Abstract

Waste engine oil bottom (WEOB) is a hazardous waste whose effect as an additive to CR+SBS modified asphalt is rarely studied. In this study, the CR+SBS asphalt binder was modified with WEOB in different concentrations (3, 6, and 9 wt%). The GC–MS and FTIR were performed to evaluate the chemical compositions of WEOB and WEOBCR+SBS asphalt. The results showed that the main constituents of WEOB were similar to the functional groups of asphalt, along with maleic anhydride (MAH). Pavement performance-related rheological tests such as RV, temperature sweep (TS), FS, MSCR, and BBR were carried out. Results show that WEOBCR+SBS-6 exhibited the best high- and low-temperature property, followed by CR+SBS-3 and CR+SBS-9. Fluorescence microscope (FM) test, bar thin layer chromatograph (BTLC) test, FTIR, and AFM tests were carried out to evaluate the micro-morphologies and modification mechanism. The analysis revealed increased trends in resin fraction as opposed to asphaltene fraction with the increase of WEOB content. FTIR analysis revealed that the amide groups in WEOBCR+SBS asphalt bonded to the free radicals of CR. Moreover, a modification mechanism was elaborated. WEOB strengthens the cross-linked structure of CR+SBS polymers, reacting with SBS to graft onto MAH-g-SBS, and the free radical of CR interacts with the amide group in WEOB to form a bond. In addition, the content of lightweight components and surface roughness of SBS specimens were in good correlation, which contributed to the rutting resistance and adhesion and self-healing performance.

1. Introduction

The large-scale construction of highway pavement is accompanied by a large consumption of asphalt, which is a nonrenewable material [1]. Hence, seeking a modifier or extenders to reduce the dependence on petroleum asphalt is desirable. As a potential substitute for modifier, waste materials could be partially or fully used in asphalt binders without compromising pavement performance; furthermore, this way of disposing of waste can reduce environmental pollution [2,3].

With millions of people around the world owning and driving cars, waste engine oil (WEO) is inevitable. Generally speaking, the waste oil will cause irreparable damage to the environment, which is why it is imperative to collect for reuse or recycling [4]. The Government Environmental Protection Bureau of America considers that most of the used oil burns up as fuel, which will cause unavoidable soil and air pollution [5]. In addition, the WEO can be reused as lubricating oil by distillation and purification, and the residual solid-liquid coexistence residue is called waste engine oil bottom (WEOB) [1,2,3,6]. This method can maximize the use of resources and become the mainstream way to dispose of used oil.

A new survey shows that America generates millions of gallons of WEOB annually [7]. On a global basis, nearly 24 million metric tons (Mt) of WEOB are generated each year [8]. In particular, nearly 2.2 Mt are produced in the European Union, in addition to the approximately 11 million Mt produced in China [9]. At present, vacuum distillation and water treatment have been studied as methods to recover WEOB. Generally speaking, WEOB looks and smells like asphalt cement, but its consistency is a bit like soft grease or heavy oil rather than semi-solid asphalt. Studies have shown that WEOB contains elements such as Ca, Cu, K, Mo, Zn and P [10]. At the same time, the infrared spectrum shows that both asphalt binder and waste engine oil contain similar functional groups and molecular structures [11]. From an economic point of view, the value of used WEOB would be much higher if it could be blended into asphalt mixtures as a partial replacement of asphalt binder rather than just as fuel.

Nevertheless, due to the continuous increase of output and the complexity of treatment processes, how to dispose of waste engine oil has become a very difficult task [7]. WEOB is the non-distillable portion during the vacuum distillation process of WEO, the whole purification process involves only physical changes [12,13]. Considering the homology between WEOB and petroleum asphalt, it has become a research hotspot to study their properties after blending them. For example, Qiu [14] found that WEOB modified asphalt has more gelation transition resulting in a sharp decline in its ductility performance [6,15]. Hesp et al. used the X-ray fluorescence method to detect WEOB in the binder blends, and they consider that the premature failure of pavement may be related to the existence of WEOB in asphalt [16]; with the deepening of research, this team found that the addition of WEOB reduced the asphalt performance at different temperatures [17,18]. On the contrary, some groups reported that WEOB was effective to increase the grade span and reduce cracking performance [19,20]. The asphalt binder fatigue life increases with the strain level within a certain range [14,21]. Because it contains light components, WEO can act as a rejuvenator to recover some properties of asphalt. In addition, adding polymer and other admixtures to WEOB modified asphalt can obtain better road performance [22]. Therefore, it has become a research hotspot to prepare a new road material which can not only alleviate environmental pollution but also improve the performance of asphalt concrete roads after mixing WEOB, polymer and asphalt.

To summarize, whether WEOB can be effectively used as an asphalt modifier needs to be further studied, especially for CR+SBS modified asphalt. Therefore, before large-scale practical application, systematic research concerning its modification behavior and mechanisms of modified asphalt should be carried out from these points of chemical, physical, rheological, and microscopic study due to the diversity in material sources. Thus, in this study, WEOB was prepared by vacuum distillation and centrifugal separation using WEO. WEOB of 3, 6, and 9 wt% was mixed with crumb CR+SBS asphalt for the synthesizing of WEOBCR+SBS composite added asphalt, and the objectives of this study are to:

- (1)

- Study the modified behavior of WEOB modified CR+SBS asphalt by evaluating the modification development process of WEOB modified asphalt;

- (2)

- Explore the modification mechanisms of CR+SBS asphalt and investigate the optimum dosage of WEOB.

The study focuses on investigating the chemical structure of WEOB modified CR+SBS asphalt by evaluating its chemical characteristics (FTIR and gas chromatography– mass spectrometry), road performance (rotational viscosity, temperature scanning, frequency scanning, MSCR), and low-temperature performance (bending beam rheometer). To this end, the morphological features (atomic force microscopy, bar thin layer chromatography and fluorescence microscopy) were analyzed, and a modification mechanism of WEOBCR+SBS asphalt was elaborated.

2. Materials and Methods

2.1. Materials

Crumb rubber (the specification is 100 mesh) was purchased from Xi′an Kangyuan rubber powder factory. SBS (YH-791) was provided by Dongguan Yucheng plasticization Co., Ltd., China. SK 70 binder was purchased from Xi’an Lingyun Petrochemical Development Co., Ltd., China, and its properties are listed in Table 1. WEOB used was purchased from Shandong Environmental Technology Co., Ltd., China. It was a byproduct of refining WEO through vacuum distillation, centrifugal separation, and other processes. After these processes, the large particle impurities and water in the WEOB are filtered and distilled. Therefore, the WEOB mainly contains metal powder, organic acid, colloid and asphalt-like substances produced by device wear. After treatment, the WEOB can also be used to prepare pre-products for gear oil, hydraulic oil and other oils. With the introduction of standardized standards for waste pollutants, the integrated unit for WEOB disposal is built at low cost.

