Abstract

This article discusses the non-destructive evaluation of the mechanical properties of green wood. To estimate the dynamic flexural modulus of elasticity (MOED), a non-destructive test (NDT) method—the frequency resonance technique (FRT)—was used. A three-point bending test was carried out to determine the static bending properties as the bending modulus of elasticity (MOE), the modulus of rupture (MOR), and bending toughness (Aw). This article presents the results of a study comparing the correlations between the dynamic and static bending parameters of beech (Fagus sylvatica L.) and oak (Quercus robur L.) wood, which was further divided into heartwood and sapwood. These species were chosen as the most widespread representatives of diffuse-porous and ring-porous hardwoods. This study found statistically significant differences in most mechanical parameters between the two species, except for MOR. Among the investigated parameters, beech had higher values than oak (by 22.1% for MOED, 9.5% for MOE, and 12.1% for Aw). Furthermore, relevant correlations (R > |0.7|) were established between MOED and between some of the static flexural parameters. These correlations were stronger for beech, which due to its more homogeneous structure showed less data variability than the ring-porous oak.

1. Introduction

The assessment of standing trees and fresh timber relies heavily on the mechanical properties of green wood [1,2]. Moisture content (MC) strongly affects the mechanical behaviour of wood due to its hygroscopic nature [3]. As MC increases to the fibre saturation point (FSP), resistance to mechanical stress decreases [4]. However, when MC is above the FSP, mechanical properties remain almost unchanged [4,5]. To ensure consistency, the mechanical properties of green wood are measured at an MC greater than 50% [1,6]. Various catalogues of the mechanical properties of green wood have been published so far: Kretschmann [7] presented different wood species’ physical parameters and mechanical properties in terms of compression, tension, shear, and bending in the green state and at 12% MC. Niklas and Spatz [6] analysed the relationships between Young’s modulus (E), MOR, the maximum strength in shear and compression, and the density of green wood (ρw) from a taxonomically broad spectrum of 161 species. Wessolly and Erb [8] proposed a list of compressive mechanical properties for green wood of different species in all orthotropic directions for the purpose of tree risk assessment. Because wooden structures, including trees, are often subjected to bending loads, mechanical properties such as MOE, MOR, and Aw are crucial parameters for assessing wood quality [9,10]. Considering all types of stress, three-point bending is one of the most complex, as it combines compression, tension, and shear [11].

To overcome the limitations of static and impact mechanical evaluation (such as destructiveness, the dimensions of the measured specimens, and repeatability), NDT methods have been developed [12,13]. Due to their versatility, different NDT techniques are used nowadays to estimate the static mechanical properties of timber and standing trees [14,15,16]. Some of these methods are based on vibro-acoustic properties such as stress wave velocity or frequency of vibrations [17,18], including FRT, which describes a number of dynamic parameters simultaneously [19,20,21]. With FRT, engineering constants such as the longitudinal dynamic modulus of elasticity (Edyn), dynamic shear modulus (G), Poisson ratios (v), and MOED can be determined based on the response of the tested specimen to dynamic loading [22,23,24]. During dynamic testing, an adiabatic process occurs (when energy within the specimen increases during the test) which causes the resulting values of the elastic constants measured with dynamic methods to always be higher than those measured with static tests [24]. Due to the nearly perfect linear relationship between Edyn and MOED in relation to E and MOE [25], these dynamic parameters can be reliably used to predict static parameters [19]. Although the prediction of static bending properties from Edyn is also possible [26], the conclusion of Faydi et al. [19] is that using MOED to predict MOE and MOR leads to a more accurate prediction than using Edyn. However, the correlation between MOED and MOR is significantly weaker than that between MOED and MOE [19]. Halabe et al. [27] determined mutually relevant linear relationships between MOED and MOE (R2 = 0.82 and 0.70) for dry and green southern pine wood, with weaker relationships between MOED and MOR (R2 = 0.41 and 0.28).

Because the influence of MC on strength change above the FSP is not as crucial as below it, dynamic properties determined by FRT are often considered constant above the FSP, in the same way as static mechanical properties [28]. Ross [29] described how this assumption can be used in monitoring moisture changes in green log stocks (with MC from 150% down to an air-dry state of 30% to 40%). This is useful because standard electrical conductivity or impedance techniques lose accuracy when measuring moisture levels above the FSP [29,30]. Using adjustment functions and constant factors, the expected mechanical properties of wood with an MC below the FSP can be determined based on the mechanical properties of green wood [30,31]. However, considering the variability of wood as a natural polymer, its mechanical properties are also influenced by its anatomical characteristics, such as ray density and the distribution of vessels [32]. Plos et al. [33] stated that the accuracy of MOE determination from MOED is dependent on species (comparing beech, Norway spruce, and European red pine) respectively on factors such as knot size and grain deviation.

This article delves into determining the static bending properties of green beech and oak wood using a non-destructive vibro-acoustic method. Numerous studies have explored the relationships between properties obtained by NDT and static mechanical properties. Most of these studies have concentrated on softwoods, with a relatively small number focusing on hardwoods [2]. A comprehensive understanding of the reliability of vibro-acoustic methods in predicting their static bending properties above the FSP remains elusive. This knowledge gap is particularly crucial for the non-destructive assessment of tree stability and the preliminary grading of fresh timber.

Purba et al. [34] stated that beech and oak are the two most important hardwood species in Europe. The same authors further add that MOE and MOR are strongly influenced by the orientation of fibres/tracheids. Therefore, variations in grain angle can significantly impact mechanical properties. Compared to other hardwood species, beech and oak are expected to have low variability in grain angle (1°–3°) [34].

The selection of both oak and beech as the focus of this study is strategic, as they aptly represent the categories of diffuse-porous and ring-porous hardwood. This distinction is critical for a more nuanced understanding of the mechanical behaviour of hardwood.

