Machining Stresses and Initial Geometry on Bulk Residual Stresses Characterization by On-Machine Layer Removal

Abstract

1. Introduction

2. Materials and Methods

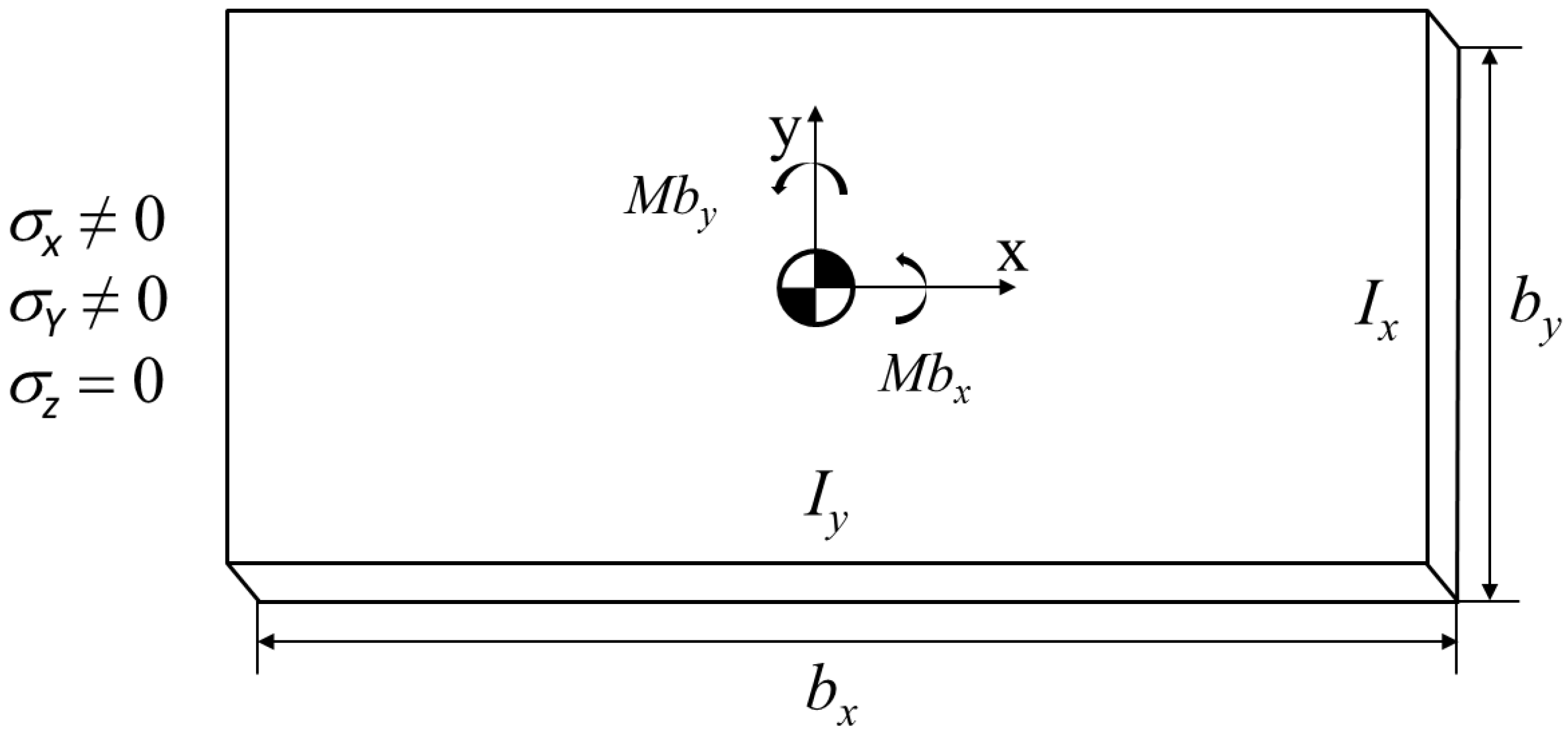

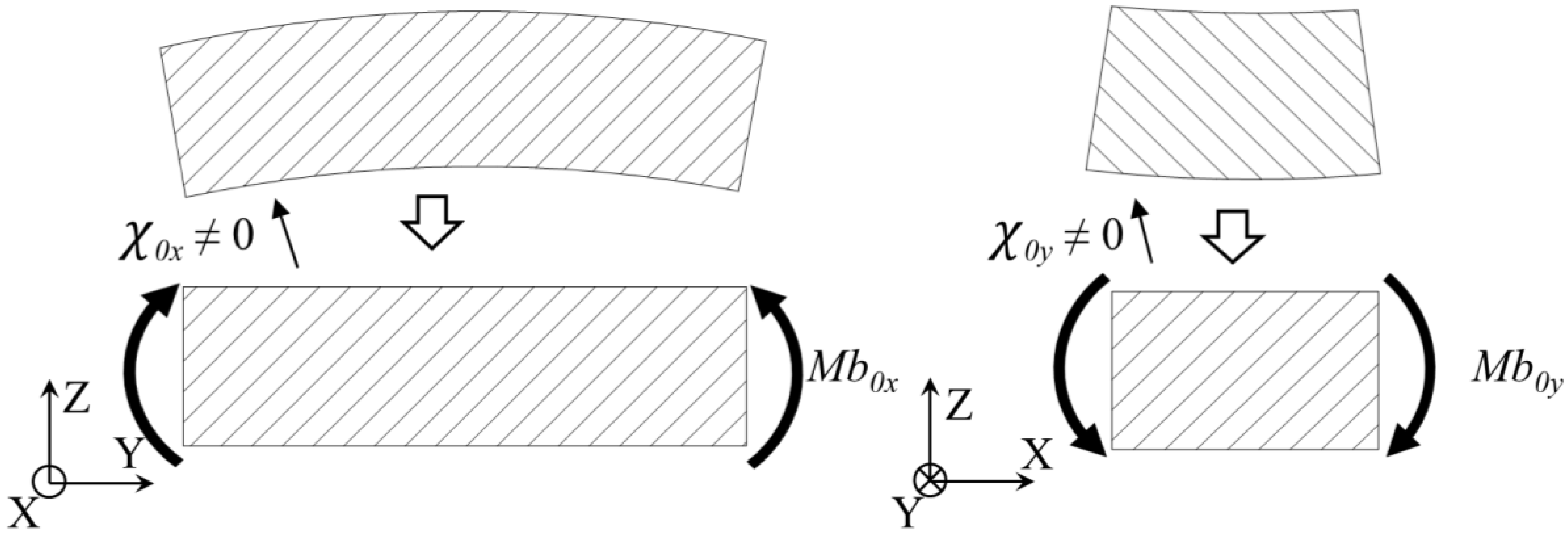

