Abstract

The corrosion-induced strength degradation of steel nails poses a critical challenge to the structural integrity of timber connection joints, particularly in hygrothermal environments. Compressed wood nails exhibit hygroscopic expansion characteristics, demonstrating their potential as a sustainable alternative to steel nails in structural connections. However, systematic investigations on their shear performance under cyclic hygrothermal conditions remain limited. This study comparatively analyzed the shear behavior evolution of compressed wood nail and galvanized steel nail connections under wet-dry cycles. Distinct failure mechanisms were observed: wood nail connections exhibited characteristic brittle fracture patterns, whereas steel nail connections demonstrated ductile failure through pull-out deformation with nail bending. Notably, compressed wood nails displayed superior environmental stability, with significantly lower degradation rates in terms of load-bearing capacity (2.8% vs. 22.3%) and stiffness (16.3% vs. 38.0%) than their steel counterparts under identical hygrothermal exposure. These findings provide critical design references and data support for implementing wood-based fasteners in moisture-prone engineering applications.

1. Introduction

The advantages of wood in construction—its accessibility, workability, and structural performance—are the primary reasons for its widespread utilization, with renewability being an increasingly significant factor [1,2]. However, its performance is negatively influenced by environmental humidity, temperature, and biological factors. The weathering resistance and durability of timber structures are critical determinants of service life, particularly in humid and rainy regions [3]. With increasing moisture content, traditional metal connectors, despite their superior initial mechanical properties, are prone to corrosion in prolonged hygrothermal environments, leading to structural performance degradation [4]. Even when subjected to galvanization or phosphate coating treatments [5], corrosion issues persist, ultimately resulting in diminished connection performance and reduced service life [6].

In recent years, compressed wood nails have emerged as potential substitutes for metal fasteners owing to their hygroscopic expansion characteristics, which are compatible with wood substrates. These wood nails exhibit distinct advantages, including corrosion resistance, dimensional stability, ease of secondary processing, absence of thermal bridging, and eco-friendliness [7]. Current research on the mechanical properties of compressed wood nails is limited. Korte et al. [8] reported that pneumatically driven wood nails nearly double the withdrawal resistance of manually installed steel nails. Wang et al. [9] demonstrated that installing compressed beech nails at a 60° installation angle in spruce–pine–fir samples under combined shear–tension loading optimizes joint performance. The literature predominantly focuses on the mechanical behavior of timber connectors under constant humidity conditions, with insufficient investigations into the dynamic effects of practical wet–dry cycling. Although Wang et al. [10] and Yermán et al. [11] considered hygrothermal cycling impacts, their research focused primarily on the withdrawal performance of wood nails. Notably, metallic fasteners under cyclic conditions experience the initial enhancement of withdrawal resistance in smooth-shank nails during early cycles, followed by significant deterioration with prolonged cycling [11,12,13].

To address these research gaps, this study systematically investigated the shear performance evolution of compressed wood dowel and galvanized steel nail connections through designed wet–dry cycling experiments. The experimental framework comparatively analyzed failure modes, load capacity degradation, and stiffness variations. The findings provide critical empirical support for substituting steel fasteners with wood dowels in moisture-prone environments, revealing fundamental differences in hygrothermal performance between lignocellulosic and metallic fasteners. These insights advance the understanding of cyclic durability in timber connections, offering practical design guidelines to increase the longevity of wood structures under fluctuating environmental conditions.

2. Materials and Methods

2.1. Materials

As shown in Table 1, the AA-grade Scots pine (Pinus sylvestris) lumber from the Sakhalin region of Russia was precisely cut into 120 samples, each measuring 38 × 140 × 300 mm in size. The lumber was weighed to determine the initial weight and calculate the density. As shown in Figure 1, the compressed beech nails (50 mm long and 4.7 mm in diameter) were manufactured by BECK Fastener Group, Mauerkirchen, Styria, Austria. Galvanized ring steel nails (50 mm long and 3.3 mm in diameter) are commercially available through Chinese suppliers. The pneumatic nail gun used was a BECK F60 CN15-PS90-H Lignoloc system (BECK Fastener Group, Mauerkirchen, Styria, Austria).

Table 1.

Material specifications.

Figure 1.

Compressed beech nails.