2. Materials and Methods

2.1. Materials

Eighty-five special orthotropic specimens of the European beech (Fagus sylvatica L.) and English oak (Quercus robur L.), with dimensions of 20 × 20 × 300 mm (anatomical orientation: tangential × radial × longitudinal), were crafted for each species. The selection and processing of specimens were based on standards for testing clear specimens of timber (without any imperfections such as knots, cracks, or decay) [35,36]. The specimens were processed from fresh timber, specifically from the lower four-meter section of five beech logs with an average diameter of 42 cm and an age of 95 years, and from three oak logs with an average diameter of 48 cm and an age of 105 years. Beech specimens were made from a cross-section of the entire trunk. For oak, 58 heartwood and 27 sapwood specimens were crafted. The selected wood was obtained from a natural forest stand (beech: 49.272045 N, 16.707335 E; 485 mls, and oak: 49.337248 N, 16.689607 E; 472 mls) at the University Forest Enterprise Masaryk Forest in Křtiny (Czechia). After being crafted, the specimens were stored underwater for 14 days and then acclimatised on a grid above the water level in a hermetically sealed box for another 14 days. Before acclimatisation, half of the samples for each species were exposed for 48 h in room conditions (20 °C, 60% relative humidity), lowering their masses to obtain a broad range of MC above the FSP for testing. After testing, MC was determined gravimetrically according to ASTM D2395 [37]. Green density (ρw) and basic density (ρb) were determined from the ratio of mass (green mass for ρw and oven-dry mass for ρb) to volume above the FSP.

2.2. Dynamic Measurement

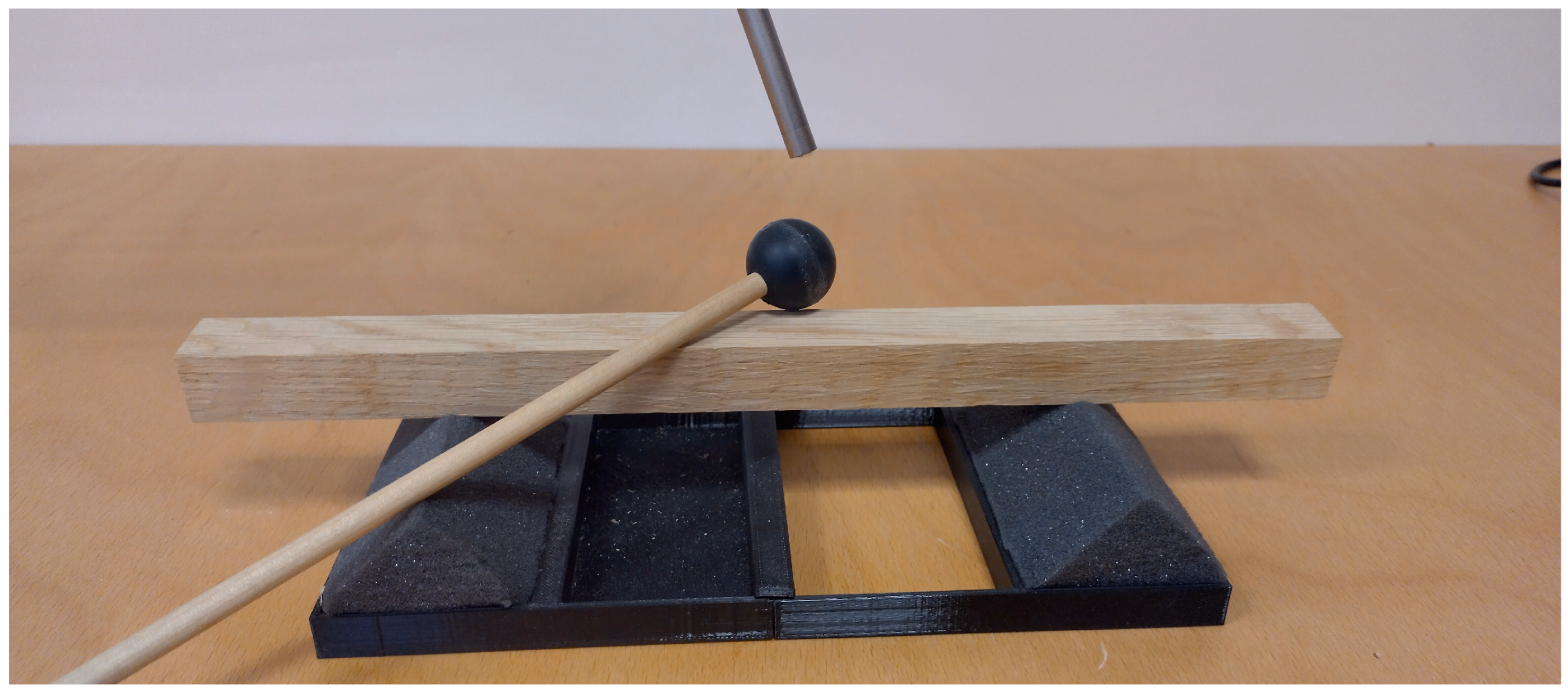

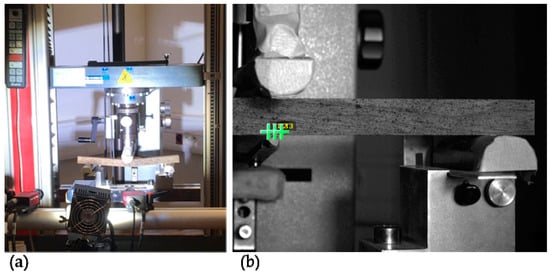

To obtain input data to calculate MOED, the FRT was used. Each specimen was freely fixed at the nodal points of the first bending mode (22.4% and 77.6% of the length), according to ASTM E1875 [23]. To support the freely fixed specimen, triangular foam prisms were used (Figure 1). After striking the centre of the specimen with a rubber mallet, the oscillation was sensed by a microphone (TM-1, Audix, Wilsonville, OR, USA) and recorded using an audio interface (UR 22MKII, Steinberg Media Technologies GmbH, Hamburg, Germany) with a sampling frequency of 44.1 kHz. Each sample was struck at least three times. Each specimen was tested in the longitudinal–tangential (LT) and longitudinal–radial (LR) bending modes.