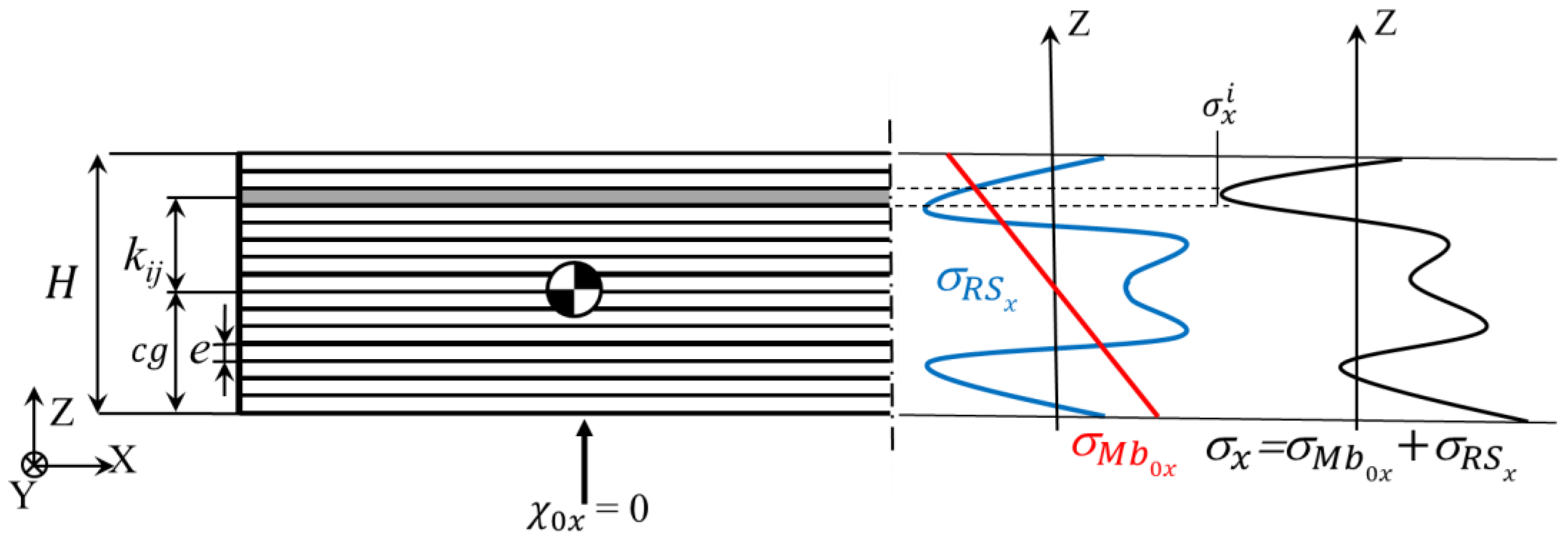

2.1. Analytical Formulation

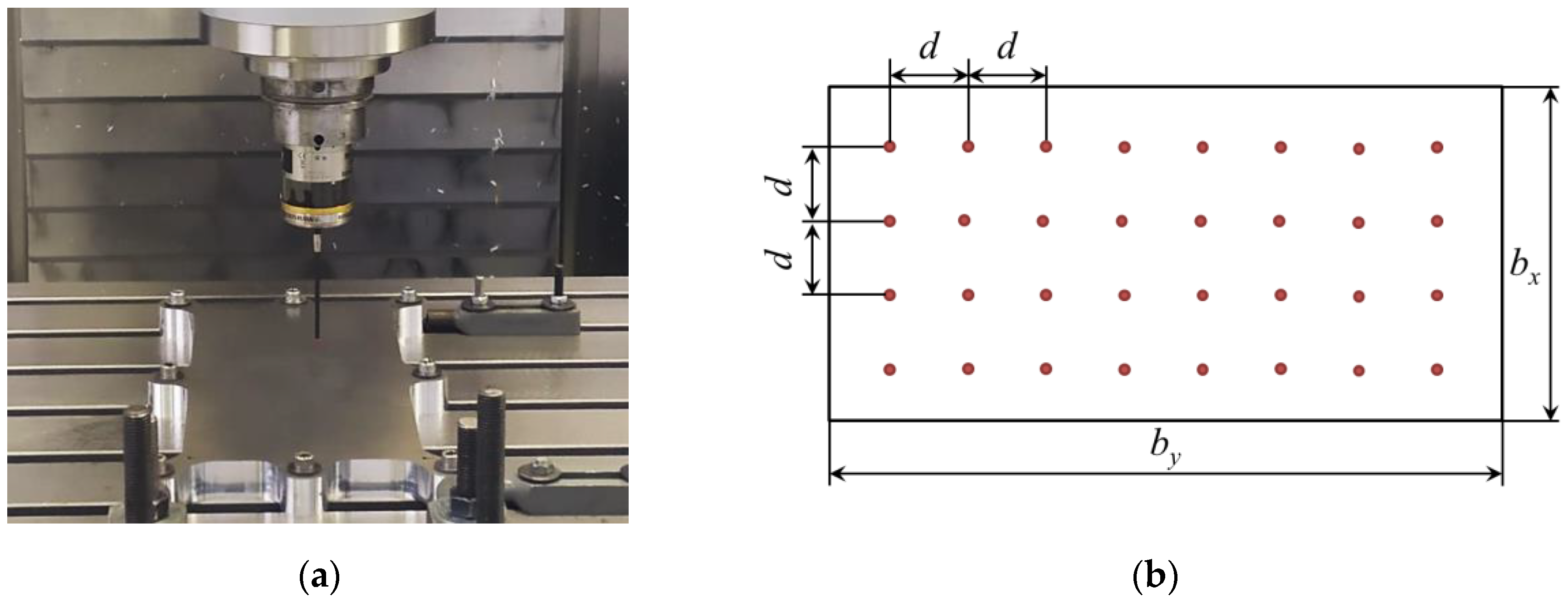

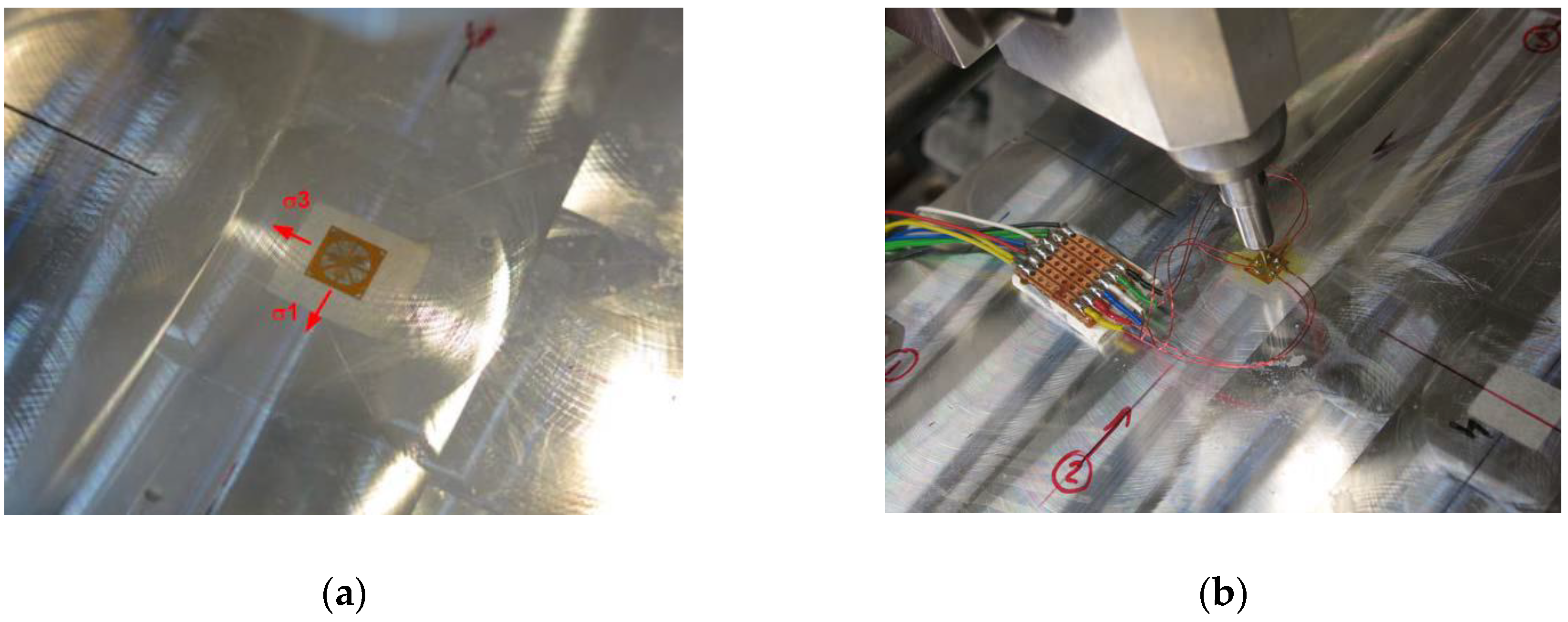

2.2. Experimental Implementation

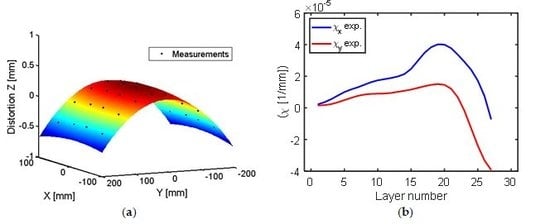

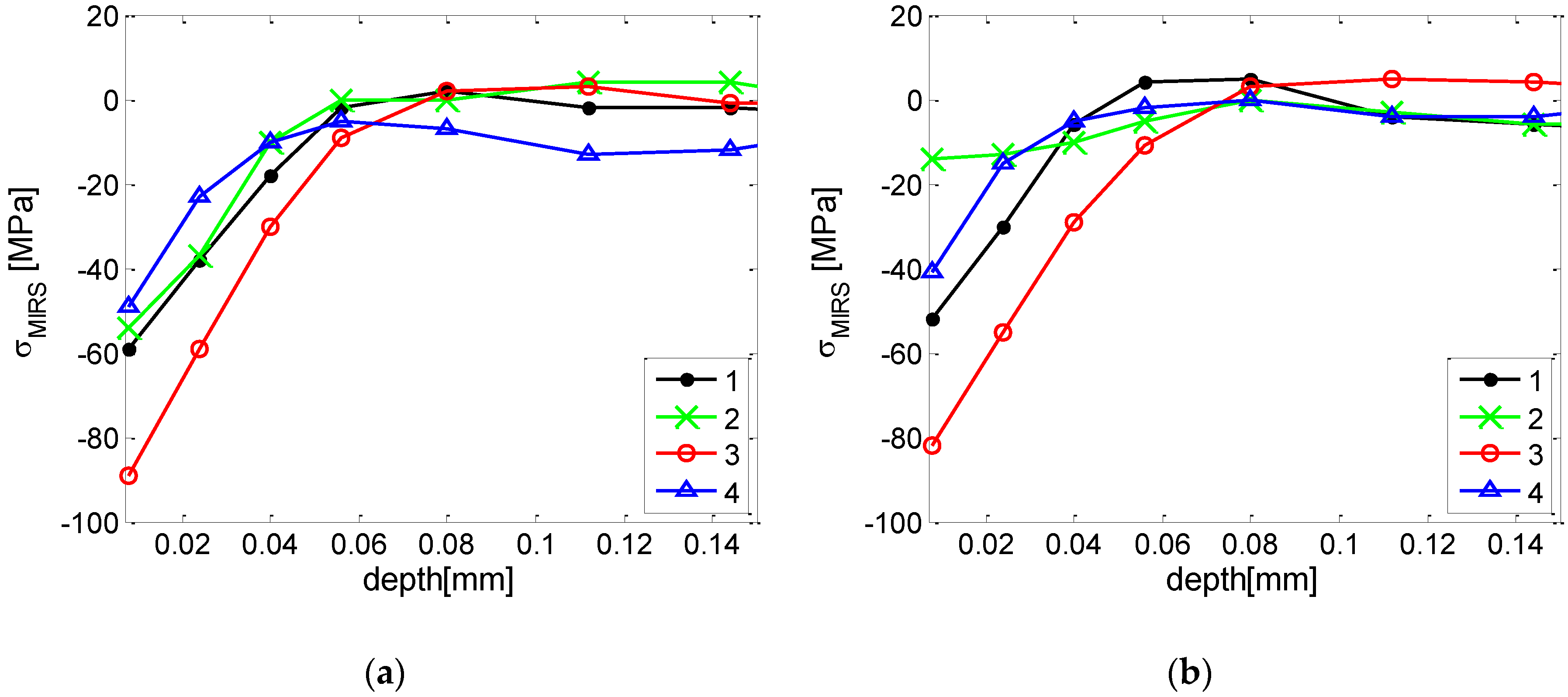