Table 1.

Properties of the SK 70 binder.

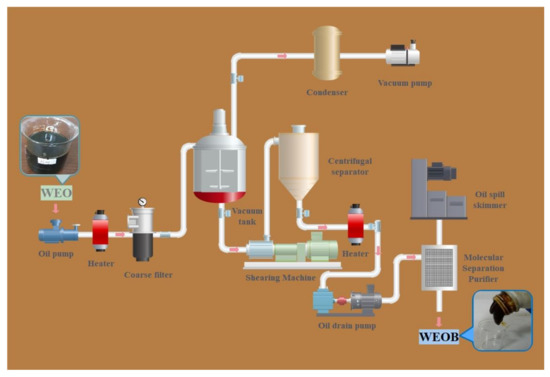

Figure 1 shows the processing technology of WEOB. Elemental compositions of WEOB are listed in Table 2.

Figure 1.

Processing technology of WEOB.

Table 2.

Elemental composition and technical properties of WEOB.

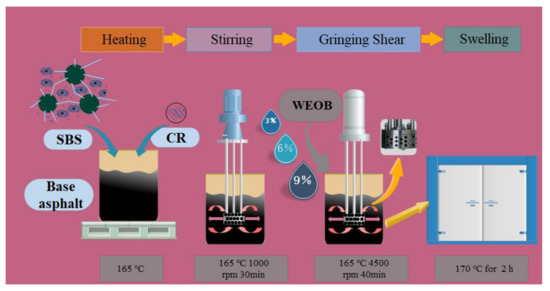

2.2. Preparation of WEOB Modified Asphalt Binder

Asphalt and engine oil are products of petroleum refining, while WEOB is obtained by oil refining. Therefore, WEOB and asphalt are compatible under heating conditions [23]. Modified binders were prepared by melting, shearing, and other processes, the details of which are presented in Figure 2. The polymer contents were selected based on the previous research [24,25,26,27], wherein the optimum value of CR and SBS were 9.5 wt% and 4.1 wt%, respectively. The CR+SBS modified asphalt without WEOB was prepared as the control group.

Figure 2.

Preparation process of WEOB/SBS modified binder.

2.3. Experimental Methods

2.3.1. High-Temperature Performance Test

The Brookfield viscosity test was conducted to assess the workability of the WEOB modified asphalt binders. The test temperature for modified SBS asphalt ranged from 110 to 180 °C [28].

All asphalt binders were temperature sweep (TS), which was swept from 40 to 80 °C at a fixed frequency of 10 rad/s. To evaluate their shear deformation properties and temperature sensitivities, the modified asphalts were frequency-scanned from 0.1 to 100 rad/s at different temperatures (30, 40, 50, 60 and 70 °C). The plate diameter and gap in the FS tests were set to 25 mm and 1 mm, respectively, at the higher temperatures (50, 60 and 70 °C), and 8 mm and 2 mm, respectively, at the lower temperatures (30 and 40 °C).

The elastic response of the WEOB modified asphalt was tested by multiple stress creep recovery (MSCR) in terms of the average recovery rate (R) and unrecoverable flexibility (Jnr). The MSCR was evaluated under two stress levels (0.1 and 3.2 KPa) at a specified high temperature.

2.3.2. Low-Temperature Performance Test

In accordance with ASTM D6648, the creep stiffness modulus (S) and creep slope (m) values were measured by the bending beam rheometer (BBR) to evaluate the crack resistance at low temperature. Test temperatures included −12 °C and −18 °C.

2.3.3. Mechanism and Micro-Morphology Analysis Methods

The chemical component of WEOB was analyzed by the gas chromatograph. The functional group characterization of WEOB and SBS modified asphalt was analyzed by FTIR (NICOLET 6700TM).

The microstructure and morphology of the WEOB modified asphalt were characterized by FM test (conducted with the NIKON microscope, Nikon Instruments Products, Americas), which is helpful for optimizing the WEOB quantity and for studying the modification mechanism.

The AFM from Bruker (Bruker Corporation, Innova, CA, USA) was proposed to characterized the morphology of the binders with the scan rate of 0.8 Hz.

The WEOB was directly placed into the potassium bromide liquid pool for infrared scanning. The scanning wave number range and resolution were 400–4000 cm−1 and 4 cm−1, respectively.

Bar thin layer chromatograph (BTLC) analyzer was conducted for quantitative analysis of asphaltene, resin, aromatic hydrocarbon, and saturated hydrocarbons in asphalt, aiming to determine the change of four components before and after asphalt modification. Benzene analytical purity was used as diluent, n-heptane, toluene, and mixed solution (toluene:ethanol = 55:45) were used as developing solution of asphaltene, resin and aromatic hydrocarbons, respectively. The scanning speed was set to 100 mm/min and the frequency was 60 Hz.

The results of properties of asphalt binders and the high and low temperature property results of asphalt mixtures were statistically analyzed with the aid of ANOVA provided in the Statistical Product and Service Solutions (SPSS) software (International Business Machines Corporation, Armonk, NY, USA). A multiple comparison procedure based on the Tukey-HSD statistical groupings was implemented on the means in ANOVA, with the confidence level of 95%. The results of the statistical groupings are presented with different letters: A, B, C and D, indicating a statistical performance property from best to worst. Double letter designations, such as B/C represent that the difference in the means is not statistically significant.

3. Results and Discussion

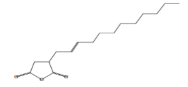

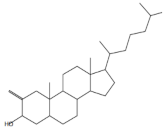

3.1. Chemical Components of WEOB

Table 3 presents the identified compounds analyzed from GC–MS chromatogram of WEOB. It is obvious to see that WEOB mainly comprises maleic anhydride, aromatic rings and linear alkanes, which belong to light molecular weight compounds with the molar mass less than 400 g/mol, and wherein the main compounds of WEOB are aromatic solvents and polyolefin oil, which resembles the light weighted compounds of asphalt and may also affect asphalt properties. Meanwhile, the composition of the WEOB also includes maleic anhydride and other anhydride products, such as Eicosanol, which is formed by degreasing and other reactions under high temperature. Moreover, it can be seen that most of these chemical compounds contain aromatic rings. The common proportions of carbon, hydrogen, oxygen, and nitrogen (CHON) elements in the bio-oil product in this study were found to be 56.31%, 6.75%, 36.59%, and 0.35%, respectively. According to the existing research, the degradation of asphalt performance can be attributed to oxidation, polymerization, and loss of low-weight compounds of asphalt [29,30]. Therefore, WEOB can supplement the light components that are lost during the aging process of asphalt.

Table 3.

The chemical composition of WEOB.

