Advances in Orthotic and Prosthetic Manufacturing: A Technology Review

Abstract

1. Introduction

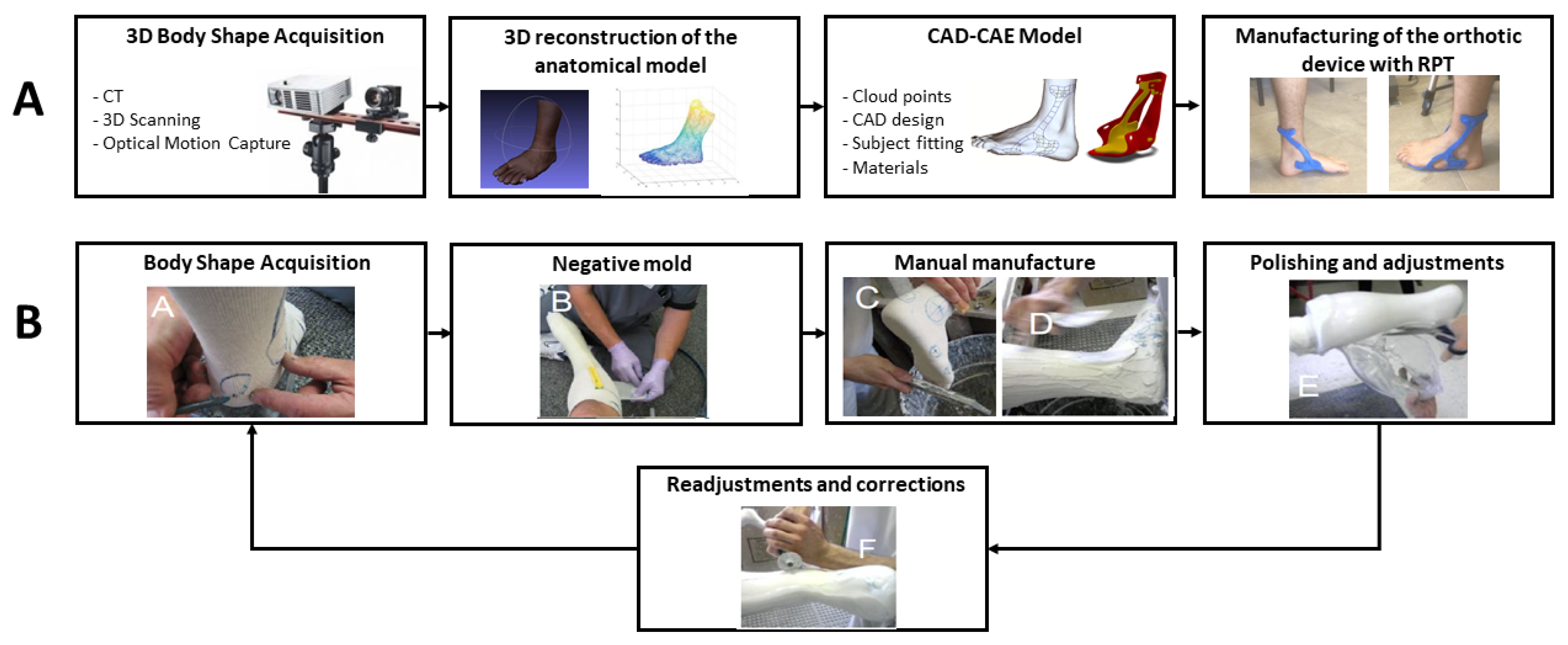

2. 3D Anatomical Data Acquisition Technologies

2.1. Computed Tomography

2.2. 3D Scanning

2.3. Optical Motion Capture System

3. Rapid Prototyping Technologies for Orthotic Devices

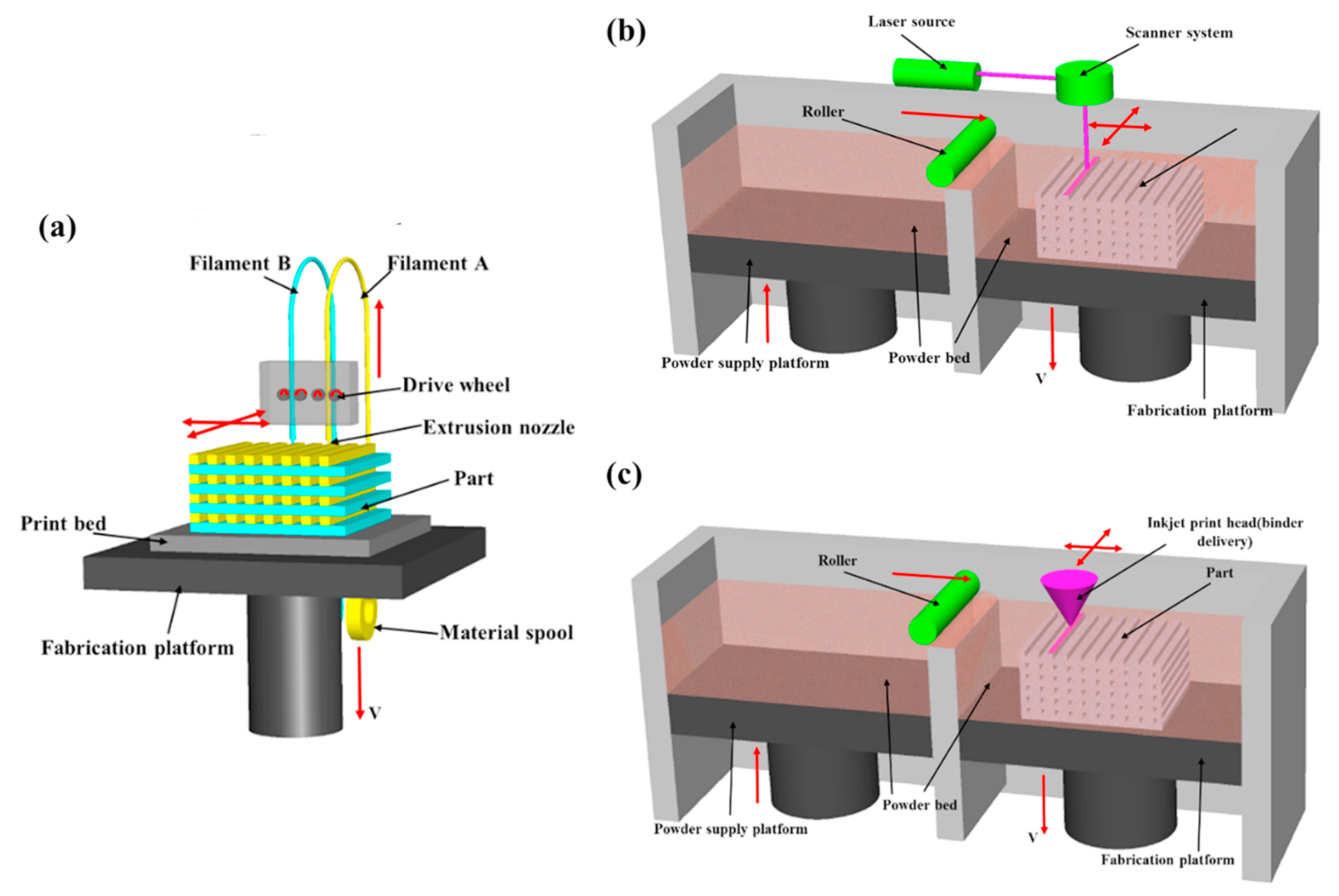

3.1. Fused Deposition Modeling (FDM)

3.2. Selective Laser Sintering (SLS)

3.3. Powder Bed and Inkjet Head 3D Printing: 3DP

4. Variable Property Rapid Prototyping

5. Material Selection for Orthotic Devices

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Webster, J. Atlas of Orthoses and Assistive Devices; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Meyer, P.R., Jr. Lower limb orthotics. Clin. Orthop. Relat. Res. 1974, 102, 58–71. [Google Scholar] [CrossRef] [PubMed]

- Mikołajewska, E.; Macko, M.; Szczepański, Z.; Mikołajewski, D. Reverse Engineering in Rehabilitation. In Encyclopedia of Information Science and Technology, 4th ed.; IGI Global: Hershey PA, USA, 2018; pp. 521–528. [Google Scholar]

- Jiang, R.; Kleer, R.; Piller, F.T. Predicting the future of additive manufacturing: A Delphi study on economic and societal implications of 3D printing for 2030. Technol. Forecast. Soc. Chang. 2017, 117, 84–97. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S. Biomedical applications of additive manufacturing: present and future. Curr. Opin. Biomed. Eng. 2017, 2, 105–115. [Google Scholar] [CrossRef]

