Abstract

Sustainable management of Construction and Demolition Waste (CDW) is key to the Circular Economy. Reusing crushed concrete as recycled concrete aggregates (RCAs) in hot-mix asphalt (HMA) is a viable CDW solution, although RCA’s high absorption can affect performance. This study evaluates the effect of partially replacing 0%, 10%, and 30% of virgin aggregate with RCA in a dense-graded HMA, assessing its moisture susceptibility and cracking resistance. Specimens were subjected to long-term water-immersion aging (3 and 6 months at 25 °C) and tested for Indirect Tensile Strength (ITS), Tensile Strength Ratio (TSR), and Cracking Tolerance Index (CT-index). RCA incorporation consistently increased ITS at all aging levels. In particular, the 30% RCA mixtures exhibited the highest strength, exceeding the absolute ITS thresholds required by various U.S. transportation agencies to ensure structural capacity. While TSR values remained below the 80% AASHTO T 283 threshold, 10% and 30% RCA mixes had higher TSR than the control, indicating a comparative improvement in moisture resistance. Conversely, the CT-index decreased with more RCA and longer immersion, particularly at 30% RCA, revealing a trade-off between strength gain and cracking tolerance under prolonged wet exposure. Overall, a 10% RCA replacement level provided the most balanced performance, supporting its technical feasibility for sustainable, performance-based mixture design.

1. Introduction

The transition towards a Circular Economy has emerged as a key strategy to address resource depletion, environmental degradation, and the increasing generation of waste. Within this framework, waste management is closely linked to urban sustainability and resource efficiency. Unlike traditional linear models that extract, use, and discard resources, the Circular Economy promotes continuous use and recovery, seeking to decouple economic growth from environmental damage [1].

Waste management is complex, integrating principles and practices from environmental science, urban planning, geography, economics, and social behavior. Its multidimensional nature demands a systemic approach that articulates technological, policy, spatial, and cultural solutions to optimize resource efficiency, minimize waste, and ensure environmental sustainability [1].

In the construction sector, the growing volume of Construction and Demolition Waste (CDW) represents both a challenge and an opportunity to advance sustainable practices. Proper management enables these wastes to be reincorporated into production through high-quality products, optimizing resource use and retaining material value for longer. This approach significantly reduces CO2 emissions and the amount of waste sent to landfills [2].

Currently, CDW is being reintroduced into the construction industry to reduce waste generated, decrease landfill demand, and mitigate dependence on virgin raw materials. Several countries have implemented strategies to achieve high reuse and recycling rates.

In the European Union (EU), CDW management is regulated by the Waste Framework Directive (WFD 2008/98/EC). In 2016, the EU generated 374 million tons of CDW, achieving an average reuse and recycling rate of 89% among member states [3]. In the United States, according to the Environmental Protection Agency (EPA) 2018 Sustainable Materials Management Fact Sheet, about 600 million tons of debris were generated from construction, renovation, and demolition of buildings, roads, and bridges [4]. Of this total, approximately 67% was hydraulic concrete and 17% asphalt concrete. Nearly 75% of this CDW was reused or recycled—mainly as aggregates for fills or subbases and in new hydraulic and asphalt concretes—while the remaining 25% was landfilled [4].

Conversely, in many developing countries, the transition towards a Circular Economy remains limited, and adequate waste management systems are often lacking. Large metropolitan areas such as Mexico City already face consequences of this deficiency, including restricted landfill capacity and scarcity of natural aggregates. Although regulations have been implemented to improve CDW management, broader impact requires replication of these efforts in other cities.

Despite progress in developed nations, CDW applications remain largely confined to low-value uses—such as fill materials or road subbases—which fail to capitalize on the structural properties that recycled concrete aggregates (RCAs) retain after their first life cycle, including load-bearing capacity, elasticity modulus, and compatibility/adherence with asphalt binder.

Under a Circular Economy approach, promoting CDW utilization as aggregates in hydraulic and asphalt concretes is essential. This strategy not only valorizes waste materials but also supports development of products with enhanced quality and structural performance [2]. Most demolition waste, especially from hydraulic concrete, can be crushed and reused as partial or total substitutes for virgin aggregates. Nevertheless, when incorporating recycled materials into new products, it is essential to ensure that their performance remains comparable to that of products made with natural aggregates [5].

In this regard, recent modifications to European standards now permit the use of recycled aggregates in hydraulic concrete [2]. However, their incorporation into asphalt concrete remains limited despite the wide availability of CDW. Since this waste represents a significant fraction of the total generated, its use as aggregate in asphalt mixtures is a technically viable alternative to reduce accumulation while leveraging its structural properties [2].

1.1. Use of RCA as Aggregate in Asphalt Mixtures

To meet growing traffic demand, especially in fast-developing urban areas, expanding roadway infrastructure is imperative. However, such works entail substantial public investment and one of the most expensive components is the wearing course, typically composed of approximately 95% natural materials (coarse and fine aggregates and mineral filler) and 5% asphalt binder. In this context, stone aggregates constitute the largest-volume input. Partial substitution of virgin aggregates with recycled aggregates can therefore be impactful [5].

Partial replacement of virgin aggregates by recycled concrete aggregates (RCAs) sourced from CDW offers a viable strategy to reduce waste generation, lower consumption of non-renewable resources, and mitigate life-cycle impacts of asphalt mixtures [5]. As concrete structures account for the majority of CDW, recycling hydraulic concrete becomes a strategic alternative for conserving natural resources and reducing energy consumption.

Vega [6] conducted a life-cycle assessment (LCA) to evaluate potential environmental impacts of using recycled concrete aggregates (RCAs) as partial replacement of natural coarse aggregates in hot-mix asphalt (HMA). Results indicated that incorporating up to 30% RCA can be considered an environmentally preferable alternative versus mixtures with 100% virgin aggregates, with reductions across all evaluated impact categories. However, RCA content above 30% increased impact scores due to reduced mechanical performance, which in turn required thicker layers and higher binder contents to compensate for RCA’s elevated absorption.

CDW is processed through controlled crushing in recycling plants to obtain RCA that can be used in multiple construction applications. Nonetheless, several studies report that RCA obtained from crushed concrete exhibits high absorption because of adhered mortar [7,8,9,10,11]. Combined with heterogeneous composition, this can yield variable or even inferior physical and mechanical properties relative to virgin aggregates—e.g., lower bulk specific gravity and poorer Los Angeles abrasion performance—especially when the recycled fraction contains lightweight porous materials such as gypsum, ceramics, mortar, and brick [5]. Pasadín and Pérez [11] observed that, compared with natural aggregates (NAs), RCA shows significantly higher water absorption and slightly lower apparent specific gravity; sand equivalent and Los Angeles abrasion (LA) values were higher for RCA than for virgin aggregates.

Macroscopically, RCA exhibits distinctive morphological features relative to natural aggregates: rougher surfaces, cementitious hues, and more pronounced fine porosity [12]. These attributes are directly associated with adhered cement mortar, whose chemical composition strongly influences reuse. The mortar is primarily composed of hydration products such as calcium-silicate-hydrate (C–S–H), calcium hydroxide (C–H), and ettringite, assuming ordinary Portland cement as the original binder [13]. The residual cementitious phases of RCA, mainly calcium-silicate-hydrate (C–S–H), calcium hydroxide (Ca (OH)2), and ettringite, modify surface polarity and play a crucial role in binder adhesion under wet conditions. Studies employing XRD and SEM–EDS analyses have demonstrated that these hydrated phases may initially enhance asphalt–aggregate bonding through additional cementitious reactivity, thereby improving early adhesion [13,14]. Nevertheless, the same high alkalinity and pore connectivity that favor initial bonding can also promote moisture absorption and hydrolytic degradation during service life, particularly under repeated wetting–drying or freeze–thaw cycles [11,15]. This dual behavior which is beneficial in the short term but detrimental to long-term durability stems from sustained secondary hydration and dissolution of calcium hydroxide within the residual mortar [16,17].

The presence of these compounds in residual mortar therefore offers an opportunity to improve performance of products manufactured with recycled aggregates, since active cementitious components may induce additional hydraulic properties. This potential behavior expands the valorization pathways of RCA in sustainable construction applications, provided that appropriate selection, characterization, and treatment processes are applied [13].

1.2. Effect of RCA on Asphalt Concrete Performance

RCA properties directly influence mixture design, volumetric characteristics, and mechanical performance of asphalt concrete [7]. Understanding how these characteristics affect overall mixture behavior—particularly volumetrics—is therefore essential. Multiple studies have documented these effects [9,10,11], reporting both potential benefits (e.g., improved adhesion and reduced resource use) and limitations (e.g., material variability and moisture sensitivity).

Paranavithana and Mohajerani [8] reported that increasing CDW content decreases key volumetric parameters—density, voids in mineral aggregate (VMA), and voids filled with asphalt (VFA). Complementarily, work at Washington State University [7] showed that optimum binder content tends to increase with recycled aggregates due to their high absorption; both bulk specific gravity (Gmb) and maximum theoretical specific gravity (Gmm) decrease, directly associated with adhered mortar on RCA surfaces.

Mills-Beale and You [9] found that higher CDW contents reduce VMA and increase air voids (Va), attributed to absorption of asphalt binder by RCA pores, which reduces effective binder content. Similarly, Pasadín and Pérez [10] observed that both optimum asphalt binder content and absorption increase with recycled course aggregate percentage, whereas effective binder content slightly decreases. The authors emphasized accounting for adhered mortar absorption, since inadequate design adjustments may overestimate VFA and VMA.

