Economic Feasibility and Operational Performance of Rotor Sails in Maritime Transport

Abstract

1. Introduction

- How sensitive (and sustainable) is rotor sail investment payback time to variations in fuel consumption and price, CO2 cost, and vessel operational parameters?

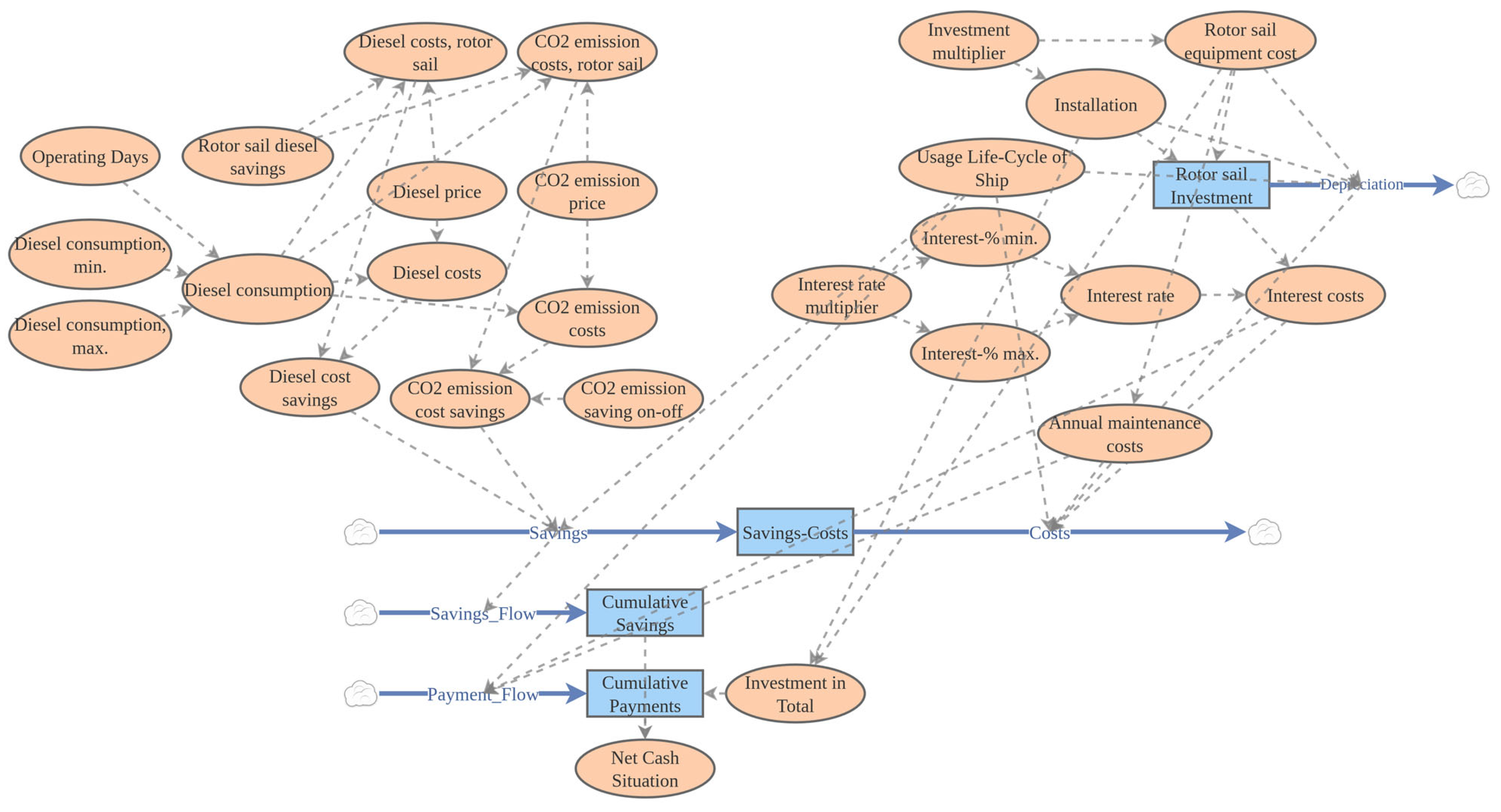

2. Simulation Model

- Diesel fuel consumption: random uniform 1–4 tons/hour (same for one year);

- Diesel price: EUR 500 per ton (could be user-altered: EUR 200–1000/ton);

- CO2 emission cost: EUR 85 per ton (could be user-altered: EUR 10–200/ton);

- Investment cost multiplier: 1 (could be user-altered: 0.1–5);

- Interest rates: random triangular 3–10% (peak at 6.5%; same for one year);

- Vessel lifecycle: 20 years (could be user-altered: 10–30 years);

- Rotor sail fuel saving rate: 7% (could be user-altered: 0–50%);

- Number of operating days: 250 (could be user-altered: 0–365);

- CO2 emission saving on–off: on, 1 (could be user-altered: off, 0; on, 1).

