Abstract

This paper reports an evaluation of the properties of medium-quality concrete incorporating recycled coarse aggregate (RCA). Concrete specimens were prepared with various percentages of the RCA (25%, 50%, 75%, and 100%). The workability, mechanical properties, and durability in terms of abrasion of cured concrete were examined at different ages. The results reveal insignificant differences between the recycled concrete (RC) and reference concrete in terms of the mechanical and durability-related measurements. Meanwhile, the workability of the RC reduced vastly since the replacement of the RCA reached 75% and 100%. The ultrasound pulse velocity (UPV) results greatly depend on the porosity of concrete and the RC exhibited higher porosity than that of the reference concrete, particularly at the transition zone between the RCA and the new paste. Therefore, the sound transmission in the RC required longer times than that in the reference concrete. Moreover, a predictive equation relating the compressive strength to the UPV was developed.

1. Introduction

As the global population grows at a fast rate, there is a great demand for concrete to develop infrastructure, urbanization, and accommodation, leading to the depletion of raw materials and natural aggregates for the production of concrete and cement manufacturing. Consequently, population growth raises concerns about greenhouse emissions and energy consumption issues. In addition to the depletion of natural aggregates and raw materials for contemporary constructions, the construction and demolition waste (CDW) existing in old structures is an imperative problem. The amount of CDW is approximately 850 million tons in the European Union, while it is 250 million tons in the USA [1,2]. The CDW is mainly landfilled or used as sub-base material, particularly in developing countries, making it a profound burden and a challenging task for environmental protection. Cutting down the exploitation of natural aggregates and reusing the CDW in the concrete industry are solutions to the problem. As soon as quality control of waste management was introduced and grew, a decrease in contamination was noticed [3]. The results show that the use of RCA from concrete significantly reduced the environmental impacts as well as the costs of the construction materials. Cement was the main contributor to both impacts [4]. Economic models were developed to show that the optimization of prices depends on: the price of demolition, transport costs, price of recycling, labor costs, and price of natural materials. The production of concrete with recycled aggregates was the most cost-effective in the case of parallel recycling of other materials and simultaneous clearing of the CDW [3].

There have been many attempts to produce RCA and recycled fine aggregate in the concrete industry. The properties of concrete containing ceramic waste aggregate and coal waste powder have been investigated [5,6]. These materials reduced greenhouses gases and showed the highest positive impact on the global warming index [5]. The red ceramics fine aggregate and artificial expanded clay coarse aggregate were used in the concrete mixture [7]. This paper analyses the surface resistivity (SR) and bulk resistivity (BR) of structural lightweight waste aggregate concrete (SLWAC) [7]. Recently, RCA was recommended for use in pavement construction (sub-base, anti-freeze layer, and sub-grade) and regular construction (as concrete, precast, and backfill), as well as for raising the ground level and for covering with soil [8]. Therefore, investigated the properties of medium-quality concrete incorporating RCA are investigated in this paper.

Lofty and Al-Fayez [1] found that replacement of the RCA by 10 to 30% and the recycled fine aggregate by 10 to 20% improved the mechanical properties and durability of concrete. The use of 50% RCA in recycled concrete (RC) provided similar durability as the reference concrete. Meanwhile, Andreu and Mirren [9] suggested 100% replacement of the natural coarse aggregate (NCA) by RCA to obtain high-performance concrete. However, the greater replacement of RCA by CDW led to higher adverse effects on concrete in terms of porosity and vulnerability [10,11,12,13,14]. The properties of concrete made using the CDW could be improved by using different techniques such as treating the CDW before using it [15,16,17], incorporating supplementary cementitious materials, or using nanosilica materials [18,19,20]. Moreover, the source and properties of the recycled materials can change the structural performance of concrete [21,22,23]. The RCA was produced from three different sources, including medium-strength concrete, high-performance concrete, and natural aggregate [23]. The results show that concrete with natural aggregates has a higher strength than that with the RC. Moreover, the recycled aggregate concrete at medium strength contains a loose and porous interfacial zone, while the dense interfacial zone was found in the high-performance concrete. The effect of the curing conditions on the performance of hardened concrete was studied in [24,25,26]. Notably, the RCA had a higher water demand than the natural aggregates, which led to reductions in the workability and durability of the RC.

The influence of the RCA on the RC properties was investigated in previous studies. However, more experimental investigations are still needed at different ages. Moreover, un-destructive tests must be conducted on the RC and evaluations of the compressive strength. Therefore, this paper reports evaluations of the mechanical properties and durability in terms of the abrasion of medium-quality concrete incorporating RCA at different ages. Concrete specimens were fabricated with various percentages of RCA (25%, 50%, 75%, and 100%).

2. Experimental Methodology

2.1. Materials

The specifications of the materials used in this study were tested by the authors. Ordinary Portland Cement (OPC), specified by ASTM C 150 [27], was used. Table 1 and Table 2 present the physical properties and chemical compositions of the used OPC, respectively.

Table 1.

Physical properties of OPC.

Table 2.

Chemical components of the OPC (unit: %).

