Abstract

Indonesia’s high logistics costs—approximately 14.6% of its GDP—pose a significant challenge to national economic competitiveness. Key contributing factors include complex geography, fragmented multimodal transport systems and inefficient container terminal operations, particularly concerning the handling of empty containers. This study investigates operational optimization in a container terminal using Agile and Lean principles, without additional investment or infrastructure expansion. It compares throughput before and after optimization, focusing on equipment productivity and reduction in idle time, especially related to equipment and human resources. Field implementation began in 2015, followed by simulation-based validation using system dynamics modeling. The terminal demonstrated a sustained increase in capacity beginning in 2016, eventually exceeding its original design capacity while maintaining acceptable berth and Yard Occupancy Ratios (BOR and YOR). Agile practices improved empty container handling, while Lean methods enhanced berthing process efficiency. The findings confirm that significant reductions in port operational costs, shipping operational costs, voyage turnover time, and logistics costs can be achieved through strategic operational reforms and better resource utilization, rather than through capital-intensive expansion. The study provides a replicable model for improving terminal efficiency in ports facing similar constraints.

1. Introduction

Indonesia’s economic competitiveness has long been hampered by disproportionately high logistics costs. According to the World Bank, logistics expenditures consume approximately 14.6% of the national gross domestic product (GDP), a stark contrast to the lower logistics burdens of neighboring Southeast Asian economies [1]. These costs are not only an economic drag but also a reflection of deep-rooted inefficiencies within the logistics ecosystem—characterized by fragmented infrastructure, regulatory complexity, and the geographic challenges of an archipelagic nation [2,3].

Within this system, container terminals serve as critical logistical nodes, yet they often suffer from capacity constraints, poor operational synchronization, and rising inefficiencies [4,5]. Terminals located in land-scarce or riverine environments are particularly vulnerable, facing extended turnaround times, low crane utilization rates, and the compounding issue of empty container traffic—consistently accounts for approximately 40% of the total throughput [6,7].

In response to these operational bottlenecks, port authorities frequently resort to capital-intensive interventions—such as infrastructure expansion or equipment upgrades—without first addressing existing inefficiencies [8,9]. This pattern reflects a deeper issue: an overreliance on static capacity indicators like quay length and yard area, with insufficient emphasis on dynamic performance metrics such as vessel waiting time, crane moves per hour, and real-time resource utilization [10,11].

Consequently, many container terminals operate below their potential—failing to utilize existing physical assets effectively. This underperformance is attributed to a lack of integrated operations planning, fragmented workflows, and suboptimal decision-making [12,13].

The notion of latent capacity—defined as the untapped throughput potential within an existing system—emerges as a promising lens to diagnose and solve these inefficiencies. Latent capacity exists when a terminal has the physical infrastructure to handle more volume but is constrained by poor coordination, underutilized equipment, or ineffective labor deployment [14,15].

This concept parallels the operations management term effective capacity, which denotes the realistic operational limit under normal conditions [16]. The gap between design and effective capacity often arises from systemic inefficiencies—echoing the foundational principles of Lean systems theory, which seek to eliminate waste in time, motion, and inventory [17,18].

Recent research has increasingly emphasized the transformative potential of Lean principles in enhancing performance across port environments. Lean thinking, originally conceptualized in manufacturing, is now applied to logistics and maritime settings to systematically eliminate waste and maximize value within constrained resources. Kuo and Lin (2020) provide robust empirical evidence from Taiwanese container terminals, illustrating that Lean management not only enhances operational efficiency—by minimizing idle time, reducing rehandling, and improving container flow—but also promotes environmental sustainability through better resource use and lower emissions [19]. Their study emphasizes that synchronized operational processes, such as real-time communication between quay and yard units and the implementation of visual control systems, can produce measurable performance gains. Similarly, Bonamigo et al. (2023) present a detailed case study of a Brazilian port terminal, where the introduction of Lean service practices such as standardized work protocols, root cause analysis for delays, and takt time coordination led to significant improvements in productivity, asset utilization, and turnaround times [20]. Importantly, these gains were achieved without any major capital investment or physical expansion, underscoring the ability of Lean operations to unlock latent capacity.

In parallel, Agile operations offer a complementary yet distinct set of capabilities—centered on adaptability, responsiveness, and decentralized decision-making. Originating from software development and flexible manufacturing systems, agility has been increasingly adopted in logistics to deal with high variability and uncertainty. Christopher (2016) argues that Agile supply chains thrive in volatile demand conditions by enabling quick reconfiguration of assets and workflows [21]. In the context of container terminals, this translates into practices such as dynamic berth scheduling based on real-time vessel (Estimated Time of Arrival) ETA updates, flexible labor rostering to meet peak loads, and mobile or reassign-able equipment pools. Liu et al. (2009) explore this in Chinese port operations, showing how Agile service orientation facilitated rapid response to fluctuating cargo volumes and minimized vessel waiting times [22]. Moreover, Salleh et al. (2020) argue that agility becomes particularly critical in environments with frequent disruptions or unpredictable shipping patterns, such as those found in developing economies [23]. Their research integrates Agile principles into the broader LARG (Lean, Agile, Resilient, Green) framework, emphasizing the need for operational resilience and environmental responsibility alongside speed and flexibility. Twrdy et al. (2013) similarly highlight the role of Agile intermodal coordination in improving throughput in European inland ports, stressing the importance of real-time decision support systems and cross-functional team collaboration [24].

Together, Lean and Agile approaches offer a powerful hybrid model for container terminal optimization—especially in resource-constrained or land-limited settings. While Lean strategies focus on efficiency and flow consistency, Agile methods provide the adaptability needed to cope with variability and disruption. The integration of these two paradigms allows terminals to enhance their effective capacity and operational responsiveness without reliance on physical expansion or high levels of automation. This synthesis is particularly relevant for developing country terminals, where infrastructure funding may be limited, but performance improvement is urgently needed to support national logistics competitiveness.

Although prior studies have examined port optimization, most focus on large hub ports, advanced automation, or simulation modeling in idealized environments [25,26,27]. Less attention has been given to resource-constrained terminals in developing economies, where agility, human-centered planning, and Lean process improvements may yield significant capacity gains without physical expansion. Moreover, the literature lacks practical frameworks that integrate Lean and Agile principles for enhancing container terminal efficiency under land and operational constraints.

The operational insights underpinning this study were derived from the author’s role as terminal manager during the period of capacity constraint and process transformation. The improvement strategies were formulated through experiential learning, continuous on-site observation, and data-driven decision-making within the terminal environment. The author led the identification of systemic inefficiencies—particularly in quay crane deployment, yard flow, and idle time—through iterative operational monitoring and informal feedback loops involving frontline personnel. These empirically grounded practices informed the adaptive implementation of Lean and Agile principles, which were progressively refined and institutionalized over time.

In the present research, this paper serves as a reference for the empirical application of Lean and Agile operational principles to unlock latent capacity in a land-constrained river port container terminal in Indonesia. The findings are particularly beneficial for terminal operators, port authorities, logistics managers, and policy-makers seeking to improve operational performance without large-scale infrastructure investment. This contribution also provides value to researchers and practitioners in maritime logistics, as it bridges practical insights with structured optimization models, supporting broader efforts to increase port efficiency, reduce vessel turnaround time, and optimize national logistics performance.

The remainder of this paper is organized as follows. Section 2 describes the materials and methods, including the research design, data collection, intervention framework, and data analysis approach. Section 3 presents the results of operational improvements at the case terminal, highlighting key performance indicators and qualitative insights. Section 4 provides a discussion of the findings in relation to the existing literature and the broader context of land-constrained port operations, emphasizing the implications of Lean and Agile strategies.

