Use of Bio-Based Plastics in the Fruit Supply Chain: An Integrated Approach to Assess Environmental, Economic, and Social Sustainability

Abstract

1. Introduction

2. Materials and Methods

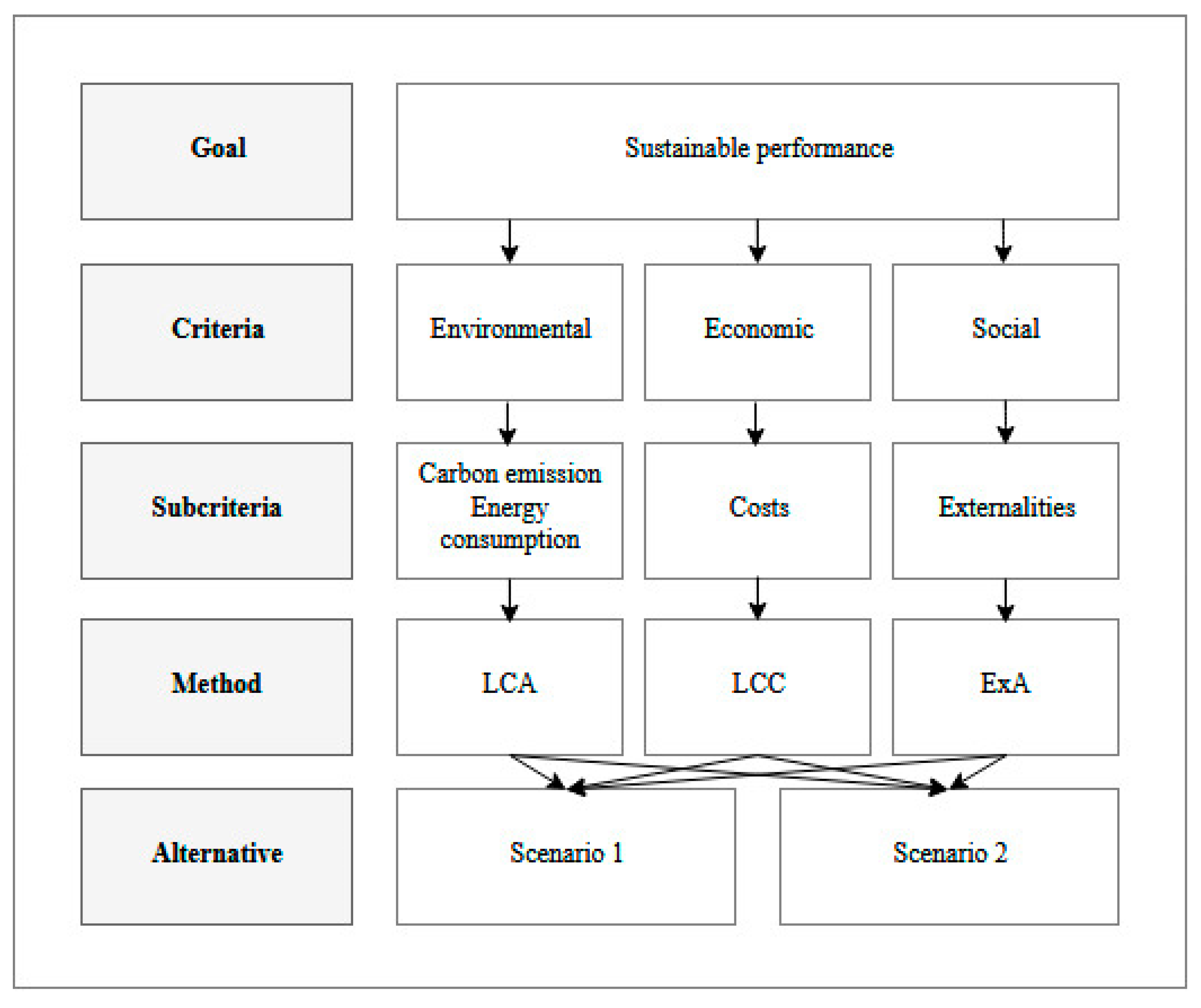

2.1. Theoretical Framework

2.2. Case Studied

2.3. Life Cycle Inventory and LCA Methodology

2.4. LCC Methodology

2.5. ExA—Externality Assessment Methodology

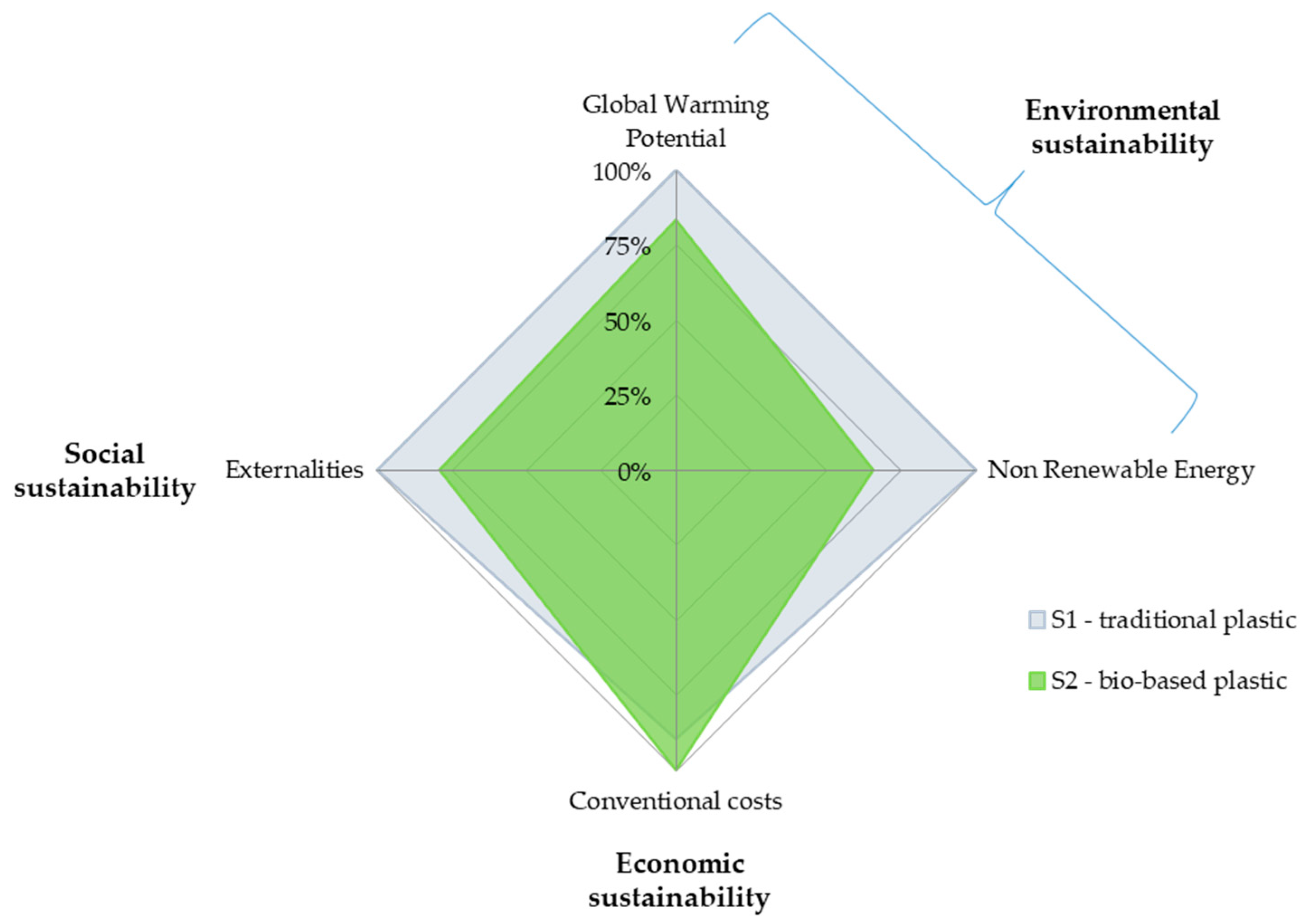

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- The World Bank. Investors Welcome Newly Released World Bank Green Bond Impact Report. Available online: http://www.worldbank.org/en/news/feature/2015/08/11/investors-welcome-world-bank-green-bond-impact-report (accessed on 22 February 2019).

- Schwartz, P. International financial institutions and biodiversity conservation. In Biodiversity and Nature Protection Law; Edward Elgar Publishing: Cheltenham, UK, 2017; pp. 399–412. [Google Scholar]

- Jolly, R.; Ray, D.B. Human security—National perspectives and global agendas: Insights from national human development reports. J. Int. Dev. 2007, 19, 457–472. [Google Scholar] [CrossRef]

- OECD. Towards Green Growth; Secretary-General of the OECD, Ed.; OECD Publishing: Paris, France, 2011; ISBN 9789264094970. [Google Scholar]

- The World Bank. Inclusive Green Growth; The World Bank: Washington, DC, USA, 2012; ISBN 978-0-8213-9551-6. [Google Scholar]

- European Commission. Europe 2020 A Strategy for a Smart, Sustainable and Inclusive Growth (COM-2010, 2020 Final). Available online: https://www.eea.europa.eu/policy-documents/com-2010-2020-europe-2020 (accessed on 19 April 2019).

