Abstract

Variance in productivity of fully mechanized timber harvesting under comparable stand and terrain conditions requires the investigation of the influence of work practices of machine operators. Work practices can vary among operators and may result in a wide range of productivity. Therefore, it is of great interest to identify positive and negative work practices of forest machine operators to improve forest work. For the qualitative analysis of work practices, 15 forest machine operator instructors were interviewed in Norway, Sweden, and Germany in semi-structured interviews. Additionally, a literature review following the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines was performed. The interviews brought up detailed positive work practices and showed negative examples of machine handling, specifically related to boom operation. The literature review retrieved 2482 articles of which 16 were examined in more detail. The review showed that work practice characteristics were only sparsely covered, however, still overlapped with the work practice recommendations from the operator instructor interviews. Further, the literature search unveiled a scientific knowledge gap related to the quantification of applied work practices. Generally, positive work practices can include using optimal working ranges from 4–6 m, frequent machine repositioning, a matched fit of operator skill and crane speed, and an assortment pile size that matches the maximum grapple loads. Training is recommended to focus on crane control in terms of movement precision and work range adherence whereby the speed-accuracy trade-off should be improved to meet productivity requirements and increase efficiency in forest machine operator work.

1. Introduction

Highly mechanized timber harvesting systems account for the largest share of total logging, which is approximately 50% in Central Europe [1,2]. In Scandinavian countries, the share of highly mechanized timber harvesting is much higher (approx. 80%) [3]. Modern forest harvesters fell, process, and deposit full stems or assortments at the machine operating trail. Forwarders load and convey the assortments to the landing [4]. The control of these forest machines is highly complex [5] and work tasks in mechanized timber harvesting bear a high mental workload on the operator [6]. Therefore, operating forest machines requires lengthy training, continuous education, and supervision, throughout the operator’s entire career. On average, up to three years of experience is required after training for a forest machine operator to reach full proficiency [7]. Work studies revealed that even experienced machine operators show productivity differences of up to 40% [8].

In recent years, operating forest machines has changed due to the introduction of new technologies. Sensor-based detection of the machine environment gained importance and opened new opportunities for forest companies [9,10]. Operator assistance systems, such as rotating cabins or boom tip control systems, were developed and are still being improved with the goal of increasing productivity and reducing the mental workload of machine operators [11,12]. More detailed analyses of operator assistance systems have shown that productivity can indeed be increased [13,14,15].

Generally, various factors affect the productivity of highly mechanized timber harvesting systems. These performance-determining factors are extensively studied and include operator-related parameters [16], stand-, timber- [17], and terrain-related characteristics [18], technical requirements [19], and organizational aspects [20]. Regarding the influence of forest machine operators on productivity, a number of studies have been conducted [7,17,21]. However, these studies focused mainly on productivity analyses of the main work elements.

Harvester and forwarder work can be categorized by these work elements. These work elements are divided into Driving/Crane use/Felling/Processing/Manipulation for the harvester [22] and Travel empty/Travel loaded/Loading/Unloading [23] for the forwarder, respectively. Studies suggest that the work method and the work practice of the forest machine operators are crucial for overall performance in highly mechanized timber harvesting systems [24,25,26,27]. Due to the interchangeable use in the literature of the terms work practice, work, and work method, it remains unclear how deeply work practices affect the productivity of forest machine operators.

Therefore, in the present study, a work practice is defined in accordance with the German REFA institute (REFA Verband für Arbeitsgestaltung, Betriebsorganisation und Unternehmensentwicklung e.V.) as part of the work process. A work practice considers the operator-related, individual way of carrying out the work process, based on the work method used. The term describes the personal scope of action within the work method, which serves as a basis for a higher performance and improved ergonomics can be achieved [28]. In some cases, the terms “work pattern” or “working behaviour” are used synonymously in the scientific forestry literature.

The definition highlights that the individual way of carrying out timber felling, -processing, and forwarding in highly mechanized harvesting systems depends largely on the skills of forest machine operators. In this context, even personal preferences can influence performance [29]. Individual work practices can be developed within all work elements and affect not only driving skills or operation planning, but also crane operation [26]. The literature on the evaluation of work practices is sparse although there is a need to identify favorable and efficient, and conversely, ineffective and mentally demanding work practices of forest machine operators to improve mechanized timber harvesting. Due to the interlaced task structure and multiple factors that can potentially affect the whole system’s productivity, the role of these work practices remains unclear and in particular, to what extent personal work practices contribute to the execution and outcome of work. However, it is assumed that productivity differences between machine operators described in the literature are caused by work practices to a significant extent.

In a nutshell, it is essential to assess beneficial work practices that contribute to performance and lead to an increased productivity. Therefore, the present study aims to give an initial overview of the work practices of forwarder and harvester operators, that can have both an impact on productivity and mental strain, but also on the wear and tear of machines. Two methods, interviews with forest machine operator instructors and a scientific literature analysis will serve as the overview of work practices.

2. Materials and Methods

For the evaluation of work practices, a multipronged approach was used to retrieve information on subject matter, expert interviews, and scientific literature. This allowed for coverage of a broad range of work practices and to compare the state-of-the-art in work practices, as reported on in the literature, to those work practices applied in-service, as reported on in the expert interviews.

2.1. Qualitative Content Analysis of Expert Interviews

Step 1—Preparation and conducting of interviews: A total of 15 expert subject matter interviews were conducted in Germany, Sweden, and Norway. To gain insights into details of instructed forest machine operator work practices, a semi-structured approach was used. Due to the complex content of interviews, the number of selected operator instructors was limited to a closed-question format survey. However, the semi-structured interview guideline revealed complex behavioral patterns that are rarely described in the work science literature. The experts in all contributing countries were selected by their expertise and their availability. All interviewees were experienced in operating forest machines and were currently working as instructors. This allowed for a high skill and proficiency level of the operators’ analyses of work practices. The forest machine operator instructors interviewed work both with beginner- and experience-level operators. The interviews were conducted between June 2019 and May 2020. Participants consented to participate voluntarily. The interview guideline was developed by researchers from all partnering countries (see Appendix A). A major goal of the guideline was to ensure consistency, meaning that all interviewees were exposed to all relevant questions and thus comparability of answers could be ensured. The interviews were recorded and then transcribed, paraphrased, and anonymized. Next, the transcripts were assigned the first letter of the country and the interview number as a pseudonym (e.g., Germany = G1–7; Sweden = S1–5; Norway = N1–3). Demographic data and experience level of the forest machine operator instructors are shown in Table 1. The 15 experts satisfied the experience criteria in all three countries to have at least two instructors and thus perspectives with, similar experience, machine manufacturer collaboration, certification, and multiple instructed machines and operators.

