Abstract

Soy molasses, a byproduct of soy protein concentrate production, offers potential as a substrate for biotechnological applications due to its rich composition of carbohydrates, proteins, lipids, and bioactive compounds. Despite this, it remains underutilized, often relegated to low-value applications such as animal feed or waste, largely due to variability in its composition, the presence of microbial inhibitors, and limited industrial awareness of its potential. This review explores the biotechnological strategies for valorizing soy molasses, focusing on its chemical and physical properties, potential applications, and the challenges associated with its use. Its high carbohydrate content supports its utilization in producing biofuels, organic acids, and polyhydroxyalkanoates (PHA), addressing the global demand for sustainable energy and materials while costing approximately 20% of the value of conventional carbohydrate sources. Additionally, bioactive compounds have extended applications to nutraceuticals and cosmetics, while proteins and lipids enable enzyme and biosurfactant production. However, challenges such as variability in composition, the presence of inhibitory compounds, and scalability issues require innovative approaches, including pre-treatment methods and strain engineering. By integrating soy molasses into a circular bioeconomy framework, industries can reduce waste, lower their carbon footprint, valorize agro-industrial residues, and generate economic value. This review underscores the untapped potential of soy molasses as a versatile, sustainable resource, while highlighting the need for continued advancements to transform it into a key player in industrial biotechnology.

1. Introduction

One of the most important strategies for combating environmental degradation has been recognized in the circular economy driven by biorefinery innovations. These systems help address specific environmental pressures such as excessive agro-industrial waste generation, greenhouse gas (GHG) emissions, and the carbon footprint associated with conventional production processes by converting biomass into valuable bio-based products. A biorefinery is a facility or system that employs a variety of technologies to convert biomass materials (feedstocks) into their individual components, like carbohydrates, acids, proteins, and triglycerides. These components can then be transformed into marketable products, chemicals, and biofuels, which maximize profitability and contribute to a sustainable, waste-minimizing economy [1,2]. This concept is central to the bioeconomy, which aims to utilize resources efficiently and sustainably, making it a key activity in reversing environmental degradation and supporting a circular economy [3].

According to the USDA Foreign Agricultural Service, Brazil is the global leader in soybean production, significantly influencing the world’s supply. In 2023/2024, Brazil produced approximately 153 million metric tons of soybeans, accounting for about 39% of global production [4]. Soybeans have many uses in Brazil. The grain can be processed domestically through crushing, which yields meal and oil for both local consumption and international trade. Soybean oil plays a key role in the food and pharmaceutical sectors, as well as in biodiesel production. Notably, more than 80% of Brazil’s biodiesel is derived from soybean oil, highlighting its critical importance in the country’s renewable energy efforts [4,5].

The byproducts generated from the processing of soybeans into refined soybean oil, soy protein concentrate (SPC, a high-protein product obtained by removing soluble carbohydrates from defatted soy meal), and soy protein isolate (SPI, an even more purified form with over 90% protein content) hold significant potential for further utilization. This approach aims to maximize resource efficiency by transforming all residues into valuable products, enhancing the functionality of a soybean-based biorefinery [6]. Soy molasses, a byproduct derived during SPC production, represents a significant underutilized resource with immense biotechnological potential. This viscous liquid contains high concentrations of carbohydrates, proteins, lipids, and bioactive compounds, making it a valuable substrate for various industrial applications. However, much of this byproduct is either discarded or used in low-value applications such as animal feed, leading to environmental concerns and economic inefficiencies [7,8].

The valorization of agro-industrial byproducts, such as soy molasses, aligns with the principles of circular bioeconomy and sustainability. By converting this waste into high-value products, industries can reduce environmental impact while generating additional revenue streams. In particular, soy molasses is rich in raffinose family oligosaccharides (RFOs) such as raffinose and stachyose, which exhibit prebiotic properties and have applications in the food and nutraceutical industries [9,10]. Furthermore, its high carbohydrate content makes it an excellent candidate for biofuel production, including bioethanol and biogas, contributing to renewable energy solutions and reducing the investment required in the process, since it costs around 20% of the value of conventional carbohydrate sources [10,11,12].

The biotechnological potential of soy molasses extends beyond energy production. It has been successfully utilized in the cultivation of microorganisms Mucor circinelloides, Aspargillus niger, Propionibacterium acidipropionici and Aureobasidium pullulans for the production of organic acids, such as lactic, malic, gluconic, and propionic acids, which have applications in food preservation and bioplastics production [7,13,14,15]. Additionally, soy molasses serves as a substrate for producing polyhydroxyalkanoates (PHA) from diazotrophic bacteria, biodegradable plastics that address the growing demand for sustainable alternatives to petroleum-based polymers [11,16]. Its protein and lipid content also supports microbial production of biosurfactants and enzymes, enhancing its industrial versatility [13].

Despite its advantages, the utilization of soy molasses faces several challenges. Variability in its composition due to differences in soybean varieties and processing methods requires standardized pre-treatment and bioprocess optimization. Additionally, the presence of inhibitory compounds such as phenolics and saponins can hinder microbial activity, requiring detoxification steps to improve fermentability [17,18,19,20,21]. However, pre-treatment stages are common in the context of biorefineries, with various methods for detoxification and decolorization for fermentation enhancement, like acidic, basic, enzymatic, and physicochemical hydrolysis to release fermentable sugars [14,17,22], and anaerobic–aerobic digestion, which reduces waste and produces an energy resource in the form of biogas [18,23].

Although various studies have explored the utilization of agro-industrial byproducts, there is a noticeable lack of comprehensive reviews dedicated specifically to soy molasses and its diverse biotechnological applications. Much of the existing literature focuses on narrow uses—such as bioethanol production or animal nutrition—without addressing the full potential of soy molasses within an integrated circular bioeconomy framework. In addition, critical aspects such as process scalability, pre-treatment techniques, and emerging applications like nanomaterials, biosurfactants, and bioplastics remain underexplored in previous reviews. This work seeks to bridge these gaps by presenting an up-to-date and multidisciplinary synthesis that highlights both the opportunities and the challenges in transforming soy molasses into a strategic resource for sustainable industrial development.

2. Soybean Processing and Byproducts

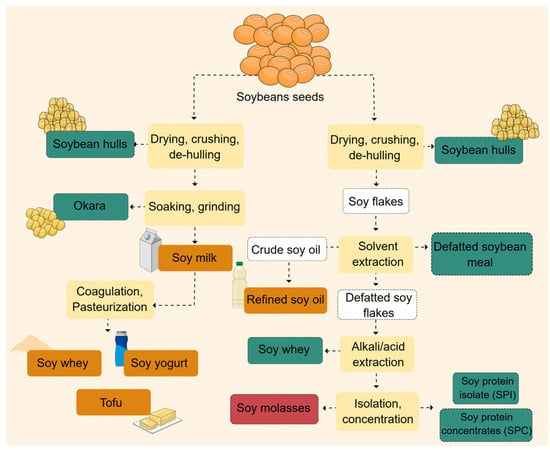

Soybean seeds are composed primarily of proteins (40–50%), fiber (3–6%), fat (18–21%), carbohydrates (30–35%), ash (3–6%), and total solids (88–92%) on a dry mass basis [24,25,26]. Hexane-based solvent extraction is the most widely used method to extract oil from soybean seeds, involving three main steps: preparation of the seeds, oil extraction, and removal of the solvent from both the oil and the meal [27,28]. In the manufacturing of soy-based products, large amounts of byproducts are generated, namely soybean hulls, okara, soybean meal, and soy molasses (Figure 1).

