Abstract

This study situates washed sheep-wool fibres as a sustainable reinforcement candidate for epoxy matrices and evaluates their mechanical response under tensile, flexural, compressive, and Charpy impact loading. The objective of this work is to assess whether short, washed sheep-wool fibres can function as a sustainable reinforcement for epoxy matrices, and to identify optimal fibre length–content windows that improve mechanical behaviour for engineering applications. Moulded–machined specimens were produced with fibre lengths of 3, 6, and 10 mm and contents of 1.0–5.0 wt.%, depending on the test; neat epoxy served as the reference. In tension, selected formulations—particularly 10 mm/1.5 wt.%—showed simultaneous increases in ultimate stress and modulus relative to the neat resin, corresponding to gains of about 10% in ultimate tensile stress and 50% in tensile modulus, at the expense of ductility. In flexure, the modulus decreases by roughly 15–35% compared with the matrix, whereas configurations with 3–6 mm at 2.5–5 wt.% raise the fracture stress by about 35–45% and improve post-peak resistance. In compression, reinforcement markedly elevates yield stress, with increases of up to about 160% at 3 mm/2 wt.%, while the ultimate strain decreases moderately. In Charpy impact, all reinforced materials underperform the resin, with absorbed energy reduced by roughly 75–93% depending on fibre length and content, with 3 mm/1 wt.% being the least affected. A two-factor analysis of variance (ANOVA) indicates that fibre length primarily governs tensile and compressive behaviour, while fibre content dominates flexural and impact responses. Overall, the findings support wool fibres as a viable reinforcement when length and content are optimized, pointing to their use in non-structural to semi-structural industrial components such as interior panels, housings, casings, protective covers, and other parts where moderate tensile/compressive performance is sufficient and material sustainability is prioritised.

1. Introduction

Wool, a natural product obtained from sheep shearing, has long been valued for its thermal and insulating properties. However, the evolution of the textile industry and the rise of synthetic fibres have drastically reduced the demand for low-grade wool, creating environmental and economic burdens due to stockpiling and disposal in producer regions [,,]. Most of the flocks that generate this coarse, heterogeneous wool are primarily farmed for meat, milk, or grazing management rather than for fibre, but the animals must still be shorn annually for health and welfare reasons, so low-grade wool continues to be produced as an unavoidable by-product with little or no market value. This situation has prompted efforts to valorise wool residues with minimal processing and reduced ecological footprint, and this motivates the present study on their use as reinforcements in epoxy composites.

Agricultural applications have drawn particular attention: unprocessed wool can act as a slow-release nitrogen fertilizer, and wool-based mats, pellets, and soil conditioners have shown promise in horticultural and forestry uses [,]. EU-funded initiatives (e.g., LIFE GREENWOOLF) have further demonstrated the feasibility of transforming low-quality wool waste into biodegradable fertilizers and mulching materials, aligning with circular-economy goals []. Despite these advances, the agricultural route alone cannot absorb the yearly surplus of low-grade wool, motivating the exploration of alternative, higher-value material uses [,].

Within materials engineering, natural fibres (e.g., flax, jute, hemp, sisal) have been widely investigated as polymer reinforcements due to their low cost, low density, renewability, and favourable life-cycle metrics, while maintaining competitive mechanical performance in selected applications [,]. Epoxy resins, in turn, are staple thermosets for advanced composite structures because of their strong adhesion, chemical resistance, and thermal stability, and they are widely used both as matrix resins and as structural adhesives in bonded, co-bonded, and co-cured composite joints in aerospace, automotive, and marine applications [,,,]. Combining epoxy matrices with natural fibres has been proposed as a route towards composites with higher renewable content and improved life-cycle metrics, even though conventional epoxy matrices are not biopolymers and are not biodegradable []. However, the performance of an epoxy composite depends sensitively on fibre–matrix interactions, load transfer, fibre length, and fibre content, which warrant systematic study [].

Compared with plant fibres, the structural use of animal fibres—particularly sheep wool—in polymer composites remains underexplored. Prior work on wool has focused more on thermal/acoustic insulation than on structural reinforcement in epoxy matrices [,]. Nonetheless, wool’s intrinsic elasticity and energy-absorption capacity suggest potential in non-structural to semi-structural components, provided that the fibre geometry and content are judiciously optimized [].

At the same time, the literature presents diverging views on key issues relevant to wool–epoxy systems. First, short-fibre micromechanics indicates that tensile stress gains hinge on effective load transfer and a critical fibre length, which may be harder to achieve with lower-modulus animal fibres [,]. Second, the impact response of natural-fibre composites varies widely: some studies report energy-absorption benefits, whereas others show degradation depending on fibre length, content, and processing-induced defects [,]. Third, opinions differ on whether washed (untreated) wool is sufficient for adhesion and moisture resistance or whether surface treatments are needed []. These divergences underscore the need for controlled, epoxy-based studies isolating the effects of fibre length and fibre content. To the best of the authors’ knowledge, there is no available study on short-fibre-reinforced epoxy composites that systematically covers fibre lengths of 3, 6, and 10 mm combined with contents of 1.0–5.0 wt.% under a unified experimental design. This lack of directly comparable data underscores the need for reference mechanical results in this length–content window to benchmark wool–epoxy systems against other short-fibre composites.

This work investigates the feasibility of using washed sheep wool fibres as reinforcements in an epoxy matrix by systematically varying the fibre length (3, 6, and 10 mm) and content (1.0–5.0 wt.%) and benchmarking against neat epoxy under standardized procedures. By disentangling the roles of length and content across tensile, flexural, compressive, and Charpy impact loading, this study provides actionable guidance for designing wool-reinforced epoxies while contributing to the circular-economy valorisation of low-grade wool. In brief, our results show that selected wool configurations can increase tensile stress/modulus and compressive yield stress relative to neat epoxy, whereas flexural modulus and impact performance are more sensitive to fibre content—clarifying when and how wool can function as an effective, sustainable reinforcement.

2. Materials and Methods

2.1. Materials

The polymer matrix was a commercial, solvent-free, two-component epoxy system, DIPOXY-2K-700 (Dipoxy International GmbH, Hanau, Germany), mixed at a 2:1 resin–hardener mass ratio, self-degassing, transparent, and suitable for cast layers of up to 10 mm. The processing time ranges from 10 to 60 min depending on temperature, and full cure is achieved within 2–14 days, following the manufacturer’s guidance.