2.2. Specimen Configuration

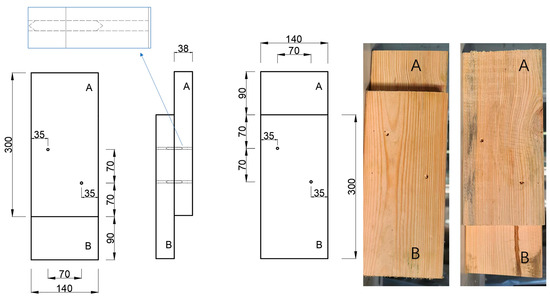

As shown in Figure 2, according to the GB 50005-2017 standard [14], the distance between the loaded end of the substrate parallel to the loading direction and the dowel center for compression members should be no less than 4 d (where d is the dowel diameter), while the distance along the unloaded end direction should be no less than 1.5 d. Additionally, the nail spacing must exceed 4 d to ensure structural integrity. Specimen fabrication involved cutting Scots pine boards for the primary and secondary components of single-shear connections. The beech nails were pneumatically driven diagonally from both sides of the boards via a nail gun, maintaining a 35 mm edge distance and a 70 mm end distance. Two nails were vertically driven into one side of Board A in an upper–lower diagonal arrangement. Then the board was turned over, and two additional nails were vertically driven in the same manner on the opposite side of Board B to prevent any contact between the nails from opposing sides. Appropriate avoidance was practiced when encountering knots, resin canals, and cracks. Control samples with identical geometries and steel nails were prepared for comparative analysis.

Figure 2.

Diagram of samples for shear strength test.

2.3. Wet–Dry Cycles

As shown in Table 2, after fabrication, the shear samples were first immersed for 3 days until they reached 60% moisture content, followed by drying at 70 °C for 40 h to achieve a final moisture content of 12%, constituting one wet–dry cycle. Five complete cycles were implemented, with shear failure tests conducted after each cycle. For comparative analysis, a control group of steel nail samples was established alongside the wood nail group. After each cycle, five samples were randomly selected from both groups for testing. Key parameters, including peak load, load–displacement curves, and post-failure morphological characteristics, were systematically recorded.

Table 2.

Arrangement of experimental plan.

2.4. Single Shear Capacity Tests

Shear failure tests were conducted in accordance with the GB/T 50329 standard [15]. A computer-controlled universal testing machine (MWW-50, Chuanbai Instrument Equipment Co., Ltd., Jinan, China) was employed for shear testing under monotonic loading at 2.5 mm/min. The samples were loaded until complete joint failure occurred with substrate separation, during which the peak load (defined as the shear capacity) was recorded. Failure modes were documented alongside computer-acquired load–displacement data, with the plotting of corresponding curves.

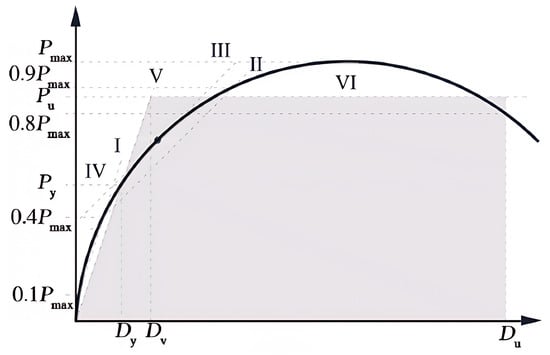

In accordance with Japanese timber structural design methodologies [16], the characteristic value analysis of load–displacement curves was conducted, as illustrated in Figure 3: (1) Secant I is defined as the line connecting the 0.1PMax and 0.4PMax points on the load–displacement curve; (2) Secant II corresponds to the line linking the 0.4PMax and 0.9PMax points; (3) Secant II is translated parallelly until it is tangential to the curve, with the tangent line designated as Secant III; (4) a horizontal line is drawn through the intersection of Secant I and Secant III, with the vertical coordinate of this intersection defining the yield load Py; and (5) extending this horizontal line to intersect the curve, the slope K = Py/Dy of the line connecting the intersection point to the origin is determined as the yield stiffness.

Figure 3.

Characteristic value analysis of load–displacement curves [17].