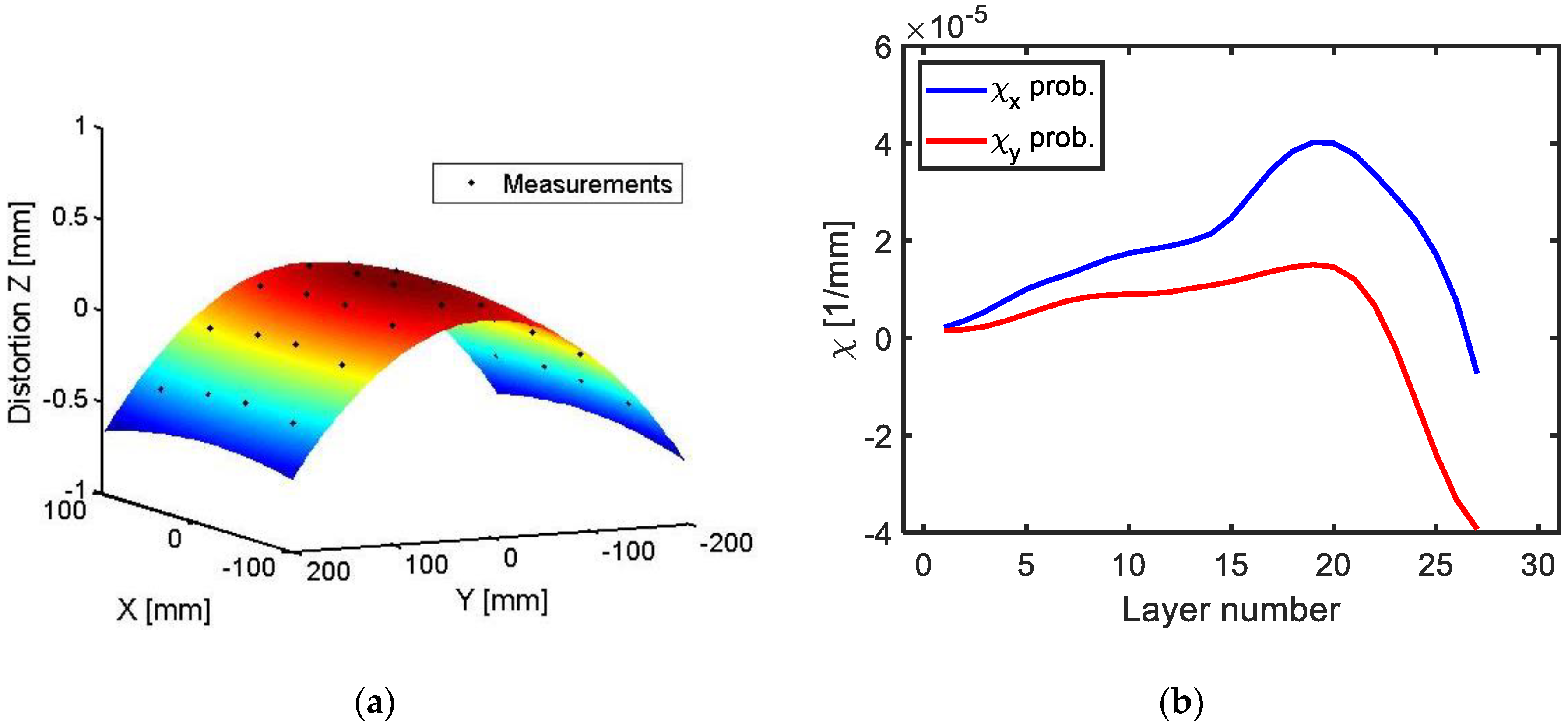

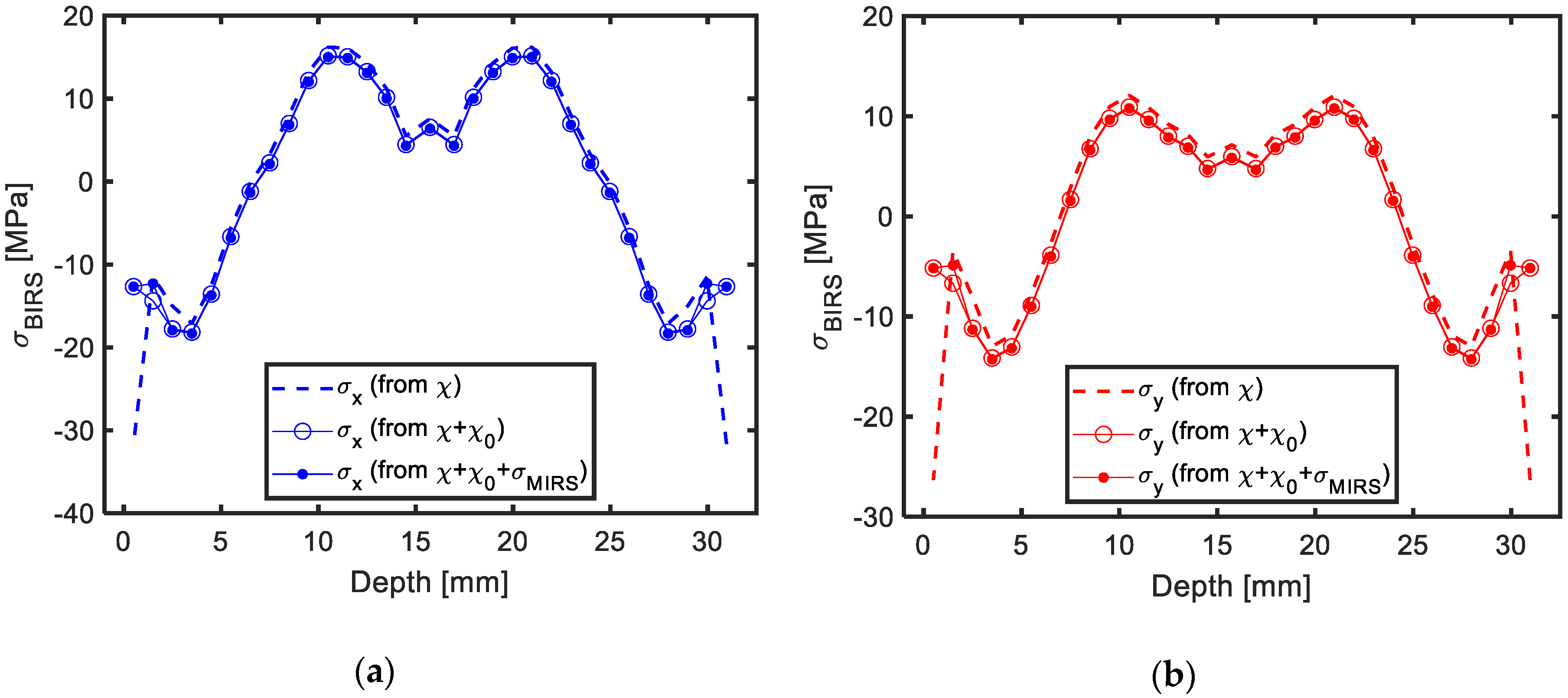

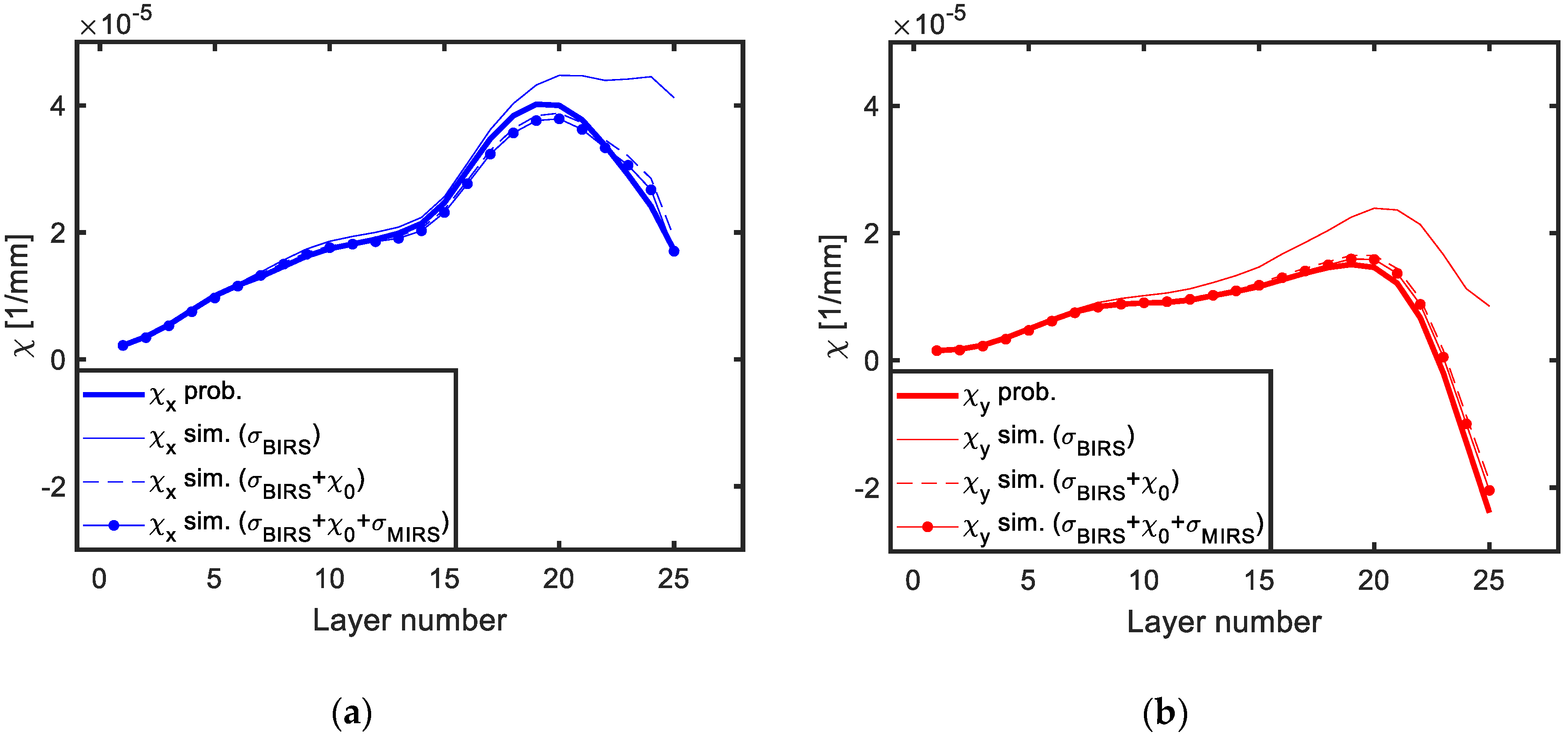

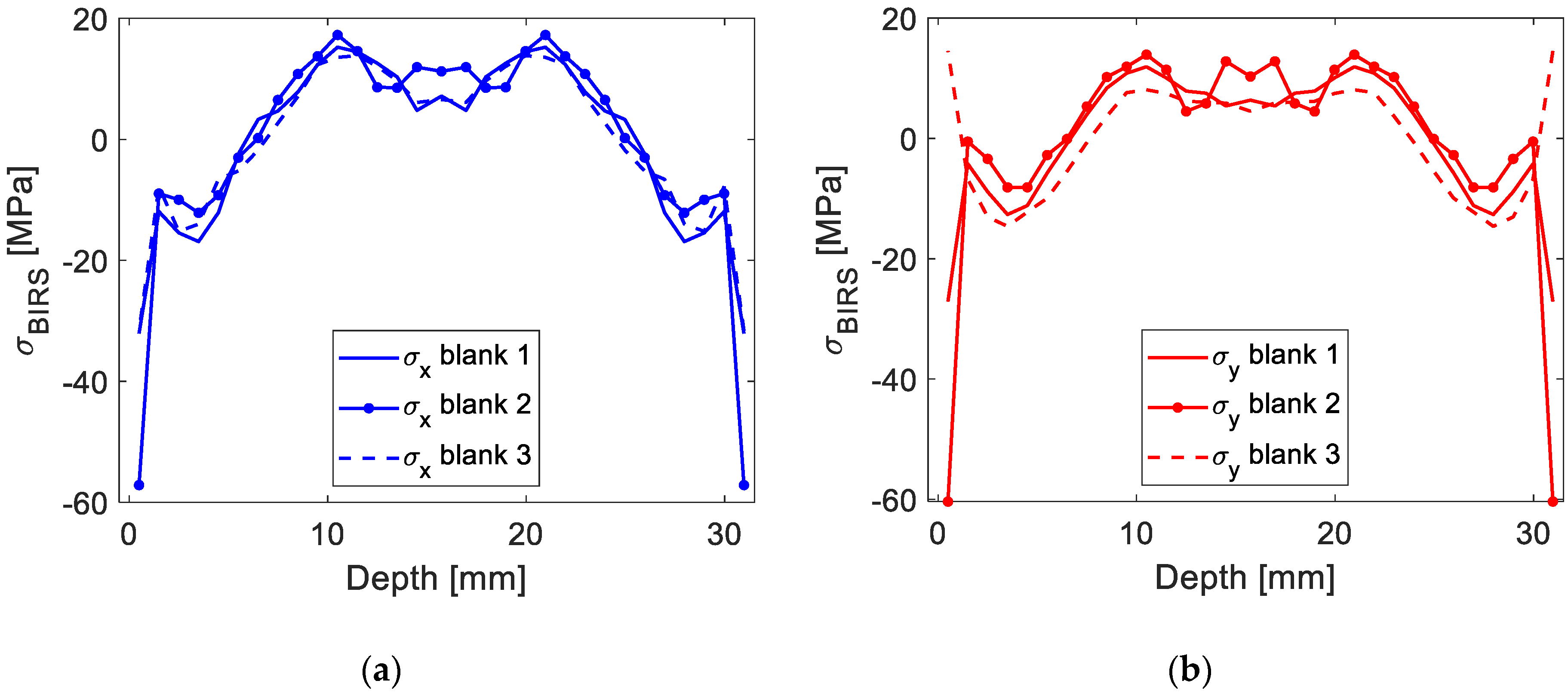

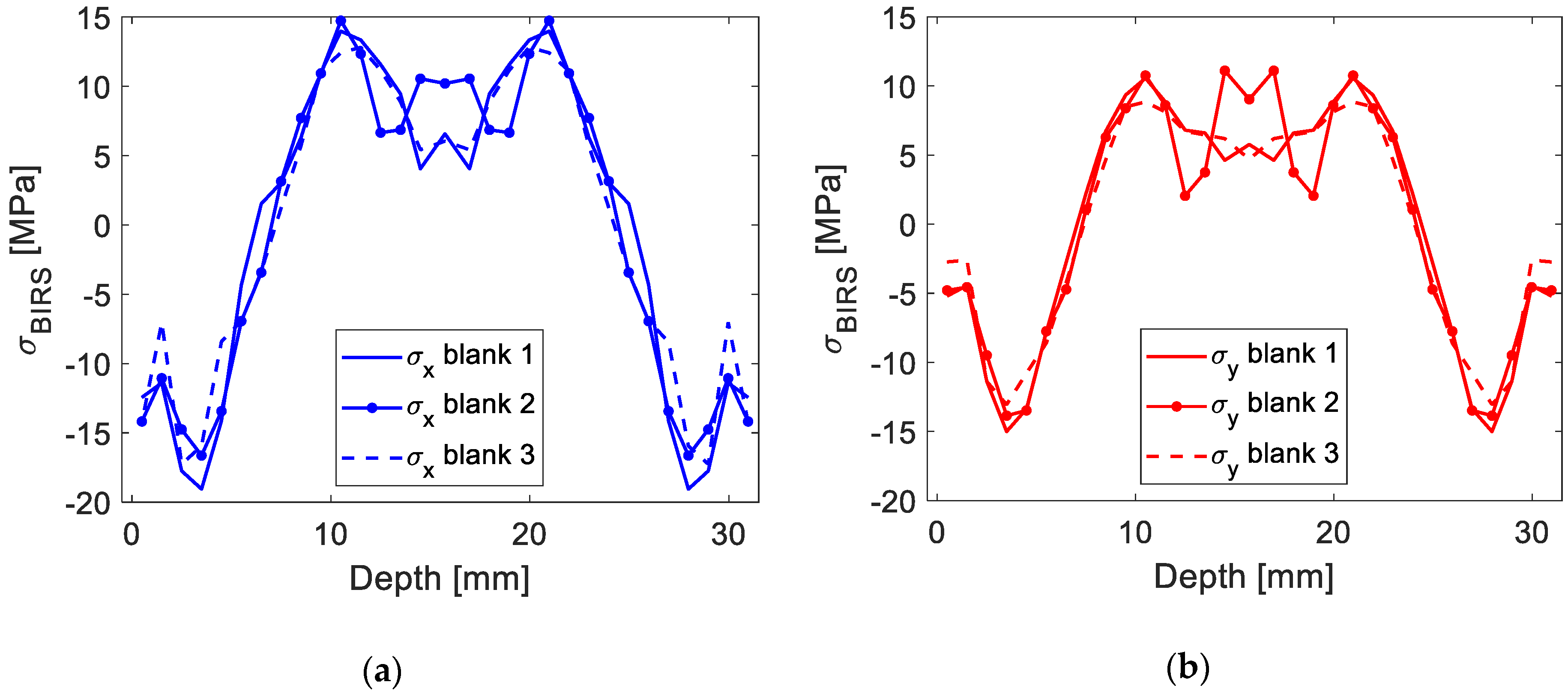

3. Results

4. Discussion

5. Conclusions

- The effects of the initial deformation and machining stresses (MIRS) must be considered for BIRS characterization due to the big influence in stress values, especially near the surface.

- Using the formulation to perform inversely the calculation of distortion, a check of the results accuracy can be done, as well as a prediction of machining distortion for face milling operations with a negligible computation time.

- The proposed characterization method enables the identification of the BIRS from measured curvatures on machining blanks accurately.

