Abstract

In 2017, Brazil launched its National Biofuel Policy (RenovaBio) to reduce greenhouse gas emissions from the transportation matrix, aligned with the National Determined Contribution commitments under the Paris Agreement. The authors of this Technical Note formed a working group that structured the methodological framework for RenovaCalc, the computational tool used by producers to quantify the carbon intensity of biofuels certified under RenovaBio. The framework is based on the Life Cycle Assessment approach, in accordance with internationally recognized standards and bioenergy policy guidelines. For the 2025 cycle, 331 production units (75% of Brazil’s total) had their biofuels under certification obtained using RenovaCalc, which is currently available for biodiesel, ethanol, biomethane, and sustainable aviation fuel produced from numerous feedstocks. The calculator is widely adopted and possibly the most important life cycle tool in Brazil.

1. Introduction

Sustainable biofuels are key for achieving a low-carbon transportation sector []. In 2017, Brazil launched its National Biofuel Policy (RenovaBio) [], which was updated in 2024 [], to foster the contribution of biofuels to reducing greenhouse gas (GHG) emissions in the country’s transportation matrix, aligned with the National Determined Contribution commitments under the Paris Agreement [,]. The policy is based on three key instruments: national reduction targets, aiming for a reduction in the overall carbon intensity (CI) of the Brazilian fuels (i.e., amount of life cycle GHG emitted per MJ of fuel); biofuel producer certification; and generation of decarbonization credits (CBIOs).

The GHG emission targets are established annually over a rolling ten-year timeframe. This mechanism ensures predictability for the fuel market and incentivizes gains in biofuel production efficiency and reduction in GHG emissions. The national targets are converted into mandatory individual targets for each liquid fuel distribution company in Brazil, proportional to their market share. Fuel distributors are obliged to reduce their carbon footprint, either by acquiring low-impact biofuels or by purchasing CBIOs [].

The certification involves a rigorous process, where biofuel producers must provide the technical data related to their biomass and biofuel production processes. These data are used to calculate the biofuel’s CI, used as the primary indicator of the environmental performance of certified biofuels. The CI value is then used to estimate the emission reduction (compared with the reference fossil fuel) and the energy-environmental efficiency score (NEEA) (subtraction of the biofuel’s CI from that of the replaced fossil fuel). The informed data and the quantification of CI and NEEA are certified by a third party to provide credibility and transparency for CBIO generation within the policy [].

Lastly, CBIOs are tradable assets generated by biofuel producers, which can be offered for sale on the Brazilian Stock Exchange (B3). The quantity of CBIOs generated is directly proportional to the amount of biofuel produced in accordance with the policy’s eligibility criteria and the producer’s NEEA. Each CBIO represents one metric ton of avoided carbon dioxide equivalent (t CO2e) emissions due to the production and use of biofuels in the country []. The target for 2025, including the missed 2024 target, was set at 49.4 million CBIOs [].

These instruments collectively ensure that RenovaBio is recognized as a market-based policy []. Although participation in the policy is voluntary, 331 plants are under certification to issue CBIOs, representing 75% of all biofuel producers in Brazil [].

Recent studies examined different aspects in the context of RenovaBio, including the CI of biofuels using certified data submitted by producers [,,,], discussions on the policy implementation [,,], and other aspects [,,,]. Although Branco et al. [] described some features of the calculation procedures, no study, to our knowledge, has explored in detail the methods adopted to obtain the life cycle GHG emissions of biofuels under the policy.

The authors of this Technical Note formed the working group that structured the methodological framework of the calculator named RenovaCalc, which was approved by the Brazilian government for producers to obtain the CI of biofuels to be certified. The resulting document describing RenovaCalc [] was submitted to a formal public consultation held by the Brazilian National Agency of Petroleum, Natural Gas, and Biofuels (ANP) and evaluated by specialists in the biofuel field in 2017. However, the document is only available in Brazilian Portuguese and has not been published elsewhere. Therefore, the objective of this Technical Note is to fill this gap by describing the features of the proposed method to allow transparency, usability, and scrutiny by the scientific community.