- European Commission. A Lead Market Initiative for Europe—European Environment Agency. Available online: https://www.eea.europa.eu/policy-documents/a-lead-market-initiative-for-europe (accessed on 20 March 2019).

- European Commission. Innovating for Sustainable Growth: A Bioeconomy for Europe—COM (2012). Available online: https://ec.europa.eu/research/bioeconomy/pdf/official-strategy_en.pdf (accessed on 19 April 2019).

- United Nations Environment Programme. Single-Use Plastics: A Roadmap for Sustainability. Available online: http://wedocs.unep.org/handle/20.500.11822/25496 (accessed on 19 February 2019).

- Kulatunga, A.K.; Karunatilake, N.; Weerasinghe, N.; Ihalawatta, R.K. Sustainable manufacturing based decision support model for product design and development process. Procedia CIRP 2015, 26, 87–92. [Google Scholar] [CrossRef]

- Institute for Bioplastics and Biocomposites. Information on Bioplastic. Available online: https://www.ifbb-hannover.de/en/. (accessed on 19 April 2019).

- Lettner, M.; Schöggl, J.-P.; Stern, T. Factors influencing the market diffusion of bio-based plastics: Results of four comparative scenario analyses. J. Clean. Prod. 2017, 157, 289–298. [Google Scholar] [CrossRef]

- Cluster Spring. Sustainable Processes and Resources for Innovation and National Growth. Available online: http://www.clusterspring.it (accessed on 22 February 2019).

- Clark, J.H.; Farmer, T.J.; Herrero-Davila, L.; Sherwood, J. Circular economy design considerations for research and process development in the chemical sciences. Green Chem. 2016, 18, 3914–3934. [Google Scholar] [CrossRef]

- Sala, S.; Farioli, F.; Zamagni, A. Progress in sustainability science: Lessons learnt from current methodologies for sustainability assessment: Part 1. Int. J. Life Cycle Assess. 2013, 18, 1653–1672. [Google Scholar] [CrossRef]

- Vinyes, E.; Asin, L.; Alegre, S.; Muñoz, P.; Boschmonart, J.; Gasol, C.M. Life cycle assessment of apple and peach production, distribution and consumption in Mediterranean fruit sector. J. Clean. Prod. 2017, 149, 313–320. [Google Scholar] [CrossRef]

- Neugebauer, S.; Forin, S.; Finkbeiner, M. From life cycle costing to economic life cycle assessment-introducing an economic impact pathway. Sustainability 2016, 8, 428. [Google Scholar] [CrossRef]

- Bovea, M.D.; Vidal, R. Increasing product value by integrating environmental impact, costs and customer valuation. Resour. Conserv. Recycl. 2004, 41, 133–145. [Google Scholar] [CrossRef]

- Craighill, A.; Powell, J.C. A Lifecycle Assessment and Evaluation of Construction and Demolition Waste; Working Paper-Centre for Social and Economic Research on the Global Environment; University of East Anglia: Norwich, UK, 1999; pp. 1–52. [Google Scholar]

- Vogtländer, J.G.; Brezet, H.C.; Hendriks, C.F. The virtual Eco-costs ’99: A single LCA-based indicator for sustainability and the Eco-costs—Value ratio (EVR) model for economic allocation: A new LCA-based calculation model to determine the sustainability of products and services. Int. J. Life Cycle Assess. 2001, 6, 157–166. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Bradley, R.; Jawahir, I.S.; Badurdeen, F.; Rouch, K. A total life cycle cost model (TLCCM) for the circular economy and its application to post-recovery resource allocation. Resour. Conserv. Recycl. 2018, 135, 141–149. [Google Scholar] [CrossRef]

- Mancuso, T.; Verduna, T.; Blanc, S.; Di Vita, G.; Brun, F. Environmental sustainability and economic matters of commercial types of common wheat. Agric. Econ. (Zemědělská Ekon) 2019, 65, 194–202. [Google Scholar] [CrossRef]

- Ferrão, P.; Ribeiro, P.; Rodrigues, J.; Marques, A.; Preto, M.; Amaral, M.; Domingos, T.; Lopes, A.; Costa, E.I. Environmental, economic and social costs and benefits of a packaging waste management system: A Portuguese case study. Resour. Conserv. Recycl. 2014, 85, 67–78. [Google Scholar] [CrossRef]

- Edwards, J.; Burn, S.; Crossin, E.; Othman, M. Life cycle costing of municipal food waste management systems: The effect of environmental externalities and transfer costs using local government case studies. Resour. Conserv. Recycl. 2018, 138, 118–129. [Google Scholar] [CrossRef]

- FAOSTAT. Faostat Database. Available online: http://www.fao.org/faostat (accessed on 22 February 2019).