Figure 1.

Overview of typical processing for the production of soy-based foods and their byproducts.

The soybean oil extraction process starts with hull removal, creating soybean flakes, followed by hexane extraction. The oil/solvent mixture (miscella) is processed to recover the crude oil, which is refined into edible oil. The solvent is recovered by evaporation or distillation. The defatted flakes are dried, ground, and marketed as soybean meal and serve as a major protein source in livestock feed. Further processing of defatted meal can produce SPC, SPI, and soy molasses [6,12]. Additionally, soybean curd residue, or okara, is a nutrient-rich byproduct from soy milk and tofu production. It is obtained from grinding and filtering soaked soybeans into a soy beverage [29,30]. Okara contains 40–60% fiber, 20–30% protein, and 10–20% fat on a dry basis, but also includes anti-nutritional factors like trypsin inhibitors and saponins, which limit its suitability for human consumption [29,31,32,33,34].

Approximately 85% of global soybean production is processed by crushing to produce defatted soybean meal and oil. Approximately 5 kg of soybeans is used to produce 1 L of soy oil, with the remaining 75–80% generated as a byproduct [12,35]. As shown in Figure 1, many byproducts from soybean processing are repurposed for creating animal feed, SPC, SPI, and soy molasses.

SPC, with a protein content of 65–72%, is made by removing soluble carbohydrates from defatted meal through acid leaching, aqueous ethanol extraction, or moist heat water leaching [36,37]. Most SPC is produced via alcohol extraction, which leaves soy molasses as a byproduct [12,38]. SPI, with over 90% protein, is created by extracting proteins from defatted meal using mild alkali, followed by precipitation at the isoelectric point [39].

Soy molasses is a viscous, brown syrup with around 25% moisture and a bittersweet taste, produced during the alcohol extraction process in the manufacturing of SPC [14,40,41]. The composition of soy molasses varies depending on factors like soybean variety, growing conditions, and year. Despite these variations, its main components are carbohydrates, including oligosaccharides (stachyose and raffinose), disaccharides (such as sucrose), and smaller amounts of monosaccharides (fructose and glucose), which together make up about 57% of the dry weight or 30% w/v [14,41]. Soy molasses also contains proteins, lipids, minerals, and phytochemicals like isoflavones and saponins, which may have health benefits [40,42]. In the industrial process, around 232 kg of soy molasses is generated for every ton of soybean meal produced [18].

The high oligosaccharide content in soy molasses limits its use in non-ruminant animal feed due to digestibility issues. However, many published studies have explored alternative uses of soy molasses, such as its use as a carbon source in microbial cultivation. This includes applications in producing malic acid [14], lipases [43], butanol [44,45], and bioethanol [42,46], offering potential value beyond feed supplementation. This diversification of uses contributes to minimizing waste and enhancing the value chain of soybean byproducts [47].

The presence of inhibitory compounds in soy molasses, such as phenolics, can require detoxification to enable their valorization. This treatment can be mediated by the cultivation of edible fungi in soy molasses, such as Morchella rotunda, Morchella vulgaris, and Morchella conica, reaching up to 56.6% of phenolic reduction. In addition, to increase the availability of fermentable sugars, acid and enzymatic hydrolysis processes can be applied to soy molasses, with documented increases of 7.6% in fermentation yields in ethanol production processes after applying enzymatic hydrolysis with commercial enzymes [38,48].

3. Characterization of Soy Molasses

The chemical composition of soy molasses plays a pivotal role in determining its suitability for various biotechnological applications. Table 1 presents a comparative overview of the chemical composition of major soy processing byproducts, highlighting the unique profile of soy molasses. Primarily, it consists of carbohydrates, including sucrose, raffinose, and stachyose, which account for 50–60% of its dry weight. These carbohydrates make soy molasses an ideal substrate for processes such as bioethanol production and organic acid fermentation [7,14]. Raffinose family oligosaccharides (RFOs), which constitute a significant fraction of these carbohydrates, also exhibit prebiotic properties, contributing to the potential use of soy molasses in the development of functional foods [8,9].

Table 1.

Comparative Composition of Soy Processing Byproducts.

Additionally, soy molasses comprises 6–8% proteins rich in essential amino acids, and 5–8% lipids, predominantly unsaturated fatty acids like linoleic and oleic acids [13,14]. These components enhance its potential for enzyme and biosurfactant production, supporting its use in various industrial processes [10,13]. These compounds may act as biostimulants or precursors for sustainable agriculture [51,52]. For instance, soy molasses has been successfully used for Bacillus species cultivation, aiming at plant growth promotion [53].

Moreover, the presence of bioactive compounds, such as soyasaponins, isoflavones, and phenolic acids, adds functional value to soy molasses, with applications extending to the nutraceutical, cosmetic, and pharmaceutical industries. These compounds exhibit antioxidant, anti-inflammatory, and antimicrobial properties [17,54,55]. In contrast, the composition and functional properties of soy molasses differ significantly from other soy processing byproducts, such as okara and soy hulls. While okara is protein- and fiber-rich, and soy hulls are primarily composed of insoluble fiber, soy molasses is distinguished by its high soluble sugar content and bioactive compounds [55]. Physical properties such as viscosity, density, and water activity are influenced by processing methods and moisture content, directly impacting storage and transport. For instance, high viscosity and density may pose pumpability challenges during handling and processing, while elevated water activity can reduce shelf-life and increase susceptibility to microbial contamination. Addressing these constraints has led to the exploration of novel solutions such as thermal pre-treatment, enzymatic liquefaction, or formulation with stabilizers, and these adaptations may also enable applications in bioadhesives, thickening agents, and other value-added products [11,19,56,57].

4. Biotechnological Strategies for Soy Molasses Valorization

Soy molasses, a nutrient-rich byproduct of SPC production, offers immense potential for biotechnological valorization. Its abundant carbohydrates, proteins, lipids, and bioactive compounds serve as a versatile substrate for producing high-value products. This section examines the main biotechnological strategies for soy molasses utilization, their mechanisms, applications, and associated challenges. A wide range of products can be obtained using soy molasses as a fermentation medium, including proteins, lipids, functional saccharides, and fuels (Table 2).

Table 2.

Comparative Analysis of Soy Molasses Valorization Strategies.

4.1. Organic Acid Production

The production of organic acids such as propionic, lactic, and acetic acids from soy molasses is well documented due to their industrial relevance. For instance, Propionibacterium acidipropionici efficiently converts raffinose and stachyose into propionic acid, achieving yields of up to 0.42 g/g [7,8]. Similarly, lactic acid production using Lactobacillus strains has been optimized with soy molasses as a carbon source, facilitating biodegradable polymer production [10,56].

Moreover, the co-production of acetic and succinic acids has been reported in mixed-culture fermentations, which enhances the economic feasibility of integrated biorefinery systems. The implementation of membrane separation or in situ product recovery techniques during fermentation further increases productivity and facilitates downstream processing, highlighting the relevance of soy molasses as a versatile and efficient substrate for organic acid biosynthesis [10,56]. To improve these processes, enzymatic hydrolysis of RFOs has been employed, increasing sugar accessibility for fermentation [9,19]. Integrated systems combining acid recovery with fermentation have enhanced yields while reducing costs [49,61].