- Gibson, I.; Srinath, A. Simplifying medical additive manufacturing: Making the surgeon the designer. Proced. Technol. 2015, 20, 237–242. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Espalin, D.; Arcaute, K.; Rodriguez, D.; Medina, F.; Posner, M.; Wicker, R. Fused deposition modeling of patient-specific polymethylmethacrylate implants. Rapid Prototyp. J. 2010, 16, 164–173. [Google Scholar] [CrossRef]

- Lantada, A.D.; Morgado, P.L. Rapid Prototyping for Biomedical Engineering: Current Capabilities and Challenges. Ann. Rev. Biomed. Eng. 2012, 14, 73–96. [Google Scholar] [CrossRef]

- Schrank, E.S.; Stanhope, S.J. Dimensional accuracy of ankle-foot orthoses constructed by rapid customization and manufacturing framework. J. Rehabil. Res. Dev. 2011, 48, 31–42. [Google Scholar] [CrossRef]

- Cobetto, N.; Aubin, C.E.; Clin, J.; Le May, S.; Desbiens-Blais, F.; Labelle, H.; Parent, S. Braces Optimized With Computer-Assisted Design and Simulations Are Lighter, More Comfortable, and More Efficient than Plaster-Cast Braces for the Treatment of Adolescent Idiopathic Scoliosis. Spine Deform. 2014, 2, 276–284. [Google Scholar] [CrossRef]

- Redaelli, D.F.; Storm, F.A.; Biffi, E.; Reni, G.; Colombo, G. A Virtual Design Process to Produce Scoliosis Braces by Additive Manufacturing. In International Conference on Design, Simulation, Manufacturing: The Innovation Exchange; Springer: Berlin, Germany, 2019; pp. 860–870. [Google Scholar]

- Bourell, D.; Stucker, B.; Cook, D.; Gervasi, V.; Rizza, R.; Kamara, S.; Liu, X. Additive fabrication of custom pedorthoses for clubfoot correction. Rapid Prototyp. J. 2010, 16, 189–193. [Google Scholar] [CrossRef]

- Langlois, K.; Moltedo, M.; Bacek, T.; Rodriguez-Guerrero, C.; Vanderborght, B.; Lefeber, D. Design and development of customized physical interfaces to reduce relative motion between the user and a powered ankle foot exoskeleton. In Proceedings of the 2018 7th IEEE International Conference on Biomedical Robotics and Biomechatronics (Biorob), Enschede, The Netherlands, 26–29 August 2018; pp. 1083–1088. [Google Scholar]

- Gibson, K.S.; Woodburn, J.; Porter, D.; Telfer, S. Functionally Optimized Orthoses for Early Rheumatoid Arthritis Foot Disease: A Study of Mechanisms and Patient Experience. Arthritis Care Res. 2014, 66, 1456–1464. [Google Scholar] [CrossRef] [PubMed]

- Pallari, J.H.P.; Dalgarno, K.W.; Woodburn, J. Mass customization of foot orthoses for rheumatoid arthritis using selective laser sintering. IEEE Trans. Biomed. Eng. 2010, 57, 1750–1756. [Google Scholar] [CrossRef] [PubMed]

- Baronio, G.; Harran, S.; Signoroni, A. A critical analysis of a hand orthosis reverse engineering and 3D printing process. Appl. Bionics Biomech. 2016, 2016, 8347478. [Google Scholar] [CrossRef] [PubMed]

- Campbell, I.; Diegel, O.; Kowen, J.; Wohlers, T. Wohlers Report 2018: 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2018. [Google Scholar]

- Zuniga, J.; Katsavelis, D.; Peck, J.; Stollberg, J.; Petrykowski, M.; Carson, A.; Fernandez, C. Cyborg beast: A low-cost 3d-printed prosthetic hand for children with upper-limb differences. BMC Res. Notes 2015, 8, 10. [Google Scholar] [CrossRef]

- De Carvalho Filho, I.F.P.; Medola, F.O.; Sandnes, F.E.; Paschoarelli, L.C. Manufacturing Technology in Rehabilitation Practice: Implications for Its Implementation in Assistive Technology Production. In Proceedings of the International Conference on Applied Human Factors and Ergonomics; Springer: Berlin, Germany, 2019; pp. 328–336. [Google Scholar]

- Fitzpatrick, A.P.; Mohanned, M.I.; Collins, P.K.; Gibson, I. Design of a patient specific, 3D printed arm cast. In Proceedings of the International Conference on Design and Technology, Geelong, Australia, 5–8 December 2016; pp. 135–142. [Google Scholar]

- Parvez, N.; Parvez, S. Andiamo Project. Available online: http://andiamo.io/ (accessed on 30 October 2019).

