Recent Advances in Sustainable Anthocyanin Applications in Food Preservation and Monitoring: A Review

Abstract

1. Introduction

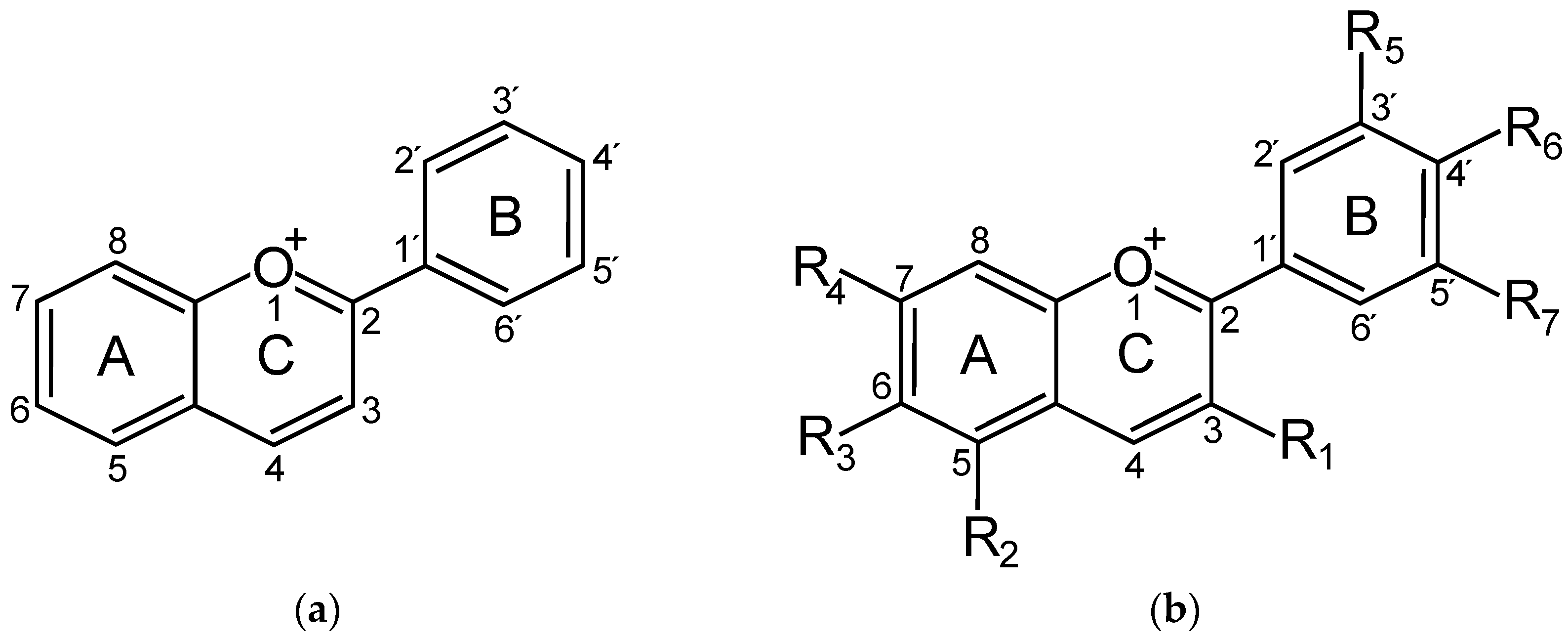

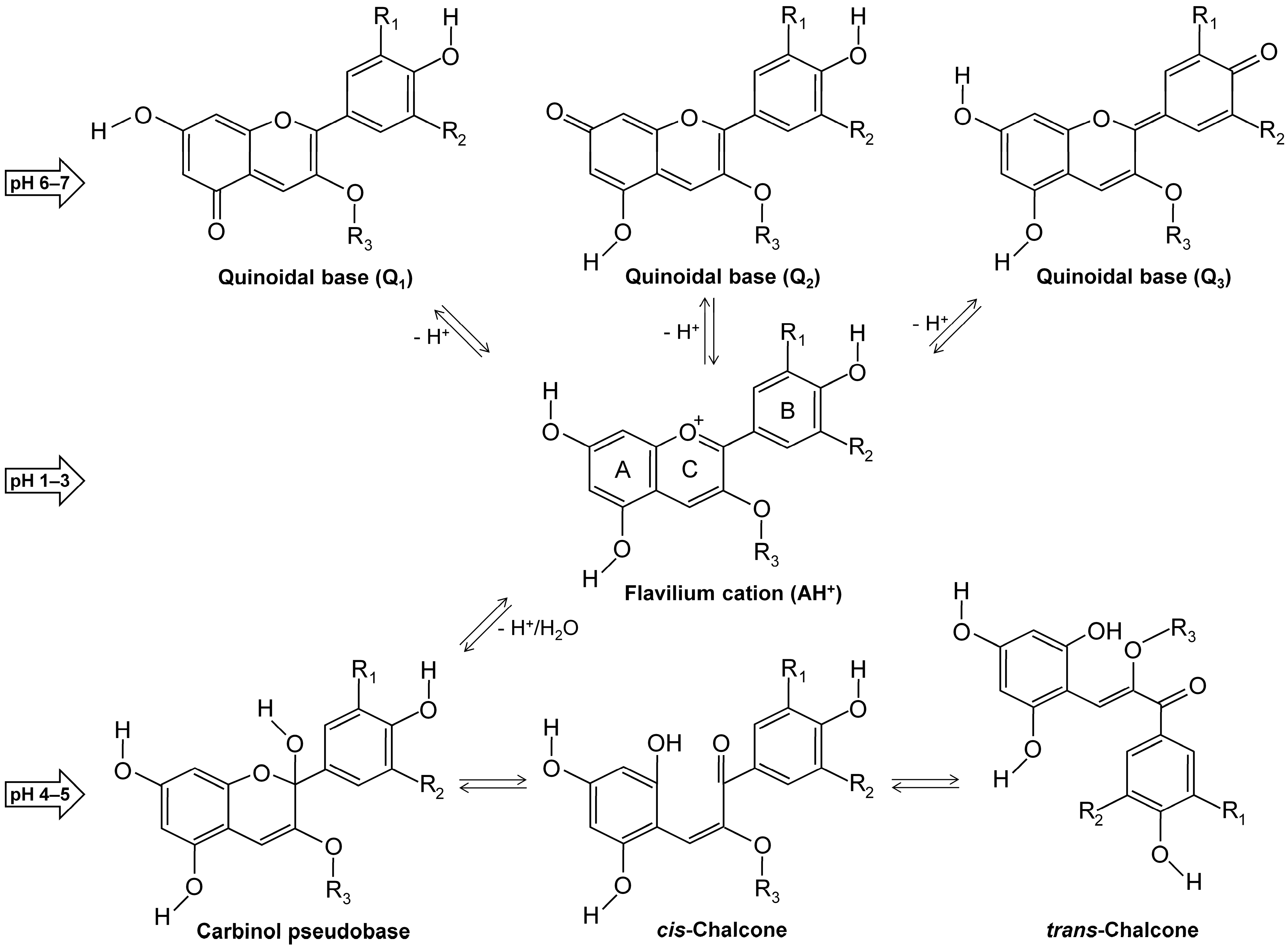

2. Chemical Structure, Color Behavior, and Stability

3. Anthocyanin Applications as Colorants and Preservatives

4. Anthocyanin Applications in Packaging

4.1. Polymer Matrices for Anthocyanin Incorporation

4.1.1. Polysaccharide-Based Matrices

- Starch-Based Films

- Chitosan-Based Films

- Cellulose and Cellulose Derivatives

- Alginate-Based Films

4.1.2. Protein-Based Matrices

- Gelatin-Based Films

- Soy Protein Isolate (SPI)

- Whey Protein Films

4.1.3. Biopolyester and Composite Matrices

- Biopolyester Matrices: Polylactic Acid (PLA)

- Blended or Composite Biopolymer Matrices

4.2. Active Food Packaging

4.3. Intelligent Food Packaging

4.4. Comparative Assessment, Mechanistic Basis, and Design Guidelines

5. Limitations and Constraints of Anthocyanin Applications in the Food Industry

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nieto, G.; Martínez-Zamora, L.; Peñalver, R.; Marín-Iniesta, F.; Taboada-Rodríguez, A.; López-Gómez, A.; Martínez-Hernández, G.B. Applications of Plant Bioactive Compounds as Replacers of Synthetic Additives in the Food Industry. Foods 2024, 13, 47. [Google Scholar] [CrossRef] [PubMed]

- Atanasov, A.G.; Zotchev, S.B.; Dirsch, V.M.; The International Natural Product Sciences Taskforce; Supuran, C.T. Natural products in drug discovery: Advances and opportunities. Nat. Rev. Drug Discov. 2021, 20, 200–216. [Google Scholar] [CrossRef] [PubMed]

- Chaachouay, N.; Zidane, L. Plant-Derived Natural Products: A Source for Drug Discovery and Development. Drugs Drug Candidates 2024, 3, 184–207. [Google Scholar] [CrossRef]

- Gǎlbǎu, C.-Ş.; Irimie, M.; Neculau, A.E.; Dima, L.; Pogačnik da Silva, L.; Vârciu, M.; Badea, M. The Potential of Plant Extracts Used in Cosmetic Product Applications—Antioxidants Delivery and Mechanism of Actions. Antioxidants 2024, 13, 1425. [Google Scholar] [CrossRef]

- Rybczyńska-Tkaczyk, K.; Grenda, A.; Jakubczyk, A.; Kiersnowska, K.; Bik-Małodzińska, M. Natural Compounds with Antimicrobial Properties in Cosmetics. Pathogens 2023, 12, 320. [Google Scholar] [CrossRef]

- Liu, J.-K. Natural products in cosmetics. Nat. Prod. Bioprospect. 2022, 12, 40. [Google Scholar] [CrossRef]

- Sisodia, A.; Chettupalli, A.K.; Bukke, S.P.N.; Rahaman, S.A.; Chaudhary, S.; Nichola, B. Toning with Nature: A Review of Natural Ingredients in Cosmetic Formulations. Nat. Prod. Commun. 2025, 20, 1–21. [Google Scholar] [CrossRef]

- Khursheed, A.; Rather, M.A.; Jain, V.; Wani, A.R.; Rasool, S.; Nazir, R.; Malik, N.A.; Majid, S.A. Plant based natural products as potential ecofriendly and safer biopesticides: A comprehensive overview of their advantages over conventional pesticides, limitations and regulatory aspects. Microb. Pathog. 2022, 173, 105854. [Google Scholar] [CrossRef]

- Zhang, P.; Duan, C.-B.; Jin, B.; Ali, A.S.; Han, X.; Zhang, H.; Zhang, M.-Z.; Zhang, W.-H.; Gu, Y.-C. Recent advances in the natural products-based lead discovery for new agrochemicals. Adv. Agrochem 2023, 2, 324–339. [Google Scholar] [CrossRef]

- Dayan, F.E.; Cantrell, C.L.; Duke, S.O. Natural products in crop protection. Bioorg. Med. Chem. 2009, 17, 4022–4034. [Google Scholar] [CrossRef] [PubMed]

- Ienașcu, I.M.C.; Căta, A.; Chiș, A.A.; Ștefănuț, M.N.; Sfîrfoagă, P.; Rusu, G.; Frum, A.; Arseniu, A.M.; Morgovan, C.; Rus, L.L.; et al. Some Brassicaceae Extracts as Potential Antioxidants and Green Corrosion Inhibitors. Materials 2023, 16, 2967. [Google Scholar] [CrossRef] [PubMed]

- Nwozo, O.S.; Effiong, E.M.; Aja, P.M.; Awuchi, C.G. Antioxidant, Phytochemical, and Therapeutic Properties of Medicinal Plants: A Review. Int. J. Food Prop. 2023, 26, 359–388. [Google Scholar] [CrossRef]

- Haj Ali, D.; Dărăban, A.M.; Ungureanu, D.; Căta, A.; Ienașcu, I.M.C.; Dinu, S.; Dehelean, C.A.; Danciu, C. An Up-to-Date Review Regarding the Biological Activity of Geranium robertianum L. Plants 2025, 14, 918. [Google Scholar] [CrossRef] [PubMed]

- Ştefănuţ, M.N.; Căta, A.; Ienaşcu, I. Comparative antioxidant activity of some Prunus genus fruits. Rev. Roum. Chim. 2015, 60, 603–608. [Google Scholar]