3.2. Viscosity

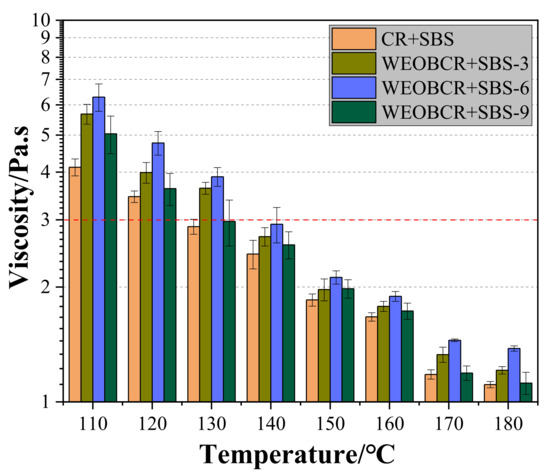

The results in Figure 3 reveal the influence of WEOB on the viscosity of WEOBCR+SBS modified binders. Regardless of WEOB content, the temperature dependency of viscosity is remarkable in that the viscosity reduces with a rise in temperature. Moreover, a higher WEOB content usually corresponds to a larger viscosity of the binder, which may be due to that incorporation of WEOB dramatically contributes to the swelling of polymer, and the internal network structure of the material is continuously developed and presents a homogeneous and compact shape. As a result, asphalt molecules are largely restricted due to the influence of dense network structure during thermal movement (or flow ability). In addition, the addition of WEOB makes the disulfide and styrene butadiene polymers establish a connecting bond with the free radicals in CR. However, upon increasing the content of WEOB from 6 to 9%, there is a rapid decrease in viscosity, the reason for this may be that the absorption of light components by CR and SBS reaches supersaturation, resulting in CR rupture.

Figure 3.

Viscosity results of the WEOBCR+SBS modified binders.

In accordance with the practical application experience, the rotational viscosity at 135 °C should be no more than 3 Pa·s. Specifically, the SBS modified asphalt with 6% WEOB has the highest viscosity, i.e., 2.93 Pa·s, while the increments at 135 °C are 24.2% of the control sample. Therefore, WEOBCR+SBS modified binders surely meet this requirement.

3.3. DSR Analysis

3.3.1. Temperature Sweep Test

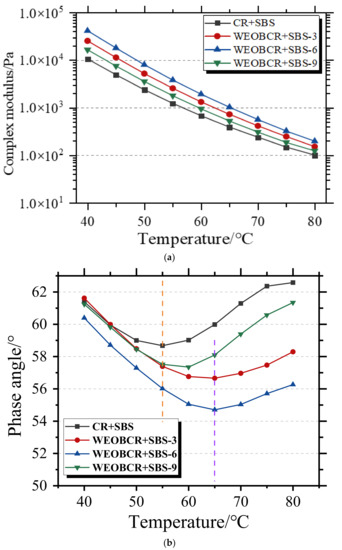

Figure 4a presents the complex modulus of WEOBCR+SBS modified asphalt binders. Regardless of WEOB content, the temperature dependency of complex modulus (G*) is remarkable in that the G* reduces as temperature rises. Moreover, it can be seen that the introduction of WEOB increases G* of the WEOBCR+SBS binder, which indicates that the existence of WEOB enhances the elastic proportion of WEOB modified asphalt more than that of CR+SBS. Specifically, G* of WEOBCR+SBS-6 is the largest, followed by WEOBCR+SBS-3, and WEOBCR+SBS-9 control group is the smallest. The phenomenon of reduction of G* at more than 6 wt% WEOB content can be attributed to the absorption of light components in WEOB by styrene butadiene polymer and that CR reached a supersaturated state, and the network structure could not be stable in the environment of too many light components.

Figure 4.

Complex modulus and phase angle of modified binders: (a) complex modulus; (b) phase angle.

Figure 4b plots the phase angles (δ) of the CR+SBS modified binders with different WEOB contents. As can be seen, the δ decreases firstly and then increase with increasing temperature, indicating the viscoelasticity of asphalt has changed. Moreover, the δ of WEOBCR+SBS-6 modified binder is the smallest compared with other samples, indicating that it has the best elastic performance. However, upon increasing the WEOB content from 6 to 9 wt%, the sharp decrease of the δ means that the viscoelastic properties of WEOBCR+SBS change from elastic to viscous. Theoretically, the addition of WEOB provides a large number of lightweight components that promote the absorption of polymer, while further increasing leads to the dissolution of asphalt [2]. Significantly, the corresponding temperature at the minimum phase angle of WEOBCR+SBS asphalt (65 °C) is significantly higher than that of control samples (55 °C), which are close to the actual temperature of pavement in summer, indicating that WEOBCR+SBS modified asphalt has the best high-temperature deformation resistance at this temperature. This shows that the WEOBCR+SBS asphalt is suitable for high-temperature summer roads and has practical application value. In addition, it can also be applied to places where vehicles change speed frequently, such as tunnel entrances.

3.3.2. Frequency Sweep Test

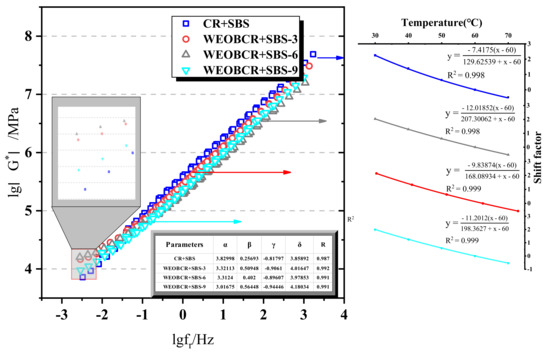

Polymers with longer reaction time in low-temperature environments and those with shorter reaction times in high-temperature environments are known to have the same stress relaxation modulus. Therefore, the rheological properties of asphalt can be obtained over a wide temperature range by defining the master curve [24].

The dynamic shear modulus (G*) evaluates the deformation resistance of asphalt binder under repeated shearing. In this study, the G* was determined at six frequencies and five temperatures in a dynamic shear rheometer [13].

where is the minimum shear modulus, is the span value of the shear modulus, and and are shape parameters.

Figure 5 plots the WLF fitting curves and master curves of modified asphalt at 60 °C. At high temperatures, the complex modulus of the WEOBCR+SBS modified asphalt becomes less sensitive to frequency than at low temperatures, because at higher temperatures the WEOB reduces the differences in viscoelastic behavior between materials over the range of test frequencies. Increasing the WEOB content gradually increases the modulus of the modified CR+SBS asphalt firstly, and then decreases, which is maximized at 6% WEOB content. Therefore, WEOBCR+SBS-6 asphalt improved viscoelastic properties at high temperature, and along with higher rutting resistance, the complex modulus is increased by about 12.1%. Conversely, the complex modulus of the CR+SBS modified asphalt is higher than WEOBCR+SBS asphalt, while WEOBCR+SBS-6 exhibits the highest G* at high frequency (low temperature). An appropriate amount of WEOB content makes the modified asphalt better than the original polymer modified asphalt in high- and low-temperature environments.

