Abstract

This study investigated the sustainable dyeing process of two natural dyes, Phellodendron Bark and camphor fruit, on oak veneer. The oak was pretreated with SC-CO2 and dyed using three methods, namely conventional water bath, SC-CO2, and vacuum pressurization, and the dyeing rate, color difference, washing fastness, and sunlight fastness were compared horizontally. BET test showed that the specific surface area of the oak was increased by 38%, the pore volume was increased by 46%, and the permeability of the oak was significantly improved after SC-CO2 pretreatment. The results of the three dyeing methods in dyeing show that vacuum-pressurized dyeing has the best effect, with a dyeing rate up to 27.64%, and an increase of 4.63%; the wood-washing color difference with SC-CO2-assisted Phellodendron Bark dyeing is only 3.15; the camphor berries’ actual air pressurized wood dyeing increased the sunlight fastness by 49%; SC-CO2-assisted Phellodendron Bark dyeing resulted in the highest crystallinity of 62.34%. This study compared the dyeing effects of different natural dyes under SC-CO2 pretreatment and different dyeing methods to solve the poor effect and low color fastness that natural dyes exhibit on wood, hoping to expand the application of wood in green, sustainable, functional materials.

1. Introduction

Wood is irreplaceable in many fields, such as construction, furniture, paper, energy fuels, etc. Compared to metals, plastics, and other materials, wood has unique natural advantages: it is renewable, biodegradable, non-toxic, and harmless [1]. The chemical industry’s growing demand for forest resources and the market’s over-harvesting of forest resources have stimulated conflicts between the supply and demand for wood, accelerating the need for environmental protection. BGCI has pointed out that the global forest crisis is a huge hidden danger for the forest industry and that there is an urgent need to research ways to increase the wood utilization rate and look for green substitutes for precious tree species. Dyeing can make the initially defective wood produce different surface colors and textures to achieve the effect of imitating those tree species, thus reducing the consumption of precious tree species, improving the application bottleneck of inferior tree species, and realizing the maximization of the sustainable use of resources [2,3].

Vegetable dyes meet the demand for green alternatives to industrial dyeing and printing due to their low biological toxicity and environmental compatibility [4,5]. Using natural plant dyes for wood dyeing can avoid the production of heavy metals, harmful halogenated substances, and other pollutants, and has become a hot research topic in the field of wood dyeing [6,7]. Commonly used chemical dyes have carcinogenic components such as aniline and heavy metals, and the wood dyed with them releases VOCs and formaldehyde, which are harmful to the environment and the human body [8]. Using natural plant dyes for wood coloring can prevent the generation of pollutants such as heavy metals and harmful halogenated substances, demonstrating excellent antibacterial and durability properties [9,10], and can also add value to agricultural materials [11]. This has become a popular research topic in the field of wood coloring. Phellodendron Bark and camphor fir fruit, as plant dyes, are harmless to the human body and have good biocompatibility [12], and both of these dyes have been shown to be ideal candidates for environmentally friendly wood dyeing. Camphor fruit pigments are extracted from the fruits of camphor (Cinnamomum camphora L.) [13], containing anthocyanosides, responsible for the red pigment, which are used in the fields of medicine, food, agriculture, and chemical industry [14], and are abundantly available. As of 2024, the area in which camphor is planted in China has exceeded 1.6 million mu, with Nanjing, Jiangsu Province, as the representative city, where camphor has become one of the most widely distributed street tree species in urban areas. However, camphor fir is prone to shedding many fruits during the autumn fruit-ripening period, which causes urban road pollution and increases the human and economic costs of municipal sanitation. Amurense Rupr. (Phelladendron amurense Rupr.) is a deciduous tree of the genus Phellodendron in the family Rutaceae, and its bark, as a source of pigment extraction, is light- and heat-resistant [15]. Extracting pigments from the fruit of camphor and the bark of Phellodendron amurense Rupr can stimulate the potential and value of plants and agricultural by-products, realize the concept of sustainable development, and reduce the dependence of traditional industries on harmful synthetic dyes [16]. However, natural dyes are primarily used in cotton fabrics, and there are still bottlenecks in the research of wood dyeing, such as low dyeing efficiency [17]. The reason for this is that plant dyes with high molecular weight and high polarity have a significantly higher diffusion resistance in the porous structure of wood than synthetic dyes, resulting in less than 20% of dyeing processes using the traditional water-bath method [18]. In addition, the hydrophobicity of the wood cell wall and the distribution of crystalline zones further hinder the penetration and fixation of dye molecules.

In order to improve the permeability of wood, the current research is mostly performed using physical aids such as chemical modification with NaOH [19] or ultrasound [20,21]. However, these methods may lead to degradation of the wood components or excessive energy consumption. Different treatments may cause different degrees of damage to the component structure of the wood, which in turn affects the mechanical properties of the wood [22,23]. Supercritical carbon dioxide (SC-CO2) pretreatment treats the extractives in the wood structure from a micromolecular point of view. It has unique physicochemical properties such as low viscosity, high diffusivity, and adjustable solvent strength [24], which researchers have emphasized in recent years [25]. When the temperature and pressure exceed a certain critical point, SC-CO2 can penetrate the ultrastructure of wood in a gas-like state and significantly improve pore connectivity by expanding the cell wall and dissolving the extractives. Yang et al. pretreated eucalyptus wood with SC-CO2, which improved its permeability by 40%; Yuhong Zhang’s team optimized the extraction of Phellodendron Bark alkaloids using SC-CO2 and proved that it is highly efficient in carrying the natural pigment [26]. Through the lipophilic pretreatment of wood or by adding a small amount of water, Jaxel et al. demonstrated that using SC-CO2-assisted dyeing can effectively improve the coloration rate and uniformity of dispersion of blue dye on wood [27,28].

Supercritical carbon dioxide (SC-CO2) and vacuum-pressurization-assisted techniques for treating extractives in the wood structure from a microscopic molecular point of view to improve the internal permeability of wood in a green and non-toxic way [29,30,31,32] have received much attention from researchers in recent years. In the study of SC-CO2 modification and assisted dyeing, it was found that this technology could increase the permeability of Paulownia fortunei sapwood by up to 140.5% [33]. In terms of auxiliary dyeing, water-saturated SC-CO2 can improve the accessibility of dyes to solid wood through swelling [28]. Adding an appropriate amount of DMSO to SC-CO2 can further enhance the dye permeability of wood [34], and SC-CO2 treatment can also increase the absorption rate and dyeing saturation of synthetic dyes to wool, polyester, nylon, and their composite textiles [35]. Alpaca fibers showed excellent washing color fastness in SC-CO2-assisted acid-dye dyeing studies [36]. Although SC-CO2 demonstrated better fiber dyeing enhancement under specific treatments [37], it is still theoretically a hydrophobic transport medium, which contradicts the hydrophilic property of wood as a material. Therefore, few studies have been conducted on SC-CO2-assisted natural-dye dyeing of wood. Vacuum-pressure impregnation drives the modifier into the wood capillary system through a pressure gradient, its dyeing efficiency is significantly higher than that of atmospheric-pressure impregnation [38,39], and it can grant wood good flame-retardant and smoke-inhibition effects [40,41]. Wang, Hao et al. successfully penetrated epoxy resin into fast-growing wood using vacuum-pressure impregnation and improved the dimensional stability and mechanical properties of the wood [42,43]. Taghiyari, Rahayu et al. investigated the effects of different vacuum pressures and pressurized impregnation times on the preservative and magnetic properties of wood [44,45,46]. However, most of these studies have focused on the effects of wood modification in terms of fire retardancy, impregnation, and dimensional stability [47,48], and the research on natural dye-stained wood is still at the starting point [27]. In order to expand the application of global sustainable forest resources in industrial products, based on the industrial manufacturing need to process materials to meet the industrial timber standards [49,50] from the macro–micro synergistic analysis perspective, careful and comprehensive consideration of the impact of different processing processes on the structure and properties of the material itself is necessary [51,52,53], in order to promote the green and sustainable development of the wood products industry [54,55,56]. Existing research focuses on single performance indicators (e.g., dyeing rate or color difference) [57], a single dyeing process, and lacks multi-dimensional characterization of dyeing mechanism (e.g., dye–wood interface binding mode, crystallinity change), and multi-process effect comparison. Therefore, it is of great significance in theoretical and practical application to combine and compare supercritical carbon dioxide technology and vacuum-pressurization technology to study their roles in the natural dye–wood system.

Oak species (Quercus spp.) of high-quality hardwood are widely distributed in North America, Europe, and East Asia. Due to their excellent material properties and unique appearance, they are used in the high-end decoration field [58,59,60,61]. The complexes formed by the phenolic hydroxyl groups of tannins and metal ions in this tree species [62,63], the π-π stacking effect of lignin aromatic ring structures, and the hydrogen bonds or ionic bonds between carboxyl groups and dye molecules [64,65] can positively enhance the dyeing depth and color fastness. However, the color difference between the heartwood and sapwood of plantation oak is large, and the dense structure makes dyeing difficult. Therefore, optimizing the dyeing technology to regulate the color is the key to enhancing the added value.