- Chevalier, T.; Chockalingam, N. Effects of foot orthoses: How important is the practitioner? Gait Posture 2012, 35, 383–388. [Google Scholar] [CrossRef]

- Dalgarno, K.; Pallari, J.; Woodburn, J.; Xiao, K.; Wood, D.; Goodridge, R.; Ohtsuki, C. Mass customization of medical devices and implants: state of the art and future directions. Virtual Phys. Prototyp. 2006, 1, 137–145. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Bourell, D.; Sreenivasan, R.; Hague, R. Sustainability of additive manufacturing: Measuring the energy consumption of the laser sintering process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 2228–2239. [Google Scholar] [CrossRef]

- Mavroidis, C.; Ranky, R.G.; Sivak, M.L.; Patritti, B.L.; DiPisa, J.; Caddle, A.; Gilhooly, K.; Govoni, L.; Sivak, S.; Lancia, M.; et al. Patient specific ankle-foot orthoses using rapid prototyping. J. Neuroeng. Rehabil. 2011, 8, 1. [Google Scholar] [CrossRef]

- Culmone, C.; Smit, G.; Breedveld, P. Additive manufacturing of medical instruments: A state-of-the-art review. In Additive Manufacturing; Elsvier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Palo, M.; Holländer, J.; Suominen, J.; Yliruusi, J.; Sandler, N. 3D printed drug delivery devices: perspectives and technical challenges. Expert Rev. Med. Devices 2017, 14, 685–696. [Google Scholar] [CrossRef]

- Jeon, O.; Lee, Y.B.; Jeong, H.; Lee, S.J.; Wells, D.; Alsberg, E. Individual cell-only bioink and photocurable supporting medium for 3D printing and generation of engineered tissues with complex geometries. Mater. Horiz. 2019, 9, 1625–1631. [Google Scholar] [CrossRef]

- Derakhshanfar, S.; Mbeleck, R.; Xu, K.; Zhang, X.; Zhong, W.; Xing, M. 3D bioprinting for biomedical devices and tissue engineering: A review of recent trends and advances. Bioact. Mater. 2018, 3, 144–156. [Google Scholar] [CrossRef] [PubMed]

- Koffler, J.; Zhu, W.; Qu, X.; Platoshyn, O.; Dulin, J.N.; Brock, J.; Graham, L.; Lu, P.; Sakamoto, J.; Marsala, M.; et al. Biomimetic 3D-printed scaffolds for spinal cord injury repair. Nat. Med. 2019, 25, 263. [Google Scholar] [CrossRef] [PubMed]

- Egan, P.F. Integrated design approaches for 3D printed tissue scaffolds: Review and outlook. Materials 2019, 12, 2355. [Google Scholar] [CrossRef] [PubMed]

- Dawood, A.; Marti, B.M.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Brit. Dent. J. 2015, 219, 521. [Google Scholar] [CrossRef]

- Tahayeri, A.; Morgan, M.; Fugolin, A.P.; Bompolaki, D.; Athirasala, A.; Pfeifer, C.S.; Ferracane, J.L.; Bertassoni, L.E. 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent. Mater. 2018, 34, 192–200. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Benabou, L.; Alfayad, S. Systematic Review of Prosthetic Socket Fabrication using 3D printing. In Proceedings of the 2018 ACM 4th International Conference on Mechatronics and Robotics Engineering, Valenciennes, France, 7–11 February 2018; pp. 137–141. [Google Scholar]

- Chae, M.P.; Rozen, W.M.; McMenamin, P.G.; Findlay, M.W.; Spychal, R.T.; Hunter-Smith, D.J. Emerging applications of bedside 3D printing in plastic surgery. Front. Surg. 2015, 2, 25. [Google Scholar] [CrossRef]

- Malik, H.H.; Darwood, A.R.; Shaunak, S.; Kulatilake, P.; Abdulrahman, A.; Mulki, O.; Baskaradas, A. Three-dimensional printing in surgery: A review of current surgical applications. J. Surg. Res. 2015, 199, 512–522. [Google Scholar] [CrossRef]