Figure 1.

Experimental setup of the frequency resonance technique for measuring the first bending mode involves supporting the sample at 22.4% and 77.6% of its length using soft supports and exciting it with a mallet at its centre.

2.3. Static Mechanical Testing

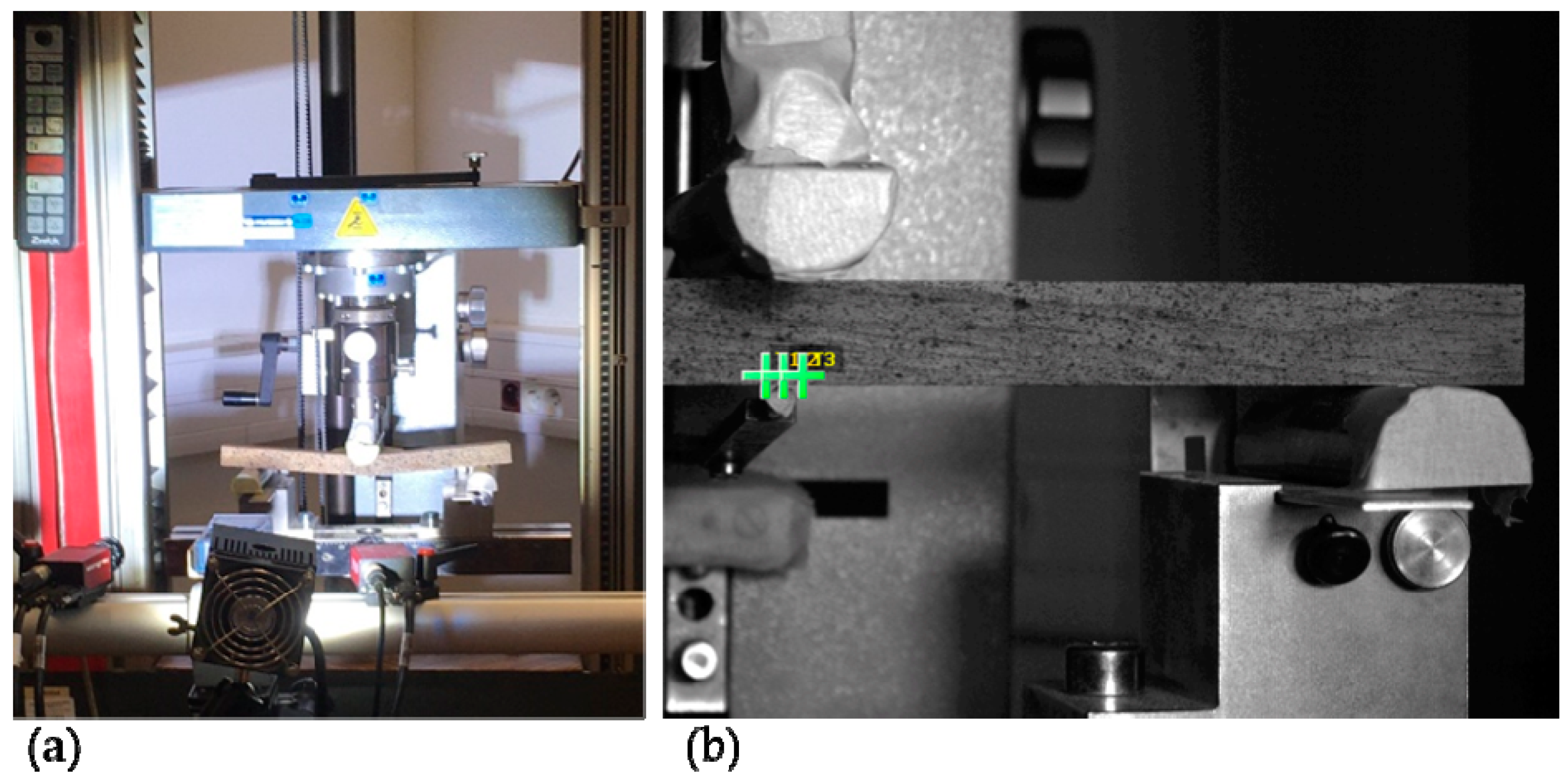

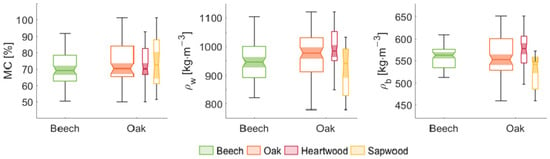

Static three-point bending tests were carried out using a universal testing machine (Zwick Z050, 50 kN, Zwick GmbH, Ulm, Germany). The design of the experiment was based on standards for three-point bending tests of small clear specimens (BS 373) [36]. The specimens were loaded at their centre in the T direction and supported by clamps with a span equal to 12 times the thickness of the specimen. Before the static testing, a random point pattern was applied to the T face of the sample using black spray. To acquire images of pattern-probe displacement in the area of greatest deflection, two cameras (AVT Stingray Copper F504B, cell size: 3.45 µm, resolution: 5 Mpx, image capture frequency: 2 fps) were used. Displacement data were determined from the pictures using MercuryRT (version 2.8) software (Sobriety Ltd., Kuřim, Czechia) using the digital image correlation (DIC) technique (Figure 2).

Figure 2.

(a) Experimental set-up of the three-point bending test with a stereoscopic pair of cameras capturing sample deflection; (b) image of the determination of point probe displacement using MercuryRT software (version 2.8).

2.4. Determination of Bending Parameters and Data Analysis

The MATLAB (MathWorks, Inc., Natick, MA, USA) environment was used to evaluate the dynamic and static mechanical testing data. Applying the fast Fourier transform to the whole specimen signal, the frequency of the first bending mode shape was determined as the highest peak in the frequency spectrum. MOED was calculated using Equation (1).

where f is the frequency of the bending mode, n is the rank of the bending mode, γ is the correction factor (n + 0.5)2, m is the mass of the specimen, l is the length of the specimen, and I is the moment of inertia of the cross-section.