4.2. Bacterial Cellulose Production

Bacterial cellulose (BC), known for its biocompatibility and high mechanical strength, can be synthesized using soy molasses. Gluconacetobacter xylinus has demonstrated high BC yields when cultivated on soy molasses compared to synthetic media [13,14,58,61,62]. Similarly, the modified SCOBY consortium of Medusomyces gisevii demonstrated a 58% increase in BC production when utilizing soy molasses as a carbon source; this improvement highlights the potential of soy molasses as an effective and economical substrate for BC production [9].

BC applications range from wound dressings to biodegradable food packaging, emphasizing its market potential [17,57]. Despite these advances, challenges such as maintaining consistent quality and scaling production persist [11,63].

4.3. Bioethanol and Biogas Production

Soy molasses is an excellent medium for microbial fermentation in biofuel production. Bioethanol provides a sustainable alternative to fossil fuels, along with biodiesel, biobutanol, biomethane, and biohydrogen. Various microorganisms, including bacteria, yeast, and fungi, are capable of fermenting sugar-rich substrates to produce bioethanol. Some of these microorganisms are Pichia stipitis, Saccharomyces cerevisiae, Hanseniaspora uvarum, and Kluyveromyces marxianu [38,46,57,64]. Saccharomyces cerevisiae effectively ferments sucrose and glucose into ethanol, achieving yields comparable to traditional substrates like molasses from sugarcane [7,15,38,65]. Furthermore, an established industrial process for ethanol production from soy molasses using S. cerevisiae has been documented in both laboratory and industrial scales. On the laboratory scale, the process achieves a productivity of 8.08 g/L.h, while the industrial yield reaches 162.7 L of absolute ethanol per ton of dry molasses [42]. However, since S. cerevisiae lacks the enzyme α-1,6-galactosidase, around 47% of the sugars in soy molasses cannot be fermented. Therefore, it is necessary to hydrolyze sugars like raffinose and stachyose before fermentation can occur [46]. Using S. cerevisiae with α-galactosidase-treated molasses significantly improved ethanol yield [21,38].

Biogas production through anaerobic digestion has also demonstrated high methane yields, leveraging the lipid and carbohydrate content of soy molasses [12,18,23,56,59]. However, inhibitors such as phenolics and saponins require pre-treatment for optimal energy recovery [16,19,60]. This demonstrates the potential of soy molasses as a valuable feedstock for efficient biofuel production.

4.4. Functional Oligosaccharides

Soy molasses contains significant concentrations of functional oligosaccharides, such as raffinose and stachyose, which exhibit prebiotic properties by stimulating beneficial gut microbiota [9,10,19]. Transforming soy molasses into functional soy oligosaccharides (FSO) represents a sustainable approach to maximizing the potential of agricultural residues. Through targeted biological processes, microorganisms selectively utilize specific carbon sources, allowing for the removal of sucrose while preserving important oligosaccharides like stachyose and raffinose [19].

Innovative methods like the biological purification process, using microorganisms such as Wickerhamomyces anomalus, have demonstrated the ability to selectively remove sucrose from soy molasses while retaining key oligosaccharides like raffinose and stachyose [7,8,10,66], while Wang et al. (2019) [57] produced other oligosaccharides by using an engineered Yarrowia lipolytica strain to hydrolyze the raffinose-family oligosaccharides in soy molasses into sucrose. The resulting soy molasses hydrolysate, rich in sucrose, was used to produce isomaltulose. Functional oligosaccharides have applications in functional foods, beverages, and nutraceuticals, but scalability and production costs remain areas for improvement [13,18,67,68].

4.5. Enzyme and Biosurfactant Production

The protein and bioactive compound content of soy molasses supports the production of industrial enzymes and biosurfactants. For instance, proteases and cellulases have been produced using soy molasses as a substrate, with applications in the detergent and textile industries [17,19,63]. Process optimization and strain engineering are critical for enhancing yields and reducing production costs [14,60].

Biosurfactants are categorized based on their chemical structure and microbial origin into various groups: glycolipids, lipopeptides, phospholipids, fatty acids, neutral lipids, and polymeric biosurfactants [69]. Sophorolipids and rhamnolipids are glycolipids that have been synthesized for use in bioremediation and cosmetics [15,50]. Commonly used biosurfactants for soil remediation include rhamnolipids, fructose lipids, sophorolipids, and lipopeptides such as surfactin and polymyxin. Notably, rhamnolipid biosurfactants, primarily produced by Pseudomonas aeruginosa, have been extensively studied for their potential in removing pesticides from contaminated soil [50,70]. Other biosurfactant applications include detergent formulations [71,72], medical applications in films to prevent microorganism adhesion in interfaces [73,74], and to prevent oral infections [75,76]. Although biosurfactants have potential applications across various industries, their commercial-scale production has not yet been fully implemented due to low yields and high production costs.

4.6. Nanomaterial Synthesis

Soy molasses has been investigated as a promising precursor for the synthesis of nanomaterials, particularly carbon dots (CDs) and graphene oxide, owing to its high content of carbohydrates and bioactive compounds. These components provide carbon-rich structures and functional groups that are favorable for nanomaterial formation. Notably, the presence of diverse organic molecules in soy molasses may eliminate the need for additional surface functionalization steps during synthesis, simplifying the process and reducing costs. CDs derived from soy molasses have demonstrated desirable optical properties, including fluorescence emission, which are suitable for applications such as bioimaging and drug delivery. Additionally, CDs have gained significant attention due to their tunable size and unique optical properties. They are zero-dimensional nanomaterials, part of the graphene family, with a structure similar to graphene oxide but differing in size [77,78]. These materials are valuable for bioimaging, drug delivery, and electronics [8,57,58].

The most applied methods for the synthesis of CDs from different biomass derivatives acting as carbon sources are acid and hydrothermal oxidation, microwave-assisted, ultrasound-assisted, and electrochemical methods. Soy molasses-derived nanomaterials combine cost-effectiveness with sustainability, also ruling out the need for surface functionalization steps, since the different molecules present in this precursor can fulfil this role, though further studies are needed to optimize these processes and analyze the impact of soy molasses as a carbon source on the final composition of CDs [54,79].

4.7. Bioplastics and Polyhydroxyalkanoates (PHA)

Soy waste has proven to be an excellent bio-based source for packaging material. Polyhydroxyalkanoates (PHA) of medium length, a type of biodegradable and biocompatible polymer with great elastomeric and adhesive properties, can be synthesized from soy molasses and other waste carbohydrates by microbial fermentation. Strains like Cupriavidus necator and Pseudomonas corrugata utilize the sugars in soy molasses to produce intracellular PHA with high efficiency, and the mass of polymer can account for up to 17% of the dry mass of cells [9,10,13].

It has also been described that Bacillus species are able to produce bioplastics with high yields from soy molasses oligosaccharides. These have been reported to accumulate up to 90% of PHA utilizing raffinose; therefore, these microorganisms are candidates for the green and low-cost industrial production of PHAs [80]. Biodegradable polymers derived from sustainable and low-cost raw materials are emerging as a key solution, benefiting a scenario of greater exploration and research into the use of residues such as soy molasses. These applications support sustainable alternatives to petroleum-based plastics used in fields like medicine, fibers, and agriculture and horticulture, aligning with global environmental goals [15,18].

