Abstract

This work focuses on assessing the potential for energy recovery from biomass obtained from unproductive lands in the Jiu Valley. The main objective of the study is to identify a viable solution for the restoration of degraded land. The research aims to utilise these lands through energy crops; the biomass is then introduced into an anaerobic digestion plant to produce biogas. The novelty of this research consists of the physical transformation of these lands into a living laboratory, intended exclusively for the cultivation and study of biomass. Maize, soybean and sorghum plants were chosen for the study. The biomass was analysed in detail to determine the total solids (TS) and volatile solids (VS) content. In maize, VS ranged from 62.67% by mass to 76.58% by mass. In soybean, VS content was between 35.35% by mass and 36.60% by mass. In sorghum, VS ranged between 35.29% by mass and 38.86% by mass. This research showed that the largest amount of biogas resulted from fresh soybean biomass. Dry biomass, with its high lignin content, significantly reduced the digestion process’s efficiency. The study highlights that it is important to use fresh biomass after an appropriate mechanical pre-treatment to optimise biogas production.

1. Introduction

The European Union adopted the European Green Deal to transform Europe into a climate-neutral and resource-efficient economy. The key objectives of the European Green Deal are climate neutrality, a circular economy, clean industries, a healthy environment, more sustainable agriculture, and climate justice and equity [1,2]. To implement the objectives, new approaches are necessary, changing the methods of production and consumption, such as promoting cleaner, more sustainable, and more energy-efficient industries, to drastically reduce greenhouse gas emissions. These EU initiatives are in synergy with the EU Soil Strategy. The EU Soil Strategy for 2030, as highlighted by refs. [3,4], aims to achieve good soil health by 2050. The strategy also proposes voluntary and legislative actions for the protection, sustainable use, and restoration of soils as the new normal. These actions are all the more justified given that food production will be necessary for a global population that could reach 9.1 billion by 2050 and over 10 billion by the end of the century [5,6]; therefore, the more intelligent use of available land, including abandoned land and fallow land, will be required [7]. At the European level, approximately 60% to 70% of soils are currently in a state of poor health [8], and soil degradation remains a pressing issue. In this context, the challenge for the Jiu Valley is to restore soil health by cultivating unproductive lands affected by mining activities and reintegrating them into the economic circuit as part of the area’s just transition towards a green economy.

European legislation stipulates that biomass should primarily fulfil the role of ensuring food security, and only after this role is secured should biomass be used for energy valorisation. Therefore, it is necessary to identify the potential of marginal lands to improve food security, support bioenergy production, or provide ecosystem services [9]. On the other hand, the supply of biomass as an efficient raw material is important to facilitate the development of the market for advanced bioenergy and biofuel technologies [10].

Identifying a sustainable biomass valuation technology cultivated on these unproductive lands can bring economic benefits to the area and contribute to achieving decarbonisation goals. In this context, research on evaluating the possibilities of using technologies [11,12] for obtaining biogas through the anaerobic digestion of biomass harvested from the Jiu Valley contributes to identifying solutions for restoring the unproductive lands in the Jiu Valley and reintroducing them into the economic circuit. The production of biomass, primarily for energy generation, presents potential economic and environmental benefits [13]. At the same time, cultivating unproductive lands with biomass will stabilise soil and increase the area for carbon dioxide absorption, meeting the requirements of the European Green Deal. Achieving biomass production from unproductive lands will contribute to climate change mitigation, ecological restoration, and biodiversity conservation [14,15,16]. By establishing maize, soybean and sorghum crops, the residents of the Jiu Valley will engage in an activity that helps integrate the unproductive lands into the natural landscape of the area. The choice of maize, soybean, and sorghum as model crops was deliberate. These species are well adapted to the pedoclimatic conditions of the Jiu Valley and are already familiar within the local agricultural tradition, which facilitates their integration into field practices. From an energy perspective, maize is one of the most productive silage crops in Europe and a reference substrate for anaerobic digestion. Soybean, with its protein-rich biomass, supports rapid microbial activity and high methane yields, while sorghum is highly resilient to drought and soil heterogeneity, making it particularly suitable for cultivation on marginal or degraded lands. Taken together, these crops provide complementary characteristics that enable a robust evaluation of both the agronomic feasibility and the bioenergy potential of unproductive lands in mining-affected regions.

Various concerns are identified around the world regarding the experimentation of the conversion of unproductive lands into sustainable energy sources. For example, the FORBIO project can be mentioned, in which the crops Arundo donax and Salix viminalis were experimented on on degraded lands in Germany and Italy, which supported economic feasibility and a reduction in greenhouse gas emissions of about 57% compared to other reference scenarios [17]. In parallel, the analysis carried out by the IEA Bioenergy shows that up to 21 million hectares of marginal lands in the EU can support perennial energy crops, such as miscanthus and grasses, with the potential to produce over 2 EJ/year by 2050 [18]. These crops have been recognised not only for their high energy yield but also for their ability to sequester carbon and improve the properties of affected soils [19].

In addition, anaerobic digestion of biomass obtained from these lands represents a promising technology. Research conducted in countries such as Poland and the United Kingdom has shown the usefulness of this method with parameters regarding soil conditions, climate and plant composition, which emphasises the need to use fresh biomass, with minimal mechanical pre-treatment, in order to maximise biogas yield [20,21].

This study contributes by demonstrating the potential of unproductive mining lands to be transformed into a living laboratory for biomass cultivation and energy recovery. By assessing maize, soybean, and sorghum under real field conditions and linking biomass composition to biogas yields, the research provides practical evidence that marginal lands can support both ecological restoration and renewable energy goals.

2. Materials and Methods

2.1. Living Lab Location and Design

The methodological framework was structured in four sequential steps: cultivation of maize, soybean, and sorghum on mining tailings and adjacent marginal lands; sampling and basic characterisation of the harvested biomass; laboratory-scale anaerobic digestion experiments under mesophilic conditions; and measurement of biogas production and substrate parameters. This integrated workflow provided a direct link between field cultivation, biomass quality, and digestion performance, ensuring that the experimental results reflected both agronomic and energetic perspectives under real environmental conditions.

