Abstract

In order to obtain bioenergy (biogas, biofuel) or pellets, different types of lignocellulosic biomass are subjected to a mechanical pretreatment, first by size reduction, then by separating, and ultimately by fracturing or bio-refining. Biomass processing mainly refers to a grinding process that occurs until reaching certain limits. The size reduction process, such as grinding, is an operation that is executed with different levels of energy consumption, considering biomass mechanical characteristics and the necessary grinding level. This paper, illustrates a comparative analysis of experimental results obtained by grinding multiple types of vegetal biomass (Miscanthus, corn stalks, alfalfa, willow) used in the process of bio-refining and bio-fracturing. Experiments were realized using both a laboratory knife mill Grindomix GM200 (Retsch GmbH, Haan, Germany), and a 22 kW articulated hammer mill, using different grinding system speeds and different hammer mill sieves. Results have shown that biomass mechanical pre-processing grinding leads to supplementary costs in the overall process through bio-refining or bio-fracturing in order to obtain bio-products or bio-energy. So, specific energy consumption for grinding using a hammer mill can reach 50–65 kJ/kg for harvested Miscanthus biomass, and 35–50 kJ/kg for dried energetic willow, using a 10 mm orifice sieve, values which increase processing costs.

1. Introduction

Sustainable development of human society implies, among many other things, the use of renewable energy resources based primarily on biomass, which reduces the conventional fuel pollution in general. Due to sale versatility, the renewable nature, and the low impact on the environment, lignocellulosic biomass is an attractive source for producing fuels and chemicals. The biomass conversion perspectives are special, as it can be processed and transformed, especially in biofuels, meaning ethanol, butanol, biogas, biohydrogen, biodiesel, syn-gas, but also many other products, can be produced [1].

It must be said that the lignocellulosic biomass category includes energy plants such as Miscanthus x giganteus, willow, poplar, acacia, paulownia, which are all plants grown in Romania. The Miscanthus x giganteus plant belongs to the C4 plant category, being a perennial plant with a calorific value of about 15.8 MJ·kg−1 in ground form or briquettes.

Approximately 2.3 kg of Miscanthus with a 14% moisture content is equivalent to one liter of diesel fuel. In a chopped state, the volumetric mass of the Miscanthus is about 130 kg·m−3 [2]. Moreover, the ash content of Miscanthus plant is about 1.5%, carbon content 48.7%, nitrogen content 0.47%, sulfur content 0.07%, cellulose content 49.22%, and lignin content 29.25%, [3].

The willow is a fast-growing plant (3.0–3.5 cm/day) that is cultivated as a short rotation energy culture and has a calorific value of about 18.7 MJ·kg−1 [4] and a yield of 6.5–24 t·ha−1 per year, depending on variety, agro-technical methods, natural conditions, and other factors. The acacia shoots strongly after the first year of plantation, and the amount of biomass obtained doubles from 8–9 t·ha−1 after the second planting year to about 20 t·ha−1 from the third year of plantation.

Durable and economical utilization of biomass resources for producing bio-energy can be enhanced through bio-refineries, a concept that includes a wide range of technologies through which biomass is separated into its chemical components (proteins, carbs, etc.). These can later be transformed in products with added value into chemical substances and biofuels. A biorefinery integrates biomass conversion processes and equipment to produce biofuels, energy, and chemicals from biomass [5,6]. Through bio-refining, all types of biomass from agricultural, forestry, food industry waste, like agricultural plant stems, wood and wood residue, organic residue (vegetal and animal), forestry residue, etc. can be produced [5]. Depending on the type of utilized biomass it is possible to obtain both biofuels as well as chemical substances that can be obtained with added value, mainly energy (electrical or thermal) but also auxiliary materials, according to the type of utilized biomass.

It should be noted that economic and environmental considerations have always led to a continuous improvement of biomass bio-refining process. In this context, fractions that could be separated from biomass during bio-refining or fractioning (food, fodder, chemical products, fuel) could generate added profits which overcome their calorific value [5].

Also, it must be said that biogas (as a product of the conversion of biomass into bioenergy) can be produced from virtually any type of biomass, although the largest resource used for obtaining biogas is farmyard manure, with a percentage of approximately 65% out of the total quantity of biomass used for biogas production. So, even if farmyard manure represents a very high percentage of raw material used for producing biogas, energy crops can also be taken into consideration as material for biogas production, [7,8].