5. Benefits and Challenges

The valorization of soy molasses through biotechnological processes offers significant environmental, economic, and social benefits. However, its implementation is not without challenges, as it requires addressing technical, economic, and scalability issues. This section examines the key advantages and obstacles associated with soy molasses utilization, supported by the recent literature. Table 3 shows an overview of the main benefits and challenges in soy molasses valorization.

Table 3.

Comparative Analysis of Benefits and Challenges in Soy Molasses Valorization.

5.1. Environmental Benefits

One of the most notable benefits of soy molasses valorization is its potential to mitigate environmental impact. Soy molasses, often discarded or underutilized, contributes to waste management challenges and environmental degradation. By converting this byproduct into high-value products, the burden on waste disposal systems is reduced, contributing to a circular bioeconomy [7,58].

Moreover, the use of soy molasses as a carbon source in biotechnological processes such as bioethanol and biogas production reduces reliance on fossil fuels, decreasing greenhouse gas emissions [10,59]. For instance, anaerobic digestion of soy molasses not only generates renewable energy but also produces nutrient-rich digestate, which can be used as biofertilizer, closing the nutrient loop [18].

Additionally, the production of biodegradable materials like polyhydroxyalkanoates (PHA) and bacterial cellulose from soy molasses aligns with global sustainability goals by reducing plastic pollution and supporting environmentally friendly alternatives [10,13].

5.2. Economic Benefits

From an economic perspective, valorizing soy molasses transforms a low-value byproduct into high-value commodities, enhancing the profitability of the soy industry [8,19]. For example, the production of prebiotics like raffinose and stachyose caters to the growing demand for functional foods, a market projected to expand significantly in the coming years [9,65]. Additionally, incorporating soy molasses into bioprocesses also reduces costs by replacing traditional substrates, which are often expensive and less sustainable [14,49]. For instance, using soy molasses in biofloc systems for aquaculture has demonstrated cost savings in feed and water quality management [12,61].

The techno-economic feasibility of valorizing agro-industrial byproducts is well illustrated by several real-world cases. A pilot-scale project in China successfully produced polyhydroxyalkanoates (PHAs) from food waste using mixed microbial cultures, achieving a PHA content of 48% and productivity of up to 20 g/L per day, while also showing potential for integration with municipal waste treatment systems [81]. In Brazil, an integrated polylactic acid (PLA) production facility utilized sugarcane ethanol and bagasse to achieve a competitive production cost of approximately USD 1.41/kg PLA and a high internal rate of return (29.4%), while also demonstrating net negative greenhouse gas emissions (−0.25 kg CO2-eq/kg PLA), highlighting the environmental and economic advantages of biorefinery integration [82].

5.3. Technical Challenges

Despite these benefits, several technical challenges hinder the broader adoption of soy molasses valorization. The complex composition of soy molasses, which includes sucrose, raffinose, and phenolic compounds, can complicate fermentation processes. While raffinose and stachyose are valuable as prebiotics, they also act as fermentation inhibitors, requiring enzymatic or microbial pre-treatment, increasing the time and investment needed in processing [7,50].

Variability in soy molasses composition due to differences in soybean varieties and processing methods further complicates its utilization. This inconsistency necessitates customized process designs and adaptive technologies, increasing production costs [11].

Additionally, phenolic and saponin compounds in soy molasses can act as antimicrobial agents, inhibiting the growth of certain microbial strains used in bioprocesses. Strategies such as detoxification or selective microbial engineering are required to address these challenges. Some environmental risks also need to be taken into consideration due to the possibility of some impact from the increase in these valorization processes, which may contribute to contamination by the chemicals used [20,68].

5.4. Economic and Scalability Challenges

Although soy molasses is a low-cost substrate, scaling up its valorization presents economic hurdles. Infrastructure for large-scale bioprocesses, including fermentation and purification systems, requires significant investment [13,17]. Furthermore, the cost of enzymatic and detoxification treatments or microbial strain engineering can offset the economic advantages of using soy molasses as a raw material [18,19].

The commercialization of soy molasses-derived products faces substantial regulatory challenges, particularly in the food and pharmaceutical sectors, where stringent quality and safety standards apply. Prebiotic oligosaccharides and biodegradable plastics must meet specific criteria to gain market approval, necessitating extensive testing and documentation [10,65]. In the U.S., prebiotic oligosaccharides derived from microbial processes are regulated under the GRAS (Generally Recognized as Safe) framework by the FDA [83]. For use in foods and infant formulas, these ingredients require extensive safety and toxicological evaluations. For example, Tata Chemicals’ GRN 000605 received GRAS status for fructooligosaccharides (FOS) produced via microbial fermentation [83]. Similarly, 2′-Fucosyllactose (2′-FL), another microbial-derived prebiotic, was granted GRAS status but required comprehensive toxicological data and consumer intake assessments [84]. These approval processes typically take 1–3 years and involve significant financial investment. For bioplastics, especially in food-contact applications, compliance with EU Regulation No. 10/2011 is mandatory, requiring migration testing to ensure safety. Products marketed as industrially compostable must meet criteria such as at least 90% biodegradation within 6 months and low levels of heavy metals [85]. These processes involve costly testing, long certification audits, and can delay market entry by 1–2 years. Overall, while soy molasses is a low-cost raw material, these regulatory requirements significantly increase development costs and time-to-market, reducing its economic advantage. Addressing these challenges early is essential for successful commercialization strategies. Additionally, consumer acceptance and awareness are crucial for market penetration. Products derived from agro-industrial byproducts, including soy molasses, require effective marketing to highlight their sustainability, safety, and quality, facing the current unethical consumer culture [8,9].

5.5. Future Perspectives

Addressing the challenges of soy molasses valorization requires a multidisciplinary approach. Advancements in strain engineering, such as developing robust microorganisms capable of utilizing complex substrates, will be pivotal, avoiding the need for pre-treatment steps and the costs associated with them [50,68]. The management of process optimization and integration of pre-treatment methods into existing bioprocess workflows can further enhance scalability and economic viability, saving both time and resources and facilitating the logistics of the process [9,19].

Additionally, government financial incentives for innovative research and industry collaborations, due to the accumulated experience in the processes into which soy molasses can be integrated, can play an important role in promoting soy molasses valorization. Policies supporting the industrial adoption of biotechnological innovations and consumer awareness campaigns emphasizing the sustainability of soy molasses-derived products are necessary to drive market growth [10,18].

In addition to the environmental and economic advantages, the valorization of soy molasses can yield significant socioeconomic benefits, particularly in rural and agricultural regions. By creating new markets for what is often treated as waste, soy molasses valorization supports income diversification for small and medium soy-processing enterprises and local cooperatives. Establishing decentralized bioprocessing units for the conversion of soy molasses into biofuels, enzymes, or functional foods can foster job creation, skill development, and technology transfer in rural communities. This is especially relevant in major soybean-producing countries like Brazil, Argentina, and India, where agro-industrial residues are abundant but often underutilized. In these contexts, integrating soy molasses into local bioeconomy initiatives can strengthen regional value chains, reduce socioeconomic inequality, and contribute to rural resilience.