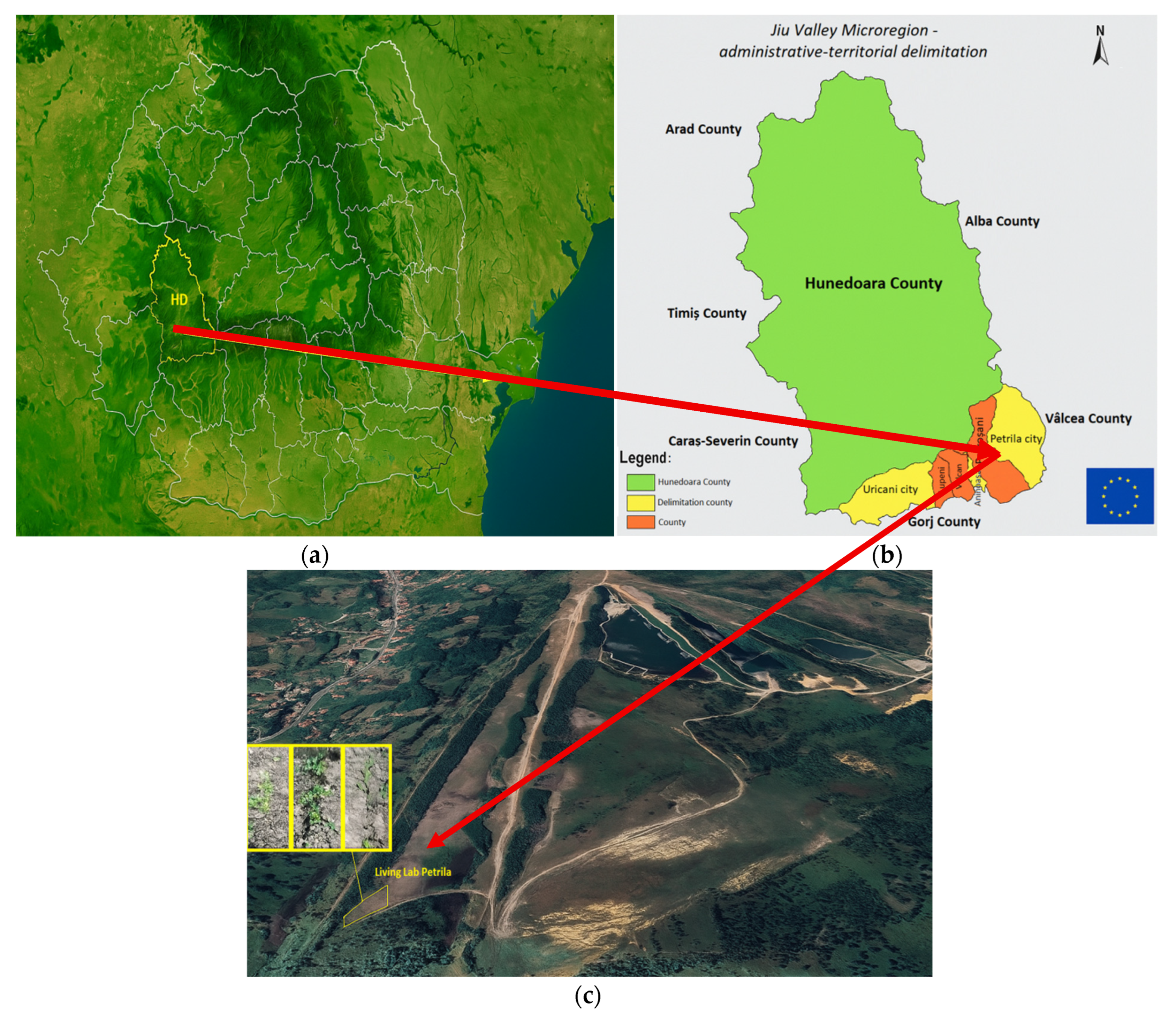

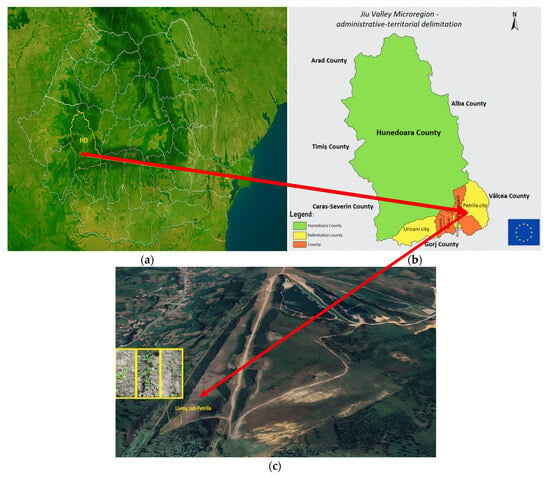

The Living Lab was constructed on a 5.000 m2 coal tailings dump. It is located at the former Petrila mine (Branch IV), Jiu Valley, Romania (Figure 1). The area was divided into three main plots, each divided into three experimental units, resulting in a total of nine plots. The design of the nine plots helped to carry out a comparative evaluation of the installed biomass crops and soil improvement treatments. Depending on the bioclimatic conditions, the three biomass species acclimatised to this area were chosen: maize, soybean and sorghum. In the three experimental plots, three plots were chosen to be the control and 6 plots to be cultivated with the aforementioned biomass, and crop rotation was carried out annually. The three control plots were established on unamended soil, without any biomass cultivation, in order to provide a reference for assessing changes induced by the experimental crops. On these control plots, baseline soil properties were monitored throughout the study, including pH, electrical conductivity (EC), organic matter content, nutrient availability (N, P, K), and potential trace metal concentrations. These measurements allowed us to evaluate natural seasonal variations and to distinguish them from the effects generated by biomass cultivation and subsequent treatments. The control plots therefore served as essential benchmarks for interpreting soil dynamics and for validating the analytical results obtained in the experimental plots. The Living Lab concept applied to these unproductive lands can constitute a replicable model of biomass cultivation, with field experimentation, application of amendments and systematic monitoring of agronomic and ecological parameters.

Figure 1.

Living Lab from Petrila Branch IV, Jiu Valley, Romania: (a) Physical map of Romania; (b) location of Hunedoara County and delimitation of the Jiu Valley micro-region; (c) location of the Living Lab on the Petrila tailings dump.

The mine tailings showed low fertility, high heterogeneity and potential contamination with heavy metals. No fertilisers were applied in the first two years; amendments were introduced in the third year. The biomass harvested from the Living Lab was processed to obtain digestate (by anaerobic digestion) and biochar (by pyrolysis). Application rates and mixing proportions were established based on preliminary laboratory analyses, with the aim of optimising nutrient availability and immobilising heavy metals. Soil samples were collected at the beginning of the experiment (2023) and after each harvest season for complete laboratory analyses, allowing for the assessment of the dynamics of soil properties and the effectiveness of the improvement treatments. Maize, sorghum and soybean crops were established on the experimental plots of the unproductive lands in the Jiu Valley in a living lab.

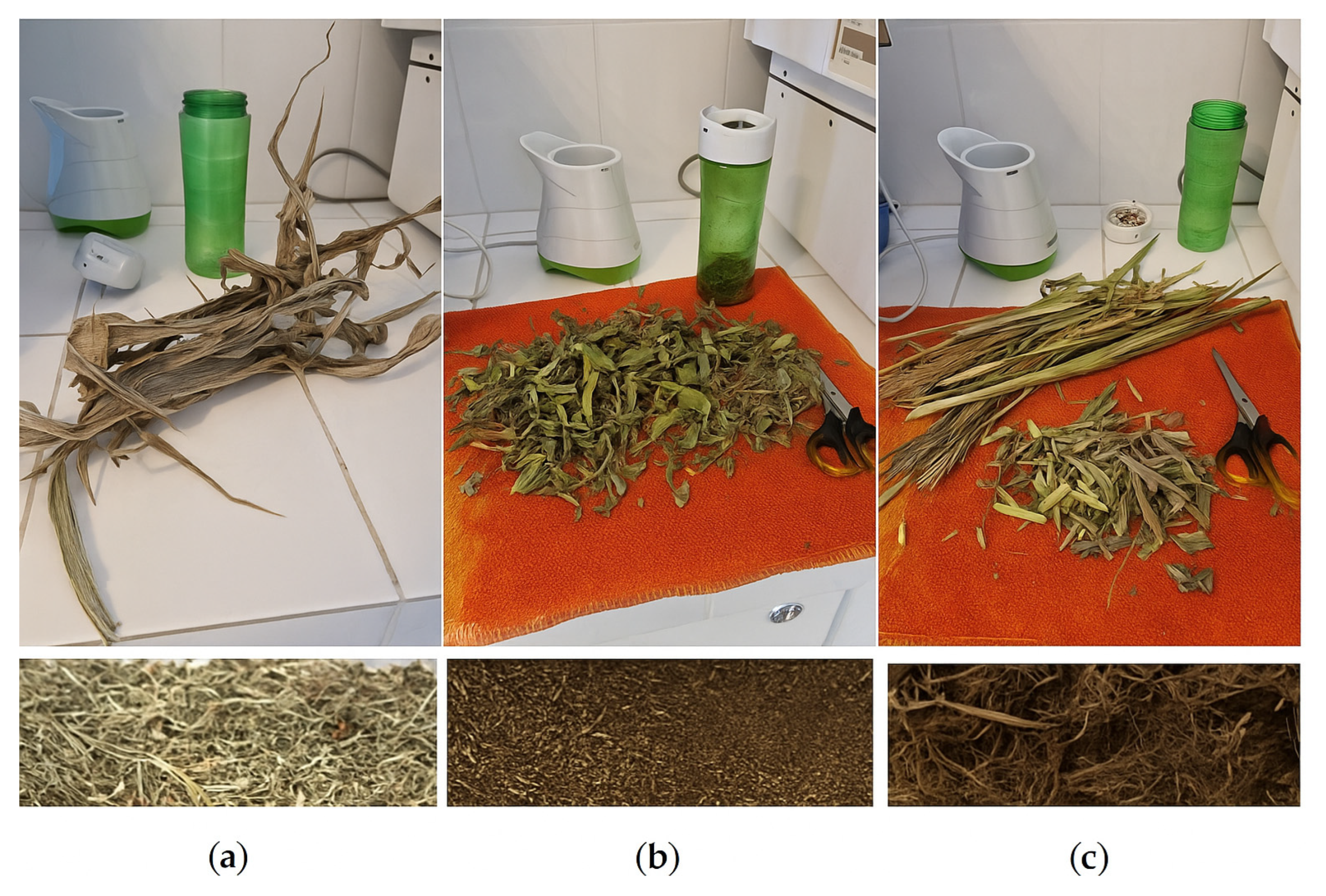

The experimental plots provided biomass (maize. soybean. and sorghum), which was mechanically pre-treated by shredding and grinding to an optimal granulation. The prepared biomass was introduced into the anaerobic digestion system, where a process happens that breaks down complex organic materials into biogas and digestate by different kinds of anaerobic bacteria without oxygen (Figure 2).

Figure 2.

Biomass before and after grinding and shredding: (a) Maize; (b) Soybean; (c) Sorghum.