Analyzed from the point of view of energetic potential in biogas production, perennial Miscanthus, switchgrass and annual maize presented a significantly lower energetic potential compared with fossil resources. At the same time these perennial crops present a higher ecological performance regarding biogas production and a lower impact on the environment, thus perennial grasses and Miscanthus presented the potential to improve sustainability in the biogas area [9].

The ecological performance of energy crops (Miscanthus, switchgrass, and maize biomass) has been analyzed by the authors [9] both from the perspective of contributing to climate change and eutrophication of freshwater and marine water, as well as acidification of agricultural soil or the replacement of fossil fuels. All stages of biomass production have been considered, up until the fermented residues are discharged from the biogas plant.

Disregarding the type of end products that are needed to be developed from lignocellulosic biomass, an initial mechanical processing is needed, which is finalized through a corresponding grinding of biomass stems and fragments.

In general, mechanical pre-treatment is considered the most important and promising preliminary stage for treating and transforming biomass into bio-fuel before passing to the next pre-treatment processes [10].

Size reduction of biomass, before all, must be a technological process through which easy transformation of biomass components into different types of matter is facilitated and that can be used in different domains (food industry, bio-fuels, chemical industry, fodder, etc.) The usual methods of biomass grinding include chopping, milling (dry or moist), and crushing through compression.

Without providing an adequate grinding degree, biomass cannot be processed efficiently. Still, biomass grinding is an energy consuming process and if the most adequate grinding equipment and the most favorable process parameters are not used, the process of transforming biomass into useful components will be inefficient or have a low efficiency [11,12].

For example, the energy consumption for biomass densification is influenced by the equipment used, the material properties, particle size/distribution, and also the lignocellulose composition, but is mainly influenced by the extrusion through the mold. An approximate value of the energy consumption of the sawdust extrusion process in order to obtain pellets is 130–135 MJ·t−1, thus, obtaining a density of about 1000 kg·m−1 [13].

Energy consumption for biomass grinding depends on the grinding machine variables, the feeding flow and the material properties, including initial particle dimensions [14,15,16]. Practically, size reduction can be achieved through dividing or shearing with sharp knives, in which the particle geometry is altered due to impact or compression [10,11,12].

Considering that excessive heating during the grinding operation and contamination of the initial biomass are factors than can negatively influence the material properties subjected to grinding, many studies attested that the process of reducing particle size dimension need to be done without affecting the material. Thus, Mani S. et.al. [17], conducted tests with a hammer mill using materials such as wheat and barley straws, corn, and switchgrass stalks. Tests had shown that switchgrass had the highest specific energy consumption for every sieve used, and also for all the moisture contents, unlike the other ground plants. For wheat straws with a moisture content between 4–7% and sieves dimensions of 0.8, 1.6, and 3.2 mm, the specific energy consumption was 185.8 MJ·t−1, 133.2 MJ·t−1, and 41.0 MJ·t−1. For the corn stalk comminution process with a moisture content of 12% and a 3.2 mm sieve orifice dimension (of the hammer mill), the energy consumption recorded was 11 Wh·t−1. It could be concluded that if the sieve orifice dimensions were smaller, the comminution specific energy consumption was higher.

Tavakoli et.al [18] measured the grinding power demand for wheat stalks using three different revolutions (400, 540, and 800 min−1), a straw thresher machine, two different evacuation sieve orifice dimensions (2.5 and 4 cm), and two different blades on the drum (88 and 176 blades respectively, on four or eight rows). Based on the results obtained, it was concluded that the grinding power demand increased in correlation to the blade drum revolution and the decrease of sieve orifice dimensions and the drum number of blades. The maximum power consumption (5.377 kW) was registered for a sieve orifice dimension of 2.5 cm and a revolution of 800 min−1, with four lines of blades, while the minimum power consumption was registered for a sieve orifice dimension of 4 cm and a revolution of 400 min−1, with eight lines of blades on the drum.

Researchers Gil et. al. [19] designed pilot biomass grinding equipment in order to conduct a large number of experiments on different types of biomass and different ground particle dimensions. Using corn stalk and biomass residues with different moisture contents and different ground particle dimensions, it could be observed a decrease of the plants moisture content of about 3–5% occurred after the grinding process for each type of biomass, which should be considered when the drying process is evaluated. Results confirmed a smaller energy consumption and a fine grain of ground particles for corn stalk regarding biomass residues.