Overall, the literature agrees that recycled aggregates derived from concrete exhibit high absorption due to the presence of residual mortar, directly affecting mixture volumetrics and resulting in higher binder demand compared with mixtures using virgin aggregates [5]. Even so, several studies have shown that asphalt concretes incorporating recycled coarse aggregates can meet technical specifications and even enhance certain mechanical properties [9,10,11]. Pasadín and Pérez [10,11] reported greater stiffness—e.g., increased resilient modulus—at certain incorporation levels and a significant extension of fatigue life. Mixtures with CDW are thus considered viable for low-volume roads, reinforcing their potential in secondary or local infrastructure [16]. The results from studies evaluating the incorporation of recycled concrete aggregates (RCAs) into asphalt mixtures are often contradictory, making it difficult to establish a general behavioral pattern. This ambiguity arises from the highly heterogeneous nature of RCA, as evidenced by its high coefficients of variation. Since performance largely depends on the specific RCA source (including this origin, the quantity and quality of adhered mortar, and crushing process), the findings of individual investigations should be regarded only as reference. Therefore, quantitative results derived from one RCA source should not be numerically extrapolated to recycled aggregates originating from different sources [8,10,11,13,14,17,18,19,20,21,22].

Consequently, incorporating recycled aggregates in asphalt concrete is technically feasible and environmentally favorable, reducing both natural resource consumption and solid waste generation. Implementation, however, requires careful economic assessment, as RCA’s high absorption increases binder demand. Therefore, defining an optimal substitution level is essential to maximize environmental and economic benefits without compromising functional performance or structural integrity over the pavement’s service life.

Moisture Damage and Fatigue Cracking in Hot-Mix Asphalt Pavements

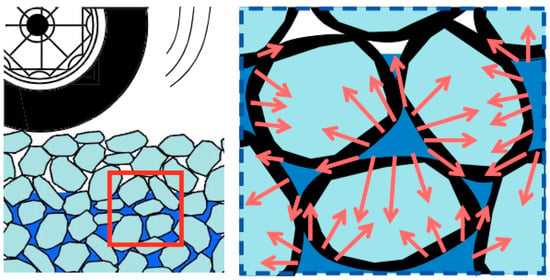

Throughout their service life, asphalt pavements are subjected to combined environmental actions and repeated traffic loading, which progressively reduce structural integrity and commonly manifest as rutting, cracking, and raveling [23]. Moisture damage is defined herein as the deterioration of asphalt mixture performance due to water ingress, arising from debonding at the binder and aggregate interface (adhesive failure) and softening of the mastic (cohesive failure) [24]. As is illustrated in Figure 1, prolonged water infiltration through the interconnected air voids further accelerates this damage, especially under repeated loading, ultimately compromising mixture integrity and hastening structural deterioration [24,25,26]. Stripping, a characteristic surface distress involving aggregate loss in the wearing course due to the combined action of moisture- and traffic-induced dynamic loads, illustrates this process; progressive weakening of the binder film encapsulating aggregates can culminate in structural failure of the pavement [24].

Figure 1.

Key factors influencing moisture-induced damage in asphalt pavements. The schematic illustrates accelerated structural deterioration due to prolonged water infiltration into interconnected air voids, especially under repeated loading [24].

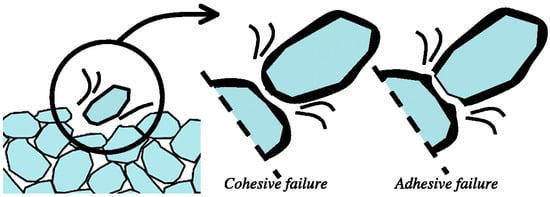

Two principal moisture related failure modes are identified in asphalt mixtures: adhesive failure, when the asphalt film separates from the aggregate surface, and cohesive failure, characterized by internal stiffness loss within the asphalt mastic (the binder and fine aggregate matrix). Both mechanisms markedly affect durability and long-term structural performance (Figure 2). In both modes, adhesion properties at the binder and aggregate interface are decisive for ensuring durability [27]. This consideration is particularly relevant for mixtures incorporating recycled aggregates from CDW, whose rough surface morphology and heterogeneous chemistry can significantly modify the quality of interaction with the asphalt binder.

Figure 2.

Cohesive versus adhesive dislodging of an aggregate from the mix [24].

Under extended water exposure, mixtures incorporating higher contents of RCA exhibit progressive reductions in Indirect Tensile Strength (ITS), Tensile Strength Ratio (TSR), and fracture energy, reflecting increased brittleness and reduced mastic cohesion. This tendency, observed in several long-term water-immersion aging studies, confirms the cumulative effect of hydric exposure on RCA-modified mixtures [28,29,30]. The gradual loss of strength parallels the decrease in fracture energy reported for dense-graded mixtures with high RCA content, indicating that the brittle nature of the residual mortar governs post-fracture behavior [9,28].

Moisture susceptibility in asphalt mixtures is commonly assessed using quantitative mechanical tests that determine the loss of fundamental properties, such as Indirect Tensile Strength (ITS). These reductions, which are directly associated with the presence of moisture, negatively affect structural and functional performance when pavements are exposed to wet or saturated conditions [31].

To formally evaluate the moisture damage resistance of asphalt mixtures, according to Superpave-based criteria, TSR for a new asphalt mixture should be at least 80% to reduce or prevent asphalt binder stripping from the aggregate. However, TSR captures only the post-conditioning loss in strength and may not reflect the absolute structural capacity of the mixture; some asphalt concretes may show high TSR while still exhibiting low absolute tensile strength.

In light of these limitations, numerous transportation authorities across different countries have incorporated supplementary criteria for dense-graded hot-mix asphalt. Typical provisions include compliance with TSR thresholds of 75–80% together with verification of minimum Indirect Tensile Strength (ITS). For illustration, the California Department of Transportation (Caltrans) specifies minimum tensile strengths of 483 kPa for conditioned specimens and 690 kPa for unconditioned specimens [32].

Recent research has examined the mechanical properties and moisture susceptibility of asphalt concrete incorporating recycled aggregates from CDW. Ossa et al. [33] produced mixtures with varying RCA contents using the Superpave methodology and reported that both average and minimum TSR decreased as RCA content increased. The authors concluded that incorporating up to 20% CDW is suitable for urban wearing courses; for higher contents, anti-stripping additives are recommended to mitigate the heightened moisture susceptibility [33].

Similarly, Pasadín and Pérez [10] evaluated Marshall-designed mixtures in which CDW partially replaced natural aggregate. Considering stiffness, permanent deformation, fatigue resistance, and moisture susceptibility, they observed a decrease in ITS with increasing CDW content under both dry and wet conditions. Nevertheless, TSR values for CDW mixtures exceeded those of the control mixture without recycled material, suggesting improved resistance to moisture-induced damage. The authors emphasized that performance depends not only on the CDW characteristics—origin, impurity content, and crushing process—but also on the physicochemical compatibility between the recycled aggregate and the asphalt binder [10].

Other studies [16,28,34] have reported slight increases in ITS for dense- and semi-dense-graded mixtures containing recycled aggregates. This behavior has been attributed to (i) higher binder contents used to compensate for RCA absorption, (ii) the angularity and rough surface texture of recycled aggregates that enhance particle interlock after compaction, and (iii) potential physicochemical interactions at the binder–aggregate interface [16].

Furthermore, Zulkati et al. (2013) noted that calcium oxide (CaO), aluminum oxide (Al2O3), and silica (SiO2) present in recycled aggregates can promote pozzolanic activity within the asphalt mixture, potentially improving binder adhesion by fostering interfacial interactions that strengthen the aggregate–binder bond [35].

On the other hand, fatigue cracking is a consequence of repeated traffic-induced loading (Figure 3). Although mechanical in origin, it is more prevalent at low temperatures, where increased mixture stiffness and brittleness reduce flexibility, so fracture under cyclic loading tends to be a consequence of reduced ductility rather than plastic deformation [36]. Moisture exposure further accelerates fatigue crack initiation by lowering stiffness and interfacial strength. In RCA-based mixtures, this effect is intensified by the porous mortar phase, which retains internal moisture and promotes microcrack coalescence under cyclic stress [13,20,37]. Consequently, pavements containing high RCA proportions exhibit reduced fatigue life, particularly under high groundwater levels or poor drainage conditions where saturation cycles are frequent [19,38]. Initially, fatigue cracks appear as fine, discontinuous surface fissures. With continued traffic, these fissures propagate and interconnect, forming larger cracking patterns. In advanced stages, alligator cracking develops, compromising structural capacity and surface functionality by reducing the integrity of the wearing course, altering profile smoothness, and facilitating the ingress of water and air; over time, these conditions accelerate internal damage, promote pothole formation, and may culminate in structural failure [36].

Figure 3.

Fatigue cracking in asphalt pavements [36].

Recently, fatigue cracking has gained prominence with the incorporation of recycled materials such as RAP (Reclaimed Asphalt Pavement), rejuvenators, and modified binders. Although intended to improve performance, these practices can be associated with increased cracking susceptibility, in part since oxidative aging of the binder is linked to reduced ductility and diminished energy dissipation under cyclic loads [39,40].