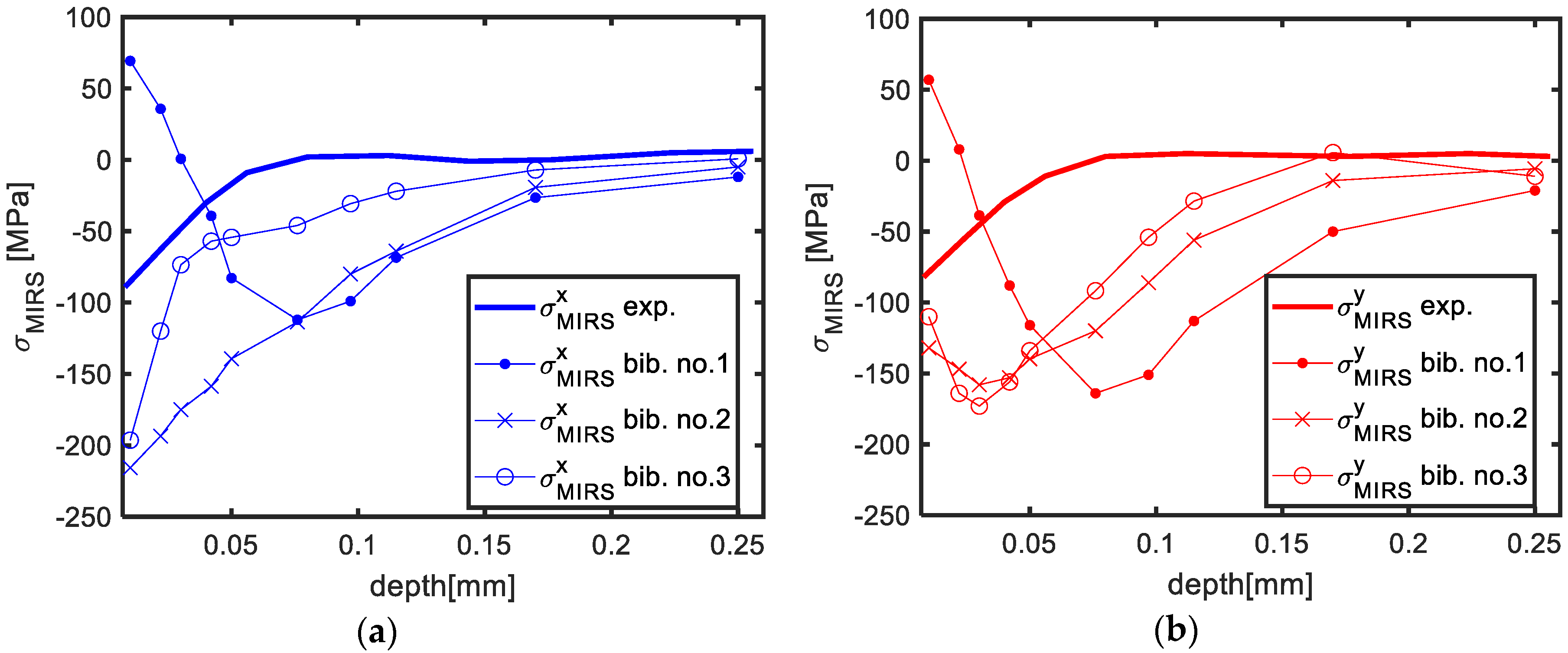

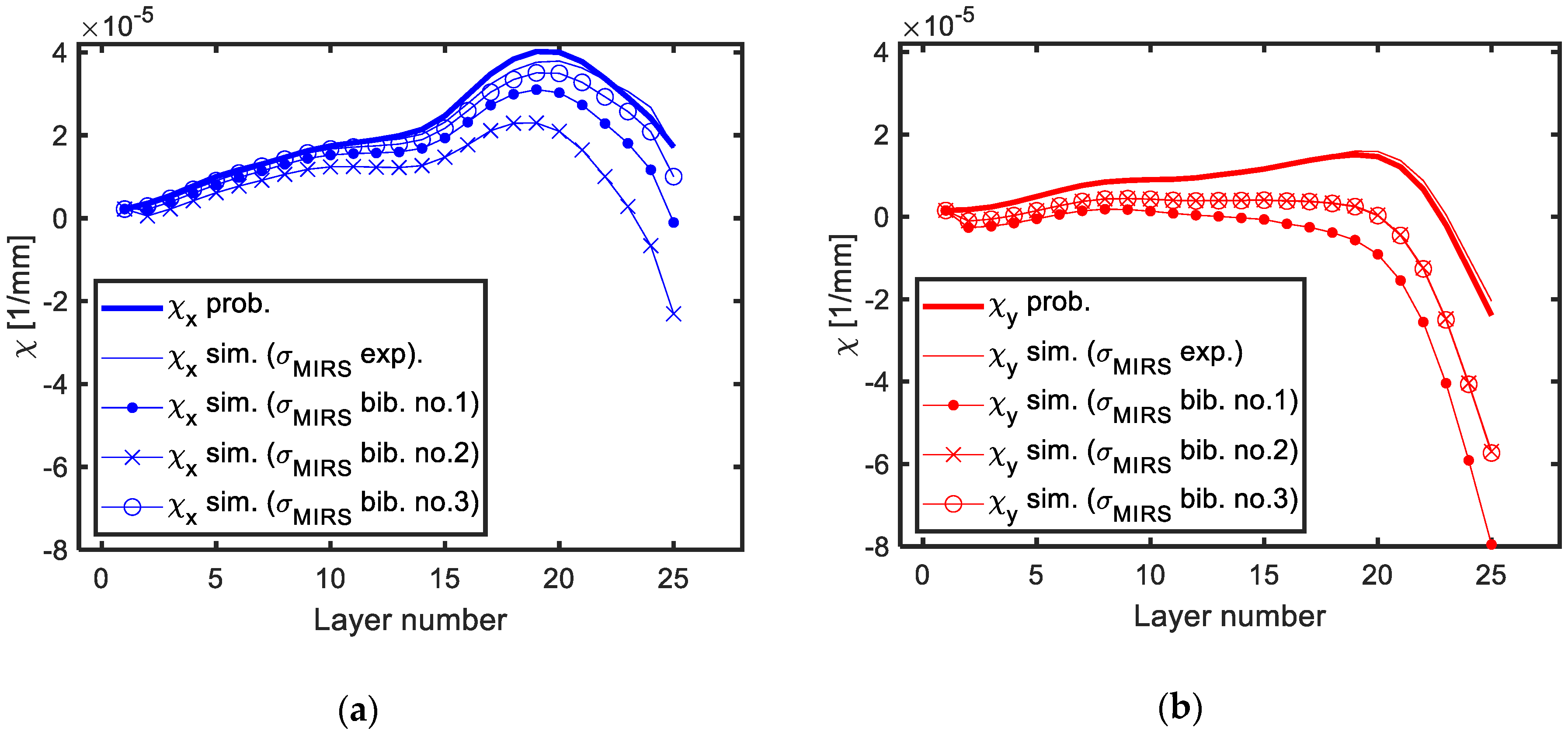

- Parametric sensitivity analysis confirms that accurate assessment of MIRS is necessary to obtain reliable results of bulk residual stresses (BIRS) by the on-machine LR method.

- The effect of the different machining conditions on the final part distortion, and by extension the effect of the MIRS, was verified by the parametric sensitivity analysis.

- The on-machine layer removal method can be implemented in industrial environments by untrained staff using common industrial machines and tools. This fact enables BIRS identification in the shop-floor and allows automation in a future prospect.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bowden, D.M.; Halley, J.E. Aluminium Reliability Improvement Program Final Report 60606; The Boeing Company: Chicago, IL, USA, 2001. [Google Scholar]

- Brinksmeier, E.; Cammett, J.T.; König, W.; Leskovar, P.; Peters, J.; Tönshoff, H.K. Residual Stresses–Measurement and Causes in Machining Processes. CIRP Ann. 1982, 31, 491–510. [Google Scholar] [CrossRef]

- Li, J.; Wang, S. Distortion caused by residual stresses in machining aeronautical aluminum alloy parts: Recent advances. Int. J. Adv. Manuf. Technol. 2017, 89, 997–1012. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Li, K.R. Comparison and analysis of main effect elements of machining distortion for aluminum alloy and titanium alloy aircraft monolithic component. Int. J. Adv. Manuf. Technol. 2014, 70, 1803–1811. [Google Scholar] [CrossRef]

- Dong, H.; Ke, Y. Study on Machining Deformation of Aircraft Monolithic Component by FEM and Experiment. Chin. J. Aeronaut. 2006, 19, 247–254. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, W.; Zhang, Y.; Chen, Z.; Liu, Q. Study on the Machining Distortion of Thin-walled Part Caused by Redistribution of Residual Stress. Chin. J. Aeronaut. 2005, 18, 175–179. [Google Scholar] [CrossRef]