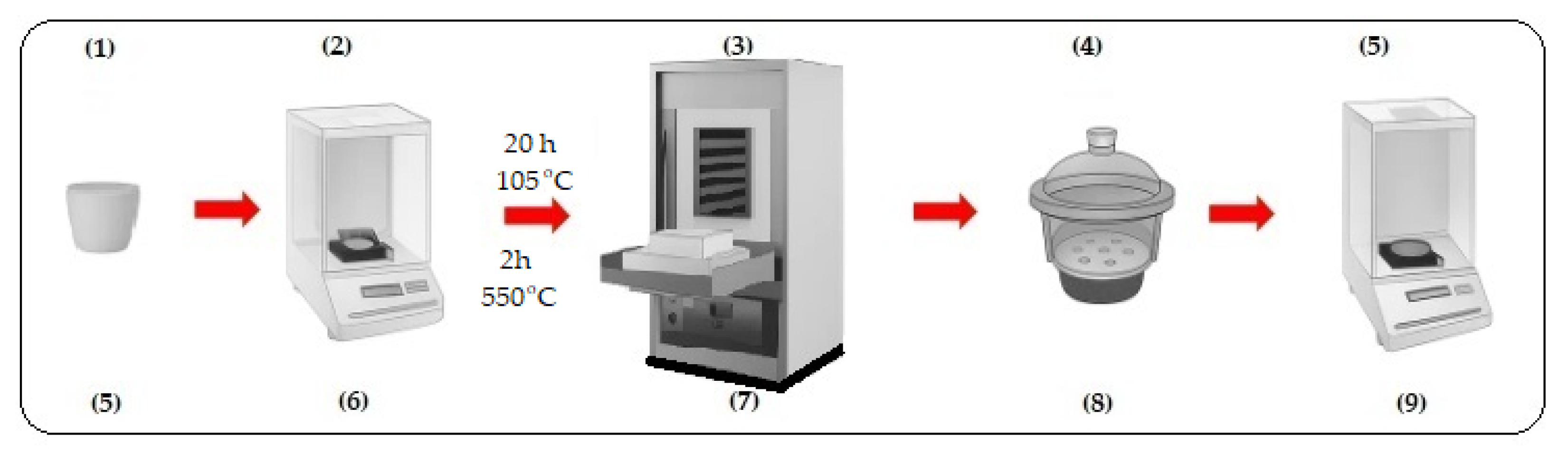

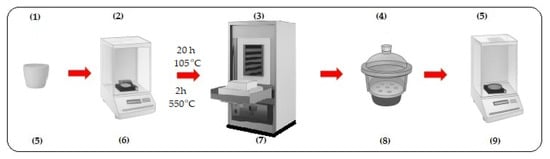

To evaluate the suitability of these crops for anaerobic digestion, the biomass composition was analysed. The means and procedures used are specific for determining the content of water (W), dry matter (TS), volatile matter (VS) and mineral matter (A) [17,18,19]. The tools and lab equipment used to measure TS and VS include crucibles, a precise electronic scale (Kern ABT 100-5M, Kern & Sohn GmbH, Balingen, Germany), an oven a muffle furnace (Nabertherm L 5/11, Nabertherm GmbH, Lilienthal, Germany), and desiccators (Kartell S.p.A., Milan, Italy), as shown in Figure 3.

Figure 3.

Equipment used for determining W, TS, VS and A for the investigated organic substance: (1). (5) Sample (crucible); (2). (6) Analytical balance (mo); (3). (7) Calcining oven; (4). (8) Desiccators; (5). (9) Analytical balance (mo).

2.2. Theory of Selecting Biomass Samples

In accordance with the principles of standardisation for representativeness and uniformity, biomass samples were collected from maize (Zea mays), soybean (Glycine max) and sorghum (Sorghum bicolor). Since biomass composition differs depending on species, plant fraction and growth stage, subsamples were taken from different anatomical parts (stems, leaves, and pods, panicles) to ensure a balanced representation [1,2]. The collected material was air-dried and subsequently oven-dried at 105 ± 2 °C to constant weight. The samples were then ground and homogenised to a particle size of <2 mm. For each biomass type, three analytical runs were prepared and analysed in parallel. For the selection of the representative sample, the lowest standard deviation among the three sample series was considered to ensure statistical robustness and reproducibility of the results [3,4]. Anaerobic digestion experiments were conducted in duplicate bioreactors for each crop sample, under identical operational conditions, to confirm reproducibility. Therefore, the quartering method was used to obtain analytical fractions, and representative subsamples were stored in airtight containers to prevent rehydration or contamination before calcinations [5]. Using these procedures, it is intended to minimise sampling errors and thus guarantee the reproducibility of thermal and chemical analyses. The biomass samples were prepared for drying and calcinations. In Figure 3, the state of the samples after the drying phase in the drying oven and calcinations is presented. The text continues here (Figure 4 and Table 1).

Figure 4.

The condition of the samples after the drying phase in the oven and calcinations: (a) biomass before calcinations (maize. soybean and sorghum); (b) biomass after calcinations.

Table 1.

The values obtained in the laboratory for the determination of total solids (TS).

Data processing, graphical visualisation, and statistical analyses were performed using OriginPro 2023 (OriginLab Corporation, Northampton, MA, USA) and Microsoft Excel 2021 (Microsoft Corporation, Redmond, WA, USA).

3. Results

The biomass samples collected in crucibles are weighed to determine the wet sample weight (mWet). The samples are then placed in an oven preheated to 105 °C and left for 20 h to remove the water content. These are weighed again to determine the amount of dry sample (mDried). The obtained results are summarised in Table 1.

Values are expressed as mean ± SD (same units as the mean; n = 3).

The variability in TS values among maize samples (82.7%, 83.8% and 69.0%) can be explained by differences in plant maturity and uneven soil moisture conditions across the experimental plots.

The dry substance (TS) is calculated as the ratio between the amount of the dried sample (mDried) and the initial amount of the wet sample (mWet) according to the following Formula (1).

where

- -

- mWet = mass of the wet sample (before drying), i.e., the sample as taken, also containing water.

- -

- mDried = mass of the dry sample (after drying at a standard temperature, usually 105 °C, to constant mass).

After determining TS, the samples are removed from the oven and allowed to cool to room temperature in desiccators. After weighing, the vessel is placed in a preheated oven at 550 °C (ignition), and after 2 h, the vessel is removed from the oven, cooled to room temperature in desiccators, and weighed. The values recorded from weighing the samples and those calculated are presented in Table 2.

Table 2.

Values measured in the laboratory for the determination (VS).

Values are expressed as mean ± SD (same units as the mean; n = 3).

We calculate the volatile substance (VS) using Formula (2).

where

- -

- mWet = mass of the wet sample (as taken, with water).

- -

- mDried = mass of the sample dried at 105 °C (total dry matter = TS).

- -

- mBurned = mass of the residue remaining after incineration at 550 °C (ash, i.e., the inorganic mineral part).

The volatile substance VS is calculated as a percentage of the wet mass (mWet). Using the formulas mWet = W + VS + A and mWet = TS + W, the following data is obtained (Table 3).

Table 3.

Results regarding biomass composition.

The ash fraction (A) was determined according to standard gravimetric methods. After drying the biomass samples at 105 °C to constant weight for TS determination, subsamples were placed in a muffle furnace at 550 °C for 4 h. The remaining inorganic residue was weighed and expressed as a percentage of the initial dry mass.