- Isaia, A.I.; Căta, A.; Olah, N.K.; Ștefănuț, M.N.; Ienașcu, I.M.C.; Bratosin, D.; Popoiu, C. Evaluation of Antioxidant Activity and Phenolic Content of 13 Selected Herbs from Romania. Rev. Chim. 2016, 67, 2001–2004. [Google Scholar]

- Muntean, D.; Ștefănuț, M.N.; Căta, A.; Buda, V.; Danciu, C.; Bănică, R.; Pop, R.; Licker, M.; Ienașcu, I.M.C. Symmetrical Antioxidant and Antibacterial Properties of Four Romanian Cruciferous Extracts. Symmetry 2021, 13, 893. [Google Scholar] [CrossRef]

- Vaou, N.; Stavropoulou, E.; Voidarou, C.; Tsigalou, C.; Bezirtzoglou, E. Towards Advances in Medicinal Plant Antimicrobial Activity: A Review Study on Challenges and Future Perspectives. Microorganisms 2021, 9, 2041. [Google Scholar] [CrossRef]

- Pacheco-Hernández, B.; Ayora-Talavera, T.; Cano-Sosa, J.; Noriega, L.G.; Pacheco-López, N.A.; Vargas-Morales, J.M.; Medina-Vera, I.; Guevara-Cruz, M.; Chim-Aké, R.; Gutiérrez-Solis, A.L.; et al. Antioxidant and Anti-Inflammatory Effects of Traditional Medicinal Plants for Urolithiasis: A Scoping Review. Plants 2025, 14, 2032. [Google Scholar] [CrossRef]

- Căta, A.; Ienașcu, I.M.C.; Frum, A.; Ursu, D.; Svera, P.; Orha, C.; Rusu, G.; Chiș, A.A.; Dobrea, C.M.; Morgovan, C.; et al. Preparation and Characterization of a Novel Salicin–Cyclodextrin Complex. Pharmaceutics 2024, 16, 369. [Google Scholar] [CrossRef]

- Trasca, D.M.; Dop, D.; Stoica, G.-A.; Niculescu, A.S.; Niculescu, C.E.; Văruț, R.M.; Singer, C.E. The Antidiabetic Activity of Wild-Growing and Cultivated Medicinal Plants Used in Romania for Diabetes Mellitus Management: A Phytochemical and Pharmacological Review. Pharmaceuticals 2025, 18, 1035. [Google Scholar] [CrossRef]

- Ștefănuț, M.N.; Căta, A.; Pop, R.; Tănasie, C.; Boc, D.; Ienașcu, I.; Ordodi, V. Anti-Hyperglycemic Effect of Bilberry, Blackberry and Mulberry Ultrasonic Extracts on Diabetic Rats. Plant Foods Hum. Nutr. 2013, 68, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Isaia, A.I.; Ienașcu, I.M.C.; Andrica, F.M.; Georgescu, D.; Bratosin, D.; Pinzaru, I.A. Preliminary In Vitro Evaluation of Seven Different Plant Extracts on A375, B164A5 and HaCaT Cell Lines. Rev. Chim. 2016, 67, 1633–1636. [Google Scholar]

- Khan, T.; Ali, M.; Khan, A.; Nisar, P.; Jan, S.A.; Afridi, S.; Shinwari, Z.K. Anticancer Plants: A Review of the Active Phytochemicals, Applications in Animal Models, and Regulatory Aspects. Biomolecules 2020, 10, 47. [Google Scholar] [CrossRef]

- Silva, M.M.; Reboredo, F.H.; Lidon, F.C. Food Colour Additives: A Synoptical Overview on Their Chemical Properties, Applications in Food Products, and Health Side Effects. Foods 2022, 11, 379. [Google Scholar] [CrossRef]

- Bhargava, N.; Sharanagat, V.S.; Mor, R.S.; Kumar, K. Active and intelligent biodegradable packaging films using food and food waste-derived bioactive compounds: A review. Trends Food Sci. Technol. 2020, 105, 385–401. [Google Scholar] [CrossRef]

- Mesías, F.; Martín, A.; Hernández, A. Consumers’ growing appetite for natural foods: Perceptions towards the use of natural preservatives in fresh fruit. Food Res. Int. 2021, 150, 110749. [Google Scholar] [CrossRef]

- Xiong, G.; Zhou, X.; Zhang, C.; Xu, X. A comprehensive review of intelligent packaging materials based on biopolymers: Role of anthocyanins, type and properties of materials, and their application in monitoring meat freshness. Int. J. Biol. Macromol. 2024, 282, 137462. [Google Scholar] [CrossRef]

- Janseerat, M.; Kolekar, M.; Somashekar Reddy, C.; Sharma, S.; Roy, S. Anthocyanin-Based Natural Color Induced Intelligent Food Packaging Sensor: A Review. Curr. Food Sci. Technol. Rep. 2024, 2, 157–167. [Google Scholar] [CrossRef]

- Dobrucka, R.; Cierpiszewski, R. Active and Intelligent Packaging Food–Research and Development—A Review. Pol. J. Food Nutr. Sci. 2014, 64, 7–15. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Suppakul, P. Active and intelligent packaging: The indication of quality and safety. Crit. Rev. Food Sci. Nutr. 2018, 58, 808–831. [Google Scholar] [CrossRef]

- Ahmed, M.W.; Haque, M.A.; Mohibbullah, M.; Khan, M.S.I.; Islam, M.A.; Mondal, M.H.T.; Ahmmed, R. A Review on Active Packaging for Quality and Safety of Foods: Current Trends, Applications, Prospects and Challenges. Food Packag. Shelf Life 2022, 33, 100913. [Google Scholar] [CrossRef]

- Vilela, C.; Kurek, M.; Hayouka, Z.; Röcker, B.; Yildirim, S.; Antunes, M.D.C.; Nilsen-Nygaard, J.; Pettersen, M.K.; Freire, C.S.R. A concise guide to active agents for active food packaging. Trends Food Sci. Technol. 2018, 80, 212–222. [Google Scholar] [CrossRef]

- Remedio, L.N.; Parada Quinayá, C. Intelligent Packaging Systems with Anthocyanin: Influence of Different Polymers and Storage Conditions. Polymers 2024, 16, 2886. [Google Scholar] [CrossRef]

- Silva, S.; Costa, E.M.; Calhau, C.; Morais, R.M.; Pintado, M.E. Anthocyanin extraction from plant tissues: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 3072–3083. [Google Scholar] [CrossRef]

- Enaru, B.; Drețcanu, G.; Pop, T.D.; Stănilă, A.; Diaconeasa, Z. Anthocyanins: Factors Affecting Their Stability and Degradation. Antioxidants 2021, 10, 1967. [Google Scholar] [CrossRef]

- Mishra, G.; Dash, S.P.; Mahapatra, S.K.; Swain, D.; Rout, G.R. Deeper insights into the physiological and metabolic functions of the pigments in plants and their applications: Beyond natural colorants. Physiol. Plant. 2025, 177, e70168. [Google Scholar] [CrossRef]

- Cappellini, F.; Marinelli, A.; Toccaceli, M.; Tonelli, C.; Petroni, K. Anthocyanins: From Mechanisms of Regulation in Plants to Health Benefits in Foods. Front. Plant Sci. 2021, 12, 748049. [Google Scholar] [CrossRef]

- Buhrman, K.; Aravena-Calvo, J.; Ross Zaulich, C.; Hinz, K.; Laursen, T. Anthocyanic Vacuolar Inclusions: From Biosynthesis to Storage and Possible Applications. Front. Chem. 2022, 10, 913324. [Google Scholar] [CrossRef]

- Dabravolski, S.A.; Isayenkov, S.V. The Role of Anthocyanins in Plant Tolerance to Drought and Salt Stresses. Plants 2023, 12, 2558. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Ahammed, G.J. Plant stress response and adaptation via anthocyanins: A review. Plant Stress 2023, 10, 100230. [Google Scholar] [CrossRef]

- Kaur, S.; Tiwari, V.; Kumari, A.; Chaudhary, E.; Sharma, A.; Ali, U.; Garg, M. Protective and defensive role of anthocyanins under plant abiotic and biotic stresses: An emerging application in sustainable agriculture. J. Biotechnol. 2023, 361, 12–29. [Google Scholar] [CrossRef]

- Pina, F.; Melo, M.J.; Laia, C.A.T.; Parola, A.J.; Lima, J.C. Chemistry and applications of flavylium compounds: A handful of colours. Chem. Soc. Rev. 2012, 41, 869–908. [Google Scholar] [CrossRef]

- Patra, S.; Makhal, P.N.; Jaryal, S.; More, N.; Kaki, V.R. Anthocyanins: Plant-based flavonoid pigments with diverse biological activities. Int. J. Plant Based Pharm. 2022, 2, 118–127. [Google Scholar] [CrossRef]

- Golovko, T.K. Plant Anthocyanins: Structure, Biosynthesis Regulation, Functions, and Ecology. Russ. J. Plant Physiol. 2023, 70, 161. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, X.; Lin, X.; Mostafa, S.; Zou, H.; Wang, L.; Jin, B. Plant anthocyanins: Classification, biosynthesis, regulation, bioactivity, and health benefits. Plant Physiol. Biochem. 2024, 217, 109268. [Google Scholar] [CrossRef]

- Dăescu, D.-I.; Păușescu, I.; Benea, I.C.; Peter, F.; Todea, A.; Zappaterra, F.; Alexa, A.A.; Buzatu, A.R. Natural and Synthetic Flavylium Derivatives: Isolation/Synthesis, Characterization and Application. Molecules 2025, 30, 90. [Google Scholar] [CrossRef]

- Wallace, T.C.; Giusti, M.M. Anthocyanins—Nature’s Bold, Beautiful, and Health-Promoting Colors. Foods 2019, 8, 550. [Google Scholar] [CrossRef] [PubMed]

- Cavalcanti, R.N.; Santos, D.T.; Meireles, M.A.A. Non-thermal stabilization mechanisms of anthocyanins in model and food systems—An overview. Food Res. Int. 2011, 44, 499–509. [Google Scholar] [CrossRef]

- Castañeda-Ovando, A.; de Lourdes Pacheco-Hernández, M.; Páez-Hernández, M.E.; Rodríguez, J.A.; Galán-Vidal, C.A. Chemical studies of anthocyanins: A review. Food Chem. 2009, 113, 859–871. [Google Scholar] [CrossRef]

- Saini, R.K.; Khan, M.I.; Shang, X.; Kumar, V.; Kumari, V.; Kesarwani, A.; Ko, E.-Y. Dietary Sources, Stabilization, Health Benefits, and Industrial Application of Anthocyanins—A Review. Foods 2024, 13, 1227. [Google Scholar] [CrossRef] [PubMed]

- Koss-Mikołajczyk, I.; Bartoszek, A. Relationship between Chemical Structure and Biological Activity Evaluated In Vitro for Six Anthocyanidins Most Commonly Occurring in Edible Plants. Molecules 2023, 28, 6156. [Google Scholar] [CrossRef]

- Prior, R.L.; Wu, X. Anthocyanins: Structural characteristics that result in unique metabolic patterns and biological activities. Free Radic. Res. 2006, 40, 1014–1028. [Google Scholar] [CrossRef]

- Wallace, T.C.; Giusti, M.M. Anthocyanins. Adv. Nutr. 2015, 6, 620–622. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhang, P.; Warner, R.D.; Fang, Z. 3-Deoxyanthocyanidin Colorant: Nature, Health, Synthesis, and Food Applications. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1533–1549. [Google Scholar] [CrossRef]

- Mattioli, R.; Francioso, A.; Mosca, L.; Silva, P. Anthocyanins: A Comprehensive Review of Their Chemical Properties and Health Effects on Cardiovascular and Neurodegenerative Diseases. Molecules 2020, 25, 3809. [Google Scholar] [CrossRef]

- He, J.; Giusti, M.M. Anthocyanins: Natural colorants with health-promoting properties. Annu. Rev. Food Sci. Technol. 2010, 1, 163–187. [Google Scholar] [CrossRef] [PubMed]