2. Materials and Methods

2.1. The General Approach

Life Cycle Assessment (LCA) (i.e., method for evaluating the environmental impacts of a product, process, or service from the extraction of raw materials to its final disposal), which is described and standardized in ISO documents [,], is the principal method adopted to calculate the CI of the biofuels certified under RenovaBio. In Brazil, the Brazilian Association of Technical Norms (ABNT) translated and compiled the LCA documents for use within the country [,,,]. While a comprehensive LCA study should comprise a variety of environmental impacts related to the protection of natural resources, ecological systems, and human health, RenovaBio focuses exclusively on the “climate change” category, given the policy’s specific objective of decarbonizing the transport sector.

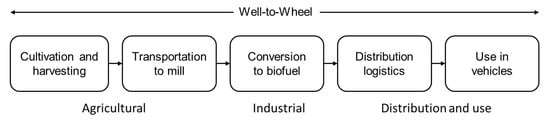

Table 1 summarizes the key features of the method. It considers a Well-to-Wheel (WtW) scope, where energy and materials consumed by productive processes are accounted for from the extraction of natural resources, production and treatment of biomass, industrial conversion, through to the biofuels’ combustion in engines, including the transportation stages along the chain. To treat the co-products, the method adopts the allocation of impacts (i.e., the process of distributing the environmental impacts of a system among its multiple products or functions) considering the energy content (lower heating values (LHVs)) of the outputs, as it appropriately values the most representative multi-output processes from the biofuel refinery types in Brazil (i.e., sugarcane converted to ethanol, sugar, and electricity, and soybean converted to oil, meal, biodiesel, and glycerine). Some features may be changed or updated when new pathways and technologies are submitted to RenovaBio (e.g., bioenergy with carbon capture and storage (BECCS); maritime and aviation fuels), and alignment with existing international protocols (e.g., the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) and the International Maritime Organization (IMO) GHG Strategy).

Table 1.

Key methodological features of the Life Cycle Assessment (LCA) adopted to calculate the carbon intensity of biofuels certified in RenovaBio.

The report “Carbon Accounting for Sustainable Biofuels”, prepared by the International Energy Agency [], presents a comparison summary of policy frameworks, including RenovaBio, the California Low Carbon Fuel Standard (CA-LCFS) [], the EU Renewable Energy Directive (EU RED) [], and CORSIA []. The same reports present a comparative table of the main features of LCA calculators, including RenovaCalc, GREET [], BioGrace [], and GHGenius [].

2.2. Additional Impacts

In addition to the emission factors retrieved from the Ecoinvent database v3.1 [] for the inputs and agricultural operations considered (e.g., the production of fertilizers and fossil fuels), this method takes into account foreground emissions of practices characteristic of biofuel production systems. This includes (i) CO2 emissions from the application of urea and limestone in the field, and direct and indirect N2O emissions from the use of fertilizers and organic residues, adopting the IPCC guidelines []; (ii) CO2 and biogenic CH4 emissions from sugarcane straw burning, using estimates from the GREET model []; and (iii) GHG emissions from fuel combustion in boilers, and trucks and agricultural machinery, using data retrieved from IPCC guidelines [] and The GHG Emissions Assessment Tool []. See Tables S6–S8 and the “Calculation of direct and indirect N2O emissions from IPCC guidelines” section of the Supporting Information (SI) for detailed information regarding numerical values and calculation procedures to obtain such emissions.

2.3. Considerations on Land Use Change

The impacts potentially associated with land use change (LUC) can have significant implications for biofuel sustainability strategies []. However, due to its complex nature, the treatment of LUC impacts in bioenergy policies is considerably variable []. The lack of consensus in the scientific community and the various uncertainties related to its quantitative assessment challenge its proper incorporation in bioenergy and decarbonization policies.

Possibilities to include LUC in the proposed method, considering the quantification of direct (DLUC) and indirect LUC (ILUC) and management strategies, were investigated [,]. As of now, RenovaBio addresses LUC through a risk-based approach, considering three main eligibility criteria: (1) no certification of biofuels made from areas with native vegetation suppression after 2018; (2) Regular Rural Environmental Registries (CAR) of farms where biomass is sourced from, used as proxies for compliance with the Native Vegetation Protection Law; and (3) compliance with the existing agroecological zoning for bioenergy feedstocks, which is currently available for palm oil [,].