- Nervi, S.; Szabó, B.A. On the estimation of residual stresses by the crack compliance method. Comput. Methods Appl. Mech. Eng. 2007, 196, 3577–3584. [Google Scholar] [CrossRef]

- Prime, M.B.; Hill, M.R. Residual stress, stress relief, and inhomogeneity in aluminum plate. Scr. Mater. 2002, 46, 77–82. [Google Scholar] [CrossRef]

- Bilkhu, R.; Ayvar-Soberanis, S.; Pinna, C.; McLeay, T. Machining Distortion in Asymmetrical Residual Stress Profiles. Procedia CIRP 2019, 82, 395–399. [Google Scholar] [CrossRef]

- Robinson, J.S.; Tanner, D.A.; Truman, C.E.; Wimpory, R.C. Measurement and Prediction of Machining Induced Redistribution of Residual Stress in the Aluminium Alloy 7449. Exp. Mech. 2011, 51, 981–993. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, L.; Yang, Y.; He, N.; Zhao, W. Machining distortion minimization for the manufacturing of aeronautical structure. Int. J. Adv. Manuf. Technol. 2014, 73, 1765–1773. [Google Scholar] [CrossRef]

- Hill, M.R.; Olson, M.D. Repeatability of the Contour Method for Residual Stress Measurement. Exp. Mech. 2014, 54, 1269–1277. [Google Scholar] [CrossRef]

- Treuting, R.G.; Read, W.T. A mechanical determination of biaxial residual stress in sheet materials. J. Appl. Phys. 1951, 22, 130–134. [Google Scholar] [CrossRef]

- Schajer, G.S.; Prime, M.B. Use of Inverse Solutions for Residual Stress Measurements. J. Eng. Mater. Technol. 2006, 128, 375. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Y.; Li, X.; Li, L.; He, N.; Zhao, G.; Chen, N.; Lan, H.; Zhou, Z. Investigation on deformation of single-sided stringer parts based on fluctuant initial residual stress. J. Mater. Process. Technol. 2019, 271, 623–633. [Google Scholar] [CrossRef]