Table 1.

Demographic data of the operator instructor interviews conducted in Germany, Sweden, and Norway (number ranges only apply to present experience).

Step 2—Interview analysis: The interview analysis was performed by using MAXQDA v. 12.3.5 software. Following the transcription and anonymization of the data, a coding system was developed to analyze the interviewees’ opinion on positive and negative work practices of forest machine operators and also to guarantee that all relevant comments on the objectives of the study could be included in the analysis.

The coding system can be described as follows: Firstly, categories were roughly clustered deductively using literature prior to analysis. Before and during the analysis, comments of forest machine operator instructors related to the study objectives were then abductively selected first by type [Forwarder, Harvester, Value, Teamwork, Teaching and communication skills], and secondly based on a category itself [Forwarder: crane settings, crane skill, loading, unloading; Harvester: Positioning and reaching for trees, felling, crane settings, crane use, other; Value: value; Teamwork: teamwork and Psychology: psychology]. The categories developed are not exclusively based on work elements, but also on other aspects that are essential for the daily work of a machine operator. While analyzing the material, a brief written summary for every interviewee’s verbal comment on a specific category should guarantee a detailed description of a work practice. It formed the basis for evaluating the operator behavior as either positive or negative, in connection to certain work aspects affected by the work practice (productivity, fuel efficiency, mental strain, machine wear and tear, occupational safety, timber value, hydraulic load). While reviewing the categories of behavior, the importance with respect to the severity in affecting the work outcome was reviewed. In addition, strategies for changing negative work practices were integrated to give advice for productivity improvements in modern cut-to-length systems. In the results section, statements were cited by using the interview number as a pseudonym (e.g., G1, S2). In the discussion of results, an integrative cross-sphere discussion approach was used with the goal of summarizing the categories to extract aspects which are important for practitioners.

2.2. Methods of the Literature Analysis

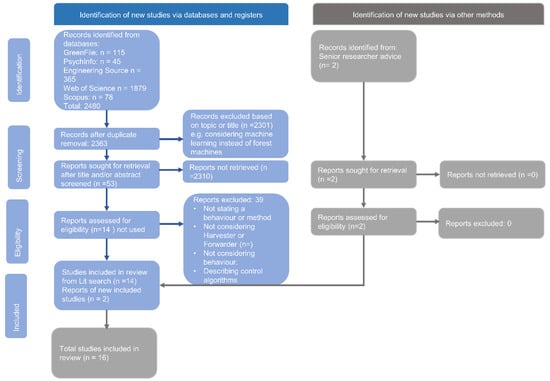

Step 1—Scientific literature database search: The guidelines recommended by the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) approach were selected as the framework for the literature analysis [30]. As no previous review on forest machine work practices was available, the focus was set on the scientific databases Scopus, PsychInfo, GreenFile, Engineering Science, and Web of Science. The following search terms and syntax were used: (‘forestry’ OR ‘forest’ OR ‘harvester’ OR ‘forest machine’ OR ‘forest harvester’ OR ‘forwarder’) AND operator AND (‘performance’ OR ‘workload’ OR ‘behaviour’ OR ‘work practice’ OR ‘work method’ OR ‘productivity’ OR ‘Skill’). Next to the online literature search, senior scientists were consulted to obtain literature recommendations (cf. Figure 1 grey column).

Figure 1.

The PRISMA flow diagram shows the process of searching for and identifying relevant literature for this review [30].

Step 2—Initial screening criteria of search results: The literature search resulted in 2480 journal articles and reports. Duplicates were removed from the results. The literature search showed low coherence of the retrieved studies of interest. Then, the journal article titles were reviewed. Articles related to other fields such as machine learning or algorithmic behavior, non-forestry harvesters (i.e., agricultural crops), or the analysis of technical properties of the machine while neglecting the operator, were excluded (see Figure 1). In addition, two recommended journal articles were included at this stage to review the procedure.

Step 3—Final inclusion criteria: The inclusion criteria for the literature retrieved from the databases were the following: (1) the article needed to undergo a peer-revision procedure and needed to be published in English. (2) The article was not a review, but rather an empirical study or structured interview. (3) The study concerned forest harvester, forest forwarder, or harwarder. (4) The study reported the behavior of the operator, a work practice or method that relates to operator behavior, and (5) the study reported an outcome variable or recommendation for the given work method or practice used. Full-text articles retrieved from the databases which did not adhere to these criteria were subsequently excluded from the study.

Step 4—Data and result extraction: The data/information of the remaining studies was extracted by (1) determination of the work practice or work method applied, (2) the measured outcome variable that was either workload, performance, skill, or work behavior, (3) the used system/machine (4), and further (5) the setting in which the study was conducted, e.g., a field test or simulator-based study.

Step 5—Results and Analysis approach: All relevant journal articles with the extracted results were listed. Then, the skill/work behavior was classified as either positive or negative with respect to the specific result. This approach resembled the method from the above-described interview analysis (for more details see Section 3.2.2).

3. Results

3.1. Results of Operator Instructor Interviews—Overview of Beneficial and Negative Work Practices of Forest Machine Operators

3.1.1. Harvester

Positioning and reaching for trees: Operator instructors describe that excessive crane reach (between crane origin and harvester head) is often a problem during both felling and processing, as crane speed and precision decreases, and machine wear and tear increases (S1, S2, S4, N2, N3). As a consequence of this, wood piles become too large and assortments get mixed (S1, S2, S4, S5). When trees are felled in a wide operating range, the stems need to be moved closer to the machine for processing. This affects not only time consumption and mental workload for the operators negatively (N2, N3), but also occupational safety (G1, G3, S1, S5). Another problem is that forest machine operators reposition the machine too infrequently, so that crane paths increase and productivity decreases (N2, N3), which is especially a problem for beginner operators. However, if harvesters are moved or relocated too frequently, this is not optimal, and also affects time consumption (S1, S4, S5). Systematic moving of felled trees from one side of the machine to the other for processing is also frequently observed (S3, S4).