Miao et. al. [20] conducted experiments regarding mechanical size reduction of Miscanthus (Miscanthus x giganteus), switchgrass (Panicum virgatum), willow (Salix babylonica), and energy cane (Saccharum spp.) using a commercial hammer mill, a knife mill, and a hammer mill Retsch SK100 (Retsch GmbH, Haan, Germany). The results showed that the specific energy consumption of biomass comminution and the aperture sizes of the milling screens were related in power-law forms. Biomass moisture content significantly influenced the grinding energy consumption, mainly for smaller dimensions of the ground material. It was possible to observe the inversely proportional variation of the size of the particles with their bulk density for all four energy plants used in the experiments. Also, the comminution ratio, obtained from the ratio of the final mean particle size and the original mean particle size, was proportional to the energy consumption for all four energy crops.

Shastri et. al. [21] confirms the importance of the grinding material process and conducts its experiments in order to determine the necessary energy for Miscanthus and switch grass particle size reduction to dimensions between 1–25.4 mm for which the densification pressure in 1.2 MPa.

Thus, in order to develop adequate machines, designers and manufacturers of grinding equipment must have at their disposal data regarding the scope and utilized material in order to identify the most adequate technological flux for processing.

In this respect, this paper presents an analysis of the grinding behavior of certain types of lignocellulosic biomass and the experimental highlighting of the grinding energy consumption using first a GM200 laboratory mill with two fixed knives and then a universal hammer mill. The analysis considered the rotor speed of the mill and the sieve orifice dimensions with which the hammer mill is equipped.

An analysis of granulometric determinations results was conducted for the ground material with the laboratory mill and their correlation to energy consumption for three types of agricultural biomass (grass, maize, alfalfa).

Ground material can be used both for pellet and briquette production through densification as well as for bioenergy (biofuel, biodiesel, biohydrogen), or bio-products (bio-food, fodder, chemical products, etc.) through biorefining process.

2. Materials and Methods

In order to present the influence of the types of biomass on energy consumption for the mechanical process of geometric size reduction, three types of biomass were used—corn stalks, alfalfa, and mountain grass, with initial particle dimensions of approximately 30–50 mm.

Initially, a laboratory mill Grindomix GM200 (Figure 1) was used, equipped with a tray and steel knives, and a 900 W motor with 2000–10,000 min−1 adjustable speed.

Figure 1.

Lab mill GRINDOMIX GM 200, [16]. Note: general view of lab mill (a); Mills steel box (b); Mills knife drum (c).

Samples of 20 grams of material were used, which were subjected to the grinding process for 60 seconds, and the consumed power was recorded through measuring the electric current with an ampermetric plyer Extech (both average values, as well as maximum values—see Table 1). Knife rotor speed values were 3000, 4500, 6000, 7500, and 9000 min–1. Plant humidity was relatively low, all types of biomass having humidity content below 14%.

Table 1.

Energy markers for grinding alfalfa, corn stalks, and mountain grass biomass.

The resulting material after grinding was subjected to a granulometric analysis using a sieve shaker. model Analysette 3 Spartan (Fritsch, Idar-Oberstein, Germany) for 180 seconds, in order to determine the grinding degree [22,23]. Dimensions of the sieve orifices being used and the material percentage remaining on each of the classifier sieves are presented in Table 2, for each of the three types of lignocellulosic biomass subjected to experiments.

Table 2.

Experimental results in the granulometric analysis test.

Grinding degree was derived through the equivalent dimension of the ground material particles, calculated with the Equation (1):

where:

- pi (%) represents the material, percentage remaining on the sieve i;

- li (mm)—medium orifice dimensions which come under each material fraction on the sieve i; 100—the total percentage of material (sum of all fractions).

For the last sieve we considered that above it exists another sieve with 4 mm orifice dimensions (through which we assumed all the particles passed).

Physical pre-treatment of lignocellulosic biomass or reducing its dimensions is a mandatory condition for chemical or bio-chemical processing in biomass bio-refining. Still, wood particle size reduction is very intensive, which differentiates wood biomass from grass biomass or from lignocellulosic stems for bio-refining [24].

In general, energy consumption for Miscanthus plant harvesting is situated between 13.5–18.5 kJ/kg, with some exceptions due to the angle of cutting knives [25] and to plant humidity, thus, continuous grinding until reaching the required dimensions is needed.