The evaluation of three-point static bending was derived from Czech technical standards [38,39], with a modified span-to-depth ratio equal to 12. Based on DIC data, deflection (ε) was evaluated as point-probe displacement on the y-axis. MOE was calculated using Equation (2).

where F10 and F40 are 10% and 40% of the maximum value of force (Fmax), ε10 and ε40 are the deflections corresponding to F10 and F40, l0 is the span length, b is the width of the cross-section, and h is the height of the cross-section.

Bending stress (σ) was calculated from the parameters obtained from the static test according to Equation (3):

MOR was determined as σ at Fmax. Using the trapezoidal method, work (W) was calculated using the area under the force-deflection curve to Fmax. Aw was determined as the value of W divided by the area (A) of the specimen cross-section according to Equation (4):

A Kruskal–Wallis ANOVA with a multiple comparison test of group means was used for the evaluation of statistical data. For the Kruskal–Wallis ANOVA, the significance level was set to p = 0.05. To determine the relevant linear relationship (R2 > 0.5), the significance level for Pearson’s correlation coefficients was set to R > |0.7|. This approach was applied due to the high variability of wood as a biological material.

3. Results and Discussion

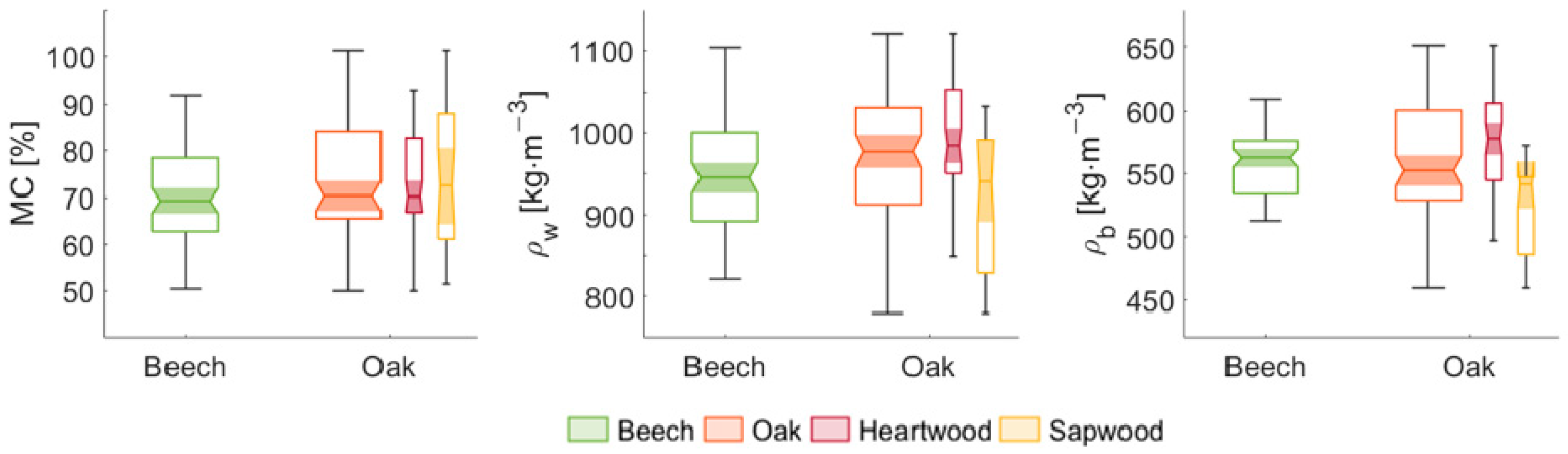

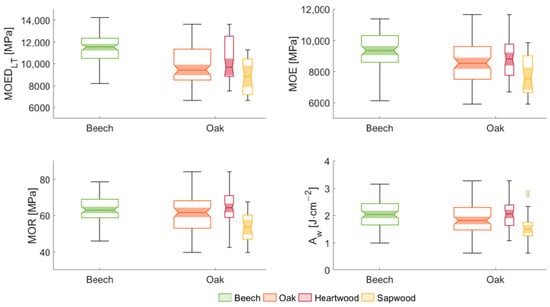

The tested species had statistically comparable MCs within a range of 50%–101%. They also had statistically comparable ρw and ρb (Table 1). The oak samples had statistically comparable MCs, but a statistically significant difference between the ρw and ρb of heartwood and sapwood was found (Figure 3).

Table 1.

Median values of MC, ρw, and ρb with the coefficient of variation (cv).

Figure 3.

Comparison of MCs and densities of the tested species with oak divided into heartwood and sapwood.

Table 2 shows the medians of all determined bending parameters of both species (oak heartwood and sapwood separately). No statistically significant difference was found between MOEDLT and MOEDLR for any tested group. Therefore, only MOEDLT could be used for further comparisons between dynamic and static parameters. As expected, MOED values were the highest of the moduli, and values of MOR were the lowest, in a ratio of median values (MOEDLT/MOE/MOR) of 183:148:1 for beech and 153:138:1 for oak (no relevant difference was found between ratios of oak heartwood and sapwood). The ratios between MOE and MOR presented by Borůvka et al. [40] and Brischke [41] for beech (96:1 and 91:1) and for oak (107:1 and 99:1) with an MC of 12% are lower than the data presented in this article and also lower than the results shown by Arnold [42] for green beech (121:1) and by Ruiz-Aquino et al. [43] for green oak (210:1 for Q. laurina and 206:1 for Q. crassifolia).

Table 2.

Median values of bending properties (cv).