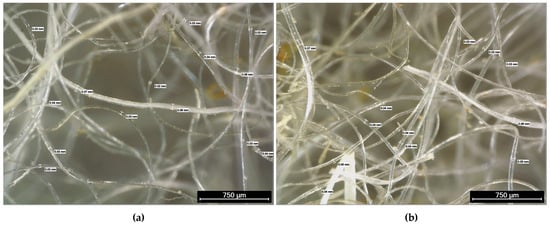

The natural reinforcement consisted of coarse wool fibres from Segureña sheep (Wool Dreamers, Cuenca, Spain), a local breed from southeastern Iberia, with medium-to-coarse texture and of non-textile grade. The fibres were subjected to a basic washing to remove superficial dirt without chemical surface treatment, and then they were used as dispersed short fibres with controlled length and weight fraction. Optical microscopy (Leica Microsystems S.L.U., L’Hospitalet de Llobregat, Spain) confirmed heterogeneity in diameter (≈ 20–70 μm overall; means ≈ 40–45 μm) and minor residues (straw/soil; low). Figure 1 shows the characterization of the wool obtained by optical microscopy.

Figure 1.

Measurements, appearance, and distribution of Segureña sheep wool reinforcement fibres obtained by optical microscopy: (a) light white fibres with low straw residues; (b) light white fibres with low straw residues (different field of view); (c) white/yellow fibres with low soil/straw residues; (d) white/yellow fibres with low soil/straw residues (different field of view).

Figure 1a–d show the heterogeneity of the fibres in thickness and arrangement, with diameters displaying significant variation and surface irregularities typical of unprocessed natural materials. Table 1 complements these qualitative observations with morphological and visual characterization, including colour, type, and presence of residues, along with the maximum, minimum, and average diameters measured in the samples.

Table 1.

Morphological and visual characterization of Segureña sheep wool fibres, including colour, type, and quantity of residues, along with the fibre diameter measurements obtained by optical microscopy.

For mould fabrication, EN AW-2024-T6 aluminium was used. To aid in demoulding and protect cavity surfaces, an fluorinated ethylene propylene (FEP) based release coating (Elite 8840, Tecnimacor S.L., Córdoba, Spain) was applied at 60–70 μm thickness.

2.2. Equipment

Moulds for tensile and flexural specimens were machined on an FTV-1 manual vertical mill (Lagun Machine Tools S.L.U., Azkoitia, Gipuzkoa, Spain). Compression and impact moulds, requiring higher precision and minimal vibration, were produced on a CNC vertical machining centre QP2026-L (Falcon Machine Tools Co., Ltd., Changhua, Taiwan) equipped with FANUC control, a high-performance spindle, linear guides, and travels of 660 mm × 520 mm × 508 mm (X, Y, Z). Dimensional finishing after moulding was carried out on a manual horizontal lathe SP/165 (Pinacho, Zaragoza, Spain).

Fibre characterization, fracture inspection, and specimen preparation used a DVM6-A digital optical microscope (Leica Microsystems S.L.U., L’Hospitalet de Llobregat, Spain) with a motorized focus, XY stage, and a CMOS sensor up to 10 MP and 37 fps. For fracture-surface inspection, the microscope was operated in reflected-light mode with an FOV 43.75 objective (nominal NA = 0.007). Images were acquired at 1600 × 1200 px (8-bit RGB), corresponding to a field of view of approximately 34.5 mm × 25.8 mm and a spatial sampling of ≈21–22 μm per pixel. The same optical configuration was used for all fracture surfaces reported in this study. Resin and wool were weighed on a WLC 2/A2 precision balance (Radwag, Toruń, Poland; 0.01 g resolution, 2 kg capacity, tare), and specimen dimensions were verified with a digital calliper (Mitutoyo Corporation, Kawasaki, Japan; 0.01 mm).

Thermal curing under a controlled temperature was performed in a 2,000,210 laboratory oven (J.P. Selecta S.A., Abrera, Barcelona, Spain; 1200 W, 0–250 °C).

Mechanical testing used a universal testing machine M-405 (Servosis S.L., Madrid, Spain; 1–500 kN, max 180 mm/min, 1200 mm crosshead travel) with tensile grips, a three-point bending fixture, and flat compression platens, while Charpy impact toughness was measured with an RKP 450 pendulum (ZwickRoell GmbH & Co. KG, Ulm, Germany; 450 J, −45 to +85 °C).

2.3. Methods

Moulded–machined specimens were fabricated to evaluate the influence of fibre length and wool mass fraction in an epoxy matrix. The experimental design was conceived to ensure traceability and reproducibility

Standard specimens for tensile, flexural, compressive, and Charpy impact tests were produced by gravity-casting of wool–epoxy mixtures into aluminium moulds, followed by machining to the final geometries specified in Table 2. The two epoxy components were weighed at a 2:1 resin–hardener mass ratio and hand-mixed for approximately 5 min. Washed Segureña wool was cut to nominal fibre lengths of 3, 6, or 10 mm and weighed to reach the target mass fractions (1.0–5.0 wt.%). For each formulation, the required amount of wool was gradually incorporated into the fresh resin under manual stirring until a visually homogeneous suspension of short, randomly oriented fibres was obtained (no laminates or stacking sequence were used). The mixtures were then poured by gravity into FEP-coated aluminium moulds: flat plate cavities for tensile, flexural, and Charpy bars, and cylindrical cavities for compression specimens. To limit air entrapment, mixing was performed manually at low speed, and the moulds were filled slowly from one side, allowing bubbles to rise to the free surface before gelation. No additional vacuum-degassing step was applied in this study. After initial gelation at room temperature, the filled moulds were cured in a ventilated oven at 60 °C for 24 h, demoulded, and finally machined to the standardized dimensions listed in Table 2.

Table 2.

Experimental matrix of moulded–machined specimens.

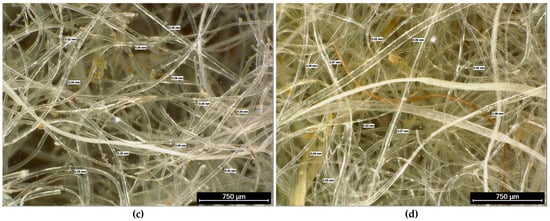

Figure 2 shows the mechanised moulds designed for the different mechanical tests carried out in this study.

Figure 2.

Mechanised moulds: (a) flexural and Charpy; (b1,b2) compression: (b1) assembled; (b2) halves apart; (c) tensile.