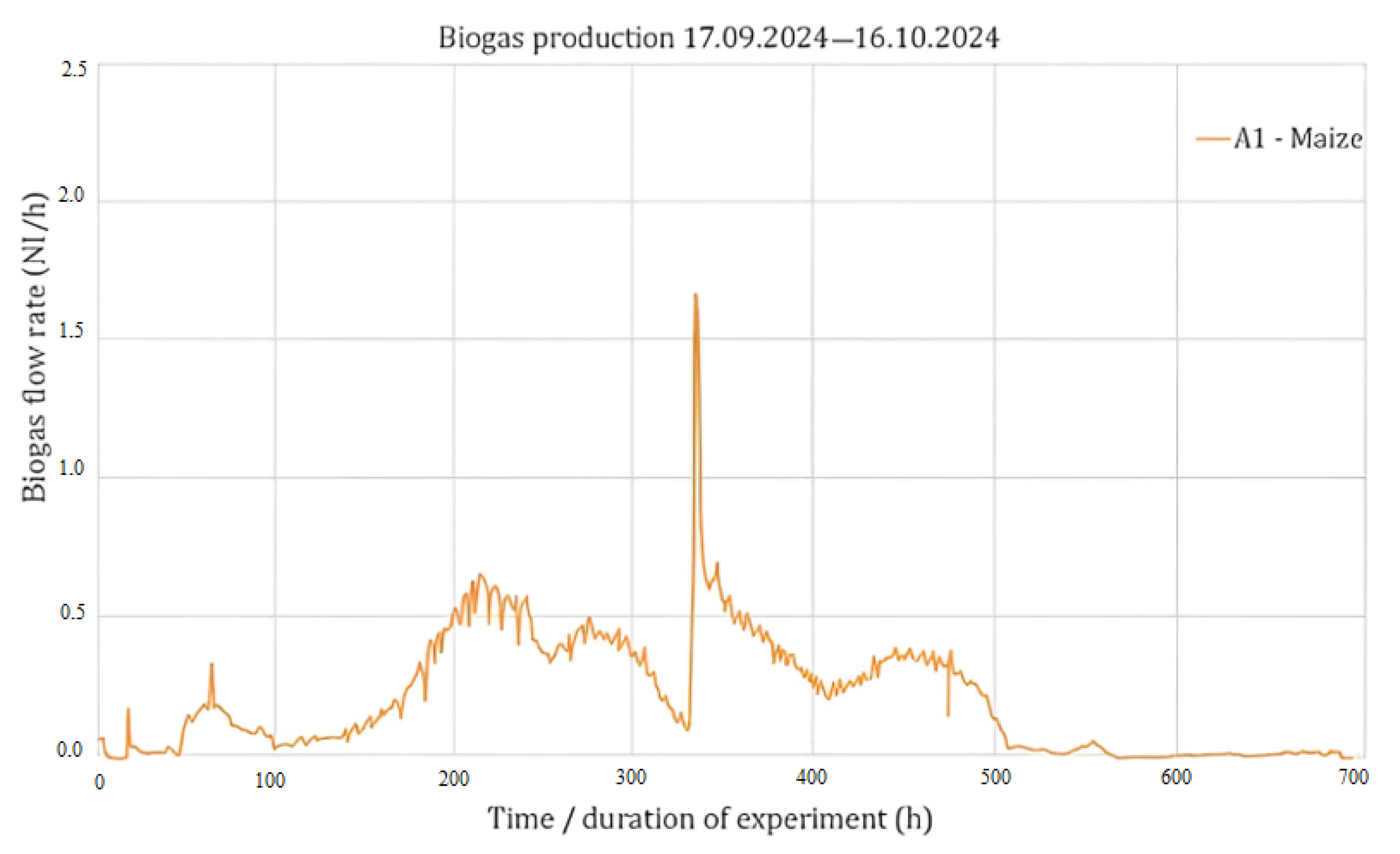

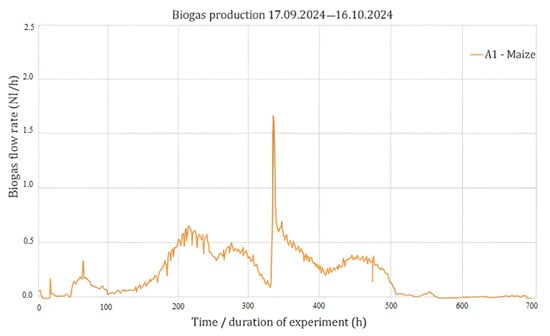

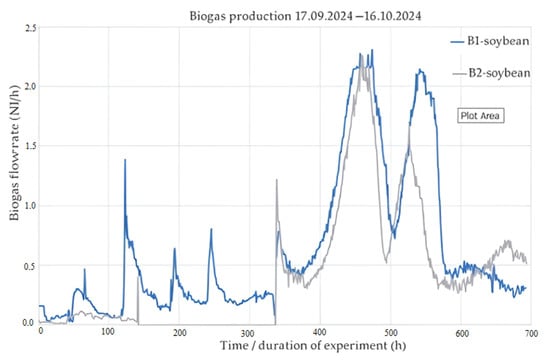

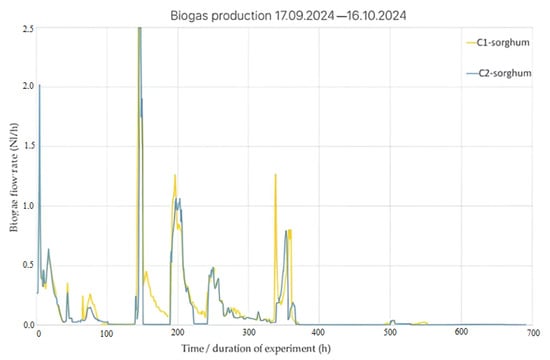

The analysed biomass is put into a BRS III-Bioreactor Simulator, which has six bioreactors, each holding 2 litres. For each biomass type (maize, soybean, sorghum), anaerobic digestion experiments were performed in at least two independent bioreactor runs under identical conditions, in order to verify reproducibility. Maize samples were tested in the A1 reactor series, soybean in the B1 and B2 series, and sorghum in the C1 and C2 series. This design allowed for a direct comparison between biomass types while maintaining replication within each crop type. Although Figure 5, Figure 6 and Figure 7 illustrate the results from one representative reactor per crop for clarity, replicate runs were conducted, and the results were consistent, confirming the robustness of the data. Each bioreactor has its mixing system, a way to sample biogas, and a system for adding and removing materials. The bioreactors are connected by elastic hoses and data cables to the measurement and data recording unit, which is connected via a cable to an internet network [20,21,22]. Through a PC, laptop, or Smartphone with internet access, a web portal [23,24] is accessed, where a special command and control platform for the used BRS experimental stand can be accessed with a username and password. The useful volume of a bioreactor is 1.8 litres, and the dry substance content in the digester has a maximum of 10%. The hydraulic retention time (HRT) is (20–30) days, from 17 September 2024 to 16 October 2024. The digestion process was monitored for a total of 30 days, until gas production stabilised. Data are presented as mean values ± standard deviation from replicate runs; no further statistical tests were applied due to the exploratory nature of the study. The loading batch, dry substance per loading batch, and water content/loading batch, as well as the mixing recipes for reactor loading, were calculated according to the sample preparation protocol [25,26,27,28].

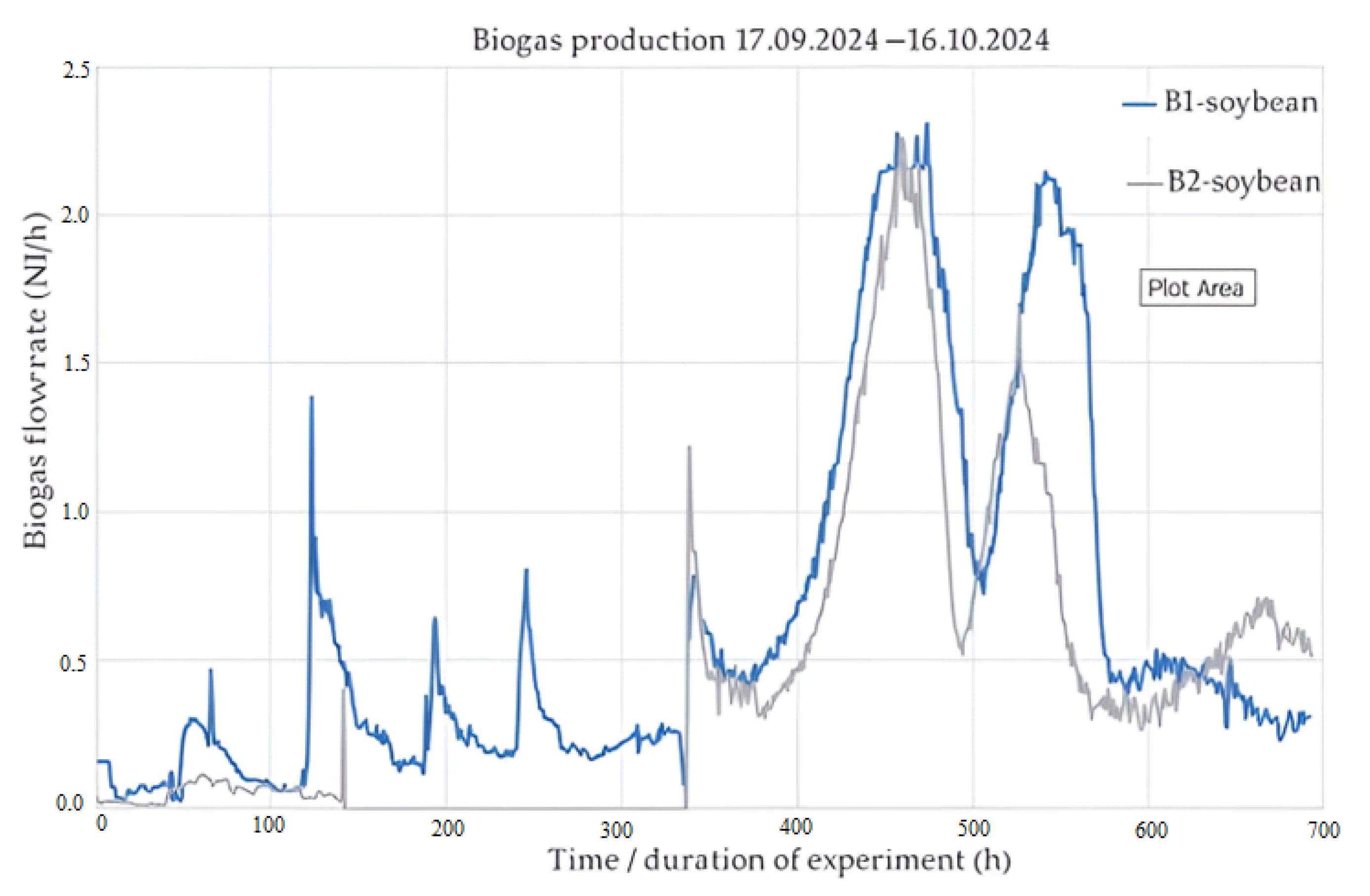

Figure 5.

Biogas production, maize sample A1.