- Tack, P.; Victor, J.; Gemmel, P.; Annemans, L. 3D-printing techniques in a medical setting: A systematic literature review. Biomed. Eng. Online 2016, 15, 115. [Google Scholar] [CrossRef]

- Tang, L.; Wang, L.; Bao, W.; Zhu, S.; Li, D.; Zhao, N.; Liu, C. Functional gradient structural design of customized diabetic insoles. J. Mech. Behav. Biomed. Mater. 2019, 94, 279–287. [Google Scholar] [CrossRef]

- Artioli, B.O.; Kunkel, M.E.; Mestanza, S.N. Feasibility Study of a Methodology Using Additive Manufacture to Produce Silicone Ear Prostheses. In World Congress on Medical Physics and Biomedical Engineering 2018; Springer: Berlin, Germany, 2019; pp. 211–215. [Google Scholar]

- Liacouras, P.; Garnes, J.; Roman, N.; Petrich, A.; Grant, G.T. Designing and manufacturing an auricular prosthesis using computed tomography, 3-dimensional photographic imaging, and additive manufacturing: a clinical report. J. Prosthet. Dent. 2011, 105, 78–82. [Google Scholar] [CrossRef]

- Liacouras, P.C.; Sahajwalla, D.; Beachler, M.D.; Sleeman, T.; Ho, V.B.; Lichtenberger, J.P. Using computed tomography and 3D printing to construct custom prosthetics attachments and devices. 3D Print. Med. 2017, 3, 8. [Google Scholar] [CrossRef] [PubMed]

- Diwakar, M.; Kumar, M. A review on CT image noise and its denoising. Biomed. Signal Process. Control 2018, 42, 73–88. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. 3D scanning applications in medical field: A literature-based review. Clin. Epidemiol. Global Health 2019, 7, 199–210. [Google Scholar] [CrossRef]

- Górski, F.; Zawadzki, P.; Wichniarek, R.; Kuczko, W.; Żukowska, M.; Wesołowska, I.; Wierzbicka, N. Automated Design of Customized 3D-Printed Wrist Orthoses on the Basis of 3D Scanning. In International Conference on Computational & Experimental Engineering and Sciences; Springer: Berlin, Germany, 2019; pp. 1133–1143. [Google Scholar]

- Grazioso, S.; Caporaso, T.; Selvaggio, M.; Panariello, D.; Ruggiero, R.; Di Gironimo, G. Using photogrammetric 3D body reconstruction for the design of patient–tailored assistive devices. In Proceedings of the IEEE 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4. 0&IoT), Naples, Italy, 4–6 June 2019; pp. 240–242. [Google Scholar]

- Barrios-Muriel, J.; Romero Sánchez, F.; Alonso, F.; Salgado, D. Design of Semirigid Wearable Devices Based on Skin Strain Analysis. J. Biomech. Eng. 2019, 141, 021008. [Google Scholar]

- Bogo, F.; Romero, J.; Pons-Moll, G.; Black, M.J. Dynamic FAUST: Registering human bodies in motion. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 6233–6242. [Google Scholar]

- Thompson, A.; McNally, D.; Maskery, I.; Leach, R.K. X-ray computed tomography and additive manufacturing in medicine: A review. Int. J. Metrol. Qual. Eng. 2017, 8, 17. [Google Scholar] [CrossRef]

- Dal Maso, A.; Cosmi, F. 3D-printed ankle-foot orthosis: a design method. Mater. Today Proc. 2019, 12, 252–261. [Google Scholar] [CrossRef]

- Parrilla, E.; Ballester, A.; Solves-Camallonga, C.; Nácher, B.; Antonio Puigcerver, S.; Uriel, J.; Piérola, A.; González, J.C.; Alemany, S. Low-cost 3D foot scanner using a mobile app. Footwear Sci. 2015, 7, S26–S28. [Google Scholar] [CrossRef]

- Chee Kai, C.; Siaw Meng, C.; Sin Ching, L.; Seng Teik, L.; Chit Aung, S. Facial prosthetic model fabrication using rapid prototyping tools. Integr. Manuf. Syst. 2000, 11, 42–53. [Google Scholar] [CrossRef]