- Peano, C.; Girgenti, V.; Baudino, C.; Giuggioli, N.R. Blueberry supply chain in Italy: Management, innovation and sustainability. Sustainability 2017, 9, 261. [Google Scholar] [CrossRef]

- Giuggioli, N.R.; Girgenti, V.; Peano, C. Qualitative performance and consumer acceptability of starch films for the blueberry modified atmosphere packaging storage. Pol. J. Food Nutr. Sci. 2017, 67, 129–136. [Google Scholar] [CrossRef]

- Blanc, S.; Accastello, C.; Girgenti, V.; Brun, F.; Mosso, A. Innovative strategies for the raspberry supply chain: An environmental and economic assessment. Qual. Access Success 2018, 19, 139–142. [Google Scholar]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, X.; Wu, Z. A sustainable performance assessment framework for plastic film supply chain management from a chinese perspective. Sustainability 2016, 8, 1042. [Google Scholar] [CrossRef]

- Toniolo, S.; Mazzi, A.; Niero, M.; Zuliani, F.; Scipioni, A. Comparative LCA to evaluate how much recycling is environmentally favourable for food packaging. Resour. Conserv. Recycl. 2013, 77, 61–68. [Google Scholar] [CrossRef]

- Leceta, I.; Etxabide, A.; Cabezudo, S.; De La Caba, K.; Guerrero, P. Bio-based films prepared with by-products and wastes: Environmental assessment. J. Clean. Prod. 2014, 64, 218–227. [Google Scholar] [CrossRef]

- Siracusa, V.; Ingrao, C.; Lo Giudice, A.; Mbohwa, C.; Dalla Rosa, M. Environmental assessment of a multilayer polymer bag for food packaging and preservation: An LCA approach. Food Res. Int. 2014, 62, 151–161. [Google Scholar] [CrossRef]

- Mohamad, R.S.; Verrastro, V.; Cardone, G.; Bteich, M.R.; Favia, M.; Moretti, M.; Roma, R. Optimization of organic and conventional olive agricultural practices from a life cycle assessment and life cycle costing perspectives. J. Clean. Prod. 2014, 70, 78–89. [Google Scholar] [CrossRef]

- Falcone, G.; De Luca, A.I.; Stillitano, T.; Strano, A.; Romeo, G.; Gulisano, G. Assessment of environmental and economic impacts of vine-growing combining life cycle assessment, life cycle costing and multicriterial analysis. Sustainability 2016, 8, 793. [Google Scholar] [CrossRef]

- Grönman, K.; Soukka, R.; Järvi-Kääriäinen, T.; Katajajuuri, J.-M.; Kuisma, M.; Koivupuro, H.-K.; Ollila, M.; Pitkänen, M.; Miettinen, O.; Silvenius, F.; et al. Framework for sustainable food packaging design. Packag. Technol. Sci. 2013, 26, 187–200. [Google Scholar] [CrossRef]

- Pålsson, H.; Finnsgård, C.; Wänström, C. Selection of packaging systems in supply chains from a sustainability perspective: The case of volvo. Packag. Technol. Sci. 2013, 26, 289–310. [Google Scholar] [CrossRef]

- Gluch, P.; Baumann, H. The life cycle costing (LCC) approach: A conceptual discussion of its usefulness for environmental decision-making. Build. Environ. 2004, 39, 571–580. [Google Scholar] [CrossRef]

- Boukherroub, T.; Ruiz, A.; Guinet, A.; Fondrevelle, J. An integrated approach for sustainable supply chain planning. Comput. Oper. Res. 2015, 54, 180–194. [Google Scholar] [CrossRef]

- Matos, S.; Hall, J. Integrating sustainable development in the supply chain: The case of life cycle assessment in oil and gas and agricultural biotechnology. J. Oper. Manag. 2007, 25, 1083–1102. [Google Scholar] [CrossRef]

- Csiszar, S.A.; Meyer, D.E.; Dionisio, K.L.; Egeghy, P.; Isaacs, K.K.; Price, P.S.; Scanlon, K.A.; Tan, Y.-M.; Thomas, K.; Vallero, D.; et al. Conceptual framework to extend life cycle assessment using near-field human Exposure modeling and high-throughput tools for chemicals. Environ. Sci. Technol. 2016, 50, 11922–11934. [Google Scholar] [CrossRef]