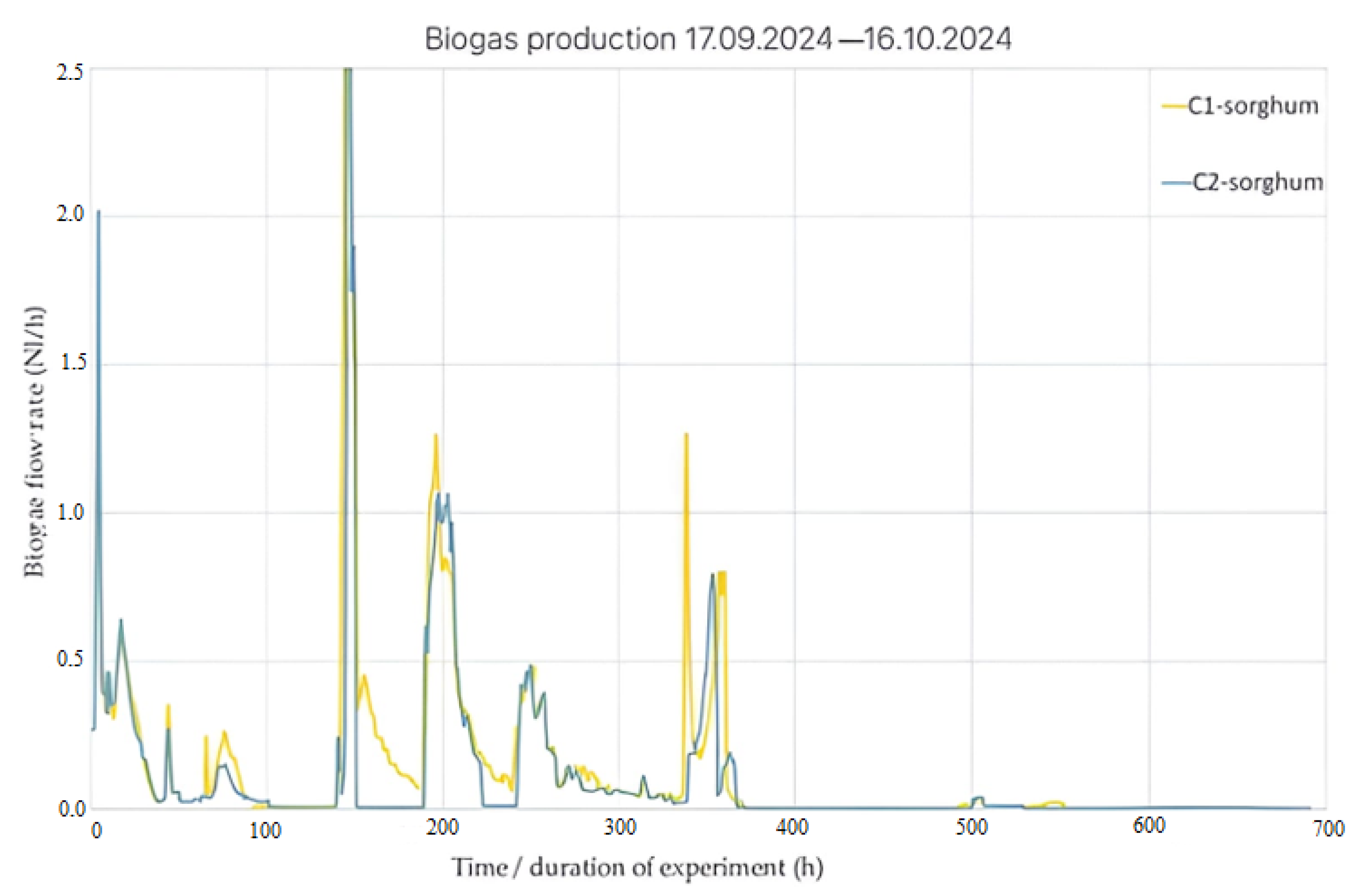

Figure 6.

Biogas production obtained from soybean B1, B2.

Figure 7.

Biogas production obtained from sorghum C1, C2.

Values are expressed as mean ± SD (same units as the mean; n = 3).

A maize sample (A1), two soybean samples (B1, B2), and two sorghum samples (C1, C2) were introduced into the bioreactor. In the process, an inoculum (for populating with anaerobic bacteria) was used, taken from the biogas production and valorisation facility in Arad [29,30,31,32].

From the total of 60 biomass samples obtained, 12 were selected to ensure statistical robustness while reducing the number of determinations. The selection was based on objective criteria: the lowest standard deviation among triplicate measurements, in order to minimise variability; balanced representation of anatomical fractions (stems, leaves, pods, panicles); and comparability across experimental runs. Each experimental group (A1, B1, B2, C1, C2) was designed as a sequence of tests under identical operating conditions, where maize, soybean, and sorghum were each introduced into the reactor in parallel. Consequently, the grouping reflects the experimental sequence rather than a separation of biomass types. This approach ensured both representativeness and consistency in evaluating the three biomasses during anaerobic digestion.

Each group (A1, B1, B2, C1, C2) corresponds to a series of anaerobic digestion runs carried out under identical conditions, in which maize, soybean, and sorghum were evaluated in parallel. The presence of all three crops within each group reflects the experimental design and allows for a direct comparison between biomass types under the same operational parameters. (Table 4)

Table 4.

Representative samples that will undergo the calcinations process.

The average values from Table 3 were used for calculating the bioreactor loading and establishing the mixing recipes. The average values obtained are centralised in Table 5.

Table 5.

Average values of biomass samples.

Based on the volatile substance content and the dry substance content, the mixing recipes for loading the bioreactors were calculated [33,34,35].

Thus, based on the VDI 4630-2006 sample preparation protocol, the mixture recipe for bioreactor loading for the maize test was prepared [36,37], and the results are centralised in Table 6.

Table 6.

Bioreactor loading mixture recipe sample A1, A2.

To load the bioreactor with fresh co-substrate, 1800 g of digestate mass was introduced, with the established dry matter content (TSmd) in the digester (max. 10% dm). The hydraulic retention time (HRT = md/mcharge) is set between 20% (by mass) and 30% (by mass) [38,39].

The daily organic loading rate (OLR) is 4.58 g/L/day (with VS1 maize). The daily discharge batch of the evacuated digestate mass is 90.00 g. The experimental values recorded in the cloud (bio process control) were graphically represented to highlight the evolution over time of biogas production [40,41,42]. For maize, we only collected data from the A1 bioreactor during the anaerobic digestion process [43]. The data from the second maize bioreactor were excluded due to process failure, which occurred because dried maize biomass with elevated lignin content was used. The high lignin fraction hindered microbial accessibility to cellulose and hemicellulose, resulting in poor substrate degradation and process instability. Similar challenges with lignocellulosic substrates have been reported in anaerobic digestion studies [44,45,46].

In Figure 5, the graphical representation of the biogas production obtained in the bioreactor where the A1 sample was introduced is shown.

As observed in Figure 5, it is noted that the biogas production was low at the beginning of the experiment because biomass cultivated for one year was used, which was in a dry state with high lignin content [47,48], hindering the digestion of the organic matter contained in the substance.

After approximately 12 days, fresh maize from the new crop was used in the experiment, which is reflected in the stabilised biogas production process.

This effect can be explained by the improved availability of easily degradable substrates (such as soluble sugars and proteins) in the fresh material, which reactivated microbial activity and balanced the digestion process. In contrast, the initial use of dried biomass with higher lignin content led to partial inhibition and slower microbial adaptation. The addition of fresh biomass therefore restored process stability and sustained methane production in the subsequent days.

To prepare the soybean for anaerobic digestion, we developed the mixture recipes for filling the digesters by considering the quantities of volatile substances and dry matter [49,50,51]. The mixture recipe for loading the bioreactor with the soybean samples, B1 and B2, was created using the guidelines from the VDI 4630-2006 sample preparation protocol [52,53]. Table 7 centralises these findings.

Table 7.

Bioreactor loading mixture recipe, sample B1, B2 soybean.

The operating parameters of the digester are as follows: the useful volume of the bioreactor is 1.80 litres, the digestate’s mass is 1800 g, and the dry matter content is set at 10% (by mass) [54,55]. The calculation of the digester loading batch was carried out as follows: the hydraulic retention time (HRT) is 20–30 days, the loading batch is 90 g/day, the dry substance on the loading batch was calculated at 9 g, and the water content/loading batch is 81.0 g [56]. The biogas production from the bioreactor that had the B1 and B2 sorghum samples, which was recorded online (bioprocess control), is shown in Figure 6.

The analysis of the obtained experimental data shows that the production of the anaerobic digestion process is low in the first few days. The stabilisation of the process occurs after approximately 10 days, as can be seen from the graphical representation [57,58,59]. The main identified cause that led to low biogas production is the fact that, in the first few days, the bioreactors were loaded with dried soybeans [60,61]. Dried biomass is characterised by a high lignin content, which negatively affects the anaerobic digestion process. Lignin forms a tough layer that makes it hard for the bacteria needed for anaerobic digestion to reach the biodegradable parts of the material, which leads to very little biogas being produced [62,63].

In the second part of the process, the bioreactors were given fresh soy that was ground into smaller pieces, and it was discovered that the fresher the biomass, the better the digestion process worked, leading to more biogas being produced [64,65].

At the same time, it was found that the improvement in biogas production is influenced by the degree of soybean grinding [66]. The finer the grinding/granulation, the more homogeneous the mixture and, consequently, the higher the biogas production [67].

Table 8 centralises the mixing recipe for the bioreactor loading of the sorghum samples, C1 and C2.

Table 8.

Bioreactor loading mixture recipe sample C1, C2 sorghum.

The operating parameters of the digester are the same except for the dry matter/co-substrate loaded into it, which was calculated to be 9 grammes; the organic matter, calculated to be 7.4 g; and the water/co-substrate content, calculated to be 10.89 g. Figure 7 graphically represents the biogas production obtained from the anaerobic digestion of sorghum (samples C1 and C2), which is recorded in the cloud (bioprocess control).