- Trouillas, P.; Sancho-García, J.C.; De Freitas, V.; Gierschner, J.; Otyepka, M.; Dangles, O. Stabilizing and modulating color by copigmentation: Insights from theory and experiment. Chem. Rev. 2016, 116, 4937–4982. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.; Yang, X.; Zhang, N.; Chen, P.; Sun, J.; Harnly, J.M.; Zhang, M. Study of UV–Vis molar absorptivity variation and quantitation of anthocyanins using molar relative response factor. Food Chem. 2024, 444, 138653. [Google Scholar] [CrossRef] [PubMed]

- Saha, S.; Singh, J.; Paul, A.; Sarkar, R.; Khan, Z.; Banerjee, K. Anthocyanin Profiling Using UV-Vis Spectroscopy and Liquid Chromatography Mass Spectrometry. J. AOAC Int. 2020, 103, 23–39. [Google Scholar] [CrossRef]

- de Freitas, V.; Mateus, N. Chemical transformations of anthocyanins yielding a variety of colours (Review). Environ. Chem. Lett. 2006, 4, 175–183. [Google Scholar] [CrossRef]

- Tanaka, Y.; Sasaki, N.; Ohmiya, A. Biosynthesis of plant pigments: Anthocyanins, betalains and carotenoids. Plant J. 2008, 54, 733–749. [Google Scholar] [CrossRef]

- Alappat, B.; Alappat, J. Anthocyanin Pigments: Beyond Aesthetics. Molecules 2020, 25, 5500. [Google Scholar] [CrossRef]

- He, F.; Liang, N.-N.; Mu, L.; Pan, Q.-H.; Wang, J.; Reeves, M.J.; Duan, C.-Q. Anthocyanins and Their Variation in Red Wines I. Monomeric Anthocyanins and Their Color Expression. Molecules 2012, 17, 1571–1601. [Google Scholar] [CrossRef]

- Zhao, Y.-W.; Wang, C.-K.; Huang, X.-Y.; Hu, D.-G. Anthocyanin stability and degradation in plants. Plant Signal. Behav. 2021, 16, e1987767. [Google Scholar] [CrossRef]

- Xue, H.; Zhao, J.; Wang, Y.; Shi, Z.; Xie, K.; Liao, X.; Tan, J. Factors affecting the stability of anthocyanins and strategies for improving their stability: A review. Food Chem. X 2024, 24, 101883. [Google Scholar] [CrossRef]

- Fonseca Feitosa, B.; Angioletti Decker, B.L.; Sousa de Brito, E.; Camargo Marques, M.; Rodrigues, S.; Barros Mariutti, L.R. Anthocyanins stability theory—Evidence summary on the effects of microencapsulation. Food Bioprod. Process. 2025, 153, 77–86. [Google Scholar] [CrossRef]

- Dangles, O.; Fenger, J.-A. The chemical reactivity of anthocyanins and its consequences in food science and nutrition. Molecules 2018, 23, 1970. [Google Scholar] [CrossRef] [PubMed]

- Kähkönen, M.; Heinonen, M. Antioxidant activity of anthocyanins and their aglycons. J. Agric. Food Chem. 2003, 51, 628–633. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Cao, Y.; Wang, F.; Li, F. Review: Enhancing the Bioavailability and Stability of Anthocyanins for the Prevention and Treatment of Central Nervous System-Related Diseases. Foods 2025, 14, 2420. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.; Li, X.; Chen, J.; Jiang, X.; Ma, X.; Sun, J.; Tian, L.; Vidyarthi, S.K.; Xu, J.; Pan, Z.; et al. A comprehensive review on innovative and advanced stabilization approaches of anthocyanin by modifying structure and controlling environmental factors. Food Chem. 2022, 366, 130611. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhao, Y.; Sun, B.; Yang, Y.; Wang, S.; Feng, Z.; Li, J. The structure of anthocyanins and the copigmentation by common micromolecular copigments: A review. Food Res. Int. 2024, 176, 113837. [Google Scholar] [CrossRef]

- Zhao, C.-L.; Yu, Y.-Q.; Chen, Z.-J.; Wen, G.-S.; Wei, F.-G.; Zheng, Q.; Wang, C.-D.; Xiao, X.-L. Stability-increasing effects of anthocyanin glycosyl acylation. Food Chem. 2017, 214, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhang, K.; Li, Z.; Zhang, J.; Zhai, X.; Zhang, N.; Du, L.; Qin, Z. Exploring the Integration of Anthocyanins with Functional Materials in Smart Food Packaging: From Stabilization to Application. Foods 2025, 14, 2896. [Google Scholar] [CrossRef] [PubMed]

- Divya; Joshi, S.; Appukuttan, J.; Chandrapala, J.; Majzoobi, M. Impact of Conventional and Advanced Techniques on Stability of Natural Food Colourants. Foods 2025, 14, 3187. [Google Scholar] [CrossRef]

- Ghosh, S.; Sarkar, T.; Das, A.; Chakraborty, R. Natural colorants from plant pigments and their encapsulation: An emerging window for the food industry. LWT 2022, 153, 112527. [Google Scholar] [CrossRef]

- Jiang, X.; Sun, J.; Bai, W. Anthocyanins in Food. In Handbook of Dietary Phytochemicals; Xiao, J., Sarker, S.D., Asakawa, Y., Eds.; Springer: Singapore, 2021; pp. 371–421. [Google Scholar] [CrossRef]

- Dey, S.; Nagababu, B.H. Applications of Food Color and Bio-Preservatives in the Food and Its Effect on the Human Health. Food Chem. Adv. 2022, 1, 100019. [Google Scholar] [CrossRef]

- Nabi, B.G.; Mukhtar, K.; Ahmed, W.; Manzoor, M.F.; Ranjha, M.M.A.N.; Kieliszek, M.; Bhat, Z.F.; Aadil, R.M. Natural pigments: Anthocyanins, carotenoids, chlorophylls, and betalains as colorants in food products. Food Biosci. 2023, 52, 102403. [Google Scholar] [CrossRef]

- Granados-Balbuena, S.Y.; Chicatto-Gasperín, V.; Santacruz-Juárez, E.; Ocaranza-Sánchez, E.; Ramírez-López, C.; García-Meza, M.G.; Tapia-López, L.; Robles de la Torre, R.R.; Robles López, M.R. Patented technologies in the extraction, preservation, and application of anthocyanins in food: A review. Appl. Food Res. 2024, 4, 100388. [Google Scholar] [CrossRef]

- Nthimole, C.T.; Kaseke, T.; Fawole, O.A. Exploring the Extraction and Application of Anthocyanins in Food Systems. Processes 2024, 12, 2444. [Google Scholar] [CrossRef]

- Molina, A.K.; Corrêa, R.C.G.; Prieto, M.A.; Pereira, C.; Barros, L. Bioactive Natural Pigments Extraction, Isolation, and Stability in Food Applications. Molecules 2023, 28, 1200. [Google Scholar] [CrossRef] [PubMed]

- Michel, M.; Eldridge, A.L.; Hartmann, C.; Klassen, P.; Ingram, J.; Meijer, G.W. Benefits and Challenges of Food Processing in the Context of Food Systems, Value Chains and Sustainable Development Goals. Trends Food Sci. Technol. 2024, 153, 104703. [Google Scholar] [CrossRef]

- Elansari, A.; Bekhit, A.E.A. Processing, Storage and Quality of Cook-Chill or Cook-Freeze Foods. In Minimally Processed Foods; Siddiqui, M.W., Rahman, M.S., Eds.; Springer: Cham, Switzerland, 2015; pp. 125–150. [Google Scholar] [CrossRef]

- Arruda, H.S.; Silva, E.K.; Araujo, N.M.P.; Pereira, G.A.; Pastore, G.M.; Marostica Junior, M.R. Anthocyanins recovered from agri-food by-products using innovative processes: Trends, challenges, and perspectives for their application in food systems. Molecules 2021, 26, 2632. [Google Scholar] [CrossRef] [PubMed]

- Khoo, H.E.; Azlan, A.; Tang, S.T.; Lim, S.M. Anthocyanidins and anthocyanins: Colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr. Res. 2017, 61, 1361779. [Google Scholar] [CrossRef]

- Ab Rashid, S.; Tong, W.Y.; Leong, C.R.; Abdul Ghazali, N.M.; Taher, M.A.; Ahmad, N.; Tan, W.-N.; Teo, S.H. Anthocyanin Microcapsule from Clitoria ternatea: Potential Bio-preservative and Blue Colorant for Baked Food. Arab. J. Sci. Eng. 2021, 46, 65–72. [Google Scholar] [CrossRef]

- Wijesekara, T.; Xu, B. A critical review on the stability of natural food pigments and stabilization techniques. Food Res. Int. 2024, 179, 114011. [Google Scholar] [CrossRef]

- Irianto, I.; Rahmana Putra, N.R.; Yustisia, Y.; Abdullah, S.; Syafruddin, S.; Paesal, P.; Irmadamayanti, A.; Herawati, H.; Raharjo, B.; Agustini, S.; et al. Green technologies in food colorant extraction: A comprehensive review. S. Afr. J. Chem. Eng. 2025, 51, 22–34. [Google Scholar] [CrossRef]

- Albuquerque, B.R.; Pinela, J.; Barros, L.; Oliveira, M.B.P.P.; Ferreira, I.C.F.R. Anthocyanin-rich extract of jabuticaba epicarp as a natural colourant: Optimization of heat- and ultrasound-assisted extractions and application in a bakery product. Food Chem. 2020, 316, 126364. [Google Scholar] [CrossRef]

- Papillo, V.A.; Locatelli, M.; Travaglia, F.; Bordiga, M.; Garino, C.; Arlorio, M.; Coïsson, J.D. Spray-dried polyphenolic extract from Italian black rice (Oryza sativa L., var. Artemide) as new ingredient for bakery products. Food Chem. 2018, 269, 603–609. [Google Scholar] [CrossRef]

- López, C.J.; Caleja, C.; Prieto, M.A.; Sokovic, M.; Calhelha, R.C.; Barros, L.; Ferreira, I.C.F.R. Stability of a cyanidin-3-O-glucoside extract obtained from Arbutus unedo L. and incorporation into wafers for colouring purposes. Food Chem. 2019, 275, 426–438. [Google Scholar] [CrossRef]

- Lavelli, V.; Sri Harsha, S.C.P.; Spigno, G. Modelling the stability of maltodextrin-encapsulated grape skin phenolics used as a new ingredient in apple puree. Food Chem. 2016, 209, 323–331. [Google Scholar] [CrossRef]

- Shamshad, A.; Ul-Haq, I.; Butt, M.S.; Nayik, G.A.; Al Obaid, S.; Ansari, M.J.; Karabagias, I.K.; Sarwar, N.; Ramniwas, S. Effect of storage on physicochemical attributes of ice cream enriched with microencapsulated anthocyanins from black carrot. Food Sci. Nutr. 2023, 11, 3976–3988. [Google Scholar] [CrossRef]

- Montibeller, M.J.; de Lima Monteiro, P.; Tupuna-Yerovi, D.S.; de Oliveira Rios, A.; Manfroi, V. Stability assessment of anthocyanins obtained from skin grape applied in kefir and carbonated water as a natural colorant. J. Food Process. Preserv. 2018, 42, e13698. [Google Scholar] [CrossRef]

- Yun, Y.; Li, J.; Pan, F.; Zhou, Y.; Feng, X.; Tian, J.; Cai, S.; Yi, J.; Zhou, L. A novel strategy for producing low-sugar pomegranate jam with better anthocyanin stability: Combination of high-pressure processing and low methoxyl & amidated pectin. LWT 2023, 179, 114625. [Google Scholar] [CrossRef]

- Trentin, J.; Mussagy, C.U.; Arantes, M.S.; Pedro, A.C.; Mafra, M.R.; Farias, F.O. Antioxidant Ready-to-Use Grape Pomace Extracts Recovered with Natural Eutectic Mixtures for Formulation of Color-Rich Gummies. Foods 2024, 13, 2840. [Google Scholar] [CrossRef] [PubMed]

- da Silva, L.P.; Pereira, E.; Prieto, M.A.; Simal-Gandara, J.; Pires, T.C.S.P.; Alves, M.J.; Calhelha, R.; Barros, L.; Ferreira, I.C.F.R. Rubus ulmifolius Schott as a novel source of food colorant: Extraction optimization of coloring pigments and incorporation in a bakery product. Molecules 2019, 24, 2181. [Google Scholar] [CrossRef] [PubMed]