- Gong, J.; You, F. Consequential life cycle optimization: General conceptual framework and application to algal renewable diesel production. ACS Sustain. Chem. Eng. 2017, 5, 5887–5911. [Google Scholar] [CrossRef]

- Baroni, L.; Cenci, L.; Tettamanti, M.; Berati, M. Evaluating the environmental impact of various dietary patterns combined with different food production systems. Eur. J. Clin. Nutr. 2007, 61, 279–286. [Google Scholar] [CrossRef]

- Wood, R.; Lenzen, M.; Dey, C.; Lundie, S. A comparative study of some environmental impacts of conventional and organic farming in Australia. Agric. Syst. 2006, 89, 324–348. [Google Scholar] [CrossRef]

- Cellura, M.; Longo, S.; Mistretta, M. Life cycle assessment (LCA) of protected crops: An italian case study. J. Clean. Prod. 2012, 28, 56–62. [Google Scholar] [CrossRef]

- Albrecht, S.; Brandstetter, P.; Beck, T.; Fullana-i-Palmer, P.; Grönman, K.; Baitz, M.; Deimling, S.; Sandilands, J.; Fischer, M. An extended life cycle analysis of packaging systems for fruit and vegetable transport in Europe. Int. J. Life Cycle Assess. 2013, 18, 1549–1567. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Mendoza, J.M.F.; Azapagic, A. Improving the environmental sustainability of reusable food containers in Europe. Sci. Total Environ. 2018, 628, 979–989. [Google Scholar] [CrossRef] [PubMed]

- Levi, M.; Cortesi, S.; Vezzoli, C.; Salvia, G. A comparative life cycle assessment of disposable and reusable packaging for the distribution of italian fruit and vegetables. Packag. Technol. Sci. 2011, 24, 387–400. [Google Scholar] [CrossRef]

- Singh, S.P.; Chonhenchob, V.; Singh, J. Life cycle inventory and analysis of re-usable plastic containers and display-ready corrugated containers used for packaging fresh fruits and vegetables. Packag. Technol. Sci. 2006, 19, 279–293. [Google Scholar] [CrossRef]

- Payen, S.; Basset-Mens, C.; Perret, S. LCA of local and imported tomato: An energy and water trade-off. J. Clean. Prod. 2015, 87, 139–148. [Google Scholar] [CrossRef]

- Webb, J.; Williams, A.G.; Hope, E.; Evans, D.; Moorhouse, E. Do foods imported into the UK have a greater environmental impact than the same foods produced within the UK? Int. J. Life Cycle Assess. 2013, 18, 1325–1343. [Google Scholar] [CrossRef]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.-J. Bio-based plastics—A review of environmental, social and economic impact assessments. J. Clean. Prod. 2018, 185, 476–491. [Google Scholar] [CrossRef]

- Vink, E.T.H.; Davies, S. Life cycle inventory and impact assessment data for 2014 Ingeo® polylactide production. Ind. Biotechnol. 2015, 11, 167–180. [Google Scholar] [CrossRef]

- Girgenti, V.; Peano, C.; Bounous, M.; Baudino, C. A life cycle assessment of non-renewable energy use and greenhouse gas emissions associated with blueberry and raspberry production in northern Italy. Sci. Total Environ. 2013, 458, 414–418. [Google Scholar] [CrossRef]

- Baudino, C.; Giuggioli, N.R.; Briano, R.; Massaglia, S.; Peano, C. Integrated methodologies (SWOT, TOWS, LCA) for improving production chains and environmental sustainability of kiwifruit and baby kiwi in Italy. Sustainability 2017, 9, 1621. [Google Scholar] [CrossRef]

- Rivera, X.C.S.; Azapagic, A. Life cycle costs and environmental impacts of production and consumption of ready and home-made meals. J. Clean. Prod. 2016, 112, 214–228. [Google Scholar] [CrossRef]

- Sierra-Pérez, J.; García-Pérez, S.; Blanc, S.; Boschmonart-Rives, J.; Gabarrell, X. The use of forest-based materials for the efficient energy of cities: Environmental and economic implications of cork as insulation material. Sustain. Cities Soc. 2018, 37, 628–636. [Google Scholar] [CrossRef]

- Blanc, S.; Brun, F.; Di Vita, G.; Mosso, A. Traditional beekeeping in rural areas: Profitability analysis and feasibility of pollination service. Qual. Access Success 2018, 19, 72–79. [Google Scholar]

