Abstract

Additive Manufacturing has significantly impacted circular design, expanding the opportunities for designing new artifacts following circular economy principles, e.g., using secondary raw materials. Small-format 3D printing has reached a broader audience of stakeholders, including end-users, when dealing with filament feedstocks from plastic and biomass waste. However, using large-format extrusion-based additive manufacturing with recycled feedstocks remains challenging, resulting in limited applications and awareness among practitioners. This work analyzes the most relevant product applications using large-format material extrusion additive manufacturing with recycled plastics and biomass waste feedstocks. It reviews the case studies from 2010 to mid-2024 dealing with new materials and applications from academic research and practical contexts. The applications were analyzed to outline the current situation and trends for large-format 3D printing with recycled plastics- and biomass-based feedstocks, focusing on secondary raw materials, manufacturability, impact on product aesthetics, application fields, and products. Despite more consolidated sectors, new technical applications using granulate feedstock systems, e.g., transportation, are emerging. Academic research studies new secondary raw materials and distributed practices through large-format 3D printing. Practitioners are exploiting different approaches to design products, optimizing building times, costs, and material usage through different manufacturing strategies, strengthening the product identity by highlighting circularity. Spreading specific expertise could enlarge the range of application sectors and products, as well as foster real-world collaborations and scaling-up. Thanks to this work, new synergies between the research and practical contexts can be encouraged for new circular economy practices, detecting and exploring new scraps, material categories, or Additive Manufacturing processes in the future.

1. Introduction

Circular economy, according to the Ellen MacArthur Foundation, aims to address global issues connected to sustainability, such as climate change, biodiversity loss, environmental pollution, and waste production [1]. This model acknowledges different strategies for keeping resources in use, also known as the “R-imperatives” or “R-strategies” [2,3], creating closed- or open-loops through reuse, remanufacturing, repurpose, repairing, or recycling, among those [4,5]. For this reason, waste, scraps, and byproducts are used as material resources as much as possible, following a cradle-to-cradle approach and avoiding “take-make-waste” models [6]. To this end, reusing and recycling materials play a crucial role in preserving virgin resources and fostering secondary raw materials, requiring shared regulations, policies, and guidelines, e.g., the European Waste Hierarchy [7,8]. Although recovery operations require further reprocessing to obtain secondary raw materials, recycling currently represents a widespread strategy for the circular economy, preventing landfilling and disposal [9]. For instance, plastics from packaging or commodity goods can be recycled and used as secondary raw materials for new products [10]. Similarly, biomass scraps or byproducts can be reused as new resources, following the principles of bioeconomy [11,12]. To this end, circular approaches to product design and development can foster resource preservation, reducing or reusing material waste for new applications with consolidated or emerging manufacturing processes [13,14,15].

Circular design practice has been significantly influenced by digital fabrication in the last decades, fostering reuse, repair, and recycling [16,17,18]. These tools envision new technical and formal product opportunities for circular economy amongst designers and engineers, especially when focusing on Additive Manufacturing (AM) [19,20]. AM technologies, commonly known as 3D printing, fabricate three-dimensional objects by depositing material through a layer-by-layer approach, usually starting from CAD files [21]. Small batches of customizable products with complex geometries can be easily manufactured thanks to AM technologies, demonstrating their economic viability within distributed manufacturing contexts [22,23]. To this extent, Distributed Recycling for Additive Manufacturing (DRAM) further exploits the on-demand localized production allowed by AM, connecting it with circular economy principles and recycling practices. DRAM aims to spread distributed networks of 3D printing systems using locally recycled feedstock, usually from waste plastics and biomass scraps [24,25]. It enables end-users, prosumers, makers, and collective spaces to recycle their own waste to fabricate new products, leading to more efficient recycling models, reduced greenhouse gas emissions, economic benefits, and users’ needs fulfillment [25,26,27]. The DRAM model represents, therefore, a promising way to foster circular design and AM exploitation in circular economy contexts.

Considering the range of materials and processes, seven categories of AM technologies can be identified, clustering similar material transformation processes or equipment architecture, e.g., Vat polymerization, Powder Bed Fusion, or Binder Jetting. In particular, Material Extrusion (MEX) AM processes have been established as the most widespread in real-world contexts for the accessibility of machinery and raw materials [28,29]. This process category allows the selective deposition of materials by means of a nozzle, either extruding melted materials through heat, i.e., thermoplastic polymers, or viscous pastes at room temperature, i.e., ceramics or composites [30]. Fused Filament Fabrication (FFF, also known as Fused Deposition Modeling, FDM, from the Stratasys trademark) melts feedstock materials in the form of filaments inside a chamber before its extrusion and represents the most well-established MEX AM technology [21]. For these reasons, FFF is commonly considered the main 3D printing process from an end-user perspective, also thanks to the democratization of this technology by the makers’ movement [31,32]. However, this affirmation is usually related to small-format systems, i.e., desktop-size 3D printers, which represent the conventional format of FFF apparatuses on the market [33], especially for recycled feedstocks or materials from products at their end-of-life [15,34,35].

Another important distinction can be made regarding scales and building volumes in AM. Large-format AM (LFAM, or Large-Scale AM, LSAM) technologies rely on 3D printing systems with building volumes equal to or higher than 1 m3, moving away from the desktop-size volumes of 20 × 20 × 20 mm and reaching industrial scales, e.g., the patented Big Area Additive Manufacturing (BAAM) process [33,36,37]. Moreover, LFAM comprehends different motion systems, ranging from gantry-based and delta-based machines to robotic arms [38]. Focusing on MEX processes for thermoplastic-based feedstocks, increasing the building volumes means switching to different feeding systems to reach the process requirements, e.g., higher deposition volumes. Using continuous feeding systems with granulate, flakes, or pellet feedstocks helps cut the costs of filament production, improve the overall extrusion quality, and reduce the reprocessing steps and their effects on thermomechanical degradation [33,39,40]. Moreover, screw-feeding extruders on large-scale apparatuses enlarge the range of available materials through direct mixing, either with single- or twin-screw systems, including secondary raw materials from scraps, byproducts, or biomasses [34,37]. These pellet-based MEX AM processes are known as Fused Granular Fabrication (FGF) or Fused Particle Fabrication (FPF) [39].

FGF allows designers and engineers to enlarge the application fields of AM to new contexts when combined with large-format systems, i.e., architecture, transportation, and sports [41,42,43]. Some industries, design studios, and professionals have been adopting large-format AM within their practice [44,45,46]. To some extent, their work contributes to defining Design for AM (DfAM) principles for large-format processes, including FGF processes, through their practice-based approach. DfAM studies the opportunities and constraints of AM, providing a set of tools, techniques, and guidelines to adapt or design shapes according to the constraints, obtaining complex geometries to be produced otherwise [47,48,49,50]. It mainly relates to three main domains, which means materials, machines and processes, and design [51]. Small-format MEX processes have been extensively studied from the DfAM perspective, exploring DRAM contexts and considering recycled material feedstocks [25,52]. However, investigations using large-format AM and secondary raw materials from scraps and byproducts are currently limited, lacking a clear analysis of the current situation in the academic and real-world context. To the best of the authors’ knowledge, no existing works focus on analyzing large-format MEX AM in DRAM contexts, especially from an application-driven perspective. Although FFF and FGF show many similarities in terms of materials and working principles, these processes deal with different physical constraints derived from the building dimensions and extrusion systems, i.e., in machinery, heat transfer, and compression models [53,54], requiring further technical knowledge and awareness amongst practitioners. This fact influences the available materials and the current product applications with LFAM in real-world contexts, developing new skill sets and design strategies during their use in real-world contexts. However, works from these realities, e.g., industries and design studios, have been scarcely considered in analyzing the exploitation of these secondary raw materials and AM technologies, lacking a holistic perspective and a more comprehensive framework.

This work analyzes the current use of large-format Material Extrusion (MEX) AM with recycled plastics and biomass waste feedstocks for new product applications. In detail, this study investigates the most relevant case studies from academic research and practical context, i.e., design practice and industrial activities, from 2010 to mid-2024 dealing with new secondary raw materials for MEX LFAM and new applications, answering the following research questions (RQs):

- RQ1: What is the current situation in the academic and practical contexts considering MEX LFAM and recycled plastics or biomass waste feedstocks as secondary raw materials? What are the similarities and differences between the two contexts?

- RQ2: What are the most used scraps or byproducts, secondary raw materials, and AM setups in the research and practical contexts?

- RQ3: What are the current product applications and emerging trends in the research and practical contexts?

- RQ4: What are the impacts on products in terms of manufacturability and aesthetics given by MEX LFAM processes with recycled plastics and biomass waste feedstocks?

After describing the research methodology (Section 2), the work presents the review analysis on (a) 23 works from the research context, including 23 products selected as case studies, and (b) 24 different companies or design studios, selecting 125 products as case studies. The selected case studies (Section 3). The selected works are analyzed from a quantitative point of view according to the following: their context and year (“General analysis”, RQ1); main scraps and/or byproducts, secondary raw materials, and 3D printing processes (“Scraps, materials, and AM process analysis”, RQ2); and field of application and products (“Application analysis”, RQ3). A quantitative and qualitative analysis of the specific products is then presented, focusing on the manufacturability and aesthetic impact of the combination between the selected AM process and secondary raw materials, i.e., MEX LFAM processes and recycled plastics or biomass waste feedstocks (“Product analysis”, RQ4). Finally, the main trends and limitations from the two contexts are resumed to stimulate further research within this research area and new real-world exploitations (RQ1).

2. Materials and Methods

This paper investigates the use of MEX LFAM systems with recycled plastic-based or biomass-based feedstock for real or potential product applications, comparing the academic and practical contexts, i.e., design and industrial activities. The review was conducted by searching the academic and practical case studies based on real applications (Section 2.1). The data from the selected entries were then collected and analyzed to address the different RQs (Section 2.2 and Section 2.3).

2.1. Case Study Research and Search Strategy

The review was conducted by searching case studies on new applications from (i) academic repositories and (ii) repositories linked to practitioners’ activity in the design and AM fields. Table 1 resumes the organization and search strategy of this study for the two contexts. In detail, this work considers applications focused on plastic-based feedstocks and MEX LFAM processes, i.e., FFF, FGF, and FPF [30], and from the following:

Table 1.

Organization of the case study research: repositories, selected keywords, eligibility, and exclusion criteria.

- Academic works with an application-driven approach to materials and technologies, i.e., including the fabrication of proofs-of-concept and demo products in their experimental activities.

- Works from companies and studios in the LFAM industry on specific materials and technologies, i.e., designing, developing, and/or fabricating products in their professional activities.

A timeframe from 2010 to 2024 was defined after a first screening of the entries from both contexts to include the first projects and works with LFAM systems. The results were screened to avoid duplicates, retired, or not accessible works, and further references were included in the selection by checking the citing and cited publications, avoiding the exclusion of relevant works due to any possible limitations from the defined query string. Reviews, meta-analyses, and theoretical works were excluded from the entries retrieved from the academic context to focus on research works with a well-defined application. The search strategy in the practical context avoided single case studies and experimentations from occasional work, focusing on applications and products from well-established companies, studios, or industries connected with AM. These choices helped in considering the best practices developed in application-driven research oriented to implementations of their results or design realities with good expertise and know-how in LFAM. The selected entries from the academic and practical contexts were then further screened to define the specific applications to be analyzed, creating a list of existing products.

After defining the selected case studies, data collection and analysis followed four main phases, each aiming to address a specific RQ:

- A first preliminary step to frame the current situation of the two contexts, identifying the research works and products from companies/studios working in the circular MEX LFAM area and analyzing the works per year (“General analysis”, RQ1).

- A second quantitative step to detect and analyze the main scraps and/or byproducts, secondary raw materials, and 3D printing processes used in the two contexts (“Scraps, materials, and AM process analysis”, RQ2).

- A third quantitative step to investigate the specific fields of application and product types manufactured with MEX LFAM and secondary raw materials, identifying the specific products to be analyzed (“Application analysis”, RQ3).

- A fourth qualitative and quantitative step to investigate the impact of MEX LFAM and secondary raw materials on product manufacturability and aesthetics, focusing on shape choices, technical features, and AM strategies starting from a selection of their proofs-of-concept and products (“Product analysis”, RQ4).

2.2. First and Second Steps: General Analysis and Scraps, Materials, and AM Process Analysis

The general analysis started by collecting and inserting the data into an Excel matrix, dividing it into columns on the main aspects connected to the academic works and products from the practical contexts. A first overview was depicted by collecting general data and descriptions, such as the type and year of publication or professional activity of the companies/studios. The main data about used scraps and/or byproducts, secondary raw materials, MEX LFAM processes, and potential applications were also collected to provide a preliminary overview of the situation, corresponding to the main clusters of the analysis.

The analysis was then deepened by searching for and collecting further details from publications or sources connected to specific products, companies, or studios. Further columns were added to each of the previous clusters, creating a comprehensive dataset for the analysis divided according to the two contexts. In case of discrepancies, other secondary resources were checked to validate the data, e.g., websites from material suppliers or previous publications. The dataset is visible at https://doi.org/10.5281/zenodo.13673019 (accessed on 8 September 2024).

2.3. Third and Fourth Steps: Application Analysis and Product Analysis

The third analysis was conducted starting from the selected works and narrowed down the applications and products selected as case studies, i.e., potential applications, proofs-of-concept, and products. The selected entries were further analyzed by collecting data about (i) the proof-of-concept or demo product from the state-of-the-art (academic research) or (ii) each company or studio activities, i.e., from their websites and projects. Results without enough information about AM technologies or lacking tangible products within real-world contexts were discarded. The applications were then screened to define a list of potential products for the second analysis. To avoid biases and overrepresentations, a maximum of eight products for each company were selected for this analysis, trying to map the most representative and diversified projects in terms of application, formal language, and AM manufacturing strategies. Projects without enough data or a clear definition of the technology were discarded, including products obtained with different materials, i.e., ceramics, or assembling components from small-format 3D printers.

