Tensile and Flexural Behaviors of Basalt Textile Reinforced Sprayed Glass Fiber Mortar Composites

Abstract

1. Introduction

2. Experimental Program

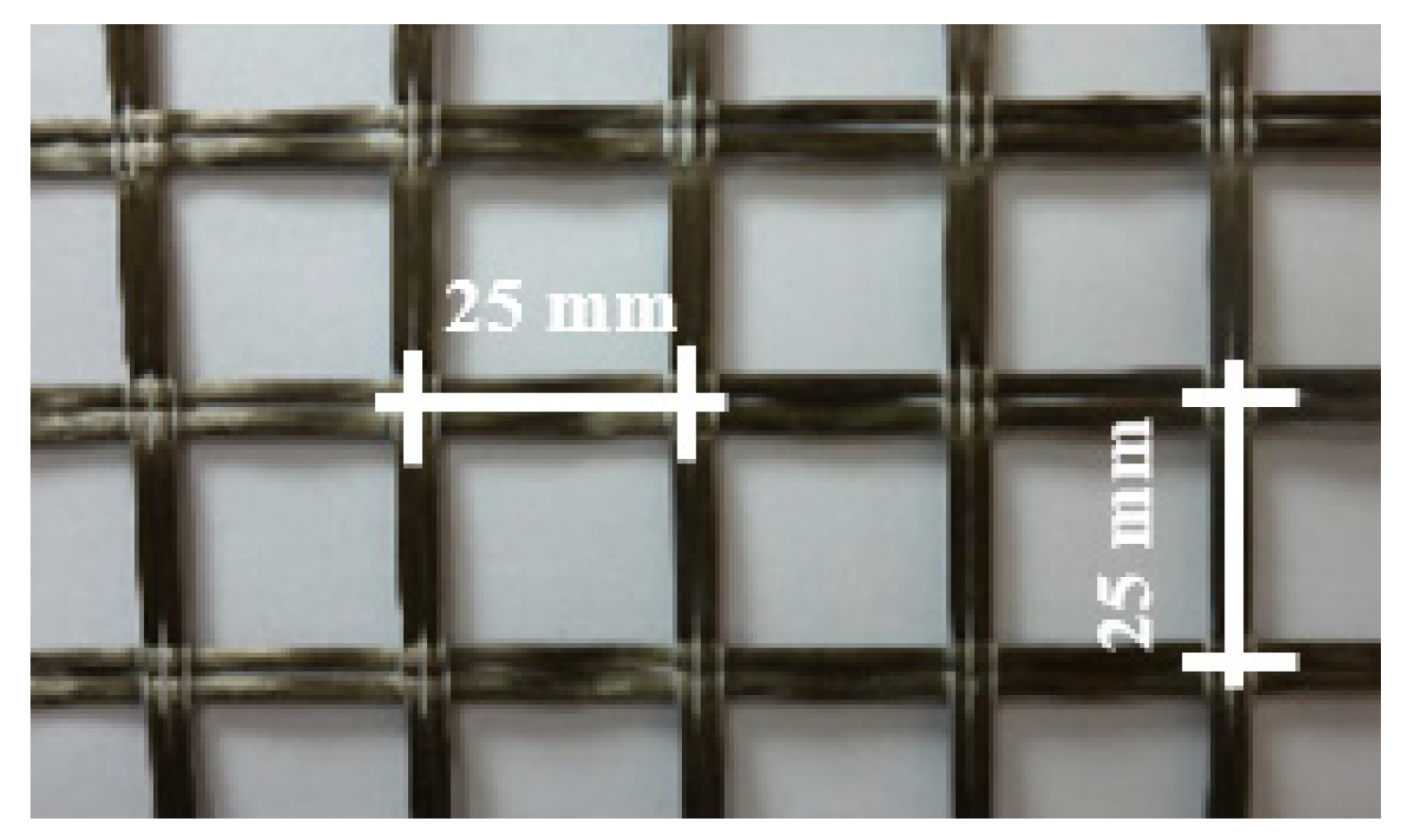

2.1. Materials

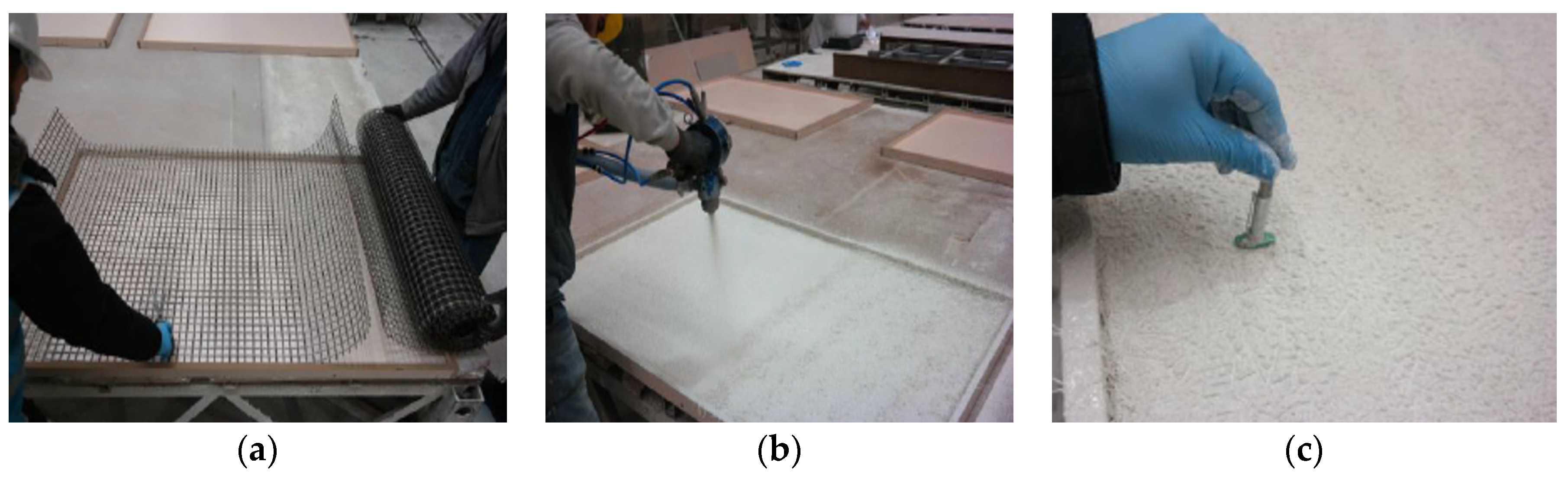

2.2. Preparation of Composite Samples

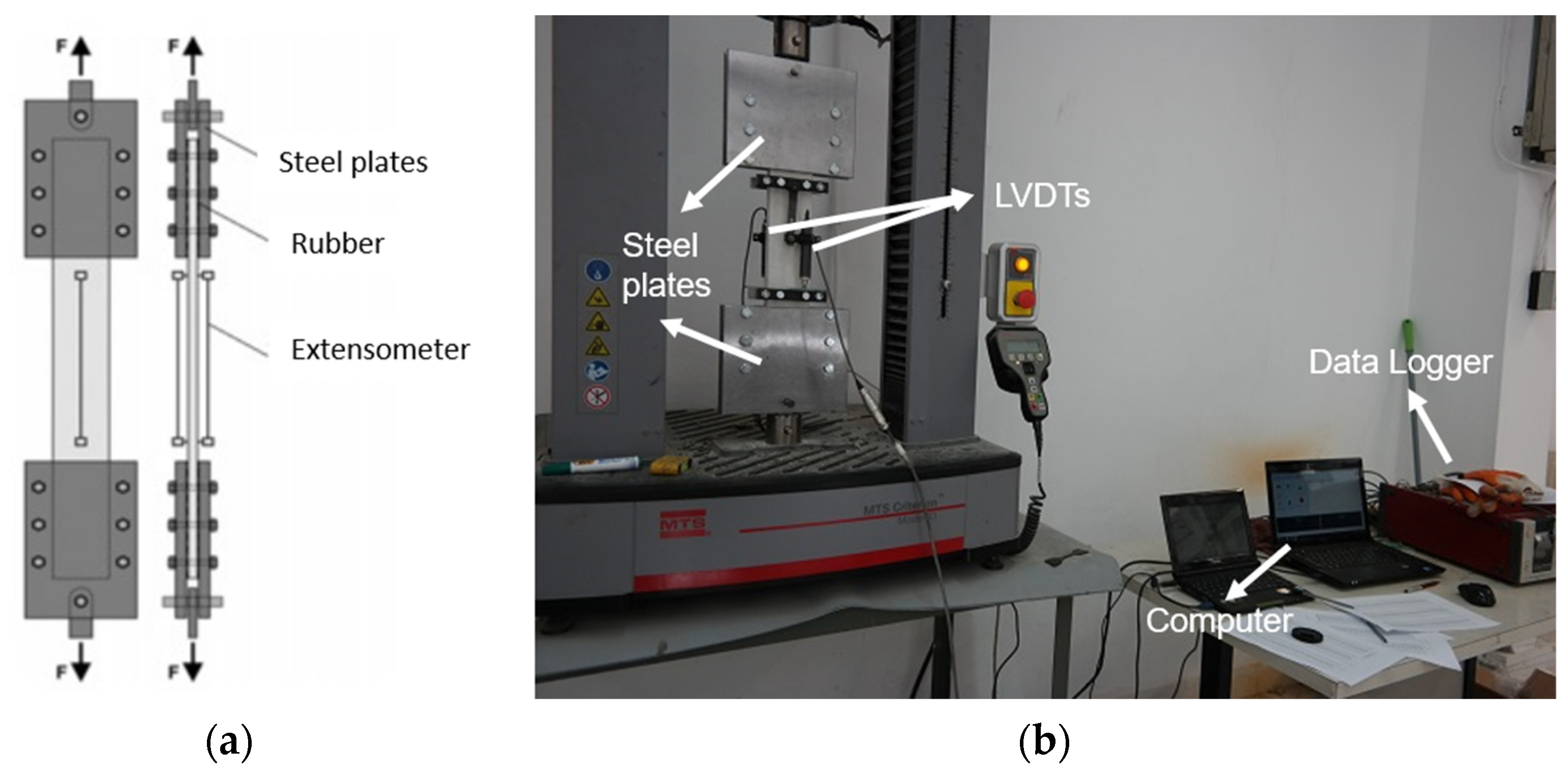

2.3. Tensile Test Procedure