All mechanical tests—tensile, flexural, compressive, and Charpy impact—were performed in accordance with the corresponding UNE-EN ISO standards. Specimens were prepared as previously described in the Section 2.1 and Section 2.2 and subsequently machined to meet the required dimensions (see Table 2). The tensile tests followed UNE-EN ISO 527-1 [] and 527-4 [], using Type 2 specimens of 250 mm × 25 mm × 4 mm(length × width × thickness) (n = 3 per configuration). Tests were carried out on a Servosis M-405 universal testing machine with a gauge length of 150 ± 1 mm between grips and a crosshead speed of 0.20 mm/s, with the lower grip fixed. The parameters recorded were yield stress (σᵧ,t), ultimate stress (σu,t), fracture stress and strain (σb,t, εb,t), and elastic modulus (Et). The tensile modulus Et was computed by linear regression over 0.05–0.25% strain on the initial linear portion of the stress–strain curve; machine/grip compliance was checked and found to be negligible for the gauge length used. Flexural tests were conducted according to UNE-EN ISO 178 [] on prismatic specimens of 100 mm × 10 mm × 4 mm (n = 5 per configuration) in a three-point bending setup, using 10 mm rollers and a support span of 64 mm. The load was applied at a controlled speed until fracture, and the ultimate flexural stress (σu,f), flexural modulus (Ef), and fracture stress (σb,f) were determined. Compression tests were performed in line with UNE-EN ISO 604 [] using cylindrical specimens (Ø20 × 25 mm; n = 5 per configuration), with machined ends to ensure parallelism. Testing was conducted on the Servosis M-405 with careful axial alignment, and stress–strain curves were used to determine the compressive yield stress (σy,c), ultimate stress (σu,c), yield strain (εy,c), and ultimate strain (εu,c). In compression, the ultimate and fracture values coincide and are reported interchangeably. The Charpy impact tests followed UNE-EN ISO 179 [], using prismatic specimens of 10 mm × 4 mm × 80 mm (height x thickness x length) (n = 5 per configuration). Specimens were V-notched (radius r = 0.25 mm) and tested with the notch facing the striker. Tests were conducted on a ZwickRoell RKP 450 pendulum (450 J, −45 to +85 °C), and the effective absorbed energy (Wef) was obtained from the loss of potential energy after fracture.

Fracture morphology was then examined to relate the observed surfaces with the mechanical behaviour reported in the different tests. The analysis aimed to identify the mechanisms governing failure in neat epoxy and wool–epoxy composites, and to explain the role of fibre length and content in crack initiation, propagation, and energy dissipation. To reinforce interpretation and ensure statistical validity, an ANOVA under the principal effects approach (PEVA) was performed using Minitab 21.2.0 (Minitab LLC, State College, USA). Fibre length and mass fraction were considered as main factors, and their effects were evaluated on tensile, flexural, compressive, and impact performance. Normality (Anderson–Darling) and homoscedasticity (Levene) were verified at α = 0.05 prior to two-factor ANOVA. In the model summaries, S denotes the standard error of regression. To ensure comparability and focus on the ultimate state, the response variable was the ultimate stress (σu) for tensile, flexural, and compressive tests, while for Charpy the effective absorbed energy was used. The analysis included main effect plots and considered interaction terms (L × W), which were reported when significant.

3. Results and Discussion

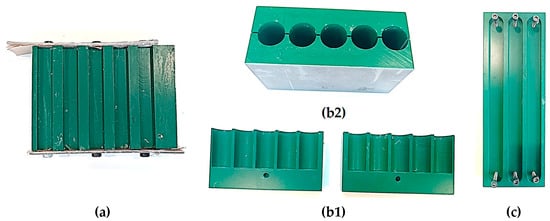

3.1. Tensile Test Results and Analysis

The tensile behaviour of epoxy–wool composites was examined as a function of fibre length (3, 6, and 10 mm) and weight content (1.5 and 3.0 wt.%). The yield stress (σy,t), ultimate and break stresses (σu,t, σb,t), elastic modulus (Et), and strain at break (εb,t) were determined, reported as the mean ± standard deviation, and compared with the neat resin. Table 3 summarizes Et and εb,t for each fibre length and content, providing a direct reference for the stiffness and ductility of each formulation.

Table 3.

Tensile properties of epoxy–wool composites (mean ± SD): modulus of elasticity and strain at break.

The incorporation of fibres alters both the stiffness and deformability of the composites. While the elastic modulus shows notable increases in some cases, the strain at break generally decreases compared to the neat resin. Figure 3 complements this by showing the evolution of the characteristic tensile stresses as a function of fibre length and content.

Figure 3.

Effects of fibre length and wool content on the tensile performance of epoxy–wool composites: yield stress, breaking stress, and ultimate tensile stress.

As shown in Table 3 and Figure 3, wool reinforcement only produces a clear increase in stiffness (Et) at 10 mm/1.5 wt.%, where the modulus reaches 490.4 ± 101.5 MPa versus 331.0 ± 39.2 MPa for the resin, i.e., an increase of approximately 50% in tensile modulus with respect to the neat epoxy. Other formulations remain similar or lower (e.g., 269.2 ± 72.7 MPa at 6 mm/1.5 wt.%, 238.0 ± 4.1 MPa at 6 mm/3.0 wt.%, 282.7 ± 20.6 MPa at 3 mm/3.0 wt.%, and 251.0 ± 27.3 MPa at 10 mm/3.0 wt.%). For ultimate stress, the maximum is ≈27 MPa at 10 mm/1.5 wt.%, about 10% higher than the ultimate tensile stress of the neat resin, whereas 3 mm and 6 mm remain at ≈20–22 MPa and the matrix at ≈24–25 MPa; increasing to 3.0 wt.% yields no improvement, even at 10 mm. Meanwhile, εb,t decreases from 5.65 ± 1.33% (unreinforced) to ≤ 0.34%, reaching 0.00% at 3 mm/3.0 wt.%. Overall, the results indicate that exceeding the critical fibre length—here, 10 mm within the tested range—and keeping moderate fractions (1.5 wt.%) will optimize Et and σu,t, whereas higher loadings are penalized by aggregation and interfacial defects. This is consistent with the findings of Patrucco et al. []—who highlighted fibre–matrix adhesion and warned about agglomeration at high loadings in wool–polymer composites—and with recent studies placing optimal short-fibre lengths between ~5 and 30 mm, depending on system and processing (e.g., 5 mm in jute/epoxy preform; 10–30 mm in sisal/PP; 30 mm in areca/epoxy), supporting the effectiveness of 10 mm as a “moderate length” [,].

It is worth noting that, for the shortest fibre length at the lowest content (3 mm/1.5 wt.%), the ultimate tensile stress decreases by about 17.5% compared with the neat epoxy. This behaviour is consistent with a defect-dominated regime in which fibres that are below or close to the effective load-bearing length do not contribute significantly to tensile reinforcement. Instead, they primarily act as additional stress concentrators (fibre ends, local stiffness mismatches, voids, and interfacial defects), promoting earlier crack initiation and limiting the potential for fibre bridging and pull-out to increase the load-carrying capacity.

3.2. Flexural Test Results and Analysis

This section examines the flexural behaviour of epoxy–wool composites with fibre lengths of 3, 6, and 10 mm at 2.5 and 5.0 wt.%. The analysis focuses on the flexural modulus (Ef) and the load-bearing capacity at peak and fracture (σu,f, σb,f), derived from load–deflection curves. The results are presented as the mean ± standard deviation relative to the neat resin. Table 4 summarizes the flexural modulus.

Table 4.

Flexural modulus of epoxy–wool composites (mean ± SD) as a function of fibre length and loading.