Felling: Forest machine operators often seem to lack a plan in which order to fell trees (S1). Several operator instructors observe that failing to achieve the intended felling direction is a problem too (S2, S3, S4). Based on the interviewees’ comments, the first tree to be felled from a harvester’s position decides where the pile is placed. Trees are sometimes felled leaning slightly backwards instead of forwards, which means that the operators’ view is hidden from the trees’ cross-section, hiding potential rot, which negatively influences wood value aspects (S1, S3, N1, N3). While processing, assortment piles should be laid out in a fan pattern. Different assortment piles processed within one harvested stem should touch each other at the machine operating trail facing end but have a separation distance of around 1.5 m at the opposite side (S5) to simplify the consecutive forwarder work.

Crane settings: Forest machine operator instructors notice poorly adjusted cranes (G1, G2, G6). In this context, crane speed is often too high (S2, S5, N1, N2, N3) or too low (N1), which affects productivity, workload, and fuel efficiency.

Crane use: While reaching the tree with the crane, it is sometimes observed that too much tension is put into the tree during felling, which affects timber value, as it induces more cracks in the stem. Furthermore, it is noticed that operators use the extension too late when reaching for a tree. A frequent, unplanned use of the extension is also observed (S1). Forest machine operators also sometimes seem to hold the harvester head too high when processing, which leads to oscillating cranes (N4, S3). After processing trees, harvester operators unnecessarily elevate the harvester head several meters, which negatively corresponds with productivity, workload, fuel consumption, and machine wear and tear (S1, S3). Moreover, if the harvester head grabs the tree too high at the stem to be harvested and not on the stem basis, this leads to correction movements with the harvester head at the stem and can negatively impact the wear and tear of the crane (S1).

Other: Forest machine operator instructors mention that weather conditions are sometimes not considered when planning the operation. For example, consideration of wind and felling direction is insufficient (S3). In thinning operations, single crane elements are not observed frequently enough. Too much focus on the head can lead to the crane causing damage to the remaining trees (G1, G2). In addition, it is observed that saw chains are often too blunt, which leads to higher fuel consumption and lower productivity (S2, S4).

3.1.2. Forwarder

Positioning: Operator instructors from Germany and Sweden confirm that forwarder positioning is a problem while operating the machine. Many operators reach too far with the crane to grab logs instead of moving the machine (G1, G3, S1, S4).

Crane settings: Interviewed operator instructors mention that a disharmony between crane and grapple settings often appears. When closing the grapple, the downward motion of the grapple sometimes does not match the upwards motion of the boom tip from lifting (S1). Operator instructors acknowledge that crane speed should harmonize to “typical” movements. The extension should be used immediately to lift a load and be fully retracted by the time the grapple passes the load space supports. If not, productivity and workload are negatively affected (S2). Full joystick signal to extension in, main boom and slewing should have the logs at an appropriate height over the ground (S4), otherwise this would negatively affect operator workload and productivity. It is observed that operators often operate cranes with too high crane speed (G3, N1, N2, N3, S2, S4), too low crane speed (S2), or that crane settings generally do not fit to the operator (G1, G3).

Crane skill: Especially when beginner forest machine operators work with the crane, they partly perform the movements of the single crane elements non-simultaneously (G1), which affects productivity and fuel efficiency. In addition, crane or joystick movements are mixed up (G4–7). Operator instructors observe that the crane extension is often not used enough or only when a pile cannot be reached without the extension (S2, S3, S4, N3). Operators sometimes forget to pull the extension in and bottoming out the main lift boom instead (G2). Even if Intelligent Boom Control (IBC) is activated, some operators unnecessarily use the extension manually (N3). Continuously holding down “grapple close” while carrying logs is observed as well (S1). After releasing the logs in the load space, the grapple is sometimes closed, which is unnecessary (S1).

Unloading: While unloading, some operators position the grapple too low when opening to release the logs onto the pile, resulting in the grapple pushing on and spreading the logs in the pile. The height at which they open the grapple should account for the space the grapple needs to open (S1, S3). While building a pile, operators should make a succession of peaks and valleys to facilitate the logs falling into place (S4). An incorrect layout of the roadside piles can be observed. The main assortment should be the closest to the access point (S2, S3, S4, N2, N4). Sometimes, an incorrect buildup of piles at the roadside makes the operators lift over the top of the pile. Placing the logs is then more difficult (S1, S2, S4). Some operators do not fill the grapple as much as possible while unloading (S2). While unloading (or loading), operators unnecessarily lift the empty grapple over the supports of the load space, instead of moving through or between the supports, which negatively influences productivity, workload, and fuel consumption (G1, G2, S2, S3, S4, N3). A clumsy release of the logs is also observed. The operators also seem to forget to adjust the height of the boom tip (S2). Mixing assortments is a problem in practice as well. Operators sometimes do not communicate on which assortments to mix in loads (S1, S4). While filling the grapple from the load space, the grapple is often opened too wide. Reaching too wide makes the logs roll over one another, making the load potentially unsafe and disordered. The operators should aim to fill the grapple by reaching deeper into the load (S4).

Loading: Some operators move the machine while having logs in the grapple. This is risky as sudden machine movements can cause the grapple to lose hold of the logs (S2). To ensure flush ends of the grappled logs, some also bump the logs’ ends against the ground. This is usually not necessary while loading (S2, S3) and negatively affects productivity. It is observed that forest machine operators start filling the load space against the “cradle”. Based on the instructor´s view, it is more productive to start loading against the supports to later allow the logs to fall into the central space (S2, S3). Moreover, sometimes the grapple is not sufficiently filled while loading (G4, S2, S4). Some operators do not want to mix assortments in the load space, which leads to increasing forwarding distances and loading time (N2, N3, S1, S2, S4). Logs are also sometimes gripped at the “wrong” point, which leads to increasing wear and tear and decreasing productivity (S1). A good organization throughout the loading process is often missed. The highest value assortment should be loaded firstly (S1) to keep the option to downgrade logs.

Other: Operator instructors observe that operators do not follow curves in the machine operating trails correctly (G3).