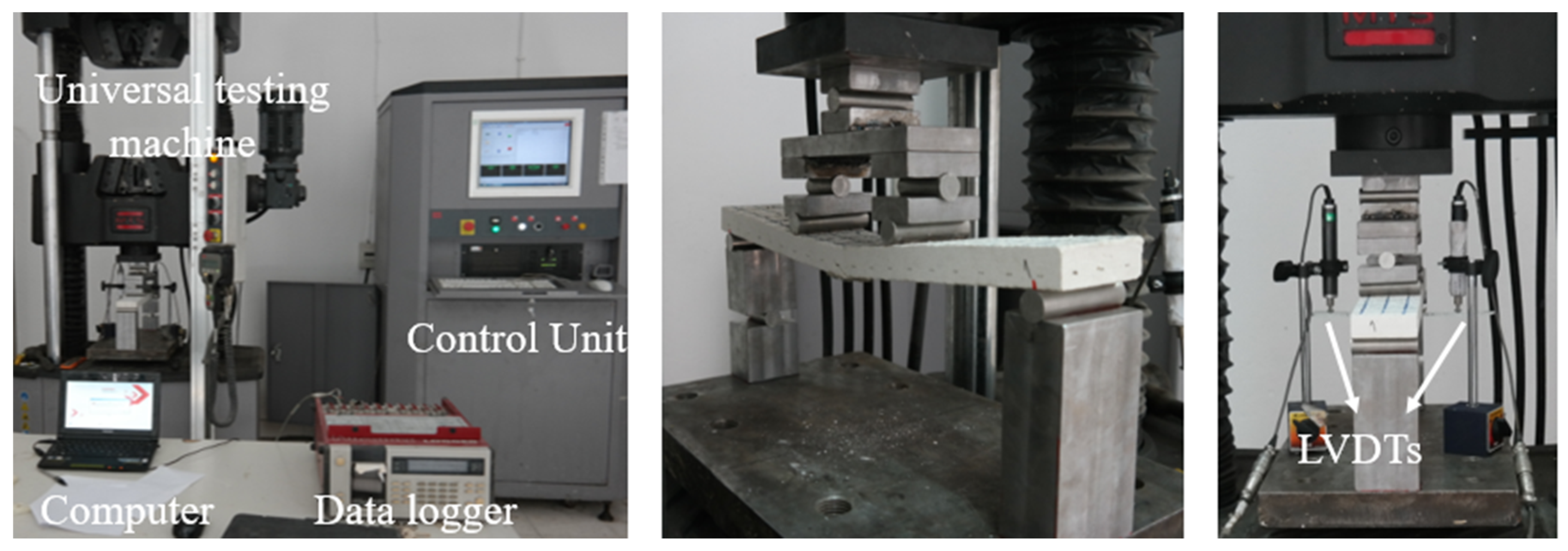

2.4. Flexural Test Procedure

3. Findings

3.1. Compressive Strength Test Findings

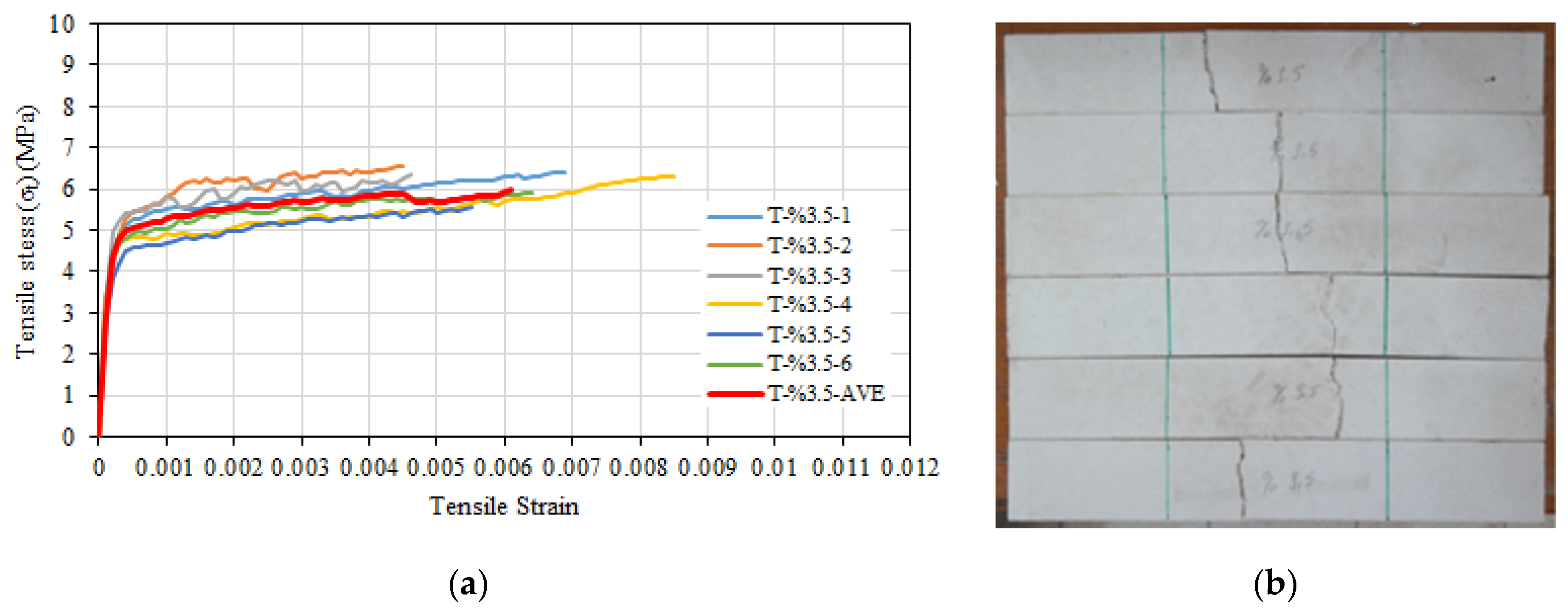

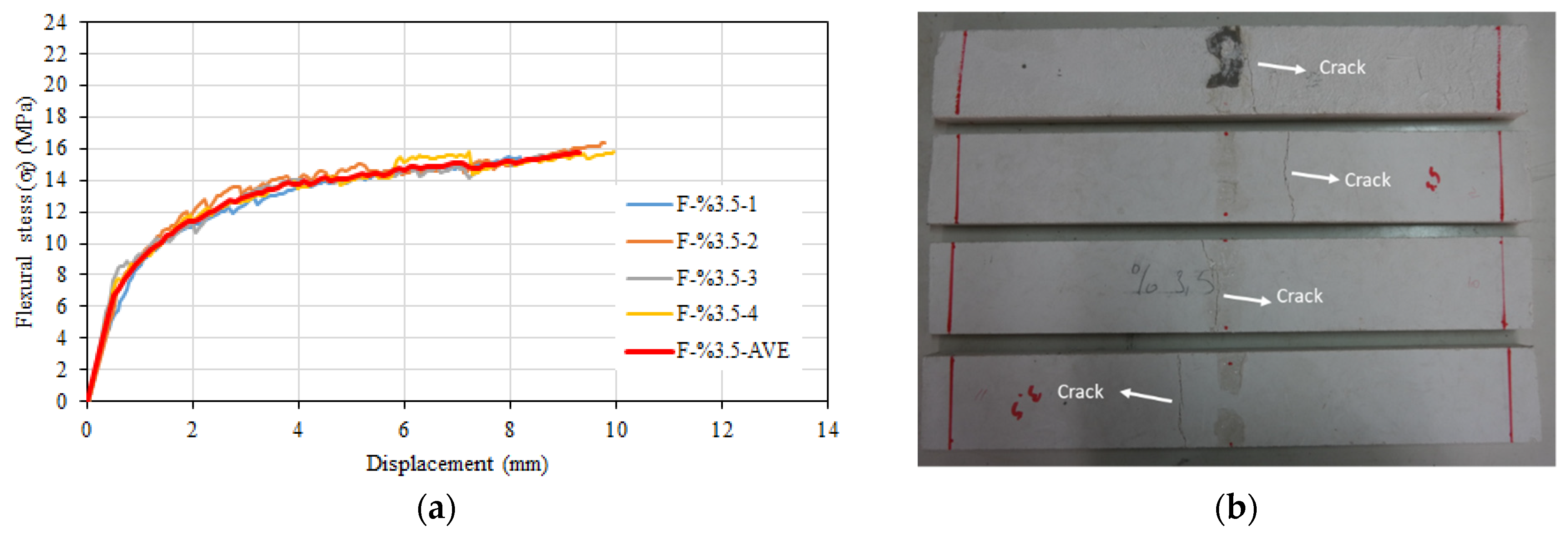

3.2. Tensile and Flexural Tests of Composite with 3.5% Glass Fiber

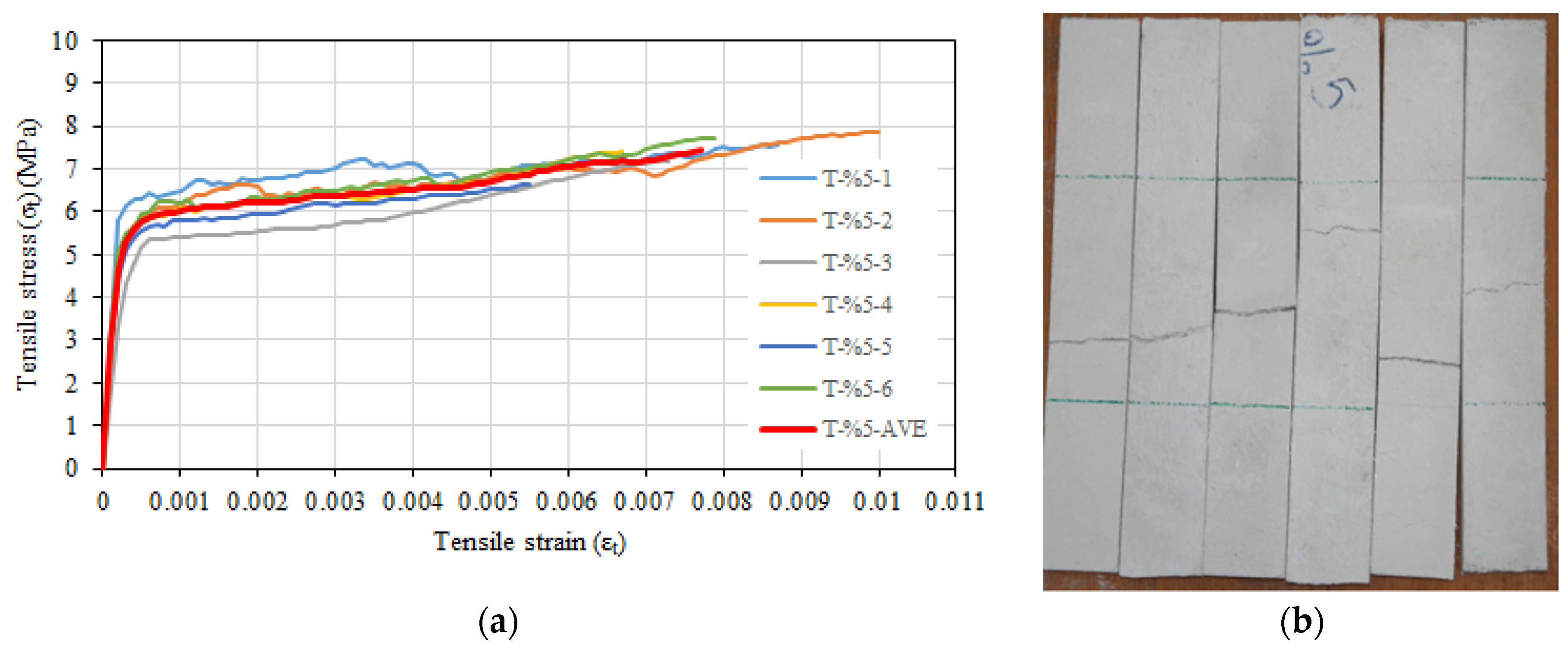

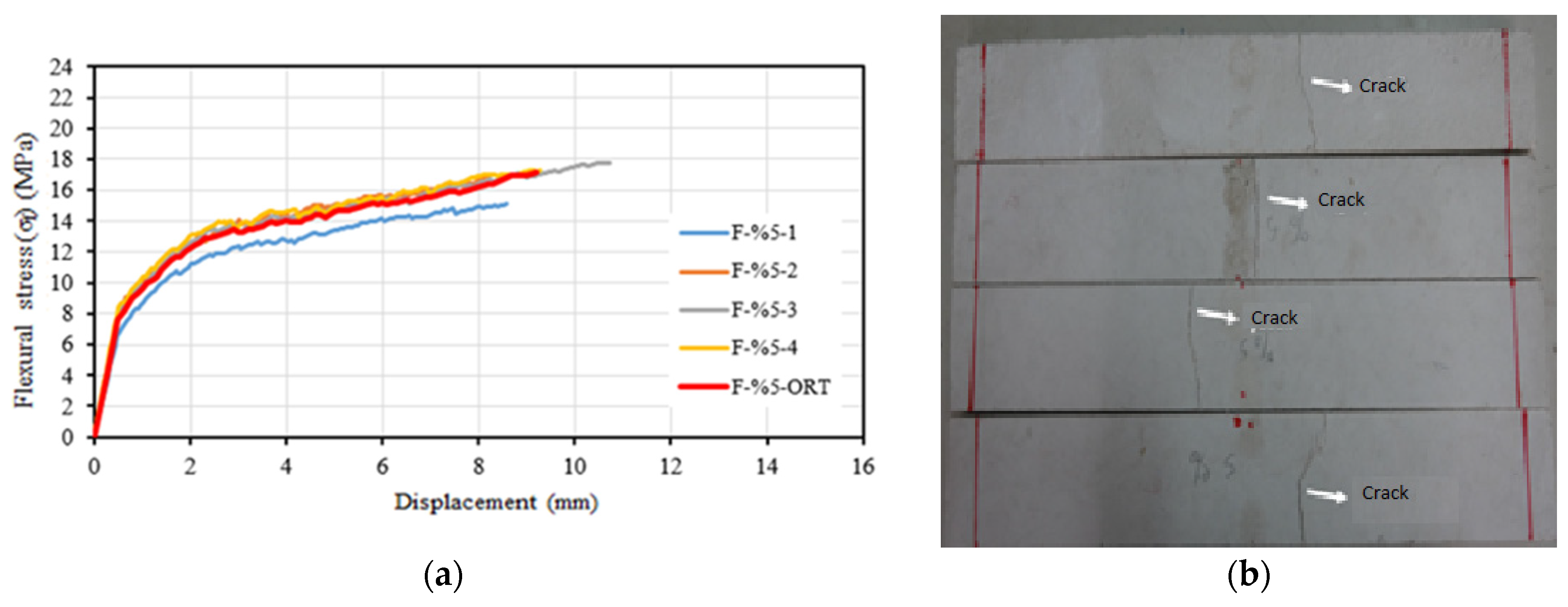