Figure 5.

G* master curve of WEOB modified binders and shift factor for G* at the reference temperature of 60 °C.

The main reason for the above phenomenon is that the light components in WEOB are absorbed and saturated by CR and SBS, which promotes the development of SBS network structure. In addition, the maleic anhydride is branched with styrene butadiene and improves the structural stability; meanwhile, the polymer chain in CR enters the asphalt, increasing the interaction between asphalt and rubber. Under the result of comprehensive action, the high- and low-temperature properties of modified asphalt are improved. In contrast, too much WEOB content will lead to the supersaturation of CR and SBS in the system, which will lead to asphalt dilution and the reduction of viscoelastic properties [22,31,32].

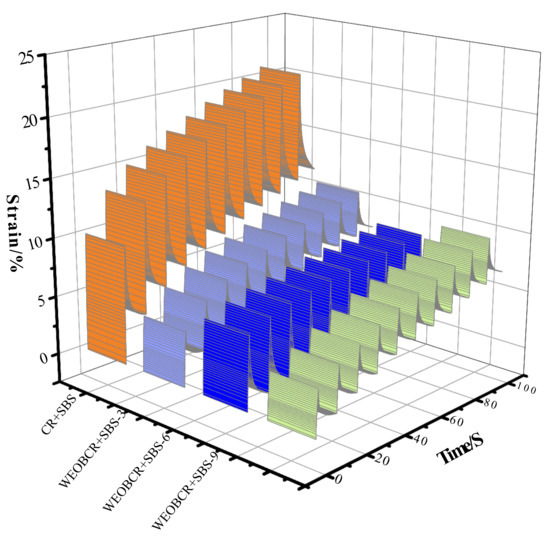

3.3.3. Creep and Recovery Behaviors of Binders

It can be seen from Figure 6 the accumulated strain result of the CR+SBS modified binders with different WEOB contents (stress level: 3.2 kPa; test temperature: 64 °C). As anticipated, the binders containing WEOB have an obvious smaller accumulated strain after ten cycles in comparison with those without WEOB, and a larger WEOB content generally corresponds to a smaller total accumulated strain. This suggests that the presence of WEOB may contribute to the high-temperature deformation resistance of the CR+SBS modified asphalt.

Figure 6.

Strain response in MSCR test (ten cycles) for binders at 64 °C and 3200 Pa.

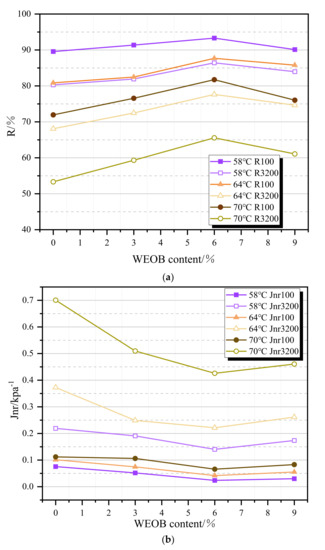

To quantitatively analyze the influence of WEOB content on the high temperature property of the CR+SBS modified asphalt, the R and Jnr are calculated based on the data (in Figure 6), which can be seen in Figure 7. Irrespective of the stress level and test temperature, the R value first increases and then decreases with adding WEOB as opposed to the Jnr value which decreases. It seems that the introduction of WEOB within the appropriate concentration range improves the high temperature recovery ability and rutting resistance of the CR+SBS modified binder; however, upon increasing WEOB content from 6 to 9%, the R and Jnr are not conducive to improving the performance, meaning that the existence of too much WEOB causes a reduction in the elastic behavior of the CR+SBS modified binder at high temperature, which is consistent with the results of FS and TS. There is no complete linear relationship between WEOB content and R and Jnr, but the high-temperature deformation resistance of WEOBCR+SBS modified asphalt is better than that of control group. The possible reason may be that the light component contained in WEOB reacts with CR and SBS polymer to form a network structure. Accordingly, the R are calculated as 71.9% for CR+SBS asphalt binder, 76.5% for WEOBCR+SBS-3 asphalt binder, 81.7% for WEOBCR+SBS-6 asphalt binder and 76.0% for WEOBCR+SBS-9 asphalt binder at 70 °C. Evidently, the comparison results of the R, WEOBCR+SBS-6 asphalt binder > WEOBCR+SBS-3 asphalt binder > WEOBCR+SBS-9 asphalt binder > CR+SBS asphalt binder, further verifies the best high-temperature application for WEOBCR+SBS-6 asphalt binder, followed by WEOBCR+SBS-3 asphalt binder, WEOBCR+SBS-9 asphalt binder and CR+SBS asphalt binder.

Figure 7.

R (a) and J (b) for WEOB modified binders at various temperatures.

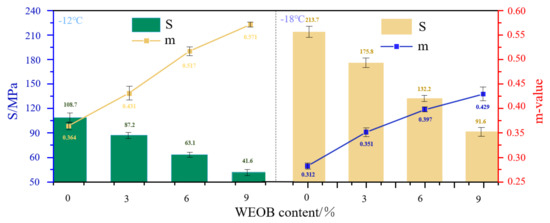

3.4. Low Temperature Property

Figure 8 gives the S and m-value results of CR+SBS modified asphalt with various WEOB contents. Apparently, the small S value and large m-value at low temperature are preferred for asphalt binder. Figure 8 shows that regardless of temperature, the addition of WEOB decreases the S value whereas increases the m-value, which indicates the better low temperature deformation resistance of the CR+SBS modified binder containing WEOB corresponding to that without WEOB. This phenomenon may be caused by some light components in WEOB, which increased the maltenes concentration of the binder. Moreover, the graft product formed by MAH and WEOB with SBS and polymer network structure formed by combination of amide group and CR radical, respectively, may also have a positive effect on the relaxation capacity and deformability.

Figure 8.

BBR test results of WEOB modified binders at −12 °C and −18 °C.

3.5. Property Comparisons among Asphalt Binders

This paragraph compares the properties of asphalt binders according to the test results and the statistical analysis results shown in Table 4. WEOB modified CR+SBS modified asphalt binders with higher complex modulus (G*) and recover rate have better high temperature than CR+SBS asphalt binder; meanwhile, with those higher m-value perform better than CR+SBS asphalt binders in low-temperature property. WEOBCR+SBS-6 asphalt binders behave a lot better than other modified asphalt binders in high temperature. Moreover, it can also be seen that although the creep rate (m-value) of WEOBCR+SBS-9 asphalt binder is larger than that of WEOBCR+SBS-6 asphalt binder, they are not statistically significant. This suggests that the WEOBCR+SBS-6 asphalt binder has low-temperature property similar to WEOBCR+SBS-9 asphalt binder.