- Llanos, I.; Lanzagorta, J.L.; Beristain, A. Part Distortion Modeling on Aluminum Slender Structural Components for Aeronautical Industry. Procedia CIRP 2017, 58, 158–162. [Google Scholar] [CrossRef]

- Dreier, S.; Denkena, B. Determination of Residual Stresses in Plate Material by Layer Removal with Machine-integrated Measurement. Procedia CIRP 2014, 24, 103–107. [Google Scholar] [CrossRef]

- Gulpak, M.; Sölter, J.; Brinksmeier, E. Prediction of Shape Deviations in Face Milling of Steel. Procedia CIRP 2013, 8, 15–20. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, Y.; Wu, Q.; Li, B. Investigation on influences of initial residual stress on thin-walled part machining deformation based on a semi-analytical model. J. Mater. Process. Technol. 2018, 262, 437–448. [Google Scholar] [CrossRef]

- Hussain, A.; Lazoglu, I. Distortion in milling of structural parts. CIRP Ann. 2019, 68, 105–108. [Google Scholar] [CrossRef]

- Tang, Z.T.; Yu, T.; Xu, L.Q.; Liu, Z.Q. Machining deformation prediction for frame components considering multifactor coupling effects. Int. J. Adv. Manuf. Technol. 2013, 68, 187–196. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Li, J. Finite element simulation and experimental investigation on the residual stress-related monolithic component deformation. Int. J. Adv. Manuf. Technol. 2015, 77, 1035–1041. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Li, J. Effect of Initial Residual Stress and Machining-Induced Residual Stress on the Deformation of Aluminium Alloy Plate. J. Mech. Eng. 2015, 61, 131–137. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, J.; Yu, D.; Feng, P.; Xu, C. Modeling of machining distortion for thin-walled components based on the internal stress field evolution. Int. J. Adv. Manuf. Technol. 2019, 103, 3597–3612. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, J.; Liu, L.; Wang, R.; Chen, W. An analytical model to predict the machining deformation of frame parts caused by residual stress. J. Mater. Process. Technol. 2019, 274, 116282. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, Y.; Wu, Q.; Song, J. An analytical model for predicting the machining deformation of a plate blank considers biaxial initial residual stresses. Int. J. Adv. Manuf. Technol. 2017, 93, 1473–1486. [Google Scholar] [CrossRef]

- Timoshenko, S.; Goodier, J.N. Theory of Elasticity; McGraw-Hill: New York, NY, USA, 1982. [Google Scholar]

- Llanos, I.; Aurrekoetxea, M.; Agirre, A.; López de Lacalle, L.N.; Zelaieta, O. On-machine Characterization of Bulk Residual Stresses on Machining Blanks. Procedia CIRP 2019, 82, 406–410. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Muñoa, J.; Salgado, M.A.; Sánchez, J.A. Improving the high-speed finishing of forming tools for advanced high-strength steels (AHSS). Int. J. of Adv. Manufac. Tech. 2006, 29, 49–63. [Google Scholar] [CrossRef]

- ASTM. E837–08 Standard Test Method for Determining Residual Stress by the Hole-Drilling Strain Gage Method; ASTM International: West Conshohocken, PA, USA, 2008; Available online: www.astm.org (accessed on 19 March 2020).

- Ammula, S.C.; Guo, Y.B. Surface Integrity of Al 7050-T7451 and Al 6061-T651 Induced by High Speed Milling. SAE Tech. Paper 2005, 114, 1135–1143. [Google Scholar]

- Huang, X.; Sun, J.; Li, J.; Han, X.; Xiong, Q. An Experimental Investigation of Residual Stresses in High-Speed End Milling 7050-T7451 Aluminum Alloy. Adv. Mech. Eng. 2013, 5, 592659. [Google Scholar] [CrossRef]

- Tang, Z.T.; Liu, Z.Q.; Wan, Y.; Ai, X. Study on Residual Stresses in Milling Aluminium Alloy 7050-T7451. In Advanced Design and Manufacture to Gain a Competitive Edge; Springer: London, UK, 2008; pp. 169–178. [Google Scholar]

- Tang, Z.T.; Liu, Q.; Pan, Y.Z.; Wan, Y.; Ai, X. The influence of tool flank wear on residual stresses induced by milling aluminum alloy. J. Mater. Process. Technol. 2009, 209, 4502–4508. [Google Scholar] [CrossRef]

- Perez, I.; Madariaga, A.; Cuesta, M.; Garay, A.; Ruiz, J.J.; Rubio, F.J.; Sanchez, R. Effect of cutting speed on the surface integrity of face milled 7050-T7451 aluminium workpieces. Procedia CIRP 2018, 71, 460–465. [Google Scholar] [CrossRef]

| Mechanical Properties | Al7050-T7451 |

|---|---|

| Tensile Yield Strength [MPa] | 469 |

| Modulus of Elasticity [GPa] | 71.7 |

| Poisson’s ratio [-] | 0.33 |

| Density [g/cm3] | 2.83 |

| Parameter | Value |

|---|---|

| Cutting speed—Vc (m·min−1) | 500 |

| Feed per tooth—f (mm) | 0.1 |

| Axial depth of cut—ap (mm) | 1 |

| Radial depth of cut—ae (mm) | 30 |

| Parameter | Exp. | Bib. No. 1 | Bib. No. 2 | Bib. No. 3 |

|---|---|---|---|---|

| Tool Diameter | 40 | 32 | 32 | 32 |

| Cutting speed—Vc (m·min−1) | 500 | 200 | 800 | 1400 |

| Feed per tooth—f (mm) | 0.1 | 0.2 | 0.2 | 0.2 |

| Axial depth of cut—ap (mm) | 1 | 1 | 1 | 1 |

| Radial engagement—(%) | 75 | 75 | 75 | 75 |

| Rake angle—(°) | 20 | 11 | 11 | 11 |

| Clearance angle—(°) | 15 | 8 | 8 | 8 |

| Corner radius—(mm) | 0.4 | 0.2 | 0.2 | 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aurrekoetxea, M.; López de Lacalle, L.N.; Llanos, I. Machining Stresses and Initial Geometry on Bulk Residual Stresses Characterization by On-Machine Layer Removal. Materials 2020, 13, 1445. https://doi.org/10.3390/ma13061445

Aurrekoetxea M, López de Lacalle LN, Llanos I. Machining Stresses and Initial Geometry on Bulk Residual Stresses Characterization by On-Machine Layer Removal. Materials. 2020; 13(6):1445. https://doi.org/10.3390/ma13061445

Chicago/Turabian StyleAurrekoetxea, Maria, Luis Norberto López de Lacalle, and Iñigo Llanos. 2020. "Machining Stresses and Initial Geometry on Bulk Residual Stresses Characterization by On-Machine Layer Removal" Materials 13, no. 6: 1445. https://doi.org/10.3390/ma13061445

APA StyleAurrekoetxea, M., López de Lacalle, L. N., & Llanos, I. (2020). Machining Stresses and Initial Geometry on Bulk Residual Stresses Characterization by On-Machine Layer Removal. Materials, 13(6), 1445. https://doi.org/10.3390/ma13061445