3.3. Tensile and Flexural Tests of Composite with 5% Glass Fiber

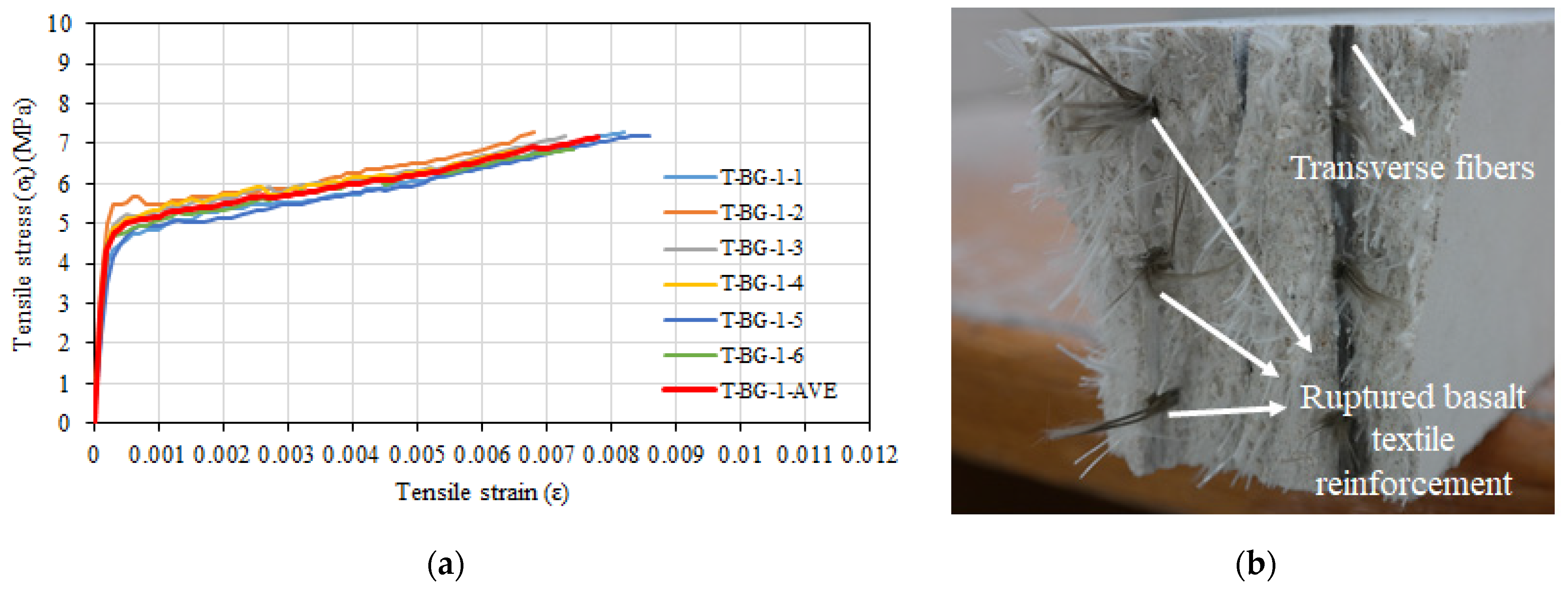

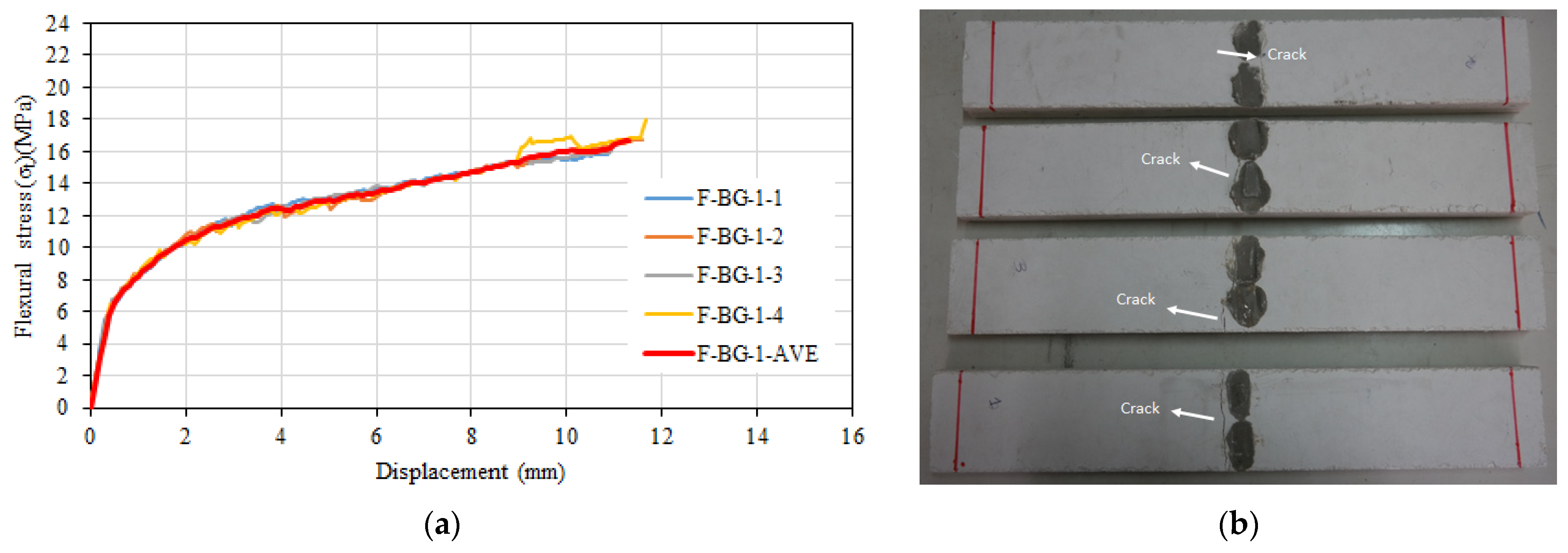

3.4. Tensile and Flexural Tests of Composites with 3.5% Glass Fiber and One Layer of Basalt Textile Reinforcement

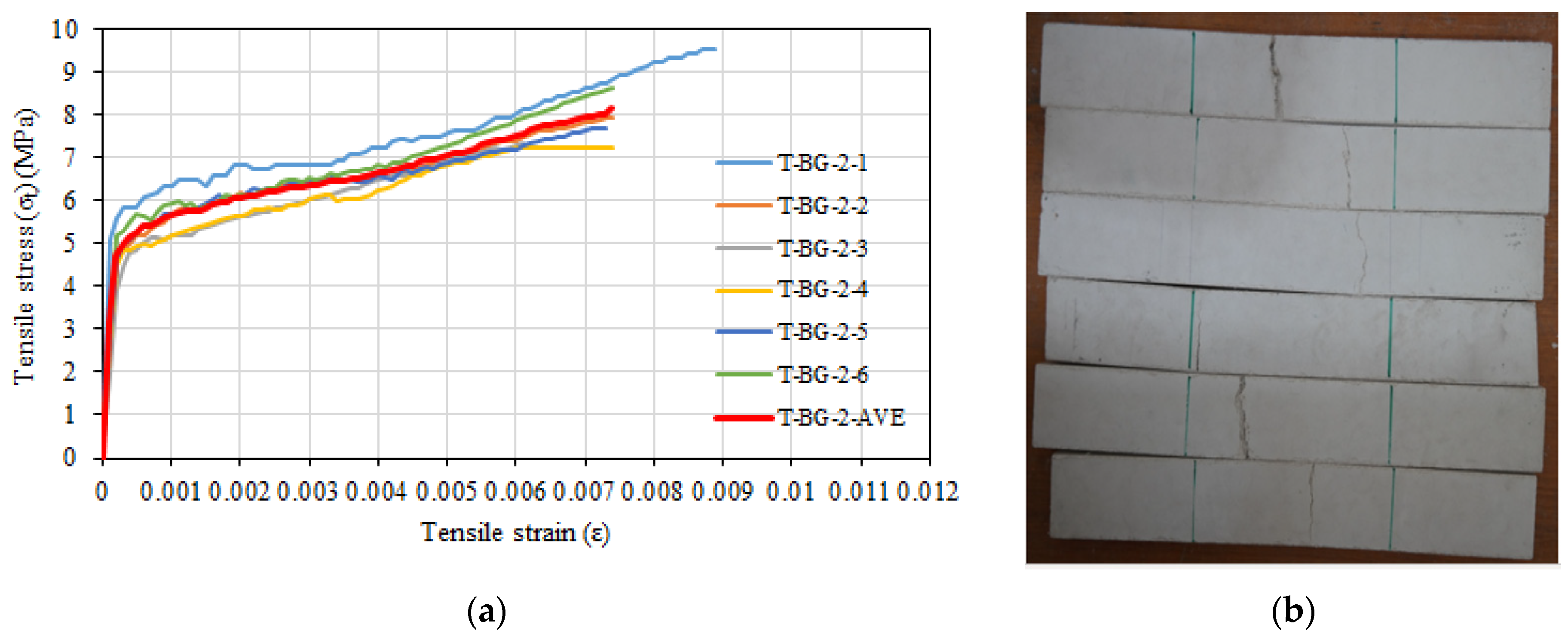

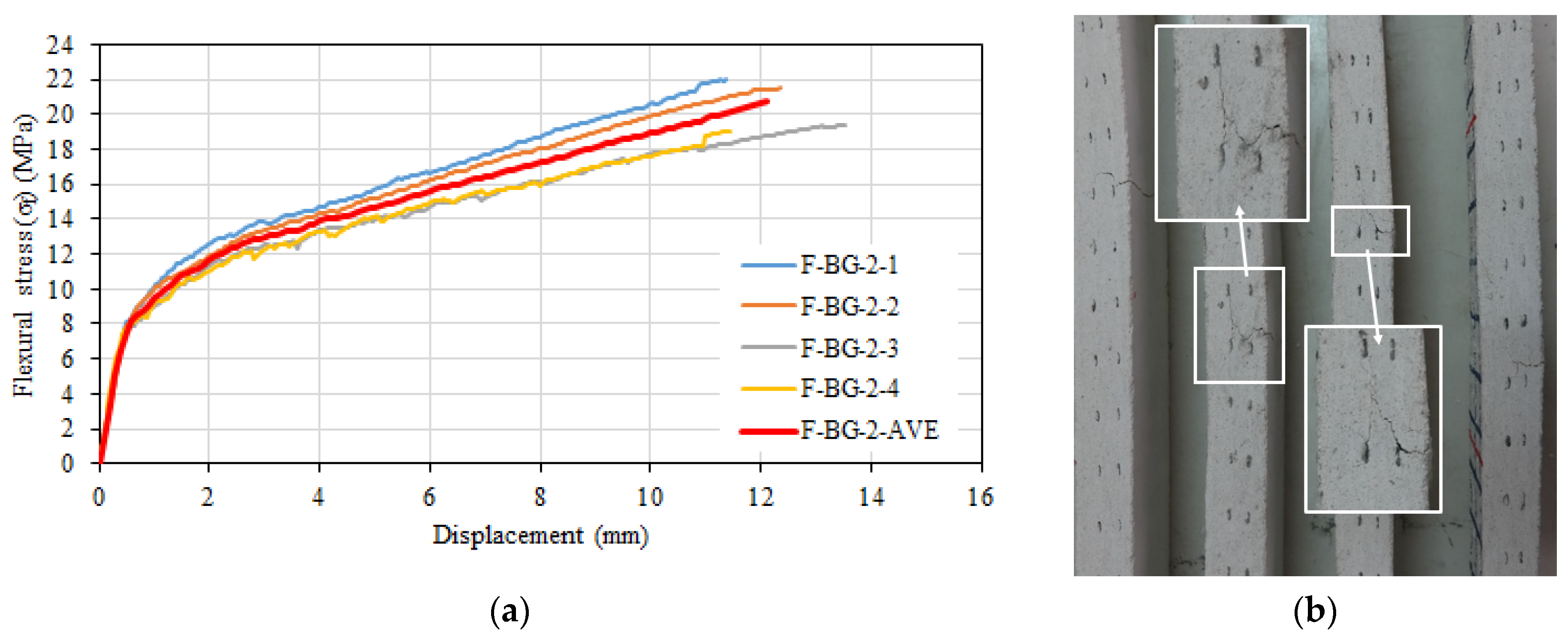

3.5. Tensile and Flexural Tests of Composite with 3.5% Glass Fiber and Two Layers of Basalt Textile Reinforcement