These criteria are intended to prevent the most harmful types of LUC—the conversion of areas of native vegetation to produce biofuels or the expansion of cropland into environmentally sensitive areas in Brazil. In addition, these criteria were in line with desirable characteristics for implementation in the first phase of the policy: reduced complexity levels and certification costs for production units, synergies with national land use policies, and capacity for compliance and assimilation by the productive sector. See Table S9 (SI) for detailed information.

2.4. Required Parameters for Calculating Biofuel Carbon Intensity

Figure 1 illustrates the life cycle stages of the WtW scope considered in this method. Accordingly, we compiled a list of parameters required for various biofuel production pathways: ethanol from sugarcane (first-, dedicated second-, and integrated first- and second-generations), ethanol from corn (dedicated and imported), ethanol from both corn and sugarcane (flex), biodiesel from various feedstocks (soybean, palm, cottonseed, and residual oils and fats), sustainable aviation fuel (SAF) from soybean through hydro-processing of esters and fatty acids (HEFA), and biomethane from residues. See Tables S12–S17 (SI) for details on all parameters (i.e., item, description, unit, and recommended verification) for the agricultural and industrial stages required to calculate the CI of biofuels under RenovaBio for each pathway. This type of information is also required and verified during certification.

Figure 1.

Life cycle stages considered in the Well-to-Wheel (WtW) scope.

2.4.1. Agricultural Stage

To characterize the agricultural stage, biofuel producers and biomass suppliers may use either primary data reflecting their actual production systems or predefined (penalized) values. The option of using penalized values was introduced to enable participation in the policy even when complete or precise data are unavailable. These penalized values are based on typical agricultural profiles to which penalty factors have been applied, representing the least favorable conditions observed in the sector. Different penalty factors were assigned according to the agricultural parameter and the type of feedstock.

For the eligibility criteria (see Section 2.2 and Table S9 (SI)) and for the parameters “total area”, “feedstock production”, and “agricultural residues collected” (see Tables S10–S17 (SI)), the policy only allows the use of primary data. For the other required parameters, such as burned area, limestone, gypsum, seeds, synthetic and organic fertilizers, fuels, and electricity use, primary or penalized data can be used.

The required agricultural parameters always refer to the total biomass production area, including areas under soil preparation, planting, cultivation, and harvesting. Annual crops such as soybean and corn complete all these stages within the same area during a single year. Sugarcane, on the other hand, is a semi-perennial crop in which not all operations occur every year. This characteristic affects the values of agricultural parameters—yield, for instance, is typically reported per harvested hectare, and when calculated over the total production area, the resulting value is lower.

In most cases, biofuel plants use a combination of primary and penalized values reported by feedstock producers, because each plant is usually sourced by several farms, owned by different companies. Therefore, biofuel producers who use data partially or entirely based on penalized values overestimate the impacts, compared with those who use solely primary data. This is expected to encourage farmers to report actual primary data for the agricultural stage. As an example, Table 2 presents typical and penalized values for sugarcane production. See Tables S19–S21 (SI) for typical and penalized values for soybean and domestic and imported corn.

Table 2.

Examples of typical and penalized values for sugarcane production.

We recommend caution when conducting studies based on information retrieved from biofuel plants certified under RenovaBio, as the use of penalized values influences the agricultural profiles, which can misrepresent the real conditions. Consequently, this can lead to inaccurate results, especially in studies focused on obtaining the average CI of biofuels produced in the country for comparative purposes. When calculating the life cycle GHG emissions from sugarcane ethanol in Brazil using data from RenovaBio, Liu et al. [] retrieved information from more than 60 certified plants, including a number that reported penalized values for their agricultural stage, but no caveats regarding the type of data used were presented in the paper, whereas Pereira et al. [] managed to filter this information and consider only plants that reported actual primary data.

In addition to penalized values for agricultural inputs, this Technical Note provides fixed values that are specific to herbicides (e.g., glyphosate, sulfentrazone, and diuron) and insecticides (e.g., teflubenzuron and bifenthrin), characteristic of sugarcane and corn production systems. For soybean, fixed values are provided for unspecified pesticides, glyphosate, and 2,4-D. See Tables S22–S24 (SI) for a complete list of pesticides and their corresponding processes in the Ecoinvent database v3.1 []. We also provide a list of the composition of N, P2O5, and K2O elements in chemical fertilizers for consultation in Table S25 (SI).