- Kainat, F.; Ali, M.; Akbar, A.; Masih, R.; Mehnaz, S.; Sadiq, M.B. Ultrasonic Extraction of Phenolic Compounds from Eggplant Peel and Formulation of Eggplant Peel Extract-Enriched Ice-Cream. J. Food Qual. 2023, 2023, 3267119. [Google Scholar] [CrossRef]

- Stoica, F.; Rațu, R.N.; Motrescu, I.; Cara, I.G.; Filip, M.; Țopa, D.; Jităreanu, G. Application of pomace powder of black carrot as a natural food ingredient in yoghurt. Foods 2024, 13, 1130. [Google Scholar] [CrossRef]

- Neves, C.; Fogeiro, È.; Cardoso, S.M.; Gonçalves, F.; Pinto, A.; Wessel, D.F. Towards the Valorization of Elderberry By-Product: Recovery and Use of Natural Ingredients for Sorbet Formulations. Appl. Sci. 2024, 14, 10328. [Google Scholar] [CrossRef]

- Huang, J.-Y.; Chen, Y.-L.; Lin, D.-Q.; Sun, L.-C.; Liu, K.; Zhang, L.-J.; Hu, Y.-Q.; Cao, M.-J. Updated insights into steady-modified anthocyanin food packaging: Novel strategies, characterization, application and future challenges. Food Chem. 2025, 483, 144113. [Google Scholar] [CrossRef]

- Almasi, H.; Forghani, S.; Moradi, M. Recent advances on intelligent food freshness indicators; an update on natural colorants and methods of preparation. Food Packag. Shelf Life 2022, 32, 100839. [Google Scholar] [CrossRef]

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.-A.T. Environmental Impact of Bioplastic Use: A Review. Heliyon 2021, 7, e07918. [Google Scholar] [CrossRef]

- Roy, S.; Ezati, P.; Khan, A.; Rhim, J.-W. New opportunities and advances in quercetin-added functional packaging films for sustainable packaging applications: A mini-review. Crit. Rev. Food Sci. Nutr. 2023, 64, 8464–8479. [Google Scholar] [CrossRef] [PubMed]

- Caźon, P.; Mateus, A.R.; Sanches Silva, A. Advances in active packaging using natural biopolymers and fruit by-products for enhanced food preservation. Food Res. Int. 2025, 213, 116439. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Kiani-Salmi, N.; Tavassoli, M.; McClements, D.J.; Ehsani, A.; Khezerlou, A.; Alizadeh Sani, M. Monitoring food spoilage using smart plant-based packaging materials: Methylcellulose/soy protein films loaded with betacyanin and carbon dots. Future Foods 2025, 11, 100610. [Google Scholar] [CrossRef]

- Kafashan, A.; Joze-Majidi, H.; Kazemi-Pasarvi, S.; Babaei, A.; Jafari, S.M. Nanocomposites of soluble soybean polysaccharides with grape skin anthocyanins and graphene oxide as an efficient halochromic smart packaging. Sustain. Mater. Technol. 2023, 38, e00755. [Google Scholar] [CrossRef]

- Amin, U.; Khan, M.U.; Majeed, Y.; Rebezov, M.; Khayrullin, M.; Bobkova, E.; Shariati, M.A.; Chung, I.M.; Thiruvengadam, M. Potentials of polysaccharides, lipids and proteins in biodegradable food packaging applications. Int. J. Biol. Macromol. 2021, 183, 2184–2198. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Chen, Z.; Zhong, B.; Liu, B. Intelligent food packaging materials: Principles, types, applications, and hydrophobization. Food Control 2025, 171, 111138. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, C.; Pu, Y.; Chen, S.; Liu, L.; Cui, Z.; Zhong, Y. Recent Advances in pH-Responsive Freshness Indicators Using Natural Food Colorants to Monitor Food Freshness. Foods 2022, 11, 1884. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Fang, D.; Kimatu, B.M.; Lyu, L.; Wu, W.; Cao, F.; Li, W. Recent advances in anthocyanin-based films and its application in sustainable intelligent food packaging: A review. Food Control 2024, 162, 110431. [Google Scholar] [CrossRef]

- de Oliveira Filho, J.G.; Cavalcante Braga, A.R.; Ribeiro de Oliveira, B.; Gomes, F.P.; Lopes Moreira, V.; Cano Pereira, V.A.; Buraelo Egea, M. The potential of anthocyanins in smart, active, and bioactive eco-friendly polymer-based films: A review. Food Res. Int. 2021, 142, 110202. [Google Scholar] [CrossRef] [PubMed]

- Oladzadabbasabadi, N.; Nafchi, A.M.; Ghasemlou, M.; Ariffin, F.; Singh, Z.; Al-Hassan, A.A. Natural anthocyanins: Sources, extraction, characterization, and suitability for smart packaging. Food Packag. Shelf Life 2022, 33, 100872. [Google Scholar] [CrossRef]

- Yücetepe, M.; Özaslan, Z.T.; Karakuş, M.Ş.; Akalan, M.; Karaaslan, A.; Karaaslan, M.; Başyiğit, B. Unveiling the multifaceted world of anthocyanins: Biosynthesis pathway, natural sources, extraction methods, copigmentation, encapsulation techniques, and future food applications. Food Res. Int. 2024, 187, 114437. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Huang, T.-S.; Yan, H.; Hu, X.; Ren, T. Novel pH-sensitive films based on starch/polyvinyl alcohol and food anthocyanins as a visual indicator of shrimp deterioration. Int. J. Biol. Macromol. 2020, 145, 768–776. [Google Scholar] [CrossRef]

- Yong, H.; Wang, X.; Zhang, X.; Liu, Y.; Qin, Y.; Liu, J. Effects of anthocyanin-rich purple and black eggplant extracts on the physical, antioxidant and pH-sensitive properties of chitosan film. Food Hydrocoll. 2019, 94, 93–104. [Google Scholar] [CrossRef]

- Thakur, R.; Pristijono, P.; Scarlett, C.J.; Bowyer, M.; Singh, S.P.; Vuong, Q.V. Starch-based films: Major factors affecting their properties. Int. J. Biol. Macromol. 2019, 132, 1079–1089. [Google Scholar] [CrossRef]

- Cheng, M.; Yan, X.; Cui, Y.; Han, M.; Wang, X.; Wang, J.; Zhang, R. An eco-friendly film of pH-responsive indicators for smart packaging. J. Food Eng. 2022, 321, 110943. [Google Scholar] [CrossRef]

- Mali, S.; Grossmann, M.V.E.; Garcia, M.A.; Martino, M.N.; Zaritzky, N.E. Barrier, mechanical and optical properties of plasticized yam starch films. Carbohydr. Polym. 2004, 56, 129–135. [Google Scholar] [CrossRef]

- Akeju, T.; Sheremet, A.; Smirnova, A.V.; Yakimenka, D.; Lee-Inwood, J.; Soto, M.; Nganyalila, A.M.; Mwambwiga, A.; Mercader, J.; Dunfield, P.F. Microbial starch degradation in arid soil: Community dynamics, environmental influences, and archaeological implications. Soil Biol. Biochem. 2025, 209, 109882. [Google Scholar] [CrossRef]

- Singh, G.P.; Bangar, S.P.; Yang, T.; Trif, M.; Kumar, V.; Kumar, D. Effect on the Properties of Edible Starch-Based Films by the Incorporation of Additives: A Review. Polymers 2022, 14, 1987. [Google Scholar] [CrossRef]

- Prietto, L.; Mirapalhete, T.C.; Pinto, V.Z.; Hoffmann, J.F.; Vanier, N.L.; Lim, L.-T.; Dias, A.R.G.; da Rosa Zavareze, E. pH-sensitive films containing anthocyanins extracted from black bean seed coat and red cabbage. LWT 2017, 80, 492–500. [Google Scholar] [CrossRef]

- Erna, K.H.; Felicia, W.X.L.; Vonnie, J.M.; Rovina, K.; Yin, K.W.; Nur’Aqilah, M.N. Synthesis and Physicochemical Characterization of Polymer Film-Based Anthocyanin and Starch. Biosensors 2022, 12, 211. [Google Scholar] [CrossRef]

- Otálora González, C.M.; Schelegueda, L.I.; Pizones Ruiz-Henestrosa, V.M.; Campos, C.A.; Basanta, M.F.; Gerschenson, L.N. Cassava Starch Films with Anthocyanins and Betalains from Agroindustrial by-Products: Their Use for Intelligent Label Development. Foods 2022, 11, 3361. [Google Scholar] [CrossRef]

- Dutta, P.K.; Dutta, J.; Tripathi, V.S. Chitin and Chitosan: Chemistry, Properties and Applications. J. Sci. Ind. Res. 2004, 63, 20–31. [Google Scholar]

- Sahariah, P.; Másson, M. Antimicrobial chitosan and chitosan derivatives: A review of the structure–activity relationship. Biomacromolecules 2017, 18, 3846–3868. [Google Scholar] [CrossRef]

- Hisham, F.; Akmal, M.H.M.; Ahmad, F.; Ahmad, K.; Samat, N. Biopolymer chitosan: Potential sources, extraction methods, and emerging applications. Ain Shams Eng. J. 2024, 15, 102424. [Google Scholar] [CrossRef]

- Haghighi, H.; Licciardello, F.; Fava, P.; Siesler, H.W.; Pulvirenti, A. Recent advances on chitosan-based films for sustainable food packaging applications. Food Packag. Shelf Life 2020, 26, 100551. [Google Scholar] [CrossRef]

- Kumar, A.; Yadav, S.; Pramanik, J.; Sivamaruthi, B.S.; Jayeoye, T.J.; Prajapati, B.G.; Chaiyasut, C. Chitosan-based composites: Development and perspective in food preservation and biomedical applications. Polymers 2023, 15, 3150. [Google Scholar] [CrossRef]

- Li, L.; Li, Q. Advancements in chitosan–anthocyanin composite films: Sustainable food preservation with biodegradable packaging. Foods 2025, 14, 1721. [Google Scholar] [CrossRef]

- Liu, X.; Xu, F.; Yong, H.; Chen, D.; Tang, C.; Kan, J.; Liu, J. Recent advances in chitosan-based active and intelligent packaging films incorporated with flavonoids. Food Chem. X 2025, 25, 102200. [Google Scholar] [CrossRef]

- Hao, Y.; Kang, J.; Guo, X.; Sun, M.; Li, H.; Bai, H.; Cui, H.; Shi, L. pH-responsive chitosan-based film containing oregano essential oil and black rice bran anthocyanin for preserving pork and monitoring freshness. Food Chem. 2023, 403, 134393. [Google Scholar] [CrossRef]

- Wang, X.; Yong, H.; Gao, L.; Li, L.; Jin, M.; Liu, J. Preparation and characterization of antioxidant and pH-sensitive films based on chitosan and black soybean seed coat extract. Food Hydrocoll. 2019, 89, 56–66. [Google Scholar] [CrossRef]

- Tavassoli, M.; Khezerlou, A.; Firoozy, S.; Ehsani, A.; Bangar, S.P. Chitosan-based film incorporated with anthocyanins of red poppy (Papaver rhoeas L.) as a colorimetric sensor for the detection of shrimp freshness. Int. J. Food Sci. Technol. 2023, 58, 3050–3057. [Google Scholar] [CrossRef]

- Barreto Alves Zacheski, J.; Berrocal Rojas, C.E.; Gerhardt, R.; Cappellari, N.P.; de Farias, B.S.; Christ Ribeiro, A.; Sant’Anna Cadaval Junior, T.R.; de Almeida Pinto, L.A. Chitosan-based films enriched with anthocyanin compounds for potential use as food packaging. Int. J. Biol. Macromol. 2025, 317, 144867. [Google Scholar] [CrossRef]

- Athanasiou, P.E.; Patila, M.; Fotiadou, R.; Giotopoulou, I.; Barkoula, N.-M.; Voutsas, E.; Stamatis, H. pH-responsive chitosan films enriched with NADES-extracted wine lees anthocyanins for in situ food monitoring. Gels 2025, 11, 676. [Google Scholar] [CrossRef]

- Yong, H.; Wang, X.; Bai, R.; Miao, Z.; Zhang, X.; Liu, J. Development of antioxidant and intelligent pH-sensing packaging films by incorporating purple-fleshed sweet potato extract into chitosan matrix. Food Hydrocoll. 2019, 90, 216–224. [Google Scholar] [CrossRef]