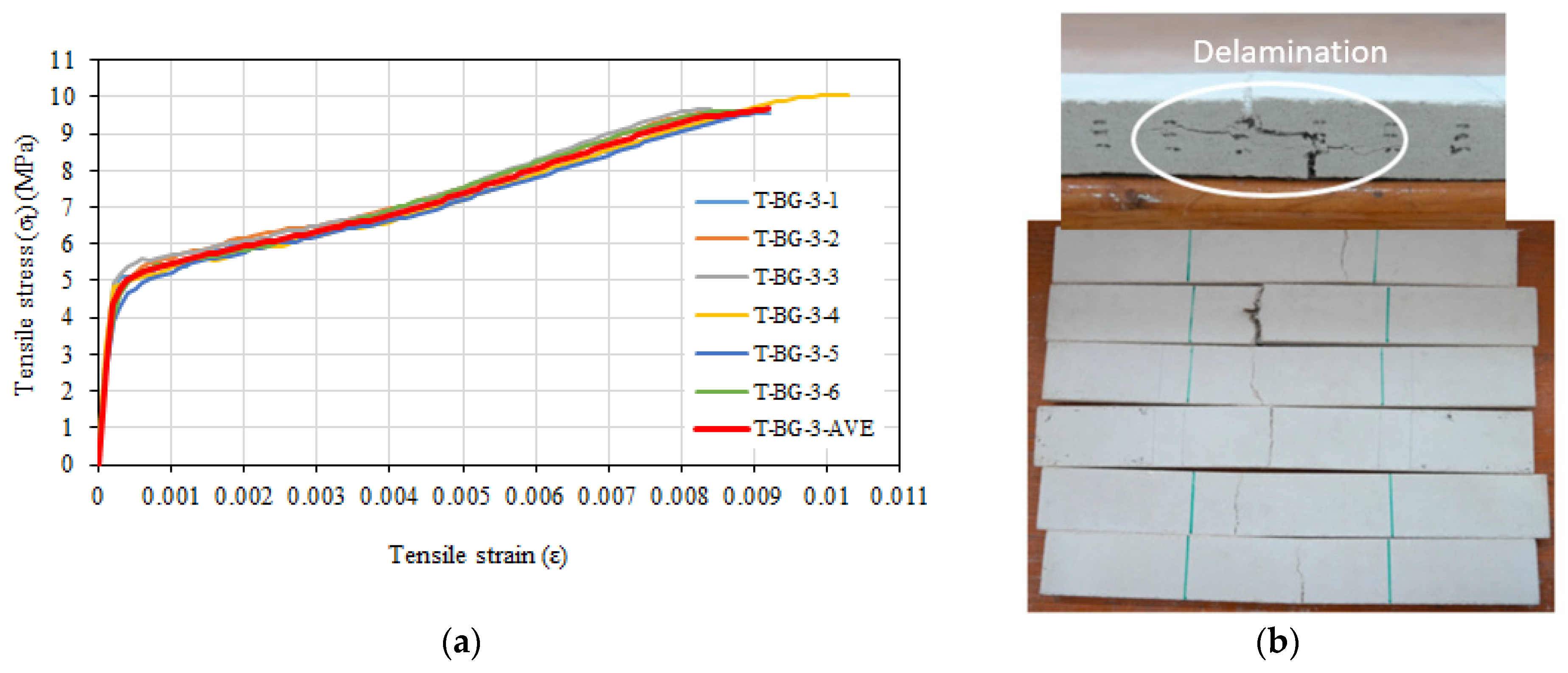

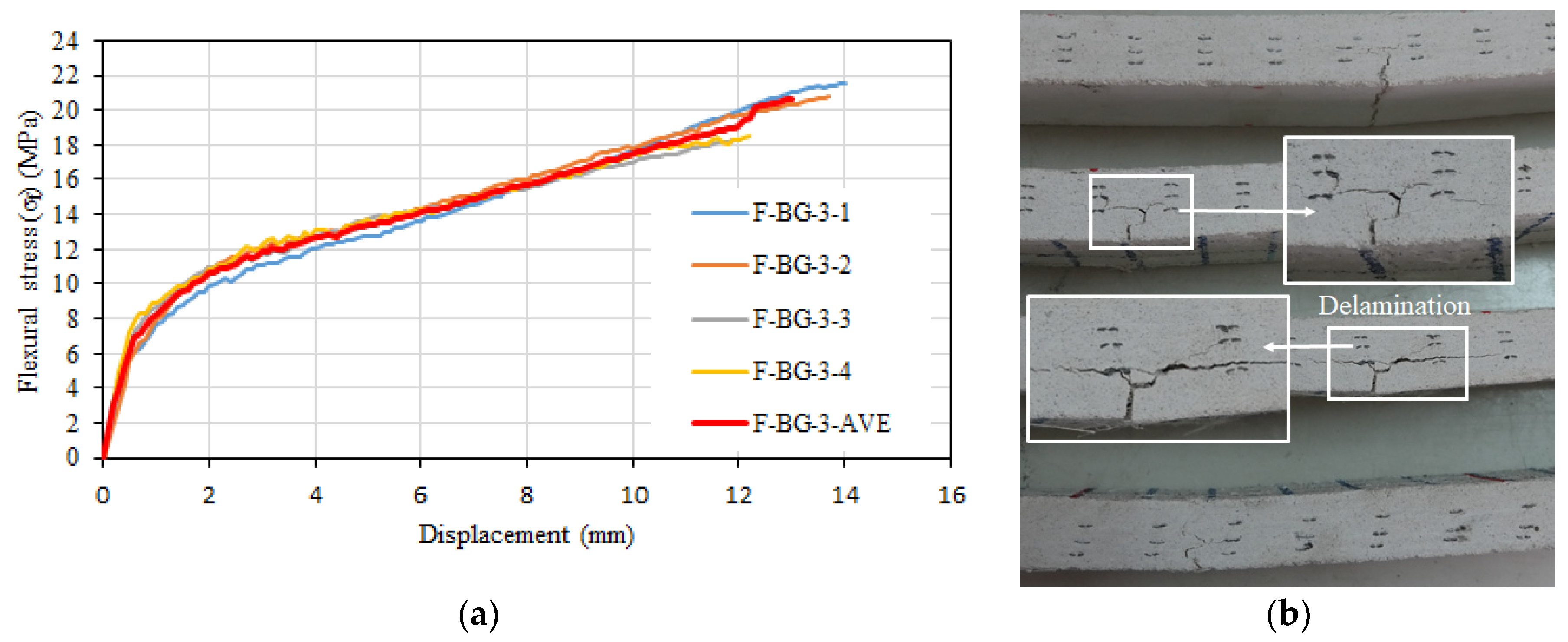

3.6. Tensile and Flexural Tests of Composite with 3.5% Glass Fiber and Three Layer of Basalt Textile Reinforcement

4. Discussion

4.1. Tensile Behavior

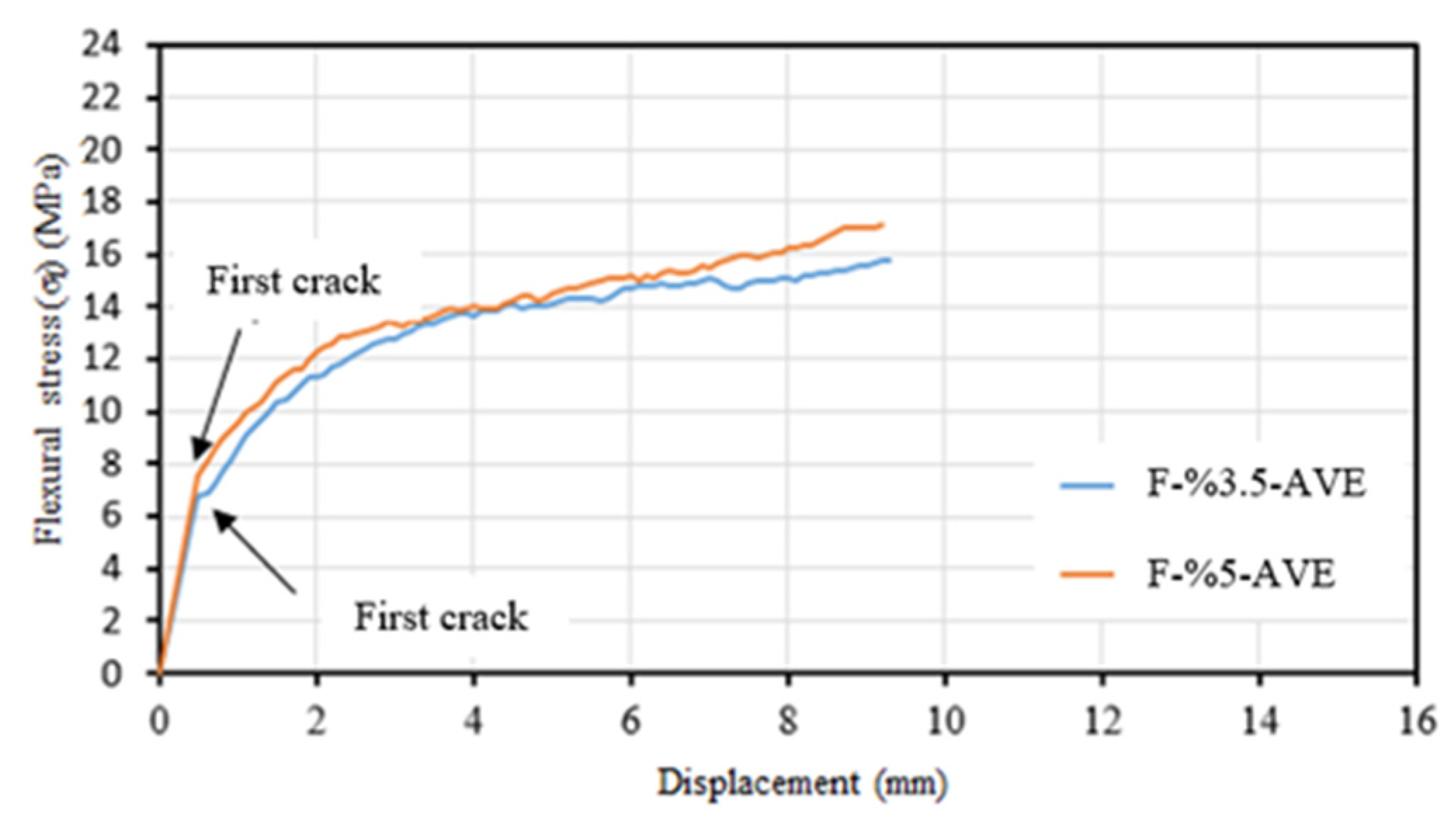

4.2. Flexural Behavior

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Durmaz, B. Bearing Strength of Fiber Reinforced Concrete Under Local Pressure. Master’s Thesis, University of Firat, Elazığ, Türkiye, 2007. [Google Scholar]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Türker, S.; Balanlı, A. Building Materials; University of Yıldız Technical: İstanbul, Türkiye, 1992; pp. 45–72. (In Turkish) [Google Scholar]

- Zhang, X.; Liu, J. Viscoelastic creep properties and mesostructure modeling of basalt fiber-reinforced asphalt concrete. Constr. Build. Mater. 2020, 259, 119680. [Google Scholar] [CrossRef]

- Parra-Montesinos, G.J. High-performance fiber-reinforced cement composites: An alternative for seismic design of structures. ACI Struct. J. 2005, 102, 668. [Google Scholar]