3. Literature Review on Rotor Sail Installations

3.1. Rotor Sail Model and Manufacturer Analysis

3.2. Reported Fuel Savings from Wind-Assisted Propulsion Systems

4. Analysis of Previous Studies

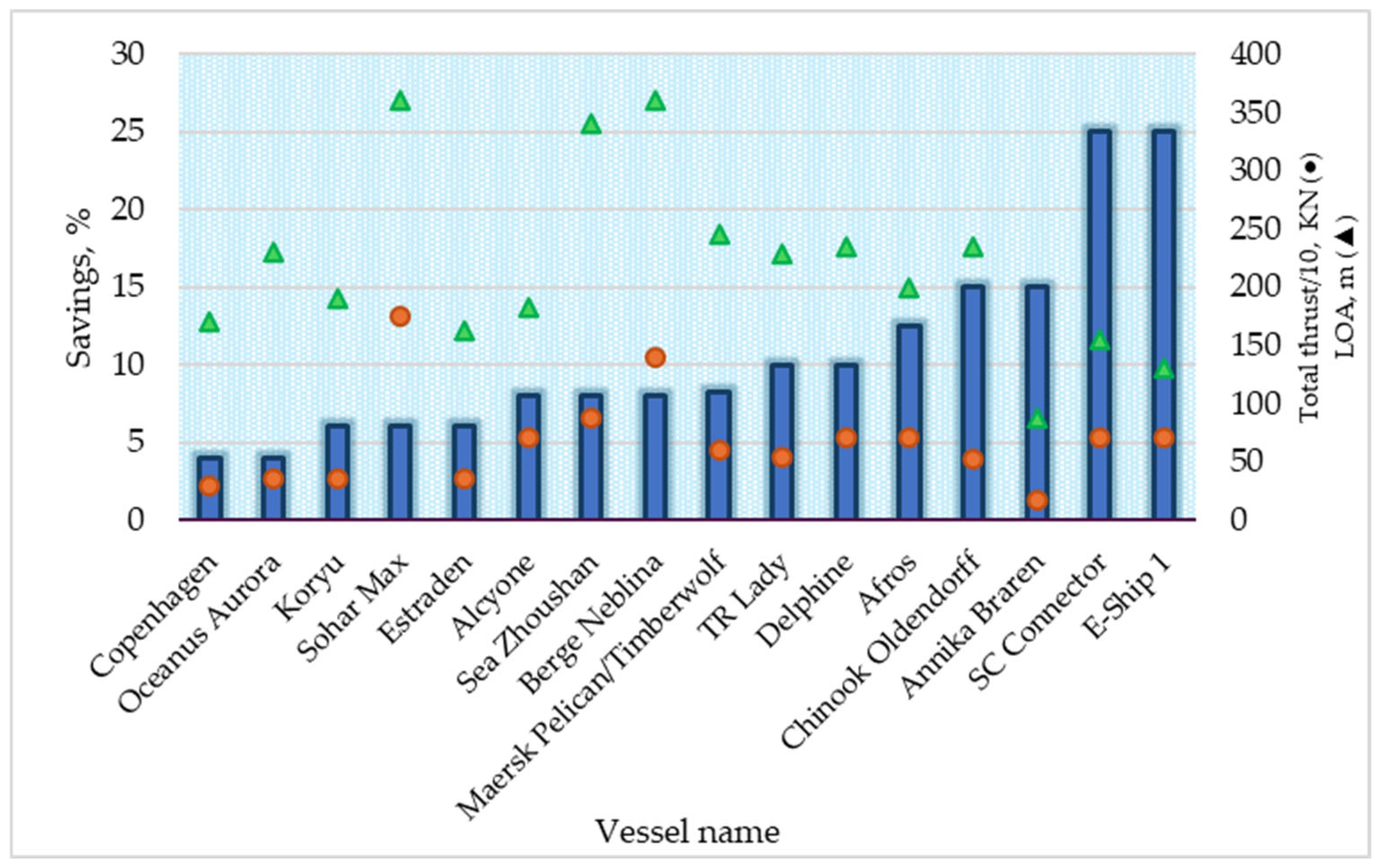

4.1. Analysis of Reported Fuel Savings from Wind-Assisted Propulsion Systems

4.2. Analysis of Factors Influencing Wind-Assisted Propulsion Efficiency

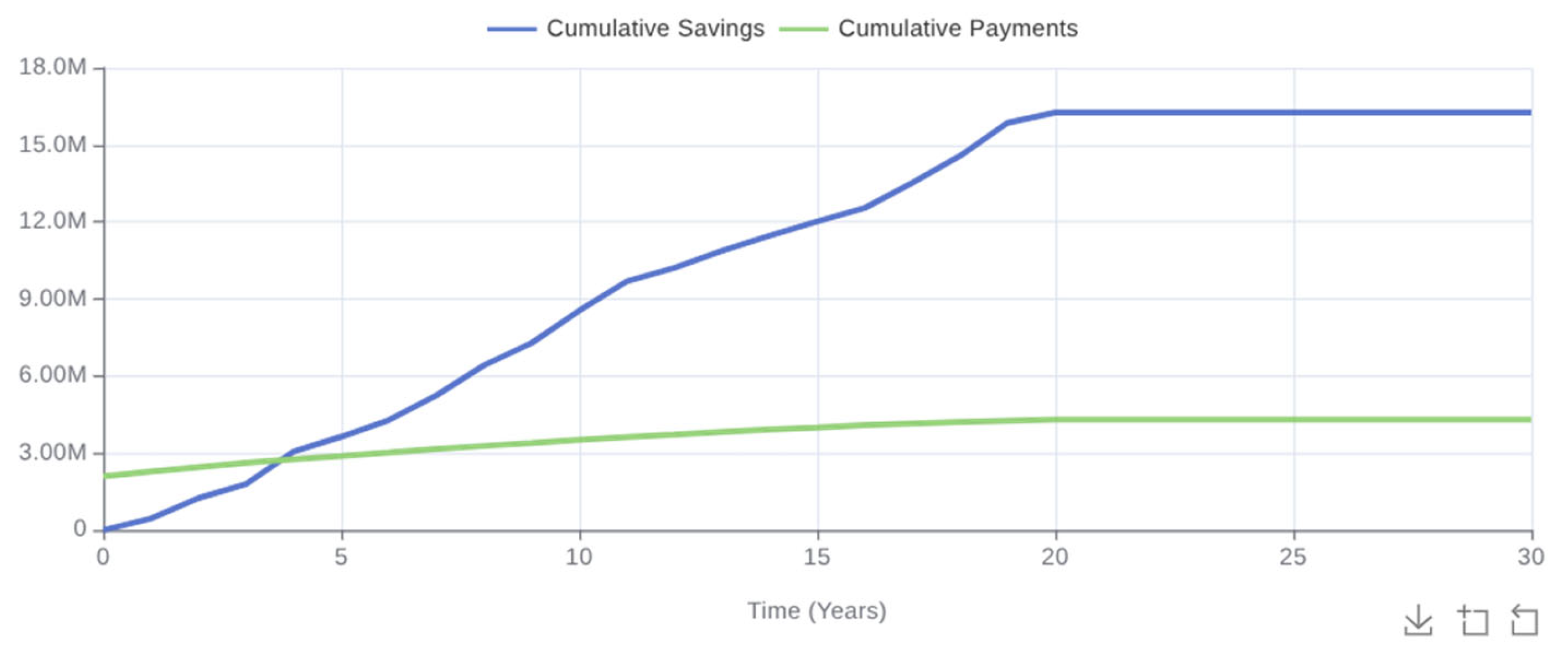

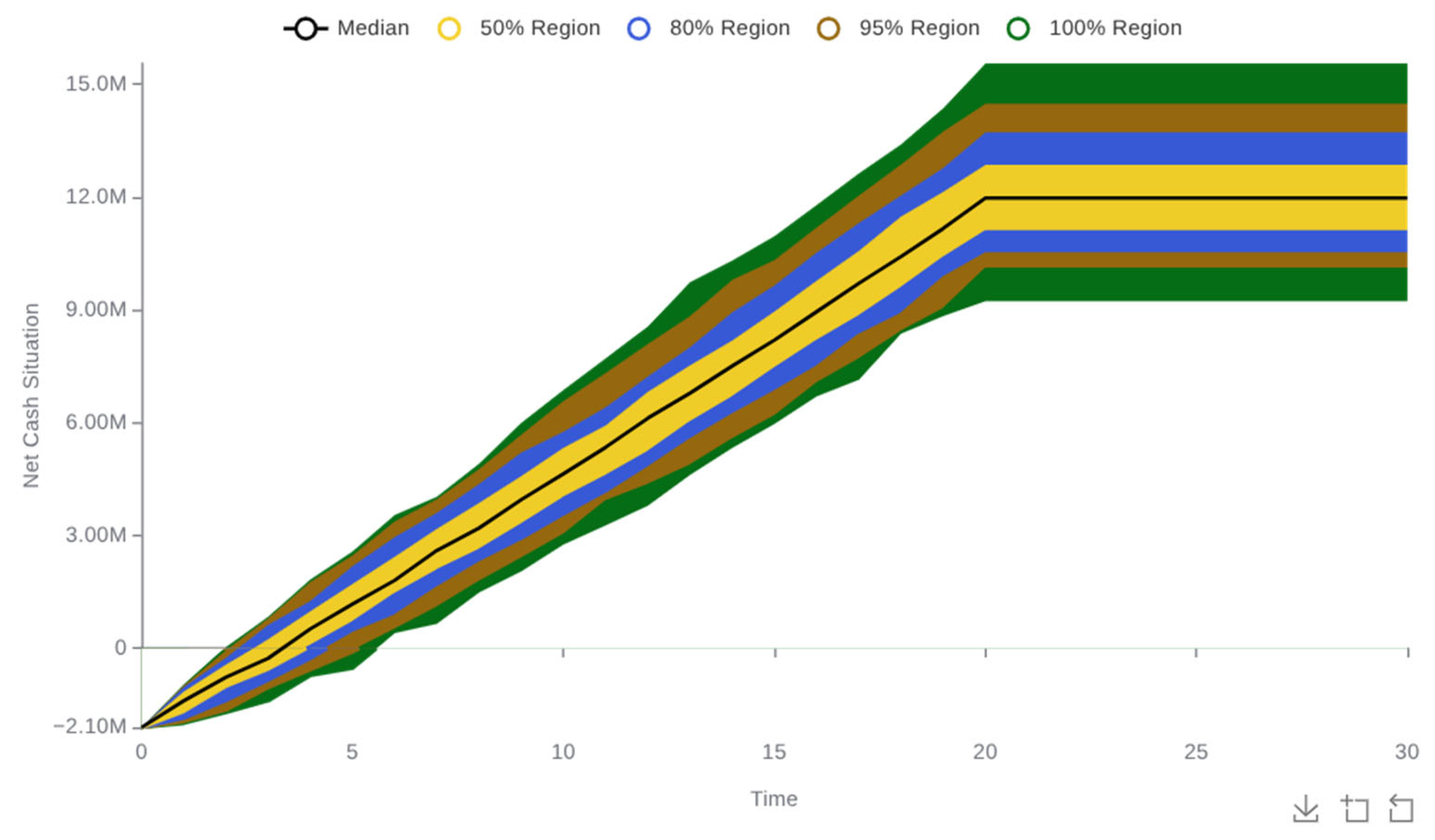

5. Simulation Model Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EMSA | European Maritime Safety Agency |

| EU ETS | European Union Emissions Trading System |

| DWT | Deadweight |

| IMO | International Maritime Organization |

| GCR | Great Circle Route |