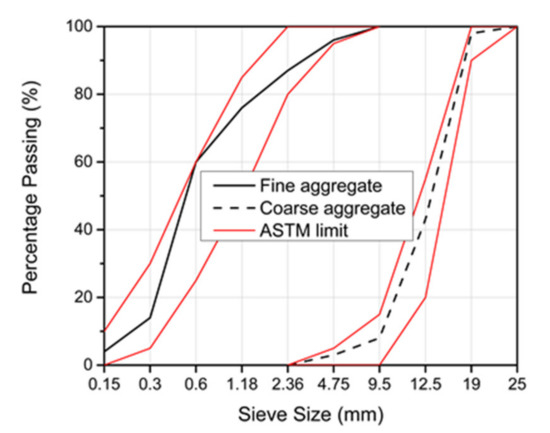

All concrete mixtures used river sand as the fine aggregate, while RCA replaced the NCA either partially or fully. The used NCA was crushed river gravel with a grain size distribution, as shown in Figure 1. The specifications of the natural aggregates followed the requirements of standard ASTM C33 [28]. The physical properties of the natural aggregates, i.e., fineness modulus; specific gravity; bulk density; absorption; moisture content; sulphate content; and soundness, were determined by the authors according to [28] and are listed in Table 3 and Table 4, respectively.

Figure 1.

Grain size distribution of the fine and coarse aggregates.

Table 3.

Properties of the natural fine aggregate.

Table 4.

Properties of the NCA and RCA.

The source of the used RCA was old reinforced concrete buildings and barriers, as shown in Figure 2. The RCA was prepared with a similar grading size distribution and maximum size to the NCA. The RCA showed lower unit weight and higher water absorption compared to those of the NCA (see Table 3).

Figure 2.

Recycling CDW as concrete aggregate.

2.2. Concrete Mixture

The laboratory program included the design of five concrete mixtures, as listed in Table 5. The concrete mixtures included a control concrete (CC) mix without RCA and four recycled concrete (RC) mixes with RCA replacements. The RCA content was varied as 25%, 50%, 75%, and 100% by volume. The concrete mix design followed the recommendations of the ACI 211.1 [29]. Moreover, the water to cement ratio was fixed at 0.45.

Table 5.

The concrete mix ratios.

2.3. Preparation of Specimens

The concrete ingredients were mixed by a mechanical mixer for about 4 min until a homogenous mix was obtained. Concrete specimens were prepared according to ASTM C31/C31M [30]. The number of prepared specimens used in each test is listed in Table 6. In the curing process, all specimens were kept in the molds for 24 h before being subjected to a moist cure for 6 days. In the following 21 days, the specimens were kept in a controlled tank at room temperature and the relative humidity was kept at 50%.

Table 6.

Prepared specimens assigned to each test.

2.4. Testing Methodology

All experiments were conducted in the Department of Civil Engineering Labs at Baghdad University, Iraq. Three specimens were tested for each group and the average results were adopted.

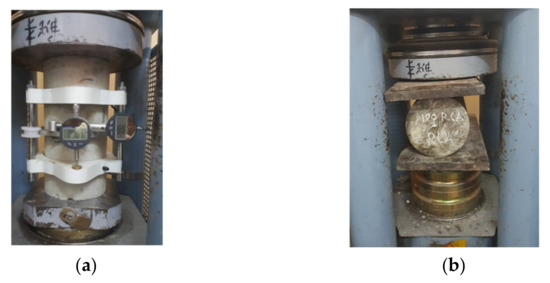

A standard compression machine was used to conduct the compression and splitting tensile tests according to [31,32], respectively. This machine was working under a force-control with a loading rate of 9.0 kN/min (see Figure 3). The static modulus of elasticity was measured in accordance with ASTM-C469 [33]. Concrete cylinders with gauge lengths of 150 mm and dial gauges with a 0.002 mm accuracy were used to measure strains, which corresponded to 40% of the ultimate concrete strength (0.4 fc’), as shown in Figure 3a.

Figure 3.

(a) Compression and modulus of elasticity tests, (b) splitting tensile tests.

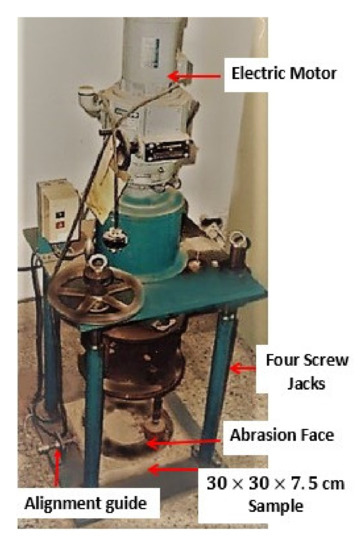

The abrasion resistance of the RC surface was investigated using the standard test method according to [34]. The abrasion tests were performed using the Revolving disk abrasion test machine. In this method, friction forces were applied by rotating steel disks to grind and rub the concrete samples (see Figure 4). Height measurements of the specimens were taken throughout the test. The test period was 60 min so as to produce significant wear on the concrete faces.

Figure 4.

Revolving disk abrasion test machine.

Non-destructive testing of specimens at the age of 28-days was performed by passing an electronic wave through the concrete specimens according to [35]. Ultrasound pulse velocity (UPV) tests were conducted on the RC cubes (150 mm × 150 mm × 150 mm). Two 50 mm transducers rods were used in this method and positioned so that they were aligned at the same level opposite to each other (see Figure 5). The transducer properties were as follows: oscillation frequency of 54 kHz and transit time accuracy of ±1%. The results of the transmission times were measured and the ultrasonic wave velocity in concrete was obtained by dividing the transmission distance (150 mm) by the measured time. After that, the concrete cubes were tested under compression.