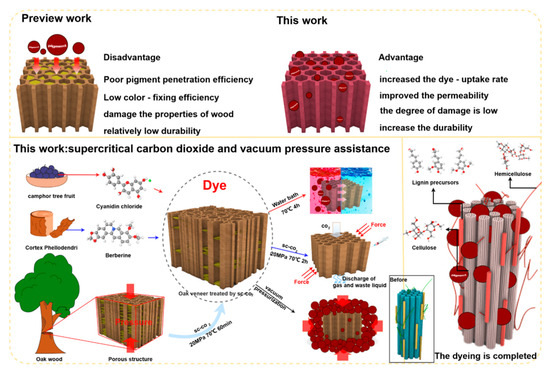

In this study, oak veneer was used as the object as Figure 1, and the natural dyes of Phellodendron Bark and camphor fruit were selected to systematically compare the comprehensive performance differences in SC-CO2-assisted dyeing, vacuum-pressurized dyeing, and the conventional water-bath method. The dyeing efficiency and stability of different processes were clarified by quantifying the dyeing rate, color difference, reflectance spectrum, and color fastness to washing and sunlight. Combined with FTIR, SEM, and XRD analyses, we elucidated the mechanisms of SC-CO2 and vacuum pressurization on dye distribution, wood microstructure, and chemical bonding. The aim is to promote the use of eco-dyeing technology through the high-value utilization of fruit-based bio-waste, combined with SC-CO2 dyeing in anhydrous media and compared with vacuum-pressurization-assisted methods, to optimize the dyeing process and reduce the cost and risk to the environment, while guaranteeing the excellent dyeing performance and color fastness. We will construct a theoretical system of efficient wood dyeing based on renewable biological resources and provide new ideas and processes to promote the dyeing industry’s further transformation to carbon-neutral and green manufacturing.

Figure 1.

A schematic diagram of the wood pretreatment and dyeing process.

2. Materials and Methods

2.1. Material

Oak veneer, 12% moisture content, air-dry density 0.68 g/cm3, size 40 mm × 40 mm × 2 mm; USA; unpretreated oak veneer, 12% moisture content, air-dry density 0.68 g/cm3, size 40 mm × 40 mm × 2 mm; USA. Pick fresh and mature camphor tree fruits (from Nanjing, China), remove the surface dust, and remove the seeds. Freeze for 24 h. Use a blender to crush them at room temperature into fruit pulp, then place the pulp in a freezer at −30 °C for later use. Put the bark of Phellodendron (from Dujiangyan, China) into an electric-heating, circulating, constant-temperature drying oven, and set the temperature at 100 °C for drying. Take an appropriate amount of the dried Phellodendron Bark, remove the surface impurities, and use a grinding machine to crush it, obtaining Phellodendron powder. Seal and store it for later use.

2.2. Methods

2.2.1. Supercritical Carbon Dioxide Pretreatment

The oak was pretreated with supercritical carbon dioxide at a pressure of 20 MPa, a treatment time of 60 min, and a treatment temperature of 70 °C. The pretreated oak was used as a backup material for dyeing.

2.2.2. SC-CO2 Pretreatment Oak-Veneer Porosity Testing

The SC-CO2 pretreated oak specimens were crushed to a section size of <3 mm, dried in an oven at 100 °C for 12 h to avoid residual moisture affecting the adsorption amount, and then loaded into sample tubes and sealed to avoid contamination. Liquid nitrogen was used for adsorption, and the change in adsorption amount was recorded to generate adsorption isotherms.

Nitrogen adsorption test was used to characterize the cell-wall pore structure of each group of test materials separately. Around 1 g of 60-mesh wood flour samples were added to the sample compartment and degassed at 80 °C for 190 min. The total pore volume (Vtotal) of the test materials was obtained based on the change in the volume of liquid nitrogen at a relative pressure of 0.99; the specific surface area of the test materials was examined according to the Brunauer–Emmett–Teller (BET) method, and the specific surface area of the samples in this paper was calculated using the nitrogen adsorption data with relative pressures between 0.04 and 0.2 were calculated using the BET equation. The calculation, Formula (1), is shown as follows:

V is the adsorption volume corresponding to the relative pressure, cm3 g−1; Vm is the saturated adsorption volume of the monomolecular layer, cm3 g−1; and C is the BE equation constant.

The test material’s cumulative pore volume and pore size distribution were then analyzed using the Barrett–Joyner–Halenda (BJH) method. This method was developed based on the Kelvin capillary condensation theory, and the parameters of pore volume, pore size distribution, total pore volume, and average pore size were obtained according to the BJH equation g. The BJH equation is shown in Formula (2):

where rk is the radius of curvature (nm) of the adsorbed gas condensed in the pores; σl is the surface tension of the liquid condensate (0.008876 N/m); Vm is the molar volume of the liquid condensate, which takes the value of 0.034752 L/mol; and Tb is the analyzed temperature, which takes the value of 77.35 K. The analyzed temperature determined the analyzed temperature of the liquid condensate.

2.2.3. Conventional Water-Bath Staining Test

Conventional water-bath dyeing was carried out using untreated material and supercritical carbon dioxide-pretreated oak veneers as test pieces. Two oak veneers in each group were repeated three times using Phellodendron Bark dye and camphor fruit dye, respectively.

Conditions: temperature, 70 °C; concentration of dye solution, 1%; time, 4 h.

Test procedure: the test material was immersed in a beaker containing 60 mL of dye solution, one piece of wood for each beaker, put into a constant temperature water bath with a set temperature, and closed using cling film to prevent excessive evaporation of water; when the end of the test was reached, the veneer was removed, the surface of the dye solution was rinsed with purified water, dried in the electric blast oven (101-3ES, Shanghai Yiheng Scientific Instrument Co., Ltd., Shanghai, China) at 103 ± 2 °C, and then the chromaticity value of the specimen was measured.

2.2.4. Supercritical Carbon Dioxide-Assisted Staining Test

Untreated wood and supercritical carbon dioxide-pretreated oak veneers were used as specimens for supercritical carbon dioxide dyeing. The process was repeated three times for two oak veneers in each group, with Phellodendron Bark dye and camphor fruit dye, respectively.

Conditions: pressure, 20 MPa; temperature, 70 °C; concentration of dye solution, 1%; time, 2 h.

Test Steps:

- (1)

- Load the test material into the kettle, load it into the supercritical carbon dioxide extractor (HM120-50-025, Jiangsu Hai’an Hongmai Machinery Co., Ltd., Nantong, China), and wait for the temperature to rise to that required for the test.

- (2)

- Open the corresponding inlet and outlet valves, open the CO2 pump to start pressurizing the system at a frequency of 18.23, and adjust the pressure stabilizing valve to stabilize the pressure after the system is pressurized to the required test pressure.

- (3)

- Each time the tracer tank is filled with 30 mL of the configured dye solution, the tracer pump is turned on at a frequency of 18.13. A total of 120 mL of dye solution is injected four times, and the timing is started when the dye solution is injected.

- (4)

- After the end of the dyeing test, open the valve to exhaust gas in small amplitude, and when the pressure drops to 4 MPa, release the remaining gas and waste liquid, remove the material, rinse the surface with pure water, dry it in an electric blast oven at 103 ± 2 °C, and measure the chromaticity value of the test piece.

2.2.5. Vacuum-Pressurized Impregnation-Assisted Dyeing Test

Untreated material and supercritical carbon dioxide-pretreated oak veneers were used as test pieces for vacuum-pressurized impregnation dyeing. Two oak veneers in each group were dyed three times, using 1% Phellodendron Bark Dye and camphor fruit dye, respectively.

The test conditions were as follows: a pressure of −0.1 MPa, pressurized to 2.5 MPa; temperature, 70 °C; concentration of dye solution, 1%; magnetic stirrer (78-1, Tianjin Cyberis Experimental Analytical Instrument Manufacturing Factory, Tianjin, China) rotational speed, 40 r/min. To achieve a deeper and more uniform dyeing, the dyeing time was set at 2 h.

- (1)

- Load the test material into the material barrel containing 120 mL of dyeing liquid between the material barrel and the kettle, with water as the temperature conduction medium; the water level should be higher than the dyeing liquid level in the material barrel to ensure that the dyed oak veneer can be completely immersed in the dyeing liquid. Lock the bolt of the pot lid to ensure safety during the test. To maximize the extraction of air inside the wood, open the dye-solution entry channel, set the pressure to −0.1 MPa, heat to the set temperature, and maintain for 30 min.

- (2)

- In order for the dye solution to quickly and evenly penetrate the wood surface and reach the internal vessels, fill the kettle with nitrogen gas pressurized to 2.5 MPa, start the timer, and run the magnetic stirrer for 5 min every 15 min during the test to prevent the dye collecting, caused by the wood remaining still.

- (3)

- At the end of the test, open the valve, release the pressure, remove the dyed veneer, use pure water to flush away the dye residue on the surface of the veneer, dry it in an electric blast oven at 103 ± 2 °C, and measure the chromaticity value of the test piece.

2.2.6. Measurement of Staining Rate

The absorbance values of the staining solution before and after dyeing (maximum absorption wavelength of Phellodendron Bark dye: 329 nm, maximum absorption wavelength of camphor fruit dye: 517 nm) were measured by using U-3900 UV–visible Spectrophotometer (Hitachi High-Technology Co., Ltd., Tokyo, Japan), and before the test started, 0.5 mL of Phellodendron Bark dye was taken out of the pre-prepared staining solution and diluted 30 times, and the absorbance was measured as A0; after the test, 1 mL of Phellodendron Bark dye was taken and diluted 10 times, and the absorbance was measured as A1. The up-dyeing rate was calculated according to Formula (3):

where A0 is the absorbance at the maximum absorption wavelength of the dye solution before staining, in Abs; A1 is the absorbance at the maximum absorption wavelength of the dye solution after staining, in Abs.

2.2.7. Determination and Analysis of Colorimetric Values

Wood color is mainly measured by a colorimeter (Ci6x, Shanghai Keheng Industrial Development Co., Ltd., Shanghai, China), using the CIE (1976) L*a*b* uniform color space, in the direction of the coordinate axes of the three-dimensional color space, which are isometric perceptions in the visual sense. L*a*b* is collectively referred to as the chromaticity value, L* is the brightness of the material value; the larger the L* value, the brighter the material is, and the smaller it is, the darker. a* represents the red-green value; the value is positive if the specimen is reddish, and the value is negative if the specimen is greenish. b* represents the yellow-blue value; the value is positive if the specimen is yellowish, and the value is negative if the specimen is bluish. Typically, the parameters L*, a*, and b* can be recorded, and the color difference ΔE*, which represents the change in surface color, is calculated according to Formulas (4) and (5). The colorimetric value is calculated according to the following formula.