To evaluate this susceptibility to cracking, numerous performance-based tests have been developed, with the IDEAL-CT (Indirect Tensile Asphalt Cracking Test) gaining significant acceptance. Notably, due to its strong correlation with field-observed cracking, several Departments of Transportation (DOTs) in the United States have promoted research aimed at proposing preliminary criteria within standardized performance-based testing frameworks. These efforts seek to facilitate quality control through the adoption of IDEAL-CT as a routine quality assurance test. A relevant example is provided by the New Jersey Department of Transportation (NJDOT), which, based on a study correlating different cracking performance tests, proposed minimum CT-index values for mixtures with high RAP content. The specifications require a CT-index greater than 180 for surface courses and greater than 140 for intermediate courses [41]. Similarly, the New York State Department of Transportation (NYSDOT) establishes a minimum CT-index of 134 for these mixtures, while the Pennsylvania Department of Transportation (PennDOT) specifies values ranging from 70 to 90, depending on the traffic level [40].

In line with these agency-based findings, several studies have demonstrated the usefulness of the Cracking Tolerance Index (CT-index) as a reliable parameter for assessing the cracking resistance of conventional asphalt mixtures. Yan et al. [42] compared different IDEAL-CT configurations and reported a strong correlation with the SCB-IFIT fracture index (R2 ≈ 0.97), with CT-index values ranging between 70 and 150 for dense-graded and gap-graded mixtures produced with conventional PG binders, highlighting the sensitivity of the parameter to binder stiffness and gradation. Similarly, Saha Chowdhury et al. [43] confirmed that mixtures exhibiting better fatigue performance also presented higher CT-index values, reinforcing its validity as an indicator of cracking tolerance. More recently, Shaikh and Gupta [41] employed predictive modeling techniques to define threshold CT-index values associated with satisfactory performance, establishing its relevance as an acceptance criterion in asphalt mixture design. Collectively, these studies suggest that CT-index values above approximately 120 may be associated with good cracking performance, whereas lower values tend to reflect reduced resistance to fatigue and thermal cracking.

Field implementation should therefore account for drainage efficiency and site-specific hydrological conditions, including proximity to groundwater and susceptibility to flooding, as these factors significantly intensify moisture-induced aging in RCA mixtures. To mitigate such effects and ensure long-term durability, the use of anti-stripping agents, polymer-modified binders, and optimized volumetric parameters—particularly voids in mineral aggregate (VMA) and voids filled with asphalt (VFA)—is strongly recommended [12,13,25,44]. Moreover, durability evaluation should extend beyond conventional Tensile Strength Ratio (TSR) analysis to include long-term immersion conditioning and fracture-based performance tests, such as the IDEAL-CT and fracture energy (Gf) assessments. These methodologies provide a more comprehensive understanding of moisture-induced damage mechanisms and the progressive loss of cohesive and adhesive integrity in RCA-modified asphalt mixtures [17,18,28].

1.3. Objectives and Scope

This study aims to quantify the effect of replacing virgin aggregates with recycled concrete aggregates (RCAs) from Construction and Demolition Waste (CDW) on the moisture susceptibility and cracking resistance of dense-graded asphalt mixtures. The experimental program evaluates three RCA replacement levels (0%, 10%, and 30% by mass) and subjects compacted specimens to accelerated water-immersion aging at room temperature for three and six months. Within this framework, the study also investigates the influence of exposure duration under wet conditions on key mechanical indicators—Indirect Tensile Strength (ITS), Tensile Strength Ratio (TSR), and Cracking Tolerance Index (CT-index)—to characterize performance variations attributable to prolonged moisture exposure. This approach provides a distinctive means of simulating high groundwater levels and persistently wet environments typical of tropical and humid climates. The resulting findings aim to inform the technical feasibility of incorporating RCA in wearing-course applications while balancing durability requirements with Circular Economy and broader sustainability objectives.

2. Materials and Methods

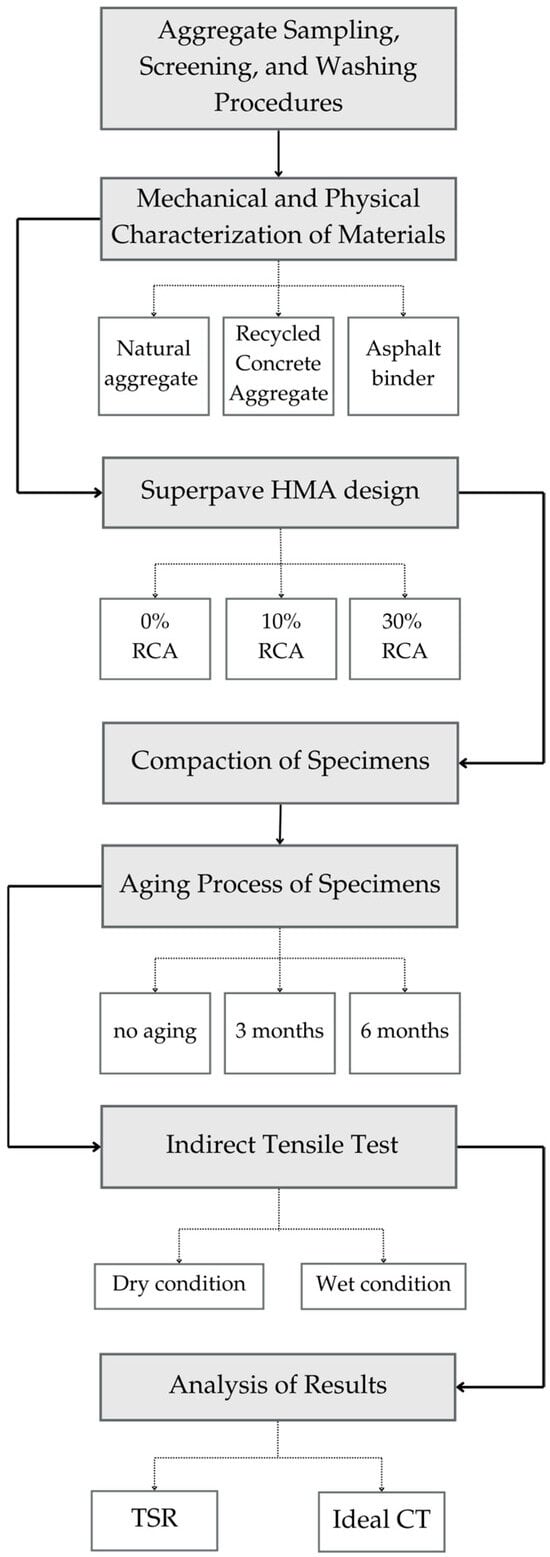

In this study, three dense-graded asphalt mixtures were fabricated using a common aggregate gradation. The single experimental variable was the mass-based replacement of virgin aggregate with recycled concrete aggregates (RCAs) at 0% (control), 10%, and 30%. For the two RCA mixtures, replacement was applied proportionally across all sieve fractions to preserve the target gradation. From the test data, two key indicators were obtained: The Tensile Strength Ratio (TSR), which quantifies the relative strength loss between wet and dry conditions, and the Cracking Tolerance Index (CT-index), derived from the load–displacement response. The overall experimental procedure is summarized in Figure 4.

Figure 4.

Diagram of the methodology used in this study.

2.1. Materials

2.1.1. Aggregates

Two aggregate types were used: a natural vesicular basalt sourced from a quarry located near Mexico City and delivered through a local asphalt plant, and a recycled aggregate obtained from CDW composed mainly of hydraulic concrete fragments from a local waste-processing facility. A single batch of each aggregate type was sourced and used for the entire experimental program to ensure consistency. Both materials were characterized per Superpave for physical and consensus properties (Table 1 and Table 2).

Table 1.

Physical properties of coarse and fine natural aggregates.

Table 2.

Physical properties of coarse and fine recycled concrete aggregates (RCAs).

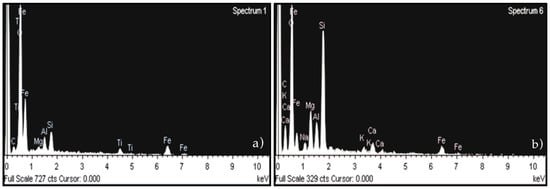

To complement the physical characterization, Energy Dispersive X-ray Spectroscopy (EDS) was conducted to identify and compare the elemental composition of the virgin basalt and RCAs.

The resulting EDS spectrograms for both aggregate types are presented in Figure 5a, b. An interpretation of the mineralogical composition based on these spectra is summarized in Table 3.

Figure 5.

Energy Dispersive X-ray Spectroscopy (EDS) spectra of the aggregates: (a) Virgin aggregate and (b) recycled concrete aggregate (RCA).

Table 3.

Inferred mineralogical composition of aggregates based on EDS elemental analysis.

2.1.2. Asphalt Binder

The PG 64-22 asphalt binder was characterized in terms of rheological and physicochemical properties, as summarized in Table 4.

Table 4.

Physical properties of the asphalt binder.

2.2. Methods

2.2.1. Hot-Mix Asphalt Design

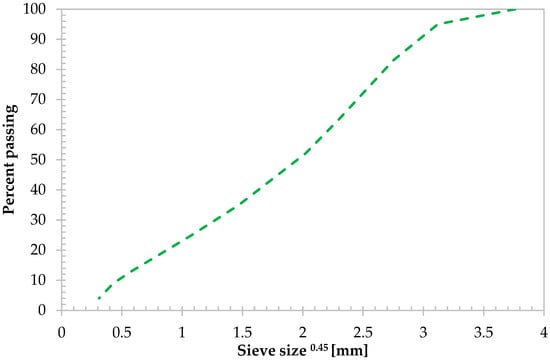

This study adopted the volumetric design from a local paving project, originally formulated to use the mineral aggregates and the asphalt binder described in Section 2.1. The aggregate gradation (Figure 6) corresponds to a dense-graded mixture with a 19.0 mm (¾ in) nominal maximum aggregate size. The optimum asphalt content (OAC) was recalculated for mixtures incorporating 10% and 30% recycled concrete aggregate (RCA) by mass, using the natural aggregate as the base. The OAC was determined by compacting 150-millimeter-diameter × 115-millimeter-high specimens with the Superpave gyratory compactor in accordance with AASHTO T 312 [62], targeting 4.0% air voids at traffic level < ESAL’s < (medium-to-high traffic) design compaction. The mixture produced with 100% natural aggregate is referred to as the control mix, and the RCA variants are denoted 10% RCA and 30% RCA. Volumetric properties of asphalt mixtures are presented in Table 5.