3.1.3. Value Recovery of Harvester and Forwarder

Value: Regarding the added value of harvesting or forwarding, the influence of various factors is mentioned. Firstly, unbeknownst to the operator, the saw motor could be worn out and not reach suitable rpm, leading to longer cutting times and consequently more cracks in the logs (S2). Secondly, not sharpening the knives of the harvester head (S2, S4) and poor measurements of control logs (calibration) (S2) negatively affect value creation. A blunt chain or not changing a worn-out chain on the harvester head on time is observed as well (S2, S4). Using worn-out feed rollers and compensating for this by pulsing the knives following along the stem with the crane tip can also occur (S4). Aggression with the crane tip while following along the stem is observed (S4), which leads to timber damage.

3.1.4. Teamwork of Harvester and Forwarder Operators

Teamwork: According to the interviewees, in the context of teamwork, there is often a lack of agreement on a system for how the harvester should stack the assortments. This deeply affects the productivity of the forwarder (S2, S3, N1, N2, N3). Sometimes, harvester operators pile assortments in places with poor ground conditions (wet, sloping), which also negatively affects forwarder productivity (S1, N1). Operator instructors mention that some harvester operators do not understand highly mechanized harvesting systems as teamwork between harvester and forwarder (S2). Additionally, some harvester operators seem to believe that bigger piles are better for forwarder operators. Based on the instructors´ comments, one full grapple per pile is optimal (S1). In contrast, forwarding productivity is negatively affected by the harvester spreading out the logs too much (S3).

3.1.5. Teaching and Communication Skills (Harvester and Forwarder)

The relationship between operator instructor and operator is considered to be highly important to the success of the coaching process. Operator instructors frequently mentioned that the first contact with the operators is important. Firstly, to get the initial impressions of the applied work practices and secondly, of the operators’ attitude towards training (i.e., receptiveness). If the opinion of operators on how the machine ought to be operated is considered, they can come up with ideas on which aspects they need to work on, also on a long-term basis (follow-up meetings) (S2). It seems to be important to praise operators when they work well or improve, not only remark on things they should do differently (S2). Recording operators on video is an appropriate way to improve their working behavior (S2, N3). Motivation of operators in exercises is important to improve their productivity in the long-term, since their performance might decrease in the early stages of testing a new work method (S1). To improve productivity, feedback such as that which is available in simulator training, is beneficial (S1). Additionally, testing other crane settings can improve skills while reducing mental workload. This is especially important while teaching younger operators. Setting up the machine and crane correctly so that it fits to the operator is mentioned as a central requirement for a successful training session (N2, N3). When asking operators to try new settings, it is important to give operators the possibility to revert to the original crane settings (S3). Furthermore, when teaching new operators, the most difficult task for the instructors seems to be adapting them to different circumstances (S4). Setting goals and objectives for the operators, which are achievable, are mentioned as well (S5).

3.2. Results of Literature Review

3.2.1. Overview of Study Layout

Sixteen studies were examined in total [4,8,24,27,31,32,33,34,35,36,37,38,39,40,41,42]. Three out of these studies [24,31,36] were simulator-based studies, and 13 studies were conducted in-field [4,8,27,32,33,34,35,37,38,39,40,41,42]. Simulator studies assessed more participants, whereas field studies range from 1–6 participants. Commonly, field studies depend on specific machines and operators driving on-site. That is why the analyzed studies considered the operators related to a specific machine (e.g., two operators for one machine, working in shifts), as participants. Generally, when reported, the operators that served as participants were experienced and had more than 10 years of experience. Four [4,27,33,36] out of the sixteen studies were assessing forwarder work whereas ten [24,31,32,34,37,38,39,40,41,42] were concerned with harvester operations, a single study was concerned with a harwarder [35], which is a combined machine of harvester and forwarder. Both thinning and clear-felling operations were the focus of the research. The variables of interest were predominantly productivity and time, but operator workload and tree damage were also assessed.

3.2.2. Synthesis and Evaluation

To identify work practices, behaviors, or skills that were beneficial to the productivity, well-being, or general performance of the system of forest machine and operator, the study outcome was filtered with respect to recommendations or results that can be used to advise and inform machine operators. Then, the results were compiled within the evaluation column of Table 2, which shows that there is a vast range of applicable situations that can benefit from informed operator behavior. The results of Table 2 will be briefly summarized here. As the machines and methods are highly complex only specific situations, methods, or single work elements were addressed within the analyzed studies. The eleven studies investigating work methods with harvester operators provided the basis of recommendations. Generally, recommendations are found independent of the type of operation (thinning or clear felling). Only one study for piling was found that researched the difference between these general operations in forestry. In thinning operations, beneficial work practices are “right angle piling” and “under the boom piling”, whereas in clear felling (forward felling), “two-sided piling” is applied by the operators [11]. Efficient work practices for both methods that were identified included: Reducing the number of times the machine drove in reverse, moving the machine frequently and realizing short tree-handling distances to avoid unnecessary boom movements, keeping movements of the stem to a minimum after felling [8], placing edge trees at 1.2 m rear distance to the boom base [34], using automated bucking while processing (in particular in spruce stands), employing a high feeding speed and processing the tree as close to the machine as possible [8], and piling the logs according to the assortments [4]. Furthermore, long-term productivity was found to be negligible if the forest manager or an experienced operator decided on the tree selection [38,39]. With respect to operator workload and fatigue, we found a study that showed increased tree damage at dawn and at the end of the shift [32]. In addition, workload was found to increase with increased slope and working in mixed stands, compared to monoculture stands [31,37]. A single study researched the work method of a harwarder and found driving along the cut edge and processing the tree directly into the load space as the most efficient method [35]. The literature search on forwarder operators showed that loading is the primary interest of the retrieved studies. [27] found log and loading angles of 45° as most beneficial within a work range of 4–6 m for a certain machine type. Moreover, the grapple load was analyzed in another study, and the assortment pile size should match the maximum grapple load, to ensure efficient handling [4]. As a new tool, a multi-assortment grapple would improve loading efficiency if the remaining trees do not obstruct the trajectory between assortments [36]. Furthermore, to mitigate the impact of vibrations on the operator while keeping a high efficiency, a driving speed of 8 kph was found to balance well-being and efficiency [33]. Overall, the recommendations on work practices are given within all work cycle elements of forwarder, harwarder, and harvester.