The valorization of soy molasses varies significantly across countries depending on regulatory frameworks, industrial maturity, and research investment. In Brazil, the world’s largest soybean producer [4], soy molasses is still predominantly used in animal feed or discarded, despite ongoing academic research highlighting its potential for biofuel [18,42], enzyme, and prebiotic production. In China, where functional foods and nutraceuticals represent a booming market, soy molasses has gained traction for producing functional oligosaccharides [19], leveraging microbial and enzymatic processes at pilot scale [68]. European countries, constrained by stricter environmental regulations and circular economy targets, have explored soy molasses in biopolymer and biosurfactant production [58] but are limited by supply chain access. In the United States, while soybean crushing is extensive, soy molasses is underexplored due to the dominance of corn-based feedstocks in industrial fermentation [7]. This heterogeneity illustrates both the opportunities and the limitations in scaling soy molasses biovalorization globally, underscoring the need for policy alignment, infrastructure development, and international collaboration.

6. Conclusions

The valorization of soy molasses represents a transformative approach to addressing the dual challenges of waste management and sustainable industrial development. As a byproduct of soy protein concentrate production, soy molasses is rich in carbohydrates, proteins, lipids, and bioactive compounds, making it an attractive substrate for diverse biotechnological applications. The conversion of this underutilized resource into high-value products, such as organic acids, biofuels, bioplastics, enzymes, and prebiotics, demonstrates its potential to contribute significantly to a circular bioeconomy.

From an environmental perspective, leveraging soy molasses reduces waste generation and supports renewable energy production, while economically, it enhances the profitability of the soybean industry by creating new revenue streams. Moreover, the development of sustainable materials, such as bacterial cellulose and polyhydroxyalkanoates, underscores its role in addressing global environmental challenges, including plastic pollution.

However, several challenges must be overcome to fully realize the potential of soy molasses. Variability in composition, the presence of inhibitory compounds, and scalability issues require advanced bioprocessing techniques and innovative solutions. The integration of pre-treatment methods, strain engineering, and process optimization is essential for improving efficiency and reducing costs. Furthermore, the successful commercialization of soy molasses-derived products depends on meeting regulatory requirements and fostering consumer acceptance.

Future research and development efforts should focus on bridging the gap between laboratory-scale studies and industrial applications. Interdisciplinary collaboration, coupled with supportive policies and industry partnerships, will be pivotal in unlocking the full potential of soy molasses as a valuable resource. By addressing these challenges, soy molasses can transition from an agricultural byproduct to a cornerstone of sustainable biotechnological innovation, offering significant environmental, economic, and societal benefits.

Author Contributions

Conceptualization, B.C.G. and H.B.S.B.; writing—original draft preparation, B.C.G., A.K.F.C., F.D.O., S.S.d.S., M.L.d.S. and H.B.S.B.; writing—review and editing, B.C.G., A.K.F.C., F.D.O., S.S.d.S., M.L.d.S. and H.B.S.B.; supervision, B.C.G. and H.B.S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported by Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) Process numbers 2021/09175-4 and 2023/09789-8, CNPq (National Council for Scientific and Technological Development, Brazil) grant #406564/2022-1.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Pires, J.R.A.; Souza, V.G.L.; Fernando, A.L. Valorization of energy crops as a source for nanocellulose production—Current knowledge and future prospects. Ind. Crops Prod. 2019, 140, e111642. [Google Scholar] [CrossRef]

- Devanthi, P.V.P.; Pratama, F.; Pramanda, I.T.; Bani, M.D.; Kadar, A.D.; Kho, K. Exploring the Potential of Aspergillus oryzae for Sustainable Mycoprotein Production Using Okara and Soy Whey as Cost-Effective Substrates. J. Fungi 2024, 10, 555. [Google Scholar] [CrossRef] [PubMed]

- Sadhukhan, J.; Martinez-Hernandez, E.; Murphy, R.J.; Ng, D.K.S.; Hassim, M.H.; Ng, K.S.; Kin, W.Y.; Jaye, I.F.M.; Hang, M.Y.L.P.; Andiappan, V. Role of bioenergy, biorefinery and bioeconomy in sustainable development: Strategic pathways for Malaysia. Renew. Sustain. Energy Rev. 2018, 81, 1966–1987. [Google Scholar] [CrossRef]

- United States Department of Agriculture (USDA) Foreign Agricultural Service. Brazil Oilseeds and Products Annual Report. 2023. Available online: https://www.fas.usda.gov/data/brazil-oilseeds-and-products-annual-7 (accessed on 10 February 2025).

- União Brasileira do Biodiesel (Ubrabio) and Fundação Getúlio Vargas (FGV). Biodiesel and Its Contribution to Brazilian Development. 2010. Available online: https://fgvenergia.fgv.br/sites/fgvenergia.fgv.br/files/ubrabio.pdf (accessed on 10 February 2025).

- Karim, A.; Osse, E.F.; Khalloufi, S. Innovative strategies for valorization of byproducts from soybean industry: A review on status, challenges, and sustainable approaches towards zero-waste processing systems. Heliyon 2025, 11, e42118. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z.; Lin, M.; Yang, S.T. Propionic acid production from soy molasses by Propionibacterium acidipropionici: Fermentation kinetics and economic analysis. Bioresour. Technol. 2018, 250, 1–9. [Google Scholar] [CrossRef]

- Pan, N.C.; Vignoli, J.A.; Baldo, C.; Pereira, H.C.B.; da Silva, R.S.S.F.; Celligoi, M.A.P.C. Agroindustrial byproducts for the production of hyaluronic acid by Streptococcus zooepidemicus ATCC 39920. Int. J. Sci. Technol. Res. 2015, 4, 114–118. [Google Scholar]

- Kalashnikova, O.B.; Pankova, E.; Sukhikh, S.; Babich, O.; Samusev, I.; Tcibulnikova, A.; Ivanova, S.; Kriger, O. Production of bacterial cellulose using a symbiotic consortium of bacteria and yeast on soy molasses medium. LWT 2024, 205, 116480. [Google Scholar] [CrossRef]

- Solaiman, D.K.Y.; Ashby, R.D.; Crocker, N.V. Bioprocess for hydrolysis of galacto-oligosaccharides in soy molasses and tofu whey by recombinant Pseudomonas chlororaphis. Biocatal. Agric. Biotechnol. 2020, 24, 101529. [Google Scholar] [CrossRef]

- Oliveira, J.M.; Michelon, M.; Burkert, C.A.V. Biotechnological potential of soy molasses for the production of extracellular polymers by diazotrophic bacteria. Biocatal. Agric. Biotechnol. 2020, 25, 101609. [Google Scholar] [CrossRef]

- Pretto, C.; Giordano, R.L.C.; Tardioli, P.W.; Costa, C.B.B. Possibilities for producing energy, fuels, and chemicals from soybean: A biorefinery concept. Waste Biomass Valorization 2018, 9, 1703–1730. [Google Scholar] [CrossRef]

- Fazili, A.B.A.; Shah, A.M.; Zan, X.; Naz, T.; Nosheen, S.; Nazir, Y.; Ullah, S.; Zhang, H.; Song, Y. Mucor circinelloides: A model organism for oleaginous fungi and its potential applications in bioactive lipid production. Biotechnol. Lett. 2022, 44, 432–444. [Google Scholar] [CrossRef]