Figure 5.

The ultrasound pulse velocity (UPV) tests.

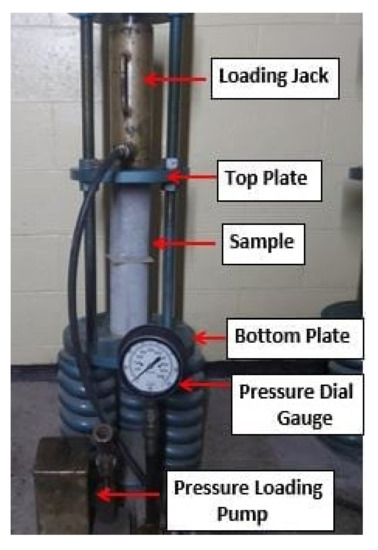

The RC specimens were exposed to sustained axial compressive loads to determine the effect of creep according to [36]. RC cylinders of 100 mm × 200 mm were used to investigate the effect of creep. The creep loading frame, as shown in Figure 6, was used to apply the sustained compressive load. The applied load was 40% of the compressive strength of the specimens. The compressive strain was measured using a dial gauge with an accuracy of 0.002 mm. This test was carried out at a conditional temperature of (21 ± 5 °C) and relative humidity of (35 ± 5%). The strain readings were taken after loading and then each week for the rest of the test. The load was modified periodically to avoid concrete relaxing strain. Finally, the load was released, and readings were taken accordingly.

Figure 6.

Creep test set up.

The RCA influence on the RC density was examined according to [37]. Concrete cubes of 150 mm × 150 mm × 150 mm were poured and set for 24 h and then cured for a further 6 days underwater (see Figure 7). The density was determined as follows: 1—the specimens were weighed in air; 2—the specimens were weighed again underwater; 3—the difference in weights was the weight of water displaced; 4—the density was the weight in air divided by the weight of water displaced.

Figure 7.

Specimens were immersed in the water tank for the absorption test.

The influence of the content of the RCA on the water absorption of the RC was explored according to [37]. RC cubes of 150 mm × 150 mm × 150 mm were used. The specimens were oven-dried and then immersed in water. The increase in mass was measured as a percentage of the dry mass. The percentage of water absorption was calculated as follows:

where A was the mass of the oven-dried specimen, at temperature (100–110) °C for no less than 24 h and B was the mass of saturated specimens after immersion in water at approximately 21 °C for no less than 48 h.

Water absorption = [(B − A)/A] × 100%

3. Results and Discussions

The workability, mechanical properties, and durability in terms of the abrasion of cured concrete (compressive and tensile splitting strength, elastic modulus, creep strain, pulse velocity, abrasion resistance, density, and water absorption) were examined at different ages.

3.1. Workability

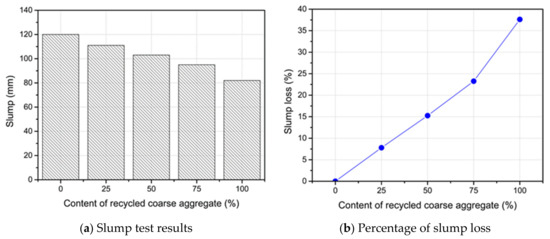

The workability of the fresh RC was examined using the slump flow test according to ASTM C143 [38]. Figure 8a demonstrates the results of the slump tests. The slump of the RC was lower than that of the CC mix. Inversely proportional relationships were found between the replacement content of the RCA and the slump test result. This low workability of RC is due to the hindrance in the movement of concrete particles by RCA particles. The higher surface area and water absorption of the RCA increased the need for water, which led to reductions in workability. The comparative analysis of slump has been performed using the percentage slump loss factor (Equation (1)).

where So is the slump in mm of the CC mix and Sf is the slump in mm of the RC mix. The workability of concrete depends mainly on the water content and grading size distribution of the used aggregate. The effect of the grading size distribution can be minimized and eliminated in this study since the RCA was prepared so as to have the same distribution as the NCA. Therefore, the slump loss of the RC could be attributed to the effective water content that was left after absorbing into the capillary pores of the coarse aggregate. As presented in Table 4, the water absorption of the RCA was much higher than that of the NCA. Consequently, the effective water–cement ratio of the RC was low in comparison to the CC mix. This reduction in the effective water–cement ratio increased as the content of the RCA increased (see Figure 8b). The same trend was obtained when different contents of the RCA were used [39,40].

Figure 8.

Workability of the RC mixtures with various contents of the RCA.