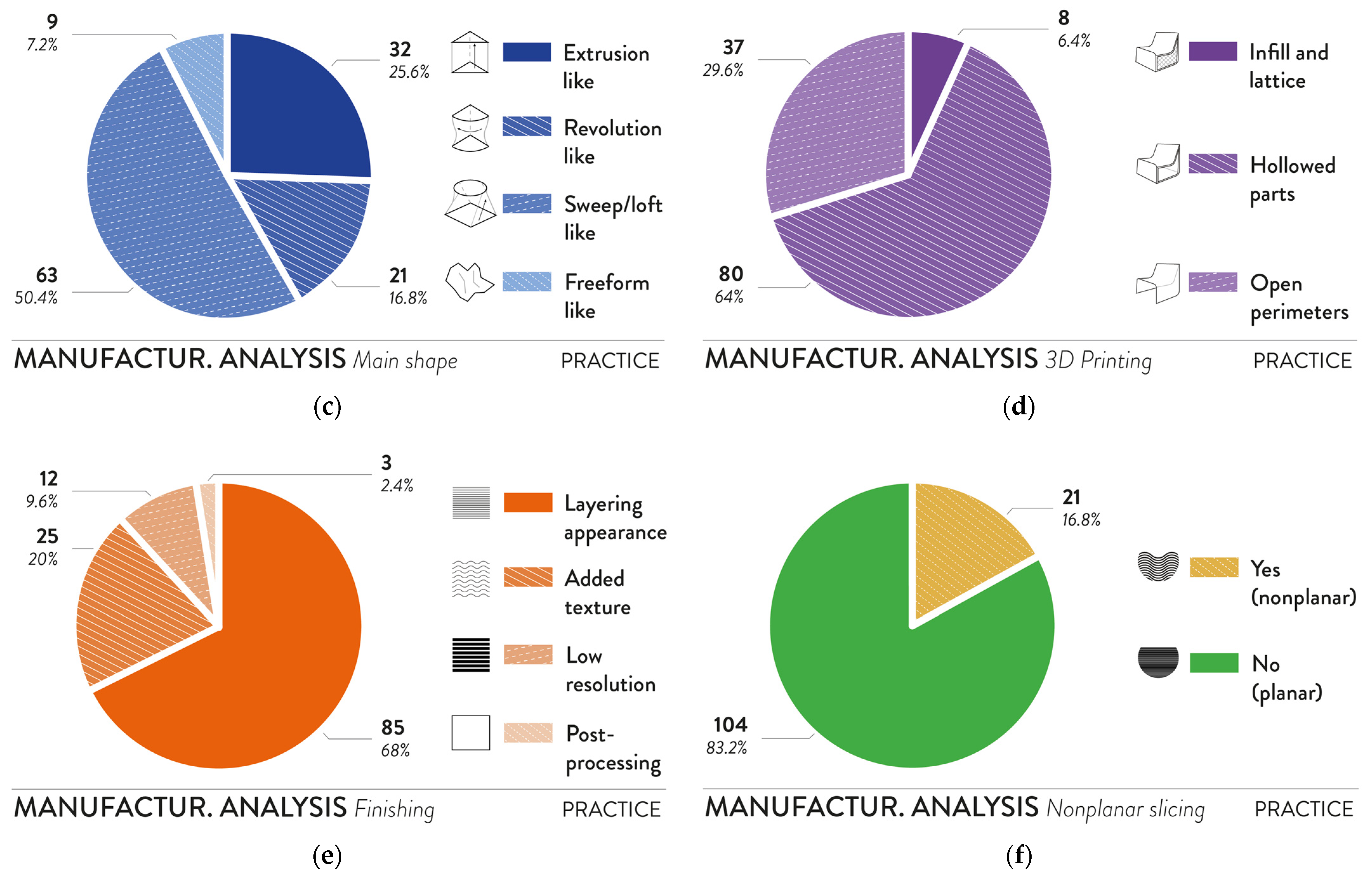

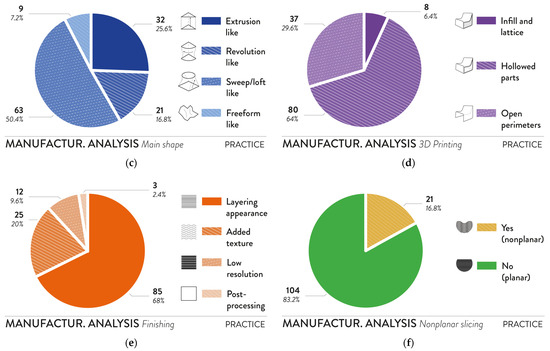

The product analysis started with the selected products, i.e., academic entries or companies/studios selected. It focused on two aspects: the form-giving approaches adopted in these products (formal analysis) and the product shape and manufacturability with MEX LFAM (manufacturability analysis). The former one considered two approaches used by designers to generate the form of artifacts:

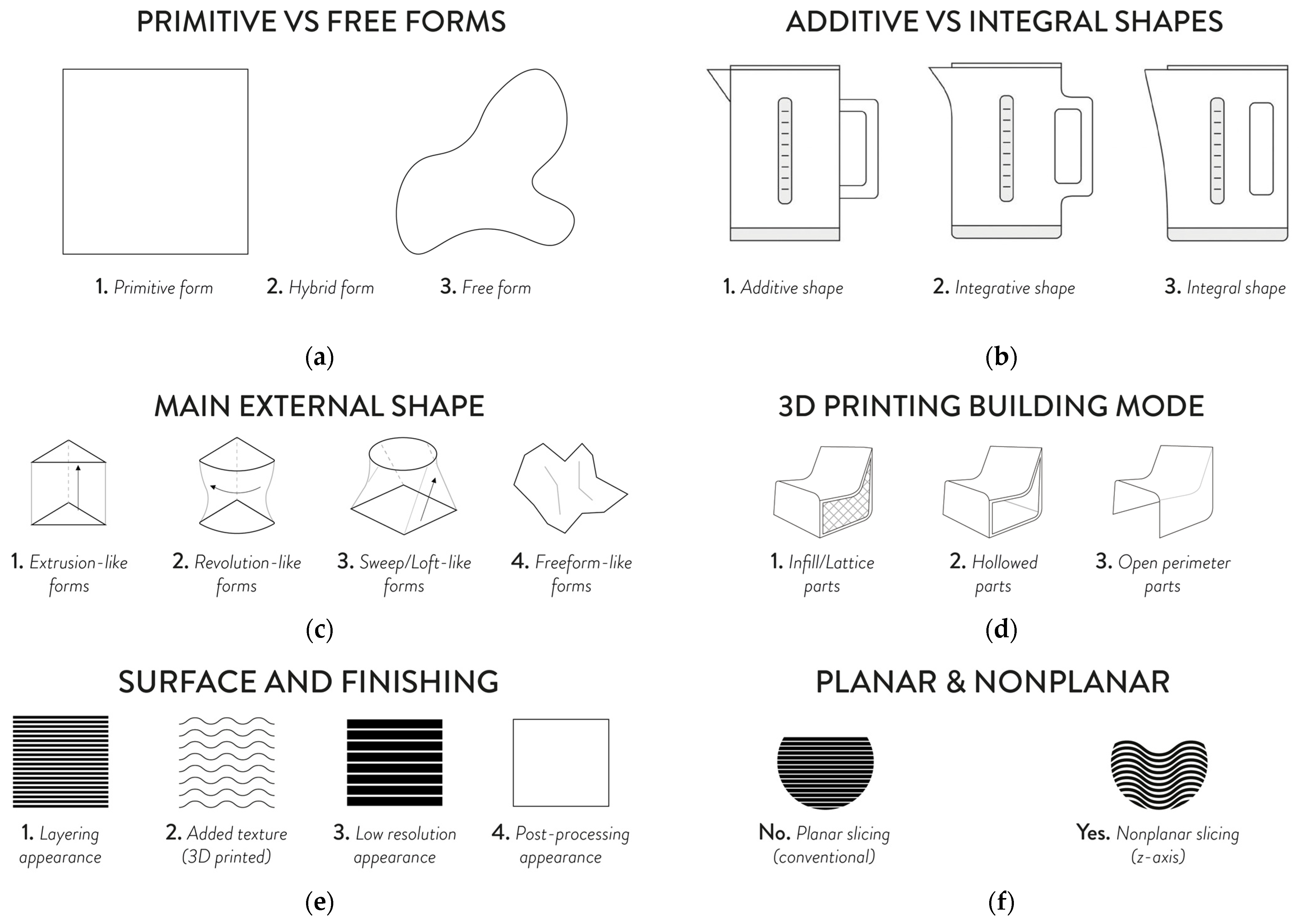

- “Primitive vs. free forms” deals with the selection of the shapes to be combined. Primitive forms refer to recognizable geometric elements in the final shape, e.g., cubes, usually resulting in static, minimalistic, and functional products. Free forms combine fluid and non-geometrical elements, often described as asymmetric, irregular, organic, and associated with dynamic and nature-like shapes [55] (Figure 1a).

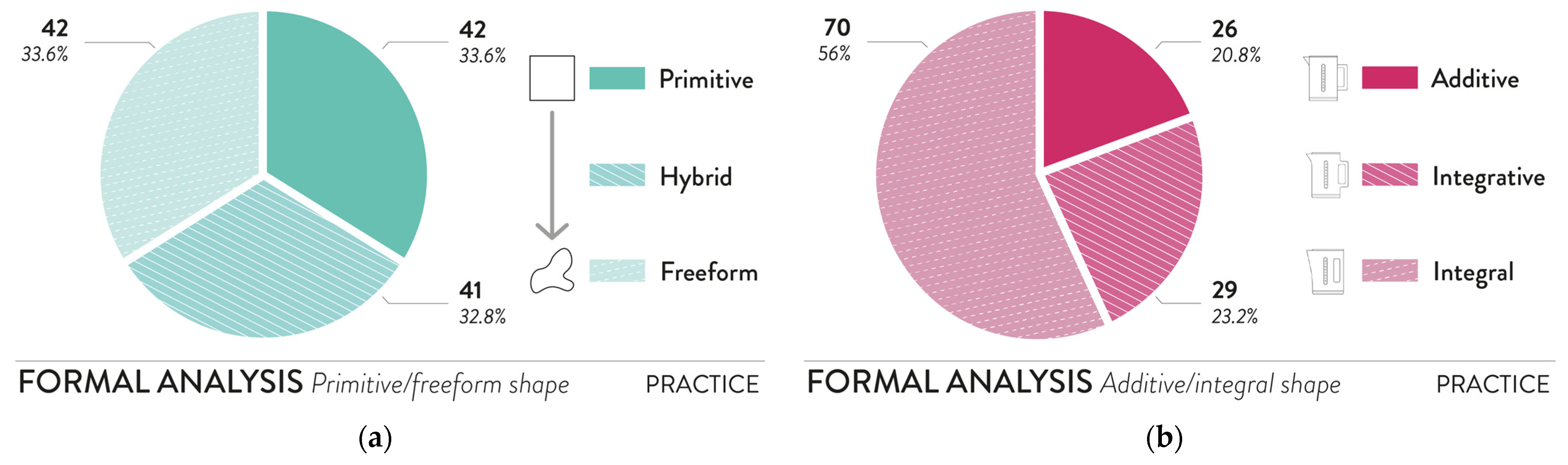

Figure 1. The clusters used for the product analysis: the two form-giving approaches (formal analysis), which means (a) primitive and free forms; and (b) additive, integrative, and integral forms adapted from Ferraris et al. [55]; four approaches to product shape and their manufacturability with MEX LFAM (manufacturability analysis), which means (c) main external shape; (d) 3D printing building mode; (e) surface appearance and finishing; and (f) planar or nonplanar slicing.

Figure 1. The clusters used for the product analysis: the two form-giving approaches (formal analysis), which means (a) primitive and free forms; and (b) additive, integrative, and integral forms adapted from Ferraris et al. [55]; four approaches to product shape and their manufacturability with MEX LFAM (manufacturability analysis), which means (c) main external shape; (d) 3D printing building mode; (e) surface appearance and finishing; and (f) planar or nonplanar slicing. - “Additive vs. integral” reflects on how different elements of products have connected each other in their overall shape, defining three different typologies: (i) additive, which makes visible the product’s functions as distinct added parts; (ii) integrative, which integrates the different functions in an overall shape but keeping them distinguishable; and (iii) integral, which hides the product’s architecture with a predominant form [56] (Figure 1b).

The second one aimed to understand how MEX LFAM processes affect the outcome of the product’s shape, finishing, and aesthetics [57]. Four main macro-areas linked to product shapes and their manufacturability were identified:

- “External main shape” refers to the external geometry and main shape of the product produced with MEX LFAM, connected to the “primitive and free forms” analysis: extrusion-like, revolution-like, sweep- and loft-like, and freeform and irregular-like (Figure 1c).

- The “3D printing building mode” focuses on the internal geometry and the approach to fabricating the whole structure using MEX LFAM: infill and lattice, hollowed parts, and open parts defined by perimeters (Figure 1d).

- “Surface appearance and finishing” analyzes the influence of MEX LFAM on the finishing of the product: layer-by-layer appearance, added texture, low-resolution layering, and post-processing (Figure 1e).

- “Planar and nonplanar slicing” considers the use of non-conventional slicing strategies for MEX LFAM affecting the shape and surface of the product [58] (Figure 1f).

The products were ranked in an Excel matrix according to the two approaches to form generation and the four macro-areas linked to shapes and manufacturability through the collected data and the pictures of each product [55].