Table 4.

Properties of asphalt binders.

3.6. Textural Characterizations

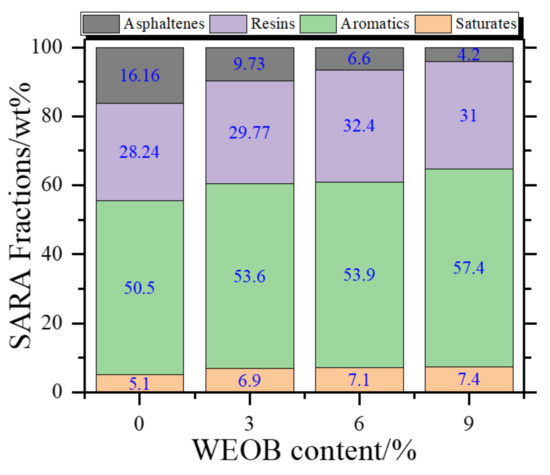

3.6.1. SARA Fractions

SARA fraction contents are the critical elements that affect the stability of the binder colloidal system and subsequently the asphalt properties. In this regard, the gravimetry test was carried out after chromatographic separation, for which the result is presented in Figure 9. It is obvious to see that the lightweight components (aromatics and saturates) of all binders increase with adding WEOB, which improves the low temperature property of bitumen because the lightweight components promote the dilution of bitumen [33]. In addition, the test results showed increased trends in resin fraction as opposed to asphaltene fraction. The possible reason for this phenomenon is that the addition of WEOB complements large amounts of aromatics, which has been proven to have good compatibility with SBS and can penetrate into SBS [33]. It is worth noting that when WEOB increases from 3 to 6 wt%, the aromatic hydrocarbon content hardly changes (from 53.6 to 53.9%), which is due to the complete absorption of the light components in WEOB by CR and SBS in asphalt. Moreover, the polarity of SBS network polymer formed after swelling is closer to resins in asphalt, so the content of resin in asphalt increases [34]. When the content of WEOB continues to increase, the aromatic hydrocarbons in asphalt reach saturation due to too many light components, so there is no increase in resins. In addition, more light components will dissolve asphaltene, which reduces the content of asphaltene.

Figure 9.

SARA fraction contents of WEOB/SBS modified binders.

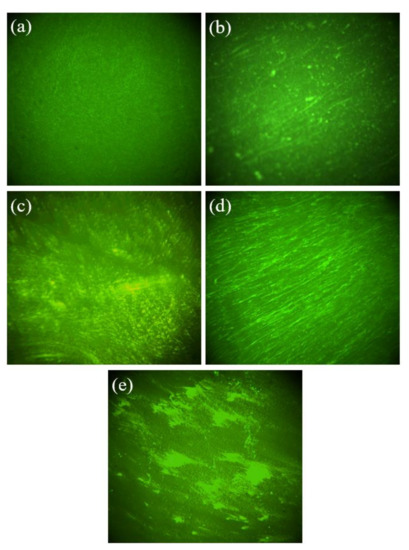

3.6.2. Fluorescence Microscopy

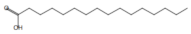

Figure 10 represents the FM images of base asphalt and CR+SBS modified binder with various WEOB contents. Figure 10a shows that the dark phase represents the base binder. As evidenced in Figure 10b, CR and SBS polymer in asphalt matrix exhibit a three-dimensional network structure with uniform light spots. The dark phase representing asphalt occupies a large area.

Figure 10.

Fluorescence microscopy for base asphalt (a) and CR+SBS modified binders with various WEOB content: (b) 0%; (c) 3%; (d) 6%; (e) 9%.

However, in Figure 10c,d, the existence of WEOB can promote the swelling and fusion of SBS network structure, and with the increase of the WEOB content, the SBS polymers dispersed in asphalt matrix transform from point structure into linear structures or even network structures that restrict the thermal movement of asphalt molecules more effectively, which is responsible for the high-temperature property improvement by adding WEOB. Moreover, CR is dispersed in asphalt in the form of particles. After absorbing light components, the volume increases and finally forms a semi continuous phase. In addition, in Figure 10d, WEOB allows SBS polymer to fully swell, making the network structures more well-distributed, and no apparent agglomerations exist. In addition, the maleic anhydride in WEOB is able to react with the SBS in asphalt to form an SBS–g–MAH ternary graft product with a uniform and stable network structure [35,36,37,38]. At the same time, the free radical of CR interacts with the amide group of WEOB to establish a bond. However, upon increasing WEOB content from 6 to 9%, the bright color is distributed in flakes, as shown in Figure 10e, because SBS and CR are diluted in the environment of too many light components, resulting in partial dissolution of the network structure and increased size of the light phase.

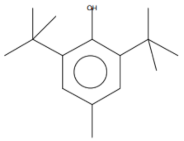

3.6.3. FTIR

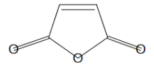

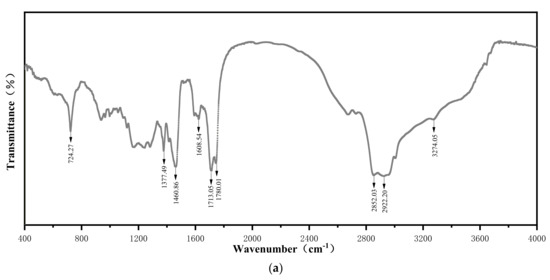

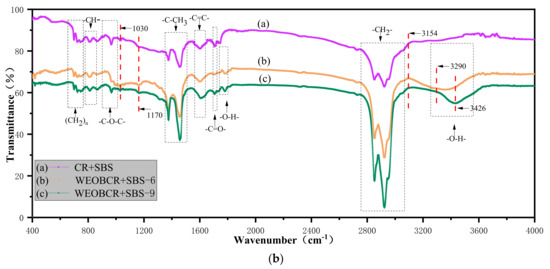

The obtained FTIR spectra of WEOB and WEOBCR+SBS asphalt are displayed in Figure 11. In Figure 11a, the 2850–2930 cm−1 region in the infrared spectrum of WEOB is the typical -CH2 stretching vibration region of the alkane group. The symmetrical stretching vibrations peak of -OH at 1780 cm−1 is the characteristic peak of maleic anhydride (MAH). Meanwhile, the peak at 1608 cm−1 represents the stretching vibration of C=C, confirming the existence of olefins. The peak at 1460 cm−1 represents the asymmetric deformation of C–CH3 [27], indicating the presence of aromatic compounds. The value peaks at 724 cm−1 and 1713 cm−1 are because of bending and stretching vibration of (CH2)n and C=O, respectively, indicating the presence of ketones or carboxylic acid in the sample [39].