3.2. Compressive Strength

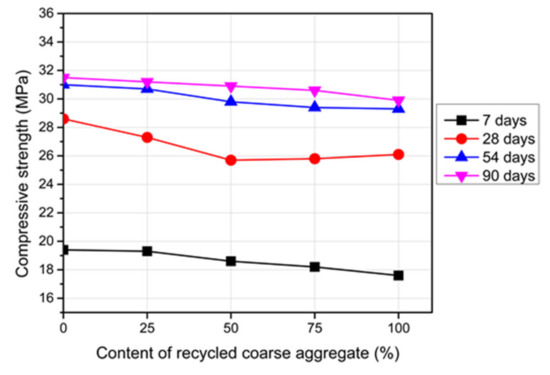

The average compressive strength of the RC with various RCA contents is exhibited in Figure 9. The presented data are the average results of three concrete cylinders tested for each group at a certain age with a standard deviation range of 2.79% to 3.15%. The compressive strength was reduced in comparison to the reference concrete. More reductions in the compressive strength of the RC were obtained as the RCA replacements increased. These reductions were in the range of 5.0–9.3%. The existence of a weaker interfacial transition zone (ITZ) between the RCA and mortar, which is considered as the strength-limiting phase in concrete [41], was the main cause of these reductions in the compressive strength. The high water absorption of the RCA, which was gathered at the aggregate surface and resulted in more pores in the ITZ, contributed to form a weaker ITZ relative to the case of using NCA [42,43]. In addition, the low strength of the RCA relative to the NCA was another cause of the lower strength of the RC [44].

Figure 9.

Compressive strength of the RC with different RCA contents.

The failure shapes were well-formed cones for both ends for concrete with the NCA and RCA (25% and 50% replacements). Whereas, the failure mode was cone shapes at the bottom ends with vertical cracks for the other replacements.

Figure 9 exhibits the development of the compressive strength versus the concrete age. It shows clearly that the compressive strength of the reference concrete and RC increased with curing time, which increased at a rapid rate at an early age. However, this rate decreased after 28 days. Moreover, the early strength of the RC was about 65–80% of its 28-day compressive strength, while the reference concrete obtained only 56% of its strength at 28 days. The strength increase of the RC was higher than that of the reference concrete [9]. This difference in the development rate could be attributed to the late reaction of the residue of the non-hydrated cement on the surface of the RCA [45,46,47].

3.3. Splitting Tensile Strength

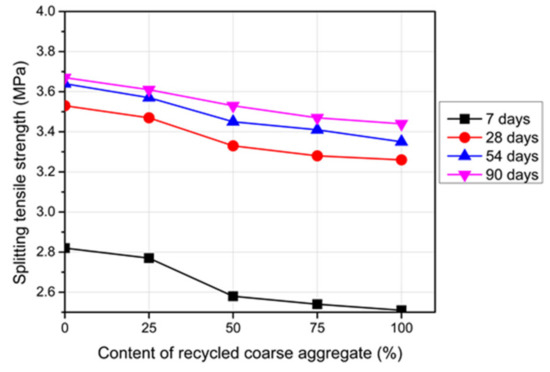

Figure 10 clarifies the experimental results of the splitting tensile strength of the reference concrete and RC at different ages. Using the RCA caused reductions in the splitting tensile strength. The higher content of RCA used, the lesser the tensile strength obtained. For 100% replacement with RCA, a 10.7% difference in the tensile strength was observed between the reference concrete and the RC at an age of 7 days. Whereas this reduction decreased to 8.3% for the age of 28 days and over. The residual cement mortar in the RCA provided weakened points, which caused reductions in the tensile strength of the RC. Previous studies confirmed 11–17% reductions in the splitting tensile strength due to 100% replacement of the RCA [39,47]. Moreover, the composition and the source of the RCA contributed significantly to these reductions.

Figure 10.

Splitting tensile strength of the RC with different RCA contents.

3.4. Elastic Modulus

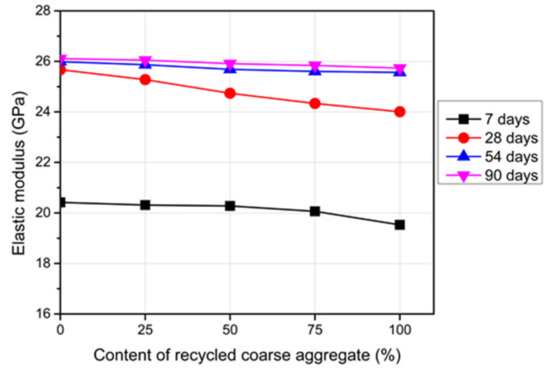

The presented data are the average results of three concrete cylinders tested for each group at a certain age with a standard deviation range of 1.50% to 2.15%. The RC showed a lower elastic modulus relative to the reference concrete, as presented in Figure 11. The difference in the elastic modulus between the RC and the reference concrete was 7.7% for a 100% RCA content after curing for 28 days; the reduction in the elastic modulus became higher when the percentage of the RCA increased. The relative lower stiffness as well as the higher porosity of the RCA were the main reasons for this reduction.

Figure 11.

Elastic modulus of the RC with different RCA contents and ages.

The difference in the elastic modulus between the reference concrete and the RC in this study was lower than that observed in previous studies [2,9,45]. This difference could be attributed to the various sources of the RCA as well as the quality control during the preparation and casting processes.