Figure 6.

Aggregate gradation curve.

Table 5.

Volumetric properties of asphalt mixtures with recycled concrete aggregate (RCA).

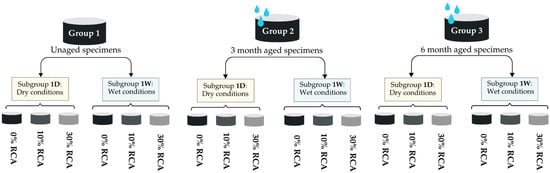

2.2.2. Preparation of Test Specimens

Specimens for Indirect Tensile Strength (ITS) testing were fabricated using a Superpave gyratory compactor (model 5850v2; Troxler Electronic Laboratories, Inc., Research Triangle Park–Durham, NC, EUA), in accordance with AASHTO T 312 (Figure 7). Cylindrical specimens measuring 150 mm in diameter and 95 mm in thickness were fabricated to a target air void content of 7 ± 0.5%, consistent with Superpave criteria for indirect tension evaluations. Specimens were assigned to three water-immersion aging levels at 25 °C (unaged, three months, and six months) and, within each level, were subdivided into wet conditioned and dry (unconditioned) subsets per AASHTO T 283 prior to testing. For each test condition (dry and wet), three replicates were prepared per mixture and aging level, yielding six specimens per mixture and aging combination and 54 specimens in total.

Figure 7.

Specimen compaction.

2.2.3. Moisture Aging

To simulate the effect of prolonged water-immersion aging on mixtures with RCA, compacted specimens were immersed in water at 25 °C for three and six months, and a no-immersion control group was included (Figure 8). PVC rings were used to provide lateral confinement and to ensure uniform immersion (Figure 9). During the immersion phase, water was replaced monthly to maintain stable conditions; no microbial growth was observed, and pH or alkalinity were not monitored. Hereafter, this moisture aging process is referred to simply as “aging”.

Figure 8.

Schematic of aging conditions and specimen testing.

Figure 9.

Moisture aging process.

2.2.4. Specimen Conditioning

After water-immersion aging, specimens were conditioned as described to enable Indirect Tensile Strength (ITS) testing, Tensile Strength Ratio (TSR) calculation in accordance with AASHTO T 283, and IDEAL-CT parameter evaluation. ITS was measured on paired dry and wet sets. Because only a subset of specimens underwent prolonged immersion (3 and 6 months), two wet-conditioning procedures were used:

- Conditioning of unaged specimens:Vacuum saturation at 13 to 17 kPa to a 70 to 80% degree of saturation, followed by freezing at −18 ± 3 °C for at least 16 h and water immersion at 60 ± 1 °C for 24 h. The post-immersion conditioning specified in AASHTO T 283 was applied after the long-term water-immersion stage to ensure methodological consistency between aging levels.

- Conditioning of aged specimens:To ensure the same saturation as the unaged specimens (70–80%), aged specimens were conditioned at 25 °C in a forced-air (convection) oven. Immediately after removal from the immersion bath, each specimen was surface-dried and weighed; specimens were then placed in the oven and re-weighed at intervals until the target saturation was reached. They were subsequently subjected to the same freeze–thaw cycle—freezing at −18 ± 3 °C for 16 h, followed by water immersion at 60 ± 1 °C for 24 h.

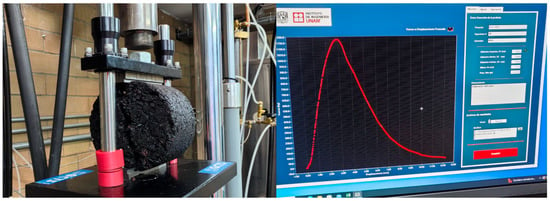

All specimens, wet and dry, were equilibrated to 25 °C for 1 to 2 h before ITS testing. A diametral compressive load was then applied at 50 mm/min using a model 661.21B-02 universal loading frame (MTS Systems Corporation; Minneapolis, MN, USA). Proprietary software developed by the Instituto de Ingeniería, UNAM, was used to control the test and record the load–displacement data for each specimen (Figure 10). The post-immersion conditioning specified in AASHTO T 283 was applied after the long-term water-immersion stage to ensure methodological consistency between aging levels.

Figure 10.

Indirect tensile testing.

2.2.5. Specimen Testing

Evaluation of Moisture Susceptibility in Hot-Mix Asphalt

The Tensile Strength Ratio (TSR) test, standardized as AASHTO T 283, is one of the most widely used methods to evaluate the susceptibility of asphalt mixtures to moisture-induced damage. It quantifies the reduction in Indirect Tensile Strength (ITS) resulting from moisture infiltration and the consequent loss of cohesion and adhesion within the mixture. Such reductions in ITS, which are directly associated with the presence of moisture, negatively affect the structural and functional performance of pavements when exposed to wet or saturated conditions [31]. Originally developed by Lottman (1978) and later refined by Tunnicliff and Root (1982) [63], this procedure was incorporated into the Superpave (Superior Performing Asphalt Pavements) system to ensure adequate durability under adverse environmental conditions [27,31]. In this study, TSR was determined following the general framework of AASHTO T 283 to provide a quantitative indicator of the loss of Indirect Tensile Strength due to moisture damage. The test applies a diametral compressive load at a constant rate of 50 mm min−1 until failure, and the peak load is used to compute ITS, as shown in Equation (1), a fundamental parameter for evaluating moisture-induced loss of mechanical integrity [64]. The resulting TSR values represent the proportion of tensile strength retained after conditioning and therefore reflect the mixture’s ability to maintain mechanical integrity under prolonged wet exposure.

where

- Maximum load (N).

- Specimen thickness (mm).

- Specimen diameter (mm).

Moisture susceptibility is then evaluated by computing the Tensile Strength Ratio (TSR), defined as the percentage ratio between the ITS of conditioned (wet) and unconditioned (dry) specimens (Equation (2)). This parameter quantifies strength loss associated with moisture and is widely used as an acceptance criterion in mixture design [65].

where

- Average ITS of dry specimens (kPa).

- Average ITS of wet specimens (kPa).

2.2.6. Evaluation of Cracking Resistance in Hot-Mix Asphalt Mixtures

To address cracking in asphalt pavements, the National Cooperative Highway Research Program (NCHRP) developed a simple, repeatable, and robust test to evaluate cracking resistance during both the mixture-design phase and production quality control [39]. The IDEAL Cracking Test (IDEAL-CT), standardized as ASTM D8225-19 [66], characterizes cracking behavior within a fracture-mechanics framework.

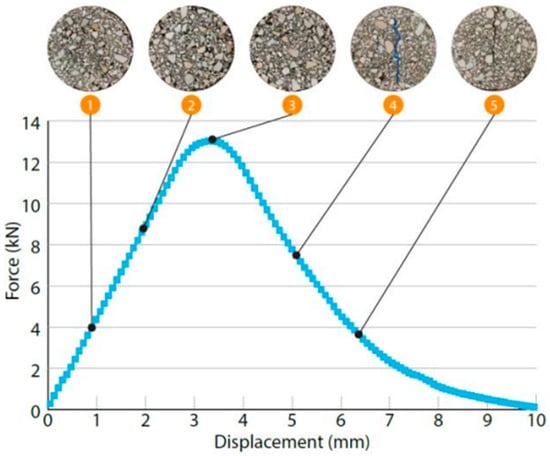

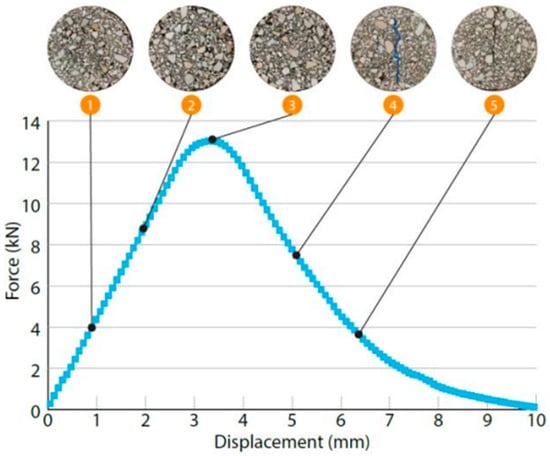

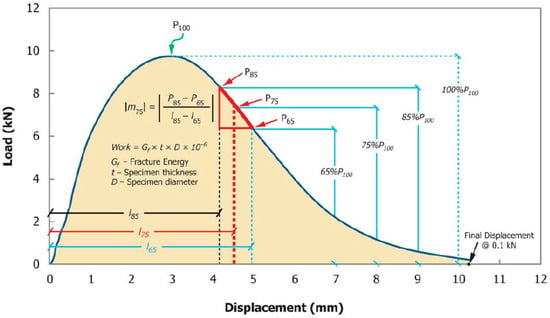

Under the IDEAL-CT protocol, compacted cylindrical specimens are tested in indirect tension (IDT) at 25 °C with a diametral load applied at 50 mm/min. Specimens have a diameter of 150 ± 2 mm and a thickness of either 62 ± 1 mm or 95 ± 1 mm, with target air voids of 7 ± 0.5% [66]. A characteristic load–displacement curve is recorded (Figure 11), typically comprising a pre-peak segment associated with elastic deformation and microcracking, and a post-peak segment associated with fracture and loss of structural integrity. The main parameter is the Cracking Tolerance Index (CT-index), defined in Equation (3) and grounded in fracture mechanics, particularly Paris’ law (Paris and Erdogan, 1963) [67] and crack-growth models by Bažant and Prat (1988) [68].

where

where

Figure 11.

