Recovery and Resilience Plan (PRR) Partnership Agreement, within the scope of the project “Projeto Lusitano—Agenda Mobilizadora para a Inovação Empresarial da Indústria Têxtil e do Vestuário de Portugal”. The authors acknowledge Fundação para a Ciência e a Tecnologia I.P. for its financial support via the project UID/00667: Unidade de Investigação e Desenvolvimento em Engenharia Mecânica e Industrial.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Paulo Soares is employed by Vanguarda–Soluções de Gestão Lda. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- John, L.; Sampayo, M.; Peças, P. Lean & Green on Industry 4.0 Context—Contribution to Understand L & G Drivers and Design Principles. Int. J. Math. Eng. Manag. Sci. 2021, 6, 1214–1229. [Google Scholar] [CrossRef]

- Peças, P.; Encarnação, J.; Gambôa, M.; Sampayo, M.; Jorge, D. PDCA 4.0: A new conceptual approach for continuous improvement in the industry 4.0 paradigm. Appl. Sci. 2021, 11, 7671. [Google Scholar] [CrossRef]

- Ahmad, S.; Miskon, S.; Alabdan, R.; Tlili, I. Towards sustainable textile and apparel industry: Exploring the role of business intelligence systems in the era of industry 4.0. Sustainability 2020, 12, 2632. [Google Scholar] [CrossRef]

- Kaur, G.; Dey, B.K.; Pandey, P.; Majumder, A.; Gupta, S. A Smart Manufacturing Process for Textile Industry Automation under Uncertainties. Processes 2024, 12, 778. [Google Scholar] [CrossRef]

- Guo, Z.; Wong, W.; Leung, S.; Li, M. Applications of artificial intelligence in the apparel industry: A review. Text. Res. J. 2011, 81, 1871–1892. [Google Scholar] [CrossRef]

- Lorente-Leyva, L.L.; Alemany, M.M.E.; Peluffo-Ordóñez, D.H. A conceptual framework for the operations planning of the textile supply chains: Insights for sustainable and smart planning in uncertain and dynamic contexts. Comput. Ind. Eng. 2024, 187, 109824. [Google Scholar] [CrossRef]

- Caballero-Morales, S.-O.; Cuautle-Gutiérrez, L.; Cordero-Guridi, J.-J.; Alvarez-Tamayo, R.-I. Six-Sigma Reference Model for Industry 4.0 Implementations in Textile SMEs. Sustainability 2023, 15, 12589. [Google Scholar] [CrossRef]

- Bao, N.; Zheng, X.; Fan, Y.; Simeone, A.; Bao, R. Enhancing garment manufacturing efficiency through human-centered scheduling. Prod. Eng. 2025, 19, 885–898. [Google Scholar] [CrossRef]

- Glogar, M.; Petrak, S.; Naglić, M.M. Digital Technologies in the Sustainable Design and Development of Textiles and Clothing—A Literature Review. Sustainability 2025, 17, 1371. [Google Scholar] [CrossRef]

- Li, J.; Su, X.; Liang, J.; Mok, P.Y.; Fan, J. Tailoring Garment Fit for Personalized Body Image Enhancement: Insights from Digital Fitting Research. J. Theor. Appl. Electron. Commer. Res. 2024, 19, 942–957. [Google Scholar] [CrossRef]

- Bandara, D.T.; Senanayake, C. Digital Twin Technology in Apparel Industry: Potential for Rebalancing of Manual Assembly Lines. In Proceedings of the 2024 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 8–10 August 2024; pp. 366–369. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Cimmino, B.; Pinto, P. Towards a mass customization in the fashion industry: An evolutionary decision aid model for apparel product platform design and optimization. Comput. Ind. Eng. 2021, 162, 107742. [Google Scholar] [CrossRef]

- Deng, M.; Liu, Y.; Chen, L. AI-driven innovation in ethnic clothing design: An intersection of machine learning and cultural heritage. Electron. Res. Arch. 2023, 31, 5793–5814. [Google Scholar] [CrossRef]

- Abdelmeguid, A.; Afy-Shararah, M.; Salonitis, K. Towards circular fashion: Management strategies promoting circular behaviour along the value chain. Sustain. Prod. Consum. 2024, 48, 143–156. [Google Scholar] [CrossRef]

- Liu, N.; Chow, P.-S.; Zhao, H. Challenges and critical successful factors for apparel mass customization operations: Recent development and case study. Ann. Oper. Res. 2020, 291, 531–563. [Google Scholar] [CrossRef]

- Wang, H. Rule-free sewing pattern adjustment with precision and efficiency. ACM Trans. Graph. 2018, 37, 1–13. [Google Scholar] [CrossRef]

- Guo, S.; Istook, C.L. Evaluation of 2D CAD Technology for Garments Customized for Body Shape. Fash. Pract. 2023, 15, 136–162. [Google Scholar] [CrossRef]

- Chen, C.-L. Value Creation by SMEs Participating in Global Value Chains under Industry 4.0 Trend: Case Study of Textile Industry in Taiwan. J. Glob. Inf. Technol. Manag. 2019, 22, 120–145. [Google Scholar] [CrossRef]