| GHG | Greenhouse gas |

| GT | Gross tonnage |

| LOA | Length overall |

| MACC | Marginal abatement cost curve |

| RoRo | Roll on roll off |

| VLGC | Very large gas carrier |

| VLOC | Very large ore carrier |

| WASP | Wind-assisted ship propulsion |

References

- European Parliament and Council. Regulation (EU) 2023/1805 on the Use of Renewable and Low-Carbon Fuels in Maritime Transport, and Amending Directive 2009/16/EC; European Union: Brussels, Belgium, 2023. Available online: https://eur-lex.europa.eu/eli/reg/2023/1805/oj (accessed on 16 December 2024).

- European Parliament and Council. Regulation (EU) 2023/1804 on the Deployment of Alternative Fuels Infrastructure, and Repealing Directive 2014/94/EU; European Union: Brussels, Belgium, 2023. Available online: https://eur-lex.europa.eu/eli/reg/2023/1804/oj (accessed on 6 January 2025).

- International Maritime Organization. Initial IMO Strategy on Reduction of GHG Emissions from Ships; IMO: London, UK, 2018; Available online: https://unfccc.int/sites/default/files/resource/250_IMO%20submission_Talanoa%20Dialogue_April%202018.pdf (accessed on 16 December 2024).

- International Maritime Organization. MEPC.203(62)—Amendments to the Annex of the Protocol of 1997 to Amend the International Convention for the Prevention of Pollution from Ships, 1973, as Modified by the Protocol of 1978 Relating Thereto; IMO: London, UK, 2011; Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.203(62).pdf (accessed on 16 December 2024).