3. Results and Discussion

This section shows the analysis of the selected case studies from the academic and practical contexts, which means 23 works from the research context, corresponding to 23 product applications, and 24 companies or design studios from the practical one, corresponding to 125 products. The first sub-section focuses on the first quantitative analysis of the works (“General analysis”). The second and third sub-sections narrow down the analysis on the two contexts, analyzing the scraps and/or byproducts, secondary raw materials, 3D printing processes (“Scraps, materials, and AM process analysis”), applications (“Application analysis”), and products (“Product analysis”). The last sub-section outlines some trends and limitations in using MEX LFAM with recycled plastic- or biomass-based secondary raw materials for product applications.

3.1. General Analysis

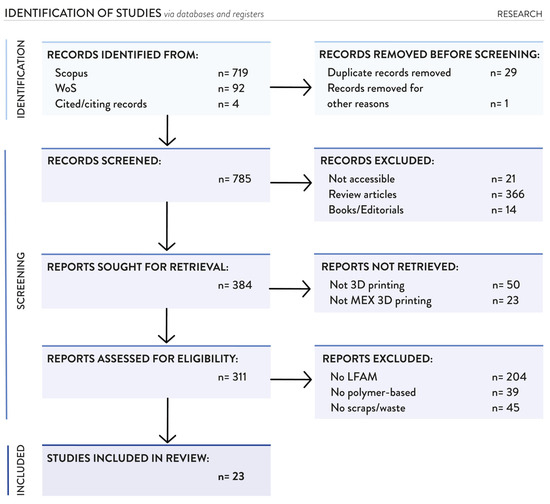

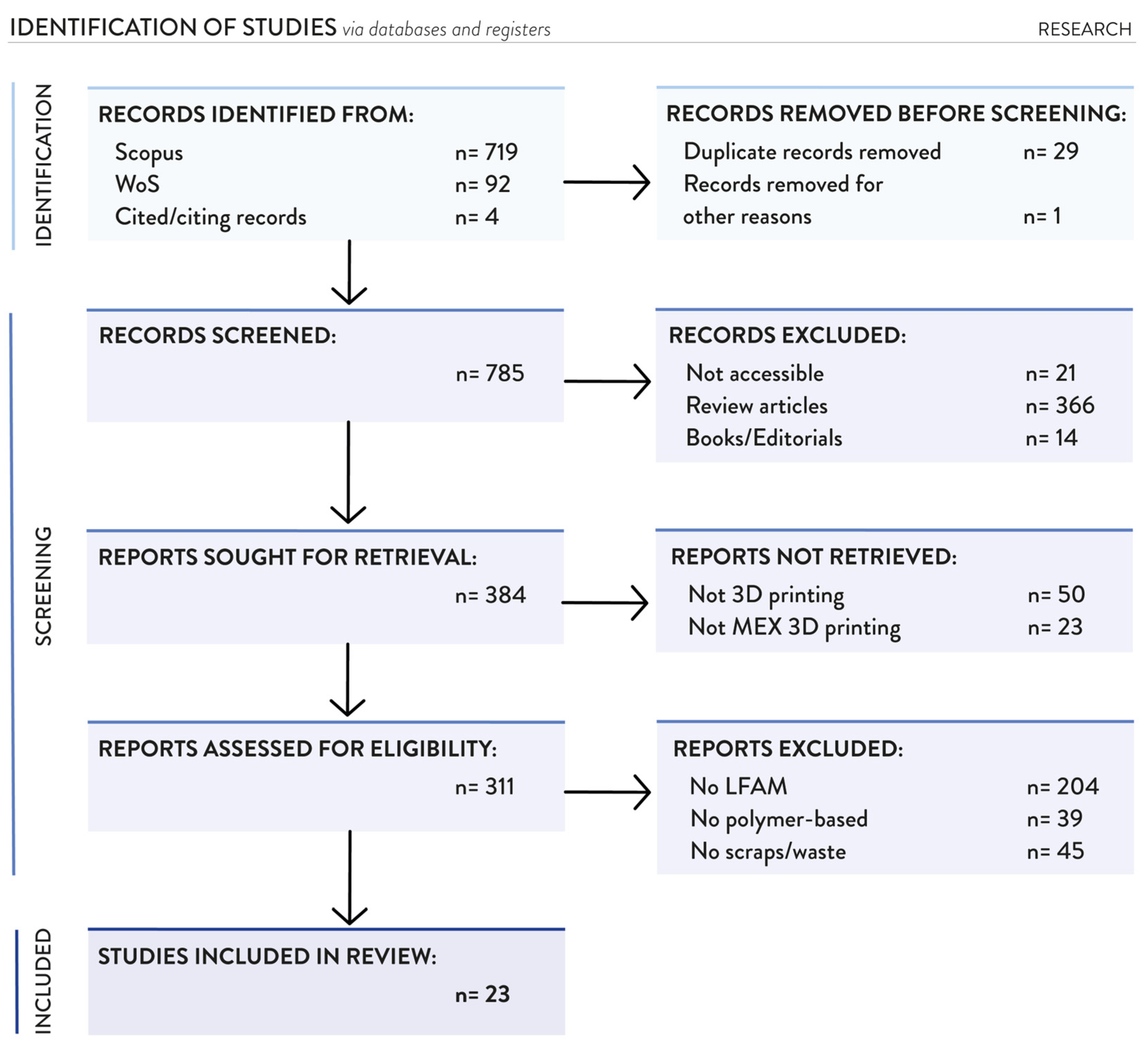

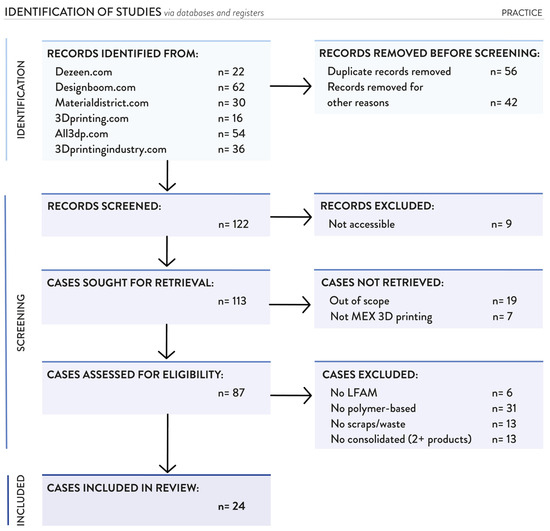

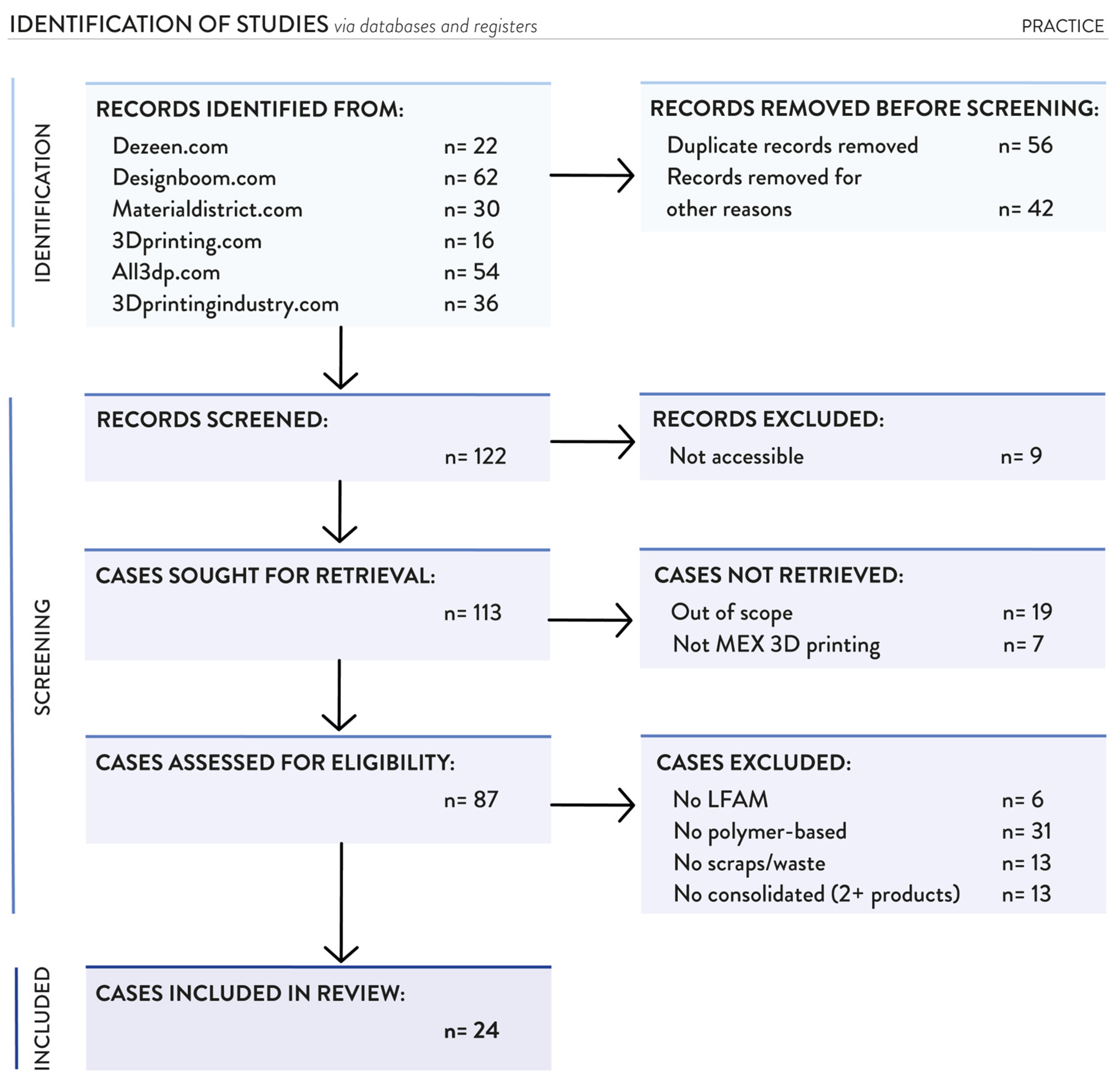

This sub-section focuses on the quantitative analysis of the two contexts connected with MEX LFAM of plastic- or biomass-based secondary raw materials. According to Table 1, Figure A1 and Figure A2 (Appendix A), 23 and 24 entries meet the eligibility criteria in the two contexts (https://doi.org/10.5281/zenodo.13673019, accessed on 8 September 2024). The review process led to the analysis of 23 and 125 product applications in the academic research and practical contexts, respectively, framing two different situations and approaches to the same topic.

In detail, the selected academic research works are mainly published as journal articles in materials science and engineering (13 entries), industrial and manufacturing engineering (5 entries), or design and sustainability fields (5 entries) (Table 2 and Table A1, Appendix B). However, a minimal amount of articles were detected during the analysis compared to the records retrieved at the beginning of the review process, which means 785 entries (Figure A1, Appendix A). This result demonstrates the recent interest in investigating potential applications of large-format extrusion-based AM processes from a circular economy perspective. Their focus is mainly to demonstrate the reliability of the selected secondary raw materials and AM technologies, legitimating their real-world use.

Table 2.

List and amount of the selected entries for (a) academic research works, according to their publication year and research focus; and (b) companies/studios from the practical context, according to their starting year of activity and activity focus.

Focusing on the practical context, most selected entries are design studios (15 entries), followed by industries mainly linked with AM manufacturing (7 entries) and foundations connected to circular economy practices (1 entry) (Table 2 and Table A2, Appendix C). In this case, a broader percentage of professional and industrial activities were included in this study compared to the academic research context, which means almost 20% of the searched entries. This fact may indicate a higher commitment to exploiting secondary raw materials for real product applications fabricated with large-format AM, hence the existence of new market niches.