Table 2.

Data extracted from the PRISMA literature review.

4. Discussion

The goal of this study was to identify positive and negative work practices of forest machine operators using two different approaches. One approach used interviews with machine operator instructors in Norway, Sweden, and Germany. The second approach used a literature review of forest machine operator work practices, in accordance with the PRISMA guidelines [30].

4.1. Discussion: Interviews

The interviews aimed to get a detailed description and informed analysis of the work practices of forest machine operators for both harvesters and forwarders. An integrative cross-sphere discussion approach for both harvester- and forwarder-related comments was followed to extract the relevant work practices.

The main results of the interview unveiled five key elements that contribute to work practice performance that are discussed below for both harvesters and forwarders.

Positioning the machine: Negative work practices often become evident while positioning the machine. “Negative” positioning, i.e., too far a distance between the machine and the tree to be harvested (harvester), or the wood pile to be loaded (forwarder), leads to increased wear and tear of the crane elements and also to decreased productivity due to longer crane paths. This is in line with other studies which revealed that increasing loading distances can have a negative impact on time consumption per loading cycle [27], and therefore productivity. Since the loading element is the most important [23] to productivity, adequate positioning towards reducing time consumption during loading is worth striving for.

Crane use: A second important aspect is the use of the crane. Both the sequential use of single crane elements and the lack of using the boom extension were identified as problematic ways of working. Based on the instructors´ statements, it can be assumed that these work practices occur particularly with beginners. Accordingly, it could be important to apply training programs such as RECO (economical driving and fuel consumption) [43] or state-certified forest machine operator training (Germany). When novice operators control the crane, productivity can be increased by using intelligent crane controls [14].

Value: Regarding value-added timber production, forest machine operator instructors highlighted the continuous maintenance of the harvester head and saw chain as a decisive factor. Based on the interviewees´ comments, respondents cited that dull chains increase the machine’s fuel consumption and decrease the value of the produced timber. Furthermore, worn-out feed rollers and the actions operators take to compensate for this introduce errors in the length measurement. There is no literature investigating feed rollers specifically, but forest machine operator instructors report that feed roller maintenance does not receive enough attention in forest operations.

Teamwork: Forest machine operators often do not seem to understand the collaboration between harvester and forwarder as a crucial aspect of overall system productivity. Based on the comments of the forest machine operator instructors interviewed, harvester operators sometimes do not know that the quality of log processing and depositing deeply affects forwarder productivity. When depositing the logs at the edge of the machine operating trail, a pile size corresponding to one full grapple seems to be optimal based on the instructors´ comments. In practice, this likely depends on stand and terrain conditions. Studies have shown that a higher degree of timber concentration along the skid trail generally increases the productivity of the forwarder [4]. Further, the assortment-related log concentration affects forwarding efficiency [44]. This shows that the optimal placement of logs by the harvester can mitigate the tedious sorting of different assortments by the forwarder during subsequent loading.

Teaching and communication skills: Operator instructors mention the significance of adaptive teaching and training activities to achieve compliance with the training to increase productivity. In this regard, scientific studies underline that the skills and the aptitude of the forest machine operator affect productivity significantly [21]. However, task complexity during crane operations can be simplified by using intelligent crane controls [13]. This suggests that future studies on training should focus on how to cope with the complexity and increase training motivation to support the mental well-being of forest machine operators. Based on the interviewees’ comments, the effectiveness of the harvester and forwarder work seems to be related to the freedom and autonomy given to the operator in the design of training and the work task while achieving clear performance goals (see Section 3.1.5).

In summary, the interviews provided detailed insights into challenges in machine operation in terms of specific work practices that are to be avoided and others which should be favored by the operators. Forest machine instructors highlighted negative work practices that they encounter in their daily work. In contrast, “beneficial” work practices were partly inferred from non-negative behavior. Interviewees could hardly determine quantitatively the general impact of the work practices on productivity or machine wear since work practices need to be assessed within their context. Thus, the impact on system productivity must be seen within the interaction of the individual machine operator and other performance-determining factors (i.e., environmental). Compared to interviews, large-scale surveys with sufficient sample size could produce statistically more accurate and representative results [45]. However, because neither the number of forest machine operators in Germany, Norway, and Sweden is known nor the research field of forest machine operator work practices has been researched in detail, it was decided to conduct subject matter expert interviews. It can be assumed, despite the limited number of interviewees, that the results have practical relevance, precisely because of the years of experience and the number of trained operators.

4.2. Discussion: Literature Search

The literature search was aimed to allow for a comparison with the actual applied practices and enrich and validate reported work practices from the interviews. Research studies on operator work practices unveiled room for improvement of productivity in all work elements. According to the studies analyzed, Forwarder operators ought to focus on diligent execution of the loading cycle, raising efficiency, and should be meticulous in assortment handling, namely the separation and size of piles. Harvester operators need to realize short tree handling distances and therefore improve on machine driving and efficient boom trajectories to ensure a short work range (see Table 2 above).

The studies included in the review are a glimpse into the diverse range of work practices that are applied by the operators in the field (see also Section 3.1). The number of studies included in the review was surprisingly limited, despite having a broad range of search terms. Only a few studies investigated a specific work practice independent of new technical systems. This may lie in the research foci of the field of forestry work science, where the effect of operators’ work patterns or method execution on productivity is less researched than equipment and machine advancements. The studies that were excluded from the review research timber harvesting on a broader scale than on the level of the work practice of the individual operator. The small number of studies found on optimal boom control, driving, and positioning of the harvester is showing that there is still a huge potential for analyzing the efficiency of specific work practices. In general, the included studies suffered from small sample sizes, which is common in the forestry sector due to limitations in access to machine operators. Therefore, some of the recommendations within the research are based on expert opinions. Still, the review unveils efficient work practices that can be used to inform operator support, training, and further increase the resource efficiency in timber harvesting.