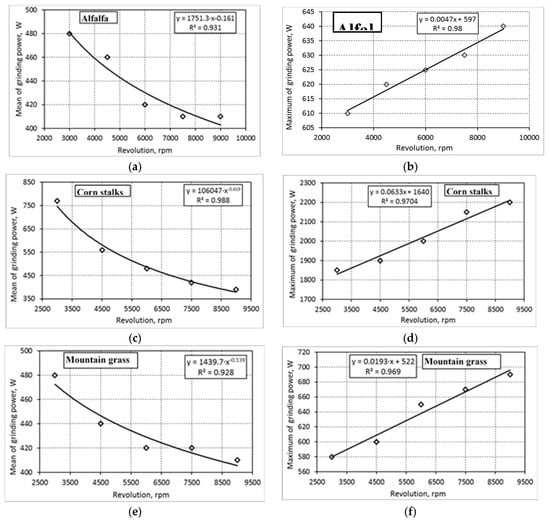

If harvested biomass is subjected to grinding with the help of hammer mills, energy consumption for mechanical pre-treatment before the fracturing process or bio-refining increases even more. So, this research continued with the determination of energy consumption of harvested biomass grinding (Miscanthus and energetic willow) using a hammer mill MC-22 from INMA Bucharest Romania (Figure 2). Determinations were realized in different working conditions regarding both the size of sieve orifices from the hammer mill and hammer construction. In this paper the results obtained from using some hammers with edges of one side, and sieves with circular orifices of 16 mm or 10 mm, are presented (the 16 mm sieve was mounted first and afterwards the 100 mm sieve)

Figure 2.

Hammer mill MC-22 (22 kW): 1. hammer mill; 2. vent; 3. support cyclone and bag for dust collecting; 4. evacuation chamber for ground material; 5. electric motor; 6. Miscanthus biomass before grinding.

Miscanthus particles had average sizes of 123–127 mm, while energetic willow particles had dimensions between 24–47 mm (over 85% of material). Miscanthus biomass humidity was between 10.02–11.39%, and in the energetic willow between 8.89–11.97%.

3. Results and Discussions

Shastri et. al. [21] confirms the importance of grinding process and conducts its experiments in order to determine the necessary energy for Miscanthus and switchgrass particle size reduction to dimensions between 1–25.4 mm for which the densification pressure is 1.2 MPa.

Thus, the values for grinding power and the specific energy consumption from this research are presented in Table 1 for all three types of biomass at each of the five values of speed revolutions. In order to calculate the specific energy consumption, the medium value of the grinding power along with the type of sample and the weight of each material probe subjected to grinding were taken into consideration.

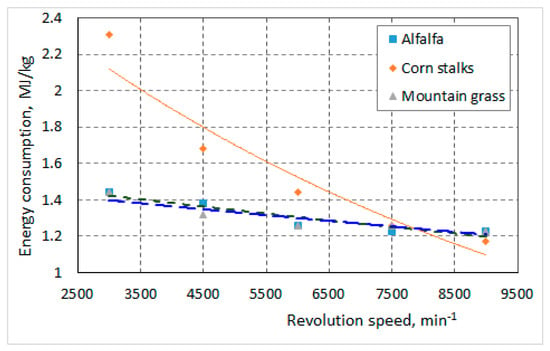

Based on the results obtained for the grinding power of biomass, medium and maximum power curves were drawn, which were recorded by the equipment and were dependent on knife drum revolution. Curves were drawn using computer regression analysis with MS Office Excel (Microsoft Office, Bucharest, Romania) using the experimental points recorded for each type of biomass at each of the five values of the knife drum revolution. These curves are graphically presented in Figure 3.

Figure 3.

Mean and maximum power variation for grinding process considering the mill drum speed of revolution. Note: mean power variation graph for alfalfa (a); maximum power variation graph for alfalfa (b); mean power variation graph for corn stalks (c); maximum power variation graph for corn stalks (d); mean power variation graph for mountain grass (e); maximum power variation graph for mountain grass (f).

The necessary average power for grinding biomass had a decreasing variation with the rotor speed, while the maximum power had an increasing tendency. If we think about the initial shock on the hammers, at each level of rotor speed, it is normal for the maximum power to be higher at higher speeds, meanwhile, as the material is grinded, the necessary power decreases as the speed increases. Variation of consumed average power for grinding versus rotor speed followed a power type distribution, with a correlation coefficient R2 of over 0.969 for all types of biomass (see Figure 3b,d,f).