- Cheng, C.; Zhou, Y.; Lin, M.; Wei, P.; Yang, S.T. Polymalic acid fermentation by Aureobasidium pullulans for malic acid production from soybean hull and soy molasses: Fermentation kinetics and economic analysis. Bioresour. Technol. 2017, 223, 166–174. [Google Scholar] [CrossRef]

- Fernandes, S.; Dias, B.; Belo, I.; Lopes, M. Soy molasses as a new and low-cost substrate for gluconic acid production by Aspergillus niger. Process Biochem. 2024, 146, 241–249. [Google Scholar] [CrossRef]

- Paulinetti, A.P.; Guerieri, F.F.; Augusto, I.M.G.; Lazaro, C.Z.; Albanez, R.; Lovato, G.; Ratusznei, S.M.; Rodrigues, J.A.D. Thermophilic and mesophilic anaerobic digestion of soy molasses: A performance vs. stability trade-off. J. Environ. Manag. 2024, 370, 112508. [Google Scholar] [CrossRef]

- Duru, K.C.; Slesarev, G.P.; Aboushanab, S.A.; Kovalev, I.S.; Zeidler, D.M.; Kovaleva, E.G.; Bhat, R. An eco-friendly approach to enhance the extraction and recovery efficiency of isoflavones from kudzu roots and soy molasses wastes using ultrasound-assisted extraction with natural deep eutectic solvents (NADES). Ind. Crops Prod. 2022, 182, 114886. [Google Scholar] [CrossRef]

- Rodrigues, B.C.G.; De Mello, B.S.; da Costa Araujo, M.L.G.; da Silva, G.H.R.; Sarti, A. Soy molasses as feedstock for sustainable generation of biomethane using high-rate anaerobic reactor. J. Environ. Chem. Eng. 2021, 9, 105226. [Google Scholar] [CrossRef]

- Yang, R.; Ma, J.; Wang, Z.; Du, Y.; Tian, S.; Fan, G.; Liu, X.; Teng, C. The Identification of a Strain for the Biological Purification of Soy Molasses to Produce Functional Soy Oligosaccharides and Optimize Purification Conditions. Foods 2024, 13, 296. [Google Scholar] [CrossRef]

- Miranda, L.C.R.; Gomes, R.J.; Mandarino, J.M.G.; Ida, E.L.; Spinosa, W.A. Acetic acid fermentation of soy molasses and characterization of the produced vinegar. Food Technol. Biotechnol. 2020, 58, 84–90. [Google Scholar] [CrossRef]

- Sancheti, A.; Thompson, E.R.; Ju, L.K. Factors influencing the enzymatic hydrolysis of soy molasses into fermentation feedstock. Enzyme Microb. Technol. 2023, 170, 110302. [Google Scholar] [CrossRef]

- Batista, V.S.F.; Nunes, G.L.; Viegas, G.I.; Lucas, B.N.; Bochi, V.C.; Emanuelli, T.; Barin, J.S.; de Menezes, C.R.; da Rosa, C.S. Extraction, characterization and microencapsulation of isoflavones from soy molasses. Cienc. Rural 2020, 50, e20190341. [Google Scholar] [CrossRef]

- De Mello, B.S.; Rodrigues, B.C.G.; Medin, K.J.D.; Sarti, A. Biological Degradation of Soy molasses by Modified Anaerobic–Aerobic Baffled Reactor. BioEnergy Res. 2023, 16, 673–682. [Google Scholar] [CrossRef]

- Singh, P.; Krishnaswamy, K. Sustainable zero-waste processing system for soybeans and soy by-product valorization. Trends Food Sci. Technol. 2022, 128, 331–344. [Google Scholar] [CrossRef]

- Van der Riet, W.; Wight, A.W.; Cilliers, J.J.L.; Datel, J.M. Food chemical investigation of tofu and its byproduct okara. Food Chem. 1989, 34, 193–202. [Google Scholar] [CrossRef]

- Redondo-Cuenca, A.; Villanueva-Suárez, M.J.; Mateos-Aparicio, I. Soybean seeds and its by-product okara as sources of dietary fibre. Measurement by AOAC and Englyst methods. Food Chem. 2008, 108, 1099–1105. [Google Scholar] [CrossRef]

- Kumar, S.P.J.; Prasad, S.R.; Banerjee, R.; Agarwal, D.K.; Kulkarni, K.S.; Ramesh, K.V. Green solvents and technologies for oil extraction from oilseeds. Chem. Cent. J. 2017, 11, 9. [Google Scholar] [CrossRef]

- Lavenburg, V.M.; Rosentrater, K.A.; Jung, S. Extraction Methods of Oils and Phytochemicals from Seeds and Their Environmental and Economic Impacts. Processes 2021, 9, 1839. [Google Scholar] [CrossRef]

- Vong, W.C.; Liu, S.-Q. Biovalorisation of okara (soybean residue) for food and nutrition. Trends Food Sci. Technol. 2016, 52, 139–147. [Google Scholar] [CrossRef]

- Khare, S.K.; Jha, K.; Gandhi, A.P. Citric acid production from okara (soy-residue) by solid-state fermentation. Bioresour. Technol. 1995, 54, 323–325. [Google Scholar] [CrossRef]

- Privatti, R.T.; Rodrigues, C.E.d.C. An overview of the composition, applications, and recovery techniques of the components of okara aimed at the biovalorization of this soybean processing residue. Food Rev. Int. 2021, 39, 726–749. [Google Scholar] [CrossRef]

- Liu, X.; Yu, X.; Xia, J.; Lv, J.; Xu, J.; Dai, B.; Xu, X.; Xu, J. Erythritol production by Yarrowia lipolytica from okara pretreated with the in-house enzyme pools of fungi. Bioresour. Technol. 2017, 244, 1089–1095. [Google Scholar] [CrossRef]

- Preece, K.; Hooshyar, N.; Zuidam, N. Whole soybean protein extraction processes: A review. Innov. Food Sci. Emerg. Technol. 2017, 43, 163–172. [Google Scholar] [CrossRef]

- Mukherjee, R.; Chakraborty, R.; Dutta, A. Role of fermentation in improving nutritional quality of soybean meal—A review. Asian-Australas. J. Anim. Sci. 2016, 29, 1523–1529. [Google Scholar] [CrossRef] [PubMed]

- Irwin, S. The Value of Soybean Oil in the Soybean Crush: Further Evidence on the Impact of the U.S. Biodiesel Boom. In farmdoc daily (7):169; Department of Agricultural and Consumer Economics, University of Illinois at Urbana-Champaign: Urbana, IL, USA, 14 September 2017. [Google Scholar]

- Middelbos, I.S.; Fahey, G.C., Jr. 9—Soybean Carbohydrates. Soybeans 2008, 269–296. [Google Scholar] [CrossRef]

- Deak, N.A.; Johnson, L.A.; Lusas, E.W.; Rhee, K.C. 19—Soy Protein Products, Processing, and Utilization. Soybeans 2008, 661–724. [Google Scholar] [CrossRef]

- Silva, F.B.D.; Romao, B.B.; Cardoso, V.L.; Filho, U.C.; Ribeiro, E.J. Production of ethanol from enzymatically hydrolyzed soy molasses. Biochem. Eng. J. 2012, 69, 61–68. [Google Scholar] [CrossRef]