The chromaticity values are , , (after dyeing) and , , (before dyeing); ∆E* indicates the color-difference value in NBS. The larger ΔE* is, the larger the difference in color between the surface wood before and after treatment, and vice versa, the smaller the color difference.

2.2.8. Analysis of Reflectance Spectra Using Different Staining Methods

The reflectance spectra of the wood veneers before and after staining were measured using the U-3900 ultraviolet spectrophotometer (HITACHI U-3900, Tokyo, Japan). The color of the wood surface can be displayed by the surface spectral reflectance curves of the wood veneers before and after staining. Since the light at specific wavelengths is absorbed by the wood, the wood can reflect less light at that wavelength. The wavelength corresponding to the peak reflectance of the curve represents the color of the measured material. The R value is positively correlated with the brightness, so the level of the R value reflects the change in brightness of the object at different wavelengths. After the oak was subjected to SC-CO2 pretreatment, the reflectance at 800 nm (R0) was measured, and the reflectance R after staining with different methods was recorded, respectively. Based on the Kubelka–Munk theory, the K/S values of different methods were calculated according to Formula (6), and the differences between the three methods were pairwise compared according to Formula (7).

K represents the absorption coefficient of the wood; S represents the scattering coefficient of the wood, reflecting its ability to scatter light; R represents the reflectance of the dyed sample, and R0 is the reflectance of the undyed sample. Generally, the larger the value of K/S, the stronger the dyeing effect.

2.2.9. Scanning Electron Microscope Micro-Morphology Analysis

The instrument used for the test: QUANTA 200 (FEI Company, Hillsboro, OR, USA); test conditions: tungsten filament; accelerating voltage: 200 V–30 kV; magnification: 20–300,000 times; resolution: 3.5 nm. Specific methods: the samples are dried sufficiently prior to the test, cut into suitable small pieces, and fixed in the double-sided conductive adhesive paste on the test bench. The samples are then sprayed with gold in a vacuum coater, and finally, the microstructure of the wood is observed.

2.2.10. Infrared Spectral Analysis

A VERTEX 80 V Fourier infrared spectrometer (BRUKER Corporation, Billerica, MA, USA) was used to characterize the characteristic groups of the veneer; the samples to be tested were kept dry and clean before testing to avoid the influence of water vapor on the data. Scanning was carried out using Smarti TR diamond ATR mode; the window background was scanned and measured to remove the interferences for 16 scans, and then the sample underwent 16 scans with a wave number range of 4000 to 500 cm−1.

2.2.11. X-Ray Diffraction Analysis

The X-ray diffractometer used for testing was the (Ultima IV) (Rigaku, Tokyo, Japan), with a copper target, scanning speed 5°/min, and scanning range 2θ = 5 to 50°. The sample size was kept within 1.5 × 1.5 cm, and the sample was kept dry with a flat surface. After the test, the relative crystallinity of wood cellulose was calculated using the Segal method according to Formula (8).

Wood crystallinity is shown in Formula (8).

CyI is the crystallinity index in %, (002) crystalline diffraction intensity in a.u., and amorphous region diffraction intensity in a.u.

2.2.12. Determination of Color Fastness to Washing

The different dyeing processes are detailed as follows: dye oak veneer is placed into a beaker containing 60 mL of pure water, in a constant-temperature water bath with a water temperature of 70 °C, for two hours. Close the water bath, remove the veneer, and use pure water to rinse clean. In 103 ± 2 °C electric blast oven drying, a colorimeter is used to measure the difference in surface color before and after water washing, calculating the difference between the colors on its surface; the smaller the color difference, the better its resistance to water washing. Use Formulas (4) and (5) in Section 2.2.6. to calculate the value of water-washing chromaticity. Refer to the international standard (ISO 105 C06; 2010) [66] to determine the color fastness to washing. According to Formula (9), calculate the gray-scale grades of the two dyes under different pretreatment conditions and using different dyeing methods. The higher the grade, the better the color fastness to washing. The formula for the gray-scale grade is as follows in Formula (9).

ΔE represents the difference in CIELab values between the sample and the control sample, and ΔE1 is the value of ΔE corresponding to a 1-level difference (calibrated using the standard gray card, with version 4.10; the value is 8.0).

2.2.13. Determination of Color Fastness to Sunlight

The oak veneer was dyed using different dyeing processes, put into the UV aging lamp, with temperature 30 °C, humidity 30%, light intensity of 38 W/m2, under UV irradiation for 100 h; then, use the colorimeter to determine the chromaticity value of its light and calculate the value of the chromatic aberration. The smaller the chromatic aberration value, the better the lightfastness. Calculate the chromaticity value by using Formulas (4) and (5) in Section 2.2.6. Refer to the international standard (ISO 105 B02: 2014) [67] for the determination of color fastness to light exposure. According to Formula (9), calculate the gray-scale grades of the two dyes under different pretreatment conditions and using different dyeing methods. The higher the grade, the better the lightfastness.

3. Results and Discussion

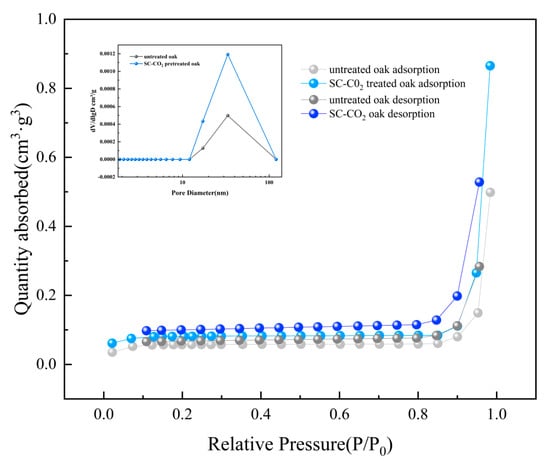

3.1. Analysis of SC-CO2 Pretreatment Oak-Veneer Porosity Test Results

Specific effects of supercritical carbon dioxide pretreatment on the pore structure of wood, assessing changes in specific surface area, pore volume, and average pore diameter before and after pretreatment.

Previous studies have found that after SC-CO2 was used to extract flavonoids from Pinus bungeana cones, prepare dry leather, and pretreat walnut shells, the specific surface area of all three increased to varying degrees, and the pore volume also increased simultaneously [68,69,70]. As shown in Table 1, the specific surface area of the treated oak increased by 38%, the pore volume increased by 46%, and the average pore diameter also slightly increased, indicating that SC-CO2 pretreatment can effectively promote pore development without affecting the main structure of the wood. It should be noted that, compared with previous studies, the porosity of oak treated with SC-CO2 did not show a significant increase. This phenomenon is mainly attributed to the dense pore structure of oak itself. The results of the nitrogen adsorption and desorption experiments shown in Figure 2 demonstrated that the untreated samples showed typical type IV isotherms, indicating their natural mesoporous characteristics. After SC-CO2 pretreatment, the adsorption capacity of the samples was enhanced in the high-relative-pressure region, and the pore size distribution was expanded to a larger scale, reflecting a significant optimization of the pore structure. This change may be attributed to the selective migration of SC-CO2 to fillers such as resins and extractives in the wood. This promotes the opening and expansion of the original pores and thus improves the pore-specific volume and connectivity. The good tunable fluid properties of SC-CO2 enable it to enter the cellular interstitial space, dissolve and remove the barriers, and expand the structural channels. At the same time, the expansion–decompression process may lead to the formation of new pores in the cell wall.

Table 1.

Specific surface area and pore size of oak before and after SC-CO2 pretreatment.

Figure 2.

Nitrogen adsorption and desorption curves and pore distribution before and after SC-CO2 pretreatment of oak wood.

The results showed that the SC-CO2 pretreatment significantly enhanced the wood’s mesopore volume and structural permeability while maintaining its macrostructure stability. This structural modification enhanced the specific surface area and adsorption properties of the wood and provided more diffusion and attachment sites for plant dyes during the subsequent wood-dyeing process, which has good potential for material modification and green functional applications.

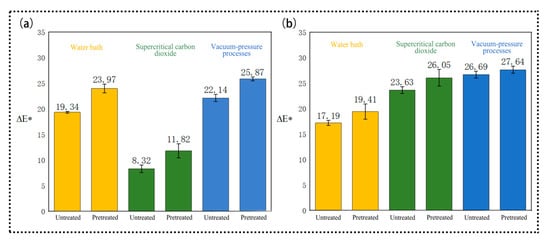

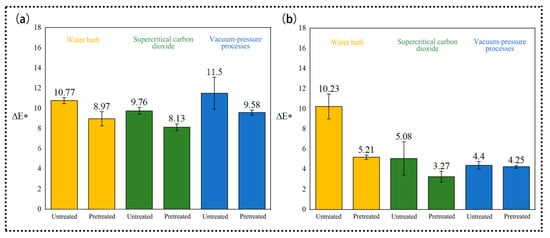

3.2. Analysis of the Results of Three Dyeing Methods to Determine the Dyeing Rate

The effects of the three dyeing methods on the staining rate of oak are shown in Figure 3. The results of the staining rate of oak dyed with Phellodendron Bark pigment in three dyeing methods are shown in Figure 3a. It can be seen that in the same dyeing method, the staining rate of oak dyed with supercritical carbon dioxide pretreatment was higher than that of untreated material; comparing the staining rate of different dyeing methods, it can be seen that the staining rate of vacuum high-pressure dyeing was the best with 25.87%, followed by the conventional water-bath dyeing with 23.97%, and supercritical carbon dioxide dyeing with the lowest at 11.82%, and this result was consistent with what has been reported.

Figure 3.

Staining rate of two dyes staining oak with three staining methods (ΔE* indicates the color difference of veneer). (a) Phellodendron amurense; (b) camphor fruits.