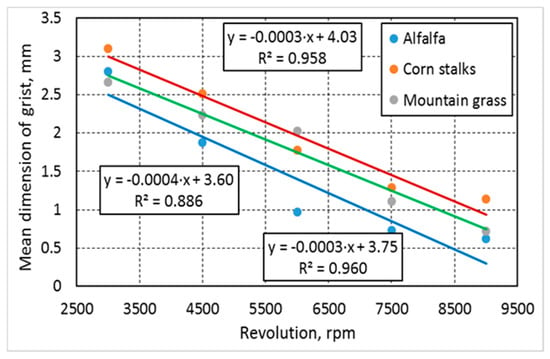

In Figure 4, the variation of consumed specific energy for grinding, in relation to the mill rotor speed, is presented for all types of biomass.

Figure 4.

Variation of average power necessary for grinding for all types of experimental biomass.

From analyzing Figure 4, smaller values of necessary energy can be seen for grinding alfalfa plants, together with mountain grass, at the majority of mill rotor speeds. Also, it was observed that corn stalks required higher values of consumed energy, especially at lower rotor speeds, even if at high speeds (over 8000 min−1) the energy values were of the same size order as the ones recorded for alfalfa and mountain grass.

Even if the initial shock felt by the knife rotor was far greater when grinding corn stalks (consumed power reaching 2200 W at 9000 min−1), still, the average value of necessary power for grinding, at the same speed, was significantly lower, this being the case in all types of biomass. In the case of corn stalks, however, the difference was greater than in the alfalfa or mountain grass. Also, in paper [26] the specific energy necessary for grinding presented a variation approximately exponentially decreasing along with the increase of mill sieve orifice dimensions from 1 to 12.7 mm for different types of lignocellulose biomass among which were Miscanthus, Salix viminalix, and switchgrass.

It could be said that in the case of corn stalks, which have a thicker exterior wall and a larger diameter compared to alfalfa or mountain grass, the initial shock was normally greater, but as the plants were grinded, the consumed power decreased constantly. Supporting this claim, the exterior/core ratio of stalks should also be considered, which is far greater in corn stalks than in alfalfa stems, or mountain grass.

If the differences between the maximum value of requested power for turning the mill rotor and the average value of consumed power were recorded when grinding, alfalfa stems were situated in the interval 130–230 W, mountain grass between 100–280 W, and in the corn stalks case, this difference was far greater, respectively between 1080–1810 W for speeds between 3000 min−1 to 9000 min−1.

In paper [27] scientists found that when the mill hammers have straight corners (90 °C), the total specific grinding energy increases up to 45% if the hammer mill rotor speed of revolution increases from 2000 to 3600 min−1 for grinding corn stalks.

In conclusion, it can be said that, when the mill rotor requires using low power, especially at the beginning of the grinding process, an adequate pre-grinding of biomass stalks would be necessary, before starting the actual grinding process.

For determining the grinding degree of alfalfa, mountain grass, and corn stalks, after passing them through the hammer mill GM200, the grinded material was subjected to a granulometric analysis with a laboratory classifier, using five superposed sieves with wire sieve surfaces and orifice sizes of 2.8 mm, 2.0 mm, 1.4 mm, 1.0 mm and 0.71 mm, starting from the largest to the smallest, from top to bottom [15].

Percent values of the ground material that remained on each of the classifier sieves are presented in Table 2, together with the equivalent average dimension values of material particles, calculated with Equation (1).

It can be seen that for the top situated classifier sieve (mesh 2.8 mm) the material percentage on the sieve decreased with the mill rotor speed, closing on the value zero, and that the percentage of material that passed through the bottom sieve (mesh 9.71 mm) increased, from a speed of 3000 min−1 to a speed of 9000 min−1.

The top sieve was the only sieve in which the same phenomenon took place, although it sometimes occurred for the 2 mm sieve, but only in the case of alfalfa and mountain grass (for which the variation is relatively non-uniform). In the case of all other sieves, variation of the percentage of material remaining on the sieves increased with the rise of mill rotor speed.

It must be outlined that, indeed, the percentage of material remaining on the top sieve was relatively greater at low speeds of the mill rotor GM200, and the percentage of material that passed through the last sieve was very small, which leads to the conclusion that for obtaining a high grinding degree (for the GM200 mill, and probably for all mills of this type), greater values of mill rotor speeds are required.

Taking into consideration the results from the paper [9], at a mill rotor speed of 3000 min−1, peripheral speeds of knives are between the interval 8.4–20 m·s−1, values that are insufficient for disintegrating lignocellulosic stalks (mainly corn stalks), while at the knife rotor speed of 9000 min−1, velocities (interior and exterior) have values three times greater.