2. Materials and Methods

2.1. Research Design

This study employed a quasi-experimental before-and-after design to rigorously evaluate the effects of Agile and Lean operational interventions on the performance of a land-constrained river port container terminal in Indonesia. The research compared throughput volumes, berth and yard utilization, and equipment productivity across three chronological phases: pre-intervention (baseline), during intervention, and post-intervention. Throughout the study, the terminal’s infrastructure and equipment inventory remained constant. This constraint allowed the observed performance changes to be attributed solely to process-based optimization.

During the baseline phase (2013–2014), the terminal operated under conventional procedures without Lean or Agile frameworks. Annual throughput approached the design limit of 220,000 TEUs, revealing inefficiencies in container flow, crane idle time, and yard congestion. These inefficiencies provided the justification for reform. In the intervention phase (2015), Agile and Lean strategies were formally introduced. No new cranes, berths, or terminal areas were added; instead, the interventions included workflow restructuring, equipment redeployment, and scheduling enhancements. The post-intervention phase (2016–2020) was used to measure and analyze improvements, benchmarked against the terminal’s original design capacity and the baseline performance.

2.2. Agile and Lean Interventions

Agile strategies were applied to enhance flexibility in handling empty containers, which accounted for a substantial portion of outbound traffic. Key measures included the implementation of twin-lift spreaders, allowing simultaneous lifting of two empty containers and thereby increasing crane handling rates without adding equipment. On the other hand, Lean strategies focused on waste elimination and synchronization. The yard layout was redesigned to separate full and empty containers, reducing congestion and improving space utilization. Empty containers were transferred from RTG-based handling to empty stackers, which are more efficient for lighter, less complex lifts.

In addition to equipment-based reforms, Lean principles were applied to operator scheduling. Work shifts were reorganized to minimize idle time caused by fatigue and excessive break durations. A detailed shift plan ensured continuous operator availability while maintaining compliance with labor regulations. Furthermore, Lean was employed in berth window planning to reduce idle berth time and vessel congestion. Berthing schedules were optimized to eliminate “broken space” between vessel calls. Improvements were also made in the pilotage and mooring processes by enhancing coordination with port authorities and ensuring the readiness of pilot boats and berth crews. Although pilotage and mooring services are provided by third parties, collaboration with these stakeholders is essential for container terminals to reduce vessel non-operating time (NOT) and improve overall efficiency.

2.3. Data Collection and Analysis

Empirical data was collected across all three phases of the study. Key performance indicators included annual TEUs throughput, crane productivity (BCH), yard throughput, vessel turnaround time, and occupancy ratios (BOR and YOR). The effects of each intervention were isolated by maintaining the same physical infrastructure and analyzing performance before and after the interventions. All operational changes were implemented within the same terminal system, and external factors (e.g., vessel mix, equipment type, and yard dimensions) remained unchanged. This isolation provided a robust foundation for attributing observed improvements directly to the Lean and Agile strategies.

2.4. Simulation Model for Validation

To complement empirical analysis and explore system scalability, a system dynamics model was developed using Vensim PLE Version 10.2.1 software. The model replicated real-world terminal operations based on accurate representations of equipment (quay cranes, yard tractors, stackers), labor shifts, vessel schedules, and yard layout. Calibration was conducted using 2015–2016 operational data to ensure that simulated outputs mirrored actual performance levels. The model included detailed assumptions about trailer cycle times, crane cycle durations, storage time, and berth availability.

To ensure model robustness, sensitivity analyses were performed under varying demand conditions, operational disruptions, and peak-hour traffic scenarios. These simulations demonstrated that throughput increases observed in real operations could be replicated and scaled under simulated conditions, confirming the validity of the interventions. Simulation results were consistent with the post-intervention operational data, reinforcing the reliability of the experimental design and confirming that gains were not attributable to exogenous factors.

2.5. Theoretical Capacity Estimation

In addition to simulation, berth capacity was estimated analytically using UNCTAD (2012) model [28,29]. This model calculates annual berth capacity based on berth length, occupancy ratio, and productivity. The formula used is as follows:

- Cb: Berth capacity

- n: Number of berth

- ∅: Acceptable berth occupancy rate (%)

- P: Annual average productivity of vessel (Box/h)

This approach allows for a dynamic estimation of capacity that considers not only the physical infrastructure but also the efficiency of operational processes and the acceptable performance limits as defined by terminal policies and regulatory standards.

3. Results

This section presents an overview of the design capacity of a river-based container terminal, its current operational condition, and the application of Agile and Lean approaches to adapt to existing constraints in order to increase capacity without infrastructure or superstructure expansion. A descriptive method was also employed as a basis for analysis and validation. Furthermore, the study discusses how optimized container handling operations have led to increased terminal capacity and explores the resulting economic impacts. These findings are intended to serve as valuable references for maritime stakeholders, particularly port authorities and terminal operators.

3.1. Design Capacity of Port

The container terminal examined in this case study is located along an inland river in Indonesia and has been operational since 2010. The terminal was developed in phases, each with corresponding infrastructure and equipment upgrades. Table 1 outlines the terminal’s design capacity across different development stages.

Table 1.

Terminal design capacity.

In Phase I, the terminal was equipped with two quay cranes, supporting a projected maximum throughput capacity of 220,000 TEUs per year. As development progressed, the terminal entered Phase III, with expanded facilities consisting of four berths and four quay cranes, enabling a projected maximum capacity of 440,000 TEUs per year.

This phased development illustrates the terminal’s original growth plan through traditional capacity expansion. However, this study aims to demonstrate that significant capacity improvements can also be achieved through operational optimization, particularly in land-constrained river ports where physical expansion is costly or unfeasible.

3.2. Container Throughput

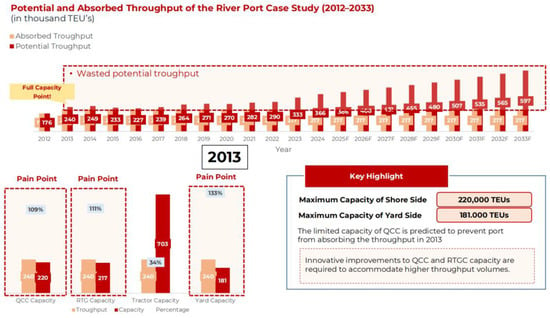

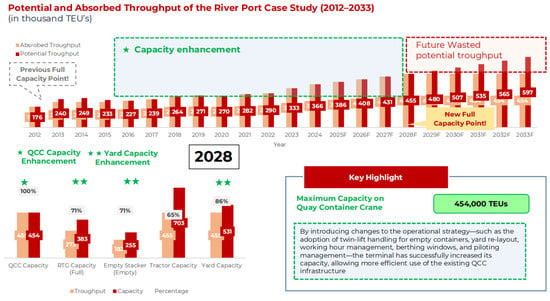

Figure 1 illustrates the actual (absorbed) and potential container throughput of the river port terminal across the period from 2012 to 2033. The year 2013 serves as a key reference point, as it marks the moment when the terminal exceeded its original design capacity by handling 240,000 TEUs—surpassing both the maximum quay crane handling capacity of 220,000 TEUs and the yard-side capacity of approximately 217,800 TEUs. This milestone signaled the emergence of structural bottlenecks and highlighted the need for process-based optimization, particularly as physical expansion was not feasible in the short term.

Figure 1.

Potential capacity underutilized: diagnosing performance gaps (2012–2033).