From the staining rate results of the three camphor fruit dyeing methods shown in Figure 3b, it can be seen that, when using the same dyeing methods for the supercritical carbon dioxide-pretreated dyed oak, the staining rates are higher than the untreated material; compared with the staining rate of different dyeing methods, it can be seen that vacuum high-pressure dyeing staining rate has the best effect with 27.64%, the supercritical carbon dioxide dyeing rate is next, in second with 26.05%, and the rate of conventional water-bath dyeing was the lowest with 19.24%. The effect of vacuum-pressure dyeing with supercritical carbon dioxide pretreatment on oak is significantly better than that of eucalyptus in previous studies [71]. The dyeing effect of SC-CO2 is superior to that of North American sugar maple, which is also a hardwood [72]. It is speculated that this is related to the dissolution of phenolic and tannin substances in oak, which forms more internal channels [73]. The K/S value of the sample can be increased due to the high solubility of the dye by SC-CO2 [74], but it will be affected when the dye reacts with the wood components [75].

By comparing the two types of pigments, it can be seen that both the supercritical carbon dioxide and vacuum-pressurized impregnation dyeing methods have a significant improvement effect on the dyeing rate of cypress wood dyed with cypress fruit pigment; for the yellow-bark pigment, only the vacuum-pressurized dyeing method can increase the dyeing rate of oak wood, while the supercritical carbon dioxide dyeing process actually reduces the dyeing rate of oak wood. This might be the result of the contradiction between the low polarity characteristics of the SC-CO2 system and the strong polarity dependence of the magnolia molecule. This makes it more difficult for the magnolia dyes to disperse and migrate in the SC-CO2 environment compared to camphorwood dye, thereby weakening their penetration and fixation effects in the wood cell wall.

3.3. Analysis of Colorimetric Values of Stained Oak by Three Dyeing Methods

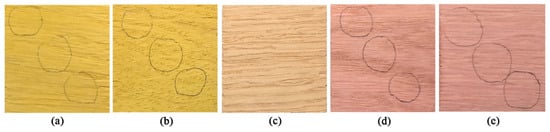

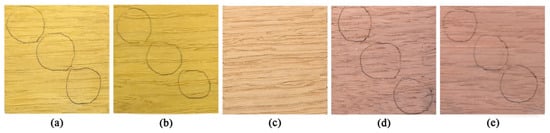

Oak veneer after water-bath dyeing with Phellodendron Bark dye, as shown in Figure 4a,b. It can be seen that after dyeing the untreated material and supercritical pretreated material, the color of the oak deviated from the original color, showing a yellow color close to the dye. The effect of oak veneer dyed with camphor fruit dye in a water bath is shown in Figure 4d,e. After dyeing the untreated material and supercritical pretreated material, it can be seen that the color of oak deviates from the original color, presenting a color close to the purple-red.

Figure 4.

Water-bath dyeing (three circular regions were selected as fixed positions for chromaticity measurements). (a) Untreated wood dyed with Phellodendron; (b) pretreated wood dyed with Phellodendron; (c) undyed oak; (d) untreated wood dyed with camphor fruit; (e) pretreated wood dyed with camphor fruit.

The effect of oak veneer after supercritical carbon dioxide-assisted Phellodendron Bark dyeing is shown in Figure 5a,b. It can be seen that after dyeing the untreated material and supercritical carbon dioxide-pretreated material, the color of the oak deviated from the original color, showing a yellow color close to the dye. The oak veneer after the dyeing effect of supercritical carbon dioxide-assisted camphor fruit dye is shown in Figure 5d,e. It can be seen that after dyeing the untreated material and supercritical carbon dioxide-pretreated material, the color of the oak deviated from the original color, showing a purple-red close to the dye.

Figure 5.

SC-CO2 dyeing (three circular regions were selected as fixed positions for chromaticity measurements). (a) Untreated wood dyed with Phellodendron; (b) pretreated wood dyed with Phellodendron; (c) undyed oak; (d) untreated wood dyed with camphor fruit; (e) pretreated wood dyed with camphor fruit.

Similar to the water bath and supercritical carbon dioxide dyeing processes, as shown in Figure 6a,b, the oak veneers dyed with Phellodendron Bark extract using vacuum–pressure impregnation exhibited a noticeable color deviation from the original material, presenting a yellow tone closer to that of the dye. The results of dyeing oak veneers with camphora fruit extract under vacuum–pressure conditions are shown in Figure 6d,e. It can be observed that both the untreated and the supercritical carbon dioxide pretreated veneers, after dyeing, shifted in color away from the original oak toward a purplish-red hue similar to that of the dye. However, compared with supercritical carbon dioxide–assisted dyeing, the colors achieved through the vacuum–pressure method were lighter for both pigments.

Figure 6.

Vacuum-pressure dyeing (three circular regions were selected as fixed positions for chromaticity measurements). (a) Untreated wood dyed with Phellodendron; (b) pretreated wood dyed with Phellodendron; (c) undyed oak; (d) untreated wood dyed with camphor fruit; (e) pretreated wood dyed with camphor fruit.

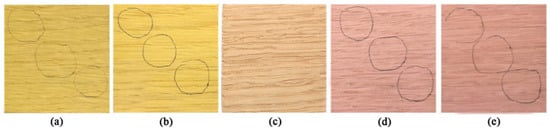

The L value represents the change in brightness, the a value represents the change in the red-green value, the b value represents the change in the yellow-blue value, and the E value represents the change in the overall color difference after dyeing. From Figure 7a, it can be seen that the brightness value ΔL of Phellodendron Bark and camphor fruit dyes is negative after dyeing wood by different methods, the brightness of wood is reduced, and the brightness of the oak is reduced more after being dyed with camphor fruit pigment; after dyeing the supercritical pretreated oak, the decrease in brightness is greater than that of the non-pre-treated oak. As shown in Figure 7b, the color of the oak tends to be green when Δa is negative after Phellodendron Bark dyeing and red when Δa is positive after camphor fruit pigment dyeing; Figure 7c shows that the color of oak tends to be yellow after Phellodendron Bark dyeing, and blue when Δb is negative after camphor fruit pigment dyeing.

Figure 7.

Effect of different staining methods on the color difference in oak. (a) The change in brightness; (b) the change in the red-green value; (c) the change in the yellow-blue value; (d) the change in the overall color difference.

Table 2 shows the analysis of variance of color-difference parameters. The analysis of variance showed that whether or not supercritical carbon dioxide pretreatment was used had a significant effect on ΔE and Δa in camphor fruit pigment-dyed oak, while different dyeing methods had statistical significance regarding ΔE, ΔL, Δa, and Δb. In Phellodendron amurense-dyed oak, whether pretreatment was used had a significant effect on ΔE, ΔL, and Δa, and the dyeing method had a significant effect on all four values. This might be because the driving force intensity of different dyeing methods could directly affect the penetration depth and distribution uniformity of the dye, thereby influencing the color-difference values of oak. In the analysis of the interaction effect of the two factors on the results, it was found that only the ΔL value of camphor fruit pigment-dyed oak had statistical significance. This might be because the molecular weight of camphor fruit pigment is smaller than that of Phellodendron amurense, and it has stronger diffusibility and is more sensitive to the synergistic effect of multiple influencing factors.

Table 2.

Analysis of variance of color-difference parameters.

Comparing the different staining methods in Figure 7, it can be seen that with the water-bath staining method of untreated and pretreated materials of oak, the brightness value L of the Phellodendron Bark pigment and the camphor fruit pigment decreased by 0.49 and 2.12, respectively, and the reddish-green value increased by 0.48 and 0.71, respectively. The bluish-yellow value b increased by 0.15 and 0.35, respectively. In the supercritical staining, the brightness value L of the Phellodendron Bark pigment and camphor fruit pigment decreased by 3.45 and 0.63, respectively. The red-green value of Phellodendron Bark pigment increased by 0.72, the red-green value of camphor fruit pigment decreased by 0.15, the blue-yellow value of Phellodendron Bark pigment b decreased by 0.09, and the yellow-blue value of camphor fruit pigment increased by 0.25. With the vacuum-pressurized dyeing, the brightness values of Phellodendron Bark pigment and camphor fruit pigment decreased by 1.27 and 2.08, the red-green value of camphor fruit pigment a increased by 0.12 and 1.44, and the blue-yellow value b increased by 2.39 and 0.9, respectively.

It can also be seen from Figure 7 that the degree of influence of supercritical dyeing on brightness was slightly higher than that of water-bath dyeing (except for Phellodendron Bark without pretreatment oak), while the influence of vacuum-pressurization dyeing on brightness was smaller than that of water-bath dyeing; the influence of supercritical dyeing of Phellodendron Bark on the a value was more substantial than that of water-bath dyeing, and the effect of vacuum pressurization was not much different from that of water-bath dyeing. In comparison, the degree of influence of supercritical dyeing of camphor fruit and vacuum-pressurization dyeing on the a value were both lower than that of water-bath dyeing (except Phellodendron Bark without pretreatment oak). The effect of Phellodendron Bark supercritical staining on the b value was lower than that of water-bath staining. The effect of vacuum pressurization did not differ much from that of water-bath staining, while the degree of effect of camphor fruit supercritical staining on the b value did not differ much from that of water-bath staining. The effect of vacuum-pressurization staining on the b-value was lower than that of water-bath staining. Supercritical dyeing and vacuum-pressurized dyeing did not significantly improve the color difference in oak, but the color difference in supercritical dyeing compared with the water-bath dyeing was also reduced. From the previous analysis, it can be seen that supercritical carbon dioxide and vacuum pressurization have improved the dyeing rate of Phellodendron Bark-dyed oak. However, the data on the color difference did not reflect the consistency, which indicates that the color difference is mainly a reaction to the change in the surface color of the oak. The increase in the dyeing rate helps the accumulation of pigment on the surface of the wood, but there is no direct connection with the color difference. The increase in the dyeing rate is more a response to the increase in the efficiency of the supercritical carbon dioxide and vacuum pressurization on the delivery of pigments to the interior of the wood rather than a direct effect on the deepening of the color or increase in color difference.