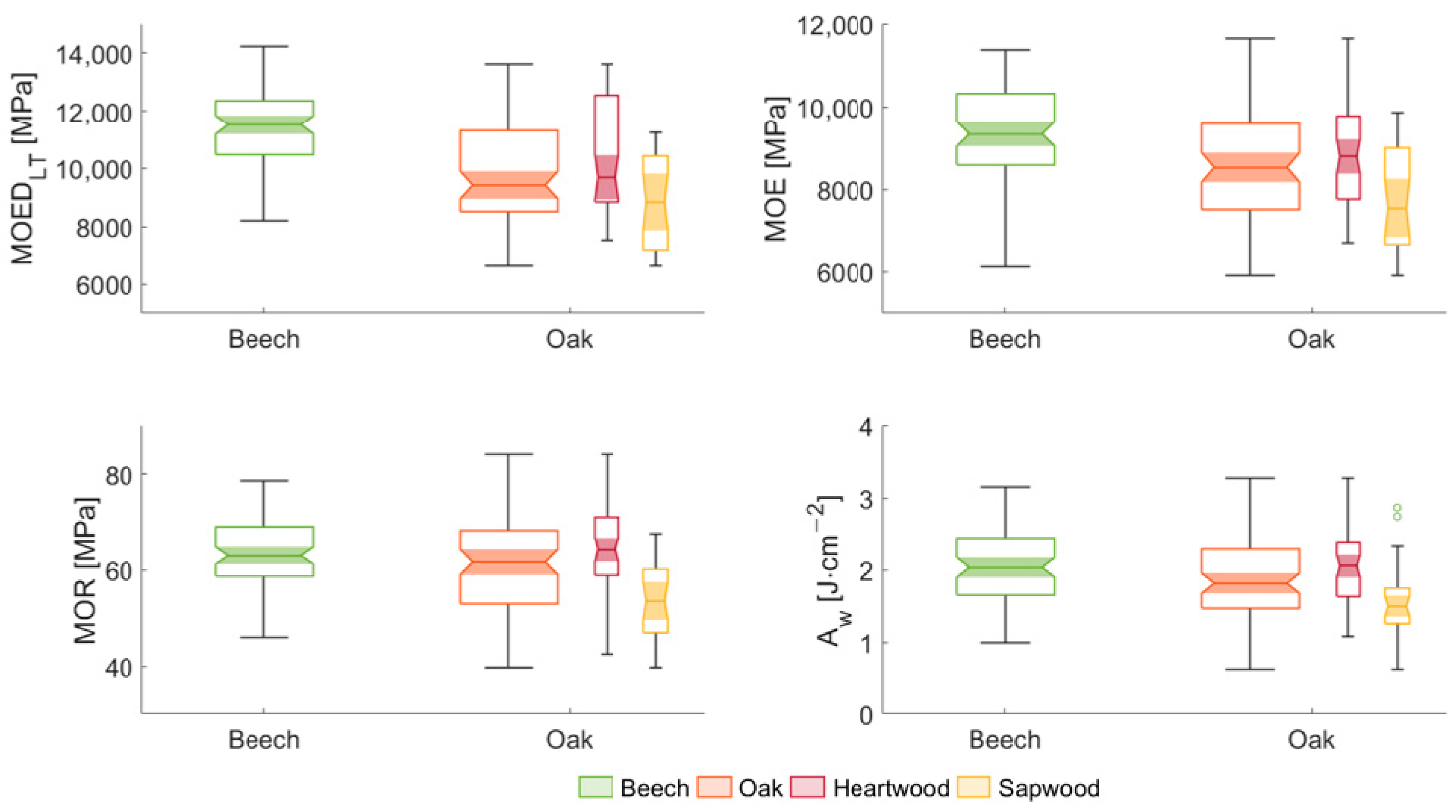

Except for MOR values, statistically significant differences for the other parameters between the two species were proved (p < 0.05). According to Table 2, beech had higher values than oak by 22.1% for MOEDLT, 16.9% for MOEDLR, 9.5% for MOE, and 12.1% for Aw. Oak had greater variability of measured data, even considering heartwood and sapwood separately. The greater variability in bending properties of oak compared to beech was also stated by Purba et al. [34]. Despite comparable MCs, no significant differences for MOR and Aw were proved between beech and oak heartwood (Figure 4). However, there were distinctions in ρw and ρb, with both densities higher for oak wood (Table 1). According to our results, even though there is a general assumption that higher density entails higher strength [44], this does not apply to representatives of diffuse- and ring-porous hardwood with an MC above the FSP examined in this study. There were statistically significant differences between all observed bending parameters when comparing oak heartwood and sapwood (both with comparable MCs and different ρb and ρw). Our results do not correspond to the conclusions presented by [44], where the material properties of sapwood and heartwood from white (Q. alba) and red oak (Q. cerris) with an MC close to 15% were compared. The authors stated that the heartwood and sapwood of each species had statistically comparable ρb. Furthermore, the authors found a significant difference in MOE and MOR between these two oak species [44]. Nevertheless, for these parameters, no difference was proved between the heartwood and sapwood of each species. A comparison of these results and the results from our study implies that differences between heartwood and sapwood bending properties increase above the FSP.

Figure 4.

Comparison of individual bending parameters between the tested groups.

There was no relevant correlation between MC and bending parameters above the FSP in either species (Table 3). Compared to the results reported by Ruiz-Aquino et al. [43] for the relationships between MC and MOE (R = 0.04), and MC and MOR (R = −0.15) in Q. laurina and Q. crassifolia, the data for Q. robur presented in this article showed closer correlations between MC and static bending parameters (MC and MOE (R = −0.44) and MC and MOR (R = −0.34)). For the oak and beech tested, ρw was the parameter with the weakest correlation to MOR. Teranishi et al. [45] reported a relevant correlation between ρw and MOR for ring-porous (R = 0.75) wood species. For oak, it was confirmed that ρb was also positively correlated with bending strength, as stated by Ruiz-Aquino et al. [43] for ρb and MOE (R = 0.47) and ρb and MOR (R = 0.45). Teranishi et al. [45] stated that in contrast to diffuse-porous hardwoods, the anatomical structure of ring-porous hardwoods is associated with a positive correlation between density and ring width. This leads to the assumption that a higher density of ring-porous hardwoods is generally linked to greater strength. The same authors did not consider this relationship to be clearly established for diffuse-porous hardwoods [45]. Their conclusions align with the results obtained in this study, where no relevant correlation was found between ρw or ρb and the bending properties of beech.