- Paterson, A. Digitisation of the Splinting Process: Exploration and Evaluation of a Computer Aided Design Approach to Support Additive Manufacture. Ph.D Thesis, Loughborough University, Loughborough, UK, 2013. [Google Scholar]

- Mali, H.S.; Vasistha, S. Fabrication of Customized Ankle Foot Orthosis (AFO) by Reverse Engineering Using Fused Deposition Modelling. In Advances in Additive Manufacturing and Joining; Springer: Berlin, Germany, 2020; pp. 3–15. [Google Scholar]

- Agudelo-Ardila, C.; Prada-Botía, G.; PH, R. Orthotic prototype for upper limb printed in 3D: A efficient solution. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 1388, p. 012016. [Google Scholar]

- Kimura, M.; Mochimaru, M.; Kanade, T. Measurement of 3D foot shape deformation in motion. In Proceedings of the ACM 5th ACM/IEEE International Workshop on Projector Camera Systems, Bali Way, CA, USA, 20 August 2008; p. 10. [Google Scholar] [CrossRef]

- Mo, S.; Leung, S.H.; Chan, Z.Y.; Sze, L.K.; Mok, K.M.; Yung, P.S.; Ferber, R.; Cheung, R.T. The biomechanical difference between running with traditional and 3D printed orthoses. J. Sports Sci. 2019, 37, 2191–2197. [Google Scholar] [CrossRef]

- Liberadzki, P.; Adamczyk, M.; Witkowski, M.; Sitnik, R. Structured-Light-Based System for Shape Measurement of the Human Body in Motion. Sensors 2018, 18, 2827. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Spintzyk, S.; Brom, J.; Huettig, F.; Keutel, C. Direct 3D printing of silicone facial prostheses: A preliminary experience in digital workflow. Journal Prosthet. Dent. 2018, 120, 303–308. [Google Scholar] [CrossRef] [PubMed]

- Schmeltzpfenning, T.; Plank, C.; Krauss, I.; Aswendt, P.; Grau, S. Dynamic foot scanning. Prospects and limitations of using synchronized 3D scanners to capture complete human foot shape while walking. In Advances in Applied Digital Human Modeling, Proceedings of the 3rd International Conference on Applied Human Factors and Ergonomics, Miami, FL, USA, 19–22 July, 2010; Karwowski, W., Salvendy, G., Eds.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Chatzitofis, A.; Zarpalas, D.; Kollias, S.; Daras, P. DeepMoCap: Deep Optical Motion Capture Using Multiple Depth Sensors and Retro-Reflectors. Sensors 2019, 19, 282. [Google Scholar] [CrossRef] [PubMed]

- Joo, H.; Simon, T.; Sheikh, Y. Total capture: A 3d deformation model for tracking faces, hands, and bodies. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–22 June 2018; pp. 8320–8329. [Google Scholar]

- Ciobanu, O.; Ciobanu, G.; Rotariu, M. Photogrammetric scanning technique and rapid prototyping used for prostheses and ortheses fabrication. Appl. Mech. Mater. 2013, 371, 230–234. [Google Scholar] [CrossRef]

- Kudelski, R.; Dudek, P.; Kulpa, M.; Rumin, R. Using reverse engineering and rapid prototyping for patient specific orthoses. In Proceedings of the IEEE 2017 XIIIth International Conference on Perspective Technologies and Methods in MEMS Design (MEMSTECH), Lviv, Ukraine, 20–23 April 2017; pp. 88–90. [Google Scholar]

- Vitali, A.; Regazzoni, D.; Rizzi, C.; Colombo, G. Design and additive manufacturing of lower limb prosthetic socket. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 10 January 2017. [Google Scholar]

- Kruth, P.P. Material Incress Manufacturing by Rapid Prototyping Techniques. CIRP Ann. Manuf. Technol. 1991, 40, 603–614. [Google Scholar] [CrossRef]

- Paterson, A.M.; Bibb, R.; Campbell, R.I.; Bingham, G. Comparing additive manufacturing technologies for customised wrist splints. Rapid Prototyp. J. 2015, 21, 230–243. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications (with Companion Media Pack) of Rapid Prototyping, 4th ed.; World Scientific Publishing Company: Singapore, 2014. [Google Scholar]