Typical load–displacement curve from an Indirect Tensile Strength (ITS) test illustrating the five stages of the cracking process in asphalt mixtures [39].

- displacement at 75% of the post-peak load relative to maximum load;

- slope of the tangential region around 75% of the post-peak segment (Figure 12);

Figure 12. Recorded load (P) versus load-line displacement (l) curve [66].

Figure 12. Recorded load (P) versus load-line displacement (l) curve [66]. - fracture energy (J/m2).

The critical region for the CT-index occurs in the post-peak segment, specifically near the point of maximum negative slope (Figure 12). For practical calculation, the slope evaluated at 75% of the post-peak load () is adopted [39]. The test also provides fracture energy (), post-peak slope (), and post-peak displacement (l75), which together inform cracking resistance and mixture ductility. The main determinants of CT-index are and the ratio , which characterizes the ductile–brittle response. A shallower post-peak slope (m75) indicates more ductile behavior; a steeper slope indicates brittleness. Likewise, greater post-peak displacement () reflects ductility. Accordingly, increases in l75/m75 lead to higher CT-index [69]. Because IDEAL-CT is sensitive to mixture characteristics—including recycled aggregate content, binder type and dosage, and aging protocol [39]—its use has expanded to RAP mixtures; however, applications to mixtures incorporating RCA remain limited in the literature. Given its strong correlation with field cracking, many road agencies worldwide have promoted research to develop preliminary criteria within standardized, performance-based testing frameworks. These efforts aim to enable routine quality assurance using IDEAL-CT tests. As an example, the New Jersey Department of Transportation (NJDOT) proposed minimum CT-index thresholds for mixtures with high RAP content: greater than 180 for surface courses and greater than 140 for intermediate courses [70].

3. Results

3.1. Load–Displacement Curves

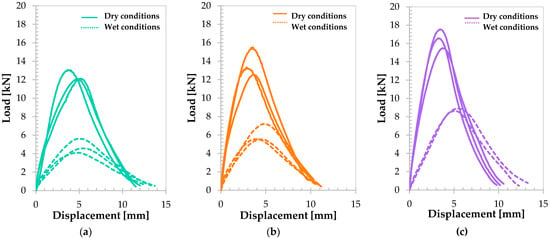

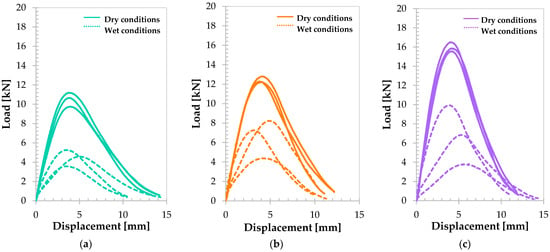

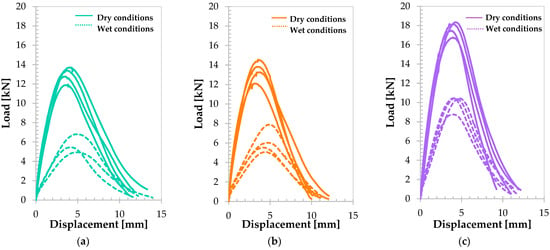

For non-aged specimens (Figure 13), higher RCA contents produced higher peak loads under both wet and dry conditions, indicating that 30% RCA increases load-carrying capacity relative to 10% RCA and 100% virgin mixtures. After three months (Figure 14), the highest peak loads were again observed for the 30% RCA mixtures, indicating that RCA can maintain or even enhance structural performance despite aging. After six months (Figure 15), 30% RCA mixtures continued to achieve the highest peak loads, although the differences relative to 10% RCA and virgin mixtures were small in both wet and dry conditions.

Figure 13.

Load–displacement curves for non-aged specimens: (a) 100% virgin; (b) 10% RCA; (c) 30% RCA.

Figure 14.

Load–displacement curves for specimens aged three months: (a) 100% virgin; (b) 10% RCA; (c) 30% RCA.

Figure 15.

Load–displacement curves for specimens aged six months: (a) 100% virgin; (b) 10% RCA; (c) 30% RCA.

To complement these findings, Table 6 summarizes the average saturation values measured under each experimental condition, both after immersion and prior to testing. These data provide a quantitative basis for evaluating the mixtures’ moisture absorption characteristics. The results indicate that higher RCA contents produced progressively greater saturation levels before testing, reflecting the influence of the recycled aggregate’s intrinsic porosity and residual mortar. It was particularly noted that the “saturation before testing” values for the “dry” specimens remained significantly higher in the 30% RCA group, indicating incomplete desaturation. This trend confirms that recycled concrete aggregates retain internal moisture even after surface drying, due to their fine connected porosity and cementitious microstructure. Consequently, mixtures with higher RCA contents preserve more internal water at equilibrium, which may partly account for their smaller moisture loss and the altered mechanical response observed under repeated wet–dry conditioning cycles.

Table 6.

Specimen saturation levels after immersion and before testing.

The curves exhibit more brittle post-peak behavior in RCA mixtures after prolonged water exposure, as load declines abruptly after the maximum. Accordingly, while RCA may improve initial structural performance, durability under extended wet conditions is a critical consideration. Across all aging levels, wet specimens were more ductile, whereas dry specimens, despite higher peak loads, exhibited distinctly brittle behavior.

3.2. Indirect Tensile Strength (ITS)

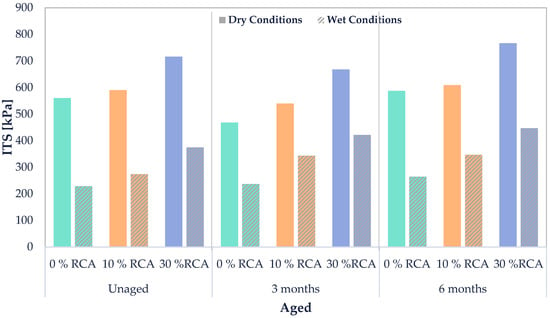

Figure 16 shows the average Indirect Tensile Strength (ITS) values, indicating that ITS increased monotonically with RCA content across all cases, with the highest values consistently observed in mixtures containing 30% RCA, both in non-aged specimens and in those aged for three and six months. In all cases, ITS values were higher under wet conditions.

Figure 16.

Mean Indirect Tensile Strength (ITS) for all analyzed mixtures.

To confirm the trends observed in Figure 15, a three-way Analysis of Variance (ANOVA) was conducted to evaluate the effect of aging time, RCA content, and conditioning type on the Indirect Tensile Strength (ITS) of the mixtures. The analysis was performed with a significance level of α = 0.05, and the results are summarized in Table 7. Prior to the analysis, the model’s assumptions were verified. The Shapiro–Wilk test for normality yielded a p-value of 0.2295, indicating that the residuals were normally distributed. Likewise, Levene’s test for homogeneity of variances resulted in a p-value of 0.6922, confirming that the variances were homogeneous across the groups.

Table 7.

Results of the three-way Analysis of Variance (ANOVA) for ITS values.

The ANOVA results revealed a statistically significant effect of all three main factors: aging time, RCA content, and conditioning type on the ITS values. Among these, conditioning type exhibited the greatest statistical influence according to the corresponding p-values. It is noteworthy that all main effects had a significant impact on the response, indicating that longer aging periods and higher RCA contents led to increased ITS values. In contrast, no significant interactions were found among the factors, suggesting that the effect of each operates independently.

Given the significance of the main effects and the absence of interactions, a post hoc Tukey Honest Significant Difference (HSD) test was performed to identify specific differences among the factor levels (Table 8). This analysis confirmed that mixtures containing 30% RCA exhibited significantly higher ITS values compared with those containing 0% and 10% RCA.

Table 8.

Post hoc multiple comparisons (Tukey HSD) for significant main effects.

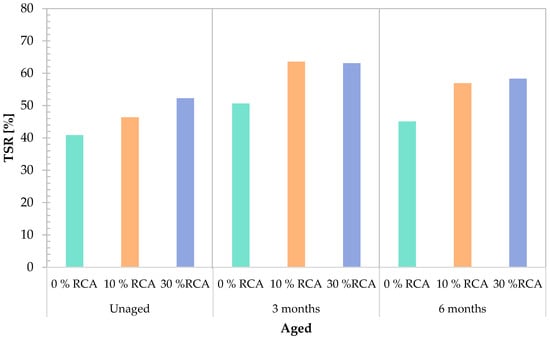

3.3. Tensile Strength Ratio (TSR)

Figure 17 shows average TSR values. In non-aged specimens, TSR increased modestly with RCA content. After three months, TSR values were higher than those of the non-aged specimens regardless of mixture, with 10% and 30% RCA showing similar TSR and both exceeding the virgin mixture. In contrast, after six months, TSR decreased relative to the three-month values, likely because wet-condition ITS remained nearly constant after aging, whereas dry-condition ITS continued to increase with RCA content and exposure time, thereby widening the dry–wet gap and lowering TSR under prolonged aging. Nonetheless, 10% and 30% RCA mixtures maintained comparable TSR, consistently higher than the virgin mixture.