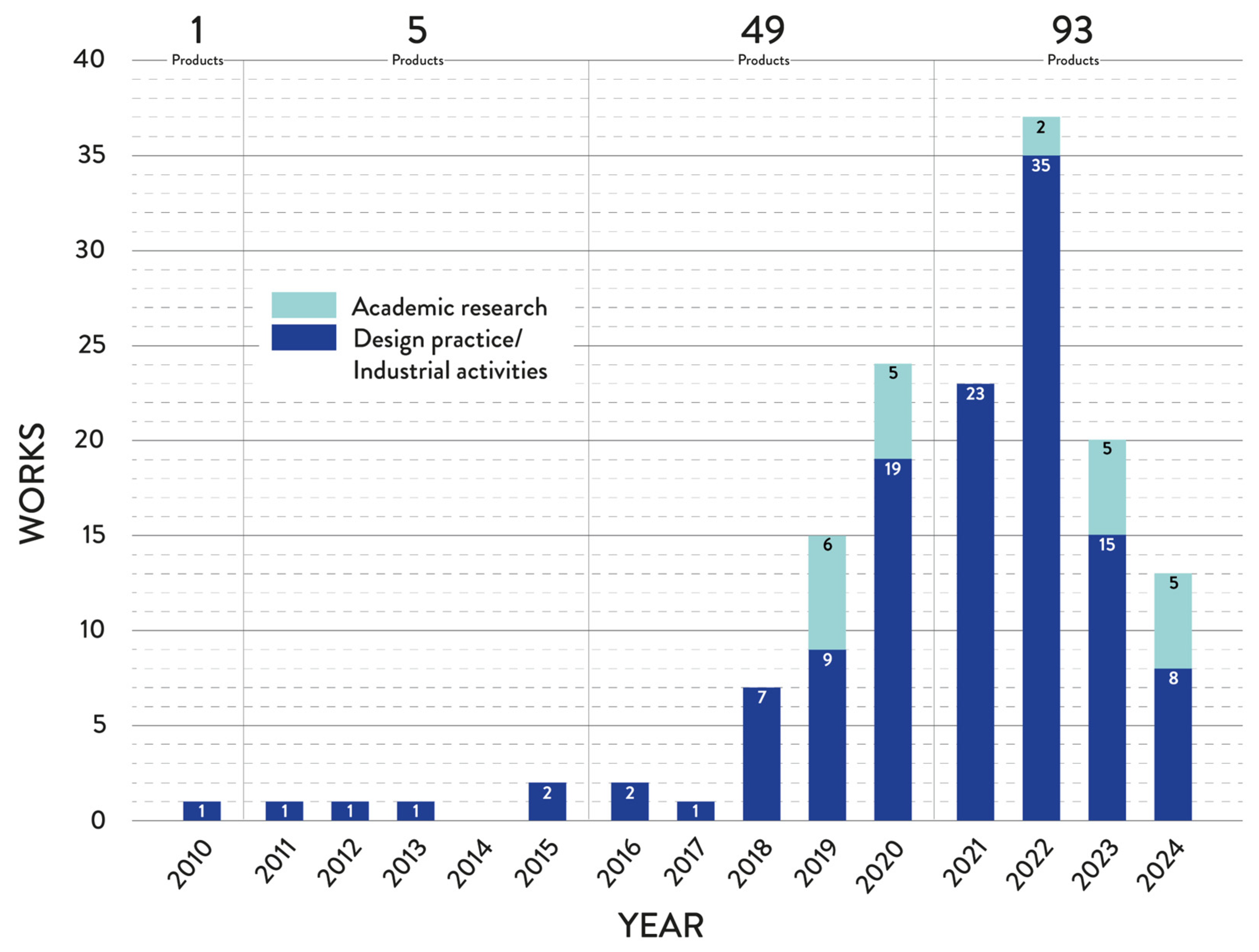

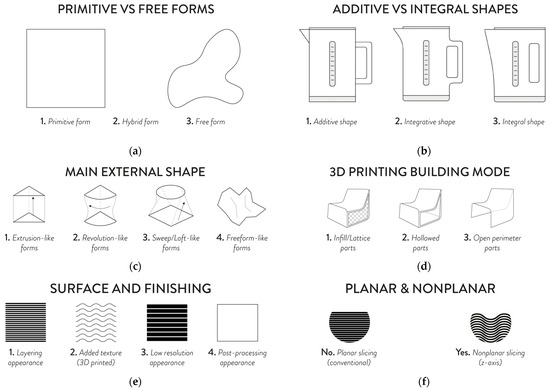

This situation is also confirmed by the number of products retrieved from the selected entries, i.e., 23 for the academic context and 125 for the practical one. As visible in Figure 2, the first real-world product application was found in 2010, whereas the first applications from the academic research contexts were only retrieved in 2019 (6 product applications). In general, a growing interest in these topics is visible in the 2016–2020 timeframe, especially from 2018, with almost ten times more applications (49 products) than in the 2011–2015 period (5 products). The current timeframe also confirms this trend, showing a two-fold increase in terms of retrieved product applications (98 entries). 2022 was the most productive year, with 25% of the analyzed case studies (37 entries). Although very recent applications from 2024 may not be published or shared yet, the retrieved entries and product case studies demonstrate the growing interest in exploiting large-format extrusion-based AM technologies with recycled plastic- or biomass-based materials in real-world contexts.

Figure 2.

General analysis of the research (light blue) and practical contexts (dark blue) according to the selected case studies (products) per year for the reviewed period (from 2010 to mid-2024).

3.2. Academic Research Context

3.2.1. Scraps, Materials, and AM Process Analysis

This sub-section analyzes the scraps, byproducts, and waste used as secondary raw materials for MEX LFAM in the academic research context, together with the specifics from the 3D printing processes (Tables S1 and S2, Supplementary Materials).

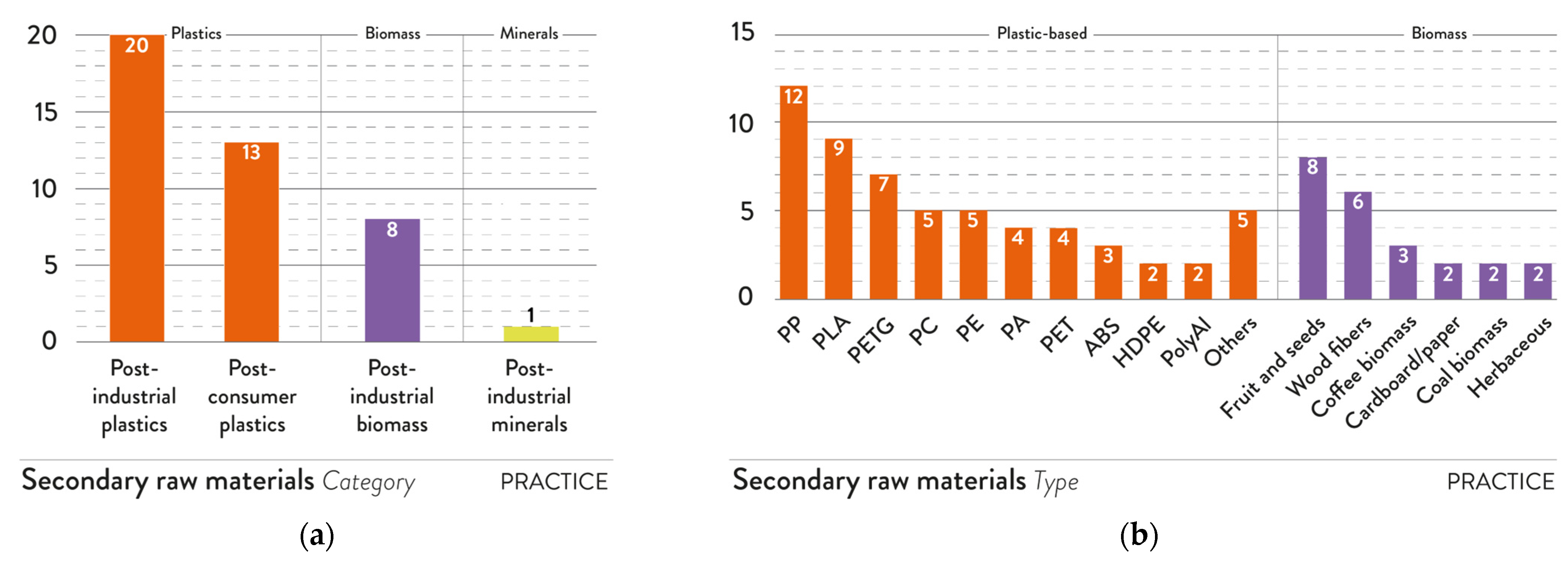

According to Figure 3a, the end-of-life materials mainly derive from industrial activities and are connected to plastic scraps or byproducts, representing more than three-fourths and two-thirds of the entries, respectively. PET (6 entries), PLA (4 entries), and ABS (3 entries) represent the most used plastics for new secondary raw materials (Figure 3b), usually from industrial suppliers or production process waste streams, e.g., water bottles [62,63,66], 3D-printed failed parts [59,68], and molding or machining processes [64,71]. Biomass scraps or byproducts are usually provided by logging [72], wood, or paper industries [77,80]. Accordingly, wood fibers or sawdust represent the most common types of waste resources, with 4 and 2 entries each (Figure 3b). In both cases, scraps or byproducts are from waste streams with significant batch dimensions, which can be reprocessed in wider quantities through LFAM processes rather than small-format AM.

Figure 3.

Scraps, secondary raw material, and AM process analysis of the research context: (a) scraps and/or byproduct category; (b) scrap and/or byproduct type; (c) secondary raw material category; (d) secondary raw material feedstock type, with a focus on bio-based and recycled feedstocks; (e) MEX LFAM process; and (f) AM system.

As shown in Figure 3c, thermoplastics and thermoplastic composites are equally explored as new secondary raw materials for MEX LFAM, including multiple recycled thermoplastics [68], thermoplastic blends [66,79] or fiber-reinforced plastics [60,70,76], and pelletized compounds [65,102]. This result is mainly affected by the AM technologies connected to plastic processing, i.e., FFF and FGF, which focus on thermoplastic-based feedstocks. However, there is a noticeable interest in granulate feedstocks (Figure 3d), e.g., pellets or flakes (28 entries), instead of filaments (1 entry) [63], justified by the common use of screw-feeding extruders on large-scale apparatuses [33,39]. Furthermore, using granulate feedstocks can help reduce reprocessing times, thermomechanical degradation of the materials, and energy consumption, leading to lower environmental impacts and performance decreases, e.g., in mechanical properties [35,40]. According to the retrieved works, the recycled feedstocks from scraps or byproducts are mainly used as thermoplastics (18 entries), e.g., recycled PET and PLA [62,75], or as a filler for new composites (11 entries), rather than matrixes (5 entries), which are often made of virgin raw materials. Bio-based feedstocks, either virgin or recycled, are mainly used for thermoplastic-based composites as plastic matrixes (7 entries) or fillers (9 entries), such as cork scraps or spent coffee grounds [67,78]. These results show a wide range of secondary raw materials, either for the type or percentage content of scraps and byproducts, hence the potential customization of material properties and qualities for new product applications.

Although the MEX AM category includes different 3D printing technologies [30], the retrieved works only deal with FFF (Fused Filament Fabrication) or FGF (Fused Granular Fabrication), as shown in Figure 3e. As a matter of fact, FFF and FGF are used to process thermoplastic and thermoplastic-based composite feedstocks, hence the most suitable MEX AM technologies for the secondary raw materials in this case. Contrarily to small-format MEX AM [39,40], FGF is the widest process used when dealing with large scales, bigger products, and printing volumes. It was used in almost all the analyzed works (22 entries), whereas only one study focused on LFAM FFF [63]. This fact is due to the higher flexibility of the material feedstock for FGF. It can be easily customized or mixed during the 3D printing process, reducing the number of reprocessing steps, e.g., compounding or filament extrusion. Using direct screw-feeding also allows higher freedom in characterizing novel material formulations from scraps and byproducts, tuning the material formulation according to the desired properties and the quality of the 3D printing process. Furthermore, it facilitates the supply of large feedstock quantities for new product applications with bigger dimensions and volumes rather than small-format AM. However, using LFAM for new materials from scraps or byproducts often requires modified 3D printing apparatuses (13 entries), such as custom screw extruders [43,69] or 3D printers [74,80]. These requirements can be achieved by using either open-source machines, e.g., GigabotX, BigRep, or Hangprinter [63,73,79], or patented setups, such as the Big Area Additive Manufacturing (BAAM) system or proprietary pellet extruders [64,76]. Machine setups are mostly based on gantry or delta three-axis systems with only three entries exploiting robotic arms [72,75,76] (Figure 3f). Nevertheless, different 3D printing parameters were explored in the retrieved works, i.e., nozzle diameter, speed, and layer height (Table S2, Supplementary Materials), implying a good versatility of MEX LFAM to process plastic- or biomass-based secondary raw materials for product applications.