Table 3.

Correlation matrix of determined parameters for each wood species. Coefficients in bold are considered significant.

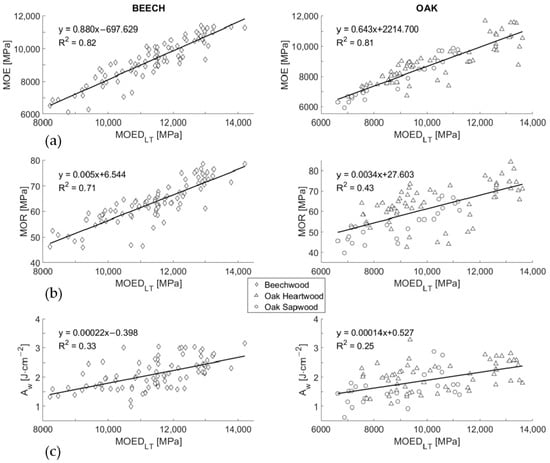

While beech had a stronger linear relationship between MOED and static parameters (Figure 5), oak had a higher correlation between MOE–MOR–Aw, so between static bending parameters themselves (Table 3). Our oak’s correlation between MOR and MOE (R = 0.88) was stronger than that of the oak with MC ranging from 18% to 25% reported by Muñoz and Gete [46] (R = 0.75) but weaker than that reported by the same authors [47] for oak with MC = 13% (R = 0.95). The division of oak into heartwood and sapwood showed that for sapwood, both MOE and MOR can be determined from MOED, while for heartwood, only MOE can (Table 4). Arnold [42] found a closer correlation between MOE and MOR (R = 0.98) for 13 specimens of beech with MCs above the FSP; however, due to the greater number of our tested specimens (85) and the known high variability of wood properties, these results can be considered comparable.

Figure 5.

Linear regression between the dynamic modulus of elasticity in bending and (a) static modulus of elasticity in bending; (b) modulus of rupture in bending; (c) bending toughness.

Table 4.

Correlation matrix of determined parameters for oak sapwood and heartwood. Coefficients in bold are considered significant.

The results obtained show that green beech MOED and MOR had a stronger correlation than the Edyn and MOR of diffuse-porous hardwoods (MC = 12%) found by Teranishi et al. [45]. Compared with the results of Borůvka et al. [40] for beech and oak (MC = 12%), the correlation of MOED and static bending strength was stronger in all cases with Edyn. This is also confirmed by the result of Faydi et al. [19], who, however, did not establish these differences as fundamentally different. Their correlation between MOED and MOE (R = 0.85) was similar to our results, and the correlation between MOED and MOR (R = 0.28) was considerably lower. According to the presented results, the relationship between MOED (in both directions of bending) and static bending parameters decreased according to the deformation area in which they were determined. For MOED and MOE, which were both determined in the linear deformation region, the linear relationship was the strongest (Figure 5a). For beech, MOR could be determined from MOED (Figure 5b) but this was not possible for oak (R2 < 0.5). Similar results of a lower correlation between MOED and MOR than between MOED and MOE were provided by Halabe et al. [27]. Nevertheless, during bending tests of green wood after the yield point, changes in deflection were much higher than changes in F [42]. This assumption can explain the weakest linear relationship among static parameters between MOED and Aw (Figure 5c), where Aw was calculated from the area under the force-deflection curve, which, in green wood, is highly influenced by the plastic zone; MOED is a dynamic parameter representing the material’s behaviour in the elastic zone.

4. Conclusions

According to the results presented and discussed in this article, the following statements can be made:

- Significant correlations were found between MOEDLT/LR and static bending properties (R = 0.91 and 0.90 between MOED and MOE; R = 0.84 and 0.66 between MOED and MOR; R = 0.58 and 0.50 between MOED and Aw). The correlation decreased with the degree of involvement of the plastic region of the stress-strain diagram on the static parameter determination. In addition to determining MOE from MOED, it was also possible to determine MOR from MOED for beech, but not for oak (R2 < 0.5). This leads to the conclusion that the possibility of determining static bending properties based on dynamic moduli is also affected by anatomical factors such as vessel dimensions and their arrangement (diffuse-porous and ring-porous species);

- MOED and MOE for oak (as an example of ring-porous hardwoods) could be predicted from ρb. This relationship can be used for a preliminary grading of the investigated species. According to the results, this is not possible for beech (as an example of diffuse-porous species);

- Compared to the similar bending properties reported in the literature for oak heartwood and sapwood with MC around 15%, there were statistically significant differences in the observed bending parameters between heartwood and sapwood above the FSP;

- Among all static parameters, the weakest (not significant) correlation with MOED was proven for Aw. This was caused by the high impact of the plastic deformation zone (typical for green wood) on Aw, while MOED is derived from the elastic material response.

This article discusses the effects of MC above the FSP on the correlation between the vibro-acoustic and static mechanical properties of green oak and beech wood. The results obtained can be applied to enhancing the non-destructive grading of green lumber and to the quality and mechanical assessment of standing trees. However, due to the variability across different wood species and the increased heterogeneity of structures, further research on this subject is necessary.

Author Contributions

Conceptualization, P.N., V.C. and J.T.; Data curation, P.N., V.C., J.Z., M.H.V. and V.Š.; Investigation, P.N., V.C. and J.Z.; Methodology, P.N.; Project administration, V.C.; Supervision, J.T.; Writing—original draft, P.N.; Writing—review and editing, P.N., V.C., J.Z., M.H.V., V.Š. and J.T. All authors have read and agreed to the published version of the manuscript.