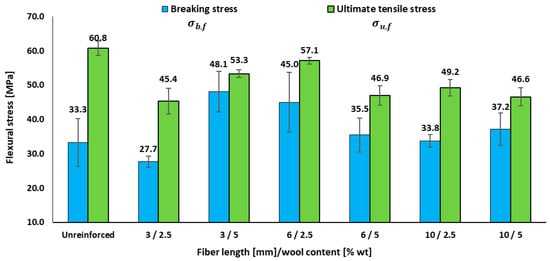

Table 4 shows the effect of reinforcement on the flexural elastic modulus, varying with fibre length and content. To complement stiffness with load-bearing capacity, Figure 4 reports the characteristic flexural stresses.

Figure 4.

Effects of fibre length and wool content on the flexural performance of epoxy–wool composites: breaking stress and ultimate flexural stress.

Table 4 confirms a reduction in flexural modulus compared to the neat resin (1961.3 ± 134.5 MPa), with composites ranging from 1237.2 to 1672.9 MPa, i.e., a decrease of approximately 15–35% relative to the neat epoxy. The highest Ef appears in 3 mm/5.0 wt.% (1672.9 ± 45.4 MPa) and 6 mm/2.5–5.0 wt.%, whereas the lowest is found at 10 mm/5.0 wt.% (1237.2 ± 149.9 MPa). This suggests that short–medium lengths and moderate fractions better preserve stiffness than longer, heavily loaded combinations. Figure 4 shows that the flexural stress of the matrix is 60.8 MPa, while most composites fall between 45.0 and 57.0 MPa, consistent with reductions in peak flexural stress in the order of 15–25%, with peaks again at 3–6 mm/5.0 wt.%. In contrast, the fracture stress exceeds the resin baseline (33.3 MPa) in several cases (45.0–48.0 MPa), corresponding to increases of roughly 35–45%, indicating post-peak load-bearing despite reductions in peak stress and modulus.

These trends align with studies on natural-fibre composites, which identify effective windows of fibre length and content, whereas excessive values promote agglomeration and poor load transfer. In wool–epoxy, Patrucco et al. [] emphasize weak interfacial bonding with thermosets and limited property gains without treatments (e.g., alkaline/silane), explaining why our 10 mm/5.0 wt.% formulations did not improve Ef or σu,f. The enhancement of σb,f is consistent with extrinsic mechanisms such as fibre bridging and pull-out, which sustain load beyond the peak. As detailed by Lubineau et al. [], these mechanisms increase post-peak toughness when interfacial traction is effective—consistent with our 3–6 mm results and contrasting with those for 10 mm/5.0 wt.% (more decohesion/porosity). Recent reviews [] similarly conclude that mechanical optima occur at moderate lengths and fractions, with fibre treatments further improving load transfer and flexural performance, mirroring the behaviour observed here.

For flexural loading, the shortest wool fibres also lead to a reduction in strength. The incorporation of 3 mm fibres produces decreases in flexural strength of up to approximately 25% relative to the neat resin, depending on fibre content, as illustrated in Figure 4. As in tension, this behaviour is consistent with a defect-dominated regime, where very short fibres mainly introduce additional stress concentrators (fibre ends, local stiffness mismatches, voids, and interfacial decohesion) in the tensile zone of the bent specimens, instead of acting as effective load-bearing bridges. This interpretation is consistent with the fracture morphologies observed around short fibres (Section 3.5).

3.3. Compressive Test Results and Analysis

This section analyses the compressive response of epoxy–wool composites with fibre lengths of 3, 6, and 10 mm and fractions of 1.0 and 2.0 wt.%. From the σ–ε curves, characteristic yield and ultimate parameters were determined and are reported as the mean ± standard deviation relative to the unreinforced resin. In this case, the maximum stress coincides with the ultimate state, so no distinction is made between the maximum and fracture stresses. For an integrated view, Table 5 summarizes the strains at yield (εy,c) and at fracture (εb,c).

Table 5.

Compressive properties of epoxy–wool composites (mean ± SD): strain at yield and strain at break as a function of fibre length and loading.

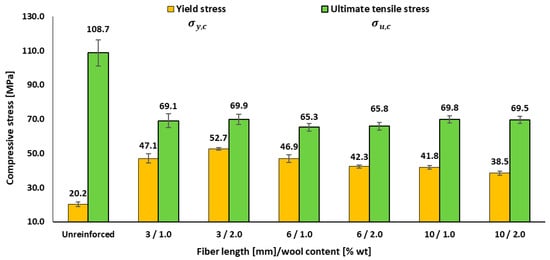

Table 5 shows an increase in compressive yield strain in the composites compared to the resin, accompanied by a slight reduction in fracture strain, with variations depending on fibre length and content. To complement these strain data, Figure 5 presents the compressive stresses—σy,c and σu,c—as a function of the different formulations.

Figure 5.

Effects of fibre length and wool content on the compressive performance of epoxy–wool composites: yield stress and ultimate compressive stress.

Table 5 shows that the compressive yield strain increases in all composites compared to the neat resin (6.6 ± 0.5%), reaching ≈ 9–11% depending on fibre length and content. In parallel, the fracture strain decreases from 62.8 ± 1.8% in the matrix to ≈ 42–52% in the reinforced systems. Figure 5 confirms that the compressive yield stress rises from 20.2 MPa in the resin to ≈ 41.8–52.7 MPa in the composites, with a maximum at 3 mm/2 wt.% (52.7 MPa). A clear trend with fibre length is observed (≈ 3 mm > 6 mm > 10 mm), along with a length-dependent effect of fibre content: at 3 mm, increasing from 1 to 2 wt.% enhances σy,c; at 6–10 mm, higher content tends to provide no improvement or even reduce σy,c. Overall, wool reinforcement raises the elastic threshold but shortens the ultimate strain, i.e., greater resistance to yielding but lower final ductility. This pattern is consistent with the micromechanics of polymer composites under compression: fibres constrain matrix shear and delay flow, but failure is governed by local instabilities (microbuckling, kink bands) and by the heterogeneity inherent to discontinuous reinforcements (fibre ends, voids, length dispersion). In recent scientific reviews, Islam et al. [] describe how kink bands emerge early and reduce ductility, while Larsson et al. [] document the sensitivity to local defects under compression—two mechanisms that explain the combination of higher σy,c with lower εb,c observed here. The best performance at 3 mm/2 wt.% suggests an effective short-fibre window, close to the critical fibre length, where load transfer is most efficient. Moving away from this window—by increasing the fibre length to 6–10 mm or raising the content at these lengths—elevates the defect density and geometric inefficiency, resulting in reduced εy,c and shortened post-yield strain. This interpretation aligns with the classical micromechanics of discontinuous reinforcements, as described by the Kelly–Tyson model and its subsequent developments [], and with later syntheses by Thomason [] emphasizing the importance of effective fibre length and its dispersion in short-fibre composites. Similarly, reviews on epoxy reinforced with natural fibres [] stress that optimal properties are achieved in moderate ranges of fibre length and content, whereas further increases penalize ductility and compressive performance, in agreement with our findings.