Figure 17.

TSR values obtained for all asphalt mixtures analyzed.

To evaluate the effects of RCA content and aging time on the Tensile Strength Ratio (TSR) values, a two-way analysis of variance (ANOVA) was performed at a significance level of α = 0.05. The results of the analysis are presented in Table 9.

Table 9.

Results of the two-way Analysis of Variance (ANOVA) for TSR.

Prior to conducting the ANOVA, model assumptions were verified. The Shapiro–Wilk normality test yielded a p-value of 0.655, indicating that the residuals followed a normal distribution.

The ANOVA results showed that aging time did not have a statistically significant effect at the 0.05 significance level, whereas RCA content exhibited a significant influence on TSR values. According to the analysis, RCA content was identified as the most influential factor.

Since the effect of RCA content was significant, a post hoc Tukey Honest Significant Difference (HSD) test was conducted to determine which groups differed from each other (Table 10). The analysis indicated that mixtures containing 30% RCA had significantly higher TSR values than those with 0% RCA.

Table 10.

Post hoc multiple comparisons (Tukey HSD) for RCA Percentage on TSR.

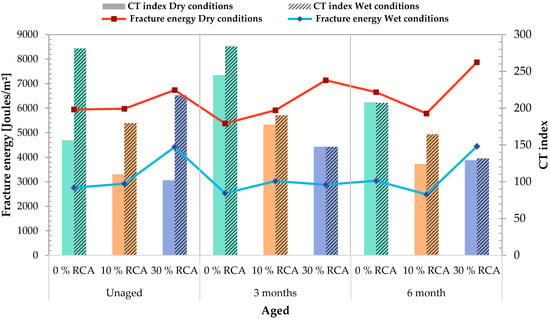

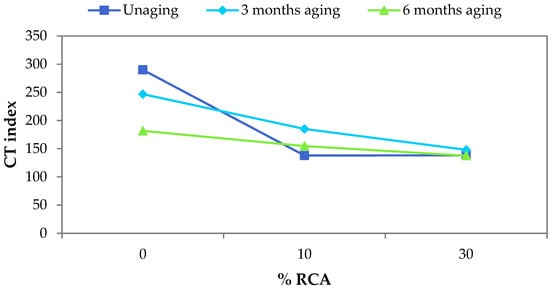

3.4. Cracking Tolerance Index (CT-Index)

CT-index values, together with average fracture energy, are presented in Figure 18. RCA increased peak load and fracture energy under both dry and wet conditions. However, CT-index declined significantly after prolonged moisture exposure, particularly for 30% RCA mixtures, indicating increased susceptibility to cracking under wet conditions. The load–displacement curves corroborate that extended moisture exposure promotes more brittle responses in both dry and wet tests; notably, 30% RCA mixtures exhibited the lowest CT-index after six months.

Figure 18.

Mean CT-index and fracture energy values for all asphalt mixtures analyzed.

To confirm the trends observed in Figure 18, a three-way Analysis of Variance (ANOVA) was conducted to evaluate the influence of different factors on the Cracking Tolerance Index (CT-index) values. The results are presented in Table 11. Prior to the analysis, model assumptions were verified. The Shapiro–Wilk normality test indicated that the residuals followed a normal distribution, while Levene’s test confirmed that variances were homogeneous across groups.

Table 11.

Results of the three-way Analysis of Variance (ANOVA) for CT-index.

The ANOVA results showed that all main effects aging time (p < 0.0001), RCA content (p < 0.0001), and conditioning type (p = 0.0014) were statistically significant, demonstrating that each factor individually exerts a significant influence on CT-index values.

A significant interaction between aging time and RCA content was also observed, indicating that the CT-index behavior results from the combined effect of both factors. Increasing RCA content tends to markedly reduce CT-index values in unaged mixtures, while this effect becomes less pronounced in aged specimens. Due to this significant interaction, the factors cannot be interpreted independently; therefore, their combined behavior was analyzed through an interaction plot (Figure 19), which presents the average CT-index values for different RCA contents and aging times.

Figure 19.

Interaction between RCA content and aging time on Cracking Tolerance Index (CT-index) values.

Three key observations can be drawn from the interaction plot (Figure 18). In specimens with 100% virgin aggregate, increasing the aging time leads to a decrease in CT-index values, indicating reduced cracking resistance. A greater negative impact is associated with RCA incorporation than with the aging process itself. In unaged specimens, the addition of any amount of RCA lowers the CT-index, resulting in values even lower than those recorded for aged specimens containing the same RCA content (10%). In specimens with 30% RCA, the initial differences caused by aging become insignificant; CT-index values remain nearly constant across all aging levels and are considerably lower than those of mixtures without RCA.

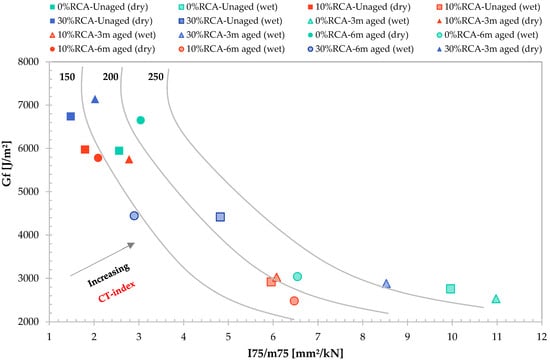

3.5. CT-Index, Gf-Versus-l75/m75 Interaction Diagram

The CT-index, Gf-versus-l75/m75 interaction diagram (Figure 20) supports interpretation of IDEAL-CT outcomes in terms of strength and ductile–brittle behavior and their implications for cracking resistance [71]. Fracture energy (Gf) is plotted on the Y-axis and the ductility parameter (l75/m75) on the X-axis; contour lines map CT-index values to combinations of Gf and l75/m75. Higher CT-index values occupy the upper-right region, while the diagram simultaneously displays Gf and l75/m75 for each point.

Figure 20.

CT-index, Gf-versus-l75/m75 interaction diagram.

4. Discussion

4.1. Load–Displacement Curves

Load–displacement responses revealed significant differences between dry and wet conditions. Generally, specimens tested in wet conditions exhibited a more ductile response after the peak load regardless of RCA content, whereas specimens tested in dry conditions showed abrupt drops after the peak that indicate immediate fracture. This behavior was consistent in unaged mixtures and in mixtures aged for three months, implying that RCA incorporation does not materially change the failure mode compared with virgin mixtures under these exposure times. However, after six months, mixtures with 30% RCA (Figure 14c) displayed predominantly brittle behavior in both dry and wet conditions. The previously observed differences between test conditions narrowed, and failure became predominantly brittle across mixtures, suggesting that prolonged moisture exposure can compromise mechanical integrity in mixtures with high RCA contents.

4.2. Indirect Tensile Strength (ITS)

ITS increased with increasing RCA content regardless of aging time and test condition. This behavior is plausibly attributed to the presence of fine particles with cementitious potential in RCA. During immersion aging, these particles hydrate, thereby activating cementitious properties and contributing to strengthening of the internal structure. ITS also rose with aging time, indicating that prolonged moisture exposure may enhance mechanical response through hydration-related mechanisms, which underscores the potential of recycled materials not only as substitutes for natural aggregates but also as active constituents for durability improvement.

This behavior is attributable to the distinct chemical composition of the RCA, which was confirmed by the Energy Dispersive X-ray Spectroscopy (EDS) analysis. The interpretation of the spectra revealed a notable presence of Ca, Mg, C, and O, corresponding to alkaline–carbonate phases from the residual cement paste and carbonated mortars contained in these aggregates. These alkaline phases are known to provide higher surface reactivity and improved acid–base compatibility with the typically acidic asphalt binders. Furthermore, the EDS results also identified siliceous domains rich in quartz, occasionally of nearly pure SiO2. This component has direct implications for the performance of the mastic and the asphalt mixture, as it imparts rigidity, thereby explaining the observed increase in ITS with the incorporation of RCA.

It is important to note that although moderate incorporation of RCA improved tensile strength due to the residual cementitious activity of adhered mortar and enhanced binder absorption, using 100% RCA would likely have the opposite effect. A full substitution of virgin aggregates would increase the overall porosity of the mixture, reduce binder film thickness, and promote premature moisture ingress. According to Pasandin and Pérez (2017) [11] and Mikhailenko (2020) [28], mixtures produced entirely with RCA will tend to exhibit lower durability and reduced binder efficiency, mainly due to the weaker mechanical integrity of the attached mortar and the Shigher heterogeneity of the recycled aggregates.

Notably, specimens tested under dry conditions and with higher RCA contents satisfied the minimum requirements established by several U.S. Departments of Transportation, including Caltrans, both in aged samples and in those not subjected to aging. In contrast, specimens without RCA and those with only 10% replacement exhibited values below the required thresholds. Importantly, the minimum values prescribed by these specifications were originally defined for specimens not exposed to water-immersion aging applied in this study.

4.3. Tensile Strength Ratio (TSR)

Although all mixtures fell short of the AASHTO T 283 threshold of 80%, those incorporating RCA consistently achieved higher TSR than the control mixture under both unaged and aged conditions, indicating comparatively lower moisture susceptibility. It is important to note that the control mixture was not designed by the authors; it corresponds to a project mixture adopted as a reference. However, to meet the AASHTO threshold, the control mix would likely require mix-design modifications and/or the use of anti-stripping additives to enhance moisture tolerance.