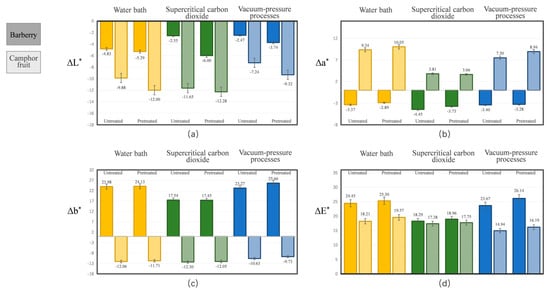

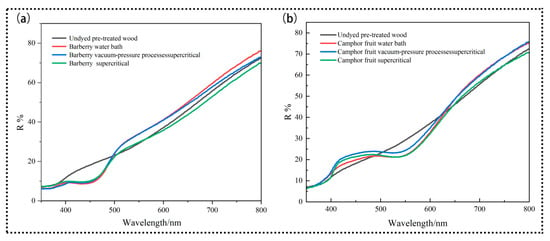

3.4. Reflectance Spectral Analysis of Dyed Oak on Three Dyeing Methods

As shown in Figure 8, before and after supercritical carbon dioxide-assisted Phellodendron Bark dye and camphor fruit dye dyeing, the R value of undyed oak veneer was higher than that of Phellodendron Bark-dyed wood in the range of 400–500 nm, which indicated that the blue-violet light absorbed by the dyed wood veneer was increased, and the blue-violet light reflected was decreased, so that the luminance was lowered, and the R-value of undyed wood was higher than that of Phellodendron Bark-dyed wood in the range of 500–700 nm. In the range of 500–700 nm, the R value of undyed wood is higher than that of Phellodendron Bark-dyed wood, which indicates that the light absorption of dyed wood veneer increases, the reflected yellow light decreases, the brightness decreases, and the wood appears yellow.

Figure 8.

Reflectance spectral curves of dyed oak on three dyeing methods with two dyes.

In the range of 400–500 nm, the R value of camphor fruit dye-stained wood is higher than that of undyed oak, indicating that the dyed wood veneer absorbs less blue-violet light and reflects more blue-violet light, showing a blue-violet color, and the luminance is elevated. In the range of 600–700 nm, the R value of camphor fruit dye-stained wood is slightly higher than that of undyed oak, indicating that the red light absorbed by the dyed wood veneer increases, the reflected red light decreases, and the luminance is slightly lower, and the wood shows a darker purplish-red color. There are numerous factors influencing the change in the R value, including but not limited to pigment concentration, tissue structure, and other conditions [76].

The effects of different natural dyes on the reflectance curves of wood are different. The reflection spectra of yellow-barked dyed oak under three methods are shown in Figure 9a. Due to the large conjugated system contained in the main component of the yellow bark alkaloids, they have a strong absorption effect on the blue-violet light within the range of 400–500 nm. Therefore, compared with the undyed oak, the dyed oak reflects less blue-violet light, and more the complementary color of yellow, making the color of the dyed oak more yellow. Within the range of 570–590 nm, due to the deposition of dye in the large vessels and cell cavities through water-bath dyeing and vacuum-pressure dyeing, the distribution is more uniform, resulting in an increase in the yellow light reflected by water-bath dyeing and vacuum-pressure dyeing, while supercritical dyeing promotes the deep penetration of the dye, causing the reflection of the oak surface to weaken and the brightness to decrease. This is consistent with the results of a previous study that analyzed the changes in the reflectivity of wood surfaces under different lighting conditions [77,78], which is consistent with the analysis of the b value in Figure 8 (the increase in b after supercritical dyeing is relatively low).

Figure 9.

Reflectance spectral curves of oak stained by three staining methods with two dyes. (a) Phellodendron amurense; (b) camphor fruits.

The reflection spectra of oak wood dyed with camphor fruit dyes under three conditions are shown in Figure 9b. Since the camphor fruit dye contains abundant anthocyanin and flavonoid substances, it has absorption effects in the green-yellow light range of 400–600 nm, and its ability to reflect blue-violet light is relatively enhanced; it has weak absorption ability for red light in the range of 620–780 nm and even partially reflects it. Therefore, compared with undyed oak wood, the dyed oak wood is blue-violet in the range of 400–500 nm; in the range of 500–600 nm, the yellow light reflected by the dyed oak wood decreases; and in the range of 620–780 nm, the overall color of the dyed oak wood is red-purple. The supercritical dyeing process enables the dye to penetrate into the interior of the wood, resulting in a relatively small increase in the reflection rate of red light. This is because the changes in the R value of the wood after dyeing are closely related to the absorption characteristics of the dye in a specific wavelength range [79], which is consistent with the analysis of the a value in Figure 8 (the a value increases less after supercritical dyeing).

The differences in K/S values of oak wood pre-treated with SC-CO2 after being dyed using three different methods are shown in Table 3. By analyzing the K/S value comparison data of the two natural dyes using three dyeing methods—water bath, SC-CO2, and vacuum pressure—we can explore the influence of different dyeing methods on the dyeing effect. In the comparison of the samples dyed with camphor fruit dye, the K/S value of SC-CO2 increased by 0.088% compared to the water-bath method, and the dyeing depth improved. This is because SC-CO2 has high diffusivity, which can promote the penetration of the dye into the wood. When comparing the vacuum-pressure method with the water-bath method, the K/S value did not increase but rather decreased. This might be because the van der Waals force between the camphor fruit dye molecules and the wood fibers is relatively weak, and the dye molecules find it difficult to stably adhere under pressure fluctuations. Compared with the vacuum-pressure method, the K/S value of SC-CO2 decreased by 0.089%, indicating that SC-CO2 has a more significant advantage in camphor fruit dyeing than the vacuum-pressure method. In the comparison of the yellow poplar bark dyeing, the K/S values under SC-CO2 and vacuum pressure were both higher than those under water-bath dyeing, increasing by 0.116% and 0.060%, respectively. This might be because the pigment molecules of the yellow poplar bark dye have strong polarity or molecular weight compatibility with the wood fibers, and the supercritical fluid can more efficiently damage the wood cell walls to promote the fixation of the dye. Similarly to the camphor fruit dyeing results, the K/S value of vacuum-pressure dyeing was 0.050% lower than that of SC-CO2. SC-CO2 is still superior. Vacuum pressure has application potential for yellow poplar bark dyeing and can be explored as an auxiliary or low-cost alternative process.

Table 3.

Comparison table of K/S values of oak wood after different staining methods.

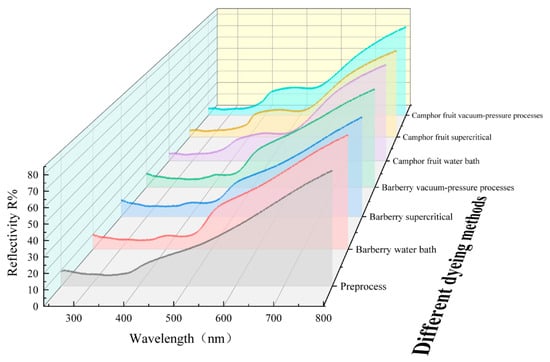

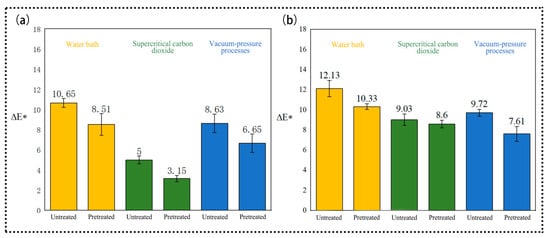

3.5. Determination of Color Fastness to Washing of Oak Dyed by Three Dyeing Methods

As shown in Figure 10a, the smaller the color difference ∆E*, the better the color fastness to washing. With pretreated and untreated Phellodendron Bark-dyed oak, compared at the level of pretreatment, it can be seen that after washing, the change in color difference in untreated dyed material is larger than that in pretreated dyed material; comparing different dyeing methods, it can be seen that the washing performance of conventional water-bath dyed oak is the worst, the washing fastness of vacuum-pressurized dyed oak is the second worst, and the washing fastness of supercritical carbon dioxide is the best. The factors influencing color fastness vary. The natural dye of rosewood is rich in insoluble phenols and flavonoids [80]. The chelation effect of the mordant and the formation of more covalent bonds between the dye and the fabric under the assistance of SC-CO2 [74,75] are all important conditions for improving color fastness. The color difference between unpretreated and supercritical dyed oak is 5, and the color difference between pretreated and supercritical dyed oak is only 3.15. This is because the SC-CO2 pretreatment causes the cell walls to swell and creates a more porous structure, enabling the anthocyanin pigments to penetrate deeper into the wood cell walls. The hydroxyl groups in its molecules can form hydrogen bonds with cellulose and hemicellulose, and also undergo π-π stacking with the aromatic rings of lignin, thereby achieving multiple points of binding with the wood matrix. Compared to dyes that merely remain on the surface, this deep binding method significantly reduces the migration and loss of anthocyanins during the water-washing process. Therefore, supercritical pretreatment can effectively improve the washing fastness of oak wood, and the supercritical carbon dioxide dyeing method can further enhance the washing fastness of oak wood.

Figure 10.

Washing color fastness of oak dyed by three dyeing methods with two dyes. (a) Phellodendron amurense; (b) camphor fruits.

When observing the camphor fruit dye dyeing pretreatment and untreated oak-veneer water fastness shown in Figure 10b, regarding the pretreatment level for comparison, it can be seen that with Phellodendron Bark, the dyeing situation is similar to that of the untreated dyed material, and the color difference is greater than the pretreatment dyed material; comparing different dyeing methods, it can be seen that the three kinds of dyeing methods on the dyeing effect of camphor fruit and Phellodendron Bark are slightly different. The water-washing performance of camphor fruit dyes under conventional water-bath dyeing conditions is the worst, the oak color difference in supercritical carbon dioxide is the second best performance, and the pretreatment and vacuum pressurization of the color difference is the best. The color difference between the pretreated and vacuum-pressurization dyeing of oak was only 7.61. This is because the SC-CO2 pretreatment not only removed some hydrophobic extractives, but also promoted the exposure of active groups such as carboxyl and phenolic hydroxyl groups in the wood. The berberine molecules in Phellodendron have a quaternary ammonium salt structure, which can achieve a more stable binding with these groups through electrostatic adsorption and hydrogen bonding. At the same time, the dyes find it easier to penetrate into the micropore structure of the cell wall after pretreatment, reducing the loose adhesion on the surface, and thus showing stronger wash resistance under water-washing conditions.