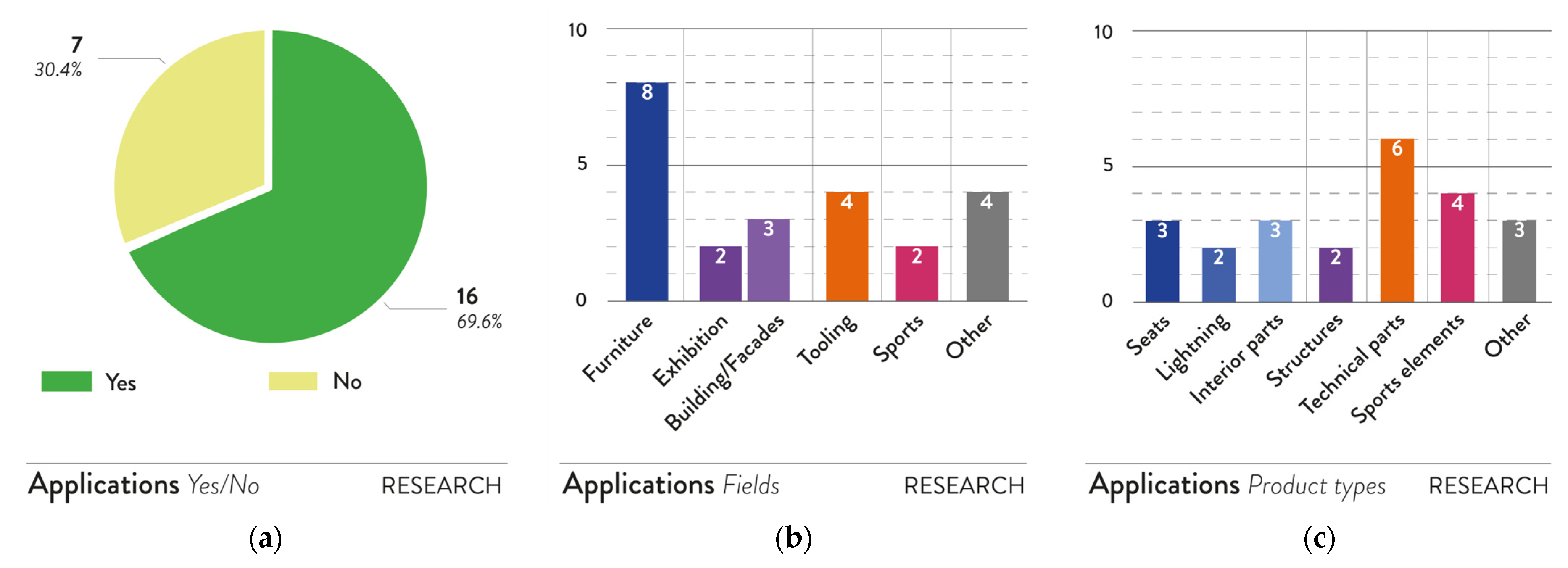

3.2.2. Application Analysis

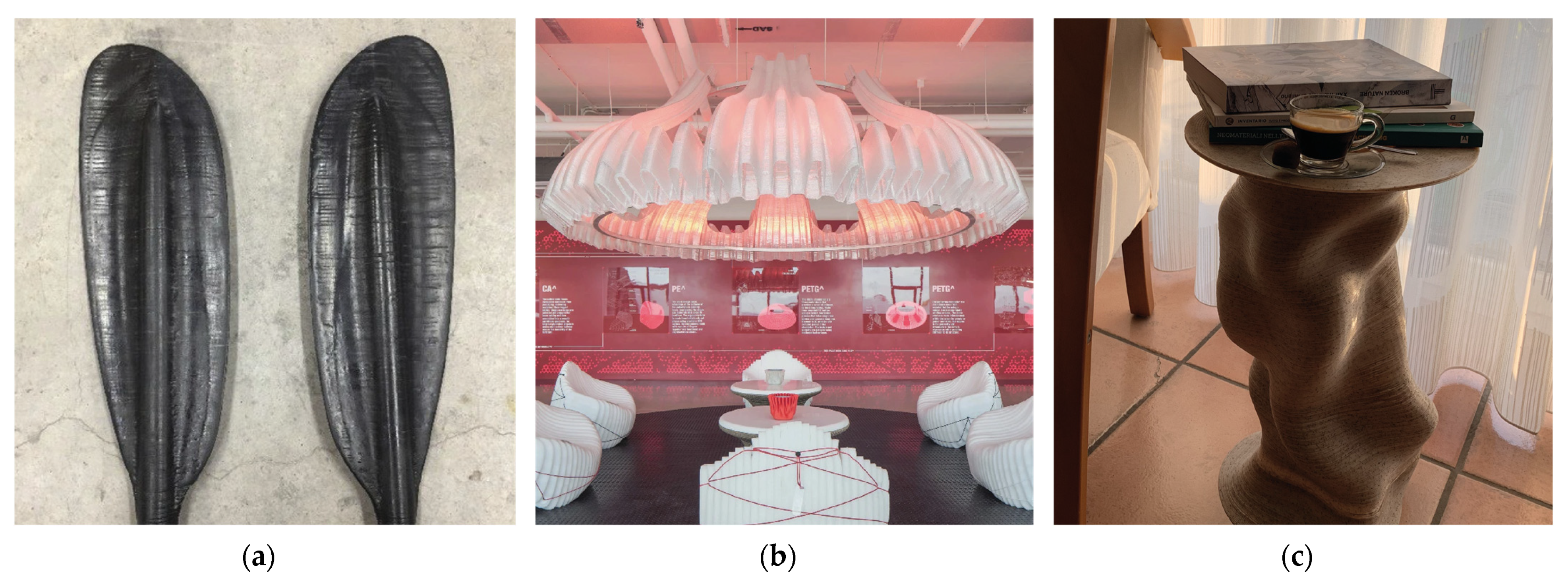

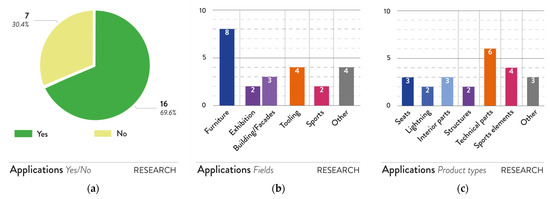

The selected works from the academic research context were then analyzed to understand the possible application fields and product categories considered during the experimental work (Table S3, Supplementary Materials). As shown in Figure 4a, only seven entries focused on materials and AM technologies without working on demo products, whereas more than two-thirds of the publications studied one possible product application at least (16 entries). According to Figure 4b, furniture (eight elements) and tooling (four elements) represent the most studied application fields, followed by the interior design macro-area (five entries), i.e., building or facade elements and exhibitions. In detail, different types of products stand out as typical categories to be explored in the academic research context (Figure 4c), especially technical parts and equipment (10 products), such as sports equipment, e.g., kayak paddles (Figure 5a), household spare parts, and molds [43,61,79]. This fact can be due to the specific materials studied in the different works, such as fiber-reinforced plastics, and the characterization performed to assess their technical properties, e.g., mechanical ones. Furniture products, such as lights (Figure 5b), stools, chairs, or tables (Figure 5c), are also commonly fabricated as proofs-of-concept (nine entries) [67,75,80]. Despite the limited amount of product case studies from academic research, these results confirm the growing interest in detecting new potential fields for secondary raw materials and LFAM processes. The results also highlight the role of research in opening new paths to be exploited in real-world scenarios [34], as well as increasing the Technology Readiness Level (TRL) of these materials and processes to reach the market.

Figure 4.

Application analysis of the research context: (a) study of new applications; (b) application fields; and (c) product types.

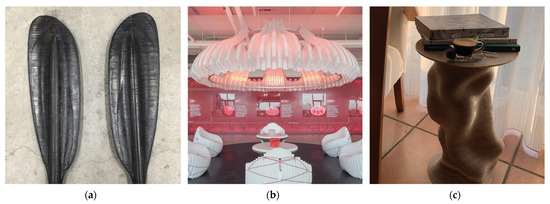

Figure 5.

Examples of demo products studied in the experimentations from the research context: (a) kayak paddles made of recycled ABS [43]; (b) “Gathering Chandelier” made in recycled PET [75]; and (c) coffee table made in virgin PLA filled with spent coffee grounds [67].

3.2.3. Product Analysis: Formal and Manufacturability Analysis

Despite the limited number of products retrieved in the research field, the product analysis provided a preliminary understanding of the shape language of the new products obtained with large-format AM and recycled feedstocks and the influence of the process itself on the final parts (Tables S4 and S5, Supplementary Materials).

The formal analysis was conducted to define the form generation approaches dealing with LFAM processes and recycled feedstocks (Figure 1a,b). As shown in Table S4 (Supplementary Materials), the analyzed products mainly have primitive shapes (11 products) [61,63,73] or hybrid (8 products) [66,75], whereas freeform approaches and organic shapes are less used [68,77]. The overall product architecture can be additive (seven products) [61,74], integrative (nine products) [75,80], or integral (seven products) [76,77]. This fact shows no significant trends in formal choices connected to the overall shape, mainly due to the focus on material characterization or manufacturability in the retrieved works.

The manufacturability analysis investigated the influence of LFAM and recycled feedstocks on the product’s shape and finishing (Figure 1c–f). According to Table S5 (Supplementary Materials), extrusion-like shapes are the most used in this context (13 products) [60,66], which can be connected to the trend in primitive shapes detected from the formal analysis. Sweep-like shapes are also quite used (6 products) [63,78], especially when using integrative or integral form-giving approaches. In this case, the main shape can also be affected by the printability of the secondary raw materials studied for LFAM, leading to fewer overhangs and complex shapes in cases of low printability, e.g., extrudate inconsistency and under-extrusions. Most products were 3D-printed using an infill or lattice structure (11 products) [43,73], showing specific design strategies for time and weight reduction only in a few cases, e.g., designing the 3D printing path in open perimeter shapes [79], or no infill (7 products) [67,80], as explained in Section 3.3. This trend can be due to the core research focus of the retrieved entries, which is mainly connected to materials or manufacturing engineering and less on product design and development (Section 3.1). The LFAM process parameters and the selected secondary raw materials studied in the retrieved works also influence the surface appearance and finishing of the 3D-printed products fabricated as demos. In this case, most retrieved products have a layer-by-layer appearance (20 products) [75,77], and the expressive-sensorial qualities are affected by the secondary raw materials and the specific scraps or byproducts, e.g., colors and patterns. Only one product used 3D-printed textures on the surfaces to modify the layer-by-layer appearance [78], whereas two underwent additional post-processing steps to achieve a smooth surface or add waterproof coatings [43,76]. However, this further processing increases costs, timings, and environmental impacts. Hence, it should be used only for value-added functions, e.g., technical requirements.

The analyzed products mostly adopt conventional strategies for slicing or designing the extrusion paths for fabrication, with only one product exploiting nonplanar slicing techniques [67]. As discussed in Section 3.3, non-conventional strategies, i.e., nonplanar slicing [58], can foster the fabrication of freeform products and optimize their fabrication strategies. However, they often require specific skills connected to product design and development. Furthermore, they are usually adopted with robotic arm systems, confirming the trend in exploring new secondary raw materials and their printability rather than the design opportunities connected to them.

3.3. Practical Context: Design Practice and Industrial Activities

3.3.1. Scraps, Materials, and AM Process Analysis

Real-world activities play a pivotal role in spreading new product applications with MEX LFAM systems and recycled materials, as well as deepening the knowledge about the exploitation of new technologies and materials from waste [18]. This sub-section analyzes the use of scraps, byproducts, and waste as secondary raw materials and MEX LFAM, i.e., waste- or biomass-based feedstock (Tables S6 and S7, Supplementary Materials).

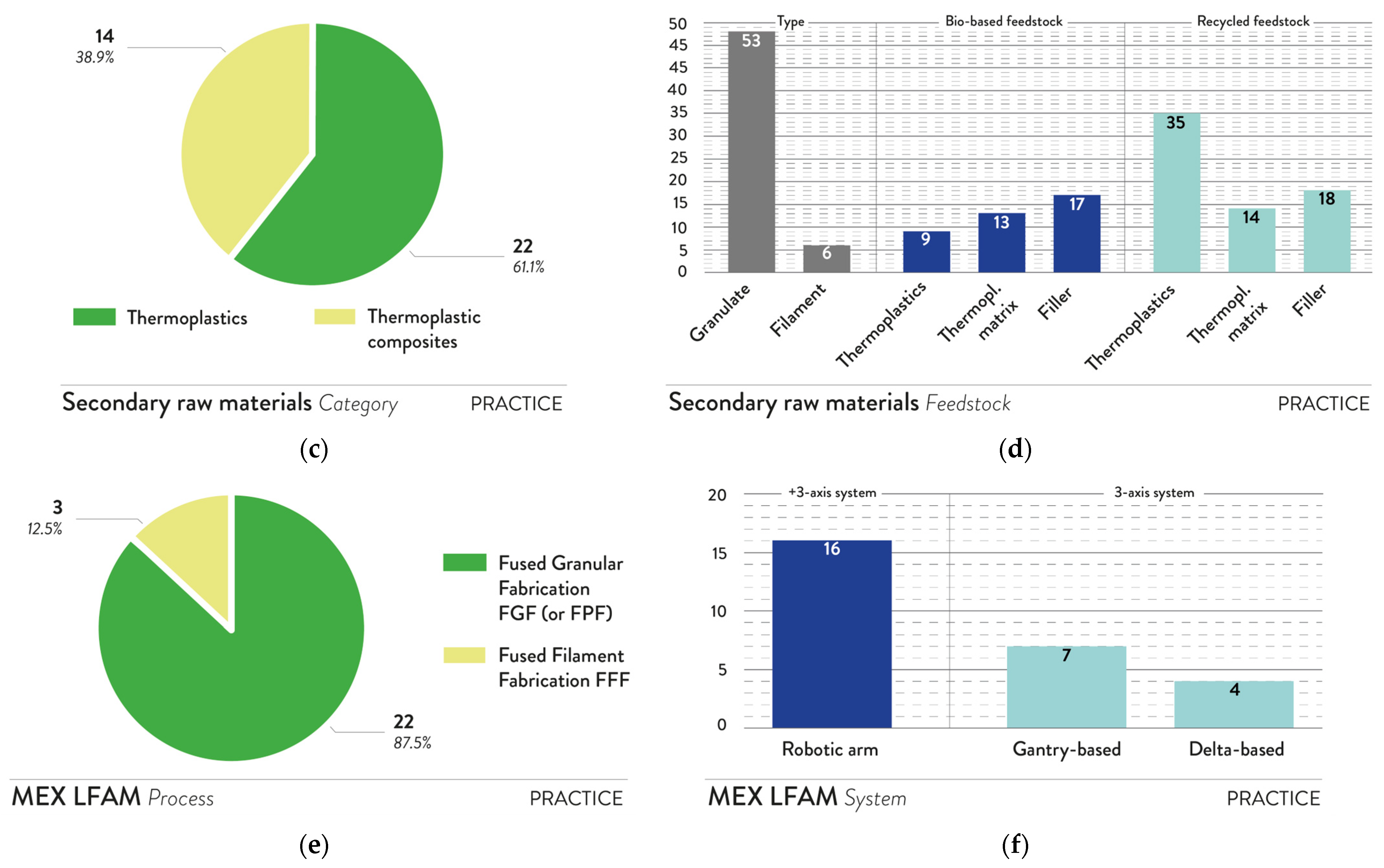

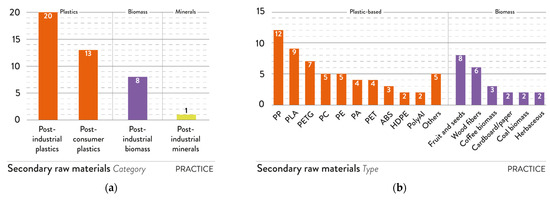

As mentioned before (Section 3.1), several studios and industries successfully connected design practice with AM and circular economy through materials-driven strategies [34]. According to Figure 6a, they mainly work with post-industrial scraps and byproducts, either plastics or biomass, corresponding to two-thirds of the entries. Post-consumer plastics are also quite spread as a starting point for new product applications (12 entries), also combining them with post-industrial mineral scraps in one case study [91]. In this context, PP (12 entries) [83,96], PLA (9 entries) [84,99], and PETG (7 entries) [44,95] are the most used plastics, followed by PC and PE with five entries each (Figure 6b) [90,97]. In most cases, studios and industries usually recycle products at their end-of-life through mechanical processes, i.e., by shredding scraps, failed parts, or disposed components [81,87]. This practice can keep in the loop the most common plastics used for consumer goods, such as plastic packaging [90,93], old house appliances [81,97], or discarded fishing nets [91,101]. Biomass waste mainly derives from the agricultural and food sectors; therefore, they originate from fruits and seeds (eight entries) and wood fibers (six entries) or focus on specific waste streams (three entries), such as spent coffee grounds [46,84], fruit husks [87,92], and wood fibers or sawdust [85,93]. However, some challenges still exist to using these scraps or byproducts, i.e., limited competitiveness of the resources [35]. As confirmed from Figure 6c, thermoplastics are mostly selected as secondary raw materials for MEX LFAM for real-world applications (22 entries), such as fully recycled plastics [83,100], thermoplastic blends [86,89], or blends with virgin materials [92,97]. This fact is also connected with the business models of some case studies [45,94,97]. These realities encourage waste collection, e.g., plastics at their end-of-life, from customers and citizens or create distributed manufacturing networks. Nevertheless, composite materials are also used in this context, and recycled plastics can be matched with fibers, e.g., glass fibers, for high-performance applications [95,96,99]. Similar to the academic field, granulate feedstocks are widely used, e.g., pellets or flakes from shredding (53 cases, Figure 6d), although filaments still represent an alternative adopted in 6 cases with FFF apparatuses [88,92]. The recycled feedstocks are reprocessed to be used as thermoplastics in most cases (35 cases), e.g., recycled PA and PETG [44,82], with significantly few examples dealing with composites, either as matrixes (14 entries) or fillers and reinforcements (18 entries). However, there is a noticeable interest in bio-based feedstocks exploring their use, especially as fillers or reinforcements (17 entries), e.g., wood fibers, hemp, or olive groves [84,90,93]. According to the results, large-format processes can help scale up recycling and upcycling processes, combining bigger volumes of waste streams and long-lasting applications.