3.4. Charpy Impact Test Results and Analysis

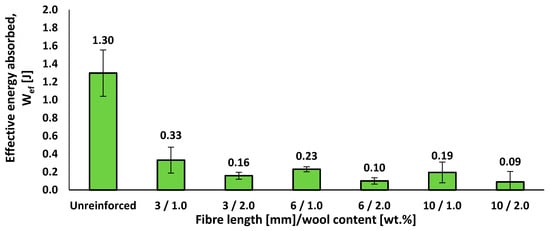

Figure 6 presents the Charpy effective energy absorption (Wef) of the epoxy–wool composites at different fibre lengths and contents, relative to the unreinforced resin.

Figure 6.

Effective energy absorbed in Charpy impact tests of epoxy–wool composites as a function of fibre length and fibre content.

In notched Charpy tests, neat epoxy absorbs Wef = 1.30 J. With short wool fibres, the energy drops to 0.33 J (3 mm/1 wt.%), 0.23 J (6 mm/1 wt.%), and 0.19 J (10 mm/1 wt.%); at 2 wt.%, it decreases further to 0.16 J, 0.10 J, and 0.09 J, respectively. Thus, the composites retain only ~7–25% of the matrix energy, with 3 mm/1 wt.% showing the best performance. A clear trend emerges: at fixed content, Wef decreases with fibre length, and at fixed length, it is higher at 1 wt.% than at 2 wt.%. This behaviour reflects short-fibre composites where interfacial decohesion dominates and the effective length is below or near the critical length, leading to more crack initiators at fibre ends and pores and less dissipative pull-out. The results align with recent reviews on natural-fibre composites and studies relating impact response to fibre length distribution and load transfer efficiency [,]. A micromechanical interpretation based on Kelly–Tyson, extended for very short fibres, further supports the idea that, outside an optimal window, higher length or content increases the interfacial area and notch sensitivity without improving load transfer [,].

3.5. Fracture Analysis and Visual Inspection

This section relates the fracture morphology observed in the specimens to the mechanical results previously reported in tension, flexure, compression, and Charpy impact. The objective is to clarify how differences between formulations (fibre length and content) originate. For this purpose, the fracture surfaces of neat epoxy are compared with those of epoxy–wool composites, using representative micro/macrographs (Figure 7, Figure 8, Figure 9 and Figure 10) and reference values from earlier tables and figures. Fractographic observations were performed with a Leica DVM6-A digital microscope operated in reflected-light mode under the optical configuration described in Section 2.2 (FOV 43.75 objective, 1600 × 1200 px, spatial sampling ≈ 21–22 μm/px), which in this study allowed us to visually distinguish individual wool fibres (≈20–40 μm in diameter) and to qualitatively identify their failure mode (predominantly fibre pull-out rather than fibre breakage).

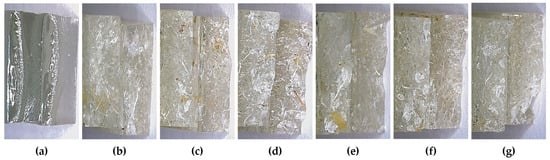

Figure 7.

Representative fracture surfaces of specimens after tensile testing (optical micrographs at high magnification obtained with the Leica DVM6-A microscope): (a) neat epoxy resin, (b) 3 mm fibres/1.5 wt.%, (c) 3 mm fibres/3.0 wt.%, (d) 6 mm fibres/1.5 wt.%, (e) 6 mm fibres/3.0 wt.%, (f) 10 mm fibres/1.5 wt.%, and (g) 10 mm fibres/3.0 wt.%.

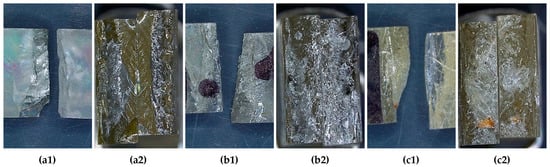

Figure 8.

Representative fracture surfaces of specimens after flexural testing (optical micrographs at high magnification obtained with the Leica DVM6-A microscope): (a) neat epoxy resin, (b) 3 mm fibres/2.5 wt.%, (c) 3 mm fibres/5.0 wt.%, (d) 6 mm fibres/2.5 wt.%, (e) 6 mm fibres/5.0 wt.%, (f) 10 mm fibres/2.5 wt.%, and (g) 10 mm fibres/5.0 wt.%.

Figure 9.

Representative fracture surfaces of specimens after compressive testing: (a) neat epoxy resin, (b) 3 mm fibres/1 wt.%, and (c) 3 mm fibres/2.0 wt.%.

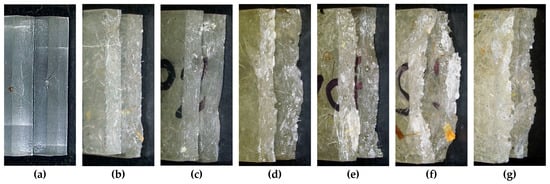

Figure 10.

Representative fracture surfaces of specimens after Charpy impact testing (optical images obtained with the Leica DVM6-A microscope): (a1) side view of the broken neat epoxy specimen; (a2) frontal close-up view of the fracture surface in neat epoxy; (b1) side view of the composite with 3 mm wool fibres at 1 wt.% loading; (b2) frontal close-up view of the fracture surface for the composite with 3 mm wool fibres at 1 wt.% loading; (c1) side view of the composite with 3 mm wool fibres at 2.0 wt.% loading; (c2) frontal close-up view of the fracture surface for the composite with 3 mm wool fibres at 2.0 wt.% loading.

The fracture surfaces reveal distinct mechanisms depending on reinforcement and formulation: (a) neat resin shows a smooth, glossy plane typical of brittle cleavage; (b–e) with 3–6 mm fibres, rougher surfaces with voids, fibre ends, and interfacial debonding appear, evidencing pull-out and matrix micro-shear; (f) at 10 mm/1.5 wt.%, the surface is highly tortuous, with long fibres pulled out or bridging the crack, consistent with the maximum tensile stress (≈27 MPa) despite low ductility; (g) at 10 mm/3.0 wt.%, smooth zones alternate with agglomerates and pores, dominated by debonding and short pull-out, explaining the drop in modulus and tensile stress compared with 10 mm/1.5 wt.% (saturation and defect effects). Overall, the transition from “smooth surface → rough with pull-out/bridging” and the contrast between 10 mm/1.5 wt.% (bridging) and 10 mm/3.0 wt.% (defects) account for the slight stiffness increase in the former and the penalty at higher fibre fractions.