3. Results and Discussion

3.1. Destruction Mode

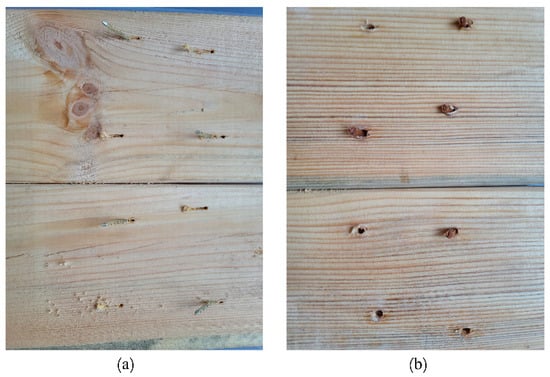

The steel nail connections initially exhibited elastic behavior under loading until reaching the yield point, beyond which nail bending induced nonlinear deformation. Upon attaining peak load capacity, connection failure occurred through ductile failure modes characterized by nail withdrawal and bending, accompanied by substrate separation due to intense interfacial tearing. In contrast, the wood nail connections predominantly failed via brittle fracture at the contact interface between laminates, with minimal slot deformation and rare intact withdrawal cases—the latter attributable to insufficient penetration depth in secondary laminates. The failure modes for single shear are shown in Figure 4. Cyclic wet–dry exposure induced progressive end–grain cracking in the Scots pine laminates due to repeated hygroscopic stress. These single-shear failure modes align with the European timber design code [18]: wood nail connections primarily fail through brittle fastener fracture, whereas their steel counterparts demonstrate ductile withdrawal failure.

Figure 4.

Failure modes for single shear: (a) steel nail connections and (b) wood nail connections.

3.2. Shear Bearing Capacity

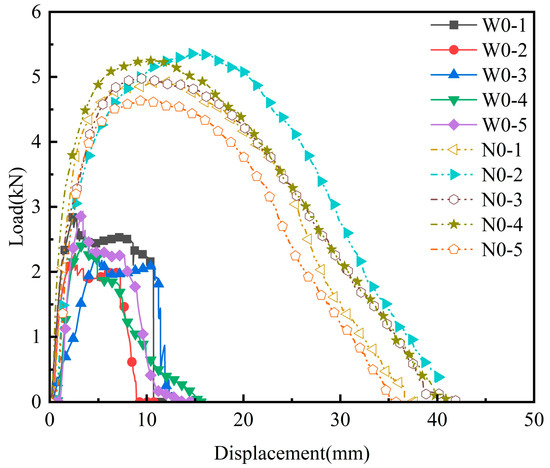

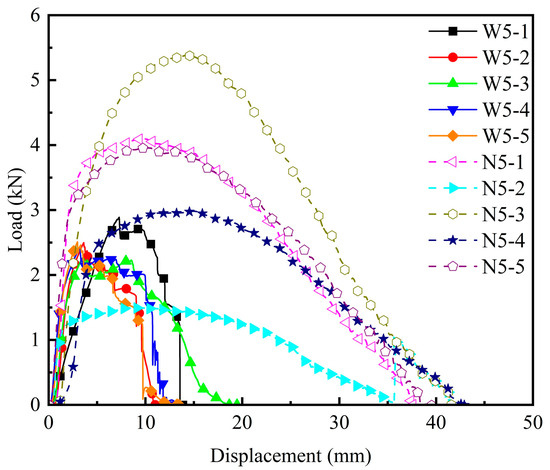

As depicted in Figure 5 and Figure 6, after five wet–dry cycles, the wood nail samples exhibited typical brittle failure characteristics with peak loads of 2.5–3.0 kN within the 0–16 mm displacement range, followed by rapid load degradation post-peak. In contrast, the steel nail samples demonstrated superior ductility, sustaining significantly higher peak loads (4.5–6.0 kN) across a 0–50 mm displacement range with gradual load reduction. Overall, while the steel connections achieved a relatively high initial load-bearing capacity, the wood nail systems presented enhanced mechanical stability under cyclic hygrothermal conditions, which is attributable to the different hygroexpansion properties and failure mechanisms of lignocellulosic and metallic materials. Elevated substrate moisture content enhanced interfacial tightness through hygroscopic expansion, whereas reduced moisture content induced shrinkage-induced gaps between the steel fasteners and substrates [19].

Figure 5.

Load–displacement curves of the untreated sample.

Figure 6.

Shear behavior comparison of the wood and steel nail connections via load–displacement curves after the fifth wet–dry cycle.