2.4.2. Industrial Stage

The policy does not provide penalized values for the industrial stage; therefore, producers are required to report primary data on product yields and energy requirements, such as the amount of biomass burned in boilers. Industrial inputs with higher contribution to the biofuels’ CI also need to be informed—such as methanol and ethanol used in biodiesel, or enzymes, sulfuric acid, ammonia, and sodium hydroxide in second-generation ethanol. Nevertheless, data on other inputs are fixed, such as the amounts of calcium oxide, n-hexane, sulfuric acid, and water in sugarcane-based routes, or alpha-, beta-, and gluco-amylases for corn ethanol, since the impacts from these chemicals are generally not significant. See Tables S26 and S27 (SI) for the fixed values considered for the industrial inputs.

2.4.3. Distribution and Use Stages

The information required for the distribution of biofuels in all production pathways refers to the logistics system, consisting of the transportation mode and distances. Producers only need to report the amount of biofuel transported per mode (i.e., road, pipeline, railway, and maritime), but not the distances. Average distribution distances from biofuel plants to fuel stations were previously determined for each biofuel and transportation mode, based on our estimations by considering typical distances between crop production areas, major cities, and ports in Brazil. In case the producer does not have information about the distribution mode of the biofuel, the method will adopt the road logistics system as standard, except for the imported corn ethanol pathway, for which the maritime system should be adopted. See Table S28 (SI) for the composition and average distances of the logistics systems adopted. For the use stage, the framework adopts the emission factors of fuel combustion (e.g., biodiesel, hydrated ethanol, and gasoline) in mobile sources presented in Table S7 (SI).

3. The Calculator (RenovaCalc) and Its Outputs

RenovaCalc is an MS Excel spreadsheet-based calculator designed to standardize and maintain consistency of the method described in this Technical Note by incorporating all necessary factors and databases. The calculator facilitates the entry of required data and parameters by the user (biofuel producer or other stakeholders) through its graphic interface and, ultimately, assists in the RenovaBio certification processes. RenovaCalc’s primary output is the CI of the assessed biofuel, which is used to calculate the emission reduction compared with the fossil fuel of reference (used for transportation) and the NEEA. Moreover, the calculator allows the user to investigate detailed results, such as the individual contribution of agricultural and industrial inputs to the overall impact.

The policy defines that biofuel producers must use RenovaCalc to submit their data and the impact assessment to RenovaBio since 2018. The current versions—v8 for soybean biodiesel and v7 for all other production pathways considered—are available for download on the webpage of the program []. See Figures S1–S3 (SI) for screenshots of RenovaCalc, specifically suited for the assessment of first-generation sugarcane ethanol in Brazil. Table 3 shows the number of certified plants and the average CI and NEEA of the various types of biofuels obtained using the calculator. From 2020 to 2024, the emissions avoided totaled 157.8 Mt CO2e, according to estimates by RenovaBio [], considering the use of biofuels instead of fossil fuels in the country’s transportation mix.

Table 3.

Biofuel plants, carbon intensity (CI), and energy-environmental efficiency score (NEEA) values certified under RenovaBio (as of October 2, 2025) [,].

4. Conclusions

This Technical Note describes the method adopted to calculate the CI of biofuels in the RenovaBio certification process. We addressed important methodological choices, such as treating LUC through a risk-based approach rather than quantitatively assessing its impacts, and the possibility of using penalized values, instead of actual primary data, for the agricultural stage, recognizing the need for improvements in the policy.