In all reinforced tensile specimens, most wool fibres fail by interfacial debonding followed by pull-out, whereas clean fibre breakage is comparatively rare. This pull-out-dominated fracture mode is consistent with the modest increase in ultimate tensile stress and the severe loss of ductility reported in Section 3.1.

The fracture surfaces after flexural testing show a clear transition between resin and composites: (a) neat resin presents a smooth, glossy plane characteristic of brittle fracture with minimal crack deviation; (b–c) 3 mm/2.5–5.0 wt.% displays rougher surfaces with numerous pull-out marks and microcavitation, evidencing short pull-out and moderate crack tortuosity, which indicate additional energy dissipation; (d–e) 6 mm/2.5–5.0 wt.% reveals longer pull-out lengths and fibre bridging zones, consistent with the formulations that best preserve flexural modulus; (f) 10 mm/2.5 wt.% shows a highly tortuous surface with long fibres partially extracted, suggesting a bridging contribution despite local heterogeneity; (g) 10 mm/5.0 wt.% alternates smooth patches with agglomerates and voids, where interfacial debonding and short pull-out dominate, consistent with the drop in Ef for this higher fibre loading. Overall, the transition from “smooth → rough with pull-out/bridging” when moving from resin to composites, together with the contrast between short/medium fibres and 10 mm/5.0 wt.%, accounts for the superior performance of intermediate formulations and the degradation observed when both fibre length and content increase simultaneously.

As in tension, the dominant fracture mechanisms are fibre pull-out and interfacial debonding, rather than complete fibre rupture, so flexural energy dissipation is mainly governed by crack deflection around partially debonded fibres.

Observations of the fracture surfaces reveal how fibre reinforcement modifies the failure behaviour of the resin under compression. (a) Neat resin exhibits a smooth surface with nearly straight axial splits and slight barrelling, typical of brittle cleavage under compression; the crack propagates with little deviation and without extensive crushing zones; (b) 3 mm/1 wt.% shows a rougher surface with oblique shear bands, local crushing, and cavities, together with debonding marks and short fibre pull-out; this microstructure suggests that the fibres constrain matrix shear, raise the yielding threshold, and promote multiple cracks rather than a single fracture plane; (c) 3 mm/2 wt.% presents a more tortuous surface with extended crushing, porosity/agglomerates, and evident pull-out; micro-buckling/kink planes are observed coalescing into a predominant axial crack. The reinforcement increases resistance to flow but concentrates instability in local zones, consistent with the lower final ductility. Overall, the transition from neat resin to composites is from clean axial splitting to crushing- and shear-dominated surfaces with debonding and fibre pull-out, which explains the increase in compressive yield stress and the reduction in compressive strain at break: greater ability to resist initial yielding, but fracture governed by local instabilities.

Fracture surface analysis reveals how fibre reinforcement modifies resin failure. In Figure 10(a1,a2), neat resin displays smooth, shiny surfaces with minimal chipping, typical of brittle, notch-controlled fracture; cracks propagate almost straight, with little deviation. In Figure 10(b1,b2), 3 mm/1 wt.% exhibits increased roughness, small cavities, shear planes, interfacial debonding, and short fibre pull-out, indicating crack deflection and energy dissipation, consistent with the highest Wef among the reinforced samples. In Figure 10(c1,c2), 3 mm/2 wt.% shows local plastic deformation, porosity, agglomerates, and flattened regions, with multiple crack initiations at defects and fibre ends; debonding and short pull-out dominate, but higher defect density and notch sensitivity reduce the dissipative contribution. Overall, the transition from neat resin to reinforced composites progresses from clean cleavage to tortuous, fibre–matrix-interacting fracture surfaces, explaining both the decrease in Wef with increased fibre content (3 mm/1 wt.% > 3 mm/2 wt.%) and the general trend in impact resistance across lengths and fibre loadings.

3.6. Statistical Analysis

In order to reinforce the experimental conclusions and quantitatively evaluate the influence of design parameters, a statistical analysis was performed on the main results obtained from the mechanical tests. Specifically, a two-factor ANOVA was applied (reinforced subset: 3, 6, and 10 mm × 1.0 to 5.0 wt.%, excluding unreinforced specimens) to study the effects of fibre length (L, mm) and wool content (W, wt.%) on the selected response of each test: tension (σu,t), flexural (σu,f), compression (σu,c), and impact (Wef). Additionally, main effects plots were generated to visualize the magnitude and individual impact of each factor. This analysis allows for the identification of statistically significant trends and provides an objective criterion for comparing the behaviour of the different formulations. Table 6 shows the results of the analysis of variance for the indicated variables.

Table 6.

Analysis of variance (ANOVA) results for the response variables: σu,t, σu,f, σu,c, and Wef.

The model summary for the selected results provides the data included in Table 7.

Table 7.

Summary of the regression models for the response variables: σu,t, σu,f, σu,c, and Wef.

The regression equations fitted for the selected response variables are presented below (Equations (1)–(4)).

| Response | Equation | |

| σu,t | 22.210 − 1.265·IL = 3 − 1.022·IL = 6 + 2.287·IL = 10 + 0.703·IW = 1.5 − 0.703·IW = 3.0 − 1.465·IL = 3·IW = 1.5 + 1.465·IL = 3·IW = 3.0 −0.282·IL = 6·IW = 1.5 + 0.282·IL = 6·IW = 3.0 + 1.747·IL = 10·IW = 1.5 − 1.747·IL = 10·IW = 3.0. | (1) |

| σu,f | 37.86 + 0.02·IL = 3 + 2.37·IL = 6 − 2.40·IL = 10 − 2.36·IW = 2.5 + 2.36·IW = 5.0 − 7.82·IL = 3·IW = 2.5 + 7.82·IL = 3·IW = 5.0 + 7.14·IL = 6·IW = 2.5 − 7.14·IL = 6·IW = 5.0 + 0.68·IL = 10·IW = 2.5 − 0.68·IL = 10·IW = 5.0 | (2) |

| σu,c | 68.256 + 1.242·IL = 3 − 2.673·IL = 6 + 1.431·IL = 10 − 0.174·IW = 1.0 + 0.174·IW = 2.0 − 0.257·IL = 3·IW = 1.0 + 0.257·IL = 3·IW = 2.0 + 0.075·IL = 6·IW = 1.0 − 0.075·IL = 6·IW = 2.0 + 0.332·IL = 10·IW = 1.0 − 0.332·IL = 10·IW = 2.0 | (3) |

| Wef | 0.1842 + 0.0608·IL = 3 − 0.0192·IL = 6 − 0.0417·IL = 10 + 0.0682·IW = 1.0 − 0.0682·IW = 2.0 + 0.0188·IL = 3·IW = 1.0 − 0.0188·IL = 3·IW = 2.0 − 0.0032·IL = 6·IW = 1.0 + 0.0032·IL = 6·IW = 2.0 − 0.0157·IL = 10·IW = 1.0 + 0.0157·IL = 10·IW = 2.0 | (4) |

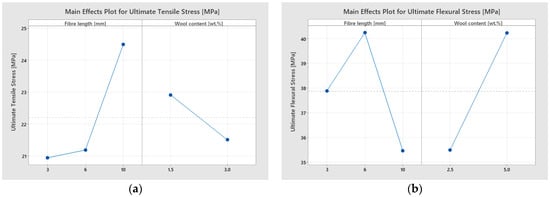

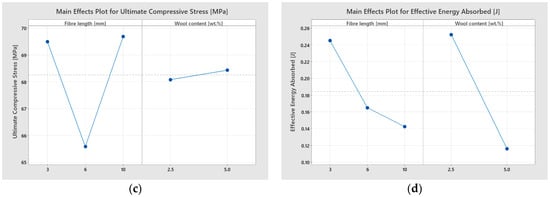

Finally, the main effects plots are provided in the accompanying Figure 11.