- International Maritime Organization. MEPC.328(76)—2021 Revised MARPOL Annex VI, Including Energy Efficiency Existing Ship Index (EEXI) and Carbon Intensity Indicator (CII); IMO: London, UK, 2021; Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.328(76).pdf (accessed on 16 December 2024).

- International Maritime Organization. 2023 IMO Strategy on Reduction of GHG Emissions from Ships; IMO: London, UK, 2023; Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/annex/MEPC%2080/Annex%2015.pdf (accessed on 16 December 2024).

- Chou, T.; Kosmas, V.; Acciaro, M.; Renken, K. A Comeback of Wind Power in Shipping: An Economic and Operational Review on the Wind-Assisted Ship Propulsion Technology. Sustainability 2021, 13, 1883. [Google Scholar] [CrossRef]

- Bordogna, S.G.; Muggiasca, S.; Giappino, S.; Belloli, M.; Keuning, J.; Huijsmans, R. The Effects of Aerodynamic Interaction on the Performance of Two Flettner Rotors. J. Wind Eng. Ind. Aerodyn. 2020, 196, 104013. [Google Scholar] [CrossRef]

- Lindstad, E.; Stokke, T.; Alteskjær, A.; Borgen, H.; Sandaas, I. Ship of the Future—A Slender Dry-Bulker with Wind-Assisted Propulsion. Marit. Transp. Res. 2022, 3, 100055. [Google Scholar] [CrossRef]

- European Maritime Safety Agency (EMSA). Rotor Sail Technology Overview; EMSA: Lisbon, Portugal, 2024. Available online: https://www.emsa.europa.eu (accessed on 15 January 2025).

- Enercon. E-Ship 1 Fuel Savings Confirmed; Enercon: Aurich, Germany, 2010; Available online: https://www.enercon.de (accessed on 15 January 2025).

- Norsepower. Norsepower Rotor Sails Confirmed Savings of 8.2% Fuel and Associated CO2 in Maersk Pelican Project. 24 October 2019. Available online: https://www.norsepower.com/post/norsepower-rotor-sails-confirmed-savings-of-8-2-fuel-and-associated-co2-in-maersk-pelican-project/ (accessed on 15 January 2025).

- Norsepower. Technical Specifications of Rotor Sails; Norsepower: Helsinki, Finland, 2025; Available online: https://www.norsepower.com/product/ (accessed on 15 January 2025).

- Anemoi Marine Technologies. Technical Specifications of Rotor Sails; Anemoi: London, UK, 2025; Available online: https://www.anemoimarine.com (accessed on 15 January 2025).

- Traut, M.; Gilbert, P.; Walsh, C.; Bows, A.; Filippone, A.; Stansby, P.; Wood, R. Propulsive Power Contribution of a Kite and a Flettner Rotor on Selected Shipping Routes. Appl. Energy 2014, 113, 362–372. [Google Scholar] [CrossRef]

- Vahs, M. Retrofitting of Flettner Rotors—Results from Sea Trials of the General Cargo Ship “Fehn Pollux”. MariGREEN Project, 2020. Available online: https://www.researchgate.net/figure/Fehn-Pollux-outbound-for-sea-trials-Source-MariGREEN_fig1_357027644 (accessed on 15 January 2025).

- CE Delft; Tyndall Centre; Fraunhofer ISI; Chalmers University. Study on the Analysis of Market Potentials and Market Barriers for Wind Propulsion Technologies for Ships; CE Delft: Delft, The Netherlands, 2016; Available online: https://cedelft.eu/publications/study-on-the-analysis-of-market-potentials-and-market-barriers-for-wind-propulsion-technologies-for-ships/ (accessed on 15 January 2025).

- Bentin, M.; Zastrau, D.; Schlaak, M.; Freye, D.; Elsner, R.; Kotzur, S. A New Routing Optimization Tool: Influence of Wind and Waves on Fuel Consumption of Ships with and without Wind-Assisted Propulsion Systems. Transp. Res. Procedia 2016, 14, 153–162. [Google Scholar] [CrossRef]

- Insight Maker. Insight Maker: Web-Based Modeling and Simulation Tool, 2025. Available online: https://insightmaker.com/ (accessed on 6 January 2025).

- Elkafas, A.G. Advanced Operational Measure for Reducing Fuel Consumption Onboard Ships. Environ. Sci. Pollut. Res. 2022, 29, 90509–90519. [Google Scholar] [CrossRef] [PubMed]

- Anemoi Marine Technologies. Ultramax Bulker Vessel Installed with Rotor Sails Named 2018’s ‘Ship of the Year’. Anemoi News, 12 December 2019. Available online: https://anemoimarine.com/ultramax-bulker-vessel-installed-with-rotor-sails-named-2018s-ship-of-the-year/ (accessed on 15 January 2025).