At the beginning of the experiment, the sorghum C1, 2 had the best biogas production, after which the process became unstable. The cause of this effect is that the loading/unloading phase of the bioreactor is very difficult to achieve for co-substrates in the form of biomass or plant residues (straw); thus, over time, it was no longer possible to maintain the optimal concentration of dry substances (TS) and volatile solids (VS) in the bioreactor; therefore, the process was destabilised [68,69]. At the beginning of the experiment, biomass cultivated for one year was used, which was in a dry state with a high lignin content that hindered the digestion of the organic matter contained in the substance [70,71,72,73].

After approximately 12 days, fresh biomass was used in the experiment, which is reflected in the stabilisation of the biogas production process.

To enable a direct comparison of the three crops, the specific methane yields were calculated on a volatile solids basis. The average methane yields obtained were approximately 92 L CH4/kg VS for soybean, 85 L CH4/kg VS for maize, and 58 L CH4/kg VS for sorghum. These values are lower than typical ranges reported in the literature (200–400 L CH4/kg VS for similar substrates [74,75,76]), which can be explained by the degraded soil conditions, the exploratory scale of the experiment, and the high lignin content of dried biomass. Nevertheless, the results confirm the superior performance of soybean under the specific conditions of the Jiu Valley.

4. Discussion

Anaerobic digestion is a feasible and efficient technology for the energetic valorisation of biomass (maize, sorghum and soybean) cultivated on unproductive lands in the Jiu Valley. The highest biogas production was obtained from soybean (B1, B2), followed by maize (A1) and sorghum (C1, C2). These differences can be explained by their biochemical composition and nutrient balance. Soybean, which provided the highest methane yield in our study, is characterised by a relatively low lignin fraction and a favourable C/N ratio, supporting rapid microbial activity and efficient conversion of volatile solids into biogas. In contrast, maize and especially sorghum contain higher proportions of lignocellulosic material, where lignin acts as a structural barrier limiting enzymatic access to cellulose and hemicellulose, a widely reported constraint to anaerobic digestion efficiency [74,75]. Moreover, the higher C/N ratio of sorghum may lead to nitrogen limitation, while soybean biomass provides a more balanced nutrient availability, preventing ammonia inhibition and ensuring process stability.

Beyond biochemical composition, variability in TS values, particularly for maize (Table 1), reflected the heterogeneity of biomass grown on marginal lands. These differences were linked to local variations in soil water availability and plant maturity, which influenced the moisture content of the harvested material. Similar variability has been reported in previous studies on energy crops cultivated under suboptimal soil conditions [74,76]. This highlights the importance of accounting for field heterogeneity when evaluating biomass quality and biogas potential on degraded lands.

Although soybean showed lower VS percentages (≈35–36%) compared to maize (62–76%) and sorghum, its higher protein and soluble carbohydrate content ensured a favourable C/N ratio, stimulated microbial activity, and accelerated methane production. By contrast, maize and especially sorghum contained higher lignin fractions, limiting microbial accessibility and constraining biogas yields.

Soybean tissues retain more water due to their higher soluble compound content; sorghum accumulates water in stalks and leaves at early maturity; maize biomass, richer in starch and fibre, dries more rapidly. These physiological traits explain observed water differences (Table 3) and their effects on TS, VS, and subsequent biogas potential.

The graphical representations in Figure 5, Figure 6 and Figure 7 further support these interpretations. Soybean (B1, B2) consistently produced the highest methane yields and showed the most stable digestion process, particularly when fresh biomass with fine granulation was used. Maize (A1) reached comparable yields only when fresh biomass was introduced, whereas dried maize biomass with higher lignin content led to process inhibition and reduced stability. Sorghum (C1, C2) generated lower methane yields overall but exhibited greater resilience under marginal conditions, maintaining relatively stable production once fresh biomass was supplied. Additionally, operational constraints influenced digestion performance, as sorghum (C1, C2) initially showed good biogas production, but later became unstable due to difficulties in maintaining optimal TS and VS concentrations in the reactor.

Dry biomass has high lignin content, which hinders microbial access to degradable fractions and reduces biogas production. This limitation can be addressed through pretreatment methods. In our study, only mechanical pre-treatment (grinding and shredding) was applied. This improved substrate homogeneity and microbial accessibility, with finer granulation proving beneficial for enhancing digestion and biogas production. However, mechanical methods alone are limited in breaking down lignocellulosic structures when lignin concentrations are high. Thermal and chemical pre-treatments (e.g., steam explosion, alkaline or oxidative agents) have been shown to significantly improve digestibility [44,45]. Future research should therefore assess the efficiency and economic feasibility of advanced pretreatment strategies, particularly under the local conditions of the Jiu Valley.

An important perspective concerns the climate benefits of substituting fossil fuels with the biogas obtained. Based on the specific methane yields measured in this study (soybean 92 L CH4/kg VS, maize 85 L CH4/kg VS, and sorghum 58 L CH4/kg VS) and considering a methane calorific value of 35.8 MJ/m3, the corresponding energy recovery was estimated at 3.29, 3.04, and 2.08 MJ/kg VS, respectively. When used to replace natural gas, these values translate into avoided greenhouse gas emissions of approximately 0.18, 0.17, and 0.12 kg CO2 eq/kg VS for soybean, maize and sorghum. Although modest compared with yields reported for crops grown on fertile soils, these results emphasise the dual role of energy crops from marginal lands in both renewable energy production and greenhouse gas mitigation, supporting the objectives of the European Green Deal.

5. Conclusions

This study demonstrates that unproductive mining lands in the Jiu Valley can be converted into valuable resources by cultivating energy crops such as maize, soybean, and sorghum, with their biomass valorised through anaerobic digestion. Among the tested crops, soybean achieved the highest methane yield and process stability due to its favourable biochemical composition, while sorghum showed lower methane yields but greater resilience under marginal soil conditions [77,78,79].

The main limitations of this research are related to the exclusive use of mechanical pretreatment, the variability in biomass yields on degraded soils, and the reduced statistical robustness of the dataset. The exploratory nature of this study and the limited number of replicates did not allow for a full inferential statistical analysis. Future studies will therefore include larger sample sizes and robust statistical approaches to validate the observed trends.

Further research will also address advanced pretreatment methods (thermal, chemical, enzymatic), explore co-digestion strategies, and include economic feasibility assessments. These directions will provide the scientific basis for scaling up biomass-to-biogas systems on marginal lands and for their integration into regional renewable energy and land restoration policies under the European Green Deal.

Author Contributions

Conceptualization, E.C.D.; Methodology, L.A.V.; Software, D.M.C.; Validation, I.I.; Formal analysis, I.A.I.; Investigation, S.M.R. and O.R.B.; Data curation, S.I.I.; Writing—review & editing, M.F.I.; Visualization, I.A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is based on the “CeSoH” research project which received funding from the Research and Innovation Program PNRR-III-C9-2022–I5, funded by the European Union-Next Generation EU, under Grant No: 760005/30.12.2022. Project code 2, The authors would like to thank all the partners of the CeSoH project for their support and acknowledge the financial support from the funding program.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article material. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Delivering the European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_ro (accessed on 13 June 2025).

- Sustainability of Crop Production from Polluted Lands. Energy, Ecology and Environment. Available online: https://link.springer.com/article/10.1007/s40974-016-0007-x (accessed on 13 June 2025).

- European Commission. Proposal for a Directive on Soil Monitoring and Resilience (Soil Monitoring Law), COM(2023)416 Final, 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52023PC0416 (accessed on 13 June 2025).

- Pancaldi, F.; Trindade, L.M. Marginal Lands to Grow Novel Bio-Based Crops: A Plant Breeding Perspective. Front. Plant Sci. 2020, 11, 227. [Google Scholar] [CrossRef]

- European Commission. EU Soil Strategy for 2030—Reaping the Benefits of Healthy Soils for People, Food, Nature and Climate. Available online: https://eur-lex.europa.eu/legal-content/RO/TXT/?uri=CELEX:52021DC0699 (accessed on 13 June 2025).

- EPRC. Energy Transition in Europe’s Coal Regions: Issues for Regional Policy. Available online: https://eprc-strath.org/publication/energy-transition-in-europes-coal-regions-issues-for-regional-policy/ (accessed on 13 June 2025).

- Gomes, H.I.; Dias-Ferreira, C.; Ribeiro, A.B. Phytoremediation for Bioenergy: Challenges and Opportunities. Environ. Technol. Rev. 2013, 2, 1–26. [Google Scholar] [CrossRef]

- Regulation (EU) 2024/1735—Net-Zero Technology Manufacturing Ecosystem. Available online: http://data.europa.eu/eli/reg/2024/1735/oj/ron (accessed on 13 June 2025).