- Alarape, K.; Adeniyi, A.; Ayodele, T.; Bello, I.A.; Sarker, N.C.; Clementson, C.; Hammed, A. Extraction and Nutritional Value of Soybean Meal Protein Isolate. Nutraceuticals 2024, 4, 503–521. [Google Scholar] [CrossRef]

- Soccol, C.R.; Pandey, A.; Larroche, C. Fermentation Processes Engineering in the Food Industry; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Loman, A.A.; Ju, L.-K. Soybean carbohydrate as fermentation feedstock for production of biofuels and value-added chemicals. Process Biochem. 2016, 51, 1046–1057. [Google Scholar] [CrossRef]

- Siqueira, P.F.; Karp, S.G.; Carvalho, J.C.; Sturm, W.; Rodríguez-León, J.A.; Tholozan, J.-L.; Singhania, R.R.; Pandey, A.; Soccol, C.R. Production of bio-ethanol from soy molasses by Saccharomyces cerevisiae at laboratory, pilot and industrial scales. Bioresour. Technol. 2008, 99, 8156–8163. [Google Scholar] [CrossRef]

- Morais Júnior, W.G.J.; Kamimura, E.S.; Ribeiro, E.J.; Pessela, B.C.; Cardoso, V.L.; de Resende, M.M. Optimization of the production and characterization of lipase from Candida rugosa and Geotrichum candidum in soy molasses by submerged fermentation. Protein Expr. Purif. 2016, 123, 26–34. [Google Scholar] [CrossRef]

- Dong, J.; Du, Y.; Zhou, Y.; Yang, S.T. Butanol production from soybean hull and soy molasses by acetone-butanol-ethanol fermentation. ACS Symp. Ser. 2014, 1178, 25–41. [Google Scholar]

- Qureshi, N.; Lolas, A.; Blaschek, H.P. Soy molasses as fermentation substrate for production of butanol using Clostridium beijerinckii BA101. J. Ind. Microbiol. Biotechnol. 2001, 26, 290–295. [Google Scholar] [CrossRef] [PubMed]

- Romão, B.B.; Silva, F.B.; Resende, M.M.; Cardoso, V.L. Ethanol production from hydrolyzed soy molasses. Energy Fuel 2012, 26, 2310–2316. [Google Scholar] [CrossRef]

- Colletti, A.; Attrovio, A.; Boffa, L.; Mantegna, S.; Cravotto, G. Valorisation of by-products from soybean (Glycine max (L.) Merr.) processing. Molecules 2020, 25, 2129. [Google Scholar] [CrossRef]

- Dedousi, M.; Fourtaka, K.; Melanouri, E.-M.; Argyropoulos, D.; Psallida, C.; Diamantis, I.; Papanikolaou, S.; Diamantopoulou, P. Detoxification of Molasses and Production of Mycelial Mass and Valuable Metabolites by Morchella Species. Appl. Sci. 2021, 11, 9481. [Google Scholar] [CrossRef]

- Guedes, A.R.; Corazza, M.L.; Zanoelo, E.F. Boiling point, specific heat and density measurements and modeling of soybean molases and its aqueous solution. J. Food Process Eng. 2016, 39, 283–295. [Google Scholar] [CrossRef]

- Rodrigues, M.S.; Moreira, F.S.; Cardoso, V.L.; Resende, M.M. Soy molasses as a fermentation substrate for the production of biosurfactant using Pseudomonas aeruginosa ATC 10145. Environ. Sci. Pollut. Res. 2017, 24, 18699–18709. [Google Scholar] [CrossRef]

- Pascoalino, L.A.; Reis, F.S.; Barros, L.; Rodrigues, M.Â.; Correia, C.M.; Vieira, A.L.; Ferreira, I.C.R.; Barreira, J.C. Effect of plant biostimulants on nutritional and chemical profiles of almond and hazelnut. Appl. Sci. 2021, 11, 7778. [Google Scholar] [CrossRef]

- Kora, A.J. Commercial bacterial and fungal microbial biostimulants used for agriculture in India: An overview. In Microbial Biostimulants for Sustainable Agriculture and Environmental Bioremediation; CRC Press: Boca Raton, FL, USA, 2022; pp. 159–175. [Google Scholar]

- Correa da Silva, A.P.F.; Dorigan, B.S.R.; da Silva-Neto, J.M.; Rosa-Magri, M.M.; Rossi, F.; Francisco, K.R.; Ceccato-Antonini, S.R.; Fontanetti, A. Soy Molasses as Culture Medium for Bacillus Species Aiming at Plant Growth Promotion. Fermentation 2024, 10, 403. [Google Scholar] [CrossRef]

- Rakicka-Pustułka, M.; Ziuzia, P.; Pierwoła, J.; Szymański, K.; Wróbel-Kwiatkowska, M.; Lazar, Z. The microbial production of kynurenic acid using Yarrowia lipolytica yeast growing on curde glycerol and soy molasses. Front. Bioeng. Biotechnol. 2022, 10, 936137. [Google Scholar] [CrossRef]

- Santo, C.M.E.; Pinheiro, I.C.; Jesus, G.F.A.; Mouriño, J.L.P.; Vieira, F.N.; Seiffert, W.Q. Soy molasses as an organic carbon source in the farming of Litopenaeus vannamei in a biofloc system. Aquac. Res. 2017, 48, 1827–1835. [Google Scholar] [CrossRef]

- Paulinetti, A.P.; Batista, L.P.P.; Lazaro, C.Z.; Albanez, R.; Ratusznei, S.M.; Lovato, G.; Rodrigues, J.A.D. Treatment of soybean processing residues for energy recovery and environmental compliance: Tehcnical and economic feasibility. Energy 2023, 279, 128061. [Google Scholar] [CrossRef]

- Wang, Z.-P.; Zhang, L.-L.; Liu, S.; Liu, X.-Y.; Yu, X.-J. Whole Conversion of Soy molasses into Isomaltulose and Ethanol by Combining Enzymatic Hydrolysis and Successive Selective Fermentations. Biomolecules 2019, 9, 353. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhao, Y. Enzyme applications in soy molasses valorization. Crit. Rev. Biotechnol. 2015, 35, 123–136. [Google Scholar]

- Lima, F.A.; Rola, J.C.; Freitas, M.M.G.; Afonso, J.M.M.A.; Resende, M.M. Acid Phosphatase Imobilization and Production Study by Trichoderma spp. in Soy molasses. Chem. Eng. Technol. 2022, 45, 979–984. [Google Scholar] [CrossRef]

- Augusto, P.E.; Lazaro, C.Z.; Albanez, R.; Ratusznei, S.M.; Lovato, G.; Rodrigues, J.A.D. Hydrogen production via dark fermentation using soy molasses as substrate. Energy J. 2024, 298, e131301. [Google Scholar] [CrossRef]

- Souza, E.F.; Furtado, M.R.; Carvalho, C.W.; Freitas-Silva, O.; Gottschalk, L.M. Production and characterization of Gluconacetobacter xylinus bacterial cellulose using cashew apple juice and soy molasses. Int. J. Biol. Macromol. 2020, 146, 285–289. [Google Scholar] [CrossRef]