Figure 11.

FTIR of WEOB modified asphalt: (a) WEOB, (b) CR+SBS modified binder with various WEOB content.

For comparison, the FTIR spectra of the CR+SBS modified asphalts with various WEOB contents are overlaid on each other. The spectra of the CR+SBS and WEOBCR+SBS asphalt are given in Figure 11b. The absorption peak at 3200–3500 cm−1 is related to tensile vibrations of the asphalt -OH group [40]. The several peaks in the 2852–2923 cm−1 wavenumber range are attributed to the stretching of the alkane -CH bond. The small peaks at 1376 and 1456 cm−1 arise from bending of the -CH bond in the -CH2 and -CH3 functional groups, respectively. The peak at 1170 cm−1 represents the stretching vibration of C-O in the ester. The absorption peaks at 1030 cm−1 are ascribed to S=O vibration of sulfoxide group [41]. In comparison with CR+SBS modified asphalt, the stretching vibration of N-H is observed at 3154, 3290 and 3426 cm−1 in WEOBCR+SBS-6 and WEOBCR+SBS-9 [42], proving the existence of an amide bond. The peak positions in the FTIR spectra of the WEOB modified CR+SBS asphalts were not significantly distinct, but the peak intensities were noticeably different. Furthermore, it is noteworthy that the characteristic peaks of MAH also appeared, proving the existence of SBS–g–MAH [35]. The functional groups and molecular structure of WEOB are thus similar to those of asphalt.

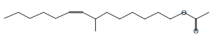

3.6.4. Atomic Force Microscope

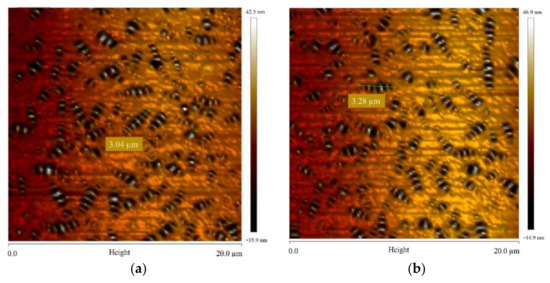

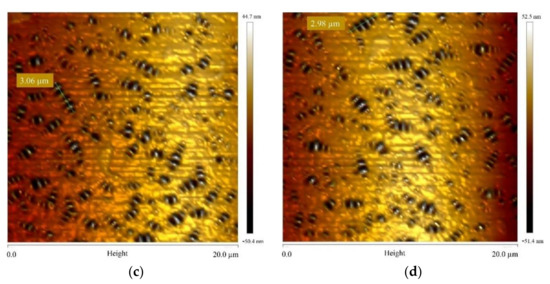

Typical topographic images of asphalt can be observed in Figure 12. Clearly, there are a lot of dark and pale lines, called “bee-like” structures, which can be shown in all topographic images of binder samples. Previous studies have shown that microcrystalline asphaltene and waxes are probably connected with the formation of “bee-like” structures.

Figure 12.

Phase images of WEOB modified CR+SBS asphalt (a) 0%, (b) 3%, (c) 6%, (d) 9%.

Figure 12a–d presents the topographic images of CR+SBS modified asphalt binder with various WEOB content. Clearly, the distribution of “bee-like” structures in the asphalt matrix is relatively uniform, but varies in size. Although the biggest size of “bee-like” structures in CR+SBS and WEOBCR+SBS modified asphalt are similar, i.e., the longest ‘‘bee-like” structures in WEOB/SBS modified asphalt are 3.04, 3.28, 3.06 and 2.98 µm for 0, 3, 6 and 9% of WEOB, respectively, the average size of “bee-like” structure which is calculated by the MATLAB software becomes smaller with addition of WEOB. The reason for this is that the introduction of WEOB can increase the content of light components which are capable of dissolving asphaltene, which is consistent with the results of BTLC. In addition, with the addition of WEOB, the “bee-like” structures in SBS modified asphalt are dispersed more evenly, which can demonstrate that the components of WEOB enhance its compatibility with asphalt binder.

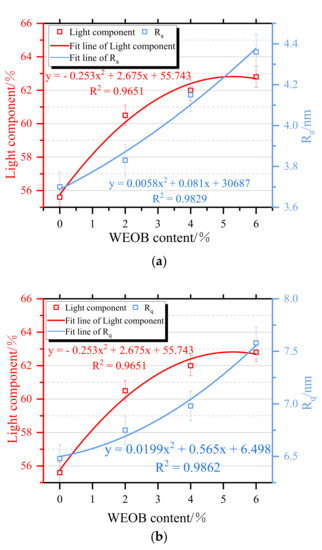

Microstructures of all binders can be quantitatively compared by means of surface roughness obtained via the Nanoscope Analysis 1.5 software (Bruker Corporation, Innova, CA, USA). Theoretically, surface roughness permits characterization of the adhesion properties of asphalt in high temperature [37]. The higher the surface roughness, the better the adhesion and self-healing properties. The average surface roughness (Ra) and root mean square of roughness (Rq) are used to evaluate the roughness of asphalt. The statistical results for the surface roughness of the binders are presented in Table 5. Clearly, the surface roughness increases as the WEOB content rises.

Table 5.

Statistical results for surface roughness.

Figure 13 shows the variation of lightweight components and surface roughness with the WEOB content. The lightweight components and surface roughness of the binders are found to be in good correlation with their WEOB contents. The Ra and Rq increased after introducing WEOB into the CR+SBS modified binder, indicating that the presence of WEOB is conducive to the improvement of adhesion properties of the CR+SBS modified binder.

Figure 13.

Ra (a) and Rq (b) of the specimens with different WEOB contents.

3.7. Analysis of Modification Mechanism

As is well known, the basic structure of SBS elastomer is a polybutadiene block flanked by two polystyrene blocks, which are separated by polystyrene domains. In the SBS asphalt, the SBS elastomer continues to expand in the light-component environment created after WEOB addition, forming a multiphase system of polymer-rich and asphaltene-rich phases. To some extent, the added WEOB provides a liquid-phase environment for the continuous expansion and development of polymers, increasing the density of the three-dimensional network structure and forming multistage microscopic particles and nanostructures of different sizes. Moreover, the free radical of CR interacts with the amide group in WEOB to establish a bond [43], so as to form a semi continuous phase and enhance the development of SBS network structure.