For the 2025 cycle, 331 production units (75% of Brazil’s total) had their biofuels under certification obtained using RenovaCalc, which is currently available for biodiesel, ethanol, biomethane, and SAF produced from numerous feedstocks. The calculator is widely adopted and possibly the most important LCA calculator in Brazil, contributing to induce life cycle thinking beyond the bioenergy sector and reduce GHG emissions in the transportation sector.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/su172310442/s1: Table S1: Carbon intensity of fossil fuels and their corresponding biofuel replacements; Table S2: Specific mass and lower heating value (LHV) of fuels; Table S3: Lower heating value (LHV) of non-fuel co-products; Table S4: Inputs and operations considered in RenovaCalc and their corresponding processes in Ecoinvent database v3.1 (2014), unless specified otherwise; Table S5: Greenhouse gas (GHG) emissions from fuel combustion in trucks and agricultural machinery; Table S6: Greenhouse gas (GHG) emissions from the field; Calculation of direct and indirect N2O emissions from IPCC guidelines (2006b); Table S7: Greenhouse gas (GHG) emissions from fuel combustion in mobile sources; Table S8: Greenhouse gas (GHG) emissions from combustion in boilers; Table S9: Criteria of eligibility to the RenovaBio program; Table S10: Parameters for the first-generation sugarcane ethanol pathway; Table S11: Parameters for the dedicated second-generation sugarcane ethanol pathway; Table S12: Parameters for the integrated first- and second-generation sugarcane ethanol pathway; Table S13: Parameters for the dedicated corn ethanol pathway; Table S14: Parameters for the integrated sugarcane and corn ethanol pathway (flex); Table S15: Parameters for the imported corn ethanol pathway; Table S16: Parameters for the biodiesel pathway; Table S17: Parameters for the soybean sustainable aviation fuel (SAF) via hydro-processed esters and fatty acids (HEFAs) pathway; Table S18: Parameters for the biomethane from residues pathway; Table S19: Typical and penalized values for the agricultural stage of soybean production; Table S20: Typical and penalized values for the agricultural stage of corn production; Table S21: Typical and penalized values for the agricultural stage of corn production in the US; Table S22: Fixed values of pesticides for the agricultural stage of sugarcane production and their corresponding processes on Ecoinvent database v3.1 (2014); Table S23: Fixed values of pesticides for the agricultural stage of corn production and their corresponding processes on Ecoinvent database v3.1 (2014); Table S24: Fixed values of pesticides for the agricultural stage of soybean production and their corresponding processes on Ecoinvent database v3.1 (2014); Table S25: Composition of nitrogen (N), phosphorus (P2O5), and potassium (K2O) in chemical fertilizers for consultation; Table S26: Fixed values of industrial inputs used for ethanol production from sugarcane and corn; Table S27: Fixed values of industrial inputs used for biodiesel and sustainable aviation fuel (SAF) production from soybean oil; Table S28: Composition and average distances (in km) of the logistics systems adopted for the biofuel production pathways; Figure S1: Screenshot of RenovaCalc (RENOVACALC_E1GC spreadsheet); Figure S2: Screenshot of RenovaCalc (_E1GC spreadsheet); Figure S3: Screenshot of RenovaCalc (_DADOSAUXILIARES spreadsheet).

Author Contributions

Conceptualization, L.G.P., M.F.C., M.I.S.F., J.E.A.S., R.M.L.N., O.C. and M.A.B.M.; Formal Analysis, L.G.P., M.F.C., N.P.R., M.T.S., J.F.P. and A.L.M.T.P.; Funding Acquisition, M.I.S.F. and M.A.B.M.; Investigation, N.P.R.; Methodology, M.F.C., M.I.S.F., J.E.A.S., M.M.R.M. and R.M.L.N.; Project Administration, M.I.S.F.; Resources, A.M.B. and M.A.B.M.; Software, M.F.C., M.T.S. and J.F.P.; Supervision, M.I.S.F.; Validation, N.P.R. and A.L.M.T.P.; Writing—Original Draft, L.G.P., M.F.C. and M.I.S.F.; Writing—Review and Editing, N.P.R., M.M.R.M., R.M.L.N., A.M.B., O.C., A.L.M.T.P. and M.A.B.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [Financiadora de Estudos e Projetos] grant number [1028—FAPED/CNPMA/FINEP—Renovacalc 01.22.0591.00 (1514/22)].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Materials. Further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors thank Danielle Machado e Silva Conde, Gustavo Bayma, Joana Borges da Rosa, Luiz Fernando de Souza Coelho, Maria Auxiliadora de Arruda Nobre, Marlon Arraes Jardim Leal, Miguel Ivan Lacerda de Oliveira, and Pietro Adamo Sampaio Mendes for their valuable contributions to this study.

Conflicts of Interest

Lucas G. Pereira, Marília I.S. Folegatti, Nilza P. Ramos, Renan M.L. Novaes, and Anna Leticia M.T. Pighinelli are researchers at Embrapa Environment. Mateus F. Chagas and Antonio Bonomi are researchers at the Brazilian Biorenewables National Laboratory (LNBR) of the Brazilian Center for Research in Energy and Materials (CNPEM). Michelle T. Scachetti and Otavio Cavalett are employed by SCS Global Services. Juliana F. Picoli is a researcher at the Center for Sustainability Studies of the Getulio Vargas Foundation (FGVces). Marcelo M.R. Moreira is employed by Agroicone. Marcelo A.B. Morandi is a researcher at Embrapa. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- IEA (International Energy Agency). Delivering Sustainable Fuels: Pathways to 2035; IEA (International Energy Agency): Paris, France, 2025; Available online: https://www.iea.org/reports/delivering-sustainable-fuels (accessed on 25 October 2025).