- Petrovic, V.; Vicente Haro Gonzalez, J.; Jorda Ferrando, O.; Delgado Gordillo, J.; Ramon Blasco Puchades, J.; Portoles Grinan, L. Additive layered manufacturing: Sectors of industrial application shown through case studies. Int. J. Prod. Res. 2011, 49, 1061–1079. [Google Scholar] [CrossRef]

- Tan, K.C.; Lee, P.V.S.; Tam, K.F.; Lye, S.L. Automation of prosthetic socket design and fabrication using computer aided design/computer aided engineering and rapid prototyping techniques. In Proceedings of the First National Symposium of Prosthetics and Orthotics, Singapore, Republic of Singapore, 28 October 1998; pp. 19–22. [Google Scholar]

- Leite, M.; Soares, B.; Lopes, V.; Santos, S.; Silva, M.T. Design for personalized medicine in orthotics and prosthetics. Proced. CIRP 2019, 84, 457–461. [Google Scholar] [CrossRef]

- Abdullah, A.M.; Mohamad, D.; Din, T.N.D.T.; Yahya, S.; Akil, H.M.; Rajion, Z.A. Fabrication of nasal prosthesis utilising an affordable 3D printer. Int. J. Adv. Manuf. Technol. 2019, 100, 1907–1912. [Google Scholar] [CrossRef]

- Melocchi, A.; Parietti, F.; Loreti, G.; Maroni, A.; Gazzaniga, A.; Zema, L. 3D printing by fused deposition modeling (FDM) of a swellable/erodible capsular device for oral pulsatile release of drugs. J. Drug Deliv. Sci. Technol. 2015, 30, 360–367. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Beaman, J.; Deckard, C. Selective laser sintering with assisted powder handling. U.S. Patent No. 4,938,816, 3 July 1990. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin, Germany, 2015. [Google Scholar]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Deckers, J.P.; Vermandel, M.; Geldhof, J.; Vasiliauskaite, E.; Forward, M.; Plasschaert, F. Development and clinical evaluation of laser-sintered ankle foot orthoses. Plast. Rubber Compos. 2018, 47, 42–46. [Google Scholar] [CrossRef]

- Vasiliauskaite, E.; Ielapi, A.; Deckers, J.; Vermandel, M.; De Beule, M.; Van Paepegem, W.; Forward, M.; Plasschaert, F. Selective laser sintered ankle foot orthosis can support drop foot gait. In 16th National Day on Biomedical Engineering; National Committee on Biomedical Engineering (NCBME): Brussels, Belgium, 1 December 2017; p. 23. [Google Scholar]

- Oxman, N. Material-Based Design Computation. Ph.D Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Evill, J. Cortex. 2013. Available online: http://www.evilldesign.com/cortex (accessed on 29 October 2019).

- Herbert, N.; Simpson, D.; Spence, W.D.; Ion, W. A preliminary investigation into the development of 3-D printing of prosthetic sockets. J. Rehabil. Res. Dev. 2005, 42, 141–146. [Google Scholar] [CrossRef] [PubMed]

- Saijo, H.; Igawa, K.; Kanno, Y.; Mori, Y.; Kondo, K.; Shimizu, K.; Suzuki, S.; Chikazu, D.; Iino, M.; Anzai, M.; et al. Maxillofacial reconstruction using custom-made artificial bones fabricated by inkjet printing technology. J. Artif. Org. 2009, 12, 200–205. [Google Scholar] [CrossRef] [PubMed]

- Ventola, C.L. Medical Applications for 3D Printing: Current and Projected Uses. Pharm. Ther. 2014, 39, 704–711. [Google Scholar]

- Oxman, N. Variable property rapid prototyping. Virtual Phys. Prototyp. 2011, 6, 3–31. [Google Scholar]

- Peng, H.; Mankoff, J.; Hudson, S.E.; McCann, J. A Layered Fabric 3D Printer for Soft Interactive Objects. In Proceedings of the ACM 33rd Annual ACM Conference on Human Factors in Computing Systems, Seoul, Korea, 18–23 April 2015; pp. 1789–1798. [Google Scholar] [CrossRef]

- Campbell, I.; Bourell, D.; Gibson, I. Additive manufacturing: Rapid prototyping comes of age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef]

- Silva, M.; Felismina, R.; Mateus, A.; Parreira, P.; Malça, C. Application of a hybrid additive manufacturing methodology to produce a metal/polymer customized dental implant. Proced. Manuf. 2017, 12, 150–155. [Google Scholar] [CrossRef]