- Berge Bulk. Berge Neblina Sets Sail with Four Carbon-Saving Rotor Sails. Berge Bulk News, 8 July 2024. Available online: https://www.bergebulk.com/berge-neblina-sets-sail-with-four-carbon-saving-rotor-sails/ (accessed on 15 January 2025).

- Anemoi Marine Technologies. Anemoi Completes Installation of Rotor Sails Onboard Vale VLOC in Largest Wind-Propulsion Project to Date. Anemoi News, 17 December 2024. Available online: https://anemoimarine.com/anemoi-completes-largest-wind-propulsion-project-to-date/ (accessed on 15 January 2025).

- Norsepower. Norsepower Unveils First Tiltable Rotor Sail Installation with Sea-Cargo Agreement. Norsepower News, 29 June 2020. Available online: https://www.norsepower.com/post/norsepower-unveils-first-tiltable-rotor-sail-installation-with-sea-cargo/ (accessed on 15 January 2025).

- Ferry Shipping News. Norsepower Will Install Rotor Sails on CLdN’s DELPHINE, World’s Largest Shortsea RoRo. Ferry Shipping News, 10 March 2022. Available online: https://ferryshippingnews.com/norsepower-will-install-rotor-sails-on-cldns-delphine-worlds-largest-shortsea-roro/ (accessed on 15 January 2025).

- Pitkänen, P. Viking Line Abandons Rotor Sail on Viking Grace after Test Period. Ilta-Sanomat, 28 April 2021. Available online: https://www.is.fi (accessed on 15 January 2025).

- Chambers, S. 325,000 dwt Giant Bulker Gets the Wind Rotor Treatment, Vale Keen on Further Sail Investments. Splash247, 14 May 2021. Available online: https://splash247.com/325000-dwt-giant-bulker-gets-the-wind-rotor-treatment-vale-keen-on-further-sail-investments/ (accessed on 15 January 2025).

- Dry Cargo International. Tufton’s Kamsarmax Bulker Installed with Anemoi Rotor Sails. Dry Cargo International, 11 October 2023. Available online: https://www.drycargomag.com/tuftons-kamsarmax-bulker-installed-with-anemoi-rotor-sails (accessed on 15 January 2025).

- SSPA Sweden AB. Speed Trial and Route Analysis of M/V Copenhagen with Flettner Rotor; SSPA Report No. RE40201042-01-00-B; SSPA Sweden AB: Gothenburg, Sweden, 2023; Available online: https://vb.northsearegion.eu/public/files/repository/20230505141934_RE40201042-01-revBCopenhagen.pdf (accessed on 15 January 2025).

- SSPA Sweden AB. Speed Trial and Route Analysis of M/V Annika Braren with Flettner Rotor; SSPA Report No. RE40201042-03-00-A; SSPA: Gothenburg, Sweden, 2021; Available online: https://vb.northsearegion.eu/public/files/repository/20220707112458_RE40201042-03-00-A.pdf (accessed on 15 January 2025).

- De Marco, A.; Mancini, S.; Pensa, C.; Calise, G.; De Luca, F. Flettner Rotor Concept for Marine Applications: A Systematic Study. Int. J. Rotating Mach. 2016, 2016, 3458750. [Google Scholar] [CrossRef]

- Comer, B.; Chen, C.; Stolz, D.; Rutherford, D. Rotors and Bubbles: Route-Based Assessment of Innovative Technologies to Reduce Ship Fuel Consumption and Emissions; Working Paper 2019-11; The International Council on Clean Transportation (ICCT): Washington, DC, USA, 2019; Available online: https://theicct.org/sites/default/files/publications/Rotors_and_bubbles_2019_05_12.pdf (accessed on 15 January 2025).

- Smith, T.; Newton, P.; Winn, G.; Rosa, A.G.L. Analysis Techniques for Evaluating the Fuel Savings Associated with Wind Assistance. In Proceedings of the 2013 Low Carbon Shipping Conference, London, UK, 9–10 September 2013. [Google Scholar]

- Lu, R.; Ringsberg, J.W. Ship energy performance study of three wind-assisted ship propulsion technologies including a parametric study of the Flettner rotor technology. Ships Offshore Struct. 2019, 15, 249–258. [Google Scholar] [CrossRef]