- Pretty, J.N.; Ball, A.S.; Lang, T.; Morison, J.I.L. Farm costs and food miles: An assessment of the full cost of the UK weekly food basket. Food Policy 2005, 30, 1–19. [Google Scholar] [CrossRef]

- Brun, F.; Mosso, A. Production costs and profitability of blueberry cultivation (in Italian). Dendronatura 2013, 34, 77–85. [Google Scholar]

- Brun, F.; Mosso, A. Comparison of profitability of raspberry cultivars (in Italian). Dendronatura 2014, 35, 76–82. [Google Scholar]

- Observatory on the Mobility Behaviour of Italians. Italians’ Demand for Mobility—Economic Report at the end of the Year; National Communications Foundation: Rome, Italy, 2015. [Google Scholar]

- ISPRA. Municipal Waste Report. Available online: http://www.isprambiente.gov.it/it (accessed on 17 November 2018).

- Sanchez Ramirez, P.K.; Petti, L. Social life cycle assessment: Methodological and implementation issues. USV Ann. Econ. Public Adm. 2011, 11, 11–17. [Google Scholar]

- Jørgensen, A.; Le Bocq, A.; Nazarkina, L.; Hauschild, M. Methodologies for social life cycle assessment. Int. J. Life Cycle Assess. 2008, 13, 96–103. [Google Scholar] [CrossRef]

- Andrews, E.S. Guidelines for Social Life Cycle Assessment of Products; UNEP/Earthprint: London, UK, 2010. [Google Scholar]

- Dreyer, L.; Hauschild, M.; Schierbeck, J. A Framework for Social Life Cycle Impact Assessment (10 pp). Int. J. Life Cycle Assess. 2006, 11, 88–97. [Google Scholar] [CrossRef]

- Varsei, M.; Polyakovskiy, S. Sustainable supply chain network design: A case of the wine industry in Australia. Omega 2017, 66, 236–247. [Google Scholar] [CrossRef]

- De Luca, A.I.; Iofrida, N.; Leskinen, P.; Stillitano, T.; Falcone, G.; Strano, A.; Gulisano, G. Life cycle tools combined with multi-criteria and participatory methods for agricultural sustainability: Insights from a systematic and critical review. Sci. Total Environ. 2017, 595, 352–370. [Google Scholar] [CrossRef]

- Watkiss, P. Aggregate economic measures of climate change damages: Explaining the differences and implications. Wiley Interdiscip. Rev. Clim. Chang. 2011, 2, 356–372. [Google Scholar] [CrossRef]

- Dietz, S. The treatment of risk and uncertainty in the US social cost of carbon for regulatory impact analysis. Economics 2012, 6, 1–12. [Google Scholar] [CrossRef]

- Nordhaus, W.D. Revisiting the social cost of carbon. Proc. Natl. Acad. Sci. USA 2017, 114, 1518–1523. [Google Scholar] [CrossRef]

- Lu, X.; Yao, T.; Fung, J.C.H.; Lin, C. Estimation of health and economic costs of air pollution over the Pearl River Delta region in China. Sci. Total Environ. 2016, 566–567, 134–143. [Google Scholar] [CrossRef]

- Waldhoff, S.; Anthoff, D.; Rose, S.; Tol, R.S.J. The marginal damage costs of different greenhouse gases: An application of FUND. Economics 2014, 8, 1–33. [Google Scholar] [CrossRef]

- Álvarez-Chávez, C.R.; Edwards, S.; Moure-Eraso, R.; Geiser, K. Sustainability of bio-based plastics: General comparative analysis and recommendations for improvement. J. Clean. Prod. 2012, 23, 47–56. [Google Scholar] [CrossRef]

- Holland, M.; Spadaro, J.; Misra, A.; Pearson, B. Costs of Air Pollution from European Industrial Facilities 2008–2012—An Updated Assessment; EEA Technical report No 20/2014; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Bickel, P.; Friedrich, R. ExternE: Externalities of Energy: Methodology 2005 Update; Office for Official Publications of the European Communities: Luxembourg, 2004; ISBN 9279004239. [Google Scholar]

- Beccali, M.; Cellura, M.; Iudicello, M.; Mistretta, M. Resource consumption and environmental impacts of the agrofood sector: Life cycle assessment of italian citrus-based products. Environ. Manag. 2009, 43, 707–724. [Google Scholar] [CrossRef]

- Qi, Y.; Yang, X.; Pelaez, A.M.; Huerta Lwanga, E.; Beriot, N.; Gertsen, H.; Garbeva, P.; Geissen, V. Macro- and micro- plastics in soil-plant system: Effects of plastic mulch film residues on wheat (Triticum aestivum) growth. Sci. Total Environ. 2018, 645, 1048–1056. [Google Scholar] [CrossRef]