When comparing the two dyes, due to the smaller molecular weight of berberine in Phellodendron compared to that of Cinnamomum camphora, and its positive charge, it can form stable electrostatic interactions and hydrogen bonds with the carboxyl and phenolic hydroxyl groups of the wood, resulting in strong fixation; while in Cinnamomum camphora, affected by the steric hindrance of glycosylation structure and the competition of water molecules, it is prone to migration and loss. Therefore, the fixation of the Phellodendron dye in the wood is more stable, and it shows better wash fastness.

Table 4 presents the results of washing fastness. The overall gray-scale ratings were relatively low, mostly ranging between 2 and 3, indicating that natural dyes are prone to dissolution or desorption during washing. Notably, samples pretreated with SC-CO2, particularly under supercritical dyeing conditions, exhibited improved ratings up to 4.0, suggesting that pretreatment effectively modifies the wood pore structure and enhances dye–substrate interactions. In contrast, vacuum-pressure dyeing increased the initial uptake but showed limited improvement in wash fastness due to significant dye loss during washing.

Table 4.

Classification table of washing gray-scale levels for oak fibers dyed with two dyes using three dyeing methods.

3.6. Determination of Sunlight Color Fastness of Oak Dyed by Three Dyeing Methods

As shown in Figure 11a, the smaller the color difference ∆E* is, the better the sunlight color fastness of Phellodendron Bark-dyed pretreated and untreated oak veneer. With a comparison at the level of pretreatment, it can be seen that after solarization, the change in the color difference in untreated dyed material is greater than that in pretreated dyed material; comparing different dyeing methods, it can be seen that the worst solar fastness is shown by the vacuum-pressurized dyed oak, followed by the water-bath dyed oak. At the same time, supercritical carbon dioxide has the best solar fastness performance, and the color difference between dyed oak after pretreatment and supercritical dyeing is 8.13. The differences in the sunlight color fastness of Phellodendron Bark-stained oak were minor.

Figure 11.

Color fastness to the sunlight of oak dyed with two dyes in three dyeing methods. (a) Phellodendron amurense; (b) camphor fruits.

The solar fastness for oak pretreated with water-bath camphor dye and oak left untreated is shown in Figure 11b; considering the pretreatment level for comparison, it can be seen that the Phellodendron Bark dyeing situation is similar to the untreated dyed material. The color-difference changes are greater than in the pretreatment of dyed material; for the conventional water-bath dyeing, supercritical pretreatment improves the solar fastness performance by nearly double. It can be seen that the supercritical carbon dioxide treatment has an apparent effect on the improvement of the solar fastness. Comparing different dyeing methods, it can be seen that the effect of the three dyeing methods on the camphor fruits dyes was slightly different compared with Phellodendron amurense, and the oak dyed with camphor fruits in a conventional water bath had the worst solarization performance; the supercritical carbon dioxide dyeing and vacuum-pressurized dyeing of the oak had better solarization fastness performance. The color difference in the pretreated oak dyed in vacuum-pressurized dyeing was only 7.61.

Comparing the different pigments, it can be seen that the color difference in camphor fruit-dyed oak after solarization is smaller than that of Phellodendron Bark-dyed oak after solarization, which shows that camphor fruit dyes are better at improving the performance of color fastness to sunlight.

Table 5 shows the results of lightfastness. The performance was slightly better than wash fastness, with ratings mainly between 2.0 and 3–4. Certain treatment combinations (e.g., camphor fruits + SC-CO2 pretreatment + supercritical dyeing) reached 3–4, reflecting moderate light stability under specific conditions. Overall, berberine-based dyes demonstrated lower lightfastness than camphor fruit pigments, attributable to the photodegradation of conjugated double bonds and phenolic hydroxyl groups in their molecular structures. SC-CO2 pretreatment promoted more uniform penetration of dyes into the wood interior, thereby reducing surface photodegradation and slightly improving lightfastness.

Table 5.

Classification table of sunlight gray levels for oak fibers dyed with two dyes using three dyeing methods.

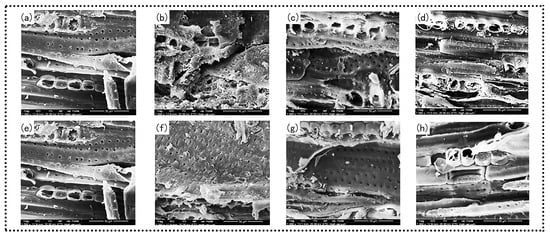

3.7. Microscopic Morphology Analysis of Stained Oak and Three Staining Methods with Scanning Electron Microscope

Figure 12a shows that the surface of wood fibers, tubular pores, and grain pores of undyed oak after supercritical carbon dioxide pretreatment are visible. After water-bath dyeing with Phellodendron Bark dye, shown in Figure 12b, the microstructure of the wood has changed, and the surfaces of the fibers, grain pores, and tubular pores are covered with a large amount of dye, which has a velvet-like texture. After supercritical carbon dioxide dyeing, shown in Figure 12c, the microstructure of the wood changed; the wood fibers appears broken and cracked, and the grain pores and tubular pores are smooth. Phellodendron Bark dye-stained oak after vacuum-pressurized impregnation dyeing treatment, shown in Figure 12d, indicated that the permeability of the oak grain holes and tubular holes is due to the decompression of the vacuum first and then the pressurization under the influence of the pressure changes outside the wood, so that the air pressure inside the wood increases from low pressure to high pressure; as a result of the pressure, the grain pore membrane was ruptured, and then subsequent pressurization throughout the process caused the dye solution to enter the wood further.

Figure 12.

SEM scanning electron microscopy 1000×. (a) unstained SC-CO2 pretreated material; (b) camphor fir dye water-bath stained material; (c) camphor fruit dye supercritical carbon dioxide stained material; (d) camphor fruit dye vacuum-pressurized stained material; (e) unstained SC-CO2 pretreated material; (f) Phellodendron Bark dye water-bath stained material; (g) Phellodendron Bark dye supercritical carbon dioxide stained material; (h) Phellodendron Bark dye vacuum-pressurized stained material.

After the water-bath dyeing treatment with camphor fructose dye, shown in Figure 12f, the wood fiber and grain pores were semi-clogged, showing a velvet-like texture. Comparing the oak veneer of the Phellodendron Bark and camphor fructose dye under water-bath dyeing with the undyed samples, there was a large amount of dye aggregation on the observation surface, which resulted in a film on the wood tissues. After the supercritical carbon dioxide dyeing treatment in Figure 12g, the wood fibers were loosened, the edges of the tubular and grain pores were transparent, and the inclusions were reduced. A comparison of the two dye-stained materials revealed that the wood was damaged to a certain extent by supercritical carbon dioxide fluids and pressures and that the surfaces were cleaner under the supercritical carbon dioxide washout. Camphor fruit dye-stained oak after the vacuum-pressurized impregnation dyeing treatment, shown in Figure 12h, found that the oak grain holes and tube holes showed similar morphological characteristics to the Phellodendron amurense dyeing, with the grain holes broken and tube holes more permeable.

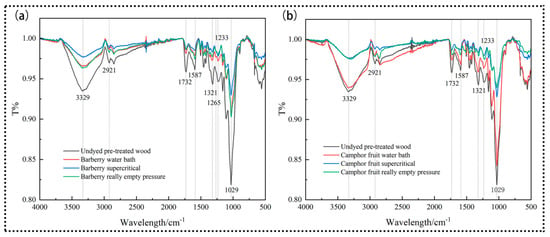

3.8. Infrared Spectral Analysis of Dyed Oak in Three Dyeing Methods

As shown in Figure 13a,b, given the hydroxyl O-H absorption peak at 3329 cm−1, the intensity of the absorption peaks of Phellodendron Bark and camphor fruit dyes in water-bath dyed oak is lower than that of undyed pretreated oak, which may be due to the breakage of the original hydrogen bonds within the wood in the process of dying, part of which is formed with the wood molecules and the dye molecules, and in addition, hydrothermal action leads to degradation of the wood components, especially cellulose and hemicellulose degradation, which may directly lead to a decrease in O-H content. In the telescopic vibration absorption peak of cellulose C-H at 2921 cm−1, the intensity of the absorption peaks of both dyes in water-bath dyed oak was lower in vacuum-pressurized camphor fruit than in undyed pretreated oak, which may be due to the mechanical adhesion of C-H in the dyes to the oak. In addition to this, the absorption peak intensities of the dyed materials between 1800 and 1000 cm−1 bands were all affected by the substitution or coverage of some cellulose and hemicellulose groups by the benzene ring C-H, methyl, and aromatic ring groups in Phellodendron amurense and camphor fruit dyes. 1732 cm−1 hemicellulose C=O, 1597 cm−1 lignin benzene ring skeleton, 1321 cm−1 at lilac-based C-O, 1233 cm−1 for guaiac-based aryl ring C-O, and 1029 cm−1 for C-O-C were lower than the intensity of the post-stained oak absorption peaks in unstained oak. The absorption peak at 1265 cm−1 in the water-bath stained pretreated oak with Phellodendron Bark dye may be due to the stretching and vibration of the aromatic aliphatic ether C-O-C in the Phellodendron Bark dye, which adheres to the surface of the oak. Comparing the different dyeing methods, it can be seen that supercritical carbon dioxide has the most significant effect on the intensity of the absorption peaks of each group in the wood, and supercritical carbon dioxide has a degrading effect on some of the wood components while helping the dye to diffuse; the degradation of lignin and hemilignin components can be inferred from the reduction in the hydroxyl O-H content, and thus the effect is more significant.