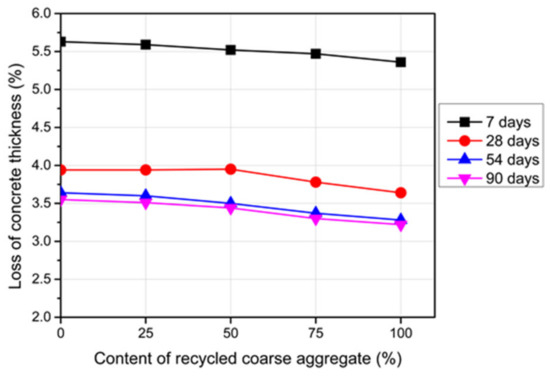

3.5. Abrasion

Mechanical degradation of concrete due to vehicular movement or pedestrian traffic causes loss of concrete mass, which is defined as abrasion. Figure 12 shows the results of the abrasion resistance of the RC and reference concrete in terms of the concrete thickness loss at different ages. The results confirm that the abrasion wear rate of the RC was lower relative to the reference concrete. This means that a higher abrasive wear resistance was obtained and this resistance was enhanced as the RCA content increased. This phenomenon could be attributed to the roughness of the RCA due to the long-adhered cement paste. The formed good bond between the new paste and the mortar of the RCA improved the abrasion resistance of the RC [48]. Moreover, the type of RCA could affect this resistance [44].

Figure 12.

Abrasion resistance of the RC with different RCA contents and ages.

The abrasion wear of the RC and reference concrete increased at an early age, which led to reductions in the concrete thickness. Notably, the concrete thickness loss was significantly high at the age of 7 days—the specimens lost approximately 5.0 mm of the thickness (see Figure 12). However, the thickness loss was insignificant after the age of 28 days.

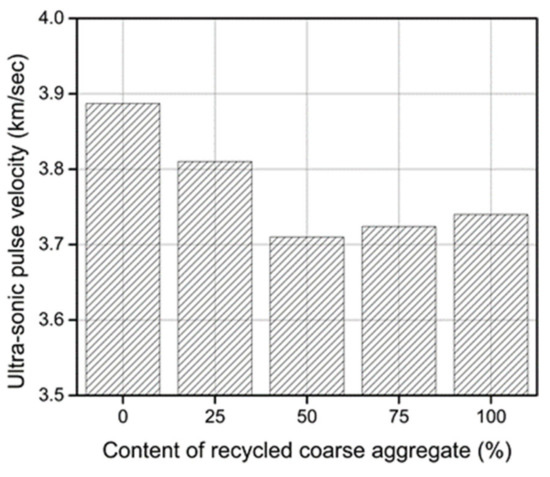

3.6. Ultra-Sonic Pulse Velocity

The measured results of the ultrasound pulse velocity (UPV) tests are shown in Figure 13. The UPV values decreased with the incorporation of the RCA in concrete. The UPV values greatly depend on the porosity of concrete and the RC exhibited higher porosity than that of the reference concrete, particularly at the transition zone between the RCA and the new paste. Therefore, the sound transmission in the RC required longer times than that in the reference concrete.

Figure 13.

Ultra-sonic pulse velocity of concrete with various contents of the recycled aggregate at the age of 28 days.

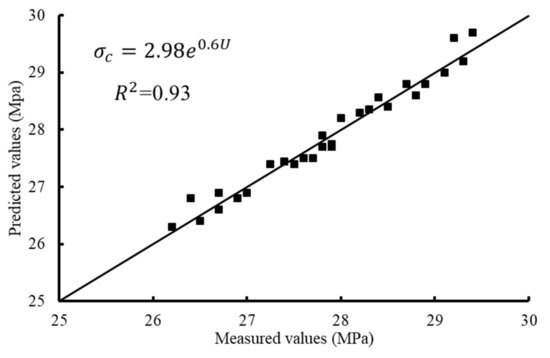

A regression analysis was conducted to develop a predictive equation that relates a criterion variable to a predictor variable. The regression analysis is useful to estimate the compressive strength of the recycled concrete using a non-destructive test (UPV test). In this research, the criterion variable included the compressive strength at 28 days and the predictor variable was the ultrasonic wave velocity. Two approaches were used to assess the adequacy of the proposed statistical regression model. The first approach was based on examining goodness of fit measures and the coefficient of multiple determinations (R2). Whereas, the second approach was based on the graphical analysis of the residuals (diagnostic plots). The Minitab statistical software V. 17 was used for the model development. Two groups of experimental results were used for this target. The first group consisted of the 30 data points that represent the original test results. The second group included an additional 15 data points (additional compressive strength tests) to be adopted for the proposed model justification. The model equation was as follows.

where σc is the compressive strength at the age of 28 days in MPa and U is the UPV (km/s100). The validation process to assess the adequacy of the proposed prediction model and measure the error or accuracy of the prediction is exhibited in Figure 14.

Figure 14.

Regression between the predicted and measured values of the compressive strength.