The chart presents two throughput trajectories: the absorbed throughput, represented by solid bars, and the potential throughput, shown with a dashed outline. The growing gap between these two values over time reflects the volume of containers that could not be accommodated due to operational constraints—what is referred to in Figure 1 as “wasted potential throughput”. This discrepancy underscores the importance of overcoming handling limitations through productivity improvements and more efficient yard and equipment deployment strategies.

The lower portion of Figure 1 further details the core constraints present in 2013, when quay crane utilization reached 109% of capacity, yard crane operations stood at 124%, and the Yard Occupancy Ratio exceeded 103%. These indicators confirmed that the terminal had reached saturation across multiple subsystems, despite a stable infrastructure layout. The forecasted data from 2014 to 2033 models the terminal’s performance trajectory under scenarios that incorporate Lean and Agile reforms implemented from 2015 onward, demonstrating how absorbed throughput gradually rises to align with potential throughput as operational improvements take effect.

Since commencing operations in 2010, the container terminal has demonstrated significant improvements in its container handling capacity. By 2012, the terminal’s throughput had reached 176,000 TEUs per year, and in 2013, it exceeded its original design capacity by handling 240,000 TEUs per year. This milestone highlighted a critical challenge for terminal operators: how to accommodate continued growth in throughput despite physical and operational limitations.

To address this, a pain point analysis was carried out to identify bottlenecks constraining terminal performance. As illustrated in Figure 1, the key highlight emphasizes a critical operational constraint at the container terminal: the maximum capacity limits of the shore side and yard side infrastructure. Specifically, the quay container crane (QCC) capacity was capped at 220,000 TEUs, and the yard-side handling capacity was constrained to 181,000 TEUs during the reference year 2013. These capacity ceilings were not due to physical space or crane quantity alone, but rather they stemmed from the inefficiencies in equipment utilization and process flow. As a result, the terminal began to experience throughput saturation as early as 2013—reaching or exceeding its design threshold without physically expanding.

This bottleneck triggered the need for non-infrastructure-based interventions. Figure 1 notes that innovative improvements in operational strategies—particularly those targeting QCC cycle times and RTGC (rubber-tired gantry crane) deployment—were essential to overcoming these limitations. By enhancing equipment coordination, reducing idle time, and applying Lean and Agile operational adjustments, the terminal was able to activate latent capacity and progressively absorb higher throughput volumes. These interventions form the foundation for the terminal’s performance recovery and projected capacity expansion over the following decade, without requiring costly capital investment in new physical assets.

These findings underscored the urgent need for operational improvements, as traditional infrastructure expansion was not feasible in the short term. Consequently, optimization efforts were focused on reducing equipment idle time, improving container flow, and enhancing yard space utilization without expanding the terminal’s physical footprint.

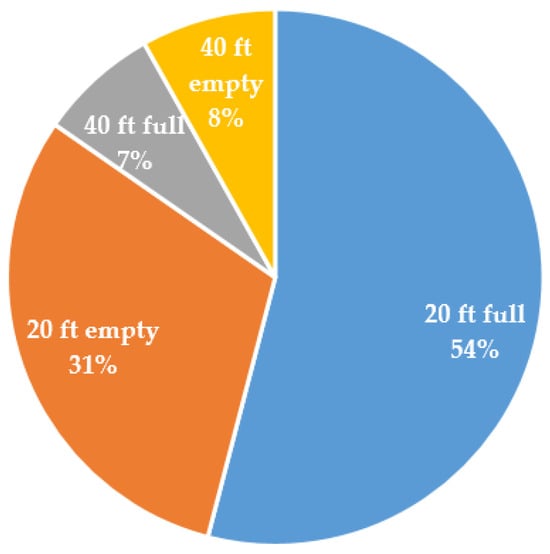

In addition to the analysis of existing capacity, further data revealed a substantial volume of empty containers, which account for approximately 40% of the total containers handled at the terminal. Typically, most of the containers unloaded at the terminal are full containers, whereas a significant portion of the containers reloaded for outbound movement are empty.

Another noteworthy finding is the dominance of 20-foot containers in terminal operations. Specifically, 54% of the containers handled are full 20-foot containers, while 31% are empty 20-foot containers. Figure 2 below illustrates the distribution of empty containers handled at this river-based terminal in Indonesia.

Figure 2.

Comparison empty container population at Indonesia River Port.

The high proportion of empty containers—largely a consequence of trade flow imbalances—can undermine container handling efficiency and disrupt regional logistics equilibrium. Nevertheless, this situation also presents an opportunity for improvement. Due to their lighter weight and less complex handling requirements, empty containers can be processed more efficiently and potentially through specialized handling systems that optimize terminal productivity without additional physical expansion.

3.3. Agile and Lean Operation Approach

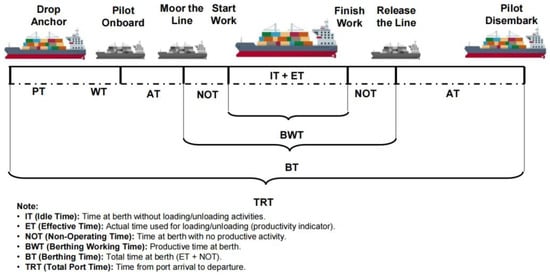

To evaluate the improvement and optimization efforts at the container terminal, it is essential to analyze the terminal’s entire operational workflow. Figure 3 illustrates the sequence of operational activities in a typical container terminal. The process begins with the arrival of the vessel in the port area, followed by anchoring and pilotage. Once the vessel reaches the berth, mooring procedures are carried out, and the unloading process commences.

Figure 3.

Port vessel operations.

As shown in Figure 3, the success and efficiency of the unloading process are influenced by multiple interdependent stakeholders—from the vessel’s arrival and pilotage to the cargo discharge and the ship’s departure. Operational inefficiencies at any point in this sequence can result in significant delays. For example, inadequate berth window scheduling may lead to vessel congestion and long waiting times, while prolonged crane idle time during container handling can extend overall unloading durations.

Such inefficiencies negatively impact the terminal’s performance and reduce throughput capacity. Therefore, the systematic application of Agile and Lean operational approaches becomes crucial. Agile practices allow the terminal to adapt swiftly to real-time operational demands, particularly in handling empty containers and unpredictable scheduling. Meanwhile, Lean principles focus on eliminating non-value-added activities, reducing idle times, and streamlining the flow of containers—thereby enhancing both equipment and labor productivity.

3.3.1. Agile Approach to Empty Container Handling: Shore Side

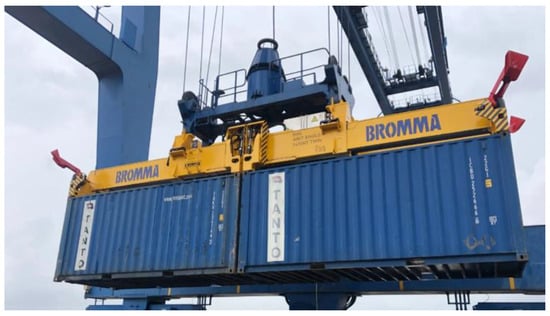

One of the most effective Agile interventions implemented at the quay side was the optimization of empty container handling through the deployment of twin-lift spreaders. Empty containers, which typically weigh only 3 to 5 tons each, present an opportunity to increase crane efficiency without increasing mechanical load. By modifying the crane handling strategy to lift two 20-foot empty containers simultaneously, the terminal was able to significantly improve crane productivity without investing in additional quay cranes or infrastructure. This operational adjustment aligns with the principles of Agile methodology, which emphasize flexibility, responsiveness, and optimal utilization of available resources to respond to fluctuating operational demands in real time.