Figure 13.

Fourier infrared spectra of two dyes before and after staining oak using three methods. (a) camphor fruit dye; (b) Phellodendron amurense dye.

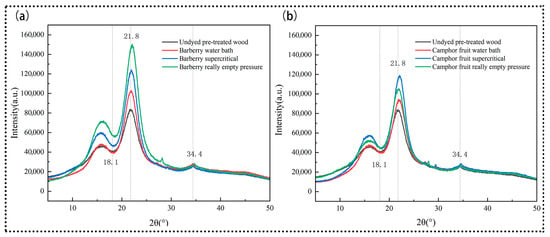

3.9. XRD Diffraction Analysis of Stained Oak by Three Staining Methods

As shown in Figure 14a,b, it can be seen that the 2θ diffraction intensity graphs of wood from supercritical carbon dioxide-pretreated oak treated with water-bath staining of Phellodendron Bark and camphor fruit have the same shape. The diffraction peak of (002 crystalline planes) is near 2θ = 21.8°, a valley appears near 2θ = 18.1° for the diffraction intensity of the amorphous zone, and there is a small peak near 2θ = 34.4° for the diffraction intensity of (040 crystalline planes). The crystallinity was calculated according to Equation (4), and the crystallinity of oak after supercritical carbon dioxide pretreatment was 50.65%, that of oak after water-bath dyeing with Phellodendron Bark dye was 61.54%, that of oak after water-bath dyeing with camphor fruit dye was 56.32%, and that of oak after dyeing with Phellodendron Bark dye with supercritical carbon dioxide-assisted dying was 62.34%. The crystallinity of oak after dyeing with supercritical carbon dioxide-assisted camphor fruit dye was 61.22%; it was 60.86% after Phellodendron amurense dye vacuum-pressurized impregnation, and 57.49% after camphor fruit dye vacuum-pressurized impregnation. The increase in crystallinity of water-bath dyeing may be because, as the dyeing process proceeds, the dye binds to the wood fibers, resulting in a tighter intermolecular bond. As a result of the increase in crystallinity, the non-crystalline zone that is susceptible to hydrolysis is reduced, and the strength of the veneer is increased. The crystallinity of Phellodendron Bark dye-stained wood and camphor fruit dye–supercritical carbon dioxide-stained wood increased. This may be because the supercritical carbon dioxide-assisted dyeing caused the hydrogen bonding between cellulose molecules to connect the neighboring molecular chains or crystalline zones, which converted some of the amorphous zones to crystalline zones, thus manifesting as an increase in the degree of crystallinity. The crystallinity of Phellodendron Bark-dyed material and camphor fruit-dyed vacuum-pressurized material were both increased, probably due to the fact that under pressure, free hydroxyl groups in the amorphous zone adsorbed water, hygroscopicity decreased, cellulose molecular chains were rearranged, wetting occurred, and the hydrogen bonding of crystalline zones was not damaged. The veneer strength and dimensional stability were increased.

Figure 14.

X-ray diffraction spectra of two dyes before and after staining oak in three ways. (a) Camphor fruit dye; (b) Phellodendron amurense dye.

4. Conclusions

In this study, we systematically evaluated the effects of three methods, conventional water-bath dyeing, supercritical carbon dioxide (SC-CO2) dyeing, and vacuum-pressurized dyeing, on the dyeing performance of SC-CO2 pretreated oak. The lateral indicators showed that SC-CO2 pretreatment effectively loosened the oak structure, improved the dye penetration, and significantly enhanced the up-dyeing rate and overall color performance of Phellodendron Bark and camphor fruit natural dyes on oak. SC-CO2 dyeing was advantageous in enhancing the weathering properties of washing fastness and sunlight fastness and improving the service life of the dyed wood. The vacuum-pressurized dyeing method was superior to the conventional method, with dyeing rates of 25.87% and 27.64%, respectively. All three dyeing methods help to improve the crystallinity of oak and enhance its structural stability. In this study, by integrating SC-CO2 and vacuum-pressurization-assisted techniques into the dyeing process with natural dyes to advance sustainable wood-dyeing practices and improve the permeability of natural dyes in oak, we explored a feasible alternative path to replace synthetic dyes in the hope of obtaining a functional dyeing material with excellent dyeing effect and green sustainability. This is expected to provide a theoretical and practical basis for potential applications in areas such as automotive interiors, green building materials, and environmentally friendly furniture, while easing the pressure on treasured tree species and minimizing the environmental impact.

Author Contributions

Conceptualization, Y.L. and Y.Q.; methodology, Y.Q.; software, Y.C.; validation, Y.L., Y.Q. and Y.C.; formal analysis, C.C. and Q.Z.; investigation, Z.Z.; resources, Y.L.; data curation, Y.Q.; writing—original draft preparation, Y.Q.; writing—review and editing, Y.C.; visualization, Y.Q.; supervision, Y.L.; project administration, J.H.; funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fan, Z.; Sun, H.; Zhang, L.; Zhao, X.; Hu, Y. Lightweight, high-strength wood prepared by deep eutectic solvent treatment as a green structural material. ACS Sustain. Chem. Eng. 2022, 10, 9600–9611. [Google Scholar] [CrossRef]

- Luo, Z.; Zhang, Y. Construction of a Chitosan/ZnO-Based Light-Resistant Coating System to Protect Dyed Wood from Ultraviolet Irradiation via Layer-by-Layer Self-Assembly. Int. J. Mol. Sci. 2022, 23, 15735. [Google Scholar] [CrossRef]

- Zhao, W.; Rong, Y.; Xu, R.; Wu, Y. Study on Transparent Basswood Dyed with Reactive Dyes and Its Properties. ACS Omega 2024, 9, 5378–5385. [Google Scholar] [CrossRef]

- Pan, J.; Xia, Z.; Lu, J.; Zhang, H.; Liu, Y. Natural Dye Extracted from Pterocarpus Santalinus Wood Waste for Green Dyeing and Its Binding Mechanism with Yak Wool Fabrics. Ind. Crops Prod. 2024, 210, 118121. [Google Scholar] [CrossRef]

- Díez, B.H.; Torres, C.A.V.; Gaudêncio, S.P. Gaudêncio. Actinomycete-Derived Pigments: A Path Toward Sustainable Industrial Colorants. Mar. Drugs 2025, 23, 39. [Google Scholar] [CrossRef]

- Saha, P.D.; Sinha, K. Natural Dye from Bixa Seeds as a Potential Alternative to Synthetic Dyes for Use in Textile Industry. Desalin. Water Treat 2012, 40, 298–301. [Google Scholar] [CrossRef]

- Fahira, N.; Gareso, P.L.; Tahir, D. Exploring wood-based strategies for dye removal: A comprehensive literature review. Bioresour. Technol. Rep. 2025, 29, 102048. [Google Scholar] [CrossRef]

- Amellal, T.; Boukhalfa, N.; Meniai, A.H. Enhanced removal of Basic Brown1 dye from aqueous solutions by Sawdust activated carbon. equilibrium, thermodynamic and kinetics. Desalin. Water Treat. 2024, 317, 100057. [Google Scholar] [CrossRef]

- Schmidt-Przewozna, K.; Roj, E. Green Sustainable Textile Supercritical Dyeing Process Using CO2 Madder (Rubia tinctorum L.) Extract. J. Nat. Fibers 2023, 20, 2277836. [Google Scholar] [CrossRef]

- Guzel, E.T.; Karadag, R.; Alkan, R. Durability, Antimicrobial Activity and HPLC Analysis of Dyed Silk Fabrics Using Madder and Gall Oak. J. Nat. Fibers 2020, 17, 1654–1667. [Google Scholar] [CrossRef]

- Elsahida, K.; Fauzi, A.M.; Sailah, I.; Siregar, I.Z. Sustainable Production of Natural Textile Dyes Industry. In IOP Conference Series: Earth and Environmental Science, Proceedings of the International Conference on Innovation in Technology and Management for Sustainable Agroindustry (itamsa 2019), 9–10 October 2019; IoP Publishing Ltd.: Bristol, UK, 2020; Volume 472, p. 12036. [Google Scholar]

- Ji, X.; Zhao, Z.; Ren, Y.; Xu, F.; Liu, J. Dyeing Properties, Color Gamut, and Color Evaluation of Cotton Fabrics Dyed with Phellodendron Amurense Rupr. (Amur Cork Tree Bark). Molecules 2023, 28, 2220. [Google Scholar] [CrossRef]

- Qi, Y.; Liu, G.; Zhang, Z.; Zhou, Z. Optimization of Green Extraction Process of Cinnamomum camphora Fruit Dye and Its Performance by Response Surface Methodology. BioResources 2023, 18, 4916–4934. [Google Scholar] [CrossRef]

- Guo, S.; Geng, Z.; Zhang, W.; Liang, J.; Wang, C.; Deng, Z.; Du, S. The Chemical Composition of Essential Oils from Cinnamomum camphora and Their Insecticidal Activity against the Stored Product Pests. Int. J. Mol. Sci. 2016, 17, 1836. [Google Scholar] [CrossRef]

- Qi, Y.; Chen, Y.; Liu, G.; Shen, L. Study on microwave extraction of berberine coloring compound and extracts stability: Process optimization by Response Surface Method (RSM). Dye. Pigment. 2025, 237, 112609. [Google Scholar] [CrossRef]

- Yamagishi, K.; Ike, M.; Tanaka, A.; Tokuyasu, K. The RURAL (reciprocal upgrading for recycling of ash and lignocellulosics) process: A simple conversion of agricultural resources to strategic primary products for the rural bioeconomy. Bioresour. Technol. Rep. 2020, 12, 100574. [Google Scholar] [CrossRef] [PubMed]