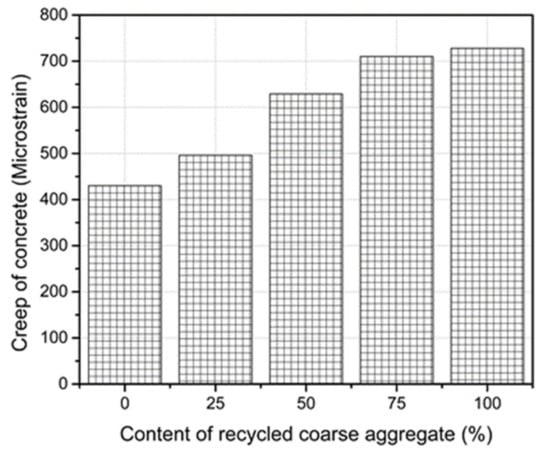

3.7. Effect of Creep

The creep tests were conducted for 90 days and the recorded creep strains are presented in Figure 15. The creep strain of the RC increased as the RCA content increased. For 100% replacement of the RCA, the creep strain increased by 67.5% relative to the reference concrete. However, only a 16% increase was obtained for the case of 25% replacement. The higher volume of cement paste in the RC compared to that of the reference concrete caused higher losses of the physically absorbed water under sustained stresses and, subsequently, led to the increase in creep strains. The adverse effects of using RCA on the concrete creep mainly include the increase in beam deflection and the reduction in the structural bearing capacity. In addition, the increase in the creep of the RC can cause excessive prestressing losses of the prestressed members [49,50,51].

Figure 15.

Creep strains of the RC with various RCA contents.

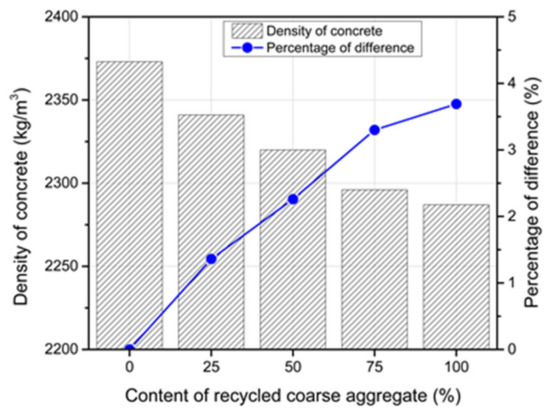

3.8. Density of the RC

The lower unit weight of the RCA relative to the NCA led to reductions in the RC density and these reductions increased as the RCA content increased (see Figure 16). For the RCA content of 100%, a reduction of 3.9% was obtained. This reduction was reported as 3.3% by Etxeberria et al. [52] and 5% by Verian [53] for the same RCA content. The adhered mortar in the RCA was lightweight compared to the NCA of the same volume, which caused the decrease in density [54].

Figure 16.

Variations in the recycled concrete density at the age of 28 days.

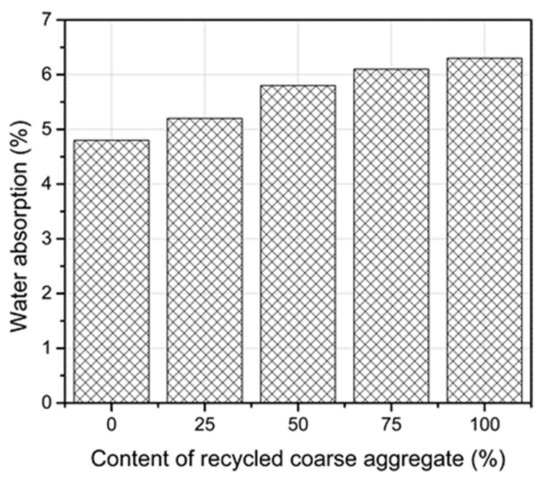

3.9. Water Absorption

Water absorption of concrete can be an indirect indication of concrete durability. Absorbed water carries aggressive ions such as sulfate, chloride, and hydrogen ions into concrete, which cause reactions with the cement paste and affect the concrete durability. Figure 17 presents the variation in the water absorption of the RC with various contents of the RCA. Due to greater water absorption of the RCA compared to the NCA (see Table 4), using the RCA increased the water absorption of the RC. A linear relationship was observed between the water absorption and the content of the RCA. For 100% replacement of the RCA, the water absorption increased by approximately 7%. Previous studies confirmed the same increase in water absorption [2,9]. The increase in the water absorption of the RC is a problem for the industry because the more water absorbed into the concrete, the easier movement of ions from external exposure into concrete is. Consequently, the corrosion resistance of the reinforced RC is affected.

Figure 17.

Water absorption of the RC with various contents of the RCA.

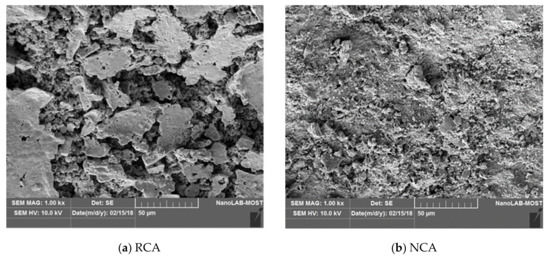

3.10. Microstructural Analysis

Figure 18 demonstrates the results of the microscopic analysis for the RCA and NCA. The good bond between the NCA and cement paste produced a much more refined surface for the reference concrete. Whereas, the RCA formed pores and roughness on the RC surface, where water accumulated and formed porous and weak ITZ. This difference led to reductions in the mechanical properties of the RC relative to the reference concrete.

Figure 18.

Microscopic analysis of the (a) RCA and the (b) NCA.