Prior to the intervention, all containers—regardless of content—were handled using single-lift spreaders. This limited the productivity of quay container cranes (QCCs), especially during vessel discharge and loading involving high proportions of empty containers. As shown in Figure 4, the implementation of twin-lift spreaders allowed for simultaneous lifting of two 20-foot empty units, directly reducing the number of crane cycles required per vessel call. This shift contributed to shorter vessel port stays and a more stable container flow.

Figure 4.

Twin-lift handling of 20ft empty containers at quay side.

Figure 5 displays the field documentation of the operational use of a twin-lift spreader on a quay container crane (QCC) during loading process for empty container at a domestic container terminal. The spreader is capable of lifting either a single 40-foot container or two 20-foot containers simultaneously, with a Safe Working Load (SWL) of 40 metric tons in single mode and 2 × 20 metric tons in twin mode. This field implementation demonstrates the spreader’s contribution to increasing operational productivity by optimizing each crane cycle.

Figure 5.

Twin-Lift Spreader operation on Quay Crane (documented during field operation).

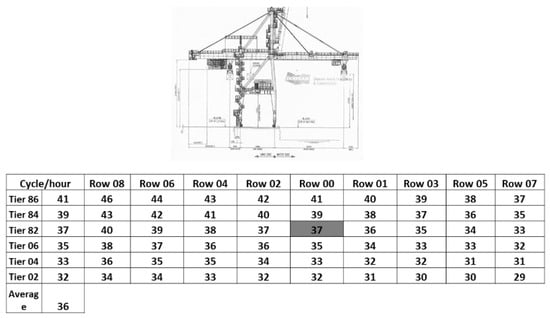

The introduction of twin-lift capability resulted in measurable gains. As detailed in Figure 6, average crane productivity increased to approximately 36 moves per hour across various container positions and tiers. Performance peaked in central rows and mid-tiers due to optimal swing and trolley movement geometry.

Figure 6.

QCC productivity improvement after twin-lift adoption.

At the container terminal used in this case study, the implementation of the twin-lift spreader for handling empty containers has led to a substantial increase in the box-to-crane ratio during operations. Initially, all containers—regardless of whether they were full or empty—were handled individually. However, with the twin-lift spreader, two empty containers can now be lifted simultaneously, effectively doubling crane efficiency during empty container operations.

Following the implementation, the average quay container crane (QCC) productivity rose significantly, reaching between 30 and 40 boxes per hour. This improvement not only increased terminal throughput but also reduced the total time required for container handling, leading to improved operational flow and decreased vessel turnaround times.

Table 2 presents a comparison of the use of the twin-lift spreader for handling empty containers against the production that can be achieved by a container crane. A comparative analysis of production outputs, before and after the adoption of the twin-lift spreader, shows a marked improvement in terminal capacity. If a terminal handles 40% empty containers and operates at an average crane speed of 30 boxes per hour, the use of twin-lift spreaders enables the terminal to increase its annual capacity from approximately 157,000 boxes to 197,000 boxes per crane. This reflects a 25% increase in capacity per crane, significantly boosting operational efficiency and throughput, particularly in terminals dealing with a high proportion of empty containers.

Table 2.

Crane capacity by BCH and lift type.

3.3.2. Agile Approach to Empty Container Handling: Yard Side

The application of the Agile approach can also be extended to the yard side, where containers are temporarily stored while awaiting unloading or transfer out of the terminal. In the previous yard layout, all containers—both full and empty—were stacked in a common area and handled by five rubber-tired gantry (RTG) cranes. This yard was originally designed to accommodate a maximum capacity of 217,000 TEUs. However, when the terminal’s throughput volume reached 240,000 TEUs, the yard was no longer able to manage the container flow effectively, causing the yard occupancy ratio (YOR) to exceed acceptable operational thresholds.

To address this challenge, a key strategy for increasing yard capacity was to adjust the handling approach for empty containers. One of the most effective solutions involved segregating the stacking area based on container status—full versus empty. Under this new configuration, the yard area managed by RTGs was dedicated exclusively to full containers, while the Container Freight Station (CFS) area was repurposed for the stacking of empty containers.

The handling of empty containers in this revised layout was transferred to two dedicated empty stackers, which are more suitable for lighter and less complex lifting operations. This separation of container types not only reduces congestion in the main yard but also enhances operational efficiency by aligning equipment use with container characteristics.

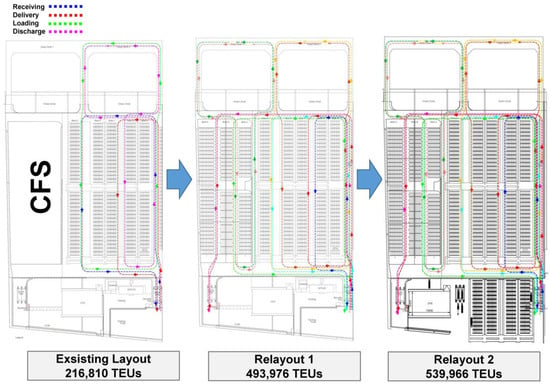

This Agile modification enables better space utilization and more efficient workflow in the yard. By isolating full and empty container operations, the terminal was able to manage growing volumes without physical expansion, while also mitigating the risk of exceeding yard capacity limits. Ultimately, this approach supports smoother yard operations and contributes to the overall operational efficiency and flexibility of the terminal. Figure 7 displays the redesign of the river port yard terminal layout.

Figure 7.

Redesign of the river port yard terminal layout.

The redesign of the yard layout has resulted in a substantial increase in container yard capacity, as demonstrated by the comparative data. Initially, the yard had a ground capacity of 4950 TEUs, which increased to 11,278 TEUs under Relayout 1, and further to 12,328 TEUs under Relayout 2. While the number of ground slots in RTG-managed yards remained constant at 990 TEUs, the addition of 791 TEUs in the empty stacker yard in both relayouts significantly contributed to improved performance.

Moreover, with consistent tiering configurations—five tiers for RTG-managed stacks and eight tiers for empty stackers—combined with a fixed average storage time of five days, the total annual yard capacity increased dramatically. The throughput rose from 216,810 TEUs per year in the original layout to 493,976 TEUs in Relayout 1, and further to 539,966 TEUs in Relayout 2.

Table 3 illustrates the effectiveness of the yard reconfiguration in optimizing space utilization and significantly enhancing the terminal’s annual throughput, all without the need for physical expansion of infrastructure.

Table 3.

Yard capacity enhancement due to container yard re-design.

This yard redesign also led to a significant reduction in the operational burden on the RTGs, which previously handled both full and empty containers. The introduction of dedicated empty stackers has enhanced the flexibility and efficiency of empty container handling. Table 4 presents a comparison of container handling capacity before and after the implementation of the redesign. As a result of these changes, the annual yard capacity has increased to 486,180 TEUs.

Table 4.

Crane capacity enhancement due to container yard redesign.

This adjustment not only optimizes operational efficiency within the yard but also improves resource allocation, enabling more effective utilization of both equipment and available space. By assigning empty container handling to empty stackers, the RTGs can now concentrate exclusively on full containers, thereby increasing their throughput and contributing to the overall productivity and capacity enhancement of the terminal.

3.3.3. Lean Approach to Operator Working Hours Management

Crane operators play a critical role in container handling operations, as the efficiency of loading and unloading processes is highly dependent on their precision, responsiveness, and skill [30]. However, excessive workloads and operational pressures can lead to operator fatigue, which negatively impacts both productivity and worker safety [31]. Therefore, improving working conditions through balanced work shifts, ergonomically designed operator facilities, and ongoing health and safety programs is essential.