- Büyüköztürk, O.; Lau, D. High Performance Concrete: Fundamentals and Application; Massachusetts Institute of Technology: Cambridge, MA, USA, 2002. [Google Scholar]

- Militký, J.; Kovačič, V.R.; Rubnerova, J. Influence of thermal treatment on tensile failure of basalt fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Novitskii, A.G. High-temperature heat-insulating materials based on fibers from basalt-type rock materials. Refract. Ind. Ceram. 2004, 45, 144–146. [Google Scholar] [CrossRef]

- Hilles, M.M.; Ziara, M.M. Mechanical behavior of high strength concrete reinforced with glass fiber. Eng. Sci. Technol. Int. J. 2019, 22, 920–928. [Google Scholar] [CrossRef]

- Ates, A.O.; Khoshkholghi, S.; Tore, E.; Marasli, M.; Ilki, A. Sprayed glass fiber–reinforced mortar with or without basalt textile reinforcement for jacketing of low-strength concrete prisms. J. Compos. Constr. 2019, 23, 04019003. [Google Scholar] [CrossRef]

- Arboleda, D.; Carozzi, F.G.; Nanni, A.; Poggi, C. Testing procedures for the uniaxial tensile characterization of fabric reinforced cementitious matrix (FRCM) composites. J. Compos. Constr. 2016, 20, 04015063. [Google Scholar] [CrossRef]

- Hojdys, Ł.; Krajewski, P. Tensile Behaviour of FRCM Composites for Strengthening of Masonry Structures—An Experimental Investigation. Materials 2021, 14, 3626. [Google Scholar] [CrossRef]

- Carloni, C.; Mazzotti, C.; Savoia, M.; Subramaniam, K.V. Confinement of masonry columns with PBO FRCM composites. In Key Engineering Materials; Trans. Tech. Publications Ltd.: Pfäffikon, Switzerland, 2015; pp. 644–651. [Google Scholar]

- Fossetti, M.; Minafò, G. Strengthening of masonry columns with BFRCM or with steel wires: An experimental study. Fibers 2016, 4, 15. [Google Scholar] [CrossRef]

- Maddaloni, G.; Cascardi, A.; Balsamo, A.; Di Ludovico, M.; Micelli, F.; Aiello, M.A.; Prota, A. Confinement of full-scale masonry columns with FRCM systems. In Key Engineering Materials; Trans. Tech. Publications Ltd.: Pfäffikon, Switzerland, 2017; pp. 374–381. [Google Scholar]

- Aiello, M.A.; Cascardi, A.; Ombres, L.; Verre, S. Confinement of masonry columns with the FRCM-system: Theoretical and experimental investigation. Infrastructures 2020, 5, 101. [Google Scholar] [CrossRef]

- Prota, A.; Marcari, G.; Fabbrocino, G.; Manfredi, G.; Aldea, C. Experimental in-plane behavior of tuff masonry strengthened with cementitious matrix–grid composites. J. Compos. Constr. 2006, 10, 223–233. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Karlos, K.; Papathanasiou, M. Textile-reinforced mortar (TRM) versus FRP as strengthening material of URM walls: In-plane cyclic loading. Mater. Struct. 2007, 40, 1081–1097. [Google Scholar] [CrossRef]

- Augenti, N.; Parisi, F.; Prota, A.; Manfredi, G. In-plane lateral response of a full-scale masonry subassemblage with and without an inorganic matrix-grid strengthening system. J. Compos. Constr. 2011, 15, 578–590. [Google Scholar] [CrossRef]

- Parisi, F.; Iovinella, I.; Balsamo, A.; Augenti, N.; Prota, A. In-plane behaviour of tuff masonry strengthened with inorganic matrix–grid composites. Compos. Part B Eng. 2013, 45, 1657–1666. [Google Scholar] [CrossRef]

- Kałuża, M.; Galman, I.; Kubica, J.; Agneloni, C. Diagonal tensile strength of AAC blocks masonry with thin joints superficially strengthened by reinforced using GFRP net plastering. In Key Engineering Materials; Trans. Tech. Publications Ltd.: Pfäffikon, Switzerland, 2015; pp. 363–370. [Google Scholar]

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile reinforced mortar (TRM) versus FRP as strengthening material of URM walls: Out-of-plane cyclic loading. Mater. Struct. 2008, 41, 143–157. [Google Scholar] [CrossRef]

- Papanicolaou, C.; Triantafillou, T.; Lekka, M. Externally bonded grids as strengthening and seismic retrofitting materials of masonry panels. Constr. Build. Mater. 2011, 25, 504–514. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; Da Porto, F.; Garbin, E.; Panizza, M. Out-of-plane behaviour of infill masonry panels strengthened with composite materials. Mater. Struct. 2014, 47, 2131–2145. [Google Scholar] [CrossRef]

- Bellini, A.; Incerti, A.; Bovo, M.; Mazzotti, C. Effectiveness of FRCM reinforcement applied to masonry walls subject to axial force and out-of-plane loads evaluated by experimental and numerical studies. Int. J. Archit. Herit. 2018, 12, 376–394. [Google Scholar] [CrossRef]

- Bednarz, Ł.; Górski, A.; Jasieńko, J.; Rusiński, E. Simulations and analyses of arched brick structures. Autom. Constr. 2011, 20, 741–754. [Google Scholar] [CrossRef]

- Garmendia, L.; Larrinaga, P.; García, D.; Marcos, I. Textile-reinforced mortar as strengthening material for masonry arches. Int. J. Archit. Herit. 2014, 8, 627–648. [Google Scholar] [CrossRef]

- Hojdys, Ł.; Krajewski, P. Laboratory tests on masonry vaults with backfill strengthened at the extrados. In Key Engineering Materials; Trans. Tech. Publications Ltd.: Pfäffikon, Switzerland, 2015; pp. 510–517. [Google Scholar]

- Giamundo, V.; Lignola, G.; Maddaloni, G.; Balsamo, A.; Prota, A.; Manfredi, G. Experimental investigation of the seismic performances of IMG reinforcement on curved masonry elements. Compo. Part B Engin. 2015, 70, 53–63. [Google Scholar] [CrossRef]

- Hojdys, L.; Krajewski, P. Glass fiber grids embedded in a cement-based matrix as strengthening of masonry structures. In Structural Analysis of Historical Constructions: Anamnesis, Diagnosis, Therapy, Controls; CRC Press: London, UK, 2016; pp. 372–376. [Google Scholar]

- Banholzer, B. Bond Behavior of Multi-Filament Yarn Embedded in a Cementitious Matrix. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2004. [Google Scholar]

- Hinzen, M.; Brameshuber, W. Improvement of serviceability and strength of textile reinforced concrete by using short fibres. In Proceedings of the 4th Colloquium on Textile Reinforced Structures (CTRS4), Dresden, Germany, 3–6 May 2009; Technische Universität Dresden: Dresden, Germany, 2009; pp. 261–272. [Google Scholar]

- Barhum, R.; Mechtcherine, V. Effect of short fibers on the behavior of textile reinforced concrete under tensile loading. In High Performance Fiber Reinforced Composites; Parra-Montesinos, G.J., Reinhard, H.W., Namaan, A.E., Eds.; Springer: Dordrecht, The Netherlands, 2012; pp. 487–494. [Google Scholar]

- Blazy, J.; Blazy, R.; Drobiec, L. Glass Fiber Reinforced Concrete as a Durable and Enhanced Material for Structural and Architectural Elements in Smart City—A Review. Materials 2022, 15, 2754–63. [Google Scholar] [CrossRef]

- ASTM_C150-07; Standard Specification for Portland Cement. American Society for Testing and Materials: West Conshohocken, PE, USA, 2012.

- ACI_Committee_363; State-of-the-Art Report on High-strength Concrete (ACI 363R-84). American Concrete Institute: Farmington Hills, MI, USA, 1984.

- Kosmatka, S.H.; Panarese, W.C.; Kerkhoff, B. Design and Control of Concrete Mixtures; Portland Cement Association: Skokie, IL, USA, 2002; Volume 5420. [Google Scholar]

- Deák, T.; Czigány, T. Chemical composition and mechanical properties of basalt and glass fibers: A comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- ASTM_C109/C109M-16a; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016.