4.4. Cracking Tolerance Index (CT-Index)

Fracture energy (Gf) and peak load were consistently higher in specimens tested in dry conditions than in specimens tested in wet conditions, reflecting a reduced capacity to sustain maximum loads in the presence of moisture. Nevertheless, specimens tested in wet conditions exhibited higher CT-index values, indicative of greater deformability after the peak load, whereas specimens tested in dry conditions, despite higher strength, demonstrated a more brittle response. After prolonged moisture exposure, CT-index in specimens tested in wet conditions declined markedly, particularly for 30% RCA, approaching the values of specimens tested in dry conditions, thereby evidencing increased cracking susceptibility under extended wet conditions.

In this study, control specimens (without RCA) demonstrated acceptable CT-index values for both surface and intermediate courses, satisfying the criteria for high-RAP content mixes from NJDOT, NYSDOT, and PennDOT. The introduction of RCA, however, detrimentally affected this parameter, a reduction that was more pronounced at higher RCA concentrations and after long-term moisture exposure. As a result, the RCA-modified mixtures failed to meet the more stringent requirements of the New York and New Jersey DOTs, although they did comply with the thresholds established by the Pennsylvania DOT.

4.5. CT-Index, Gf-Versus-l75/m75 Interaction Diagram

The interaction diagram indicates that the highest CT-index values occur in specimens tested in wet conditions, albeit with low fracture energy due to lower peak loads. Conversely, the highest Gf values are observed in specimens tested in dry conditions; despite their high energy, their CT-index is low owing to brittle behavior after the peak. Points with higher Gf often coincide with low l75/m75, which is consistent with higher ITS observed at greater RCA contents and longer aging, trends that are plausibly linked to hydration of cementitious particles. Yet, the increased strength is accompanied by greater brittleness, as specimens tend to fail abruptly after the peak.

5. Conclusions

In this experimental study, incorporating recycled concrete aggregates (RCAs) from Construction and Demolition Waste (CDW) consistently increased the Indirect Tensile Strength (ITS) of asphalt mixtures across all aging conditions, with the highest values observed in mixtures containing 30% RCA, both in non-aged specimens and in those aged for three and six months. This outcome is likely due to the residual cementitious activity of fine RCA particles activated during immersion, plausibly attributed to secondary hydration during immersion aging. The interpretation of the Energy Dispersive X-ray Spectroscopy (EDS) analysis confirmed the distinct chemical composition of the RCA, revealing a notable presence of Ca, Mg, C, and O, corresponding to alkaline–carbonate phases. Although Tensile Strength Ratio (TSR) values remained below the AASHTO 80% threshold, the use of RCA was associated with comparatively better performance, since mixtures containing 10% and 30% RCA exhibited higher TSR than the virgin control in both unaged and aged states, indicating lower moisture susceptibility. At the unaged and short-term immersion stages, wet-condition tests showed a more ductile response (characterized by higher CT-index and lower fracture energy) relative to dry tests at the same age; however, prolonged water immersion reduced the Cracking Tolerance Index (CT-index), particularly at 30% RCA, reflecting increased brittleness and susceptibility to moisture-induced cracking. The decrease in CT-index values after extended immersion was most pronounced for mixtures with 30% RCA, whose values approached those of dry-condition specimens, confirming greater cracking susceptibility under prolonged wet exposure. Considering the overall mechanical response, a 10% RCA replacement level appears to offer the most balanced behavior, improving tensile strength and moisture resistance without significantly compromising cracking tolerance. Although mixtures with 30% RCA displayed the highest ITS values, their reduced CT-index after long-term immersion indicates a potential trade-off between strength and durability. Therefore, 10% RCA can be preliminarily regarded as the optimal substitution level for sustainable mix design, pending further validation through rutting and durability performance testing. After six months of immersion, all mixtures displayed predominantly brittle behavior, more pronounced at higher RCA contents, suggesting that prolonged moisture exposure can compromise mechanical integrity in highly substituted mixtures. These findings focus exclusively on experimental evidence, confirming the technical feasibility of using RCA in asphalt mixtures and highlighting the need to optimize the substitution level to balance strength improvement (ITS) and cracking resistance (CT-index) under extended moisture exposure. Furthermore, the results suggest that RCA’s alkaline and siliceous composition contributes to its cementitious reactivity and adhesion potential, enhancing mechanical response in early stages. However, at higher replacement levels and longer immersion periods, increased porosity and reduced binder film thickness promote moisture ingress, accelerating stiffness loss and cracking susceptibility. Thus, future work should integrate rutting, durability, and life-cycle assessment (LCA) analyses to quantify long-term benefits and sustainability indicators, supporting the incorporation of RCA in performance-balanced and environmentally responsible asphalt mixture designs.

Author Contributions

Methodology, A.O.; Investigation, M.H.; Resources, A.O.; Writing—review & editing, M.H., A.O. and M.T.-V.; Supervision, A.O. and M.T.-V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to express their gratitude to Ergon Asfaltos México for the donation of the asphalt binder used in this research and to Concretos Reciclados, S.A. de C.V. for providing the recycled concrete aggregates. Their valuable contributions were essential to the successful completion of the experimental program.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HMA | Hot-Mix Asphalt |

| VMA | Voids in Mineral Aggregate |

| VFA | Voids Filled with Asphalt |

| CDW | Construction and Demolition Waste |

| RCA | Recycled Concrete Aggregates |

| RAP | Reclaimed Asphalt Pavement |

| ITS | Indirect Tensile Strength |

| TSR | Tensile Strength Ratio |

| IDEAL CT | IDEAL Cracking Test |

| CT-index | Cracking Tolerance Index |

References

- Vardopoulos, I. Cities in Flux: Waste, the Shadow of Circularity, and the (Elusive) Promise of Sustainability. Sustainability 2025, 17, 705. [Google Scholar] [CrossRef]

- Wahlström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; Eionet Report—ETC/WMGE 2020/1; European Environment Agency: Copenhagen, Denmark, 2020. [Google Scholar]

- García, C.J.; Caro, D.; Foster, G.; Pristera, G.; Gallo, F.; Tonini, D. Techno-Economic and Environmental Assessment of Construction and Demolition Waste Management in the European Union; European Union Publications Office: Luxembourg, Luxembourg, 2024. [Google Scholar]

- U.S. Environmental Protection Agency. Facts and Figures about Materials, Waste, and Recycling: Construction and Demolition Debris Material. U.S. EPA. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/construction-and-demolition-debris-material (accessed on 20 August 2024).

- Gedik, A. A review on the evaluation of the potential utilization of construction and demolition waste in hot mix asphalt pavements. Resour. Conserv. Recycl. 2020, 161, 104956. [Google Scholar] [CrossRef]

- Vega, A.; Santos, J.; Martínez-Argüelles, G. Life Cycle Assessment of Hot-Mix Asphalt Containing Recycled Concrete Aggregates for Pavement Construction. Rev. Int. Eng. Pavements 2020, 23, 923–936. [Google Scholar] [CrossRef]

- Bhusal, S.; Li, X.; Wen, H. Evaluation of effects of recycled concrete aggregate on volumetrics of HMA. Transp. Res. Rec. J. Transp. Res. Board 2011, 2205, 36–39. [Google Scholar] [CrossRef]

- Paranavithana, S.; Mohajerani, A. Effects of recycled concrete aggregates on properties of asphalt concrete. Resour. Conserv. Recycl. 2006, 48, 1–12. [Google Scholar] [CrossRef]

- Mills-Beale, J.; You, Z. The mechanical properties of asphalt mixtures with recycled concrete aggregates. Constr. Build. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Laboratory evaluation of hot-mix asphalt containing construction and demolition waste. Constr. Build. Mater. 2013, 43, 497–505. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Moisture damage resistance of hot-mix asphalt made with recycled concrete aggregates and crumb rubber. J. Clean. Prod. 2017, 165, 405–414. [Google Scholar] [CrossRef]

- Giri, J.P.; Panda, M.; Sahoo, U.C. Performance of bituminous mixes containing treated recycled concrete aggregates and modified by waste polyethylene. J. Mater. Civ. Eng. 2018, 30, 04018184. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y.; Sreeram, A.; Wu, Q.; Chen, G.; Cheng, S.; Chen, Z.; Chen, X. Potential use of recycled concrete aggregate (RCA) for sustainable asphalt pavements of the future: A state-of-the-art review. J. Clean. Prod. 2022, 344, 130893. [Google Scholar] [CrossRef]

- Sapkota, K.; Yaghoubi, E.; Wasantha, P.L.P.; Van Staden, R.; Fragomeni, S. Mechanical Characteristics and Durability of HMA Made of Recycled Aggregates. Sustainability 2023, 15, 5594. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Fatigue performance of bituminous mixtures made with recycled concrete aggregates and waste tire rubber. Constr. Build. Mater. 2017, 157, 26–33. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Reyes-Lizcano, F.A.; Rondón-Quintana, H.A. Use of recycled concrete aggregates in asphalt mixtures for pavements: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 725–741. [Google Scholar] [CrossRef]

- Pandurangan, K.; Dayanithy, A.; Om Prakash, S. Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Omar, H.A.; Yusoff, N.I.M.; Ceylan, H.; Mubaraki, M. Effects of aging on the mechanical properties of asphalt mixtures using a new approach. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 548–557. [Google Scholar]

- Varveri, A.; Avgerinopoulos, S.; Kasbergen, C.; Scarpas, A.; Collop, A. Influence of air void content on moisture damage susceptibility of asphalt mixtures: Computational study. Transp. Res. Rec. 2014, 2446, 8–16. [Google Scholar] [CrossRef]