The application of Lean principles to operator management focuses on reducing non-value-adding time, particularly idle time related to workforce inefficiencies. Idle time has a direct and significant effect on the productivity of container handling operations. Table 5 illustrates the potential loss in crane productivity resulting from operator break periods. For example, if idle time due to breaks totals three hours per day, the terminal could lose approximately 30,000 to 40,000 container moves per year per crane.

Table 5.

Potential productivity loss due to operator break time.

This approach requires a well-defined strategy because, on one hand, container terminals must ensure the constant availability of operators to meet operational demands, while on the other hand, adequate rest periods must be provided to maintain operator well-being and performance. In particular, crane operators must remain physically and mentally fit for duty, which necessitates a balanced approach to shift planning.

Therefore, operator work schedules must be carefully designed to accommodate working hours, rest periods, and designated days off, in full compliance with labor regulations and employee rights. This balance is crucial to sustaining both operational continuity and workforce welfare.

Table 6 presents the shift scheduling system for quay container crane (QCC) operators. A total of 12 operators are employed to manage 2 QCCs across 3 shifts. Through the implementation of this structured scheduling system, the terminal is able to ensure that operators are adequately rested while maintaining high levels of operational readiness.

Table 6.

QCC operator shift scheduling.

Proper shift planning plays a critical role in maintaining safety standards, maximizing productivity, and minimizing operational downtime, all of which contribute to the overall efficiency and resilience of terminal operations.

Figure 8 illustrates the outcomes resulting from the optimization of operator shift schedules, specifically for the quay container crane (QCC). The scheduling system is designed to ensure that at least two operators are available at all times, thereby enabling the continuous and uninterrupted handling of containers.

Figure 8.

Optimization of weekly operator working hours.

Through the implementation of this optimized scheduling strategy, the terminal is able to maintain operational continuity, minimize the risk of downtime, and ensure that labor requirements for each shift are consistently met. This approach not only enhances workforce efficiency but also contributes to overall terminal productivity and service reliability.

3.3.4. Lean Approach to Berthing Windows

Vessel congestion is a critical issue that must be avoided in container terminal operations due to its adverse impact on operational efficiency and logistics costs [32]. The primary causes of congestion often include misaligned vessel arrival schedules, insufficient coordination with shipping companies, and delays in loading or unloading caused by equipment failures or excessive idle time [32]. To mitigate these challenges, it is essential to implement a well-coordinated vessel scheduling system supported by accurate and timely information sharing. Additionally, adherence to pre-established handling schedules during vessel operations is vital.

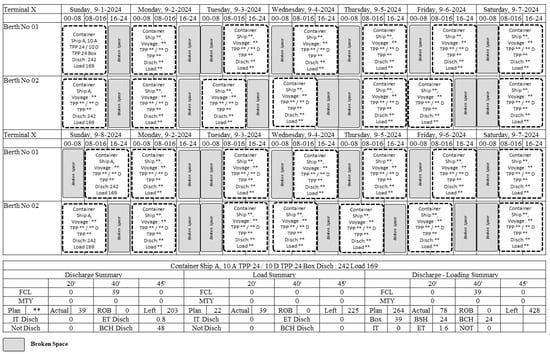

A core Lean strategy for reducing vessel congestion and improving berth efficiency is the use of predefined berthing windows. These windows act as scheduled docking slots that coordinate vessel arrival with terminal resource availability, reducing queueing, unplanned delays, and underutilization of quay cranes. Once a stable berthing window system is established, the next step in Lean implementation is to identify and reduce “broken space”—idle time gaps between vessel operations caused by misalignment or delays.

Figure 9 illustrates an example of daily berthing schedules where several gaps—referred to as broken spaces—remain unused between vessel operations across two berths. These gaps are indicators of inefficiencies in berth planning and ship call allocation. Unused time slots reduce the effective use of quay length and labor, especially when ship arrivals are uncoordinated or irregular. Figure 9 gives a visual representation of a week-long berthing plan across two berths, showing idle time slots (broken space) between vessel operations. These gaps represent underutilized berth time caused by inconsistent vessel arrivals or un-optimized scheduling. Reducing this broken space is a key Lean objective to increase berth efficiency and minimize congestion.

Figure 9.

Identification of broken space in daily berthing schedule. The symbol ** refers to vessel specifications that were excluded from the publication due to confidentiality.

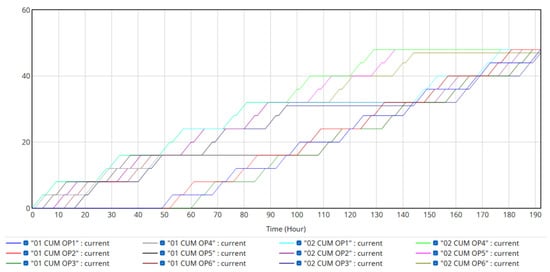

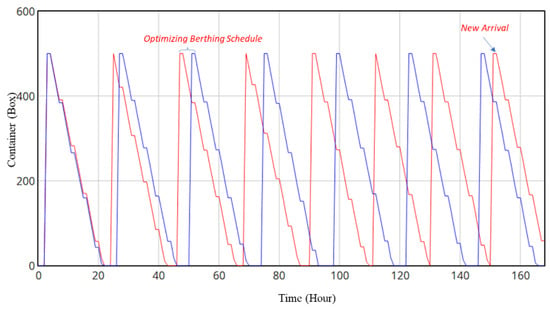

To address this issue, berth windows can be dynamically optimized to fill these gaps with additional or rescheduled ship calls, thereby minimizing idle time. Figure 10 presents a simulation result comparing un-optimized berthing (in blue) with optimized berth scheduling (in red). The optimized schedule demonstrates improved container flow and higher berth utilization, enabling more vessel calls to be accommodated within the same operational period. This Lean-based dynamic scheduling ensures smoother operations, reduces total waiting time, and maximizes equipment use without requiring additional berth infrastructure.

Figure 10.

Simulation of dynamic berth scheduling to minimize broken space.

3.3.5. Lean Approach to Pilotage and Berthing Process

Delays in pilotage and berthing processes are among the primary causes of productivity loss at container terminals. Factors such as the limited availability of pilot boats, adverse weather conditions, or unprepared berths can significantly increase vessel waiting times and disrupt the terminal’s operational schedule. These delays negatively impact the efficiency of loading and unloading operations, affect workforce deployment, and ultimately reduce terminal throughput.

To address these challenges, a Lean approach is essential for identifying and eliminating waste within the piloting and berthing process. This involves streamlining coordination between port authorities, pilotage services, and terminal operators, as well as ensuring real-time communication and resource readiness.

Table 7 presents the estimated productivity loss resulting from inefficiencies in the pilotage and berthing process. If a vessel experiences a three-hour delay, the terminal could lose up to 50,000 TEUs annually in throughput potential, highlighting the critical importance of optimizing these operational stages.

Table 7.

Potential productivity loss due to piloting and berthing process.

To reduce productivity losses caused by pilotage delays and inefficiencies in the berthing process, several strategic solutions are required. For pilotage, closer coordination with pilot service providers is essential to ensure that pilot boats are available in alignment with scheduled vessel arrival times. In addition, providing adequate and responsive transport for pilots to reach anchorage points can help accelerate the pickup and transfer process, reducing overall waiting time.