- Ahmadzai, H.; Tutundjian, S.; Elouafi, I. Policies for Sustainable Agriculture and Livelihood in Marginal Lands: A Review. Sustainability 2021, 13, 8692. [Google Scholar] [CrossRef]

- Von Cossel, M.; Lewandowski, I.; Elbersen, B.; Staritsky, I.; Van Eupen, M.; Iqbal, Y.; Mantel, S.; Scordia, D.; Testa, G.; Cosentino, S.L.; et al. Marginal Agricultural Land Low-Input Systems for Biomass Production. Energies 2019, 12, 3123. [Google Scholar] [CrossRef]

- An Overview of Process Monitoring for Anaerobic Digestion. Biosyst. Eng. 2021, 207, 106–119. [CrossRef]

- TRACER Project. Possible Transition Scenarios from Coal and Financing Opportunities for Jiu Valley Micro-Region. Available online: https://www.researchgate.net/ (accessed on 13 June 2025). [CrossRef]

- He, Y.; Jaiswal, D.; Liang, X.; Sun, C.; Long, S.P. Perennial biomass crops on marginal land improve both regional climate and agricultural productivity. GCB Bioenergy 2022, 14, 558–571. [Google Scholar] [CrossRef]

- Biomass Production from Neglected and Underutilised Tall Perennial Grasses on Marginal Lands in India: A Brief Review. Available online: https://www.researchgate.net/publication/325650688_Biomass_production_from_neglected_and_underutilized_tall_perennial_grasses_on_marginal_lands_in_India_a_brief_review (accessed on 13 June 2025).

- Malec, M. The Prospects for Decarbonisation in the Context of Reported Resources and Energy Policy Goals: The Case of Poland. Energy Policy 2022, 161, 112763. [Google Scholar] [CrossRef]

- Greening the Heartlands of Coal in Europe. Available online: https://www.researchgate.net/publication/320068825_Greening_the_Heartlands_of_Coal_in_Europe (accessed on 13 June 2025).

- VDI. VDI 4630—Fermentation of Organic Materials—Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Tests; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2016; Available online: https://www.vdi.de/en/home/vdi-standards/details/vdi-4630-fermentation-of-organic-materials-characterization-of-the-substrate-sampling-collection-of-material-data-fermentation-tests (accessed on 13 June 2025).

- Morán-Alonso, N.; Viedma-Guiard, A.; Simón-Rojo, M.; Córdoba-Hernández, R. Agricultural Land Suitability Analysis for Land Use Planning: The Case of the Madrid Region. Land 2025, 14, 134. [Google Scholar] [CrossRef]

- Forage Crops in the Bioenergy Revolution: From Fields to Fuel. Available online: https://www.researchgate.net/publication/388209921_Forage_Crops_in_the_BioenergyRevolution_From_Fields_to_Fuel (accessed on 13 June 2025).

- Regulation (EU) 2019/1009—EU Fertilising Products. Available online: http://data.europa.eu/eli/reg/2019/1009/oj/ron (accessed on 13 June 2025).

- Sweet Sorghum—An Alternative Energy Crop. Available online: https://www.researchgate.net/publication/229013045_SWEET_SORGHUM-AN_ALTERNATIVE_ENERGY_CROP (accessed on 13 June 2025).

- Chen, W.; Xie, Q.; Guo, L. Innovative Approaches in Agricultural Sustainability and Environmental Impact Management: Challenges and Opportunities. Agriculture 2024, 14, 2316. [Google Scholar] [CrossRef]

- The Biogas Market in Southern and Eastern Europe: Promoting Biogas by Non-Technical Activities. Available online: https://www.researchgate.net/publication/229042957_The_biogas_market_in_Southern_and_Eastern_Europe_Promoting_biogas_by_non-technical_activities (accessed on 13 June 2025).

- Roman, A.; Bucura, F.; Botoran, O.R.; Radu, G.-L.; Niculescu, V.-C.; Soare, A.; Ion-Ebrasu, D.; Vagner, I.; Dunca, E.-C.; Șandru, C.; et al. Thermochemical Processing of Agricultural Waste into Biochar with Potential Application for Coal-Mining Degraded Soils. Results Eng. 2025, 26, 105497. [Google Scholar] [CrossRef]

- Restoration of Degraded Soil for Sustainable Agriculture. Available online: https://www.researchgate.net/publication/335382275_Restoration_of_Degraded_Soil_for_Sustainable_Agriculture (accessed on 13 June 2025).

- Singh, R.; Singh, O.V. Energy Crops and Their Implications on Soil and Environment. Agron. J. 2009, 101, 600–607. [Google Scholar] [CrossRef]

- Is Energy Cropping in Europe Compatible with Biodiversity?—Opportunities and Threats to Biodiversity from Land-Based Production of Biomass for Bioenergy Purposes. Available online: https://www.researchgate.net/publication/257421265_Is_energy_cropping_in_Europe_compatible_with_biodiversity__Opportunities_and_threats_to_biodiversity_from_land-based_production_of_biomass_for_bioenergy_purposes (accessed on 13 June 2025).

- Potential Land Availability for Energy Crops Production in Europe. Available online: https://www.researchgate.net/publication/259255432_Potential_land_availability_for_energy_crops_production_in_Europe (accessed on 13 June 2025).

- Zhang, J.; Chang, N.; Fagerholm, C.; Qiu, M.; Shuai, L.; Egan, R.; Yuan, C. Techno-economic and environmental sustainability of industrial-scale productions of perovskite solar cells. Renew. Sustain. Energy Rev. 2022, 158, 112146. [Google Scholar] [CrossRef]

- Perea-Moreno, M.-A.; Samerón-Manzano, E.; Perea-Moreno, A.-J. Biomass as Renewable Energy: Worldwide Research Trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef]

- Hall, D.O. Biomass for Energy in the Developing Countries, 1st ed.; Elsevier: Amsterdam, The Netherlands, 1981; Available online: https://shop.elsevier.com/books/biomass-for-energy-in-the-developing-countries/hall/978-0-08-028689-1 (accessed on 13 June 2025).

- Organic Waste Recycling: Technology, Management and Sustainability, 4th ed.; IWA Publishing: London, UK, 2016. [CrossRef]

- A Sustainable Second-Generation Biomass for Bioenergy. In Jatropha curcas L: A Potential 2G Energy Crop to Produce Biofuel in Bangladesh; Springer: Cham, Switzerland, 2025. [CrossRef]

- (PDF) A Review of Bioethanol Production from Plant-Based Waste Biomass by Yeast Fermentation. Available online: https://www.researchgate.net/publication/313236834_A_Review_of_Bioethanol_Production_from_Plant-based_Waste_Biomass_by_Yeast_Fermentation (accessed on 13 June 2025).

- Rupasinghe, R.L.; Perera, P.; Bandara, R.; Amarasekera, H.; Vlosky, R. Insights into Properties of Biomass-Energy Pellets Made from Mixtures of Woody and Non-Woody Biomass: A Meta-Analysis. Energies 2024, 17, 54. [Google Scholar] [CrossRef]

- Dida, G. Biotechnology Towards Energy Crops. CABI Agric. Biosci. 2024, 5, 24. [Google Scholar] [CrossRef]

- Batidzirai, B.E.; Smeets, M.W.; Faaij, A.P.C. Harmonising Bioenergy Resource Potentials—Methodological Lessons from Review of State-of-the-Art Bioenergy Potential Assessments. Renew. Sustain. Energy Rev. 2012, 16, 6598–6630. [Google Scholar] [CrossRef]

- (PDF) Land Use Requirements of Solar and Wind Power Generation: Understanding a Decade of Academic Research. Available online: https://www.researchgate.net/publication/345638945_Land_Use_Requirements_of_Solar_and_Wind_Power_Generation_Understanding_a_Decade_of_Academic_Research (accessed on 13 June 2025).

- Bioenergy Plants: A Sustainable Solution for Heavy Metal Phytoremediation. In Bioenergy Crops; CRC Press: Boca Raton, FL, USA, 2022. [CrossRef]

- Grippi, D.; Clemente, R.; Bernal, M.P. Chemical and Bioenergetic Characterisation of Biofuels from Plant Biomass: Perspectives for Southern Europe. Appl. Sci. 2020, 10, 3571. [Google Scholar] [CrossRef]

- Olguin-Maciel, E.; Singh, A.; Chable-Villacis, R.; Tapia-Tussell, R.; Ruiz, H.A. Consolidated Bioprocessing—An Innovative Strategy Towards Sustainability for Biofuels Production from Crop Residues: An Overview. Agronomy 2020, 10, 1834. [Google Scholar] [CrossRef]

- Masjedi, A.; Crawford, M.M.; Carpenter, N.R.; Tuinstra, M.R. Multi-Temporal Predictive Modelling of Sorghum Biomass Using UAV-Based Hyperspectral and LiDAR Data. Remote Sens. 2020, 12, 3587. [Google Scholar] [CrossRef]

- Jain, S.; Tembhurkar, A.R. Sustainable Amelioration of Fly-Ash Dumps Linking Bio-Energy Plantation, Bioremediation and Amendments: A Review. J. Environ. Manag. 2022, 314, 115124. [Google Scholar] [CrossRef]

- Manyi-Loh, C.E.; Lues, R. Anaerobic Digestion of Lignocellulosic Biomass: Substrate Characteristics (Challenge) and Innovation. Fermentation 2023, 9, 755. [Google Scholar] [CrossRef]

- Hendriks, A.T.W.M.; Zeeman, G. Pretreatments to Enhance the Digestibility of Lignocellulosic Biomass. Bioresour. Technol. 2009, 100, 10–18. [Google Scholar] [CrossRef]

- Mussoline, W.; Esposito, G.; Giordano, A.; Lens, P.N.L. Anaerobic Digestion of Rice Straw: A Review. Crit. Rev. Environ. Sci. Technol. 2013, 43, 895–915. [Google Scholar] [CrossRef]

- Biological and Biosystems Engineering for Processing of Switchgrass Feedstocks (for Biofuel Production). In Compendium of Bioenergy Plants; CRC Press: Boca Raton, FL, USA, 2014; Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/b16681-11/biological-biosystems-engineering-processing-switchgrass-feedstocks-biofuel-production-arpan-jain-terry-walker-karl-kelly (accessed on 13 June 2025).