- Vaish, A.; Vaish, R. 3D printing and its applications in Orthopedics. J. Clin. Orthop. Trauma 2018, 9, S74–S75. [Google Scholar] [CrossRef]

- Ciobanu, O.; Soydan, Y.; Hizal, S. Customized foot orthosis manufactured with 3D printers. In Proceedings of the 8th International Symposium on Intelligent Manufacturing Systems, Antalya, Turkey, 27–28 September 2012. 7p. [Google Scholar]

- Paton, J.; Jones, R.B.; Stenhouse, E.; Bruce, G. The physical characteristics of materials used in the manufacture of orthoses for patients with diabetes. Foot Ankle Int. 2007, 28, 1057–1063. [Google Scholar] [CrossRef]

- Ma, Z.; Lin, J.; Xu, X.; Ma, Z.; Tang, L.; Sun, C.; Li, D.; Liu, C.; Zhong, Y.; Wang, L. Design and 3D printing of adjustable modulus porous structures for customized diabetic foot insoles. Int. J. Lightweight Mater. Manuf. 2019, 2, 57–63. [Google Scholar] [CrossRef]

- Faustini, M.C.; Neptune, R.R.; Crawford, R.H.; Stanhope, S.J. Manufacture of passive dynamic ankle-foot orthoses using selective laser sintering. IEEE Trans. Biomed. Eng. 2008, 55, 784–790. [Google Scholar] [CrossRef] [PubMed]

- Walbran, M.; Turner, K.; McDaid, A. Customized 3D printed ankle-foot orthosis with adaptable carbon fibre composite spring joint. Cogent Eng. 2016, 3, 1227022. [Google Scholar] [CrossRef]

- Trauner, K.B. The emerging role of 3D printing in arthroplasty and orthopedics. J. Arthroplast. 2018, 33, 2352–2354. [Google Scholar] [CrossRef]

- Tsai, W.; Yang, Y.; Chen, C.H. A wearable 3D printed elbow exoskeleton to improve upper limb rehabilitation in stroke patients. In Smart Science, Design & Technology: Proceedings of the 5th International Conference on Applied System Innovation (ICASI 2019), Fukuoka, Japan, 12–18 April 2019; CRC Press: Boca, Raton, FL, USA, 2019; p. 231. [Google Scholar]

- Ang, B.W.; Yeow, C.H. Print-it-Yourself (PIY) glove: a fully 3D printed soft robotic hand rehabilitative and assistive exoskeleton for stroke patients. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 1219–1223. [Google Scholar]

| Material | Process |

|---|---|

| Liquid base | Stereolithography (SLA) |

| Solid ground curing (SGC) | |

| UV light-curing (ULC) | |

| Ballistic particle manufacturing (BPM) | |

| Solid base | Laminated object manufacturing (LOM) |

| Fused deposition modeling (FDM) | |

| Powder base | Selective laser sintering (SLS) |

| 3D printing (Polymer injection) |

| FDM | SLS | 3DP | |

|---|---|---|---|

| Model | Dimension STT 768 | spro 60 SD SLS | uPrint System |

| Production Time (h) | 7 | 3 | 7 |

| Active volume (mm) | 203 × 203 × 305 | 381 × 330 × 457 | 203 × 152 × 152 |

| Material | ABS P400 | Duraform PA (Nylon 12) | ABS P430 |

| Material consumption (g) | 40 | 20.15 | 55 |

| Cost ($/kg) | 190 | 90 | 30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Rodríguez Salgado, D. Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials 2020, 13, 295. https://doi.org/10.3390/ma13020295

Barrios-Muriel J, Romero-Sánchez F, Alonso-Sánchez FJ, Rodríguez Salgado D. Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials. 2020; 13(2):295. https://doi.org/10.3390/ma13020295

Chicago/Turabian StyleBarrios-Muriel, Jorge, Francisco Romero-Sánchez, Francisco Javier Alonso-Sánchez, and David Rodríguez Salgado. 2020. "Advances in Orthotic and Prosthetic Manufacturing: A Technology Review" Materials 13, no. 2: 295. https://doi.org/10.3390/ma13020295

APA StyleBarrios-Muriel, J., Romero-Sánchez, F., Alonso-Sánchez, F. J., & Rodríguez Salgado, D. (2020). Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials, 13(2), 295. https://doi.org/10.3390/ma13020295