- Yong, H.; Liu, J.; Qin, Y.; Bai, R.; Zhang, X.; Liu, J. Antioxidant and pH-sensitive films developed by incorporating purple and black rice extracts into chitosan matrix. Int. J. Biol. Macromol. 2019, 137, 307–316. [Google Scholar] [CrossRef]

- Khezerlou, A.; Tavassoli, M.; Alizadeh-Sani, M.; Ehsani, A.; McClements, D.J. Smart packaging for food spoilage assessment based on Hibiscus sabdariffa L. Anthocyanin-loaded chitosan films. J. Compos. Sci. 2023, 7, 404. [Google Scholar] [CrossRef]

- Li, Y.; Wu, K.; Wang, B.; Li, X. Colorimetric indicator based on purple tomato anthocyanins and chitosan for application in intelligent packaging. Int. J. Biol. Macromol. 2021, 174, 370–376. [Google Scholar] [CrossRef]

- Grzybek, P.; Dudek, G.; van der Bruggen, B. Cellulose-based films and membranes: A comprehensive review on preparation and applications. Chem. Eng. J. 2024, 495, 153500. [Google Scholar] [CrossRef]

- Romão, S.; Bettencourt, A.; Ribeiro, I.A.C. Novel features of cellulose-based films as sustainable alternatives for food packaging. Polymers 2022, 14, 4968. [Google Scholar] [CrossRef]

- Channa, I.A.; Ashfaq, J.; Wasti, M.; Memon, A.G.; Hasan, M.; Shar, M.A.; AlHazaa, A.; Tiliakos, A. pH-responsive halochromic films based on carboxymethyl cellulose infused with anthocyanin or curcumin dye extracts for smart packaging applications. Hybrid Adv. 2025, 10, 100476. [Google Scholar] [CrossRef]

- Kaewprachu, P.; Romruen, O.; Jaisan, C.; Rawdkuen, S.; Klunklin, W. Smart colorimetric sensing films based on carboxymethyl cellulose incorporated with a natural pH indicator. Int. J. Biol. Macromol. 2024, 259, 129156. [Google Scholar] [CrossRef]

- Kaewprachu, P.; Jaisan, C.; Rawdkuen, S.; Osako, K. Colorimetric indicator films based on carboxymethyl cellulose and anthocyanins as a visual indicator for shrimp freshness tracking. Heliyon 2024, 10, e31527. [Google Scholar] [CrossRef]

- Boonsiriwit, A.; Itkor, P.; Sirieawphikul, C.; Lee, Y.S. Characterization of natural anthocyanin indicator based on cellulose bio-composite film for monitoring the freshness of chicken tenderloin. Molecules 2022, 27, 2752. [Google Scholar] [CrossRef]

- Freitas, P.A.V.; Silva, R.R.A.; de Oliveira, T.V.; Soares, R.R.A.; Junior, N.S.; Moraes, A.R.F.; Pires, A.C.D.S.; Soares, N.F.F. Development and characterization of intelligent cellulose acetate-based films using red cabbage extract for visual detection of volatile bases. LWT 2020, 132, 109780. [Google Scholar] [CrossRef]

- Shayan, M.; Gwon, J.; Koo, M.S.; Lee, D.; Adhikari, A.; Wu, Q. pH-responsive cellulose nanomaterial films containing anthocyanins for intelligent and active food packaging. Cellulose 2022, 29, 9731–9751. [Google Scholar] [CrossRef]

- Tohamy, H.-A.S. A novel anthocyanins hydroxyethyl cellulose film for intelligent chicken meat packaging with mechanical study, DFT calculations and molecular docking study. Sci. Rep. 2025, 15, 27311. [Google Scholar] [CrossRef]

- Acharyya, P.P.; Sarma, M.; Kashyap, A. Recent advances in synthesis and bioengineering of bacterial nanocellulose composite films for green, active and intelligent food packaging. Cellulose 2024, 31, 7163–7187. [Google Scholar] [CrossRef]

- Abdelkader, R.M.M.; Hamed, D.A.; Gomaa, O.M. Red cabbage extract immobilized in bacterial cellulose film as an eco-friendly sensor to monitor microbial contamination and gamma irradiation of stored cucumbers. World J. Microbiol. Biotechnol. 2024, 40, 258. [Google Scholar] [CrossRef]

- Mohammadalinejhad, S.; Almasi, H.; Moradi, M. Immobilization of Echium amoenum anthocyanins into bacterial cellulose film: A novel colorimetric pH indicator for freshness/spoilage monitoring of shrimp. Food Control 2020, 113, 107169. [Google Scholar] [CrossRef]

- Moradi, M.; Tajik, H.; Almasi, H.; Forough, M.; Ezati, P. A novel pH-sensing indicator based on bacterial cellulose nanofibers and black carrot anthocyanins for monitoring fish freshness. Carbohydr. Polym. 2019, 222, 115030. [Google Scholar] [CrossRef]

- Yerramathi, B.B.; Muniraj, B.A.; Donadi, J.; Bandi, K.; Kola, M. Transformation of alginate based films into food packaging material—Confines and possibilities as a renewable resource: A review. React. Funct. Polym. 2025, 215, 106358. [Google Scholar] [CrossRef]

- Santos, L.G.; Alves-Silva, G.F.; Martins, V.G. Active-intelligent and biodegradable sodium alginate films loaded with Clitoria ternatea anthocyanin-rich extract to preserve and monitor food freshness. Int. J. Biol. Macromol. 2022, 220, 866–877. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, H.; Jiang, Z.; Ding, X.; Chen, W.; Ma, N.; Xu, S.; Yang, L. Intelligent active packaging of sodium alginate and pectin mixed with Aronia melanocarpa anthocyanins and tea polyphenols for shrimp freshness monitoring and preservation. Int. J. Biol. Macromol. 2024, 283, 137754. [Google Scholar] [CrossRef]

- Santos, L.G.; Alves-Silva, G.F.; Gomes, B.M.; Martins, V.G. A novel sodium alginate active films functionalized with purple onion peel extract (Allium cepa). Biocatal. Agric. Biotechnol. 2021, 35, 102096. [Google Scholar] [CrossRef]

- Santos, L.G.; Martins, V.G. Multifunctional alginate films blended with polyphenol-rich extract from unconventional edible sources: Bioactive properties, UV-light protection, and food freshness monitoring. Int. J. Biol. Macromol. 2024, 262, 130001. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, R.; Han, J.; Ren, L.; Jiang, L. Protein-based packaging films in food: Developments, applications, and challenges. Gels 2024, 10, 418. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; He, Y.; Wen, L.; Nan, H.; Zheng, F.; Liu, H.; Lu, S.; Wu, M.; Zhang, H. A review of the interaction between anthocyanins and proteins. Food Sci. Technol. Int. 2021, 27, 470–482. [Google Scholar] [CrossRef]

- Shaik, M.I.; Azhari, M.F.; Sarbon, N.M. Gelatin-based film as a color indicator in food-spoilage observation: A review. Foods 2022, 11, 3797. [Google Scholar] [CrossRef]

- Musso, Y.S.; Salgado, P.R.; Mauri, A.N. Smart gelatin films prepared using red cabbage (Brassica oleracea L.) extracts as solvent. Food Hydrocoll. 2019, 89, 674–681. [Google Scholar] [CrossRef]

- Hematian, F.; Baghaei, H.; Nafchi, A.M.; Bolandi, M. Preparation and characterization of an intelligent film based on fish gelatin and anthocyanin to monitor the freshness of rainbow trout fish fillet. Food Sci. Nutr. 2023, 11, 379–389. [Google Scholar] [CrossRef]

- Chen, L.; Ramezan, Y.; Pourramezan, H.; Najafi, A.; Kamkari, A.; Goksen, G.; Huang, Z.; Zhang, W. Soy protein isolate (spi)-based films/coatings for food packaging: Research progress on properties and applications. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70181. [Google Scholar] [CrossRef]

- Wang, S.; Marcone, M.; Barbut, S.; Lim, L.-T. The impact of anthocyanin-rich red raspberry extract (ARRE) on the properties of edible soy protein isolate (SPI) films. J. Food Sci. 2012, 77, C497–C505. [Google Scholar] [CrossRef]

- Kandasamy, S.; Yoo, J.; Yun, J.; Kang, H.-B.; Seol, K.-H.; Kim, H.-W.; Ham, J.-S. Application of whey protein-based edible films and coatings in food industries: An updated overview. Coatings 2021, 11, 1056. [Google Scholar] [CrossRef]

- Rajendran, D.S.; Venkataraman, S.; Jha, S.K.; Chakrabarty, D.; Kumar, V.V. A review on bio-based polymer polylactic acid potential on sustainable food packaging. Food Sci. Biotechnol. 2024, 33, 1759–1788. [Google Scholar] [CrossRef]

- León-Vázquez, B.B.; Rodríguez-Félix, F.; Torres-Arreola, W.; Aubourg, S.P.; Graciano-Verdugo, A.Z.; Plascencia-Jatomea, M.; Quintero-Reyes, I.E.; Urías-Torres, M.Á.; Moreno-Robles, A.L.; Tapia-Hernández, J.A.; et al. Design and characterization of polylactic acid/cellulose acetate films incorporating black carrot extract rich in anthocyanins as a pH-sensitive food packaging. Int. J. Biol. Macromol. 2025, 317, 144840. [Google Scholar] [CrossRef]

- Akbari, S.M.; Nikoo, A.M. Fabrication of pH-sensitive smart indicator film from polylactic acid and elderberry anthocyanin for monitoring chicken spoilage. Packag. Technol. Sci. 2025, 38, 640–659. [Google Scholar] [CrossRef]

- Latiff, N.F.; Sulaiman, N.F.; Shaik, M.I.; Mohamad, N.J.; Khairul, W.M.; Daud, A.I.; Sarbon, N.M. Halochromic smart film: A gelatin-based pH-sensitive film embedded with anthocyanin from roselle (Hibiscus sabdariffa) extracts for potential food spoilage indicator application. J. Food Sci. 2025, 90, e70134. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, W.; Li, Z.; Zhang, N.; Wang, S.; Shi, J.; Zhai, X.; Zhang, J.; Shen, T. Preparation of a dual-functional active film based on bilayer hydrogel and red cabbage anthocyanin for maintaining and monitoring pork freshness. Foods 2023, 12, 4520. [Google Scholar] [CrossRef]

- Nadi, M.; Razavi, S.M.A.; Shahrampour, D. Fabrication of green colorimetric smart packaging based on basil seed gum/chitosan/red cabbage anthocyanin for real-time monitoring of fish freshness. Food Sci. Nutr. 2023, 11, 6360–6375. [Google Scholar] [CrossRef]

- Li, R.; Wang, S.; Feng, H.; Zhuang, D.; Zhu, J. An intelligent chitosan/gelatin film via improving the anthocyanin-induced color recognition accuracy for beef sub-freshness differentiation monitoring. Food Hydrocoll. 2024, 146, 109219. [Google Scholar] [CrossRef]

- Hailu, F.W.; Fanta, S.W.; Tsige, A.A.; Delele, M.A. Development of simple and biodegradable pH indicator films from cellulose and anthocyanin. Discov. Sustain. 2025, 6, 220. [Google Scholar] [CrossRef]

- Chen, H.; Meng, X.; Zhang, F.; Chen, J.; Ding, X.; Jian, T.; Niu, G.; Tong, B.; Gai, Y.; Zhao, H.; et al. Development of chitosan-carboxymethyl cellulose edible films loaded with blackberry anthocyanins and tea polyphenols and their application in beef preservation. Food Hydrocoll. 2025, 164, 111198. [Google Scholar] [CrossRef]

- Karadag, A.; Ozkan, K.; Sagdic, O. Development of microencapsulated grape juice powders using black ‘Isabel’ grape peel pectin and application in jelly formulation with enhanced in vitro bioaccessibility of anthocyanins. J. Food Sci. 2024, 89, 2067–2083. [Google Scholar] [CrossRef]

- Becerril, R.; Nerín, C.; Silva, F. Bring Some Colour to Your Package: Freshness Indicators Based on Anthocyanin Extracts. Trends Food Sci. Technol. 2021, 111, 495–505. [Google Scholar] [CrossRef]

- Rosales-Murillo, S.S.; Sánchez-Bodón, J.; Hernández Olmos, S.L.; Ibarra-Vázquez, M.F.; Guerrero-Ramírez, L.G.; Pérez-Álvarez, L.; Vilas-Vilela, J.L. Anthocyanin-Loaded Polymers as Promising Nature-Based, Responsive, and Bioactive Materials. Polymers 2024, 16, 163. [Google Scholar] [CrossRef]

- Otoni, C.G.; Espitia, P.J.P.; Avena-Bustillos, R.J.; Mchugh, T.H. Trends in antimicrobial food packaging systems: Emitting sachets and absorbent pads. Food Res. Int. 2016, 83, 60–73. [Google Scholar] [CrossRef]

- Camo, J.; Beltrán, J.A.; Roncalés, P. Extension of the display life of lamb with an antioxidant active packaging. Meat Sci. 2008, 80, 1086–1091. [Google Scholar] [CrossRef]

- Kuorwel, K.K.; Cran, M.J.; Sonneveld, K.; Miltz, J.; Bigger, S.W. Essential oils and their principal constituents as antimicrobial agents for synthetic packaging films. J. Food Sci. 2011, 76, R164–R177. [Google Scholar] [CrossRef]

- Shen, N.; Wang, T.; Gan, Q.; Liu, S.; Wang, L.; Jin, B. Plant flavonoids: Classification, distribution, biosynthesis, and antioxidant activity. Food Chem. 2022, 383, 132531. [Google Scholar] [CrossRef]

- Bai, Z.; Huang, X.; Meng, J.; Kan, L.; Nie, S. Survey of Chinese Cowpea Cultivars for Phenolic Compounds and Antioxidant Activity. Curr. Top. Nutraceutical Res. 2019, 17, 337–348. Available online: https://www.nchpjournals.com/Manuscript?id=1283 (accessed on 4 September 2025).