- Huang, W.M.; Chen, J.H.; Nagarajan, D.; Lee, C.K.; Varjani, S.; Lee, D.J.; Chang, J.S. Immobilization of Chlorella sorokiniana AK-1 in bacterial cellulose by co-culture and its application in wastewater treatment. J. Taiwan Inst. Chem. Eng. 2022, 137, 104286. [Google Scholar] [CrossRef]

- Kanwugu, O.N.; Ibn-Wuni, I.; Shevyrin, V.A.; Williams, T.C.; Glukhareva, T.V. Biovalorisation of agro-industrial wastes into astaxanthin by Xanthophyllomyces dendrorhous. Appl. Microbiol. Biotechnol. 2024, 108, 429. [Google Scholar] [CrossRef]

- Geremew Kassa, M.; Asemu, A.M.; Belachew, M.T.; Satheesh, N.; Abera, B.D.; Alemu Teferi, D. Review on the application, health usage, and negative effects of molasses. CyTA-J. Food 2024, 22, 2321984. [Google Scholar] [CrossRef]

- Paulinetti, A.P.; Augusto, I.M.G.; Batista, L.P.P.; Tavares, A.G.B.; Albanez, R.; Ratusznei, S.M.; Lovato, G.; Rodrigues, J.A.D. Anaerobic digestion as a core process for sustainable energy production in the soybean biorefinery: A techno-economic assessment. Sustain. Horiz. 2022, 3, 100024. [Google Scholar] [CrossRef]

- Fu, Z.; Cheng, S.; Ma, J.; Basit, R.A.; Du, Y.; Tian, S.; Fan, G. Identification of Yeast Strain YA176 for Bio-Purification of Soy Molasses to Produce Raffinose Family Oligosaccharides and Optimization of Fermentation Conditions. Appl. Biochem. Biotechnol. 2025, 197, 943–963. [Google Scholar] [CrossRef] [PubMed]

- Ta, X.; Wang, B.; Bai, J.; Yu, J.; Chen, H.; Wang, C. The source, extraction, purification, physiological function, and application of stachyose in the food industry. Food Chem. 2024, 461, 140791. [Google Scholar] [CrossRef]

- Aljuraifani, A.; Berekaa, M.M.; Ghazwani, A.A. Bacterial biopolymer (polyhydroxyalkanoate) production from low-cost sustainable sources. Appl. Microbiol. Biotechnol. 2018, 96, 333–340. [Google Scholar] [CrossRef]

- Ramírez, I.M.; Tsaousi, K.; Rudden, M.; Marchant, R.; Alameda, E.J.; Román, M.G.; Banat, I.M. Rhamnolipid and surfactin production from olive oil mill waste as sole carbon source. Bioresour. Technol. 2015, 198, 231–236. [Google Scholar] [CrossRef]

- Morillo, E.; Villaverde, J. Advanced technologies for the remediation of pesticide-contaminated soils. Sci. Total Environ. 2017, 586, 576–597. [Google Scholar] [CrossRef] [PubMed]

- Inès, M.; Mouna, B.; Marwa, E.; Dhouha, G. Biosurfactants as Emerging Substitutes of Their Synthetic Counterpart in Detergent Formula: Efficiency and Environmental Friendly. J. Polym. Environ. 2023, 31, 2779–2791. [Google Scholar] [CrossRef]

- da Silva, I.A.; de Almeida, F.C.G.; Alves, R.N.; Cunha, M.C.C.; de Oliveira, J.C.M.; Fernandes, M.L.B.; Sarubbo, L.A. The Formulation of a Natural Detergent with a Biosurfactant Cultivated in a Low-Cost Medium for Use in Coastal Environmental Remediation. Fermentation 2024, 10, 332. [Google Scholar] [CrossRef]

- Ceresa, C.; Fracchia, L.; Sansotera, A.C.; De Rienzo, M.A.D.; Banat, I.M. Harnessing the Potential of Biosurfactants for Biomedical and Pharmaceutical Applications. Pharmaceutics 2023, 15, 2156. [Google Scholar] [CrossRef]

- Wang, X.; An, J.; Cao, T.; Guo, M.; Han, F. Application of Biosurfactants in Medical Sciences. Molecules 2024, 29, 2606. [Google Scholar] [CrossRef]

- Khairunnisa, Z.; Tuygunov, N.; Cahyanto, A.; Aznita, W.H.; Purwasena, I.A.; Noor, N.S.M.; Azami, N.H.; Zakaria, M.N. Potential of microbial-derived biosurfactants for oral applications—A systematic review. BMC Oral. Health 2024, 24, 707. [Google Scholar] [CrossRef]

- Hashim, Z.A.; Maillard, J.Y.; Wilson, M.J.; Waddington, R.J. Determining the potential use of biosurfactants in preventing endodontic infections. Eur. J. Oral. Sci. 2022, 130, e12900. [Google Scholar] [CrossRef] [PubMed]

- Demchenko, A.P.; Dekaliuk, M.O. Novel fluorescent carbonic nanomaterials for sensing and imaging. Methods Appl. Fluoresc. 2013, 1, e042001. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chung, T.S. Graphene oxide membranes for nanofiltration. Curr. Opin. Chem. Eng. 2017, 16, 9–15. [Google Scholar] [CrossRef]

- Mello, B.S.; Rodrigues, B.C.G.; Sarti, A. Comparative performance of high-rate anaerobic reactors for biodegradation of soy molasses. Environ. Technol. Innov. 2021, 24, 101937. [Google Scholar] [CrossRef]

- Full, T.D.; Jung, D.O.; Madigan, M.T. Production of poly-β-hydroxyalkanoates from soy molasses oligosaccharides by new, rapidly growing Bacillus species. Lett. Appl. Microbiol. 2006, 43, 377–384. [Google Scholar] [CrossRef]

- Wu, M.; Gong, X.; Liu, X.; Tu, W.; Yu, P.; Zou, Y.; Wang, H. Comprehensive techno-environmental evaluation of a pilot-scale PHA production from food waste in China. Environ. Sci. Technol. 2022, 57, 1467–1478. [Google Scholar] [CrossRef]

- Bressanin, J.M.; de Mesquita Sampaio, I.L.; Geraldo, V.C.; Klein, B.C.; Chagas, M.F.; Bonomi, A.; Maciel Filho, R.; Cavalett, O. Techno-economic and environmental assessment of polylactic acid production integrated with the sugarcane value chain. Sustain. Prod. Consum. 2022, 34, 244–256. [Google Scholar] [CrossRef]

- FDA. U.S. Food and Drug Administration: Agency Response Letter GRAS Notice No. GRN 000623. 2018. Available online: https://www.fda.gov/food/gras-notice-inventory/agency-response-letter-gras-notice-no-grn-000623?utm (accessed on 6 June 2025).

- FDA. U.S. Food and Drug Administration: GRAS Notice 735 for 2′-Fucosyllactose. 2017. Available online: https://manuals.plus/m/160d17fa98647fce09de187d4c6fd18a48192ecbdc62847e1ca69929c7eb7dd2?utm (accessed on 6 June 2025).

- European Commission. COM(2018) 35, Report on the Impact of the Use of Oxo-Degradable Plastics, Including Oxo-Degradable Plastic Carrier Bags, on the Environment, 16 January 2018. Available online: https://docs.european-bioplastics.org/PR/2017/EUBP_PR_EU_Plastics_Strategy_180117.pdf (accessed on 6 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).