As shown in Table 3, the steel nail connections exhibited an initial peak load reduction from 4996 to 4310 N after wet-dry cycling, primarily due to differential dimensional changes between the Scots pine substrates (hygroscopic expansion/shrinkage) and annularly threaded steel nails, which enlarged interfacial gaps and degraded mechanical interlocking. Subsequent cycles revealed that the load recovery (Cycle 3) was attributed to corrosion-induced frictional enhancement between the oxidized nail surfaces and wood fibers [10]. Further cycling intensified hygro-mechanical decoupling, with peak load deterioration resuming as the cumulative hygroexpansion mismatch exacerbated interfacial discontinuities. The yield loads fluctuated around 2500 N. Displacement at the peak load increased incrementally from 10 to 13 mm across cycles. These results demonstrate the nonlinear cyclic dependency of the load-bearing capacity and deformation of steel connections [20], where hygrothermal effects first decrease, then transiently increase, and ultimately degrade performance. This cyclic degradation pattern provides critical evidence for the durability limitations of metallic fasteners in hygrothermal environments compared to those of wood nails.

Table 3.

Influence of wet–dry cycles on the shear performance of the steel nail connection nodes.

As shown in Table 4, the wood nail connections exhibited significantly lower peak loads than their steel counterparts, with the untreated samples achieving 2588 N (51.8% of the initial capacity of steel connections). After five wet-dry cycles, the wood nail peak loads stabilized at 64.8% of the degraded steel connections, demonstrating minimal reduction (2.8%, from 2588 to 2514 N), whereas the steel connections experienced a 22.3% decline (4996 to 3882 N). The wood nail yield loads ranged from 1299 to 1701 N, with displacement variations remaining marginal except for a notable fourth-cycle decrease to 2.87 mm. Brittle fracture dominated wood nail failure, typically occurring below 5 mm displacement with rapid load decay and ultimate displacement under 15 mm, confirming inferior ductility compared to that of steel systems [21]. These results reveal nonmonotonic peak load responses in wood nails under cycling (humidity-sensitive behavior) and adaptive displacement adjustments reflecting deformation capacity evolution [22]. The quantitative analysis of the performance of the compressed beech nails during hygrothermal cycling validated their environmental stability, providing critical durability design parameters for timber engineering applications.

Table 4.

Influence of wet–dry cycles on the shear performance of the compressed beech nail connection nodes.

As shown in Table 5, the between-group and within-group variances of the steel nail group were 10.3 and 4.5 times higher, respectively, than those of the beech nail group, demonstrating greater sensitivity to moisture fluctuations and higher specimen-to-specimen variability in steel nails. Comparative analysis revealed distinct performance characteristics after five wet–dry cycles: the steel nail samples presented superior ultimate load-bearing capacity, whereas the wood nail connections presented enhanced load stability with minimal performance degradation (2.8% reduction vs. 22.3% for steel). The pronounced variability in steel connection shear performance stemmed from mismatched hygroexpansion/shrinkage coefficients between annularly threaded steel nails and Scots pine laminates. Compared to the pine laminates, the compressed wood nails, featuring hygroscopic expansion compatibility, achieved tight interfacial embedding, thereby generating enhanced frictional resistance that restrained deformation. Conversely, the steel fasteners experienced cyclic hygromechanical decoupling—hygroscopic expansion of the laminate enhanced interfacial tightness with steel fasteners at elevated moisture content, temporarily improving their load—bearing performance, whereas moisture reduction induced shrinkage-induced interfacial gaps that diminished the structural capacity. These contrasting behaviors underscore the critical role of material-specific hygroexpansion compatibility in determining cyclic durability.

Table 5.

Variance analysis of maximum load.