In addition, the dilute propyl position of the SBS molecule grafts with MAH to form the SBS–g–MAH ternary graft, which increases the polarity of SBS and improves the compatibility between the asphalt and SBS polymer, thus forming a stable network structure. The WEOB modification of SBS occurs by a two-phase process: continuous swelling of SBS and the grafting reaction between SBS and MAH [34,44,45]. However, when the WEOB content exceeds a certain level, the absorption of light components by CR and SBS reaches supersaturation, resulting in CR rupture.

4. Conclusions

This study investigated the effect of WEOB on the chemical compounds and rheological properties of WEOB-modified CR+SBS asphalt binders, and elucidated the modification mechanism. Therefore, the following conclusions can be drawn:

WEOB is a complex mixture of mainly small molecular compounds, such as aromatic solvents and polyolefin oil, which resemble the aromatic hydrocarbons in asphalt. The new characteristic peak appeared in the infrared spectrum of the WEOBCR+SBS asphalt, indicating a chemical reaction in the modification process.

Incorporation of WEOB improves the high-temperature elasticity and low-temperature viscosity of the CR+SBS bitumen. For three kinds of WEOB modified CR+SBS bitumen, WEOBCR+SBS-9 exhibits the best high- and low-performance properties.

The asphalt morphology observations revealed that when introduced to CR+SBS asphalt, WEOB acts as a solvent that improves the swelling characteristics of the asphalt, enhances the interactions between polymers, and condenses the network structure. The free radical of CR interacts with the amide group in WEOB to establish a bond, so as to form a semi continuous phase and enhance the development of SBS network structure. Moreover, the SBS–g-MAH ternary graft product increased the polarity of the SBS, improving the compatibility between the asphalt and polymer.

The results of the research may reveal a trend on how WEOB affected the mechanical properties of CR+SBS modified asphalt. However, the problem is that the source of WEOB is limited. Therefore, a follow-up study should focus on increasing the number of different samples; moreover, the aging resistance of the modified asphalt binders should be evaluated, to verify and evaluate the overall performance of WEOB modified CR+SBS asphalt.

Author Contributions

Conceptualization, C.L. and Q.W.; methodology, Q.W.; software, C.L.; validation, C.L. and Q.W.; investigation, C.L.; resources, Q.W.; writing—original draft preparation, C.L.; visualization, Q.W.; supervision, C.L.; project administration, C.L.; funding acquisition, C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Key annual R&D Program of Shaanxi Province: Adaptability and Countermeasures of Rail Transit Shield Engineering crossing ground Cracks Segment (Project Number: 2020SF-390).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pelitli, V.; Doğan, Ö.; Köroğlu, H.J. Waste oil management: Analyses of waste oils from vehicle crankcases and gearboxes. Glob. J. Environ. Sci. Manag. 2017, 3, 11–20. [Google Scholar]

- You, T.; Shi, Y.; Mohammad, L.N.; Cooper, S.B. Laboratory performance of asphalt mixtures containing re-refined engine oil bottoms modified asphalt binders. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 88–95. [Google Scholar]

- Cooper, S.B.; Mohammad, L.N.; Elseifi, M.A. Laboratory performance of asphalt mixtures containing recycled asphalt shingles and re-refined engine oil bottoms. J. Mater. Civ. Eng. 2017, 29, 04017106. [Google Scholar]

- Essawy, A.I.; Saleh, A.M.M.; Zaky, M.T.; Farag, R.K.; Ragab, A.A. Environmentally friendly road construction. Egypt. J. Pet. 2013, 22, 189–198. [Google Scholar]

- Barborak, R.C.; Coward, C.E.; Lee, R.E. Detection and estimation of re-refined engine oil bottoms in asphalt binders: Texas department of transportation’s approach with wavelength dispersive X-ray fluorescence spectroscopy. Transp. Res. Rec. J. Transp. Res. Board 2016, 2574, 48–56. [Google Scholar]

- Qurashi, I.A.; Swamy, A.K. Viscoelastic properties of recycled asphalt binder containing waste engine oil. J. Clean. Prod. 2018, 182, 992–1000. [Google Scholar]

- Liu, S.; Peng, A.; Wu, J.; Zhou, S.B. Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr. Build. Mater. 2018, 191, 1210–1220. [Google Scholar]

- Wielinski, J.; Kriech, A.; Huber, G.; Horton, A.; Osborn, L.J.R.M.; Design, P. Analysis of vacuum tower asphalt extender and effect on bitumen and asphalt properties. Road Mater. Pavement Des. 2015, 16, 90–110. [Google Scholar]

- Arnold, T.; Nelson, G. Recycled engine oil bottoms as asphalt binder additive. Fall River MA 2015, 262, 47–55. [Google Scholar]

- Bennert, T.; Ericson, C.; Pezeshki, D.; Haas, E.; Shamborovskyy, R.; Corun, R. Laboratory Performance of Re-Refined Engine Oil Bottoms (Reob) Modified Asphalt; Asphalt Paving Technology 2016, AAPT 2016; Association of Asphalt Paving Technologist: Atlantic City, NJ, USA, 2016; pp. 163–207. [Google Scholar]

- Johnson, K.-A.N.; Hesp, S.A.J.T.R.R. Effect of waste engine oil residue on quality and durability of shrp materials reference library binders. Transp. Res. Rec. 2014, 2444, 102–109. [Google Scholar]

- Aleer, S.; Adetutu, E.M.; Makadia, T.H.; Patil, S.; Ball, A.S. Harnessing the hydrocarbon-degrading potential of contaminated soils for the bioremediation of waste engine oil. Water Air Soil Pollut. 2010, 218, 121–130. [Google Scholar]

- Wang, W.; Jia, M.; Jiang, W.; Lou, B.; Jiao, W.; Yuan, D.; Li, X.; Liu, Z. High temperature property and modification mechanism of asphalt containing waste engine oil bottom. Constr. Build. Mater. 2020, 261, 119977. [Google Scholar]

- Qiu, Y.; Ding, H.; Rahman, A.; Wang, W. Damage characteristics of waste engine oil bottom rejuvenated asphalt binder in the non-linear range and its microstructure. Constr. Build. Mater. 2018, 174, 202–209. [Google Scholar]

- Mensching, D.J.; Andriescu, A.; DeCarlo, C.; Li, X.; Youtcheff, J.S. Effect of extended aging on asphalt materials containing re-refined engine oil bottoms. Transp. Res. Rec. 2017, 2632, 60–69. [Google Scholar]

- Hesp, S.A.M.; Shurvell, H.F. X-ray fluorescence detection of waste engine oil residue in asphalt and its effect on cracking in service. Int. J. Pavement Eng. 2010, 11, 541–553. [Google Scholar]

- Kaskow, J.; van Poppelen, S.; Hesp, S.A.M. Methods for the quantification of recycled engine oil bottoms in performance-graded asphalt cement. J. Mater. Civ. Eng. 2018, 30, 04017269. [Google Scholar]