In Figure 5, the variation of material particle equivalent dimensions is presented, for each of the three types of vegetal dried biomass, in relation to the mill rotor speed.

Figure 5.

Variation of ground material equivalent dimensions, according to mill rotor speed.

As seen in Figure 5 the average equivalent dimension (calculated with Equation (1)) had greater values at reduced knife rotor speeds, decreasing as the speed increased, in all types of biomass subjected to experimental determinations. This variation was approximately linear, the correlation coefficient R2, determined through regression analysis on the computer, had relatively high values (over 0.88). It resulted that as the GM200 mill rotor speed increased, the material was ground more extensively, but the grinding energy also increased.

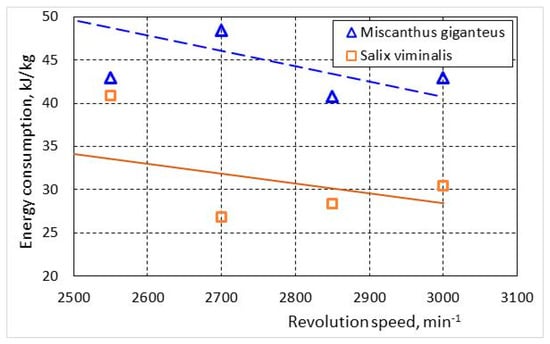

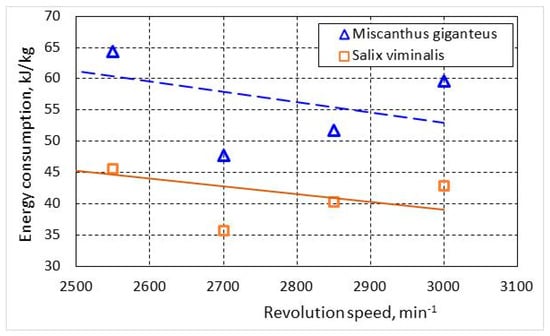

For wood biomass of willow and lignocellulosic biomass of Miscanthus, both having moisture content founder 12%, grinded with a hammer mill, variation of the energy consumption versus mill rotor speed is graphically presented in Figure 6 and Figure 7. It must be mentioned that willow biomass had the same initial particle dimensions as those that resulted from harvesting (meaning under 50 mm), but its humidity content decreased under normal conditions following storage in a dry chamber for 6 months.

Figure 6.

Variation of the energy consumption when grinding willow and Miscanthus biomass using a hammer mill and a 16 mm orifice sieve.

Figure 7.

Variation of the energy consumption when grinding willow and Miscanthus biomass using a hammer mill and a 10 mm orifice sieve.

From analyzing the graphical data from Figure 6 and Figure 7, the general tendency of a decrease in specific consumed energy was observed, for grinding both types of biomass, as the mill rotor speed increased, even if the experimental determined values present random variations. Moreover, for using a sieve with smaller circular orifice size (10 mm instead of 16 mm), the necessary energy for grinding increased, for both types of biomass. Graphical data showed smaller values for grinding willow biomass, but it must be taken into consideration the fact that initial particle dimensions for willow were far smaller compared to the ones from the Miscanthus biomass.

In the given conditions, costs for pre-processing lignocellulosic and wood biomass increase if the grinding equipment is not chosen correctly, as well as parameters of working regimes of these types of equipment. Fracturing and bio-refining biomass for obtaining bio-products and bio-fuels also includes costs for pre-treating and mechanical pre-processing, like biomass grinding.

4. Conclusions

This paper presents experimental results regarding energy consumption, respective to the power necessity, for grinding some types of dried vegetal biomass, including alfalfa, mountain grass, and corn stalks, using a hammer mill with fixed knives, as well as obtained results for grinding Miscanthus and willow biomass using an articulated hammer mill.

From the experiments realized using the laboratory mill GM200, it was found that mountain grass and alfalfa require the smallest values of grinding power, compared to the corn stalks, more so for higher mill rotor speeds. Thus, the average necessary power for grinding alfalfa and mountain grass was between the limits of 480–410 W, for the mill rotor speeds from 3000 min−1 to 9000 min−1. For corn stalks the average necessary power for grinding was between 750–390 W, at the same speeds of the mill rotor.