4.3. Literature Review and Interview Result Synthesis and Limitations

The interviews and the literature review showed overlapping results with respect to crane control, assortment piling, and assortment handling of harvesters and forwarders. For instance, keeping tree-handling distances short, within a range of 4 to 6 m, is good practice, as well as piling assortments in sizes matching the capacity of the grapple. Notably, there is a large difference in the number of work practices described by the operator instructors and the ones found in the literature. Within the interviews, instructors elaborated in fine detail on many work practices they observe in the field and instruct. Specifically, the forest machine operator instructors made detailed statements on the relation between working ranges, optimal machine (re)positioning, appropriate crane settings, best practice training concepts, and adequate machine maintenance. This information cannot or only rarely be found in the literature. The literature review results revealed a vast knowledge gap on the detailed description and specifically, the quantification of work practices. In line, the literature covered a small range of practices; not many studies covered each element of the work task and thus lacked in-depth analyses. The shortage of evidence needs to be enriched to bolster the statements of operator instructors with quantitative data.

In this regard, the interviews shed light on a large amount of advantageous and disadvantageous work practices that are not or insufficiently described in the scientific literature, such as the effect of the felling direction on processing and log piling. Herein, the interplay of reaching distance and repositioning of the machine or the advantages of fan patterns of piles, pile sizes, locations, or loading angles on forwarding efficiency or operator strain (see Section 3.1.1.) remain to be supported by scientific evidence. Furthermore, the negative effect of improper crane settings on wear and tear, fuel efficiency, value recovery, and the operators’ mental load needs to be determined. In line, the effects of the consequences such as additional stem relocation or failure to control for rot while bucking due to visual obstruction cannot be found in the scientific literature, although play an important role in practice according to the instructors. The future challenges of forest research lay in the interaction of work practices such as the above example of the felling direction and the processing location on the operator task level, but also in the demand imposed by the triad of task, machine, and work environment. Altogether is known to reduce efficiency, where the extent of each of the work practices requires thorough quantification.

For system design, we encourage next to the recent automation advances such as boom-tip controls to ease the precision motion of the crane including operator recommendations, e.g., on stem handling. Operator training can be improved with a focus on the interaction of the work phases whereby enhanced crane efficiency needs to be trained considering the advantages of proper positioning, but also on a higher goal level with the focus on low-wear handling of forestry machines. Currently, machine operator training is based on the experience of the instructors, which contributes to the present study by giving a detailed view on work practices which potentially optimize the work system. The complex and diverse emerging picture of advantageous and disadvantageous work practices goes beyond conventional training (and the above-cited scientific literature), which is often based on national education curricula that may diverge for countries, vary in the applied methods, and is inaccessible to the broader scientific community. Nonetheless, the link between the interview results to real-world operations can be considered accurate and relevant since instructor recommendations come directly from application and show overlap with scientific studies [8,27]. Despite the individual instructor views in three different countries, coherent statements on work practices across Norway, Sweden, and Germany were found. However, a full representative coverage despite a thorough conduct cannot fully be ensured with 15 interviews. That is why a few groups or categories are built on a few coherent statements.

5. Conclusions

Work practices can be described as the machine operators’ implementation style of a given work method, that affects system productivity and machine wear and tear. However, the instructors´ descriptions of work practices are based on subjective observations of forest machine operators. When setting goals for work practice optimization, the instructors usually refer to machine positioning, crane work, value creation, teamwork between harvester and forwarder, as well as motivation and stress. Due to the high level of experience of the interviewed forest machine operator instructors and overlap with the scientific literature, a practical relevance can be assumed.

Although work practices can also be defined by means of the literature, the number of studies found was rather small and touched upon few but distinct task domains of machine operator work. Although there are extensive studies on the influence of the machine operator on system productivity, a large proportion of the studies reviewed examined the effects of a specific factor on productivity. Few studies considered also forest development or mental strain.

This study combined a thorough literature review and the analysis of 15 exploratory interviews to investigate an almost untouched field of forest research—the forest machine operator work practices and their potential effect on system productivity, fuel consumption of forest machines, and machine wear and tear. There is a plethora of factors that potentially affect harvester and forwarder productivity, with the human operator at the heart of the operation. Due to the extensive challenges associated with establishing both ecologically considerate and scientifically valid laboratory conditions in forest operations research, the evidence of the actual effect of specific work practices still needs to be investigated further. However, previous studies including exploratory interviews suggest that work practices may have a strong impact on productivity and machine wear and tear. Technical developments that ease machine control, the shortage of labor, and new silvicultural requirements due to climate change urge to set an increasing focus on operator performance in work systems, despite the introduction of automation. Efficient work practices are essential for future mechanized timber harvesting and ought to be addressed in research to raise the quality of operator training and support system design. By that, the research line of work practice performance may unlock new productivity potential of mechanized timber harvesting.

Author Contributions

The authors F.H. and F.A.D. equally contributed to this article; conceptualization, methodology, and interview conduction was performed by M.E., F.H., E.H. and F.A.D.; analysis of the interviews was performed by F.H., M.E. and F.A.D.; literature research was performed by F.A.D., M.E. and F.H.; the manuscript was drafted and written together by F.H. and F.A.D.; G.R., T.W. and D.J. critically revised the article. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded within the EU-project AVATAR under the umbrella of the ERA-NET Cofound ForestValue by Fachagentur Nachwachsende Rohstoffe e.V. (FNR, Germany), The Research Council of Norway (Forskningsradet) and The Swedish Innovation Agency (VINNOVA). ForestValue has received funding from the European Union´s Horizon 2020 research and innovation programme under grant agreement No. 773324. We acknowledge support through the open access publication funds of the Göttingen University. We also acknowledge support by Eva Mayr-Stihl Stiftung.

Informed Consent Statement

Informed consent was obtained from all participants involved in the study.

Data Availability Statement

To keep anonymity of the interviewees, public accessibility of the interviews is not given.

Acknowledgments

The authors would like to thank all forest machine operator instructors in Sweden, Norway, and Germany for their cooperation and the worthful knowledge they shared.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Interview guideline with ten main questions.

Table A1.