- Kurek, M.; Garofulić, I.E.; Bakić, M.T.; Ščetar, M.; Uzelac, V.D.; Galić, K. Development and evaluation of a novel antioxidant and pH indicator film based on chitosan and food waste sources of antioxidants. Food Hydrocoll. 2018, 84, 238–246. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, Y.; Zhu, W.; Xu, W.; Ma, C.; Liu, X.; Liu, F. Development of a photothermal antibacterial film using purple corncob anthocyanin and its application in cherry tomato preservation. Food Biosci. 2025, 64, 105772. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhang, F.; Mi, S.; Yu, W.; Sang, Y.; Wang, X. Preparation of chitosan/polyvinyl alcohol antibacterial indicator composite film loaded with AgNPs and purple sweet potato anthocyanins and its application in strawberry preservation. Food Chem. 2025, 463, 141442. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, J.; Xu, J.; Li, Y.; Zhang, X.; Zhang, W. Preparation and characterization of chitosan/corn starch based films loaded with Vaccinium vitis-idaea anthocyanin nanocomplexes and the application in shrimp preservation. Int. J. Biol. Macromol. 2025, 303, 140734. [Google Scholar] [CrossRef]

- Wang, S.; Xia, P.; Wang, S.; Liang, J.; Sun, Y.; Yue, P.; Gao, X. Packaging films formulated with gelatin and anthocyanins nanocomplexes: Physical properties, antioxidant activity and its application for olive oil protection. Food Hydrocoll. 2019, 96, 617–624. [Google Scholar] [CrossRef]

- Deng, J.; Shi, H. Enhanced stability of anthocyanins and phages by titanium dioxide-loaded cyclodextrin-metal organic frameworks: Application as a cherry tomato preservative. Food Biosci. 2025, 66, 106280. [Google Scholar] [CrossRef]

- Xu, M.; Fang, D.; Shi, C.; Xia, S.; Wang, J.; Deng, B.; Kimatu, B.M.; Guo, Y.; Lyu, L.; Wu, Y.; et al. Anthocyanin-loaded polylactic acid/quaternized chitosan electrospun nanofiber as an intelligent and active packaging film in blueberry preservation. Food Hydrocoll. 2025, 158, 110586. [Google Scholar] [CrossRef]

- Hao, J.; Wang, J.; Wang, J.; Wang, S.; Zhao, C.; Fan, Z. A novel multifunctional bioactive film based on Gelidium amausli polysaccharide incorporated with lingonberry anthocyanin for fish freshness monitoring and preservation. LWT 2025, 215, 117173. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Lv, J.; Yang, J.; Liu, X.; Zhang, X.; Zhang, W. Fabrication and characterization of blue honeysuckle anthocyanins-loaded nanocomposite films and the application in pork preservation. Food Hydrocoll. 2024, 149, 109600. [Google Scholar] [CrossRef]

- Song, S.; Ji, R.; Xu, J.; Yang, X.; An, Q.; Zhang, X.; Zhang, W. Preparation and characterization of highly stable pH-sensitive multifunctional films based on co-pigment-anthocyanin conjugate system for pork monitoring and preservation. Food Hydrocoll. 2025, 164, 111151. [Google Scholar] [CrossRef]

- Li, R.; Feng, H.; Wang, S.; Zhuang, D.; Wen, Y.; Zhu, J. A double-layer film based on the strategy of tannic acid-anthocyanin co-pigmentation and tannic-crosslinked-gelatin/reduced Ag nanoparticles for beef preservation and monitoring. Food Chem. 2024, 460, 140642. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Gao, J.; Liu, X.; Zhang, X.; Zeng, X.; Zhang, X.; Zhao, P. Preparation of soybean isolate protein/xanthan gum/agar-Lycium ruthenicum anthocyanins intelligent indicator films and its application in mutton preservation. Int. J. Biol. Macromol. 2024, 283, 137751. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, Y.; Yong, H.; Liu, J.; Zhang, X.; Liu, J. Preparation and characterization of active and intelligent packaging films based on cassava starch and anthocyanins from Lycium ruthenicum Murr. Int. J. Biol. Macromol. 2019, 134, 80–90. [Google Scholar] [CrossRef]

- Mustafa, P.; Niazi, M.B.K.; Jahan, Z.; Samin, G.; Hussain, A.; Ahmed, T.; Naqvi, S.R. PVA/starch/propolis/anthocyanins rosemary extract composite films as active and intelligent food packaging materials. J. Food Saf. 2019, 40, e12725. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Saha, N.; Zandraa, O.; Pummerova, M.; Saha, P. Essential oil based PVP-CMC-BC-GG functional hydrogel sachet for ‘cheese’: Its shelf life confirmed with anthocyanin (isolated from red cabbage) bio stickers. Foods 2020, 9, 307. [Google Scholar] [CrossRef]

- Wang, S.; Li, R.; Han, M.; Zhuang, D.; Zhu, J. Intelligent active films of sodium alginate and konjac glucomannan mixed by Lycium ruthenicum anthocyanins and tea polyphenols for milk preservation and freshness monitoring. Int. J. Biol. Macromol. 2023, 253, 126674. [Google Scholar] [CrossRef]

- Sun, G.; Chi, W.; Xu, S.; Wang, L. Developing a simultaneously antioxidant and pH-responsive κ-carrageenan/hydroxypropyl methylcellulose film blended with Prunus maackii extract. Int. J. Biol. Macromol. 2020, 155, 1393–1400. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Tavassoli, M.; Hamishehkar, H.; McClements, D.J. Carbohydrate-based films containing pH-sensitive red barberry anthocyanins: Application as biodegradable smart food packaging materials. Carbohydr. Polym. 2021, 255, 117488. [Google Scholar] [CrossRef] [PubMed]

- Seftiono, H.; Pramesti, D.A.; Sumiasih, I.H. Color indicator film from butterfly pea (Clitoria Ternatea L.) as smart packaging in broiler chicken meat. Int. J. Appl. Biol. 2021, 5, 13–25. Available online: https://journal.unhas.ac.id/index.php/ijoab/article/view/13431 (accessed on 14 May 2025).

- Chayavanich, K.; Thiraphibundet, P.; Imyim, A. Biocompatible film sensors containing red radish extract for meat spoilage observation. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2020, 226, 117601. [Google Scholar] [CrossRef]

- Guo, Z.; Han, L.; Yu, Q.; Lin, L. Effect of a sea buckthorn pomace extract-esterified potato starch film on the quality and spoilage bacteria of beef jerky sold in supermarket. Food Chem. 2020, 326, 127001. [Google Scholar] [CrossRef]

- Musso, Y.S.; Salgado, P.R.; Mauri, A.N. Smart edible films based on gelatin and curcumin. Food Hydrocoll. 2017, 66, 8–15. [Google Scholar] [CrossRef]

- Luchese, C.L.; Abdalla, V.F.; Spada, J.C.; Tessaro, I.C. Evaluation of blueberry residue incorporated cassava starch film as pH indicator in different simulants and foodstuffs. Food Hydrocoll. 2018, 82, 209–218. [Google Scholar] [CrossRef]

- Liu, D.; Cui, Z.; Shang, M.; Zhong, Y. A colorimetric film based on polyvinyl alcohol/sodium carboxymethyl cellulose incorporated with red cabbage anthocyanin for monitoring pork freshness. Food Packag. Shelf Life 2021, 28, 100641. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Tavassoli, M.; McClements, D.J.; Hamishehkar, H. Multifunctional halochromic packaging materials: Saffron petal anthocyanin loaded-chitosan nanofiber/methyl cellulose matrices. Food Hydrocoll. 2021, 111, 106237. [Google Scholar] [CrossRef]

- Lan, W.; Wang, S.; Zhang, Z.; Liang, X.; Liu, X.; Zhang, J. Development of red apple pomace extract/chitosan-based films reinforced by TiO2 nanoparticles as a multifunctional packaging material. Int. J. Biol. Macromol. 2021, 168, 105–115. [Google Scholar] [CrossRef] [PubMed]

- Goodarzi, M.M.; Moradi, M.; Tajik, H.; Forough, M.; Ezati, P.; Kuswandi, B. Development of an easy-to-use colorimetric pH label with starch and carrot anthocyanins for milk shelf life assessment. Int. J. Biol. Macromol. 2020, 153, 240–247. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Li, S.; Ji, T.; Wu, W.; Sameen, D.E.; Ahmed, S.; Qin, W.; Dai, J.; Liu, Y. Development and optimization of dynamic gelatin/chitosan nanoparticles incorporated with blueberry anthocyanins for milk freshness monitoring. Carbohydr. Polym. 2020, 247, 116738. [Google Scholar] [CrossRef]

- Tirtashi, F.E.; Moradi, M.; Tajik, H.; Forough, M.; Ezati, P.; Kuswandi, B. Cellulose/chitosan pH-responsive indicator incorporated with carrot anthocyanins for intelligent food packaging. Int. J. Biol. Macromol. 2019, 136, 920–926. [Google Scholar] [CrossRef]

- Weston, M.; Phan, M.A.T.; Arcot, J.; Chandrawati, R. Anthocyanin-based sensors derived from food waste as an active use-by date indicator for milk. Food Chem. 2020, 326, 127017. [Google Scholar] [CrossRef]

- Zhang, Q.; Lin, G.; Wang, H.; Jin, M.C.; Dang, H.; Zhang, J.; Guo, R.; Yan, H.; Niu, B.; Wang, H. Development of smart packaging film incorporated with sodium alginate-chitosan quaternary ammonium salt nanocomplexes encapsulating anthocyanins for monitoring milk freshness. Int. J. Biol. Macromol. 2024, 263, 130336. [Google Scholar] [CrossRef] [PubMed]

- Jafarzadeh, S.; Nafchi, A.M.; Salehabadi, A.; Oladzad-abbasabadi, N.; Jafari, S.M. Application of bio-nanocomposite films and edible coatings for extending the shelf life of fresh fruits and vegetables. Adv. Colloid Interface Sci. 2021, 291, 102405. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Pu, Y.; Chen, L.; Jiang, H.; Xu, Y.; Cao, J.; Jiang, W. A comprehensive review of intelligent packaging for fruits and vegetables: Target responders, classification, applications, and future challenges. Compr. Rev. Food Sci. Food Saf. 2023, 22, 842–881. [Google Scholar] [CrossRef] [PubMed]

- Bhowmik, S.; Agyei, D.; Ali, A. Smart chitosan films as intelligent food packaging: An approach to monitoring food freshness and biomarkers. Food Packag. Shelf Life 2024, 46, 101370. [Google Scholar] [CrossRef]