Figure 6.

Scraps, secondary raw material, and AM process analysis of the practical context: (a) scraps and/or byproduct category; (b) scrap and/or byproduct type; (c) secondary raw material category; (d) secondary raw material feedstock type, with a focus on bio-based and recycled feedstocks; (e) MEX LFAM process; and (f) AM system.

Focusing on MEX AM, the retrieved case studies use FGF or FFF processes (Figure 6e), with only three studios or industries using filament feeding systems [88,92,101]. Again, FGF represents a flexible option to use a broader variety of feedstocks, fabricate bigger parts, and reprocess larger volumes of waste streams, e.g., from industry or citizenship actions [45,97]. Accordingly, the 3D printing apparatus has been modified, customized, or fully developed to improve printability in most cases (17 entries), either as research and craft activity, e.g., in design studios [81,87], or standardized development processes, such as for AM system producers [94,100]. Furthermore, some case studies rely on 3D printing systems developed by other established industries in the LFAM sector, which also exploit their own technologies for product applications with new secondary raw materials [94,95,97]. Despite some collaborative approaches, the processes and equipment are mostly proprietary or patented. Contrarily to the research context, no open-source machines were retrieved in the selected case studies, and few details are available on the main hardware modifications and 3D printing parameters. Furthermore, machine setups are mostly based on multi-axis robotic arms (16 entries) [45,98], achieving more intricate geometries and freeform shapes compared to three-axis systems (Figure 6f) [85,87,100]. Both facts arise from this specific context, where 3D printing is part of the core business of the analyzed entries and contributes to their existence and market competitiveness. Therefore, offering broader opportunities in terms of achievable shapes, 3D printing setups, and materials becomes a strategy to establish new market niches.

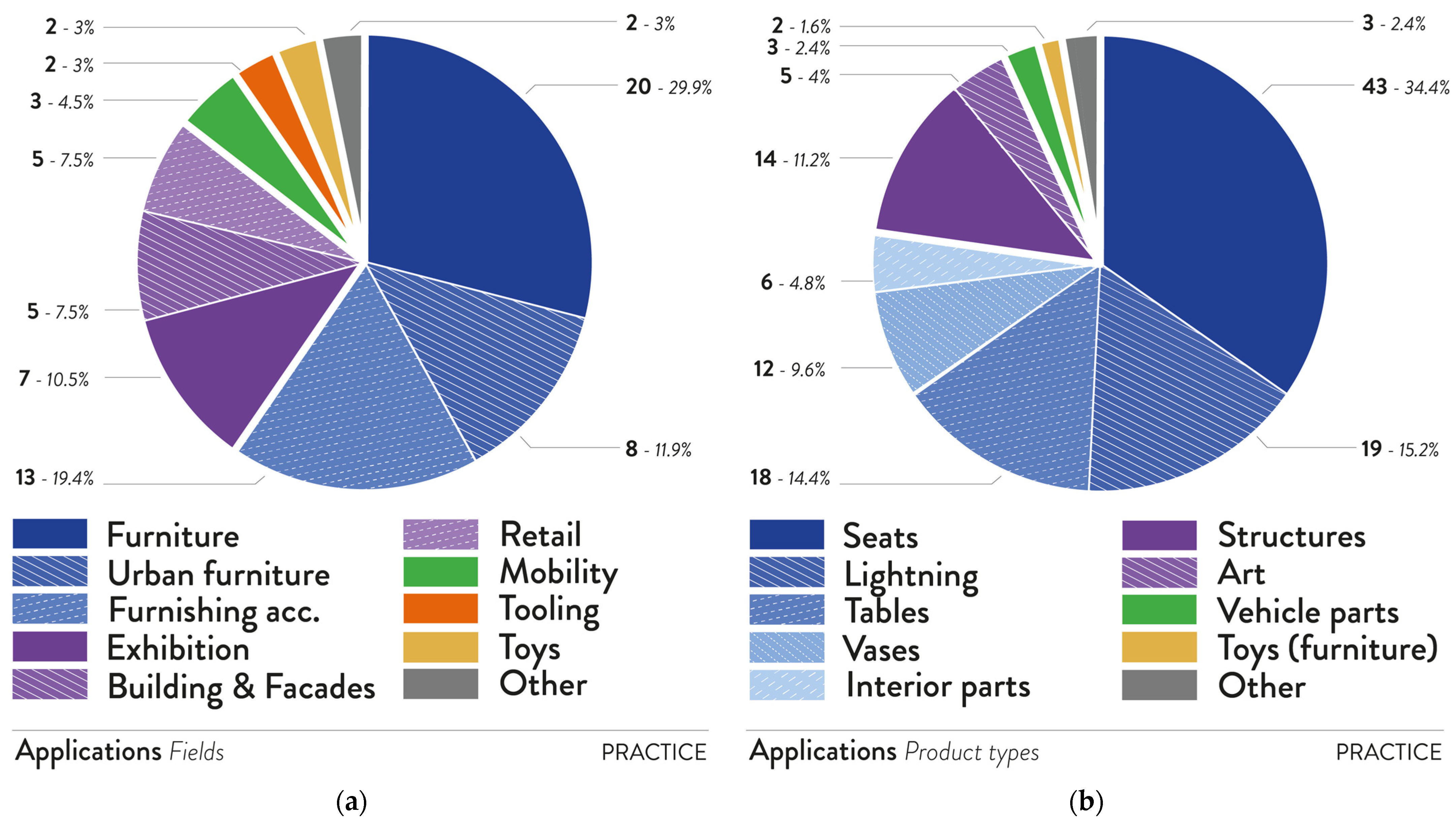

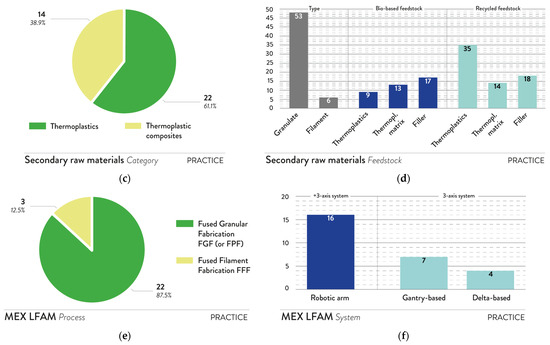

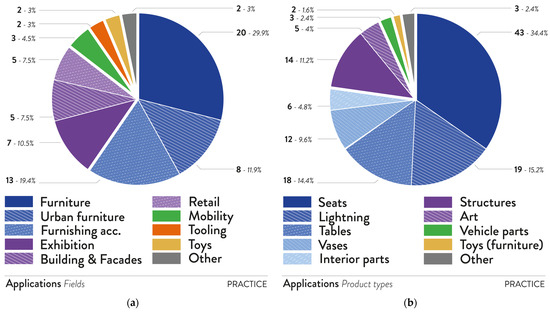

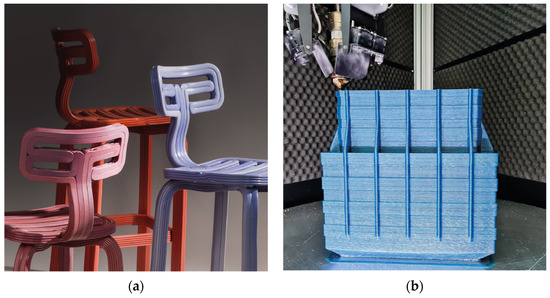

3.3.2. Applications Analysis

The analysis of the case studies outlined the trends in the application fields and product categories explored using MEX LFAM processes and new secondary raw materials from recycled plastics and biomass waste (Table S8, Supplementary Materials). As from Figure 7a, more than half of the case studies (~60%) relate to the furniture sector, including indoor furniture, urban and outdoor furniture, and furnishing accessories, i.e., vases and lightning elements. Another well-represented macro-area is the interior and architectural design (~25%) that comprehends artifacts for exhibitions, stands, and retail, as well as structural and decorative parts of buildings and facades. Other applications represent around one-tenth of the entries and include technical sectors, i.e., mobility and transportation or tooling, and specific markets, i.e., fashion, toys, and sports. This fact is connected to the increased dimensions, feed, flow rates, and freeform shapes achievable through LFAM, especially with robotic arms. Furthermore, these features fit well with the average scale of the products from the retrieved sectors. In general, the case studies are mostly connected to long-lasting types of products, also with structural constraints. As shown in Figure 7b, almost 80% of the cases relate to the furniture sector, especially seats (~34%), including benches, chairs (Figure 8a), lounge chairs, lightning elements (~15%), or interior parts (~5%), such as lamps and room dividers [81,87,97]. Structures are also a spread typology of products, usually connected with exhibitions, interiors, and architectural design [82,84,98]. Parts for other sectors represent only ~6% of the case studies (8 products), usually connected with transportation, e.g., boat components [96,98] or toys [84,99]. According to the analysis, these case studies are mostly linked to small production batches, e.g., stool series (Figure 8b) [87], or even almost unique parts, such as design explorations from studios [44,46], leading to customized outcomes in terms of materials and geometries. Nevertheless, these practices contribute to legitimizing the role of MEX LFAM in fostering circular economy practices by creating new market niches and spreading these products to different user audiences.

Figure 7.

Application analysis of the practical context: (a) application fields; and (b) product types.

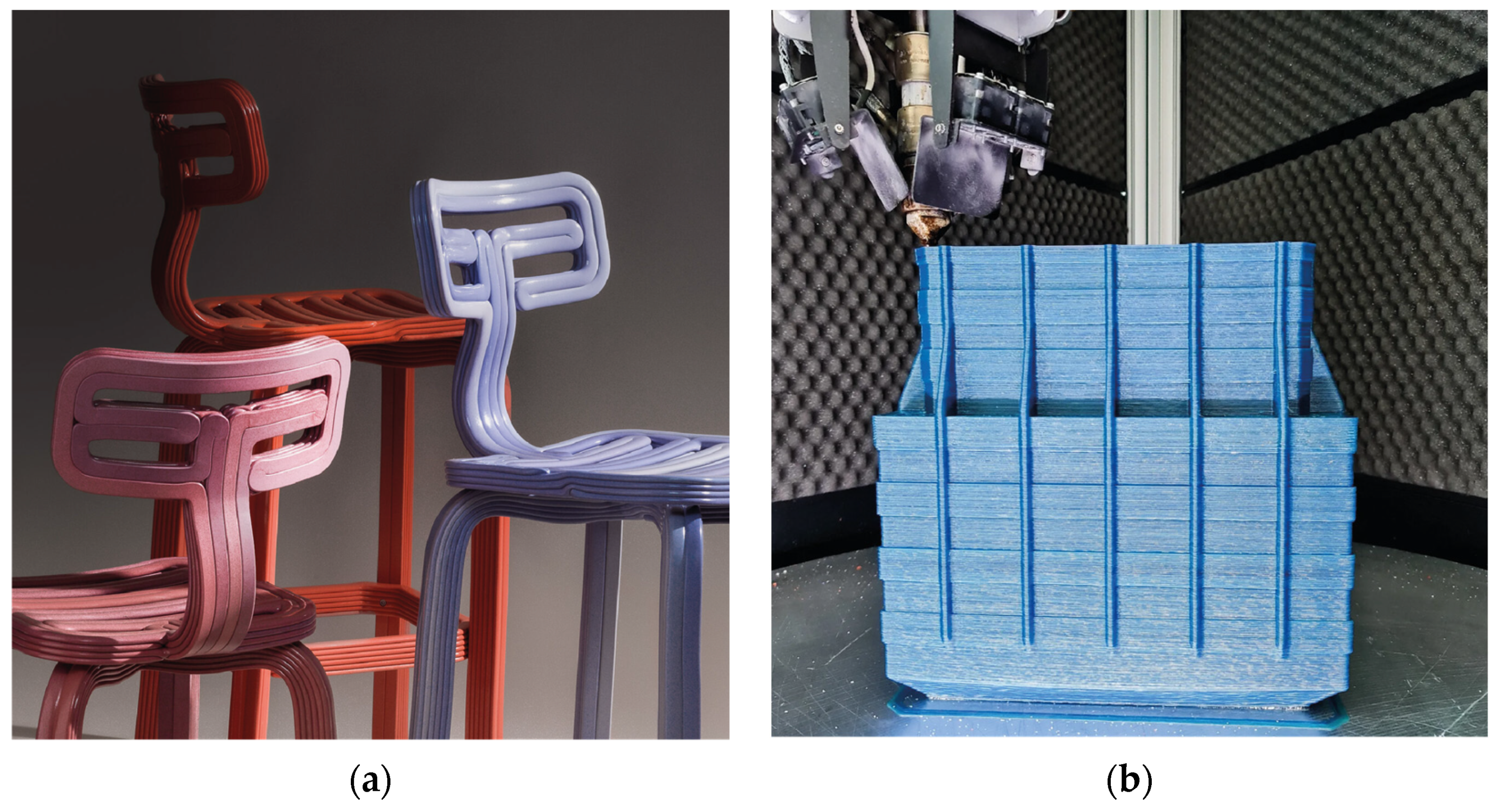

Figure 8.