- Girgenti, V.; Peano, C.; Giuggioli, N.R.; Giraudo, E.; Guerrini, S. First results of biodegradable mulching on small berry fruits. Acta Hortic. 2012, 926, 571–576. [Google Scholar] [CrossRef]

- Almenar, E.; Samsudin, H.; Auras, R.; Harte, B.; Rubino, M. Postharvest shelf life extension of blueberries using a biodegradable package. Food Chem. 2008, 110, 120–127. [Google Scholar] [CrossRef]

- Van der Harst, E.; Potting, J.; Kroeze, C. Multiple data sets and modelling choices in a comparative LCA of disposable beverage cups. Sci. Total Environ. 2014, 494, 129–143. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Biopolymer production and end of life comparisons using life cycle assessment. Resour. Conserv. Recycl. 2017, 122, 295–306. [Google Scholar] [CrossRef]

- Soroudi, A.; Jakubowicz, I. Recycling of bioplastics, their blends and biocomposites: A review. Eur. Polym. J. 2013, 49, 2839–2858. [Google Scholar] [CrossRef]

- Asiedu, Y.; Gu, P. Product life cycle cost analysis: State of the art review. Int. J. Prod. Res. 1998, 36, 883–908. [Google Scholar] [CrossRef]

- Meeks, D.; Hottle, T.; Bilec, M.M.; Landis, A.E. Compostable biopolymer use in the real world: Stakeholder interviews to better understand the motivations and realities of use and disposal in the US. Resour. Conserv. Recycl. 2015, 105, 134–142. [Google Scholar] [CrossRef]

- Changwichan, K.; Silalertruksa, T.; Gheewala, S.H. Eco-efficiency assessment of bioplastics production systems and end-of-life options. Sustainability 2018, 10, 952. [Google Scholar] [CrossRef]

- Benoît-Norris, C.; Vickery-Niederman, G.; Valdivia, S.; Franze, J.; Traverso, M.; Ciroth, A.; Mazijn, B. Introducing the UNEP/SETAC methodological sheets for subcategories of social LCA. Int. J. Life Cycle Assess. 2011, 16, 682–690. [Google Scholar] [CrossRef]

- Ahmed, T.; Shahid, M.; Azeem, F.; Rasul, I.; Shah, A.A.; Noman, M.; Hameed, A.; Manzoor, N.; Manzoor, I.; Muhammad, S. Biodegradation of plastics: Current scenario and future prospects for environmental safety. Environ. Sci. Pollut. Res. 2018, 25, 7287–7298. [Google Scholar] [CrossRef] [PubMed]

- Comăniţă, E.-D.; Hlihor, R.M.; Ghinea, C.; Gavrilescu, M. Occurrence of plastic waste in the environment: Ecological and health risks. Environ. Eng. Manag. J. 2016, 15, 675–685. [Google Scholar] [CrossRef]

- Herbes, C.; Beuthner, C.; Ramme, I. Consumer attitudes towards biobased packaging—A cross-cultural comparative study. J. Clean. Prod. 2018, 194, 203–218. [Google Scholar] [CrossRef]

- Wageningen University. Biobased Food Packaging through the Eyes of the Consumer. Available online: https://www.wur.nl/en/article/Biobased-food-packaging-through-the-eyes-of-the-consumer.htm (accessed on 22 February 2019).

| Phase | Flow or Activity [Unit] | Input LCA | Input LCC | ||

|---|---|---|---|---|---|

| S1 | S2 | S1 | S2 | ||

| Material/Machinery | Costs | ||||

| Nursery | Rooting | Substratum (kg ha−1) | = | ||

| Mulching | PE (kg ha−1) | = | |||

| Fertigation system | Polyvinyl (kg ha−1) | = | |||

| Compost mix (kg ha−1) | = | ||||

| Water (m3 ha−1) | = | ||||

| Cultivation | Soil preparation, planting, management | Plough, harrow, and cultivator (h ha−1) | = | ||

| Diesel (l h−1) | = | ||||

| Harvest | = | ||||

| Irrigation system | PVC (kg ha−1) | = | |||

| Water (m3 ha−1) | = | ||||

| Electricity (kWh ha−1) | = | ||||

| Organic fertilization | Manure (t ha−1) | = | |||

| Mineral fertilization | Compost (t ha−1) | = | |||

| Mulching | PE (kg ha−1) | Materbì (kg ha−1) | sheet laying/sheet removal | only sheet laying | |