- Vespignani, L.; Bonanni, M.; Marradi, M.; Pizzo, B.; Bianchini, R.; Goli, G. Naturalized Dyes: A New Opportunity for the Wood Coloring. Polymers 2023, 15, 3632. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yu, Z.; Zhang, Y.; Qi, C.; Chang, W. Evaluation of Ultrasonic-Assisted Dyeing Properties of Fast-Growing Poplar Wood Treated by Reactive Dye Based on Grey System Theory Analysis. J. Wood Sci. 2018, 64, 861–871. [Google Scholar] [CrossRef]

- Qi, Y.; Zhou, Z.; Xu, R.; Dong, Y.; Zhang, Z.; Liu, M. Effect of NaOH Pretreatment on Permeability and Surface Properties of Three Wood Species. ACS Omega 2023, 8, 40362–40374. [Google Scholar] [CrossRef]

- Khafri, H.Z.; Ghaedi, M.; Asfaram, A.; Safarpoor, M. Synthesis and Characterization of ZnS:Ni-NPs Loaded on AC Derived from Apple Tree Wood and Their Applicability for the Ultrasound Assisted Comparative Adsorption of Cationic Dyes Based on the Experimental Design. Ultrason. Sonochemistry 2017, 38, 371–380. [Google Scholar] [CrossRef]

- Qi, Y.; Zhou, Z.; Xu, R.; Dong, Y.; Liu, M.; Shen, L.; Han, J. Research on the Dyeing Properties of Chinese Fir Using Ultrasonic-Assisted Mulberry Pigment Dyeing. Forests 2023, 14, 1832. [Google Scholar] [CrossRef]

- Hu, W.; Yu, R. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas. Cienc. Y Tecnol. 2023, 25, 39. [Google Scholar] [CrossRef]

- Hu, W.-G.; Wan, H. Comparative study on weathering durability properties of phenol formaldehyde resin modified sweetgum and southern pine specimens. Maderas. Cienc. Y Tecnol. 2022, 24, 1–14. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, L.; Liu, H. Green and Efficient Processing of Wood with Supercritical CO2: A Review. Appl. Sci. 2021, 11, 3929. [Google Scholar] [CrossRef]

- Machado, N.D.; Mosquera, J.E.; Cejudo-Bastante, C.; Goñi, M.L.; Martini, R.E.; Gañán, N.A.; Mantell-Serrano, C.; Casas-Cardoso, L. Supercritical Impregnation of PETG with Olea europaea Leaf Extract: Influence of Operational Parameters on Expansion Degree, Antioxidant and Mechanical Properties. Polymers 2024, 16, 1567. [Google Scholar] [CrossRef]

- Zhang, Y.; Wen, H. The supercritical carbon dioxide extraction of berberine from Phellodendron amurense. For. Prod. Chem. Ind. 2010, 30, 103–106. [Google Scholar]

- Jaxel, J.; Fontaine, L.; Krenke, T.; Hansmann, C.; Liebner, F. Bio-inspired conformational lipophilization of wood for scCO2-assisted colouring with disperse dyes. J. Supercrit. Fluids 2019, 147, 116–125. [Google Scholar] [CrossRef]

- Jaxel, J.; Liebner, F.W.; Hansmann, C. Solvent-free dyeing of solid wood in water-saturated supercritical carbon dioxide. ACS Sustain. Chem. Eng. 2020, 8, 5446–5451. [Google Scholar] [CrossRef]

- Liu, H.; Xie, Y.; Li, Z.; Zhang, X. Comparative Study on Supercritical Carbon Dioxide Dewatering and Conventional Kiln Drying of Bamboo Strips. J. Supercrit. Fluids 2024, 204, 106121. [Google Scholar] [CrossRef]

- Tong, K.; Zhang, H.; Zhang, Y.; Liu, J.; Wu, Y. An Ultraviolet Radiation Protective Transparent Wood Film Retained Natural Wood Texture and Tactile Properties. Polymer 2024, 311, 127560. [Google Scholar] [CrossRef]

- Zheng, J.; Zhu, X.; Yang, L. Dewatering of Juglans mandshurica Wood Using Supercritical Carbon Dioxide. Materials 2023, 16, 5521. [Google Scholar] [CrossRef]

- Zheng, J.; Xu, X.; Yang, L. Dewatering Characteristics of Juglans mandshurica Wood Using Supercritical Carbon Dioxide: A Comparison with Conventional Drying. Dry. Technol. 2024, 42, 926–935. [Google Scholar] [CrossRef]

- Northeast Forestry University; Xu, H.; Reza Taghiyari, H.; Clauson, M.; Milota, M.R.; Morrell, J.J. Oregon State University Effect of Supercritical Carbon Dioxide Treatment on Gas Permeability of Paulownia fortunei Heartwood and Sapwood. Wood Fiber Sci. 2019, 51, 69–73. [Google Scholar] [CrossRef]

- Jaxel, J.; Gusenbauer, C.; Böhmdorfer, S.; Liebner, F.; Hansmann, C. Improving Single-Step scCO2 Dyeing of Wood by DMSO-Induced Micro-Swelling. J. Supercrit. Fluids 2020, 165, 104978. [Google Scholar] [CrossRef]

- Mousa, A.A.; Mohamed, F.A.; Abd El-Megied, S.A.; Youssef, Y.A. Dyeing of Synthetic Fiber-Based Wool Blended Fabrics in Supercritical Carbon Dioxide. Sci. Rep. 2024, 14, 30604. [Google Scholar] [CrossRef]

- Basilio, B.G.O.; Cholán, D.R.V.; Silva, M.E.T.; Socantaype, F.V.H.; Malpartida, J.L.S.; Flores, S.M.F.; Navarro, S.M.T.; López, E.V.C. Operation parameters of alpaca fiber dyeing with supercritical fluid. J. Supercrit. Fluids 2025, 216, 106432. [Google Scholar] [CrossRef]

- Sasaki, K.; Hirogaki, K.; Tabata, I.; Nakane, K. Supercritical fluid dyeing of polyester fabrics using polymeric nanofibers loaded with disperse dye. J. Supercrit. Fluids 2024, 211, 106289. [Google Scholar] [CrossRef]

- Tao, M.; Liu, X.; Xu, W. Effect of the Vacuum Impregnation Process on Water Absorption and Nail-Holding Power of Silica Sol-Modified Chinese Fir. Forests 2024, 15, 270. [Google Scholar] [CrossRef]

- Nguyen, N.; Ozarska, B.; Fergusson, M.; Vinden, P. Investigation into the Optimal Dyeing Method for Bluegum (Eucalyptus globulus) Veneer. BioResources 2018, 13, 6444–6464. [Google Scholar] [CrossRef]

- Li, L.; Chen, Z.; Lu, J.; Wei, M.; Huang, Y.; Jiang, P. Combustion Behavior and Thermal Degradation Properties of Wood Impregnated with Intumescent Biomass Flame Retardants: Phytic Acid, Hydrolyzed Collagen, and Glycerol. ACS Omega 2021, 6, 3921–3930. [Google Scholar] [CrossRef] [PubMed]

- Guan, P.; Li, P.; Wu, Y.; Li, X.; Yuan, G.; Zuo, Y. Comparative Study on the Properties of Inorganic Silicate and Organic Phenolic Prepolymer Modified Poplar Wood by Vacuum Cycle Pressurization. J. Renew. Mater. 2022, 10, 2451–2463. [Google Scholar] [CrossRef]

- Wang, D.; Ling, Q.; Nie, Y.; Zhang, Y.; Zhang, W.; Wang, H.; Sun, F. In-Situ Cross-Linking of Waterborne Epoxy Resin inside Wood for Enhancing Its Dimensional Stability, Thermal Stability, and Decay Resistance. ACS Appl. Polym. Mater. 2021, 3, 6265–6273. [Google Scholar] [CrossRef]

- Hao, X.; Li, M.; Huang, Y.; Sun, Y.; Zhang, K.; Guo, C. High-Strength, Dimensionally Stable, and Flame-Retardant Fast-Growing Poplar Prepared by Ammonium Polyphosphate-Waterborne Epoxy Impregnation. ACS Appl. Polym. Mater. 2022, 4, 1305–1313. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Bayani, S.; Militz, H.; Papadopoulos, A.N. Heat Treatment of Pine Wood: Possible Effect of Impregnation with Silver Nanosuspension. Forests 2020, 11, 466. [Google Scholar] [CrossRef]

- Sürdem, S.; Eserog, C.; Yörükog, A. Combustion and Decay Resistance Performance of Scots Pine Treated with Boron and Copper Based Wood Preservatives. Drv. Ind. 2022, 73, 397–404. [Google Scholar] [CrossRef]

- Rahayu, I.; Prihatini, E.; Ismail, R.; Darmawan, W.; Karlinasari, L.; Laksono, G.D. Fast-Growing Magnetic Wood Synthesis by an In-Situ Method. Polymers 2022, 14, 2137. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Yang, F.; Yang, L.; Wang, J.; Zhou, J.; Wang, J. A Highly Transparent Compressed Wood Prepared by Cell Wall Densification. Wood Sci. Technol. 2022, 56, 669–686. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, S.; Mei, C.; Ma, E. Performance Improvement of Poplar Wood Based on the Synergies of Furfurylation and Polyethylene Glycol Impregnation. Holzforschung 2022, 76, 825–837. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Su, N.; Fang, C. High-performance engineered bamboo units with customizable radius based on pressure-drying technology: Multi-scale mechanical properties. Constr. Build. Mater. 2024, 457, 139472. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.-Y.; Ding, K.-Q.; Jiang, M.-H. Immersion polishing post-treatment of PLA 3D printed formed parts on its surface and mechanical performance. BioResources 2023, 18, 7995–8006. [Google Scholar] [CrossRef]

- Zou, Y.; Pan, P.; Zhang, N.; Yan, X. Effect of Nano-Silver Solution Microcapsules Mixed with Rosin-Modified Shellac Microcapsules on the Performance of Water-Based Coating on Andoung Wood (Monopetalanthus spp.). Coatings 2024, 14, 286. [Google Scholar] [CrossRef]