- Potential Contribution of Biomass to the Sustainable Energy Development. Available online: https://www.researchgate.net/publication/223631907_Potential_Contribution_of_Biomass_to_the_Sustainable_Energ_Development (accessed on 13 June 2025).

- Susilawati, S.; Surdianto, Y.; Erythrina, E.; Bhermana, A.; Liana, T.; Syafruddin, S.; Anshori, A.; Nugroho, W.A.; Hidayanto, M.; Widiastuti, D.P.; et al. Strategic, Economic, and Potency Assessment of Sorghum Development in the Tidal Swamplands of Central Kalimantan, Indonesia. Agronomy 2023, 13, 2559. [Google Scholar] [CrossRef]

- The Impact of Drought on Sorghum Production, and Farmers’ Varietal and Trait Preferences, in North-Eastern Ethiopia: Implications for Breeding. Available online: https://www.researchgate.net/publication/322003237_The_impact_of_drought_on_sorghum_production_and_farmer’s_varietal_and_trait_preferences_in_the_north_eastern_Ethiopia_implications_for_breeding (accessed on 13 June 2025).

- Nieman, C.C.; Franco, J.G.; Raper, R.L. Inconsistent Yield Response of Forage Sorghum to Tillage and Row Arrangement. Agronomy 2024, 14, 1510. [Google Scholar] [CrossRef]

- Grain Sorghum Response to NPK Fertiliser in the Guinea Savanna of Ghana. Available online: https://www.researchgate.net/publication/230744602_Grain_Sorghum_Response_to_NPK_Fertilizer_in_the_Guinea_avanna_of_Ghana (accessed on 13 June 2025).

- Biological Characteristics and Productivity of Sweet Sorghum Varieties under Arid Conditions in South-Eastern Kazakhstan. Available online: https://ibn.idsi.md/ro/vizualizare_articol/134084 (accessed on 13 June 2025).

- Effect of Tithonia Biomass and Mineral Fertiliser Application on Soybean Performance in Degraded Technosols from Tantalum Mining in Gatumba, Rwanda. Available online: https://ir-library.ku.ac.ke/items/4c34921b-5ccb-44eb-8b16-473549afede8 (accessed on 13 June 2025).

- Shortall, O.K. “Marginal Land” for Energy Crops: Exploring Definitions and Embedded Assumptions. Energy Policy 2013, 62, 19–27. [Google Scholar] [CrossRef]

- Dale, V.H.; Efroymson, R.A.; Kline, K.L. The Land Use–Climate Change–Energy Nexus. Landsc. Ecol. 2012, 27, 909–930. [Google Scholar] [CrossRef]

- Muth, D.J., Jr.; Bryden, K.M. An Integrated Model for Assessment of Sustainable Agricultural Residue Removal Limits for Bioenergy Systems. Environ. Model. Softw. 2013, 39, 50–69. [Google Scholar] [CrossRef]

- Bioenergy Crops in the Perspective of Climate Change. In Biotechnology and Omics Approaches for Bioenergy Crops; Springer: Singapore, 2024. [CrossRef]

- An Integrated Landscape Management Approach to Sustainable Bioenergy Production. Available online: https://www.researchgate.net/publication/318041494_An_Integrated_Landscape_Management_Approach_to_Sustaiable_Bioenergy_Production (accessed on 13 June 2025).

- Shilpi, S.; Lamb, D.; Bolan, N.; Seshadri, B.; Choppala, G.; Naidu, R. Waste to Watt: Anaerobic Digestion of Wastewater-Irrigated Biomass for Energy and Fertiliser Production. J. Environ. Manag. 2019, 239, 73–83. [Google Scholar] [CrossRef]

- Fertiliser Microdosing Technology in Sorghum, Millet and Maize Production at Small-Scale Level in Africa: A Review. Available online: https://www.researchgate.net/publication/325149697_Fertilizer_Microdosing_Technology_in_Sorghum_Millet_and_Maize_Production_at_Small-Scale_Level_in_Africa_A_Review (accessed on 13 June 2025).

- The Environmental Sustainability of Anaerobic Digestion as a Biomass Valorisation Technology. Available online: https://www.researchgate.net/publication/230619254_The_environmental_sustainability_of_anaerobic_digestion_as_a_biomass_valorization_technology (accessed on 13 June 2025).

- Gerwin, W.; Repmann, F.; Galatsidas, S.; Vlachaki, D.; Gounaris, N.; Baumgarten, W.; Volkmann, C.; Keramitzis, D.; Kiourtsis, F.; Freese, D. Assessment and Quantification of Marginal Lands for Biomass Production in Europe Using Soil-Quality Indicators. SOIL 2018, 4, 267–290. [Google Scholar] [CrossRef]

- Tampio, E.; Marttinen, S.; Rintala, J. Liquid Fertiliser Products from Anaerobic Digestion of Food Waste: Mass, Nutrient and Energy Balance of Four Digestate Liquid Treatment Systems. J. Clean. Prod. 2016, 125, 22–32. [Google Scholar] [CrossRef]

- Kiesel, A.; von Cossel, M.; Clifton-Brown, J.; Lewandowski, I. Valorisation of marginal agricultural land in the bioeconomy. GCB Bioenergy 2023, 15, 1418–1423. [Google Scholar] [CrossRef]

- Biomass Production on Trace Element-Contaminated Land: A Review. Available online: https://www.researchgate.net/publication/277520351_Biomass_Production_on_Trace_Element-Contaminated_Land_A_Review (accessed on 13 June 2025).

- Concepts of Agricultural Marginal Lands and Their Utilisation: A Review. Available online: https://www.researchgate.net/publication/365426629_Concepts_of_agricultural_marginal_lands_and_their_utilisation_A_review (accessed on 13 June 2025).

- Growing Dedicated Energy Crops on Marginal Lands and Ecosystem Services. Available online: https://www.researchgate.net/publication/305786328_Growing_Dedicated_Energy_Crops_on_Marginal_Lands_and_Ecosystem_Services (accessed on 13 June 2025).

- Slade, R.; Bauen, A.; Gross, R. Global Bioenergy Resources. Nat. Clim. Chang. 2014, 4, 99–105. [Google Scholar] [CrossRef]

- University of Petroșani. PNRR—CeSoH Project Page. Available online: https://www.upet.ro/cesoh-p1-upet (accessed on 13 June 2025).

- Midden, C.; Harris, J.; Shaw, L.; Sizmur, T.; Pawlett, M. The Impact of Anaerobic Digestate on Soil Life: A Review. Appl. Soil Ecol. 2023, 191, 105066. [Google Scholar] [CrossRef]

- Thornton, P.K.; Jones, P.G.; Ericksen, P.J.; Challinor, A.J. Agriculture and Food Systems in Sub-Saharan Africa in a 4 °C+ World. Phil. Trans. R. Soc. A 2011, 369, 1033–1055. [Google Scholar] [CrossRef] [PubMed]

- Economy and Forecast—Article. Available online: https://econ-forecast.org.ua/?page_id=523&lang=uk (accessed on 13 June 2025).

- Sun, Z.; Liu, Q.; Li, Y.; Pan, J. Deciphering the Impact of Lignin on Anaerobic Digestion: Focus on Inhibition Mechanisms and Methods for Alleviating Inhibition. ACS Omega 2024, 9, 25018–25031. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Wang, M.; Zhou, D.; Pan, S. Methane Yield Predictive Model Based on the Composition of Biomass: Focus on the Anaerobic Digestion Mode and Regression Method. BioResources 2020, 15, 3850–3858. [Google Scholar] [CrossRef]

- Herrmann, C.; Idler, C.; Heiermann, M. Biogas Crops Grown on Marginal Lands: Cultivation Practice, Biogas Production and Costs. Biosyst. Eng. 2016, 152, 12–26. [Google Scholar] [CrossRef][Green Version]

- McKendry, P. Energy Production from Biomass (Part 1): Overview of Biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Harangi-Rákos, M.; Fári, M. The Effect of Bioenergy Expansion: Food, Energy, and Environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Schröder, P.; Beckers, B.; Daniels, S.; Gnädinger, F.; Maestri, E.; Marmiroli, N.; Mench, M.; Millan, R.; Obermeier, M.M.; Oustriere, N.; et al. Intensify Production, Transform Biomass to Energy and Novel Goods and Protect Soils in Europe—A Vision How to Mobilise Marginal Lands. Sci. Total Environ. 2018, 616–617, 1101–1123. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).