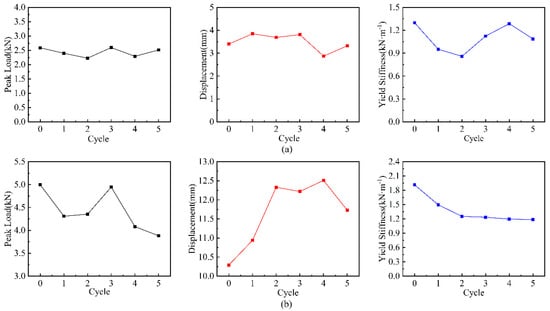

3.3. Stiffness

The yield stiffness of the single-shear samples was evaluated through the characteristic value analysis of load–displacement curves in accordance with the Japanese timber design code, as shown in Figure 7, Table 3 and Table 4. Compared to the wood nail connections (1.299 kN·m−1), untreated steel nail connections presented a 47.42% higher initial yield stiffness (1.915 kN·m−1), indicating an approximately 1.5-fold superiority. Progressive hygrothermal cycling induced a gradual decline in steel connection stiffness from 1.915 to 1.186 kN·m−1 (38.02% reduction), whereas the wood nail connections demonstrated cyclic stability with stiffness fluctuating between 0.859 and 1.299 kN·m−1 (within a 15% variation margin), ultimately decreasing by 16.32% (1.299 → 1.087 kN·m−1). This divergence stems from the compressed beech nails maintaining dimensional compatibility with the Scots pine substrates through matched hygroexpansion coefficients, sustaining tight interfacial bonding despite wet–dry effects. Conversely, the steel fasteners experienced accelerated stiffness degradation due to corrosion-induced geometric deterioration and cumulative hygromechanical mismatch, which amplified interfacial discontinuities and deformation.

Figure 7.

Peak load, displacement, and yield stiffness—cycles of fasteners: (a) wood nail connection node and (b) steel nail connection node.

4. Conclusions

The effects of designed wet–dry cycling experiments on the shear performance of compressed beech nail and galvanized annularly threaded steel nail connections. The key conclusions of this study are as follows:

- (1)

- Compressed beech nail connections predominantly failed via brittle fastener fracture at the timber interface, with minimal intact withdrawal. In contrast, the failure of steel nails involved ductile nail withdrawal accompanied by bending deformation and wood fiber tear-out at the substrate interfaces.

- (2)

- Compared to the wood nails, the untreated samples (0 cycles) demonstrated significant performance disparities: The steel connections presented nearly double the ultimate load (4996 vs. 2588 N) and a 1.5-fold greater yield stiffness (1915 vs. 1299 N/mm). After cycling, the steel connections experienced a 22.3% load capacity loss and 38.02% stiffness degradation, whereas the wood nail systems maintained stable performance with only a 2.8% reduction, confirming the superior hygrothermal durability of the lignocellulosic fasteners.

- (3)

- Cyclic exposure induced minimal displacement (2.4% decrease) and load capacity (2.8% reduction) variations in the wood nails, reflecting exceptional dimensional stability. Conversely, the steel connections exhibited substantial displacement (14.0% increase) and load (22.3% decrease) fluctuations, necessitating moisture-proof measures to mitigate corrosion-induced performance decay.

Author Contributions

Conceptualization, W.F., X.Z. and X.H.; methodology, H.L.; software, W.F.; validation, W.F., X.Z. and X.H.; formal analysis, W.F.; investigation, X.Z. and X.H.; data curation, W.F.; writing—original draft preparation, W.F.; writing—review and editing, H.L.; visualization, W.F.; supervision, X.Z. and X.H.; project administration, H.L.; funding acquisition, H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors sincerely acknowledge the Key Laboratory of Wood Materials Science and Application, Beijing, China, the Ministry of Education, Beijing, China, and the Beijing Key Laboratory of Wood Science and Engineering Beijing, China, for providing equipment support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pramreiter, M.; Nenning, T.; Malzl, L.; Konnerth, J. A plea for the efficient use of wood in construction. Nat. Rev. Mater. 2023, 8, 217–218. [Google Scholar] [CrossRef]

- Lestari, L.; Ikaputra, I. Toward Sustainable Construction Using Wood Material: A Review of Indicator-based Sustainability Assessments. Int. J. Eng. Appl. Sci. 2024, 4, 77–90. [Google Scholar] [CrossRef]

- Kamperidou, V. The Biological Durability of Thermally- and Chemically-Modified Black Pine and Poplar Wood Against Basidiomycetes and Mold Action. Forests 2019, 10, 1111. [Google Scholar] [CrossRef]

- Ottenhaus, L.; Li, M.; Smith, T.J.; Quenneville, P. Ductility of dowelled and nailed CLT and LVL connections under monotonic and cyclic loading. In Proceedings of the Australian Earthquake Engineering Society 2016 Conference, Melbourne, Australia, 25–27 November 2016. [Google Scholar]