Figure 11.

Main effects plots showing the influence of fibre length and wool content on the responses obtained from mechanical tests: (a) ultimate tensile stress, (b) ultimate flexural stress, (c) ultimate compressive stress, and (d) effective energy absorbed (impact).

- Ultimate Tensile Stress

The parameter σu,t was highly sensitive to fibre length (L) (p = 0.007), whereas wool content (W) did not show a statistically significant effect (p = 0.113). The L × W interaction was significant (p = 0.024), indicating that the effect of L depends on the level of W. The model explains R2 = 58.40% with S = 1.744 MPa, allowing trends to be discriminated with moderate reliability. This pattern is consistent with the means and the main effects plots associated with tension.

- Ultimate Flexural Stress

The parameter σu,f showed a clear dependence on W (p = 0.037), whereas L was not significant (p = 0.211). A highly significant L × W interaction was observed (p < 0.001), indicating that the magnitude of the effect of wool content varies with fibre length (and vice versa). The model reached R2 = 63.11% with S = 5.855 MPa, confirming a well-defined effect structure consistent with the main effects and interaction plots.

- Ultimate Compressive Stress

For σu,c, L was the only significant factor (p = 0.004), whereas W (p = 0.731) and the L × W interaction (p = 0.887) showed no effects within the evaluated range. The model fit yielded R2 = 37.95% with S = 2.738 MPa; despite the higher dispersion typical of this test, the model reliably isolated the length-dependent gradient observed in the main effects plots.

- Effective Energy Absorbed

Wef was governed by W (p = 0.001), whereas L showed a marginal contribution (p = 0.052) and the L × W interaction was not significant (p = 0.710). The model yielded R2 = 52.38% with S = 0.0896, reproducing in the main effects plots the systematic reduction in Wef as the content increased within the studied range.

Overall, the two-factor ANOVA confirmed that the mechanical response depends differentially on fibre length and wool content, depending on the test. In tension, σu,t is governed by L, with a significant L × W interaction; σu,f depends on W and shows a pronounced L × W interaction; σu,c is controlled by L; and for Wef, the determining factor is W. The adjusted R2 values (≈25–55%) and standard errors indicate models adequate for discriminating trends within the studied range. The main effects and interaction plots consistently visualize these patterns in agreement with the p-values, showing that short-to-medium fibre lengths and moderate contents maximize performance in a test-dependent manner. These conclusions provide an objective framework for comparing formulations and guiding adjustments of L and W in future developments.

4. Conclusions

The mechanical response of wool-reinforced epoxy composites was evaluated as a function of fibre length (3, 6, and 10 mm) and content. The main findings are as follows:

- 1.

- Tension: The best-performing formulation (10 mm/1.5 wt.%) increased the ultimate tensile stress by ≈10% and tensile modulus by ≈50%, while very short fibres at low content (3 mm/1.5 wt.%) reduced tensile strength by ≈17.5%.

- 2.

- Flexure: Wool decreased the flexural modulus by ≈15–35%, but selected combinations (3–6 mm/5 wt.%) increased the flexural fracture stress by ≈35–45%.

- 3.

- Compression: The highest improvement was obtained for 3 mm/2 wt.% fibres, with an increase of ≈160% in compressive yield stress compared with neat epoxy.

- 4.

- Impact: All wool-filled composites exhibited reduced Charpy impact energy (≈75–93% decrease), with the least severe drop occurring for 3 mm/1 wt.%.

Overall, wool fibres can effectively modify the mechanical response of epoxy, offering improved tensile and compressive properties for selected fibre configurations, with potential use in non-structural or semi-structural components where sustainable materials are preferred.

Author Contributions

Conceptualization, G.G.-V. and Ó.R.-A.; methodology, Ó.R.-A.; validation, G.G.-V.; formal analysis, C.R.-D. and G.G.-V.; investigation, C.R.-D. and Ó.R.-A.; resources, G.G.-V.; data curation, Ó.R.-A.; writing—original draft preparation, C.R-D.; writing—review and editing, C.R.-D. and G.G.-V.; supervision, G.G.-V. and Ó.R.-A.; project administration, G.G.-V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors wish to thank engineering graduates from the University of Córdoba, Juan Montilla and Mario Vicente Sánchez, for their valuable assistance in specimen fabrication and mechanical testing.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- de Rancourt, M.; Fois, N.; Lavín, M.P.; Tchakérian, E.; Vallerand, F. Mediterranean Sheep and Goats Production: An Uncertain Future. Small Rumin. Res. 2006, 62, 167–179. [Google Scholar] [CrossRef]

- Zygoyiannis, D. Sheep Production in the World and in Greece. Small Rumin. Res. 2006, 62, 143–147. [Google Scholar] [CrossRef]

- Midolo, G.; Porto, S.M.C.; Cascone, G.; Valenti, F. Sheep Wool Waste Availability for Potential Sustainable Re-Use and Valorization: A GIS-Based Model. Agriculture 2024, 14, 872. [Google Scholar] [CrossRef]

- Lal, B.; Sharma, S.C.; Meena, R.L.; Sarkar, S.; Sahoo, A.; Balai, R.C.; Gautam, P.; Meena, B.P. Utilization of Byproducts of Sheep Farming as Organic Fertilizer for Improving Soil Health and Productivity of Barley Forage. J. Environ. Manag. 2020, 269, 110765. [Google Scholar] [CrossRef]

- Szczecina, J.; Niemiec, M.; Szatkowski, P. Using the Natural Properties of Sheep Wool in the Design of Drought-Reducing Composites. Anim. Sci. Genet. 2025, 21, 65–74. [Google Scholar] [CrossRef]