- Ferreira, D.V.; de Gusmão, A.P.H.; de Almeida, J.A. A multicriteria model for assessing maturity in industry 4.0 context. J. Ind. Inf. Integr. 2024, 38, 100579. [Google Scholar] [CrossRef]

- Bertola, P.; Teunissen, J. Fashion 4.0. Innovating fashion industry through digital transformation. Res. J. Text. Appar. 2018, 22, 352–369. [Google Scholar] [CrossRef]

- Oosterom, E.B.; Baytar, F.; Akdemir, D.; Kalaoglu, F. Predicting consumers’ garment fit satisfactions by using machine learning. AUTEX Res. J. 2024, 24, 20230016. [Google Scholar] [CrossRef]

- Yang, Y.-I.; Yang, C.-K.; Chu, C.-H. A virtual try-on system in augmented reality using RGB-D cameras for footwear personalization. J. Manuf. Syst. 2014, 33, 690–698. [Google Scholar] [CrossRef]

- Sterev, N.; Milusheva, V. Competitiveness of Textile Producers in Digital Business Era. Strateg. Policy Sci. Educ. Strateg. Obraz. Nauchnata Polit. 2024, 32, 29–41. [Google Scholar] [CrossRef]

- Nouinou, H.; Asadollahi-Yazdi, E.; Baret, I.; Nguyen, N.Q.; Terzi, M.; Ouazene, Y.; Yalaoui, F.; Kelly, R. Decision-making in the context of Industry 4.0: Evidence from the textile and clothing industry. J. Clean. Prod. 2023, 391, 136184. [Google Scholar] [CrossRef]

- Deepthi, B.; Bansal, V. Industry 4.0 in Textile and Apparel Industry: A Systematic Literature Review and Bibliometric Analysis of Global Research Trends. Vis. J. Bus. Perspect. 2024, 28, 157–170. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Sampayo, M.; Peças, P. CPSD2: A new approach for cyber-physical systems design and development. J. Ind. Inf. Integr. 2022, 28, 100348. [Google Scholar] [CrossRef]

- Martinho, R.; Lopes, J.; Jorge, D.; de Oliveira, L.C.; Henriques, C.; Peças, P. IoT Based Automatic Diagnosis for Continuous Improvement. Sustainability 2022, 14, 9687. [Google Scholar] [CrossRef]

- Hidayatno, A.; Rahman, I.; Irminanda, K.R. A Conceptualization of Industry 4.0 Adoption on Textile and Clothing Sector in Indonesia. In Proceedings of the 2019 5th International Conference on Industrial and Business Engineering, Hong Kong, China, 27 September 2019; ACM: New York, NY, USA, 2019; pp. 339–343. [Google Scholar] [CrossRef]

- Marshall, J.; Thompson-Whiteside, S.; Jan, T. Barriers to the adoption of industry 4.0 technologies within the Australian fashion industry. Int. J. Fash. Des. Technol. Educ. 2025, 18, 321–331. [Google Scholar] [CrossRef]

- Falani, L.A.; de Aguiar, C.R.L.; Forno, A.J.D. Initial overview of industry 4.0 in textile companies from Santa Catarina. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Sao Paulo, Brazil, 5–8 April 2021; IEOM Society International: Southfield, MI, USA, 2021; pp. 551–562. [Google Scholar] [CrossRef]

- Jahromi, G.S.; Ghazinoory, S. Clothing industry in transition from Industry 4.0 to Industry 5.0. J. Text. Inst. 2025, 116, 365–379. [Google Scholar] [CrossRef]

- Monteiro, R.A.; Junior, D.S.G.; Sobral, E.F.M.; de Barros Falcão, P.H.; de Melo, F.J.C.; Bastos-Filho, C. Global Trends and Practices of Industry 4.0 Applications in the Clothing Sector: A Systematic Literature Review. Adm. Sci. 2024, 14, 258. [Google Scholar] [CrossRef]

- Mim, I.Z.; Rayhan, M.G.S.; Syduzzaman, M. Prospects and current scenario of industry 4.0 in Bangladeshi textile and apparel industry. Heliyon 2024, 10, e32044. [Google Scholar] [CrossRef]

- Van Ta, C.; Jin, B.E.; Cho, H.J. Examining the relationship between firm characteristics and Industry 4.0 technology adoption in Vietnam’s apparel industry. Int. J. Fash. Des. Technol. Educ. 2024, 17, 404–419. [Google Scholar] [CrossRef]

- Hillaire, J.M.; Baytar, F. All-3D apparel development: Establishing the rules to enable 3D weaving from 3D digital garments. J. Eng. Fiber. Fabr. 2024, 19, 1–12. [Google Scholar] [CrossRef]

- Dove, T. Facilitating Teaching and Learning with Made to Measure Fashion Design and Creation MOOC Courses. Int. J. Inf. Educ. Technol. 2020, 10, 792–796. [Google Scholar] [CrossRef]

- Majumdar, A.; Garg, H.; Jain, R. Managing the barriers of Industry 4.0 adoption and implementation in textile and clothing industry: Interpretive structural model and triple helix framework. Comput. Ind. 2021, 125, 103372. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).