On the berthing side, it is critical to enhance operator competencies through regular training and simulation exercises, particularly for mooring procedures. Improving the skills and responsiveness of berthing personnel ensures that vessels are safely and efficiently moored, thereby reducing delays and enhancing overall terminal operational performance.

3.4. Achieving a Maximized Design Capacity (Capacity and BOR)

The implementation of Agile and Lean operational strategies has enabled the terminal to significantly enhance its container handling capacity, particularly without relying on physical infrastructure expansion. Since the original design capacity of 220,000 TEUs was surpassed in 2013, continuous operational improvements—including twin-lift spreaders, optimized yard layouts, and dynamic berth scheduling—have raised the terminal’s effective capacity ceiling. By 2024, throughput reached 360,000 TEUs, and projections estimate a peak of 454,000 TEUs by 2026. As shown in Figure 11, this capacity enhancement reflects the transition from constrained performance toward full utilization of shore-side (QCC) and yard-side assets. Figure 11 also highlights key capacity boosts attributed to Agile handling of empty containers, dedicated equipment deployment, and Lean reorganization of terminal resources.

Figure 11.

Throughput growth and capacity enhancement following Lean and Agile implementation (2016–2033).

Forecasted and historical throughput of the river port terminal showing absorbed and potential capacity over time explained in Figure 11. Figure 11 illustrates the impact of process-based interventions—such as twin-lift spreader adoption, crane efficiency, and yard reallocation—on total system capacity. Key milestones include the surpassing of the original design threshold in 2013, the strategic capacity increases in 2024 and 2026, and the projection of full operational utilization at 454,000 TEUs. Sub-figures below highlight improvements in quay and yard-side resource use, including RTGC and empty stacker productivity gains, that supported the terminal’s capacity leap without physical expansion.

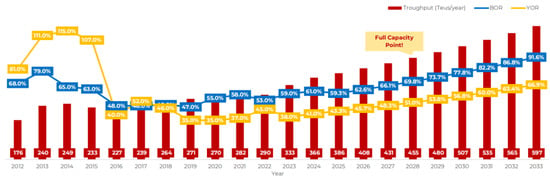

In addition to increased throughput, operational efficiency metrics such as the Berth Occupancy Ratio (BOR) and Yard Occupancy Ratio (YOR) also improved substantially. In 2014, the BOR peaked at 80%, exceeding the recommended efficiency thresholds and causing operational delays. Following targeted Lean interventions initiated in 2016, both BOR and YOR were significantly reduced—reaching a balanced range of approximately 35–45%. As throughput gradually increased beyond 2020, occupancy ratios rose again but remained within acceptable thresholds, stabilizing around 60% for BOR and 65% for YOR by 2026. Figure 12 illustrates the correlation between throughput growth and occupancy efficiency, confirming that the Agile–Lean transformation not only expanded capacity but also enhanced terminal performance quality and sustainability. This figure visualizes throughput (TEUs), Berth Occupancy Ratio (BOR), and Yard Occupancy Ratio (YOR) from 2012 to 2033. Figure 12 demonstrates the significant reduction in occupancy ratio following Lean reforms initiated in 2016. While throughput increases steadily, BOR and YOR are maintained within optimal efficiency limits—stabilizing below 65% despite volume growth. The trend underscores the role of non-infrastructure strategies in balancing capacity expansion with resource efficiency.

Figure 12.

Improvement of BOR and YOR through Lean optimization strategies (2012–2033).

3.5. Statistical Validation of Operational Improvements

To statistically validate the effectiveness of Lean and Agile operational interventions, key performance metrics from the baseline period (2013–2014) were compared with those from the post-intervention period (2016–2024) using two-sample t-tests and 95% confidence intervals. As shown in Table 8, container throughput increased significantly from a baseline mean of 244,546 TEUs to 282,292 TEUs post-intervention (t = 2.63, p = 0.0312), with a 95% confidence interval for the mean difference of [26,059; 89,868]. Net crane productivity (BCH) improved from 23.5 to 34.5 moves/hour (t = 5.58, p = 0.0002), confirming a substantial gain attributed to the implementation of twin-lift spreaders and workflow adjustments. Berth Occupancy Ratio (BOR) decreased from 72.0% to 52.8% (t = −4.05, p = 0.0128), while Yard Occupancy Ratio (YOR) dropped dramatically from 113.0% to 38.2% (t = −8.08, p = 0.0018), highlighting the effectiveness of yard relayout and equipment specialization. These results confirm that the observed improvements are not only operationally significant but also statistically robust.

Table 8.

Statistical validation of improvements.

3.6. Economic Outcomes from a Maximized Design Capacity

Table 9 presents the economic impact of increasing the design capacity of the container terminal through operational optimization, achieved without additional infrastructure investment. The terminal’s maximum capacity increased by 94%, from 220,000 TEUs to 454,000 TEUs. At the same time, port operating costs were reduced by 15%.

Table 9.

Economic outcomes from a maximized design capacity.

The expansion of terminal capacity led to a decrease in voyage turnaround time, which subsequently resulted in an increase in the number of vessel calls. This improvement lowered the fixed operational costs incurred by shipping lines and simultaneously increased their revenues, as indicated by the percentage gain in ship productivity.

Overall, these changes contributed to a 25% reduction in logistics costs per ton, demonstrating the tangible benefits of applying Agile and Lean operational strategies. These results confirm the effectiveness of such approaches in enhancing both terminal efficiency and economic performance—offering a scalable, cost-efficient solution for ports facing physical and financial constraints. Table 9 shows the economic outcomes from a maximized design capacity.

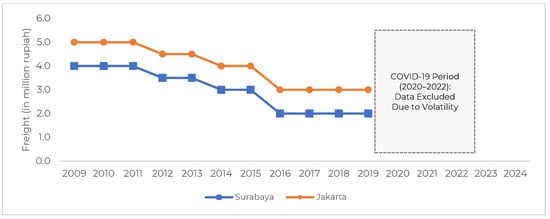

Between 2009 and 2019, the average freight rates from Indonesia’s major hub ports to inland river ports experienced a consistent downward trend. As shown in Figure 13, freight costs from Surabaya decreased from IDR 4 million per trip in 2009 to IDR 2 million by 2016, stabilizing at this lower level thereafter. Similarly, rates from Jakarta dropped from IDR 5 million in 2009 to IDR 3 million by 2016, also remaining constant through 2019.

Figure 13.

Average freight rate trends from Jakarta and Surabaya to river ports (2009–2019).

This reduction in freight rates reflects notable efficiency gains in the maritime logistics system, attributable to several interlinked improvements. These include optimized terminal operations through Lean and Agile strategies, improved vessel scheduling, enhanced port connectivity, and more effective coordination between shipping lines and port authorities. By reducing port stay times, increasing crane productivity, and stabilizing berth allocations, the cost per voyage decreased—benefiting both logistics providers and regional economies. The declining trend in freight rates serves as indirect evidence of the broader economic benefits resulting from non-infrastructure-based port optimization.

The shaded area labeled “COVID-19 Period (2020–2022)” represents the timeframe during which freight rates experienced extreme and unpredictable volatility due to global disruptions in shipping and logistics. These anomalies were excluded from the trend analysis to maintain consistency and avoid distortion of long-term freight efficiency patterns.