- Mason, J.; Larkin, A.; Bullock, S.; van der Kolk, N.; Broderick, J.F. Quantifying Voyage Optimisation with Wind Propulsion for Short-Term CO2 Mitigation in Shipping. Ocean Eng. 2023, 289, 116065. [Google Scholar] [CrossRef]

| Vessel Name | DWT, t | Rotor Producer | Installation Type |

|---|---|---|---|

| Type | Gross Tonnage (GT) | Number | Year |

| Year Built | LOA, m | Configuration, m | Fuel Savings, % |

| Afros | 64,000 | Anemoi | Retrofit |

| Bulk carrier | 36,452 | 4 | 2018 |

| 2018 | 200 | 16 × 2 | 12.5 |

| Alcyone | 50,000 | Norsepower | Retrofit |

| Tanker | 29,507 | 2 | 2024 |

| 2022 | 183 | 35 × 5 | 8 |

| Annika Braren | 5023 | EcoFlettner | Retrofit |

| Bulk carrier | 2996 | 1 | 2021 |

| 2020 | 87 | 18 × 3 | 2–4.5, max 15.0 |

| Berge Neblina | 388,000 | Anemoi | Retrofit |

| Bulk carrier | 195,199 | 4 | 2024 |

| 2013 | 361 | 35 × 5 | 8 |

| Berlin | 4814 | Norsepower | Retrofit |

| Ferry | 22,319 | 1 | 2022 |

| 2016 | 170 | 30 × 5 | N/A 3 |

| Buran | 11,861 | Norsepower | Newbuild |

| Tanker | 18,500 | 2 | 2025 |

| 2025 | 150 | 24 × 4 | N/A |

| Ex Dietrich Oldendorf/Chinook Oldendorf | 100,117 | Norsepower | Retrofit |

| Bulk carrier | 53,219 | 3 | 2024 |

| 2020 | 235 | 24 × 4 | 10–15 |

| Camellia Dream | 206,863 | Norsepower | Retrofit |

| Bulk carrier | 108,115 | 2 | 2024 |

| 2014 | 300 | 35 × 5 | N/A |

| Cemcommander | 5876 | Norsepower | Retrofit |

| Cement carrier | 4351 | 2 | 2024 |

| 2024 | 113 | 24 × 4 | N/A |

| Copenhagen | 4814 | Norsepower | Retrofit |

| Ferry | 22,319 | 1 | 2020 |

| 2016 | 170 | 30 × 5 | 4 |

| Delphine | 27,687 | Norsepower | Retrofit |

| Ro-Ro | 74,273 | 2 | 2023 |

| 2018 | 234 | 35 × 5 | 7–10 |

| E-Ship 1 | 10,020 | Enercon | Retrofit |

| Ro-Lo | 12,968 | 4 | 2010 |

| 2010 | 130 | 27 × 4 | 25 |

| Estraden | 9741 | Norsepower | Retrofit |

| Ro-ro | 18,205 | 2 | 2015 |

| 1999 | 163 | 18 × 3 | 6.1 |

| Koryu | 53,762 | Norsepower | Retrofit |

| Combination carrier | 30,784 | 1 | 2024 |

| 2013 | 190 | 35 × 5 | N/A |

| Northern Pathfinder | N/A | Norsepower | Newbuild |

| Gas carrier | 10,627 | 1 | 2024 |

| 2024 | 130 | 28 × 4 | N/A |

| Northern Pioneer | N/A | Norsepower | Newbuild |

| Gas carrier | 10,627 | 1 | 2024 |

| 2024 | 130 | 28 × 4 | N/A |

| Oceanus Aurora | 58,551 | Norsepower | Newbuild |

| VLGC | 53,531 | 2 | 2024 |

| 2023 | 230 | 20 × 4 | 4 |

| Sea Zhoushan | 325,000 | Norsepower | Newbuild |

| Bulk carrier | 173,666 | 5 | 2021 |

| 2021 | 340 | 24 × 4 | 8 |

| SC Connector | 8843 | Norsepower | Retrofit |

| Ro-ro | 12,251 | 2 | 2021 |

| 1997 | 155 | 35 × 5 | 25 |

| Sohar Max | 400,315 | Anemoi | Retrofit |

| Bulk carrier | 201,757 | 5 | 2024 |

| 2012 | 360 | 35 × 5 | 6 |

| TR Lady | 82,000 | Anemoi | Retrofit |

| Bulk carrier | 44,642 | 3 | 2023 |

| 2017 | 229 | 24 × 5 | 10 |

| Viking Grace | 6107 | Norsepower | Retrofit |

| Ferry | 57,565 | 1 | 2018–2021 1 |

| 2013 | 218 | 24 × 4 | 231–315 2 |

| Yodohime | 85,022 | Norsepower | Retrofit |

| Bulk carrier | 47,181 | 1 | 2024 |

| 2016 | 229 | 24 × 4 | N/A |

| Ex. Maersk Pelican/Timberwolf/N/A | 109,647 | Norsepower | Retrofit |

| Tanker | 61,724 | 2 | 2018 |

| 2008 | 245 | 30 × 5 | 8.2 |

| Study | Name | Number Rotor Configuration, m | Methodology | Savings, % Per Rotor Route |