Also, specific energy consumption was between the limits of 0.40–0.34 kWh·kg−1 for alfalfa stalks and mountain grass, while for corn stalks this energy consumption was between the limits of 0.65–0.32 kWh·kg−1, in the speed interval 3000–9000 min−1.

It was observed that for the same speeds of the mill rotor, corn stalks were ground less than the other two types of biomass, while alfalfa obtained the highest level of grinding, especially at speeds of over 6000 min−1.

When using mills with articulated hammers, specific energy consumption reached 14–18 kWh·t−1 for harvested Miscanthus biomass, and 10–14 kWh·t−1 for dried energetic willow biomass, while using a sieve with 10 mm orifices. For bio-refining and fracturing, biomass particle dimensions must be relatively reduced, and grinding should be continued until reaching the desired dimensions. These consumption values actually mean 14–18 kWh/Mg for Miscanthus biomass, and approximately 10–14 kWh/mg for energetic willow biomass.

If a kWh of electrical energy costs approximately 10 euro cents for industrial consumers or even more, then for processing large quantities of biomass, just the biomass grinding process (or mechanical pre-processing) has relatively high costs.

Obtained results should be used for choosing the mechanical pre-processing equipment for biomass, but also the working regimes, mainly when they are used for transforming biomass into bio-fuel or bio-products, through bio-refining or chemical fracturing.

Author Contributions

Conceptualization, G.P. and G.V.; Formal analysis, M.D. and P.T.; Funding acquisition, G.M. and M.C.; Investigation, G.M. and M.C.; Methodology, G.P. and G.V.; Supervision, G.P. and G.V.; Validation, O.N.; Writing—original draft, G.M. and M.C.; Writing—review and editing, G.M., M.D. and P.T.

Funding

This research was funded by the Sectoral Operational Programme Human Resources Development 2007–2013 of the Ministry of European Funds through the Financial Agreement POSDRU/159/1.5/S/132395 and this work has also been funded by National Grants GNaC 2018 ARUT, Internal Research Grant, through the Financial Agreement 06/15.10.2018.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xiu, S.; Shahbazi, G. Development of Green Biorefinery for Biomass Utilization: A Review. Trends Renew. Energy 2015, 1, 4–15. [Google Scholar] [CrossRef]

- Available online: http://www.miscanthus.com/ro/page/about-miscanthus.6 (accessed on 12 April 2019).

- Bilandzija, N.; Jurisic, V.; Voca, N.; Leto, J.; Matin, A.; Grubor, M.; Krick, T. Energy valorization of miscanthus x giganteus biomass: A case study Croatia. J. Process. Energy Agric. 2017, 21, 32–36. [Google Scholar] [CrossRef]

- Manzone, M. Energy and moisture losses during poplar and black locust logwood storage. Fuel Process. Technol. 2015, 138, 194–201. [Google Scholar] [CrossRef]

- De Jong, E.; Jungmeier, G. Biorefinery Concepts in Comparison to Petrochemical Refineries. In Industrial Biorefineries and White Biotechnology; Pandey, A., Höfer, R., Taherzadeh, M., Nampoothiri, K.M., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 3–33. [Google Scholar]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412. [Google Scholar] [CrossRef]

- Steinfeld, H.; Gerber, P.; Wasenaar, T.; Castel, V.; Rosales, M.; de Haan, C. Livestock’s long shadow. In Environmental Issues and Options; Food and Agriculture Organisation (FAO) of United Nations: Rome, Italy, 2006. [Google Scholar]

- Moiceanu, G.; Dinca, M.; Paraschiv, G.; Voicu, G.; Chitoiu, M. Biogas, the future of modern society. In Proceedings of the 4th International Conference on Thermal Equipment, Renewable Energy and Rural Development TE-RE-RD, Targoviste, Romania, 4–6 June 2015; pp. 273–278. [Google Scholar]

- Kiesel, A.; Wagner, M.; Lewandowski, I. Environmental Performance of Miscanthus, Switchgrass and Maize: Can C4 Perennials Increase the Sustainability of Biogas Production. Sustainability 2017, 9, 5. [Google Scholar] [CrossRef]

- Kamarludin, S.N.C.; Jainal, M.S.; Azizan, A.; Safaai, N.S.M.; Rafizan, A.; Daud, M. Mechanical Pretreatment of Lignocellulosic Biomass for Biofuel Production. Appl. Mech. Mater. Process Adv. Mate. Eng. 2014, 625, 838–841. [Google Scholar] [CrossRef]