- Kumar, P.S.; Shuprajhaa, T.; Rajendran, A.; Dhandapani, K. Banana flower bract anthocyanin based pH sensitive, intelligent film indicator developed using banana starch and its derivative. Food Packag. Shelf Life 2024, 46, 101375. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Ramaswamy, H. Design and testing of an electrospun nanofiber mat as a pH biosensor and monitor the pH associated quality in fresh date fruit (Rutab). Polym. Test. 2019, 75, 76–84. [Google Scholar] [CrossRef]

- Yi, F.; Hou, F.; Zhan, S.; Song, L.; Chen, X.; Han, X.; Zhang, R.; Wang, X.; Liu, Z. Highly sensitive smart chitosan/zein film cross-linked with Fe2+ chelated red radish anthocyanins nanoparticles for mushroom freshness monitoring. Food Res. Int. 2025, 201, 115572. [Google Scholar] [CrossRef]

- Singh, S.; Nwabor, O.F.; Syukri, D.M.; Voravuthikunchai, S.P. Chitosan-polyvinyl alcohol intelligent films fortified with anthocyanins isolated from Clitoria ternatea and Carissa carandas for monitoring beverage freshness. Int. J. Biol. Macromol. 2021, 182, 1015–1025. [Google Scholar] [CrossRef]

- Huang, J.; Liu, J.; Chen, M.; Yao, Q.; Hu, Y. Immobilization of roselle anthocyanins into polyvinyl alcohol/hydroxypropyl methylcellulose film matrix: Study on the interaction behavior and mechanism for better shrimp freshness monitoring. Int. J. Biol. Macromol. 2021, 184, 666–677. [Google Scholar] [CrossRef]

- Kang, S.; Wang, H.; Xia, L.; Chen, M.; Li, L.; Cheng, J.; Li, X.; Jiang, S. Colorimetric film based on polyvinyl alcohol/okra mucilage polysaccharide incorporated with rose anthocyanins for shrimp freshness monitoring. Carbohydr. Polym. 2020, 229, 115402. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Tavassoli, M.; Mohammadian, E.; Ehsani, A.; Khaniki, G.J.; Priyadarshi, R.; Rhim, J.-W. pH-responsive color indicator films based on methylcellulose/chitosan nanofiber and barberry anthocyanins for real-time monitoring of meat freshness. Int. J. Biol. Macromol. 2021, 166, 741–750. [Google Scholar] [CrossRef] [PubMed]

- Nazaruddin, N.; Afifah, N.; Bahi, M.; Susilawati, S.; Sani, N.D.M.; Esmaeili, C.; Iqhrammullah, M.; Murniana, M.; Hasanah, U.; Safitri, E. A simple optical pH sensor based on pectin and Ruellia tuberosa L-derived anthocyanin for fish freshness monitoring. F1000Research 2021, 10, 422. [Google Scholar] [CrossRef]

- Sun, W.; Liu, Y.; Jia, L.; Saldana, M.D.A.; Dong, T.; Jin, Y.; Sun, W. A smart nanofibre sensor based on anthocyanin/poly L-lactic acid for mutton freshness monitoring. Int. J. Food Sci. Technol. 2021, 56, 342–351. [Google Scholar] [CrossRef]

- Yan, J.; Cui, R.; Qin, Y.; Li, L.; Yuan, M. A pH indicator film based on chitosan and butterfly pudding extract for monitoring fish freshness. Int. J. Biol. Macromol. 2021, 177, 328–336. [Google Scholar] [CrossRef]

- Zhai, X.; Shi, J.; Zou, X.; Wang, S.; Jiang, C.; Zhang, J.; Huang, X.; Zhang, W.; Holmes, M. Novel colorimetric films based on starch/polyvinyl alcohol incorporated with roselle anthocyanins for fish freshness monitoring. Food Hydrocoll. 2017, 69, 308–317. [Google Scholar] [CrossRef]

- Liu, J.; Wang, H.; Guo, M.; Li, L.; Chen, M.; Jiang, S.; Li, X.; Jiang, S. Extract from Lycium ruthenicum Murr. Incorporating κ-carrageenan colorimetric film with a wide pH–sensing range for food freshness monitoring. Food Hydrocoll. 2019, 94, 1–10. [Google Scholar] [CrossRef]

- Liu, B.; Xu, H.; Zhao, H.; Liu, W.; Zhao, L.; Li, Y. Preparation and characterization of intelligent starch/PVA films for simultaneous colorimetric indication and antimicrobial activity for food packaging applications. Carbohydr. Polym. 2017, 157, 842–849. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Y.; Bai, R.; Zhang, X.; Yuan, L.; Liu, J. Preparation of pH-sensitive and antioxidant packaging films based on κ-carrageenan and mulberry polyphenolic extract. Int. J. Biol. Macromol. 2019, 134, 993–1001. [Google Scholar] [CrossRef] [PubMed]

- Zang, Z.; Tang, S.; Li, Z.; Chou, S.; Shu, C.; Chen, Y.; Chen, W.; Yang, S.; Yang, Y.; Tian, J.; et al. An Updated Review on the Stability of Anthocyanins Regarding the Interaction with Food Proteins and Polysaccharides. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4378–4401. [Google Scholar] [CrossRef] [PubMed]

- Fu, W.; Li, S.; Helmick, H.; Hamaker, B.R.; Kokini, J.L.; Reddivari, L. Complexation with Polysaccharides Enhances the Stability of Isolated Anthocyanins. Foods 2023, 12, 1846. [Google Scholar] [CrossRef]

- Zhu, F. Starch Based Films and Coatings for Food Packaging: Interactions with Phenolic Compounds. Food Res. Int. 2025, 204, 115758. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Guo, J.; Zhong, Z.; Chen, J.; Jin, P.; Zheng, Y.; Wu, Z. Integrated Smart Packaging of Modified Silica/Anthocyanin/Nanocellulose for Preservation and Monitoring. Foods 2025, 14, 1888. [Google Scholar] [CrossRef]

- Zhang, L.; Yao, L.; Zhao, F.; Yu, A.; Zhou, Y.; Wen, Q.; Wang, J.; Zheng, T.; Chen, P. Protein and Peptide-Based Nanotechnology for Enhancing Stability, Bioactivity, and Delivery of Anthocyanins. Adv. Healthc. Mater. 2023, 12, e2300473. [Google Scholar] [CrossRef] [PubMed]

- Leong, C.R.; Daud, N.S.; Tong, W.Y.; Cheng, S.Y.; Tan, W.N.; Hamin, N.S.; Pa’ee, K.F. Gelatine Film Incorporated with Clitoriaternatea-Derived Anthocyanin Microcapsules, a Food Packaging Material Effective Against Foodborne Pathogens. Food Technol. Biotechnol. 2021, 59, 422–431. [Google Scholar] [CrossRef]

- Wu, Y.; Yin, Z.; Qie, X.; Chen, Y.; Zeng, M.; Wang, Z.; Qin, F.; Chen, J.; He, Z. Interaction of Soy Protein Isolate Hydrolysates with Cyanidin-3-O-Glucoside and Its Effect on the In Vitro Antioxidant Capacity of the Complexes Under Neutral Condition. Molecules 2021, 26, 1721. [Google Scholar] [CrossRef]

- Mihalca, V.; Kerezsi, A.D.; Weber, A.; Gruber-Traub, C.; Schmucker, J.; Vodnar, D.C.; Dulf, F.V.; Socaci, S.A.; Fărcaș, A.; Mureșan, C.I.; et al. Protein-Based Films and Coatings for Food Industry Applications. Polymers 2021, 13, 769. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, L.; Wang, J.; Xue, Z.; Zhang, M.; Ma, X.; Wang, G.; Lv, S. Preparation and Application of pH-Sensitive Film Containing Anthocyanins Extracted from Lycium ruthenicum Murr. Materials 2023, 16, 3828. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Wild, F.; Bugnicourt, E.; Cinelli, P.; Lindner, M.; Schmid, M.; Weckel, V.; Müller, K.; Rodriguez, P.; Staebler, A.; et al. State of the Art in the Development and Properties of Protein-Based Films and Coatings and Their Applicability to Cellulose Based Products: An Extensive Review. Coatings 2016, 6, 1. [Google Scholar] [CrossRef]

- Dăescu, D.I.; Dreavă, D.M.; Todea, A.; Peter, F.; Păușescu, I. Intelligent Biopolymer-Based Films: Promising New Solutions for Food Packaging Applications. Polymers 2024, 16, 2256. [Google Scholar] [CrossRef]

- Roy, S.; Malik, B.; Chawla, R.; Bora, S.; Ghosh, T.; Santhosh, R.; Thakur, R.; Sarkar, P. Biocompatible Film Based on Protein/Polysaccharides Combination for Food Packaging Applications: A Comprehensive Review. Int. J. Biol. Macromol. 2024, 278, 134658. [Google Scholar] [CrossRef]

- Chung, C.; Rojanasasithara, T.; Mutilangi, W.; McClements, D.J. Stabilization of natural colors and nutraceuticals: Inhibition of anthocyanin degradation in model beverages using polyphenols. Food Chem. 2016, 212, 596–603. [Google Scholar] [CrossRef] [PubMed]

- Căta, A.; Ienaşcu, I.M.C.; Tănasie, C.; Ştefănuț, M.N. Thermal degradation of anthocyanin pigments in bilberry, blackberry and black mulberry extracts in the presence of some added food antioxidants. Rev. Roum. Chim. 2019, 64, 893–899. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, X.; Zheng, H.; Li, J.; Wu, X.; Xu, J.; Zhen, Z.; Du, C. The application of encapsulation technology in the food industry: Classifications, recent advances, and perspectives. Food Chem. X 2024, 21, 101240. [Google Scholar] [CrossRef]

- Yang, M.; Lin, J.; Zhang, M.; Zhuang, Y.; Li, Y.; Wang, B.; Zhang, Z.; Liu, J.; Fei, P. Recent advances in the development and application of anthocyanin-based intelligent active food packaging: A review. Food Chem. 2025, 492, 145309. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant Phenolics: Extraction, Analysis and Their Antioxidant and Anticancer Properties. Molecules 2010, 15, 7313–7352. [Google Scholar] [CrossRef] [PubMed]

- Mungwari, C.P.; King’ondu, C.K.; Sigauke, P.; Obadele, B.A. Conventional and Modern Techniques for Bioactive Compounds Recovery from Plants: Review. Sci. Afr. 2025, 27, e02509. [Google Scholar] [CrossRef]

- Chemat, F.; Abert-Vian, M.; Fabiano-Tixier, A.-S.; Strube, J.; Uhlenbrock, L.; Gunjevic, V.; Cravotto, G. Green extraction of natural products: Origins, current status, and future challenges. Trends Anal. Chem. 2019, 118, 248–263. [Google Scholar] [CrossRef]

- Singh, S.; Gaikwad, K.K.; Lee, Y.S. Anthocyanin—A Natural Dye for Smart Food Packaging Systems. Korean J. Packag. Sci. Tech. 2018, 24, 167–180. [Google Scholar] [CrossRef]

- Rezazadeh, A.; Ghasempour, Z. Anthocyanin Stabilization in Beverages. In Natural Products in Beverages. Reference Series in Phytochemistry; Mérillon, J.M., Rivière, C., Lefèvre, G., Eds.; Springer: Cham, Switzerland, 2025; pp. 675–709. [Google Scholar] [CrossRef]

- Ścibisz, I.; Ziarno, M.; Mitek, M. Color Stability of Fruit Yogurt During Storage. J. Food Sci. Technol. 2019, 56, 1997–2009. [Google Scholar] [CrossRef]

- Martinsen, B.K.; Aaby, K.; Skrede, G. Effect of temperature on stability of anthocyanins, ascorbic acid and color in strawberry and raspberry jams. Food Chem. 2020, 316, 126297. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Amaya, D.B. Natural food pigments and colorants. Curr. Opin. Food Sci. 2016, 7, 20–26. [Google Scholar] [CrossRef]

- Yang, M.; Koo, S.I.; Song, W.O.; Chun, O.K. Food matrix affecting anthocyanin bioavailability: Review. Curr. Med. Chem. 2011, 18, 291–300. [Google Scholar] [CrossRef]

- Ou, S.J.L.; Yu, J.; Zhou, W.; Liu, M.H. Effects of Anthocyanins on Bread Microstructure, and Their Combined Impact on Starch Digestibility. Food Chem. 2022, 374, 131744. [Google Scholar] [CrossRef]

- U.S. Food and Drug Administration. Color Additives in Foods. 2023. Available online: https://www.fda.gov/food/color-additives-information-consumers/color-additives-foods (accessed on 28 August 2025).