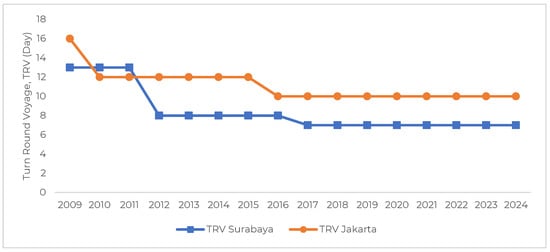

The average voyage turnover time from Indonesia’s major hub ports to inland river ports has demonstrated a sustained improvement from 2009 to the present. As illustrated in Figure 14, voyages originating from Surabaya saw a reduction in turnover time from 13 days in 2009 to 8 days by 2012, followed by a further decline to 7 days by 2017, which has remained consistent through to the most recent period. A comparable pattern was observed for voyages from Jakarta, where turnover time decreased from 16 days in 2009 to 12 days by 2010, remained stable until 2015, and subsequently declined to 10 days from 2016 onward. These reductions reflect enhanced scheduling efficiency, improved port coordination, and the cumulative impact of process optimization initiatives implemented over the last decade.

Figure 14.

Trends in voyage turnover time from Jakarta and Surabaya to river ports (2009–2019).

These improvements reflect increased efficiency across multiple aspects of the maritime logistics chain, including better coordination between ports and shipping lines, Lean-based terminal operations that minimized port stay duration, and improved intermodal connectivity. The reduction in turnaround time not only enhances vessel utilization but also translates into lower per-unit shipping costs and improved schedule reliability—critical factors for supporting economic competitiveness and sustainable domestic trade logistics.

4. Discussion

This study demonstrates the practical viability of applying Agile and Lean approaches to optimize container terminal operations—particularly in river ports constrained by limited land and aging infrastructure. By rethinking equipment use and operational workflows rather than expanding physical capacity, significant throughput gains were achieved. The findings provide strong empirical evidence that process-level innovation can be a powerful lever in improving port productivity, especially in secondary terminals facing investment barriers.

The Agile approach, centered on enhancing the handling of empty containers, addressed one of the most persistent inefficiencies in container terminals. By introducing twin-lift spreaders, crane productivity increased from 20–25 to 30–40 boxes per hour, directly translating into a 25% increase in annual crane handling capacity. For port managers, this suggests that investments in operational agility—such as specialized equipment and adaptive deployment practices—can yield capacity gains comparable to infrastructure expansion but at a fraction of the cost.

In parallel, Lean strategies targeting yard layout and operator scheduling unlocked additional efficiencies. The segregation of full and empty containers, and the reassignment of empty-handling from RTGs to dedicated stackers, increased yard capacity by up to 122%. This supports previous research that emphasizes the impact of process flow redesign on terminal space utilization [7,32]. Moreover, introducing rotating operator shifts mitigated downtime due to workforce breaks, improving labor productivity while complying with labor regulations. Simulations showed that eliminating just three hours of idle time per crane per day could recover throughput losses of up to 40,000 boxes annually, highlighting the critical importance of synchronized workforce and equipment planning.

From an economic perspective, the interventions nearly doubled the port’s throughput—from 220,000 TEUs to 454,000 TEUs—without requiring new superstructures. This resulted in a 15% reduction in internal port costs and a 25% decrease in logistics costs per ton. Such improvements translate into broader regional competitiveness by lowering freight rates and voyage turnaround times. Freight charges for key domestic routes (Surabaya and Jakarta) declined by 40–50%, and average round-trip time dropped by 6–7 days. These metrics reflect the holistic value of operational optimization not just for terminal efficiency, but also for supply chain resilience and customer satisfaction.

Despite these positive results, the study has several limitations. The interventions were tested in a single river port, and the findings may not fully generalize to deep-sea terminals with different vessel sizes, cargo mixes, and operational environments. The simulation model also assumed consistent vessel arrival patterns and did not account for extreme disruptions such as weather conditions, labor strikes, or geopolitical instability. Additionally, the case terminal operates under a one-way traffic pattern, where cargo flows are heavily imbalanced, resulting in a high proportion of empty containers, accounting for approximately 40% of total throughput. This structural characteristic may limit the transferability of the findings to ports with more balanced trade flows. Moreover, over 90% of the containers handled are 20-foot domestic units, which affects yard density, handling equipment choices, and cycle times. These cargo and equipment compositions, while representative of many domestic Indonesian terminals, may not reflect conditions at larger international or transshipment ports. Future research should explore alternative scenarios using stochastic simulations and apply the framework to other terminal types, such as transshipment hubs, gateway ports, or automated terminals. Cross-terminal benchmarking studies are also recommended to evaluate the scalability and adaptability of Agile and Lean strategies across diverse operational contexts.

In conclusion, this research offers a replicable blueprint for maximizing the latent capacity of container terminals using Agile and Lean principles. For port authorities and terminal operators, it presents a practical alternative to infrastructure-heavy solutions—an especially valuable contribution for regions grappling with urban congestion, limited funding, or ecological zoning restrictions.

5. Conclusions

This study demonstrated that significant capacity gains in land-constrained container terminals can be achieved through operational optimization, without the need for additional infrastructure. By applying Agile and Lean methodologies, the terminal’s annual throughput increased by 94%, from 220,000 to 454,000 TEUs. This was accomplished by optimizing equipment usage—most notably, through the deployment of twin-lift spreaders for empty containers—and reconfiguring yard layouts to separate full and empty container handling. These interventions allowed for more efficient space and equipment utilization, reducing congestion and enhancing throughput.

Beyond these operational gains, the study identified substantial economic benefits. Voyage turnaround times were shortened—by up to 6 days in some corridors—enabling increased ship calls and higher terminal productivity. Freight rates dropped significantly as a result, lowering logistics costs and improving service reliability. The study also highlighted the critical role of workforce management in terminal performance. Adjustments to operator scheduling, particularly for crane operations, proved essential in reducing idle time and maintaining consistent productivity.

This research contributes to the port logistics literature by providing empirical evidence of how Agile and Lean principles can be systematically applied in real-world port operations. Unlike traditional approaches that rely on infrastructure expansion, this study offers a cost-effective framework for maximizing latent capacity using process innovation. For terminal operators and policymakers, these findings offer practical guidance on how to improve competitiveness and service levels in environments where land, funding, or political support for expansion may be limited.

However, the study has several limitations. The optimization strategies were validated within a single river terminal context, and findings may not fully translate to larger or more complex port systems. The simulation models were based on stable arrival patterns and operational assumptions, which may not account for variability due to external disruptions, such as weather events or geopolitical instability.

Future research should focus on testing the adaptability of Agile and Lean approaches across different terminal types, such as transshipment hubs or automated ports, incorporating stochastic variables into simulation models to better capture real-world uncertainties, and exploring the integration of digital twin technology to enable real-time optimization in dynamic and complex port environments.

In summary, this study advances both the theory and practice of port operations by demonstrating that performance improvements are possible without capital-intensive investments. The proposed approach offers a scalable, replicable model for terminal efficiency—particularly relevant for emerging economies and secondary ports seeking to enhance their role in global trade.

Author Contributions

Writing—original draft, P.B.S.; Supervision, H.D.A. and R.O.S.G.; Project administration, D.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the findings of this study are available from the corresponding author upon reasonable request. Due to confidentiality agreements and commercial sensitivity, the operational data used in this research cannot be publicly shared.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BOR | Berth Occupancy Ratio |

| CFS | Container Freight Station |

| ETA | Estimated Time of Arrival |

| QCC | Quay Container Crane |

| RTG | Rubber-Tired Gantry |

| TEU | Twenty-foot Equivalent Unit |

| YOR | Yard Occupancy Ratio |

References

- Subiyanto, E.; Suyoto, Y.T. Determining value of logistics costs in projects: Empirical findings based-on executing several cement projects in Indonesia. Heliyon 2020, 6, e04352. [Google Scholar] [CrossRef] [PubMed]

- Arnold, J. The Role of Transport Infrastructure, Logistics, and Trade Facilitation in Asian Trade. In Pan-Asian Integration; Palgrave Macmillan: London, UK, 2009; pp. 351–437. Available online: http://link.springer.com/10.1057/9780230236974_6 (accessed on 1 April 2025).