4. Discussion on the Practical Aspects of Using RC

The ACI 318-19 code [55] specified that 17 MPa is the minimum compressive strength requirement for concrete used in structural members. As a consequence of the experimental test results in terms of the compressive strength and density, the RCA produced from old reinforced concrete buildings and barriers can be used to produce RC, which can be used as structural concrete in the field of construction. However, reductions in elastic modulus and increase in creep deformations should be considered in the design of the long-term behavior. Moreover, additional protections to the RC surface should be provided against the aggressive environment and vehicular or pedestrian traffic to protect the steel reinforcement against corrosion due to the increase in the water absorption and abrasion wear rate.

5. Conclusions

This paper reports an evaluation of the properties of medium-quality concrete incorporating RCA. Concrete specimens were poured with various contents of the RCA (25%, 50%, 75%, and 100%). The workability, mechanical properties, and durability in term of abrasion of cured concrete were examined at different ages. According to the experimental results, the following findings were concluded.

- The high demand for water of the RCA significantly affected the workability as well as the durability of the RC. The workability of the RC was reduced by 8% to 38%.

- The compressive strength was reduced by 5.0–9.3%, in comparison to the reference concrete. More reductions in the compressive strength of the RC were obtained as the RCA replacements increased.

- For 100% replacement of the RCA, a 10.7% difference of the tensile strength was observed between the reference concrete and the RC at the age of 7 days. Whereas, this reduction decreased to 8.3% at an age of 28 days and over. The residual cement mortar in the RCA provided weakened points, which caused reductions in the tensile strength of the RC.

- The concrete thickness loss was significantly high at an early age (age of 7 days), where the thickness of the specimens decreased by approximately 5.0 mm. However, the thickness loss was insignificant after 28 days.

- The provided regression analysis is useful to estimate the compressive strength of the recycled concrete using a non-destructive test with a goodness of fit of 0.93.

- For 100% replacement of the RCA, the creep strain increased by 67.5% relative to the reference concrete. However, only a 16% increase was obtained for the case of 25% replacement. The higher volume of cement paste in the RC compared to that of the reference concrete caused higher losses of the physically absorbed water under the sustained stresses and, subsequently, led to this increase in the creep strains.

- Using the RCA as a replacement for the NCA led to an increase in the water absorption of the RC and a linear proportion was observed between the content of the RCA and water absorption. For 100% replacement of the RCA, the water absorption increased by approximately 7%.

Author Contributions

Conceptualization and methodology, A.A. (Abbas Allawi); Experiment and validation, A.A. (Amjad Albayati); Resources, Software, Writing—original draft, D.V.P.T. and T.N.C.; Supervision, visualization, Writing—review & editing, Y.T.H.N. and A.E.-Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The support provided by the Department of Civil Engineering at the University of Baghdad is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lotfy, A.; Al-Fayez, M. Performance evaluation of structural concrete using controlled quality coarse and fine recycled concrete aggregate. Cem. Concr. Compos. 2015, 61, 36–43. [Google Scholar] [CrossRef]

- Soares, D.; de Brito, J.; Ferreira, J.; Pacheco, J. Use of coarse recycled aggregates from precast concrete rejects: Mechanical and durability performance. Constr. Build. Mater. 2014, 71, 263–272. [Google Scholar] [CrossRef]

- Curović, N.; JP Elektromreža Srbije. Recycled concrete: Ecology and economic criterias. Appl. Eng. Sci. 2016, 14, 271–274. [Google Scholar] [CrossRef] [Green Version]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Aghayan, I.; Khafajeh, R.; Shamsaei, M. Life cycle assessment, mechanical properties, and durability of roller compacted concrete pavement containing recycled waste materials. Pavement Res. Technol. 2021, 14, 595–606. [Google Scholar] [CrossRef]

- Lan, H.; Zhang, Y.; Cheng, M.; Li, Y.; Jing, Z. An intelligent humidity regulation material hydrothermally synthesized from ceramic waste. Build. Eng. 2021, 40, 102336. [Google Scholar] [CrossRef]

- Horňáková, M.; Lehner, P. Relationship of Surface and Bulk Resistivity in the Case of Mechanically Damaged Fibre Reinforced Red Ceramic Waste Aggregate Concrete. Materials 2020, 13, 5501. [Google Scholar] [CrossRef]

- Ryou, J.S.; Lee, Y.S. Characterization of Recycled Coarse Aggregate (RCA) via a Surface Coating Method. Int. J. Concr. Struct. Mater. 2014, 8, 165–172. [Google Scholar] [CrossRef] [Green Version]

- Andreu, G.; Miren, E. Experimental analysis of properties of high performance recycled aggregate concrete. Constr. Build. Mater. 2014, 52, 227–235. [Google Scholar] [CrossRef]

- Berredjem, L.; Arabi, N.; Molez, L. Mechanical and durability properties of concrete based on recycled coarse and fine aggregates produced from demolished concrete. Constr. Build. Mater. 2020, 246, 118421. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete – A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Muñoz, P.; Moriconi, G. Combined effects of recycled hydrated cement and recycled aggregates on the mechanical properties of concrete. Constr. Build. Mater. 2017, 132, 365–375. [Google Scholar] [CrossRef]

- Marie, I.; Mujalli, R. Effect of design properties of parent concrete on the morphological properties of recycled concrete aggregates. Eng. Sci. Technol. 2019, 22, 334–345. [Google Scholar] [CrossRef]