Funding

The static part of this research was funded by the Internal Grant Schemes of Mendel University in Brno, registration no. CZ.02.2.69/0.0/0.0/19_073/0016670, funded by the ESF. The authors gratefully acknowledge the Ministry of Education Youth and Sports in the Czech Republic [project “Tree Dynamics: Understaning of Mechanical Response to Loading”, Grant Number #LL1909, ERC CZ], for the dynamic part of this research.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Correction Statement

This article has been republished with a minor change. The change does not affect the scientific content of the article.

References

- Spatz, H.C.; Pfisterer, J. Mechanical Properties of Green Wood and Their Relevance for Tree Risk Assessment. Arboric. Urban For. 2013, 39, 218–225. [Google Scholar]

- Llana, D.F.; Short, I.; Harte, A.M. Use of Non-Destructive Test Methods on Irish Hardwood Standing Trees and Small-Diameter Round Timber for Prediction of Mechanical Properties. Ann. For. Sci. 2020, 77, 62. [Google Scholar] [CrossRef]

- Mvondo, R.R.N.; Meukam, P.; Jeong, J.; Meneses, D.D.S.; Nkeng, E.G. Influence of Water Content on the Mechanical and Chemical Properties of Tropical Wood Species. Results Phys. 2017, 7, 2096–2103. [Google Scholar] [CrossRef]

- Nocetti, M.; Brunetti, M.; Bacher, M. Effect of Moisture Content on the Flexural Properties and Dynamic Modulus of Elasticity of Dimension Chestnut Timber. Eur. J. Wood Wood Prod. 2014, 73, 51–60. [Google Scholar] [CrossRef]

- Sandoz, J.L. Moisture Content and Temperature Effect on Ultrasound Timber Grading. Wood Sci. Technol. 1993, 27, 373–380. [Google Scholar] [CrossRef]

- Niklas, K.J.; Spatz, H.C. Worldwide Correlations of Mechanical Properties and Green Wood Density. Am. J. Bot. 2010, 97, 1587–1594. [Google Scholar] [CrossRef]

- Kretschmann, D.E. Chapter 5—Mechanical Properties of Wood. In Wood Handbook—Wood as an Engineering Material; Forest Products Laboratory (US): Madison, WI, USA, 2010; pp. 1–46. [Google Scholar]

- Wessolly, L.; Erb, M. Manual of Tree Statics and Tree Inspection; Patzer Verlag: Berlin/Hanover, Germany, 2016. [Google Scholar]

- Ray, P.M.; Bret-Harte, M.S. Elastic and Irreversible Bending of Tree and Shrub Branches under Cantilever Loads. Front. Plant Sci. 2019, 10, 59. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, Y.; Ishiguri, F.; Aiso, H.; Takashima, Y.; Hiraoka, Y.; Iki, T.; Ohshima, J.; Iizuka, K.; Yokota, S. Inheritance of Static Bending Properties and Classification of Load-Deflection Curves in Cryptomeria Japonica. Holzforschung 2021, 75, 105–113. [Google Scholar] [CrossRef]

- Walley, S.M.; Rogers, S.J. Is Wood a Material? Taking the Size Effect Seriously. Materials 2022, 15, 5403. [Google Scholar] [CrossRef]

- Niemz, P.; Mannes, D. Non-Destructive Testing of Wood and Wood-Based Materials. J. Cult. Herit. 2012, 13 (Suppl. S3), S26–S34. [Google Scholar] [CrossRef]

- Madhoushi, M.; Boskabadi, Z. Relationship between the Dynamic and Static Modulus of Elasticity in Standing Trees and Sawn Lumbers of Paulownia Fortunei Planted in Iran. Cienc. Tecnol. 2019, 21, 35–44. [Google Scholar] [CrossRef]

- Grabianowski, M.; Manley, B.; Walker, J.C.F. Acoustic Measurements on Standing Trees, Logs and Green Lumber. Wood Sci. Technol. 2006, 40, 205–216. [Google Scholar] [CrossRef]

- Yang, T.H.; Wang, S.Y.; Lin, C.J.; Tsai, M.J. Evaluation of the Mechanical Properties of Douglas Fir and Japanese Cedar Lumber and Its Structural Glulam by Nondestructive Techniques. Constr. Build. Mater. 2008, 22, 487–493. [Google Scholar] [CrossRef]

- Qin, R.; Qiu, Q.; Lam, J.H.M.; Tang, A.M.C.; Leung, M.W.K.; Lau, D. Health Assessment of Tree Trunk by Using Acoustic-Laser Technique and Sonic Tomography. Wood Sci. Technol. 2018, 52, 1113–1132. [Google Scholar] [CrossRef]

- Arciniegas, A.; Prieto, F.; Brancheriau, L.; Lasaygues, P. Literature Review of Acoustic and Ultrasonic Tomography in Standing Trees. Trees 2014, 28, 1559–1567. [Google Scholar] [CrossRef]

- Baar, J.; Tippner, J.; Gryc, V. Wood Anatomy and Acoustic Properties of Selected Tropical Hardwoods. IAWA J. 2016, 37, 69–83. [Google Scholar] [CrossRef]

- Faydi, Y.; Brancheriau, L.; Pot, G.; Collet, R. Prediction of Oak Wood Mechanical Properties Based on the Statistical Exploitation of Vibrational Response. BioResources 2017, 12, 5913–5927. [Google Scholar] [CrossRef]

- Nop, P.; Tippner, J. Influence of Dimensions of Wooden Samples for Determination of Acoustic Parameters and Sound Timbre. Appl. Acoust. 2022, 196, 108895. [Google Scholar] [CrossRef]

- Tippner, J.; Vojáčková, B.; Zlámal, J.; Kolařík, J.; Paulic, V.; Funai, J. The Role of Geometry Precision in Frequency-Resonance Method for Non-Destructive Wood Assessment—Numerical Case Study on Sugar Maple. Wood Mater. Sci. Eng. 2022, 18, 792–800. [Google Scholar] [CrossRef]