- Brooks, D.H. Regional Cooperation, Infrastructure and Trade Costs in Asia. In Trade Facilitation and Regional Cooperation in Asia; Edward Elgar Publishing: Gloucestershire, UK, 2010; Available online: https://china.elgaronline.com/view/edcoll/9781848449862/9781848449862.00005.xml (accessed on 1 April 2025).

- He, J.; Zhang, L.; Deng, Y.; Yu, H.; Huang, M.; Tan, C. An allocation approach for external truck tasks appointment in automated container terminal. Adv. Eng. Inform. 2023, 55, 101864. [Google Scholar] [CrossRef]

- Steenken, D.; Voß, S.; Stahlbock, R. Container terminal operation and operations research-a classification and literature review. OR Spectr. 2004, 26, 3–49. [Google Scholar]

- Zhen, L.; Jiang, X.; Lee, L.H.; Chew, E.P. A Review on Yard Management in Container Terminals. Ind. Eng. Manag. Syst. 2013, 12, 289–304. [Google Scholar] [CrossRef]

- Abdul Rahman, N.S.F.; Ismail, A.; Lun, V.Y.H. Preliminary study on new container stacking/storage system due to space limitations in container yard. Marit. Bus. Rev. 2016, 1, 21–39. [Google Scholar] [CrossRef]

- Wahyuni, S.; Taufik, A.A.; Hui, F.K.P. Exploring key variables of port competitiveness: Evidence from Indonesian ports. Compet. Rev. An. Int. Bus. J. 2020, 30, 529–553. [Google Scholar] [CrossRef]

- Hsu, W.-K.K.; Huang, S.-H.S.; Huynh, N.T. An assessment of operating efficiency for container terminals in a port—An empirical study in Kaohsiung Port using Data Envelopment Analysis. Res. Transp. Bus. Manag. 2023, 46, 100823. [Google Scholar] [CrossRef]

- Zhou, L.; Suh, W. A Comprehensive Study on Static and Dynamic Operational Efficiency in Major Korean Container Terminals Amid the Smart Port Development Context. Sustainability 2024, 16, 5288. [Google Scholar] [CrossRef]

- Notteboom, T.; Pallis, A.; Rodrigue, J.-P. Port Economics, Management and Policy; Routledge: London, UK, 2021; Available online: https://www.taylorfrancis.com/books/9780429318184 (accessed on 1 April 2025).

- Novaes Mathias, T.; Inutsuka, H.; Shinoda, T.; Sugimura, Y. Operational performance evaluation of a container terminal using data mining and simulation. Asian Transp. Stud. 2024, 10, 100127. [Google Scholar] [CrossRef]

- Nikolaou, P.; Dimitriou, L. Lessons to be Learned from Top-50 Global Container Port Terminals Efficiencies: A Multi-Period DEA-Tobit Approach. Marit. Transp. Res. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Jonker, T.; Duinkerken, M.B.; Yorke-Smith, N.; de Waal, A.; Negenborn, R.R. Coordinated optimization of equipment operations in a container terminal. Flex. Serv. Manuf. J. 2021, 33, 281–311. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, C.; Wang, J. The Research of Simulation and Optimization of Multimodal Transport System Based on Intelligent Materials on Container Terminal Job Scheduling. 2011, pp. 479–483. Available online: http://link.springer.com/10.1007/978-3-642-23777-5_78 (accessed on 1 April 2025).

- Stevenson, W.J.; Kull, T. Operations and Supply Chain Management, 14th ed.; McGraw-Hill Education: New York, NY, USA, 2020. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation, 1st ed.; Simon & Schuster: New York, NY, USA, 1996. [Google Scholar]

- Olesen, P.; Powell, D.; Hvolby, H.-H.; Fraser, K. Using lean principles to drive operational improvements in intermodal container facilities. J. Facil. Manag. 2015, 13, 266–281. [Google Scholar] [CrossRef]

- Kuo, S.-Y.; Lin, P.-C. Determinants of green performance in container terminal operations: A lean management. J. Clean. Prod. 2020, 275, 123105. [Google Scholar] [CrossRef]

- Bonamigo, A.; Arcanjo, P.; Goncalves, M.; Pereira, N.; Cunha da Silveira, D. Lean 4.0 in port management: An alternative to support the development of the circular economy in the sector. Acta Logist. 2023, 10, 291–304. [Google Scholar] [CrossRef]

- Christopher, M. Logistics & Supply Chain Management, 5th ed.; Pearson Education: London, UK, 2016. [Google Scholar]

- Liu, W.; Xu, H.; Zhao, X. Agile Service Oriented Shipping Companies in The Container Terminal. Transport 2009, 24, 143–153. [Google Scholar] [CrossRef]

- Salleh, S.; Mortadha, N.M.S.; Alzakri, A. Three-Dimensional Model of Ionic Species Concentration and Flux During Localised Corrosion of Steel in Marine Environment. J. Adv. Res. Micro Nano Eng. 2024, 25, 27–38. [Google Scholar] [CrossRef]

- Twrdy, E.; Petrovič, M.; Batista, M. Limitation and restrictions on the admission of postpanamax container ships in the port of Koper. Brodogr. An. Int. J. Nav. Archit. Ocean. Eng. Res. Dev. 2013, 64, 456–471. [Google Scholar]

- Chu, C.; Huang, W. Determining container terminal capacity on the basis of an adopted yard handling system. Transp. Rev. 2005, 25, 181–199. [Google Scholar] [CrossRef]

- Monteiro, J.L.; Lukmandono Santoso, P.I.; Prabowo, R. Maritime industry—ports and supporting activities: Literature review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1010, 012019. [Google Scholar] [CrossRef]

- Raj, A.; Shrikumar, M.; Saha, S.K. Vessel Turnaround Time Reduction in Ports. In Building Climate Neutral Economies Through Digital Business and Green Skills; IGI Global Scientific Publishing: Hershey, PA, USA, 2024; pp. 67–94. [Google Scholar] [CrossRef]

- UNCTAD. UNCTAD Ad Hoc Expert Meeting on Assessing Port Performance; UNCTAD: Geneva, Switzerland, 2012; p. 21. [Google Scholar]

- Fan, H.; Shi, L.; Tan, C.; Jang, M.; Zhao, T.; Gao, P. Comparison Analysis on the Calculation of Berth Throughput Capacity of Container Terminal between China and South Korea. In Proceedings of the International Conference on Transportation Engineering 2009, Chengdu, China, 25–27 July 2009; American Society of Civil Engineers: Reston, VA, USA; pp. 923–928. [Google Scholar] [CrossRef]

- Sarkar, B.D.; Shankar, R. Understanding the barriers of port logistics for effective operation in the Industry 4.0 era: Data-driven decision making. Int. J. Inf. Manag. Data Insights 2021, 1, 100031. [Google Scholar] [CrossRef]

- Caldwell, J.A.; Caldwell, J.L.; Thompson, L.A.; Lieberman, H.R. Fatigue and its management in the workplace. Neurosci. Biobehav. Rev. 2019, 96, 272–289. [Google Scholar] [CrossRef] [PubMed]

- Michail, N.A.; Melas, K.D. Measuring the impact of port congestion on containership freight rates. Marit. Transp. Res. 2025, 8, 100130. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).