Interview guideline with ten main questions.

| No. | Question(s) |

|---|---|

| 1 | What are the most common/important problems that machine operators have with their driving skill/work method/work practice? |

| 2 | Can you give an example where you have helped an operator develop the driving skill/work method and made it a big difference? |

| 3 | Is the problem describable with machine data (angle, speed, position,…)? |

| 4 | What aspects of work are mainly affected (mental/physical workload, productivity, value preservation, safety, soil impact…)? |

| 5 | How big are the effects? How common is the problem? |

| 6 | How do you notice this problem? What indicators is it that you observe? |

| 7 | What strategy do you have to help the operator improve this aspect? What difficulties or obstacles can there be for the operator to change or improve? |

| 8 | Skill and work method relationship (Does the skill level affect which work method the operator uses? Do some work methods require more skill than others?) |

| 9 | Harvester affecting forwarder (What problems with the harvester work method/skill has the most effect for the forwarder? What effect?) |

| 10 | Crane settings (What are the consequences of a poorly set up crane? How do you notice? What are the most common/important problems with the settings? |

References

- Kuratorium für Waldarbeit und Forsttechnik e.V. (KWF). Lastenheft Harvestervermessung; KWF-Bericht Nr. 41; KWF: Groß-Umstadt, Germany, 2010. [Google Scholar]

- Bayerische Staatsforsten AöR. Maschinen. 2022. Available online: https://www.baysf.de/de/wald-bewirtschaften/holzernte/maschinen.html (accessed on 20 October 2022).

- Karjalainen, T.; Zimmer, B.; Berg, S.; Welling, J.; Schwaiger, H.; Finer, L.; Cortijo, P. Energy, 530 Carbon and Other Material Flows in the Life Cycle Assessment of Forestry and Forest Products: 531 Achievements of the Working Group 1 of the COST Action E9 2001; Discussion Paper 10; European Forest Institute: Joensuu, Finland, 2001; p. 43. Available online: https://efi.int/sites/default/files/files/publication-bank/2018/dp_10.pdf (accessed on 20 October 2022).

- Väätäinen, K.; Ala-Fossi, A.; Nuutinen, Y.; Röser, D. The Effect of Single Grip Harvester’s Log Bunching on Forwarder Efficiency. Balt. For. 2006, 12, 64–69. [Google Scholar]

- Gellerstedt, S. Operation of the Single-Grip Harvester: Motor-Sensory and Cognitive Work. Int. J. For. Eng. 2002, 13, 35–47. [Google Scholar] [CrossRef]

- Grzywinski, W.; Tomczak, A.; Jelonek, T.; Wandycz, A. Assessment of Multifunction Machines Operators´ Workload during Mechanized Timber Harvesting. In Integrované Ťažbovo-Dopravné Technológie—Integrated Logging Technology; Technická Univerzita Vo Zvolene, Lesnícka Fakulta: Poznan, Poland, 2008; pp. 55–61. Available online: https://www.researchgate.net/profile/Stanimir-Stoilov/publication/331731680_Comparative_Analysis_of_Three_Wood_Transport_Systems_from_Bulgarian_Danube_Islands/links/5c89fe60299bf14e7e7aeb50/Comparative-Analysis-of-Three-Wood-Transport-Systems-from-Bulgarian-Danube-Islands.pdf#page=55 (accessed on 20 October 2022).

- Purfürst, F.T. Learning Curves of Harvester Operators. Croat. J. For. Eng. 2010, 31, 89–97. [Google Scholar]

- Ovaskainen, H.; Uusitalo, J.; Väätäinen, K. Characteristics and Significance of a Harvester Operators’ Working Technique in Thinnings. Int. J. For. Eng. 2004, 15, 67–77. [Google Scholar] [CrossRef]

- Öhman, M.; Miettinen, M.; Kannas, K.; Jutila, J.; Visala, A.; Forsman, P. Tree Measurement and Simultaneous Localization and Mapping System for Forest Harvesters. In Field and Service Robotics; Laugier, C., Siegwart, R., Eds.; Springer Tracts in Advanced Robotics; Springer: Berlin/Heidelberg, Germany, 2008; Volume 42, pp. 369–378. [Google Scholar]

- Lindroos, O.; Ringdahl, O. Estimating the Position of the Harvester Head—A Key Step towards the Precision Forestry of the Future? Croat. J. For. Eng. 2015, 36, 147–164. [Google Scholar]

- Deere, J. 910 G Rückezug. 2022. Available online: https://www.deere.de/de/rueckezuege/910g/ (accessed on 20 October 2022).

- Deere, J. Intelligente Kransteuerung. 2022. Available online: https://www.deere.de/de/forstmaschinen/ibc/ (accessed on 20 October 2022).

- Manner, J.; Gelin, O.; Mörk, A.; Englund, M. Forwarder Crane’s Boom Tip Control System and Beginner-Level Operators. Silva Fenn. 2017, 51, 1717. [Google Scholar] [CrossRef]

- Manner, J.; Mörk, A.; Englund, M. Comparing Forwarder Boom-Control Systems Based on an Automatically Recorded Follow-up Dataset. Silva Fenn. 2019, 53, 15. [Google Scholar] [CrossRef]

- Zemánek, T.; Filo, P. Influence of Intelligent Boom Control in Forwarders on Performance of Operators. Croat. J. For. Eng. 2022, 43, 47–64. [Google Scholar] [CrossRef]

- Purfürst, T.; Lindroos, O. The Correlation between Long-Term Productivity and Short-Term Performance Ratings of Harvester Operators. Croat. J. For. Eng. 2011, 32, 509–519. [Google Scholar]

- Belisario, A.V.; Fiedler, N.C.; de Assis do Carmo, F.C.; Moreira, G.L. Influence of Log Length on the Productivity of Wood Harvesting and Transportation. Floresta 2022, 52, 17–24. [Google Scholar] [CrossRef]

- Proto, A.R.; Macri, G.; Visser, R.; Harrill, H.; Russo, D.; Zimbalatti, G. A Case Study on the Productivity of Forwarder Extraction in Small-Scale Southern Italian Forests. Small-Scale For. 2018, 17, 71–87. [Google Scholar] [CrossRef]

- Eriksson, M.; Lindroos, O. Productivity of Harvesters and Forwarders in CTL Operations in Northern Sweden Based on Large Follow-up Datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Zimbalatti, G.; Proto, A.R. Productivity of Forwarders in South Italy. In Proceedings of the 44th FORMEC Symposium, Padova, Italy, 11–14 July 2010; Available online: https://www.formec.org/proceedings/27-italy-2010-proceedings.html (accessed on 20 October 2022).