|---|---|---|---|---|

| Traut et al. (2014), [15] | N/A RoRo 7000 | 1 35 × 5 | Numerical modeling and wind data analysis | 4 1/r Dunkirk to Dover |

| N/A Product tanker 8000 | 14 1/r London to Milford Haven | |||

| N/A General cargo 5500 | 21 1/r Varberg to Gillingham | |||

| N/A Bulk carrier 50,000 | 5 1/r Tubarao to Grimsby | |||

| N/A Container ship 30,000 | 2 1/r Yantian to Felixstowe | |||

| Bentin et al. (2016), [18] | BBC Hudson | 4 25 × 4 | Real-world wind and wave data collection, route optimization simulations, and WASP mathematical modeling | 36 1, 6 1/r (Great Circle Route), up to 53 1, 13 1/r (optimized route), 14 1–28 1, 3.5 1–7 1/r (reverse route) Baltimore–Wilhelmshaven |

| General cargo | ||||

| 17,500 | ||||

| De Marco et al. (2016), [31] | N/A 74,983 | 2 28 × 4 | Numerical modeling | up to 30 2, 15 2/r |

| Comer et al. (2019), [32] | E-Ship 1 | see Table 1 | Route-based simulation approach, AIS data, and global meteorological data | 8.3 1 (2.1 1/r) at low Portugal–Uruguay |

| 47 1 (11.8 1/r) at high The Netherlands–Portugal | ||||

| Estraden | 1.6 1 (0.8 1/r) at low UK–The Netherlands | |||

| 9.0 1(4.5 1/r) at high UK–The Netherlands | ||||

| Viking Grace | 0.4 1/r at low Sweden–Finland | |||

| 2.8 1/r at high Sweden–Finland | ||||

| Maersk Pelican | 1.8 1 (0.9 1/r) at low Algeria–Singapore | |||

| 4.7 1 (2.4 1/r) at high South Korea–Spain | ||||

| Fehn Pollux | 1 18 × 3 | 1.0 1/r at low Italy–Algeria | ||

| 6.6 1/r at high Spain–Egypt | ||||

| Lu et al. (2020), [34] | N/A 100,000–120,000 | 1 18 × 3 | Simulation model “ShipJourney” | 8.9 1/r Cape Lopez, Gabon–Point Tupper, Canada |

| 6.5 1/r Angra dos Reis, Brazil–Rotterdam, The Netherlands | ||||

| Mason et al. (2024), [35] | N/A N/A 80,000 DWT | 4 35 × 5 | Simulation using the VOIDS routing model and Blue Wasp’s Pelican performance model | 4.9–8.7 3/r at high 14 routes |

| 1.0–4.9 3/r at low 14 routes | ||||

| Smith et al. (2013), Chou et al. (2021), [7,33] | N/A Chemical tanker 10,000 DWT | N/A | N/A | 10–50 1/n/a Buenos Aires–WesternApproaches |

| N/A Ro-Ro 7000 DWT | 4 1/n/a Dunkirk–Dover | |||

| Vahs (2021), [16] | Fehn Pollux | 1 18 × 3 m | Sea trials and real-world performance testing | 5 1–20 1/r North Sea |

| General cargo | ||||

| 4211 DWT | ||||

| 1996 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carjova, K.; Hilmola, O.-P.; Tapaninen, U. Economic Feasibility and Operational Performance of Rotor Sails in Maritime Transport. Sustainability 2025, 17, 5909. https://doi.org/10.3390/su17135909

Carjova K, Hilmola O-P, Tapaninen U. Economic Feasibility and Operational Performance of Rotor Sails in Maritime Transport. Sustainability. 2025; 17(13):5909. https://doi.org/10.3390/su17135909

Chicago/Turabian StyleCarjova, Kristine, Olli-Pekka Hilmola, and Ulla Tapaninen. 2025. "Economic Feasibility and Operational Performance of Rotor Sails in Maritime Transport" Sustainability 17, no. 13: 5909. https://doi.org/10.3390/su17135909

APA StyleCarjova, K., Hilmola, O.-P., & Tapaninen, U. (2025). Economic Feasibility and Operational Performance of Rotor Sails in Maritime Transport. Sustainability, 17(13), 5909. https://doi.org/10.3390/su17135909