- EFSA Panel on Food Additives and Nutrient Sources added to Food (ANS). Scientific Opinion on the Re-Evaluation of Anthocyanins (E 163) as a Food Additive. EFSA J. 2013, 11, 3145. Available online: https://efsa.onlinelibrary.wiley.com/doi/epdf/10.2903/j.efsa.2013.3145 (accessed on 3 November 2025).

- U.S. Food and Drug Administration (FDA). Color Additives: Grape Color Extract; Permanently Listed, Exempt from Certification. Available online: https://hfpappexternal.fda.gov/scripts/fdcc/index.cfm?set=ColorAdditives&id=GrapeColorExtract (accessed on 30 October 2025).

- U.S. Food and Drug Administration (FDA). Color Additives: Grape Skin Extract (Enocianina); Permanently Listed, Exempt from Certification. Available online: https://hfpappexternal.fda.gov/scripts/fdcc/index.cfm?set=ColorAdditives&id=GrapeSkinExtract (accessed on 30 October 2025).

- U.S. Food and Drug Administration (FDA). Color Additives: Butterfly Pea Flower Extract; Permanently Listed, Exempt from Certification. Available online: https://hfpappexternal.fda.gov/scripts/fdcc/index.cfm?set=ColorAdditives&id=ButterflyPeaFlowerExtract (accessed on 30 October 2025).

- Tsuchiya, K.; Mani, G.; Arita, H.; Hirano, Y. Food Packaging Sheet and Indicator. WO2023008380A1, 2 February 2023. [Google Scholar]

- Kong, B.; Wang, Q.; Li, X.; Xu, J.; Chen, Q. Preparation Method and Application of Edible Anthocyanin Preservative Film for Shrimps with Preservation Effect. CN114479143A, 13 May 2022. [Google Scholar]

| References | Source of Anthocyanins | Extraction Method/Other Formulation Components | Applications | Advantages, Perspectives |

|---|---|---|---|---|

| [89] | Jabuticaba epicarp | Heat-assisted and Ultrasound-assisted extraction in acidified ethanol | Natural colorant in macarons | Potential use as natural food colorants; more stable color than the commercial colorant E163 during a 6-day shelf-life |

| [91] | Arbutus unedo L. | Heat-assisted extraction | Natural colorant in wafers | Good antioxidant and antifungal activity; potential industrial application as alternative source for natural colorant |

| [90] | Oryza sativa L., var. Artemide | Heat-assisted extraction in acidified ethanol/Microencapsulation of Artemide rice extract in maltodextrin and arabic gum | Functional ingredient for bakery foods | Stable and useful ingredients for functional foods and nutraceuticals; could minimize the production costs, turning a secondary product into a high added-value one |

| [86] | Clitoria ternatea flowers | Distilled water–acetic acid extraction/Microencapsulation of anthocyanins in maltodextrin | Blue colorant for baked food products (Muffins) | Improved the color stability index of anthocyanins by micro-encapsulation; broad spectrum antibacterial activity against foodborne Gram-bacteria |

| [94] | Grape skin | Acetate buffer extraction | Natural food colorant in kefir (and carbonated water) | Natural additive in beverages or dairy products; can substitute the synthetic colorants in processed food |

| [93] | Black carrot | Ethanolic extraction/Microencapsulation of anthocyanins in gum arabic and maltodextrin | Functional additive for ice cream products | Significant potential to stabilize the anthocyanins during processing and storage of ice cream and other products |

| [96] | Grape pomace | Eutectic mixture extraction (choline chloride, acetic and citric acids) | Gummy candies natural food dye | Sustainable source of natural colorants in the food industry; suitable for incorporation into functional food products |

| [97] | Rubus ulmifolius Schott fruits | Heat-assisted extraction | Natural colorant (rose/purple) in donuts | Good coloring capacity, maintains nutritional value; antimicrobial properties; high coloring potential that could be used to replace artificial additives |

| [98] | Eggplant peels | Ultrasound-assisted extraction | Functional ingredient to improve the antioxidant potential of ice-cream | Extract-enriched ice-cream showed higher antioxidant potential and consumer acceptability than the blank ice-cream formulation |

| [99] | Black carrot pomace | Ultrasound-assisted extraction in acidified ethanol | Colorant and functional ingredient in yogurt formulations | Improves the nutritional and color of the yogurts, providing a visually appealing product; improves yogurt’s bioactive content and antioxidant capacity |

| [100] | Elderberry pomace | Extraction in water | Natural food additive in blueberry sorbet | Higher antioxidant activity compared to the control; better consumer acceptability; prebiotic potential: stimulate the growth of probiotic bacteria |

| References | Source of Anthocyanins | Extraction Method | Applications | Film Matrix/Other Active Components | Advantages/Disadvantages |

|---|---|---|---|---|---|

| [185] | Purple corncob | Ultrasonic assisted extraction with ethanol | Cherry tomato preservation | Chitosan matrix | Photothermal properties, hydrophobicity, thermal stability, high bactericidal activity and tensile strength/Generated heat could affect the texture, taste, and nutritional content of delicate products; limited applicability |

| [189] | Grape peels | Ultrasonic assisted extraction with ethanol | Cherry tomato preservation | γ-cyclodextrin metal- organic framework loaded with titanium dioxide | Improved resistance of anthocyanins to high temperature, UV light and oxidation; phage stability extended to 30 days at room temperature; effective and efficient antioxidant and bacteriostatic effects |

| [190] | Blueberry | - | Blueberry preservation | Polylactic acid/quaternized chitosan electrospun nanofiber | Enhanced water resistance; antioxidant and antimicrobial properties; great potential in extending the shelf life of blueberries/Reduced stiffness and gas barrier properties of the film |

| [186] | Purple sweet potato | - | Strawberry preservation | Chitosan/polyvinyl alcohol film matrix loaded with silver-nanoparticles | Excellent antibacterial properties; antibacterial indicator composite packaging materials for fruits and vegetables preservation/Excessive anthocyanin content led to a decrease in brightness |

| [191] | Lingonberry | Ultrasonic assisted extraction with ethanol | Fish (crucian carp) preservation | Gelidium amausli polysaccharide matrix | Strong antioxidant activity; free radical scavenging ability, antibacterial properties, and oxygen barrier performance; enhances the shelf life of the fish/Small sample size, restricting the generalizability of the findings |

| [187] | Vaccinium vitis-idaea | Sonication extraction in ethanol | Shrimp preservation | Chitosan/corn starch matrix | Effective preservation of shrimp; durable antibacterial and antioxidant properties; superior mechanical, moisture-resistance, and thermal stability qualities; suitable for long-term food packaging |

| [156] | Aronia melanocarpa | Ultrasonic extraction in acidic ethanol | Shrimp preservation | Sodium alginate/pectin matrix | Good antioxidant and antibacterial properties; capability to extend the shelf life of shrimp by approximately 12 h compared with the control group; substantial potential for food preservation |

| [192] | Blue honeysuckle | Sonication extraction in ethanol | Pork preservation | Chitosan/polyvinyl alcohol blend matrix | Antibacterial properties and durable antioxidant properties; suitable for long-term food packaging, effectively prolonging the storage period of pork |

| [193] | Wild cranberries | Ultrasonic crusher with ethanol | Pork preservation | κ-carrageenan/potato starch matrix | Antioxidant and antimicrobial properties (especially against Staphylococcus aureus); extended the shelf life of pork by up to 40 h compared to control group |

| [175] | Blackberry anthocyanins | Ultrasonic assisted extraction with ethanol | Beef preservation | Chitosan-carboxymethyl cellulose matrix | Protein breakdown capacity, improved oxidative stability, preventing the growth of aerobic bacteria on beef, extending its shelf life; good tensile strength, elongation at break, lower UV–vis light transmittance, and water vapor permeability |

| [194] | Purple sweet potato | Ethanol extraction | Beef preservation | Double-layer film: inner layer, agar; outer layer, κ-carrageenan-oregano essential oil Pickering emulsion/silver nanoparticles | Outstanding antioxidant and antimicrobial properties, with deceleration of beef spoilage rates; enhanced hydrophobicity and UV–vis barrier properties; good capabilities in food preservation |

| [195] | Lycium ruthenicum Murr. | Ethanol extraction | Mutton preservation | Soybean isolate protein/xanthan gum/agar | Mechanical and waterproof properties; strong antioxidant activity, significantly extending the shelf life of lamb meat during storage |

| [196] | Lycium ruthenicum Murr. | Ethanol extraction | Pork preservation | Cassava starch | Water vapor and ultraviolet-visible light barrier ability, tensile strength and antioxidant potential; can be used as active packaging films to extend the shelf life of food |

| [197] | Red cabbage | Ethanol–water extraction | Pasteurized milk preservation | Polyvinyl alcohol/starch | Good antibacterial activity against foodborne bacteria, like, E. coli and MRSA; can be utilized effectively for enhancing shelf life of food |

| [198] | Red cabbage | - | Gouda cheese preservation | Carboxymethyl cellulose/polyvinyl pyrrolidone/guar gum | Good antimicrobial, physical, mechanical, and thermal properties; the shelf life of cheese was extended for more than 10–12 day compared to the conventional packaging system/Reduced biodegradability of films with essential oil addition |

| [199] | Lycium ruthenicum | - | Milk preservation | Sodium alginate/konjac glucomannan | Significantly improved mechanical, barrier and antioxidant/antibacterial properties; excellent preservation effect in milk |

| [200] | Prunus maackii pomace | Ethanol extraction | Oil preservation | κ-carrageenan/hydroxypropyl methylcellulose | Increased flexibility, barrier properties, and antioxidant properties in the film, extending the oil’s shelf life; potential use for oil packaging |

| [188] | Cranberry | - | Olive oil preservation | Chitosan hydrochloride/carboxymethyl | Improved mechanical properties, thermal stability, and antioxidant capacity; edible packaging film suitable for extending the shelf life of fatty foods |

| References | Source of Anthocyanins | Extraction Method | Applications | Film Matrix/Other Active Components | Advantages/Disadvantages |

|---|---|---|---|---|---|

| [190] | Blueberry | - | Blueberry freshness monitoring | Polylactic acid/quaternized chitosan electrospun nanofiber | Dual functions including quality control and color monitoring; pH color responsive properties; good potential as a pH indicator in intelligent packaging/Reduced stiffness and gas barrier properties of the film |

| [186] | Purple sweet potato | - | Strawberry freshness monitoring | Chitosan/polyvinyl alcohol matrix | pH sensitivity and UV–visible light barrier properties; promising applications in fruit and vegetable freshness monitoring/Excessive anthocyanin content led to the decrease in brightness |

| [219] | Brassica oleracea L. | Macerated in ethanol–water mixture | Rutab fruit monitoring | Polyvinyl alcohol nanofiber | Real time monitoring of pH-linked changes within the package; reversible and stable pH sensor; rapid and sensitive detection of pH and associated changes in Rutab fruit during storage |

| [220] | Red radish | - | Mushroom freshness monitoring | Chitosan/zein composite nanoparticles | pH-sensitive smart film; rapid analysis, high sensitivity, low-cost and high accuracy; development of a mini WeChat program that could directly read the freshness of mushrooms/Limited by environmental factors (lighting or ambient temperature,) affecting the RGB readings |

| [191] | Lingonberry | Ultrasonic extraction with ethanol | Fish (crucian carp) freshness monitoring | Gelidium amausli polysaccharide matrix | Smart film sensitive to pH variations; excellent gas-sensing sensitivity; real-time freshness monitoring |

| [156] | Aronia melanocarpa | Ultrasonic extraction with acidic ethanol | Shrimp freshness monitoring | Sodium alginate/pectin matrix | UV-blocking properties; potential as a pH indicator for the development of intelligent packaging films; substantial potential for monitoring food freshness |

| [193] | Wild cranberries | Ultrasonic crusher with ethanol | Pork freshness monitoring | κ-carrageenan/potato starch matrix | pH-sensitive smart packaging film; good color sensitivity; significantly improved optical, mechanical and barrier properties |