- Purfürst, T.; Erler, J. The Human Influence on Productivity in Harvester Operations. Int. J. For. Eng. 2011, 22, 15–22. [Google Scholar] [CrossRef]

- Nuutinen, Y. Possibilities to Use Automatic and Manual Time Studies on Harvester Operators. Ph.D. Thesis, University of Eastern Finland, Joensuu, Finland, 2013. [Google Scholar]

- Ghaffarian, M.R.; Stampfer, K.; Sessions, J. Forwarding Productivity in Southern Austria. Croat. J. For. Eng. 2007, 28, 169–175. Available online: http://www.crojfe.com/site/assets/files/3894/reza-1.pdf (accessed on 15 June 2022).

- Ovaskainen, H.; Palander, T.; Tikkanen, L.; Hirvonen, H.; Ronkainen, P. Productivity of Different Working Techniques in Thinning and Clear Cutting in a Harvester Simulator. Balt. For. 2011, 17, 288–298. [Google Scholar]

- Danilovic, M.; Tomasevic, I.; Gacic, D. Efficiency of John Deere 1470D ECOIII Harvester in Poplar Plantations. Croat. J. For. Eng. 2011, 32, 533–548. Available online: https://hrcak.srce.hr/72656 (accessed on 15 June 2022).

- Ovaskainen, H. Timer Harvester Operators´ Working Technique in First Thinning and the Importance of Cognitive Abilities on Work Productivity. Ph.D. Thesis, University of Joensuu, Joensuu, Finland, 2009. [Google Scholar] [CrossRef]

- Hartsch, F.; Schönauer, M.; Breinig, L.; Jaeger, D. Influence of Loading Distance, Loading Angle and Log Orientation on Time Consumption of Forwarder Loading Cycles: A Pilot Case Study. Forests 2022, 13, 384. [Google Scholar] [CrossRef]

- REFA-Fachausschuss Forstwirtschaft. Arbeitsverfahren, Arbeitsmethode, Arbeitsweise. In Arbeitsstudien, Arbeitsorganisation und Qualitätsmanagement in der Forstwirtschaft; Verlag Institut für Arbeitsorganisation e.V.: Stuttgart, Germany, 1998; pp. 43–44. [Google Scholar]

- Olson, W.A.; Sarter, N.B. Automation Management Strategies: Pilot Preferences and Operational Experiences. Int. J. Av. Psych. 2000, 10, 327–341. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Labelle, E.R. The Effect of New Silvicultural Trends on the Mental Workload of Harvester Operators. Croat. J. For. Eng. 2020, 41, 177–190. [Google Scholar] [CrossRef]

- Bembenek, M.; Tsioras, P.A.; Karaszewski, Z.; Zawieja, B.; Bakinowska, E.; Mederski, P.S. Effect of Day or Night and Cumulative Shift Time on the Frequency of Tree Damage during CTL Harvesting in Various Stand Conditions. Forests 2020, 11, 743. [Google Scholar] [CrossRef]

- Vasiliauskas, G.; Butkus, R.; Zinkevicius, R. Driving Speed Influence on Operator Vibration Exposure in Forwarding Operations. In Proceedings of the 20th International Scientific Conference Engineering for Rural Development, Jelgava, Letonia, 26–28 May 2021; pp. 1789–1794. Available online: https://www.tf.llu.lv/conference/proceedings2021/Papers/TF393.pdf (accessed on 20 October 2022).

- Ovaskainen, H.; Uusitalo, J.; Sassi, T. Effect of Edge Trees on Harvester Positioning in Thinning. For. Sci. 2006, 52, 659–669. [Google Scholar]

- Andersson, J.; Eliasson, L. Effects of Three Harvesting Work Methods on Harwarder Productivity in Final Felling. Silva Fenn. 2004, 38, 195–202. [Google Scholar] [CrossRef][Green Version]

- Manner, J.; Berg, S.; Englund, M.; Ericsson, B.T.; Mörk, A. Innovative Productivity Improvements in Forest Operations: A Comparative Study of the Assortment Grapple Using a Machine Simulator. J. For. Sci. 2020, 66, 443–451. [Google Scholar] [CrossRef]

- Szewczyk, G.; Spinelli, R.; Magagnotti, N.; Mitka, B.; Tylek, P.; Kulak, D.; Adamski, K. Perception of the Harvester Operator’s Working Environment in Windthrow Stands. Forests 2021, 12, 168. [Google Scholar] [CrossRef]

- Eberhard, B.; Hasenauer, H. Tree Marking versus Tree Selection by Harvester Operator: Are There Any Differences in the Development of Thinned Norway Spruce Forests? Int. J. For. Eng. 2021, 32, 42–52. [Google Scholar] [CrossRef]

- Holzleitner, F.; Langmair, M.; Hochbichler, E.; Obermayer, B.; Stampfer, K.; Kanzian, C. Effect of Prior Tree Marking, Thinning Method and Topping Diameter on Harvester Performance in a First Thinning Operation—A Field Experiment. Silva Fenn. 2019, 53, 10178. [Google Scholar] [CrossRef]

- Labelle, E.R.; Bergen, M.; Windisch, J. The Effect of Quality Bucking and Automatic Bucking on Harvesting Productivity and Product Recovery in a Pine-Dominated Stand. Eur. J. For. Res. 2017, 136, 639–652. [Google Scholar] [CrossRef]

- Labelle, E.; Huss, L. Creation of Value through a Harvester On-Board Bucking Optimization System Operated in a Spruce Stand. Silva Fenn. 2018, 52, 1–22. [Google Scholar] [CrossRef]

- Uusitalo, J.; Kokko, S.; Kivinen, V.-P. The Effect of Two Bucking Methods on Scots Pine Lumber Quality. Silva Fenn. 2004, 38, 291–303. [Google Scholar] [CrossRef]

- RECO—Økonomisk Kjøring og Drivstofforbruk—Kursbeskrivelse. Available online: https://skogkurs.no/artikkel/reco/ (accessed on 8 November 2022).

- Manner, J.; Nordfjell, T.; Lindroos, O. Effects of the number of assortments and log concentration on time consumption for forwarding. Silva Fenn. 2013, 47, 1030. [Google Scholar] [CrossRef]

- Negro, F.; Espinoza, O.; Brunori, A.; Cremonini, C.; Zanuttini, R. Professionals’ Feedback on the PEFC Fair Supply Chain Project Activated in Italy after the “Vaia” Windstorm. Forests 2021, 12, 946. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).