- ASTM E1876-15; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus and Poisson’s Ratio by Impulse Excitation of Vibration. American Society for Testing and Materials: Philadelphia, PA, USA, 2013. [CrossRef]

- ASTM E1875-20; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus and Poisson’s Ratio by Sonic Resonance. American Society for Testing and Materials: Philadelphia, PA, USA, 2020. [CrossRef]

- Bucur, V. A Review on Acoustics of Wood as a Tool for Quality Assessment. Forests 2023, 14, 1545. [Google Scholar] [CrossRef]

- Chauhan, S.; Sethy, A. Differences in Dynamic Modulus of Elasticity Determined by Three Vibration Methods and Their Relationship with Static Modulus of Elasticity. Cienc. Tecnol. 2016, 18, 373–382. [Google Scholar] [CrossRef]

- Guntekin, E.; Ozkan, S.; Yilmaz, T. Prediction of Bending Properties for Beech Lumber Using Stress Wave Method. Cienc. Tecnol. 2014, 16, 93–98. [Google Scholar] [CrossRef]

- Halabe, U.B.; Bidigalu, G.M.; Gangarao, H.V.S.; Ross, R.J. Nondestructive Evaluation of Green Wood Using Stress Wave and Transverse Vibration Techniques. Mater. Eval. 1995, 55, 1013–1018. [Google Scholar]

- Carreira, M.R.; Dias, A.A. Influence of Moisture Content on the Dynamic Modulus of Elasticity; Influência do Teor de Umidade no Módulo de Elasticidade Dinâmico; Influencia del Contenido de Humedad en el Módulo Dinámico de Elasticidad. Res. Soc. Dev. 2022, 11, e232111133687. [Google Scholar] [CrossRef]

- Ross, R.J. (Ed.) Nondestructive Evaluation of Wood, 2nd ed.; General Technical Report FPL-GTR-238; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2015; 169p.

- Unterwieser, H.; Schickhofer, G. Influence of Moisture Content of Wood on Sound Velocity and Dynamic MOE of Natural Frequency and Ultrasonic Runtime Measurement. Eur. J. Wood Wood Prod. 2011, 69, 171–181. [Google Scholar] [CrossRef]

- Rais, A.; Pretzsch, H.; van de Kuilen, J. European Beech Log and Lumber Grading in Wet and Dry Conditions Using Longitudinal Vibration. Holzforschung 2020, 74, 939–947. [Google Scholar] [CrossRef]

- Emmerich, L.; Wülfing, G.; Brischke, C. The Impact of Anatomical Characteristics on the Structural Integrity of Wood. Forests 2019, 10, 199. [Google Scholar] [CrossRef]

- Plos, M.; Fortuna, B.; Šuligoj, T.; Turk, G. From Visual Grading and Dynamic Modulus of European Beech (Fagus sylvatica) Logs to Tensile Strength of Boards. Forests 2022, 13, 77. [Google Scholar] [CrossRef]

- Purba, C.Y.C.; Dlouha, J.; Ruelle, J.; Fournier, M. Mechanical Properties of Secondary Quality Beech (Fagus sylvatica L.) and Oak (Quercus petraea (Matt.) Liebl.) Obtained from Thinning, and Their Relationship to Structural Parameters. Ann. For. Sci. 2021, 78, 81. [Google Scholar] [CrossRef]

- ASTM D143-22; Standard Test Methods for Small Clear Specimens of Timber. American Society for Testing and Materials: Philadelphia, PA, USA, 2022.

- BS 373; British Standard: Methods of Testing Small Clear Specimens of Timber. British Standard Institution: London, UK, 1957.

- ASTM D2395; Standard Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials. American Society for Testing and Materials: Philadelphia, PA, USA, 2014.

- ČSN 49 0115; Wood. Determination of the Modulus of Rupture in Static Bending [in Slovak]. Office for Standardization and Measurement: Prague, Czech Republic, 1979.

- ČSN 49 0116; Wood. Method for Determination of Modulus of Elasticity in Static Bending [in Slovak]. Office for Standardization and Measurement: Prague, Czech Republic, 1986.

- Borůvka, V.; Novák, D.; Šedivka, P. Comparison and Analysis of Radial and Tangential Bending of Softwood and Hardwood at Static and Dynamic Loading. Forests 2020, 11, 896. [Google Scholar] [CrossRef]

- Brischke, C. Interrelationship between Static and Dynamic Strength Properties of Wood and its Structural Integrity. Drv. Ind. 2017, 68, 53–60. [Google Scholar] [CrossRef]

- Arnold, M. Effect of Moisture on the Bending Properties of Thermally Modified Beech and Spruce. J. Mater. Sci. 2010, 45, 669–680. [Google Scholar] [CrossRef]

- Ruiz-Aquino, F.; González-Peña, M.M.; Valdez-Hernández, J.I.; Romero-Manzanares, A.; Fuentes-Salinas, M. Mechanical Properties of Wood of Two Mexican Oaks: Relationship to Selected Physical Properties. Eur. J. Wood Wood Prod. 2018, 76, 69–77. [Google Scholar] [CrossRef]

- Merela, M.; Čufar, K. Density and Mechanical Properties of Oak Sapwood versus Heartwood. Drv. Ind. 2013, 64, 323–334. [Google Scholar] [CrossRef]

- Teranishi, M.; Koizumi, A.; Hirai, T. Evaluation of Quality Indexes of Bending Performance and Hardness for Hardwoods. J. Wood Sci. 2008, 54, 423–428. [Google Scholar] [CrossRef]

- Muñoz, G.R.; Gete, A.R. Prediction of Strength and Elasticity in Oak Beams on the Basis of External Wood Characteristics. Adv. Mater. Res. 2013, 778, 152–158. [Google Scholar] [CrossRef]

- Muñoz, G.R.; Gete, A.R. Relationships between Mechanical Properties of Oak Timber (Quercus robur L.). Holzforschung 2011, 65, 749–755. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).