- Mayer-Laigle, C.; Blanc, N.; Rajaonarivony, R.K.; Rouau, X. Comminution of Dry Lignocellulosic Biomass, a Review: Part I. From Fundamental Mechanisms to Milling Behaviour. Bioengineering (Basel) 2018, 5, 41. [Google Scholar] [CrossRef] [PubMed]

- Mayer-Laigle, C.; Rajaonarivony, R.K.; Blanc, N.; Rouau, X. Comminution of Dry Lignocellulosic Biomass: Part II. Technologies, Improvement of Milling Performances, and Security Issues. Bioengineering (Basel) 2018, 5, 50. [Google Scholar] [CrossRef] [PubMed]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenny, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application, 2011. Biofulels Bioprod. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Hall, C.W.; Davis, D.C. Processing Equipment for Agricultural Products; The AVI Publishing Company Inc.: Westport, CT, USA, 1979. [Google Scholar]

- Manlu, Y.; Womac, A.R.; Igathinathame, C.; Sokhansanj, S.; Narayan, S. Direct Energy Measurement Systems for Rotary Biomass Grinder–Hammermill. In Proceedings of the ASABE Meeting Presentation no., Knoxville, TN, USA, 9–12 July 2006. [Google Scholar]

- Moiceanu, G.; Voicu, P.; Paraschiv, G.; Voicu, G.; Chitoiu, M. Miscanthus plant energy consumption during grinding with a lab mill Grindomix GM 200. In Proceedings of the 3th International Conference on Thermal Equipment, Renewable Energy and Rural Development TE-RE-RD, Berdiansk, Ukraine, 20–22 June 2013; pp. 203–208. [Google Scholar]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Tavakoli, H.; Mohtasebi, S.S.; Jafari, A.; Mahdavinejad, D. Power requirement for particle size reduction of wheat straw as a function of straw threshing unit parameters. Aust. J. Crop. Sci. 2009, 3, 231–236. [Google Scholar]

- Gil, M.; Gonzalez, A.; Gil, A. Evaluation of milling energy requirements of biomass residues in a semi-industrial pilot plant for co-firing. In Proceedings of the 16th European Biomass Conference and Exhibition, Valencia, Spain, 2–6 June 2008. [Google Scholar]

- Miao, Z.; Grift, T.E.; Hansena, A.C.; Tinga, K.C. Energy requirement for comminution of biomass in relation to particle physical properties. Ind. Crops Prod. 2011, 33, 504–513. [Google Scholar] [CrossRef]

- Shastri, Y.N.; Miao, Z.; Rodríguez, L.F.; Grift, T.E.; Hansen, A.C.; Ting, K.C. Determining optimal size reduction and densification for biomass feedstock using the BioFeed optimization model. Biofuels Bioprod. Biorefin. 2014, 8, 423–437. [Google Scholar] [CrossRef]

- ISO 3310/1: 1990. Test Sieves—Technical Requirements and Testing—Part 1: Test Sieves of Metal Wire Cloth = DIN 4188; ISO: Geneva, Switzerland, 1990. [Google Scholar]

- Zeglen, K.; Grygier, D.; Ambroziak, A.; Tulej, M. Particle size distribution determination methods comparison based on sieve analysis and laser method. Interdiscip. J. Eng. Sci. 2016, 4, 19–23. [Google Scholar]

- Zhu, J.Y. Physical Pretreatment—Woody Biomass Size Reduction—for Forest Biorefinery. In Sustainable Production of Fuels, Chemicals, and Fibers from Forest Biomass; American Chemical Society: Washington, DC, USA, 2011; pp. 89–107. [Google Scholar]

- Maughan, J.D.; Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Impact of Blade Angle on Miscanthus Harvesting Energy Requirement. Trans. ASABE 2013, 57, 999–1005. [Google Scholar]

- Miao, Z.; Grift, T.E.; Ting, K.C. Size Reduction and Densification of Lignocellulosic Biomass Feedstock for Biopower, Bioproducts, and Liquid Biofuel Production. Encycl. Agric. Food Biol. Eng. 2014. [Google Scholar] [CrossRef]

- Bitra, V.S.; Womac, A.R.; Chevanan, N.; Miu, P.I.; Igathinathane, C.; Sokhansanj, S.; Smith, D.R. Direct mechanical energy measures of hammer mill comminution of switchgrass, wheat straw, and corn stover and analysis of their particle size distributions. Powder Technol. 2009, 193, 32–45. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).