- Jia, X.; Huang, B.; Bowers, B.F.; Zhao, S. Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues. Constr. Build. Mater. 2014, 50, 683–691. [Google Scholar]

- Villanueva, A.; Ho, S.; Zanzotto, L. Asphalt modification with used lubricating oil. Can. J. Civ. Eng. (Can.) 2008, 35, 148–157. [Google Scholar]

- Paliukaite, M.; Assuras, M.; Hesp, S.A. Effect of recycled engine oil bottoms on the ductile failure properties of straight and polymer-modified asphalt cements. Constr. Build. Mater. 2016, 126, 190–196. [Google Scholar]

- Al-Omari, A.A.; Khedaywi, T.S.; Khasawneh, M.A. Laboratory characterization of asphalt binders modified with waste vegetable oil using superpave specifications. Int. J. Pavement Res. Technol. 2018, 11, 68–76. [Google Scholar]

- Duan, S.; Muhammad, Y.; Li, J.; Maria, S.; Meng, F.; Wei, Y.; Su, Z.; Yang, H. Enhancing effect of microalgae biodiesel incorporation on the performance of crumb rubber/sbs modified asphalt. J. Clean. Prod. 2019, 237, 117725. [Google Scholar]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar]

- Dong, Z.; Yang, C.; Luan, H.; Zhou, T.; Wang, P. Chemical characteristics of bio-asphalt and its rheological properties after cr/sbs composite modification. Constr. Build. Mater. 2019, 200, 46–54. [Google Scholar]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Developing enhanced modified bitumens with waste engine oil products combined with polymers. Constr. Build. Mater. 2018, 160, 714–724. [Google Scholar]

- Li, Y.; Shen, A.; Lyu, Z.; Wang, S.; Formela, K.; Zhang, G. Ground tire rubber thermo-mechanically devulcanized in the presence of waste engine oil as asphalt modifier. Constr. Build. Mater. 2019, 222, 588–600. [Google Scholar]

- Li, J.; Zhang, F.; Liu, Y.; Muhammad, Y.; Su, Z.; Meng, F.; Chen, X. Preparation and properties of soybean bio-asphalt/sbs modified petroleum asphalt. Constr. Build. Mater. 2019, 201, 268–277. [Google Scholar]

- American Association of State and Highway Transportation Officials. 316-13, A.T. In Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer; American Association of State and Highway Transportation Officials: Washington, DA, USA, 2013. [Google Scholar]

- Podolsky, J.H.; Buss, A.; Williams, R.C.; Hernández, N.; Cochran, E.W. Effects of aging on rejuvenated vacuum tower bottom rheology through use of black diagrams, and master curves. Fuel 2016, 185, 34–44. [Google Scholar]

- Nurul Hidayah, M.K.; Hainin, M.R.; Hassan, N.A.; Abdullah, M.E. Rutting evaluation of aged binder containing waste engine oil. Adv. Mater. Res. 2014, 911, 405–409. [Google Scholar]

- Zhang, R.; Wang, H.; Gao, J.; You, Z.; Yang, X. High temperature performance of sbs modified bio-asphalt. Constr. Build. Mater. 2017, 144, 99–105. [Google Scholar]

- Qian, C.; Fan, W.; Liang, M.; He, Y.; Ren, S.; Lv, X.; Nan, G.; Luo, H. Rheological properties, storage stability and morphology of cr/sbs composite modified asphalt by high-cured method. Constr. Build. Mater. 2018, 193, 312–322. [Google Scholar]

- Hong, W.; Mo, L.; Pan, C.; Riara, M.; Wei, M.; Zhang, J. Investigation of rejuvenation and modification of aged asphalt binders by using aromatic oil-sbs polymer blend. Constr. Build. Mater. 2020, 231, 117154. [Google Scholar]

- Lu, H.; Ye, F.; Yuan, J.; Yin, W. Properties comparison and mechanism analysis of naphthenic oil/sbs and nano-mmt/sbs modified asphalt. Constr. Build. Mater. 2018, 187, 1147–1157. [Google Scholar]

- Shi, H.; Shi, D.; Li, C.; Luan, S.; Yin, J.; Li, R.K.J.M.L. Preparation of functionalized graphene/sebs-g-mah nanocomposites and improvement of its electrical, mechanical properties. Mater. Lett. 2014, 133, 200–203. [Google Scholar]

- Zhang, A.; Chao, L. Chemical initiation mechanism of maleic anhydride grafted onto styrene-butadiene-styrene block copolymer. Eur. Polym. J. 2003, 39, 1291–1295. [Google Scholar]

- Zhang, H.; Wu, X.; Cao, D.; Zhang, Y.; He, M. Effect of linear low density-polyethylene grafted with maleic anhydride (lldpe-g-mah) on properties of high density-polyethylene/styrene-butadiene-styrene (hdpe/sbs) modified asphalt. Constr. Build. Mater. 2013, 47, 192–198. [Google Scholar]

- Wang, M.; Liu, L. Investigation of microscale aging behavior of asphalt binders using atomic force microscopy. Constr. Build. Mater. 2017, 135, 411–419. [Google Scholar]

- Sun, D.; Lu, T.; Xiao, F.; Zhu, X.; Sun, G. Formulation and aging resistance of modified bio-asphalt containing high percentage of waste cooking oil residues. J. Clean. Prod. 2017, 161, 1203–1214. [Google Scholar]

- Jia, M.; Zhang, Z.; Wei, L.; Wu, X.; Cui, X.; Zhang, H.; Lv, W.; Zhang, Q. Study on properties and mechanism of organic montmorillonite modified bitumens: View from the selection of organic reagents. Constr. Build. Mater. 2019, 217, 331–342. [Google Scholar]

- Zhang, F.; Li, J.; Yaseen, M.; Han, M.; Yin, Y.; Yang, S. Preparation methods and performance of modified asphalt using rubber–plastic alloy and its compounds. J. Mater. Civ. Eng. 2018, 30, 04018163. [Google Scholar]

- Pavia, D.L.; Lampman, G.M.; Kriz, G.S.; Vyvyan, J.A. Introduction to Spectroscopy. Cengage Learning: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical characterization of biobinder from swine manure: Sustainable modifier for asphalt binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar]

- Du, P.; Chen, Z.; Zhang, H. Rheological and aging behaviors of base and sbs modified asphalt with thermochromic microcapsule. Constr. Build. Mater. 2019, 200, 1–9. [Google Scholar]

- Jiang, W.; Yuan, D.; Shan, J.; Ye, W.; Lu, H.; Sha, A. Experimental study of the performance of porous ultra-thin asphalt overlay. Int. J. Pavement Eng. 2020, 33, 1–13. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).