Examples of products retrieved from the practice context, i.e., design practice and industrial activities: (a) “Chubby” chairs by Dirk Van Der Kooij (reprinted with the permission from Studio Kooij) [81] and (b) “Velaskello” stool by SuperForma (reprinted with the permission from SuperForma S.r.l.) [87].

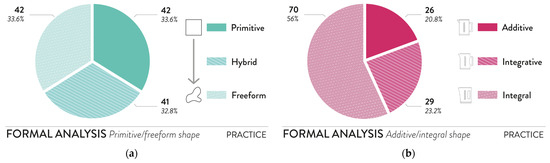

3.3.3. Product Analysis: Formal and Manufacturability Analysis

The selected products from the retrieved companies or studios were analyzed to understand the formal language of new products for MEX LFAM and recycled feedstock, as well as the influence of the process on the objects (Tables S9 and S10, Supplementary materials).

The formal analysis investigated the form generation approaches used by companies or studios (Figure 1a,b), reported in Table S9 (Supplementary Materials). On the one side, primitive, hybrid, and freeform approaches are equally adopted in practical contexts (Figure 9a), showing a significant commitment to exploring all the different shape opportunities enabled by AM. On the other side, integral approaches are mostly used for products, representing ~56% of the cases, according to Figure 9b. In general, this fact is consistent with the use of AM to achieve complex geometries and part integration, reducing the assembled components in a product and including them in its overall shape [51]. Focusing on the specific companies and product typologies, three main trends can be highlighted in using the different form-giving approaches: (a) artifacts with a freeform and integral shape (32 products), (b) objects with a primitive and integral form (24 products), and (c) parts with mixed approaches. The former group is strictly connected to the formal possibilities enabled by AM technology, which allows designing organic and complex shapes in a single step, e.g., part integration. Hence, the multiple functions of products are incorporated in a single main shape, which predominates over the others. Light elements and seats mainly follow this trend in formal languages, such as Stratum (The New Raw) [45], Elemental (Post Industrial Crafts) [89], or Nital (Nagami) [44]. For instance, it is possible to incorporate the seating area, the back, and the legs in the main shape of a chair. Moreover, these products mainly exploit well-established secondary raw materials for AM, such as recycled commodity thermoplastics [44,45]. Primitive and integral forms of the second group are also linked to the capability of AM to integrate different parts in one component, especially for tables and lightning, e.g., Pixel brick (Aectual) [97], Amphora (Model N°) [85], or Alp round (Lowpoly) [84]. This formal combination is often combined with secondary raw materials from less conventional scraps or byproducts, such as thermoplastic-based composites or biomass scraps, e.g., drink bricks or coffee scraps [84,97]. In addition, some products adopt mixed options, e.g., hybrid and integrative or hybrid and integral, whereas additive approaches are less used combined to freeform shapes. Dealing with bigger dimensions, volumes, and weights, the additive approach for products from LFAM means assembling different components or manufacturing parts with challenging features for large-format 3D printing, i.e., overhangs.

Figure 9.

Product analysis of the practical context: formal analysis on (a) primitive vs. freeform shape form-giving approach, and (b) additive vs. integral shape form-giving approach; manufacturability analysis on (c) main external shape, (d) 3D printing building mode, (e) surface appearance and finishing, and (f) planar or nonplanar slicing.

The influence of LFAM of recycled feedstock on the product shape and finishing (Figure 1c–f) was investigated to find some connections with the formal analysis (Table S10, Supplementary Materials). As resumed in Figure 9c, sweep- and loft-like shapes are the most used when designing new products (~50%), such as Trusschair (Wasp) [94] and Lumbar (VanPlestik) [83]. Extrusion-like shapes are also used with LFAM (~26%), e.g., Boxy (Aectual) [97] and Twine (HagenHinderdael) [88], although they do not fully exploit the design freedom allowed by AM. To this extent, customization and reduced manufacturing times may justify extruded shapes for big and heavy parts, e.g., reducing costs and times for their transportation and assembly. In this case, the approach follows the principles of time, weight reduction, and material waste optimization (Figure 9d). Only ~6% of the case studies were printed using an infill, which strongly affects the 3D printing times and the overall weight. These products can also be challenging to remove from the 3D printing bed, dealing with excessive weight or a wide contact area from dense infill grids or bottom layers. Furthermore, these case studies mostly used lower percentages, reaching around 10% of infill density for structural purposes or components, i.e., boats and technical components (Drifty, HB3D) [96]. The preferred configuration is the hollowed shape (64%), commonly linked to the “spiral” or “vase” 3D printing mode, reducing the required timings and feedstock to achieve the final shape (Satellite, Kooij, or 3D bar, Caracol AM) [81,99]. This choice also helps manage some technical constraints from the increased format of LFAM and the use of secondary raw materials, e.g., thermal and compressive models of the bigger extrusion paths deposited by the extrusion head [53]. Furthermore, supports and complex overhangs are usually avoided, as their use generates high amounts of scraps or increases the possibility of failures and damages. In some cases, manufacturing hollowed parts or shapes defined by perimeters allows designers and engineers to “design extrusion paths”, trying to minimize timings and materials by controlling the movements of the 3D printing system. This strategy results in products where the extruded path is often quite visible and recognizable, influencing its aesthetics and using the extruded line as a formal element to define its product’s aesthetic and identity, e.g., Eel (Ekbacken Studios) and Aurora (Superforma) [87,91]. These aspects also affect the surface appearance and finishing. According to Figure 9e, the extrusion path is used as a feature to define the surface texture of the product. Hence, the layer-by-layer appearance is used as a texture to be kept rather than hiding through post-processing (68%). Some examples show gradients or random-like color differences through the extrusion path, such as for Ermis (The New Raw) [45]. This color variation generally comes from the pellet-based feeding system. Moreover, recycled feedstocks can add further randomness in the color patterns, e.g., from different scrap batches or variations in biomass, e.g., bar counter (Lowpoly) [84]. These are meant to be valorized or even designed in 3D-printed products, highlighting the product uniqueness and customization. In other cases, these effects are emphasized by nozzle diameters and thicker layer heights, reproducing a “low resolution” effect (~10%). In this case, the path is explicitly shown to the users, creating a linear pattern on the surface, such as Tripod Maxi (Post Industrial Crafts) [89] and Chubby (Kooij) [81]. Its choice is linked to technical and economic constraints, cutting time and costs. Designers and engineers can, therefore, consider it an opportunity to exploit technical features rather than a constraint, potentially representing a driver in defining the product’s aesthetic and identity. The layer-by-layer appearance can be partially or completely hidden through 3D-printed textures (20%) or additional post-processing (~2%). The former case generally creates some textures during the extrusion process, emphasizing their pattern rather than the layer-by-layer appearance, i.e., pleats, waves, drapes, or knits (Mawj, Nagami) [44]. As the latter strategy adds further manufacturing steps, post-processing is less frequent in big parts with complex geometries because it increases manufacturing times and costs. Post-processing is generally connected to specific performances to be reached, e.g., low values of roughness for vehicles (Beluga, Caracol AM) [99]. Although some case studies used post-processing, it is usually avoided for new design applications with LFAM and recycled feedstocks, valorizing the finishing given by the process and the secondary raw materials.

Since designers and engineers are shifting their mindset from “designing 3D-printed volumes and surfaces” to “designing extrusion paths” thanks to generative design tools, they are also exploiting additional strategies to use AM and non-conventional extrusion path generation [103]. Among those, nonplanar slicing allows using curvilinear layers and bent parts to fabricate freeform products. It mainly consists of nonlinear movements of the extruder head on the z-axis, which conventionally follows planar paths on the xy plane [58]. This technique is mainly used for products fabricated with a robotic arm, which has more degrees of freedom and better positions the extrusion head during fabrication. Although most companies or design studios analyzed in this work use robotic arms (Figure 9b), only ~17% of the case studies adopted nonplanar strategies, e.g., The Elements (The New Raw) [45] or Cool Egg (Triboo) [90] (Figure 9f). This discrepancy mainly shows a gap in the practical implementation of curvilinear paths and nonplanar slicing, despite its potential to reduce the use of supports. It is still seen as an experimental strategy requiring high expertise and vertical knowledge of AM technologies or further development to achieve consistent extrusion paths with recycled feedstocks.

3.4. New Product Applications with MEX LFAM and Recycled Feedstock

Some trends emerged from the analysis of academic research and practical fields focused on new product applications with MEX LFAM and recycled plastic- or biomass-based secondary raw materials. In detail:

- Academic context. Although MEX LFAM and recycled feedstocks started to be studied in 2018, applications from the academic field have been studied since 2019. In this case, publications mostly involve materials and manufacturing engineering or design and sustainability fields. They aim to demonstrate the reliable use of the studied technologies and materials by fabricating a demo product, mostly furniture or tooling equipment. Custom three-axis 3D printing systems are usually selected for the investigations, especially when dealing with emerging material formulations and granulate feedstocks, e.g., thermoplastic blends or fiber-reinforced plastics.

- Practical context. The use of MEX LFAM with recycled feedstocks has been increasing in the last few years, especially since 2018. Different industrial and design realities are approaching these technologies to develop their products, ranging from machinery producers to design studios, often collaborating with education, research, or industry institutions. Custom robotic arms are quite used in this context, also connected to patented processes. Recycled commodity thermoplastics are often used for well-established applications and products, such as furniture, and some investigations consider more technical sectors, e.g., transportation, conventional product scraps, and biomass-based feedstock.

Despite the common interest, similarities and differences in studying or using MEX LFAM and recycled feedstocks were also detected from the analysis of the two contexts. These aspects are connected to the materials, technologies, and applications, as well as to specific aspects related to product shape and manufacturability. In detail:

- Materials. Scraps and byproducts can be either from post-industrial polymers and biomass, e.g., provided by industrial supply chains or the agro-industrial sector, or post-consumer plastics, such as commodity goods. The academic sector exploits a wider range of granulate material formulations, such as blends or composites, whereas design and industrial projects mostly explore recycled thermoplastics, starting to explore bio-based secondary raw materials as fillers and reinforcements.

- AM technology. FGF and granulate feedstocks are widespread in both contexts, despite some case studies on filaments from the practical context. Custom or modified AM systems are mostly used, allowing to further customize materials and processes. The academic sector mainly exploits three-axis systems, e.g., gantry or delta, either patented or open source, whereas proprietary robotic arms are widely adopted from the practical context.

- Applications. There are some consolidated fields for MEX LFAM with recycled feedstocks, i.e., furniture and architectural design, which mainly use AM for customization and complex shapes. Realizing architectural and interior design parts can speed up production times and exploit big waste streams, detecting valuable market niches. However, new technical applications have been emerging, especially in the academic context, usually connected to transportation, sports, and high-performance parts.

- Formal language and product shape. Despite a limited commitment to shape exploration from the academic context, most products from MEX LFAM follow integral form-giving approaches, integrating their function into the main product shape. Primitive or freeform geometries are used, defining two approaches corresponding to specific application fields, e.g., tooling or furniture. Both approaches aim to reduce material usage, optimize volumes and weights, i.e., through part integration, and achieve good printability of the secondary raw materials, e.g., constant extrudate.

- Manufacturing influence on products. MEX LFAM often uses sweep- or loft-like geometries for new products with recycled feedstock. However, extrusion-like shapes can be selected for large-scale applications when speeding up production compared to other technologies or studying new material formulations, e.g., in the academic field. Especially in real-world contexts, 3D-printed artifacts tend to avoid infill and optimize perimeters and extrusion paths to reduce 3D printing times, tune structural properties, and limit material usage. The layer-by-layer appearance is widely used or emphasized as a distinguishing element of the product identity, except for functional purposes or technical applications. “Designing extrusion paths” and using non-conventional slicing techniques, i.e., nonplanar slicing, progressively help to overcome process constraints and reduce material usage. However, their real-world exploitation requires high-level technical skill sets, limiting their adoption.

3.5. Limitations and Future Perspectives for LFAM and Recycled Feedstock

The analysis of this work also highlighted some limitations in using MEX LFAM with recycled feedstocks. First, the range of applications is mainly restricted to furniture-related sectors or architectural and interior design. Technical applications are currently limited to some demo products or only explored in the academic context. Despite the focus of this work on biomass-based and plastic feedstocks, different material feedstocks can be selected for technical applications, e.g., metals and ceramics. Metal alloys and powders combined with binders can be processed with MEX [104] and other AM processes, such as Binder Jetting and Direct Energy Deposition [105]. Nevertheless, the use of recycled metal feedstocks is still limited to small-format apparatuses [106], as well as the exploitation of non-MEX LFAM processes for recycled feedstocks. Ceramics can also be exploited in MEX LFAM, e.g., concrete with contour crafting 3D printing or Direct Ink Writing [107], representing an emerging opportunity mostly for construction and architecture. Considering MEX LFAM and plastic-based feedstocks, surface finishing from big nozzles and thick layer heights may significantly affect the properties of final products, especially using recycled feedstock or achieving inconsistent extrudates. For this reason, their post-processing increases the time and cost of components, making them less attractive from an industrial perspective. This issue should be considered for products with constraints regarding surface properties or wide surfaces to be post-processed, mostly from technical sectors. Finally, the scale of LFAM processes with plastic-based feedstocks changes the thermal and compressive behavior of the parts, i.e., requiring long cooling times and deforming the layers for the overall weights. These technical constraints require higher levels of expertise among designers and engineers in real-world scenarios, especially to exploit non-conventional slicing strategies to fabricate freeform-like products or optimize material usage.