| Greenhouse cover | PE (kg ha−1) | = | |||

| Metal (kg ha−1) | = | ||||

| Hail-proof net | PE (kg ha−1) | = | |||

| Chemical treatment | Active substance (kg ha−1) | = | |||

| Transport from farm gate to post-harvesting | Road transport (km kg) | = | |||

| Transformation | Refrigeration | Electricity (kWh kg−1) | = | ||

| Flow packaging | Electricity (kWh kg−1) | = | |||

| PET tray (g kg−1) | PLA tray (g kg−1) | ≠ | |||

| PET wrapping (g kg−1) | = | ||||

| Transport from post-harvesting gate to point of sale | Road transport (km kg) | = | |||

| Sale | Refrigeration | Electricity (kWh kg−1) | = | ||

| Handling | Electricity (kWh kg−1) | = | |||

| Consumption | Transport | Road transport (km kg−1) | = | ||

| Refrigeration | Electricity (kWh kg−1) | = | |||

| End of life | Disposal | Incineration 20%/sanitary landfill 80% | = | ||

| GWP | NRE | Costs | Externalities | |||||

|---|---|---|---|---|---|---|---|---|

| kg CO2eq | MJ primary | €∙FU−1 | €∙FU−1 | |||||

| S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | |

| Nursery | 0.0054 | 0.0054 | 0.4896 | 0.4896 | 0.0121 | 0.0121 | 0.00019 | 0.00015 |

| Cultivation | 0.1525 | 0.1058 | 3.5017 | 1.9637 | 0.5419 | 0.5413 | 0.00690 | 0.00554 |

| Transformation | 0.1935 | 0.1692 | 5.0854 | 2.9894 | 0.6144 | 0.7541 | 0.00622 | 0.00382 |

| Sale | 0.0893 | 0.0893 | 1.3260 | 1.3260 | 0.0409 | 0.0409 | 0.02243 | 0.01802 |

| Consumption | 0.1350 | 0.1350 | 1.8870 | 1.8870 | 0.0045 | 0.0045 | 0.04239 | 0.03406 |

| End-of-life | 0.0318 | 0.0318 | 0.0253 | 0.0253 | 0.0014 | 0.0014 | 0.00035 | 0.00028 |

| Total | 0.6075 | 0.5366 | 12.3150 | 8.6810 | 1.2154 | 1.3545 | 0.07850 | 0.06190 |

| S1 | S2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type of Cost | €∙FU−1 | % | €∙FU−1 | % | |||||

| Machinery | 0.1643 | 13.5% | 0.1643 | 12.1% | |||||

| Labor | 0.7078 | 58.2% | 0.7077 | 52.2% | |||||

| Materials and services | 0.2531 | 20.8% | 0.3797 | 28.0% | |||||

| Mulching | 0.0022 | 0.18% | 0.0018 | 0.13% | |||||

| Plastic flow pack | 0.0630 | 5.18% | 0.1900 | 14.03% | |||||

| Other expenses | 0.0902 | 7.4% | 0.1028 | 7.6% | |||||

| Total | 1.2154 | 100% | 1.3545 | 100% | |||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanc, S.; Massaglia, S.; Brun, F.; Peano, C.; Mosso, A.; Giuggioli, N.R. Use of Bio-Based Plastics in the Fruit Supply Chain: An Integrated Approach to Assess Environmental, Economic, and Social Sustainability. Sustainability 2019, 11, 2475. https://doi.org/10.3390/su11092475

Blanc S, Massaglia S, Brun F, Peano C, Mosso A, Giuggioli NR. Use of Bio-Based Plastics in the Fruit Supply Chain: An Integrated Approach to Assess Environmental, Economic, and Social Sustainability. Sustainability. 2019; 11(9):2475. https://doi.org/10.3390/su11092475

Chicago/Turabian StyleBlanc, Simone, Stefano Massaglia, Filippo Brun, Cristiana Peano, Angela Mosso, and Nicole Roberta Giuggioli. 2019. "Use of Bio-Based Plastics in the Fruit Supply Chain: An Integrated Approach to Assess Environmental, Economic, and Social Sustainability" Sustainability 11, no. 9: 2475. https://doi.org/10.3390/su11092475

APA StyleBlanc, S., Massaglia, S., Brun, F., Peano, C., Mosso, A., & Giuggioli, N. R. (2019). Use of Bio-Based Plastics in the Fruit Supply Chain: An Integrated Approach to Assess Environmental, Economic, and Social Sustainability. Sustainability, 11(9), 2475. https://doi.org/10.3390/su11092475