- Yang, S.L.; Baek, C.; Park, H.B. Effect of Aging and Moisture Damage on Fatigue Cracking Properties in Asphalt Mixtures. Appl. Sci. 2021, 11, 10543. [Google Scholar] [CrossRef]

- Yang, S.L.; Baek, C.; Park, H.B. Fatigue Cracking Characteristics of Asphalt Pavement Structure under Aging and Moisture Damage. Sustainability 2023, 15, 4815. [Google Scholar] [CrossRef]

- Solaimanian, M.; Kennedy, T.W.; Elmore, W.E. Long Term Evaluation of Stripping and Moisture Damage in Asphalt Pavements Treated with Lime and Antistripping Agents; Report No. CTR 0-1286-1F; Texas Department of Transportation: Austin, TX, USA, 1993. [Google Scholar]

- Kringos, N.; Scarpas, A.; Copeland, A.; Youtcheff, J. Modeling of combined physical and mechanical moisture-induced damage in asphaltic mixes. Part 2: Moisture susceptibility parameters. Int. J. Pavement Eng. 2008, 9, 129–151. [Google Scholar] [CrossRef]

- Kringos, N.; Scarpas, A.; Kasbergen, C.; Selvadurai, P. Modelling of combined physical–mechanical moisture-induced damage in asphaltic mixes, Part 1: Governing processes and formulations. Int. J. Pavement Eng. 2008, 9, 115–128. [Google Scholar] [CrossRef]

- Caro, S.; Masad, E.; Bhasin, A.; Little, D.N. Moisture susceptibility of asphalt mixtures, Part 1: Mechanisms. Int. J. Pavement Eng. 2008, 9, 81–98. [Google Scholar] [CrossRef]

- Kringos, N.; Scarpas, A. Physical and mechanical moisture susceptibility of asphaltic mixtures. Int. J. Solids Struct. 2008, 45, 2671–2685. [Google Scholar] [CrossRef]

- TRB Committee on Bituminous-Aggregate Combinations to Meet Surface Requirements; California Department of Transportation; Federal Highway Administration. Moisture sensitivity of asphalt pavements: A national seminar. In Proceedings of the Transportation Research Board Seminar, San Diego, CA, USA, 4–6 February 2003. [Google Scholar]

- Mikhailenko, P.; Kakar, M.R.; Piao, Z.; Bueno, M.; Poulikakos, L. Incorporation of recycled concrete aggregate (RCA) fractions in semi-dense asphalt (SDA) pavements: Volumetrics, durability and mechanical properties. Constr. Build. Mater. 2020, 264, 120166. [Google Scholar] [CrossRef]

- Gul, W.A.; Guler, M. Rutting susceptibility of asphalt concrete with recycled concrete aggregate using revised Marshall procedure. Constr. Build. Mater. 2014, 55, 341–349. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Silva, H.M.R.D.; Oliveira, J.R.M.; Moura, C.F.N.; Loureiro, C.D.A.; Silvestre, J.D.; Rodrigues, M.M.M. Mechanical and Environmental Performance of Asphalt Concrete with High Amounts of Recycled Concrete Aggregates (RCA) for Use in Surface Courses of Pavements. Sustainability 2024, 16, 248. [Google Scholar] [CrossRef]

- Lottman, R.P. Predicting Moisture-Induced Damage to Asphaltic Concrete; National Cooperative Highway Research Program Report No. 192; Transportation Research Board, National Research Council: Washington, DC, USA, 1978. [Google Scholar]

- California State Transportation Agency, Department of Transportation. Standard Specifications, 2024 ed.; State of California, Department of Transportation: Sacramento, CA, USA, 2024; p. 575. Available online: https://dot.ca.gov/-/media/dot-media/programs/design/documents/f00203402018stdspecs-a11y.pdf (accessed on 2 October 2024).

- Ossa, J.L.; García, E.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–389. [Google Scholar] [CrossRef]

- Lee, C.-H.; Du, J.-C.; Shen, D.-H. Evaluation of pre-coated recycled concrete aggregate for hot mix asphalt. Constr. Build. Mater. 2012, 28, 66–71. [Google Scholar] [CrossRef]

- Zulkati, A.; Karim, M.R.; Hainin, M.R. Mechanistic performance of asphalt-concrete mixture incorporating coarse recycled concrete aggregate. J. Mater. Civ. Eng. 2013, 25, 1299–1305. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. A manual for design of hot-mix asphalt with commentary (NCHRP Report 673). In NCHRP Report Series; The National Academies Press: Washington, DC, USA, 2011. [Google Scholar] [CrossRef]

- Lou, K.; Jia, S.; Xiao, P.; Wu, H.; Wu, Y. Effects of Moisture Infiltration on Interfacial Characteristics of Fiber Asphalt Mastic-Aggregate and the Cracking Resistance of Mixture. Materials 2025, 18, 53. [Google Scholar] [CrossRef] [PubMed]

- Richardson, A.; Coventry, K.; Bacon, J. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. J. Clean. Prod. 2011, 19, 272–277. [Google Scholar] [CrossRef]

- Zhou, F. Development of an IDEAL Cracking Test for Asphalt Mix Design, Quality Control, and Quality Assurance; Final Report for NCHRP IDEA Project 195; Texas A&M Transportation Institute: College Station, TX, USA, 2019. [Google Scholar]

- Harder, G.A. Balanced Mix Design. Asphalt Magazine. 2023, pp. 15–20. Available online: https://asphalt.mydigitalpublication.com/summer-2023/page-14 (accessed on 2 September 2025).

- Shaikh, S.; Gupta, A. Assessing cracking resistance and threshold limits of bituminous mixtures with IDEAL-CT and predictive modeling techniques. Constr. Build. Mater. 2024, 449, 138349. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, Y.; Bahia, H.U. Comparison between SCB-IFIT, un-notched SCB-IFIT and IDEAL-CT for measuring cracking resistance of asphalt mixtures. Constr. Build. Mater. 2020, 252, 119060. [Google Scholar] [CrossRef]

- Saha Chowdhury, P.; Noojilla, S.L.A.; Reddy, M.A. Evaluation of fatigue characteristics of asphalt mixtures using Cracking Tolerance index (CTIndex). Constr. Build. Mater. 2022, 342 Pt B, 128030. [Google Scholar] [CrossRef]

- Hussein, F.K.; Ismael, M.Q.; Huseien, G.F. Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Moisture Susceptibility Evaluation. J. Compos. Sci. 2023, 7, 428. [Google Scholar] [CrossRef]

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- AASHTO T85; Standard Method of Test for Specific Gravity and Absorption of Coarse Aggregate. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020.

- AASHTO T84; Standard Method of Test for Specific Gravity and Absorption of Fine Aggregate. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020.

- ASTM C1252; Standard Test Methods for Uncompacted Void Content of Fine Aggregate (as Influenced by Particle Shape, Surface Texture, and Grading). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D2419; Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D5821; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4791; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C131; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C88; Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D92; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D1525; Standard Test Method for Vicat Softening Temperature of Plastics. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2023.

- AASHTO T316; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020.

- ASTM D6373; Standard Specification for Performance Graded Asphalt Binder. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D113; Standard Test Method for Ductility of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- AASHTO T 312; Standard Method for Preparing and Determining the Density of Hot Mix Asphalt (HMA) Specimens by Means of the SHRP Gyratory Compactor. ASTM International: West Conshohocken, PA, USA, 2004.

- Tunnicliff, D.G.; Root, R.E. Use of Antistripping Additives in Asphaltic Concrete Mixtures. Proc. Assoc. Asph. Paving Technol. 1982, 51, 265–295. [Google Scholar]

- AASHTO T 283-14; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. AASHTO: Washington, DC, USA, 2015.

- McGennis, R.B.; Kennedy, T.W.; Machemehl, R.B. Stripping and Moisture Damage in Asphalt Mixtures; Research Report No. 253-1; Center for Transportation Research, Bureau of Engineering Research, University of Texas at Austin: Austin, TX, USA, 1984. [Google Scholar]

- ASTM D8225-19; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. ASTM International: West Conshohocken, PA, USA, 2019.

- Paris, P.C.; Erdogan, F. A Critical Analysis of Crack Propagation Laws. J. Basic Eng. 1963, 85, 528–534. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Prat, P.C. Microplane Model for Brittle-Plastic Material: I. Theory. J. Eng. Mech. 1988, 114, 1672–1688. [Google Scholar] [CrossRef]

- Bairgi, B.K.; Verma, M.; Tran, N.; Yin, F.; Moraes, R.; Rodezno, C.; Martin, A.E.; Montañez, J.; Arámbula-Mercado, E. Establishing Strategies to Improve Cracking Resistance of High Recycled Binder Ratio Asphalt Mixtures. Transp. Res. Rec. 2024, 2678, 1048–1059. [Google Scholar] [CrossRef]

- Bennert, T.; Haas, E.; Wass, E. Indirect Tensile Test (IDT) to Determine Asphalt Mixture Performance Indicators during Quality Control Testing in New Jersey. Transp. Res. Rec. 2018, 2672, 395–403. [Google Scholar] [CrossRef]

- Yin, F.; West, R.; Powell, B.; Du Bois, C.J. Short-Term Performance Characterization and Fatigue Damage Prediction of Asphalt Mixtures Containing Polymer-Modified Binders and Recycled Plastics. Transp. Res. Rec. J. Transp. Res. Board 2023, 2679, 742–759. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).