These constraints also represent possible research opportunities, impacting the practical and industrial contexts, as supported by recent publications and projects retrieved in the third quarter of 2024. In the next few years, LFAM can foster the use of new secondary raw materials by connecting different stakeholders, for example, establishing new industrial symbiosis practices [108,109]. The growing interest by industrial partners and policymakers can lead to a wider variety of recycled material feedstocks, e.g., metal waste, and LFAM apparatuses, either MEX or non-MEX-based. This high commitment also encourages scaling up opportunities, improving the TRL of existing small-format solutions at the lab scale, and helping them reach the market, e.g., DIW for product applications [110]. At the same time, optimizing recycling processes and developing more accessible AM equipment and methods will further increase the opportunities for new circular applications with LFAM, e.g., aerospace [111,112]. Finally, education and dissemination activities represent a crucial step to widen the exploitation of MEX LFAM and recycled feedstocks, e.g., providing the skillset to study new material formulations or exploit optimization and non-conventional slicing. Some realities have already been involved in this process, e.g., working as a service for other companies or organizing seminars [86,87]. This fact helps gain direct experience in the process, hence a higher level of experimentation and formal complexity. Broader collaboration networks of stakeholders, such as companies, universities, and research facilities, can further support new product applications, for instance, by studying and sharing data and procedures.

4. Conclusions

This work investigated the relevant case studies from the academic and practical contexts dealing with new product applications fabricated with large-format MEX AM of recycled plastics and biomass waste feedstocks. The objective was to understand the current situation and detect some trends and limits by analyzing 23 publications and 24 companies or design studios, considering 23 and 125 different products for the analysis, respectively. First, the selected and their main application fields were analyzed considering the activity year, the studied scraps and byproducts, the new secondary raw materials, and the 3D printing process. The aesthetics impact and manufacturability of products using MEX LFAM and recycled feedstocks were then investigated, highlighting some form-giving approaches and manufacturing aspects adopted in the different sectors. The main trends and principles, together with some limitations, were finally outlined after the analysis to stimulate further research and knowledge transfer on the topics.

The interest in using large-format MEX AM processes is progressively growing in both contexts, especially in the last five years and in real-world applications. New products also come from collaborations between industries, designers, and different institutions, relying on comprehensive expertise on materials, technologies, and design principles. Recycled thermoplastics from common consumer goods and biomass-based waste feedstock from the agro-industrial sector have been exploited for LFAM extruders and custom 3D printing systems, representing promising alternatives to virgin materials in both contexts. Some application fields, i.e., furniture, are quite widespread, whereas some technical sectors are starting to approach LFAM with recycled feedstocks for specific markets, i.e., transportation and tooling. These 3D-printed products usually follow an integral form-generation approach, using primitive or freeform shapes. Optimized extrusion paths, 3D printing times, and material usage are the key aspects considered in fabricating artifacts with MEX LFAM and recycled feedstocks. Layer-by-layer appearance becomes a feature to strengthen the product identity when using LFAM, together with the secondary raw material patterns. However, technical applications still require post-processing steps to fulfill their functions, increasing timing and costs.

Future research should focus on expanding the range of MEX LFAM applications for recycled feedstocks, especially for technical sectors, as well as evaluating the environmental impacts through real-world case studies. Spreading the expertise and practical knowledge related to these processes and materials can positively impact design practice and sustainable production and consumption, especially fostering design freedom enabled by AM for secondary raw materials within real-world contexts.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su16187966/s1, Table S1: List of the selected works (academic research context) analyzed according to the waste/scrap/byproduct (category and type) and secondary raw material (type and composition); Table S2: List of the selected works (academic research context) analyzed according to the MEX LFAM processes (features and setups), and the main 3D printing parameters (nozzle diameter, feed rate, and layer height); Table S3: List of the selected works (academic research context) analyzed according to the application fields and the demo products studied in the experimentations selected for the case study analysis (product names or description, year, and types; Table S4: List of the selected works (academic research context) analyzed according to the demo products studied in the experimentations selected for the case study analysis (product names or description, year, and types) and the form-giving approaches adopted in their development [55]; Table S5: List of the selected works (academic research context) analyzed according to the demo products studied in the experimentations selected for the case study analysis (product names or description, year, and types) and the approaches to product shape manufacturability with MEX LFAM: main external shape (1. Extrusion-like; 2. revolution-like; 3. Sweep/loft-like; 4. Freeform/irregular like); 3D printing building mode (1. Infill/lattice; 2. Hollowed parts; 3. Open perimeter parts); surface and finishing appearance (1. Layering; 2. Added texture; 3. Low-resolution layers; 4. Post-processing); and use of nonplanar slicing; Table S6: List of the selected companies/studios (practice context, i.e., design practice and industrial activities) analyzed according to the waste/scrap/byproduct (category and type) and secondary raw material (type and composition); Table S7: List of the selected companies/studios (practice context, i.e., design practice and industrial activities) analyzed according to the main information on MEX LFAM processes (features, machine, and specific setups); Table S8: List of the selected companies/studios (practice context, i.e., design practice and industrial activities) analyzed according to the application fields and the products selected for the case study analysis (product names or description, year, and types); Table S9: List of the selected companies/studios (practice context, i.e., design practice and industrial activities) analyzed according to the products selected for the case study analysis (product names or description, year, and types) and the form-giving approaches adopted in their development [55]; Table S10: List of the selected companies/studios (practice context, i.e., design practice and industrial activities) analyzed according to the products selected for the case study analysis (product names or description, year, and types) and the approaches to product shape manufacturability with MEX LFAM: main external shape (1. Extrusion-like; 2. revolution-like; 3. Sweep/loft-like; 4. Freeform/irregular like); 3D printing building mode (1. Infill/lattice; 2. Hollowed parts; 3. Open perimeter parts); surface and finishing appearance (1. Layering; 2. Added texture; 3. Low-resolution layers; 4. Post-processing); and use of nonplanar slicing.

Author Contributions

Conceptualization, A.R. and M.L.; methodology, A.R.; software, A.R.; validation, A.R. and M.L.; formal analysis, A.R.; investigation, A.R.; resources, A.R.; data curation, A.R.; writing—original draft preparation, A.R.; writing—review and editing, A.R. and M.L.; visualization, A.R.; supervision, M.L.; project administration, M.L.; funding acquisition, M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Publicly available data sets were analyzed in this study. The data can be found here: [https://doi.org/10.5281/zenodo.13673019 (accessed on 8 September 2024)]. If these data are used, please cite them in the following way: [data set] Alessia Romani and Marinella Levi. 2024. Large-Format Material Extrusion Additive Manufacturing for circular economy practices: a focus on product applications with materials from recycled plastics and biomass waste; https://doi.org/10.5281/zenodo.13673019 (accessed on 8 September 2024).

Acknowledgments

The authors acknowledge M.P. for the preliminary support for case study collection.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| ABS | Acrylonitrile Butadiene Styrene |

| AM | Additive Manufacturing |

| ASA | Acrylonitrile Styrene Acrylate |

| BAAM | Big Area Additive Manufacturing |

| CF | Carbon Fibers |

| DfAM | Design for Additive Manufacturing |

| DRAM | Distributed Recycling for Additive Manufacturing |

| FDM | Fused Deposition Modeling (Stratasys trademark) |

| FFF | Fused Filament Fabrication |

| FGF | Fused Granular Fabrication |

| FPF | Fused Particle Fabrication |

| GF | Glass Fibers |

| HDPE | High-Density Polyethylene |

| LDPE | Low-Density Polyethylene |

| LFAM | Large-Format Additive Manufacturing |

| LSAM | Large-Scale Additive Manufacturing |

| MEX | Material Extrusion |

| PA | Polyamide |

| PC | Polycarbonate |

| PE | Polyethylene |

| PES | Polyethersulfone |

| PET | Polyethylene Terephthalate |

| PETG | Polyethylene Terephthalate Glycol |

| PLA | Polylactic Acid |

| PP | Polypropylene |

| PPE | Polyphenylene Ether |

| RQ | Research Question |

| TRL | Technology Readiness Level |

| UHMWPE | Ultra-High-Molecular-Weight Polyethylene |

Appendix A. Search Record Screening and Selection

Figure A1.

PRISMA flow diagram showing the selection process of the literature review (academic research context) starting from the records identified through the query strings defined in this work.

Figure A1.

PRISMA flow diagram showing the selection process of the literature review (academic research context) starting from the records identified through the query strings defined in this work.

Figure A2.

PRISMA flow diagram showing the selection process of the companies/studios (practice context, i.e., design practice and industrial activities) starting from the records identified through the query strings defined in this work (Websites in the picture: Dezeen.com; Designboom.com; Materialdistrict.com; 3Dprinting.com; All3dp.com; 3Dprintingindustry.com, accessed on 8 September 2024).

Figure A2.

PRISMA flow diagram showing the selection process of the companies/studios (practice context, i.e., design practice and industrial activities) starting from the records identified through the query strings defined in this work (Websites in the picture: Dezeen.com; Designboom.com; Materialdistrict.com; 3Dprinting.com; All3dp.com; 3Dprintingindustry.com, accessed on 8 September 2024).

Appendix B. Academic Research

Table A1.

List of the selected works (academic research context) with their publication year and type, secondary raw materials, and MEX (Material Extrusion) LFAM (Large Format Additive Manufacturing) processes used in the experimental activities, and the fields of application studied as demo products (if any).

Table A1.

List of the selected works (academic research context) with their publication year and type, secondary raw materials, and MEX (Material Extrusion) LFAM (Large Format Additive Manufacturing) processes used in the experimental activities, and the fields of application studied as demo products (if any).

| Year | Ref. | Type | Material | MEX LFAM Process | Application Field |

|---|---|---|---|---|---|

| 2018 | 1. Horta et al. [72] | Journal article (Manufacturing) | Recycled HDPE with pine sawdust | FGF-FPF; robotic arm; direct extrusion | No applications. |

| 2. Woern et al. [59] | Journal article (Materials) | Recycled PLA, PP, ABS, PET | FGF-FPF; three-axis system; direct extrusion | No applications. | |

| 2019 | 3. Zhao et al. [60] | Journal article (Materials.) | Virgin PLA with poplar fibers | FGF-FPF; three-axis system; direct extrusion | Furniture, urban furniture |

| 4. Byard et al. [43] | Journal article (Manufacturing) | Recycled ABS, PP | FGF-FPF; three-axis system; direct extrusion | Sports | |

| 5. Reich et al. [61] | Journal article (Materials) | Recycled PC | FGF-FPF; three-axis system; direct extrusion | Tooling, household appliances | |

| 2020 | 6. Little et al. [62] | Journal article (Materials) | Recycled PET | FGF-FPF; three-axis system; direct extrusion | Medical, tooling, military |

| 2022 | 7. Bañón and Raspall [63] | Journal article (Materials) | Recycled PET | FFF; three-axis system; filament feeding | Building and facades |

| 8. Petsiuk et al. [73] | Journal article (Manufacturing) | Recycled PLA | FGF-FPF; three-axis system; direct extrusion | Tooling | |

| 2023 | 9. Romani et al. [79] | Journal article (Sustainability) | Recycled PC, PC-ABS blend | FGF-FPF; three-axis system; direct extrusion | Sports, furniture |

| 10. Oberloier et al. [74] | Journal article (Manufacturing) | Recycled LDPE | FGF-FPF; three-axis system; direct extrusion | Furniture | |

| 11. Burger et al. [76] | Journal article (Design) | Recycled PETG with GFR | FGF-FPF; robotic arm; direct extrusion | Building and facades | |

| 12. Korey et al. [64] | Journal article (Materials) | Recycled CF-ABS compounds | FGF-FPF; three-axis system; direct extrusion | No applications. | |

| 13. Copenhaver et al. [65] | Journal article (Materials) | Recycled pine fiber PLA compounds | FGF-FPF; three-axis system; direct extrusion | No applications. | |

| 14. Brodmann et al. [77] | Conference paper (Design) | Virgin PLA and wood fibers | FGF-FPF; three-axis system; direct extrusion | Building and facades | |

| 15. Raspall and Bañón [75] | Conference paper (Manufacturing) | Recycled PET | FGF-FPF; robotic arm; direct extrusion | Furniture, furnishing elements | |

| 2024 | 16. Suescun Gonzales et al. [66] | Journal article (Materials) | Recycled PET and HDPE blends | FGF-FPF; three-axis system; direct extrusion | Furniture |

| 17. Burgos-Pintos et al. [78] | Journal article (Design) | Virgin ASA with cork dust | FGF-FPF; three-axis system; direct extrusion | Furniture, furnishing elements | |

| 18. Paramatti et al. [67] | Journal article (Materials) | Virgin PLA with spent coffee grounds | FGF-FPF; three-axis system; direct extrusion | Furniture | |

| 19. Romani et al. [68] | Journal article (Materials) | Multi recycled PLA | FGF-FPF; three-axis system; direct extrusion | Exhibition | |

| 20. Nguyen et al. [69] | Journal article (Materials) | Recycled PET, PETG | FGF-FPF; three-axis system; direct extrusion | No applications. | |

| 21. Saavedra-Rojas et al. [70] | Journal article (Materials) | Virgin PLA or PLA with wood fibers | FGF-FPF; three-axis system; direct extrusion | No applications. | |

| 22. Walker et al. [71] | Journal article (Materials) | Recycled CF-ABS compounds | FGF-FPF; three-axis system; direct extrusion | No applications. | |

| 23. Suvanjumrat et al. [80] | Journal article (Sustainability) | Virgin PLA with parawood powder | FGF-FPF; three-axis system; direct extrusion | Furniture |