- Brazil Bill 13,576. Available online: https://www.planalto.gov.br/ccivil_03/_ato2015-2018/2017/lei/l13576.htm (accessed on 25 September 2024).

- Brazil Bill 15,082. Available online: https://legislacao.presidencia.gov.br/atos/?tipo=LEI&numero=15082&ano=2024&ato=457QzaE1UNZpWT7e9 (accessed on 15 February 2025).

- Brazil Nationally Determined Contribution (NDC). Towards Achieving the Objective of the United Nations Framework Convention on Climate Change. Available online: https://unfccc.int/documents/497170 (accessed on 25 September 2024).

- Brazil Nationally Determined Contribution (NDC). National Determination to Contribute and Transform. Available online: https://unfccc.int/sites/default/files/2024-11/Brazil_Second%20Nationally%20Determined%20Contribution%20%28NDC%29_November2024.pdf (accessed on 14 January 2025).

- Brazil RenovaBio. Available online: https://www.gov.br/mme/pt-br/assuntos/secretarias/petroleo-gas-natural-e-biocombustiveis/renovabio-1 (accessed on 17 October 2025).

- ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels. RenovaBio: Individual Targets for 2025; ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels: Rio de Janeiro, Brazil, 2024. Available online: https://www.gov.br/anp/pt-br/assuntos/renovabio/metas-individuais-compulsorias-definitivas-de-reducao-de-emissoes-de-gases-causadores-do-efeito-estufa-para-2025 (accessed on 20 October 2025).

- Aguiar, D.R.D.; Taheripour, F.; Silva, D.A.L. Ethanol Fuel in Brazil: Policies and Carbon Emission Avoidance. Biofuels 2025, 16, 248–258. [Google Scholar] [CrossRef]

- ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels. Certification of Efficient Production or Import of Biofuels; ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Tiburcio, R.S.; de Macêdo, T.R.; Neto, A.M.P. Brazilian Biofuels Policy (RenovaBio): Overview and Generation of Decarbonization Credits by Biodiesel Production Facilities. Energy Sustain. Dev. 2023, 77, 101334. [Google Scholar] [CrossRef]

- Branco, J.E.H.; Prates, R.C.; Oliveira, A.L.D.N.; de Carvalho, A.K.F. Evaluation of the Greenhouse Gas Emissions of the Brazilian Biodiesel and the Impact of the Mandatory Blending of the Biofuel into Commercial Diesel Fuel. Chemosphere 2025, 376, 144268. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Kwon, H.; Wang, M.; O’Connor, D. Life Cycle Greenhouse Gas Emissions of Brazilian Sugar Cane Ethanol Evaluated with the GREET Model Using Data Submitted to RenovaBio. Environ. Sci. Technol. 2023, 57, 11814–11822. [Google Scholar] [CrossRef] [PubMed]

- Pereira, L.G.; Folegatti, M.I.S.; Ramos, N.P.; de Andrade, C.A.; Pighinelli, A.L.M.T.; Galindo, R.; Seabra, J.E.A. Negative Emission Strategies to Reduce the Carbon Intensity of Brazilian Sugarcane Ethanol under RenovaBio. Clean. Energy Syst. 2025, 12, 100208. [Google Scholar] [CrossRef]

- Lazaro, L.L.B.; Grangeia, C.S.; Santos, L.; Giatti, L.L. What Is Green Finance, after All?—Exploring Definitions and Their Implications under the Brazilian Biofuel Policy (RenovaBio). J. Clim. Financ. 2023, 2, 100009. [Google Scholar] [CrossRef]

- Lazaro, L.L.B.; Thomaz, L.F. Stakeholder Participation in the Formulation of Brazilian Biofuel Policy (RenovaBio). Ambient. Soc. 2021, 24. [Google Scholar] [CrossRef]