- European Commission. Life Greenwoolf—Green Hydrolysis Conversion of Wool Wastes into Organic Nitrogen Fertilisers (LIFE12 ENV/IT/000439) 2012; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Zheljazkov, V.D.; Stratton, G.W.; Pincock, J.; Butler, S.; Jeliazkova, E.A.; Nedkov, N.K.; Gerard, P.D. Wool-Waste as Organic Nutrient Source for Container-Grown Plants. Waste Manag. 2009, 29, 2160–2164. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Action Plan 2020; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Ismadi; Amin, Y.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Nurindah; Iswanto, A.H.; et al. A Comprehensive Review on Natural Fibers: Technological and Socio-Economical Aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural Fiber–Reinforced Composites: A Review on Material, Manufacturing, and Machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- May, C. (Ed.) Epoxy Resins: Chemistry and Technology, 2nd ed.; Routledge: New York, NY, USA, 2018; ISBN 978-0-203-75671-3. [Google Scholar]

- Petrie, E.M. Epoxy Adhesive Formulations; McGraw-Hill Professional: New York, NY, USA, 2005. [Google Scholar]

- Sam-Daliri, O.; Jiang, Y.; Flaherty, D.; Walls, M.; Kennedy, C.; Flanagan, M.; Ghabezi, P.; Finnegan, W. Mechanical Analysis of Unidirectional Glass Fibre Reinforced Epoxy Composite Joints Manufactured by Adhesive Bonding and Co-Curing Techniques. Mater. Des. 2025, 258, 114739. [Google Scholar] [CrossRef]

- Hudson, T.B.; Georgiou, N.A.; Smith, A.J.; Cano, R.J.; Kang, J.H. Co-Bonding of Aerospace Composite Joints with Reflowable Adherend Interfaces. J. Compos. Mater. 2025. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A Review on Natural Fibre-Based Composites—Part II: Application of Natural Reinforcements in Composite Materials for Automotive Industry. J. Nat. Fibers 2005, 1, 23–65. [Google Scholar] [CrossRef]

- Zolfakkar, M.; El-Tayeb, N.; Halawa, T. Towards Sustainable Composites: Evaluation of Mechanical Properties, Erosion Behavior and Applications of Natural Fiber-Epoxy Composites. J. Compos. Mater. 2024, 58, 2151–2168. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance Evaluation and Research of Alternative Thermal Insulations Based on Sheep Wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Patrucco, A.; Zoccola, M.; Anceschi, A. Exploring the Potential Applications of Wool Fibers in Composite Materials: A Review. Polymers 2024, 16, 2360. [Google Scholar] [CrossRef]

- Semitekolos, D.; Pardou, K.; Georgiou, P.; Koutsouli, P.; Bizelis, I.; Zoumpoulakis, L. Investigation of Mechanical and Thermal Insulating Properties of Wool Fibres in Epoxy Composites. Polym. Polym. Compos. 2021, 29, 1412–1421. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B. Effects of Fiber Length and Fiber Orientation Distributions on the Tensile Strength of Short-Fiber-Reinforced Polymers. Compos. Sci. Technol. 1996, 56, 1179–1190. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile Properties of Fibre-Reinforced Metals: Copper/Tungsten and Copper/Molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Thomason, J.L.; Rudeiros-Fernández, J.L. A Review of the Impact Performance of Natural Fiber Thermoplastic Composites. Front. Mater. 2018, 5, 60. [Google Scholar] [CrossRef]

- Thomason, J. The Influence of Fibre Cross Section Shape and Fibre Surface Roughness on Composite Micromechanics. Micro 2023, 3, 353–368. [Google Scholar] [CrossRef]

- Islam, A.; Ahamed, B.; Saifullah, A.; Bhuiyan, A.H.; Haq, E.; Sayeed, A.; Dhakal, H.N.; Sarker, F. Response of Short Jute Fibre Preform Based Epoxy Composites Subjected to Low-Velocity Impact Loadings. Compos. Part C Open Access 2024, 14, 100488. [Google Scholar] [CrossRef]

- UNE-EN ISO 527-1:2020; Plastics—Determination of Tensile Properties—Part 1: General Principles (ISO 527-1:2019). AENOR Asociación Española de Normalización: Madrid, Spain, 2020.

- UNE-EN ISO 527-4:2024; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites (ISO 527-4:2023). AENOR Asociación Española de Normalización: Madrid, Spain, 2024.

- UNE-EN ISO 178-1:2020; Plastics—Plastics—Determination of Flexural Properties (ISO 178:2019). AENOR Asociación Española de Normalización: Madrid, Spain, 2020.

- UNE-EN ISO 604:2003; Plastics—Determination of Compressive Properties (ISO 604:2002). AENOR Asociación Española de Normalización: Madrid, Spain, 2003.

- UNE-EN ISO 179-1:2024; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test (ISO 179-1:2023). AENOR Asociación Española de Normalización: Madrid, Spain, 2024.

- Lubineau, G.; Alfano, M.; Tao, R.; Wagih, A.; Yudhanto, A.; Li, X.; Almuhammadi, K.; Hashem, M.; Hu, P.; Mahmoud, H.A.; et al. Harnessing Extrinsic Dissipation to Enhance the Toughness of Composites and Composite Joints: A State-of-the-Art Review of Recent Advances. Adv. Mater. 2024, 36, 2407132. [Google Scholar] [CrossRef]

- Nagaraja, S.; Anand, P.B.; K, M.K.; Ammarullah, M.I. Synergistic Advances in Natural Fibre Composites: A Comprehensive Review of the Eco-Friendly Bio-Composite Development, Its Characterization and Diverse Applications. RSC Adv. 2024, 14, 17594–17611. [Google Scholar] [CrossRef]

- Larsson, R.; Brambati, G.; Gutkin, R. Compressive Failure and Kink-Band Formation Modeling. Eur. J. Mech.-A/Solids 2023, 99, 104909. [Google Scholar] [CrossRef]

- Thomason, J.L. The Influence of Fibre Length, Diameter and Concentration on the Impact Performance of Long Glass-Fibre Reinforced Polyamide 6,6. Compos. Part A Appl. Sci. Manuf. 2009, 40, 114–124. [Google Scholar] [CrossRef]

- Aliotta, L.; Lazzeri, A. A Proposal to Modify the Kelly-Tyson Equation to Calculate the Interfacial Shear Strength (IFSS) of Composites with Low Aspect Ratio Fibers. Compos. Sci. Technol. 2020, 186, 107920. [Google Scholar] [CrossRef]

- Seid, A.M.; Adimass, S.A. Review on the Impact Behavior of Natural Fiber Epoxy Based Composites. Heliyon 2024, 10, e39116. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Mo, Z.; Chouw, N.; Jayaraman, K.; Xu, Z. A Critical Review on the Properties of Natural Fibre Reinforced Concrete Composites Subjected to Impact Loading. J. Build. Eng. 2023, 77, 107497. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Su, S.; Jiang, N. Prediction Models of Mechanical Properties of Jute/PLA Composite Based on X-Ray Computed Tomography. Polymers 2024, 16, 160. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).