- Chung, P.P.; Wang, J.; Durandet, Y. Deposition processes and properties of coatings on steel fasteners—A review. Friction 2019, 7, 389–416. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Rammer, D.R. Modelling the effect of nail corrosion on the lateral strength of joints. For. Prod. J. 2012, 62, 160–166. [Google Scholar]

- BECK Fastener Group. LIGNOLOC® Wooden Nails; BECK Fastener Group: Mauerkirchen, Austria, 2023. [Google Scholar]

- Korte, H.; Koch, G.; Krause, K.C.; Koddenberg, T.; Siemers, S. Wood nails to fix softwoods: Characterization of structural deformation and lignin modification. Eur. J. Wood Wood Prod. 2018, 76, 979–988. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Y.; Duo, Y.; Zhou, B.; Que, Z. The Influence of Wood Nail Diagonal Connection on SPF Connection Performance. J. Build. Technol. 2021, 52, 294–296. [Google Scholar]

- Wang, S.; Wang, F.; Kong, F.; Ma, P.; Chen, Z.; Que, Z. Influence of repeated wetting and drying on withdrawal capacity of wooden nails and metal nails. Constr. Build. Mater. 2023, 409, 133991. [Google Scholar] [CrossRef]

- Yermán, L.; Ottenhaus, L.M.; Montoya, C.; Morrell, J. Effect of repeated wetting and drying on withdrawal capacity and corrosion of nails in treated and untreated timber. Constr. Build. Mater. 2021, 284, 122878. [Google Scholar] [CrossRef]

- Que, Z.L.; Yang, L.; Wang, F.B.; Xu, Y.; Pan, B.; Wang, Y.B. The effect of salinity on the nail-holding power of dimension lumber. J. Southwest Forest. Univ. 2014, 34, 100–103. [Google Scholar] [CrossRef]

- Kang, S.M.; Morrell, J.J.; Smith, D. Effect of incising and preservative treatment on nail-holding capacity of douglas-fir and hem-fir lumber. For. Prod. J. 1999, 49, 43–45. [Google Scholar]

- GB/T 50005-2017; Standard for Design of Steel Structures. China Architecture & Building Press: Beijing, China, 2017.

- GB/T 50329-2012; Standard Test Methods for Wooden Structures. China Architecture & Building Press: Beijing, China, 2012.

- Japan 2 × 4 Home Builders Association. Structural Design Guidelines for Wood Frame Construction; Japan 2 × 4 Home Builders Association: Tokyo, Japan, 2002; pp. 213–241. (In Japanese) [Google Scholar]

- Xue, Y.Y.; Zhu, X.D.; Zhang, X.W.; Qi, P.F.; Li, J.J.; Liu-hao-ran, Z.H.U.; Yao, L.H. Single Shear Performance of Components Connected by Beech-self-Tapping-Screw Composite Dowels. Chin. J. Wood Sci. Technol. 2022, 36, 68–74. [Google Scholar]

- EN 1995-1-1; Eurocode 5—Design of Timber Structures-Part1.1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2006.

- Silva, C.; Branco, J.M.; Ringhofer, A.; Lourenço, P.B.; Schickhofer, G. The influences of moisture content variation, number and width of gaps on the withdrawal resistance of self tapping screws inserted in cross laminated timber. Constr. Build. Mater. 2016, 125, 1205–1215. [Google Scholar] [CrossRef]

- Gao, Q.; Sun, Q.; Xin, H.; Zhang, Y.; Liu, Y. Hygrothermal aging effects on fatigue behavior of web-flange junctions from pultruded I-shaped GFRP Beam. J. Build. Eng. 2025, 100, 111683. [Google Scholar] [CrossRef]

- Gerber, C.; Collado, K.; Morrell, J.J. Impact of moisture cycling on lateral resistance of resin-impregnated compressed beech nails in radiata pine timber. Int. Wood Prod. J. 2021, 12, 147–151. [Google Scholar] [CrossRef]

- Wang, S.; Wang, F.; Ma, P.; Kong, F.; Beck, C.; Siemers, S.; Que, Z. Eco-friendly wooden nails: Bonding mechanisms and withdrawal resistance in sustainable timber connections. J. Clean. Prod. 2025, 486, 144606. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).