- Grangeia, C.; Santos, L.; Lazaro, L.L.B. The Brazilian Biofuel Policy (RenovaBio) and Its Uncertainties: An Assessment of Technical, Socioeconomic and Institutional Aspects. Energy Convers. Manag. X 2022, 13, 100156. [Google Scholar] [CrossRef]

- Kim, J.; Thompson, W. Market Effects, Greenhouse Gas Reductions and Costs of Brazil’s RenovaBio Programme. J. Agric. Econ. 2025, 76, 405–417. [Google Scholar] [CrossRef]

- Sica, P.; Marabesi, A.O.; Seleghim, A.R.; Das, K.C.; Baptista, A.S. Effects of Vinasse Concentration on Biogas Production: An Experimental Work and Case Study in the Context of RenovaBio in Brazil. Bioresour. Technol. Rep. 2024, 25, 101698. [Google Scholar] [CrossRef]

- Pereira, L.G.; Ramos, N.P.; Pighinelli, A.L.M.T.; Novaes, R.M.L.; Seabra, J.E.A.; Debiasi, H.; Hirakuri, M.H.; Folegatti, M.I.S. State-Level Inventories and Life Cycle GHG Emissions of Corn, Soybean, and Sugarcane Produced in Brazil. Sustainability 2025, 17, 8482. [Google Scholar] [CrossRef]

- Matsuura, M.I.S.F.; Scachetti, M.T.; Chagas, M.F.; Seabra, J.E.A.; Bonomi, A.M.; Bayma, G.; Picoli, J.F.; Morandi, M.A.B.; Ramos, N.P.; Cavalett, O.; et al. RenovaCalc: Method and Tool to Account for the Carbon Intensity of Biofuels Under the RenovaBio Program. Available online: https://www.gov.br/anp/pt-br/assuntos/consultas-e-audiencias-publicas/consulta-audiencia-publica/2018/arquivos-consultas-e-audiencias-publicas-2018/cap-10-2018/cp10-2018_nota-tecnica-renova-calc.pdf (accessed on 25 October 2025). (In Portuguese)

- ISO 14040:2006; Environmental Management—Life-Cycle Assessment—Principles and Framework. ISO International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 25 October 2025).

- ISO 14044:2006; Environmental Management—Life-Cycle Assessment—Requirements and Guidelines. ISO International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 25 October 2025).

- NBR ISO 14040; Environmental Management: Life Cycle Assessment—Principles and Framework. ABNT Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2014. (In Portuguese)

- NBR ISO 14044; Environmental Management: Life Cycle Assessment: Requirements and Guidelines. ABNT Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2014. (In Portuguese)

- NBR ISO/TS 14067; Greenhouse Gases: Carbon Footprint of Products: Requirements and Guidance on Quantification and Communication. ABNT Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2015. (In Portuguese)

- NBR ISO 14025; Labels and Environmental Declarations: Type III Environmental Declarations: Principles and Procedures. ABNT Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2015. (In Portuguese)

- Ecoinvent. Ecoinvent Database v3.1. Available online: https://support.ecoinvent.org/ecoinvent-version-3.1 (accessed on 28 November 2024).

- IPCC (Intergovernmental Panel on Climate Change). Climate Change 2013—The Physical Science Basis. Fifth Assessment Report (AR5); Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013. [Google Scholar]

- IEA (International Energy Agency). Carbon Accounting for Sustainable Biofuels; IEA (International Energy Agency): Paris, France, 2024; Available online: https://iea.blob.core.windows.net/assets/79f31c02-0efe-41ca-ac15-9d076bf2cd29/CarbonAccountingforSustainableBiofuels.pdf (accessed on 25 October 2025).

- CARB (California Air Resource Board). Low Carbon Fuels Standard; CARB (California Air Resource Board): Sacramento, CA, USA, 2010. Available online: https://ww2.arb.ca.gov/our-work/programs/low-carbon-fuel-standard (accessed on 15 September 2025).

- EU (European Union). Directive 2023/2413; EU (European Union): Brussels, Belgium, 2023; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32023L2413&qid=1699364355105 (accessed on 15 September 2025).

- ICAO (International Civil Aviation Organization). Carbon Offsetting and Reduction Scheme for International Aviation; ICAO (International Civil Aviation Organization): Montreal, Canada, 2016; Available online: https://www.icao.int/CORSIA (accessed on 15 September 2025).