- Ismail, S.; Kwan, W.H.; Ramli, M. Mechanical strength and durability properties of concrete containing treated recycled concrete aggregates under different curing conditions. Constr. Build. Mater. 2017, 155, 296–306. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Mechanical properties of concrete containing 100% treated coarse recycled concrete aggregate. Constr. Build. Mater. 2018, 163, 496–507. [Google Scholar] [CrossRef]

- Kazemian, F.; Rooholamini, H.; Hassani, A. Mechanical and fracture properties of concrete containing treated and untreated recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 690–700. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Wang, Y.; Hughes, P.; Niu, H.; Fan, Y. A new method to improve the properties of recycled aggregate concrete: Composite addition of basalt fiber and nano-silica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar] [CrossRef]

- Li, W.; Long, C.; Tam, V.W.Y.; Poon, C.S.; Hui-Duan, W. Effects of nano-particles on failure process and microstructural properties of recycled aggregate concrete. Constr. Build. Mater. 2017, 142, 42–50. [Google Scholar] [CrossRef]

- Wang, Q.; Geng, Y.; Wang, Y.; Zhang, H. Drying shrinkage model for recycled aggregate concrete accounting for the influence of parent concrete. Eng. Struct. 2020, 202, 109888. [Google Scholar] [CrossRef]

- Djerbi, A. Effect of recycled coarse aggregate on the new interfacial transition zone concrete. Constr. Build. Mater. 2018, 190, 1023–1033. [Google Scholar] [CrossRef]

- Nasr, M.; Shubbar, A.; Abed, Z.-A.; Ibrahim, M. Properties of eco-friendly cement mortar contained recycled materials from different sources. Build. Eng. 2020, 31, 101444. [Google Scholar] [CrossRef]

- Pickel, D.; Tighe, S.; West, J.S. Assessing benefits of pre-soaked recycled concrete aggregate on variably cured concrete. Constr. Build. Mater. 2017, 141, 245–252. [Google Scholar] [CrossRef]

- Eckert, M.; Oliveira, M. Mitigation of the negative effects of recycled aggregate water absorption in concrete technology. Constr. Build. Mater. 2017, 133, 416–424. [Google Scholar] [CrossRef]

- Souche, J.-C.; Devillers, P.; Salgues, M.; Garcia Diaz, E. Influence of recycled coarse aggregates on permeability of fresh concrete. Cem. Concr. Compos. 2017, 83, 394–404. [Google Scholar] [CrossRef]

- ASTM C150/C150M-20. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Committee 211. Recommended Practice for Selecting Proportions for Normal and Heavyweight Concrete; ACI 211.1-19; American Concrete Institute: Detroit, MI, USA, 2019. [Google Scholar]

- ASTM C31/C31M-19a. Standard Practice for Making and Curing Concrete Test Specimens in the Field; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM C39/C39M-20. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM C496/C496M-17. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C469/C469M-14e1. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM C779/C779M-00. Standard Test Method for Abrasion Resistance of Horizontal Concrete Surfaces; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- ASTM C597-02. Standard Test Method for Pulse Velocity Through Concrete; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM C512-02. Standard Test Method for Creep of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM C642-97. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- ASTM C143/C143M-15a. Standard Test Method for Slump of Hydraulic Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Hoffmann, C.; Schubert, S.; Leemann, A.; Motavalli, M. Recycled concrete and mixed rubble as aggregates: Influence of variations in composition on the concrete properties and their use as structural material. Constr. Build. Mater. 2012, 35, 701–709. [Google Scholar] [CrossRef]

- Mehta, P.K.M.; Paulo, J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Poon, C.S.; Kou, S.C.; Lam, L. Influence of recycled aggregate on slump and bleeding of fresh concrete. Mater. Struct. 2006, 40, 981–988. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- De Brito, J.; Pereira, A.S.; Correia, J.R. Mechanical behavior of non-structural concrete made with recycled ceramic aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conservat. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Öz, H.Ö.; Taha, I.; Yasemin, M.T. Failure characteristics of self-compacting concretes made with recycled aggregates. Constr. Build. Mater. 2015, 98, 334–344. [Google Scholar] [CrossRef]

- Matias, D.; de Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregates – Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Huang, G.X.; Hui, R.Y.; Wang, X.J. Concrete Creep and Shrinkage; China Electric Power Press: Beijing, China, 2012. [Google Scholar]

- Asamoto, S.; Ohtsuka, A.; Kuwahara, Y.; Miura, C. Study on effects of solar radiation and rain on shrinkage, shrinkage cracking and creep of concrete. Cem. Concr. Res. 2011, 41, 590–601. [Google Scholar] [CrossRef]

- Ma, J.X.; Dehn, F. Shrinkage and creep behavior of an alkali-activated slag concrete. Struct. Concr. 2017, 18, 801–810. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Verian, K.P. Using Recycled Concrete as Coarse Aggregate in Pavement Concrete. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2012. [Google Scholar]

- McNeil, K.; Kang, T.H.K. Recycled Concrete Aggregates: A Review. Int. J. Concr. Struct. Mater. 2013, 7, 61–69. [Google Scholar] [CrossRef] [Green Version]

- ACI Committee 318. Building Code Requirements for Structural Concrete: (ACI 318-19); American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).