- RILEM_Technical_Committee. Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete: Uniaxial tensile test: Test method to determine the load bearing behavior of tensile specimens made of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; de Felice, G.; Focacci, F.; Hojdys, Ł.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M. Experimental investigation of tensile and bond properties of Carbon-FRCM composites for strengthening masonry elements. Compos. Part B Eng. 2017, 128, 100–119. [Google Scholar] [CrossRef]

- Leone, M.; Aiello, M.A.; Balsamo, A.; Carozzi, F.G.; Ceroni, F.; Corradi, M.; Gams, M.; Garbin, E.; Gattesco, N.; Krajewski, P. Glass fabric reinforced cementitious matrix: Tensile properties and bond performance on masonry substrate. Compos. Part B Eng. 2017, 127, 196–214. [Google Scholar] [CrossRef]

- ASTM_C947-03; Standard Test Method for Flexural Properties of Thin-Section Glass-Fiber-Reinforced Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016; p. 3.

- Ghugal, Y.M.; Deshmukh, S.B. Performance of alkali-resistant glass fiber reinforced concrete. J. Reinf. Plast. Compos. 2006, 25, 617–630. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Influence of polypropylene, glass and steel fiber on the thermal properties of concrete. Materials 2021, 14, 1888. [Google Scholar] [CrossRef]

- Kwan, A.; Chu, S. Direct tension behaviour of steel fibre reinforced concrete measured by a new test method. Eng. Struct. 2018, 176, 324–336. [Google Scholar] [CrossRef]

- Zhu, Z.-F.; Wang, W.-W.; Harries, K.A.; Zheng, Y.-Z. Uniaxial tensile stress-strain behavior of carbon-fiber grid-reinforced engineered cementitious composites. J. Compos. Constr. 2018, 22, 04018057. [Google Scholar] [CrossRef]

- Valeri, P.; Ruiz, M.F.; Muttoni, A. Modelling of textile reinforced concrete in bending and shear with elastic-cracked stress fields. Eng. Struct. 2020, 215, 110664. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V. Mechanical characterization of different FRCM systems for structural reinforcement. Constr. Build. Mater. 2017, 145, 565–575. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U. Effect of using multiple fabric plies on the tensile behaviour of carbon textile reinforced mortar. In Proceedings of the 8th Euro-American Congress Construction Pathology, Rehabilitation Technology and Heritage Management, Granada, Spain, 28 September 2020; pp. 2255–2261. [Google Scholar]

- Rambo, D.A.S.; de Andrade Silva, F.; Toledo Filho, R.D.; Gomes, O.d.F.M. Effect of elevated temperatures on the mechanical behavior of basalt textile reinforced refractory concrete. Mater. Des. 2015, 65, 24–33. [Google Scholar] [CrossRef]

- Portal, N.W. Usability of Textile Reinforced Concrete: Structural Performance, Durability and Sustainability; Chalmers University of Technology: Göteborg, Sweden, 2015. [Google Scholar]

- Kong, K.; Mesticou, Z.; Michel, M.; Larbi, A.S.; Junes, A. Comparative characterization of the durability behaviour of textile-reinforced concrete (TRC) under tension and bending. Compos. Struct. 2017, 179, 107–123. [Google Scholar] [CrossRef]

- Wang, W.; Konstantinidis, N.; Austin, S.A.; Buswell, R.A.; Cavalaro, S.; Cecinia, D. Flexural behaviour of AR-Glass textile reinforced 3D printed concrete beams. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication Digital Concrete, Online, 6–9 July 2020; Bos, F.P., Lucas, S.S., Wolfs, R.J.M., Salet, T.A.M., Eds.; 2020; pp. 728–737. [Google Scholar] [CrossRef]

- Wafa, F.F. Properties and applications of fiber reinforced concrete. JKAU Eng. Sci. 1990, 2, 49–63. [Google Scholar]

| Constituent/Property | White Portland Cement | Portland Cement | Deák et al. wt% [40] |

|---|---|---|---|

| SiO2 (%) | 17.95 | 19.34 | 42.43–55.69 |

| Al2O3 (%) | 2.98 | 4.55 | 14.21–17.97 |

| Fe2O3 (%) | 0.21 | 2.77 | 10.80–11.68 |

| CaO (%) | 59.40 | 62.43 | 7.43–8.88 |

| MgO (%) | 2.87 | 2.61 | 4.06–9.45 |

| SO3 (%) | 3.09 | 2.89 | <5 |

| Na2O (%) | 0.43 | 0.09 | <5 |

| K2O (%) | 0.36 | 0.74 | <5 |

| Loss on ignition (%) | 11.60 | 2.09 | - |

| Glass Fiber | Basalt Textile Reinforcement | |

|---|---|---|

| Fiber length | About 24 mm | - |

| Filament Diameter | 14 µm | 8–9 µm |

| Density | 2.8 g/cm3 | 2.62–2.65 g/cm3 |

| Modulus of Elasticity | 74 GPa | - |

| Tensile strength | 1500 MPa | 95 kN/m |

| Softening point | 860 °C | - |

| ZrO2 content | 17% | - |

| Surface weight | - | 303 g/m2 |

| Breaking strain | 2% | 5% |

| Mesh Size | - | 25 mm |

| Fiber Ratio in the Mortar (% by Weight) | Average Compressive Strength (MPa) | ||

|---|---|---|---|

| fc (MPa) | Std. Dev. | CoV | |

| 3.5 | 43.0 | 2.1 | 4.9 |

| 5.0 | 46.1 | 1.7 | 3.7 |

| σt (MPa) | εt | Euncracked (MPa) | Ecracked (MPa) | |

|---|---|---|---|---|

| Mean | 5.98 | 0.0061 | 27,692 | - |

| Standard deviation | 0.34 | 0.0015 | 2404 | - |

| Coefficient of variation (%) | 5.69 | 24.6 | 8.68 | - |

| σt (MPa) | εt | Euncracked (MPa) | Ecracked (MPa) | |

|---|---|---|---|---|

| Mean | 7.42 | 0.0077 | 26,916 | - |

| Standard deviation | 0.43 | 0.0016 | 5624 | - |

| Coefficient of variation (%) | 5.75 | 20.39 | 20.89 | - |

| σt (MPa) | εt | Eunracked (MPa) | Ecracked (MPa) | |

|---|---|---|---|---|

| Mean | 7.17 | 0.0078 | 26,463 | 396 |

| Standard deviation | 0.21 | 0.0007 | 4092 | 31 |

| Coefficient of Variation (%) | 2.93 | 8.97 | 15.5 | 7.8 |

| σt (MPa) | εt | Euncracked (MPa) | Ecracked (MPa) | |

|---|---|---|---|---|

| Mean | 8.16 | 0.0074 | 26,066 | 501 |

| Standard deviation | 0.88 | 0.0009 | 3205 | 80 |

| Coefficient of Variation (%) | 10.8 | 12.1 | 12.3 | 16 |

| σt (MPa) | εt | Euncracked (MPa) | Ecracked (MPa) | |

|---|---|---|---|---|

| Mean | 9.7 | 0.0091 | 27,404 | 554 |

| Standard deviation | 0.20 | 0.0006 | 2711 | 37 |

| Coefficient of Variation (%) | 2.06 | 6.59 | 9.9 | 6.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ates, A.O.; Durmuş, G.; Ilki, A. Tensile and Flexural Behaviors of Basalt Textile Reinforced Sprayed Glass Fiber Mortar Composites. Materials 2023, 16, 4251. https://doi.org/10.3390/ma16124251

Ates AO, Durmuş G, Ilki A. Tensile and Flexural Behaviors of Basalt Textile Reinforced Sprayed Glass Fiber Mortar Composites. Materials. 2023; 16(12):4251. https://doi.org/10.3390/ma16124251

Chicago/Turabian StyleAtes, Ali Osman, Gökhan Durmuş, and Alper Ilki. 2023. "Tensile and Flexural Behaviors of Basalt Textile Reinforced Sprayed Glass Fiber Mortar Composites" Materials 16, no. 12: 4251. https://doi.org/10.3390/ma16124251

APA StyleAtes, A. O., Durmuş, G., & Ilki, A. (2023). Tensile and Flexural Behaviors of Basalt Textile Reinforced Sprayed Glass Fiber Mortar Composites. Materials, 16(12), 4251. https://doi.org/10.3390/ma16124251