- ANL (Argonne National Laboratory). R&D GREET 2024; ANL (Argonne National Laboratory): Lemont, IL, USA, 2024. Available online: https://greet.anl.gov/index.php?content=greetdotnet (accessed on 12 August 2025).

- EU. BioGrace. Available online: http://www.biograce.net/content/ghgcalculationtools/recognisedtool/ (accessed on 20 April 2025).

- S; T. Squared GHGenius v5.02b. Available online: https://www.ghgenius.ca/ (accessed on 9 February 2024).

- IPCC (Intergovernmental Panel on Climate Change). N2O Emissions from Managed Soils, and CO2 Emissions from Lime and Urea Application, 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006; Chapter 11; Volume 4. [Google Scholar]

- IPCC (Intergovernmental Panel on Climate Change). Stationary Combustion; Gómez, D.R., Watterson, J.D., Americano, B.B., Ha, C., Marland, G., Matsika, E., Namayanga, L.N., Osman-Elasha, B., Saka, J.D.K., Treanton, K., Eds.; IPCC (Intergovernmental Panel on Climate Change): Geneva, Switzerland, 2006; Chapter 2; Volume 2. [Google Scholar]

- FGV Fundação Getúlio Vargas—Center for Sustainability Studies. Brazilian Program of the GHG Protocol. Available online: https://eaesp.fgv.br/centros/centro-estudos-sustentabilidade/projetos/programa-brasileiro-ghg-protocol (accessed on 13 February 2025).

- Calvin, K.; Cowie, A.; Berndes, G.; Arneth, A.; Cherubini, F.; Portugal-Pereira, J.; Grassi, G.; House, J.; Johnson, F.X.; Popp, A.; et al. Bioenergy for Climate Change Mitigation: Scale and Sustainability. GCB Bioenergy 2021, 13, 1346–1371. [Google Scholar] [CrossRef]

- Novaes, R.M.L.; Amaral, D.R.; Morandi, M.A.B.; Folegatti-Matsuura, M.I.S.; Brandão, M. Comment on “The Importance of GHG Emissions from Land Use Change for Biofuels in Brazil: An Assessment for Current and 2030 Scenarios”. Resour. Conserv. Recycl. 2024, 201, 107207. [Google Scholar] [CrossRef]

- Moreira, M.; Novaes, R.M.; Scachetti, M.T.; Chagas, M.F.; Seabra, J.E.A.; Matsuura, M.I.S.; Bonomi, A. Proposal to Account for Land Use Change under the National Policy of Biofuels (RenovaBio). In Proceedings of the VI Brazilian Conference on Life Cycle Management, Brasília, Brazil, 17–20 June 2018. (In Portuguese). [Google Scholar]

- ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels. Resolution 984; ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels: Rio de Janeiro, Brazil, 2025; Available online: https://atosoficiais.com.br/anp/resolucao-n-984-2025-regulamenta-a-certificacao-da-producao-ou-importacao-eficiente-de-biocombustiveis-de-que-trata-o-art-18-da-lei-no-13-576-de-26-de-dezembro-de-2017-e-o-credenciamento-de-firmas-inspetoras?origin=institui (accessed on 25 October 2025).

- ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels. RenovaCalc V7 and V8; ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels: Rio de Janeiro, Brazil, 2022. Available online: https://www.gov.br/anp/pt-br/assuntos/renovabio/arq/renovacalc/ (accessed on 7 October 2025).

- ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels. Dynamic Panel—RenovaBio; ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels: Rio de Janeiro, Brazil, 2022; Available online: https://app.powerbi.com/view?r=eyJrIjoiZTU5NWY0NGYtNzg2OC00NTk5LWI5OTItMTYxMmYxNGI1OTczIiwidCI6IjQ0OTlmNGZmLTI0YTYtNGI0Mi1iN2VmLTEyNGFmY2FkYzkxMyJ9 (accessed on 12 October 2025).

- ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels. Dynamic Panels—Fuel Supply; ANP Brazilian National Agency for Petroleum, Natural Gas, and Biofuels: Rio de Janeiro, Brazil, 2020. Available online: https://www.gov.br/anp/pt-br/centrais-de-conteudo/paineis-dinamicos-da-anp/paineis-dinamicos-do-abastecimento (accessed on 10 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).