A New, Carbon-Negative Precipitated Calcium Carbonate Admixture (PCC-A) for Low Carbon Portland Cements

Abstract

1. Introduction

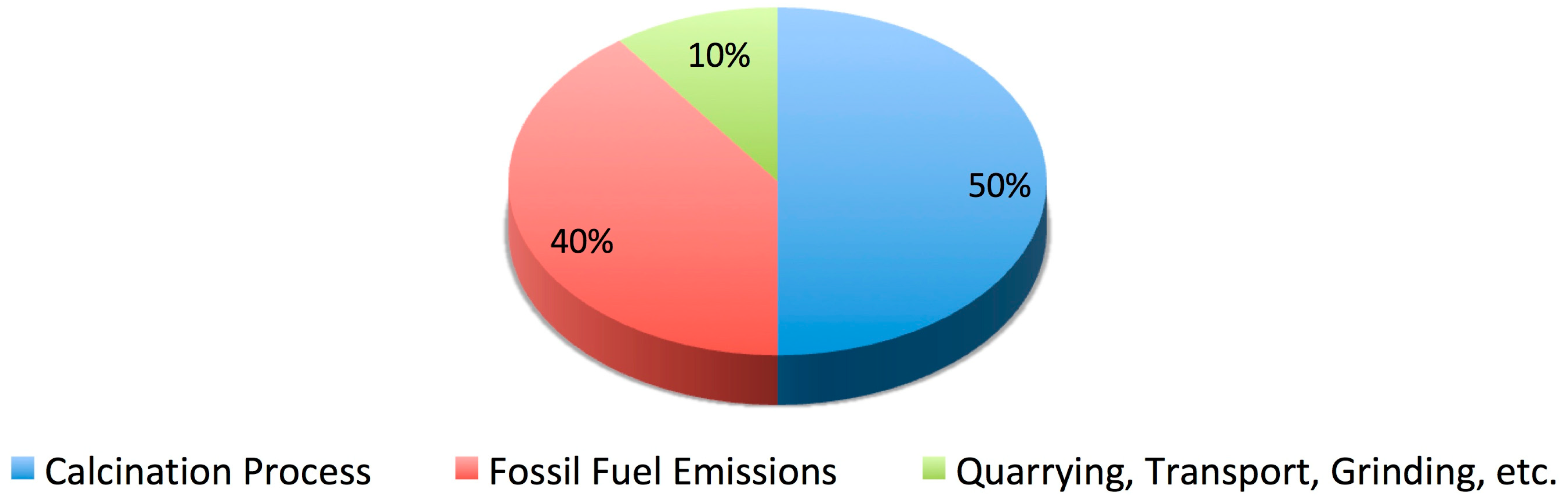

1.1. Background

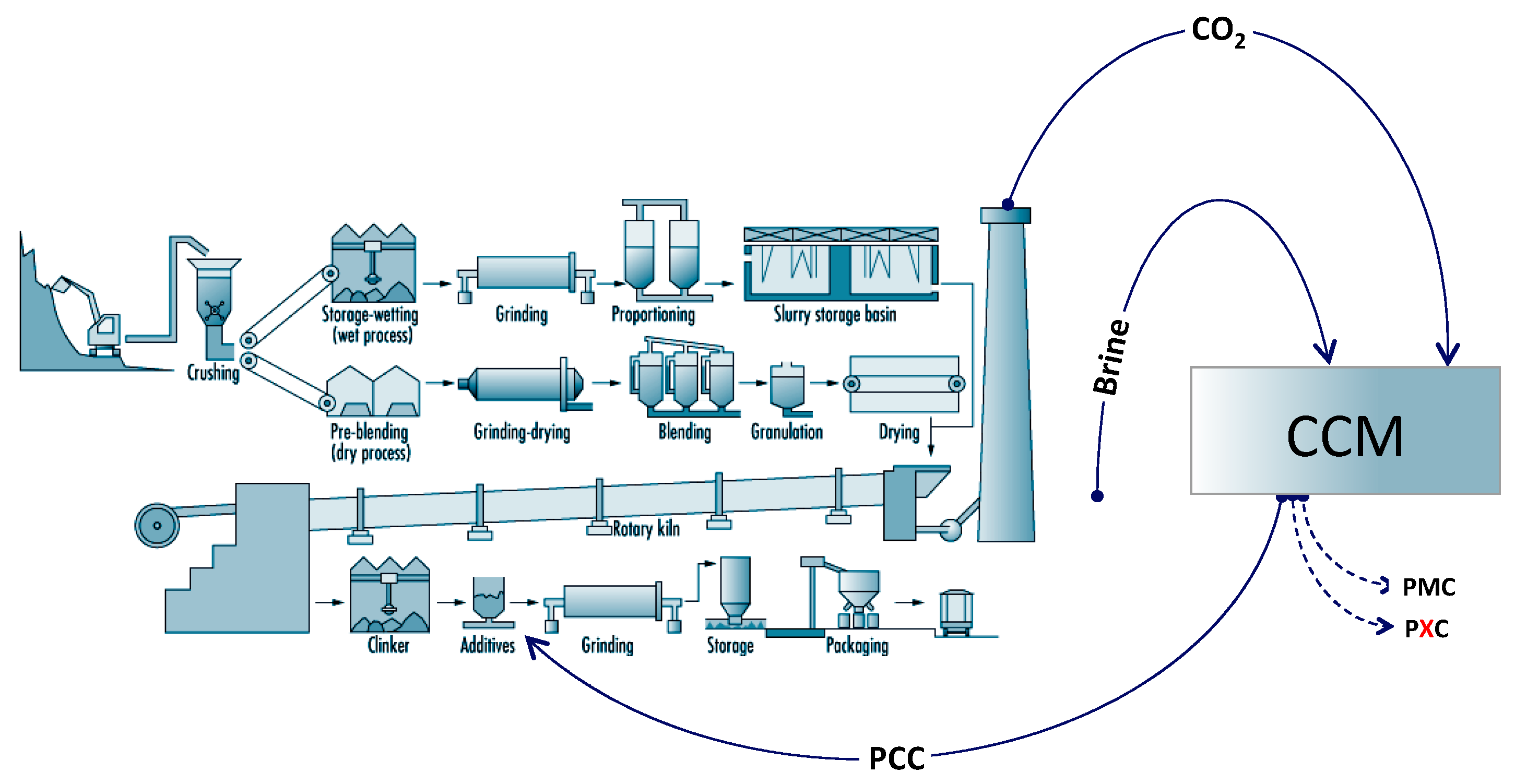

1.2. Carbon Capture and Utilisation in Cement Production

2. Materials and Methods

2.1. Materials

2.2. X-ray Diffraction (XRD) Analysis

2.3. Rheological Data

2.4. Compressive Strength

2.5. Scanning Electron Microscope (SEM) Imaging

3. Results and Discussion

3.1. XRD Analysis

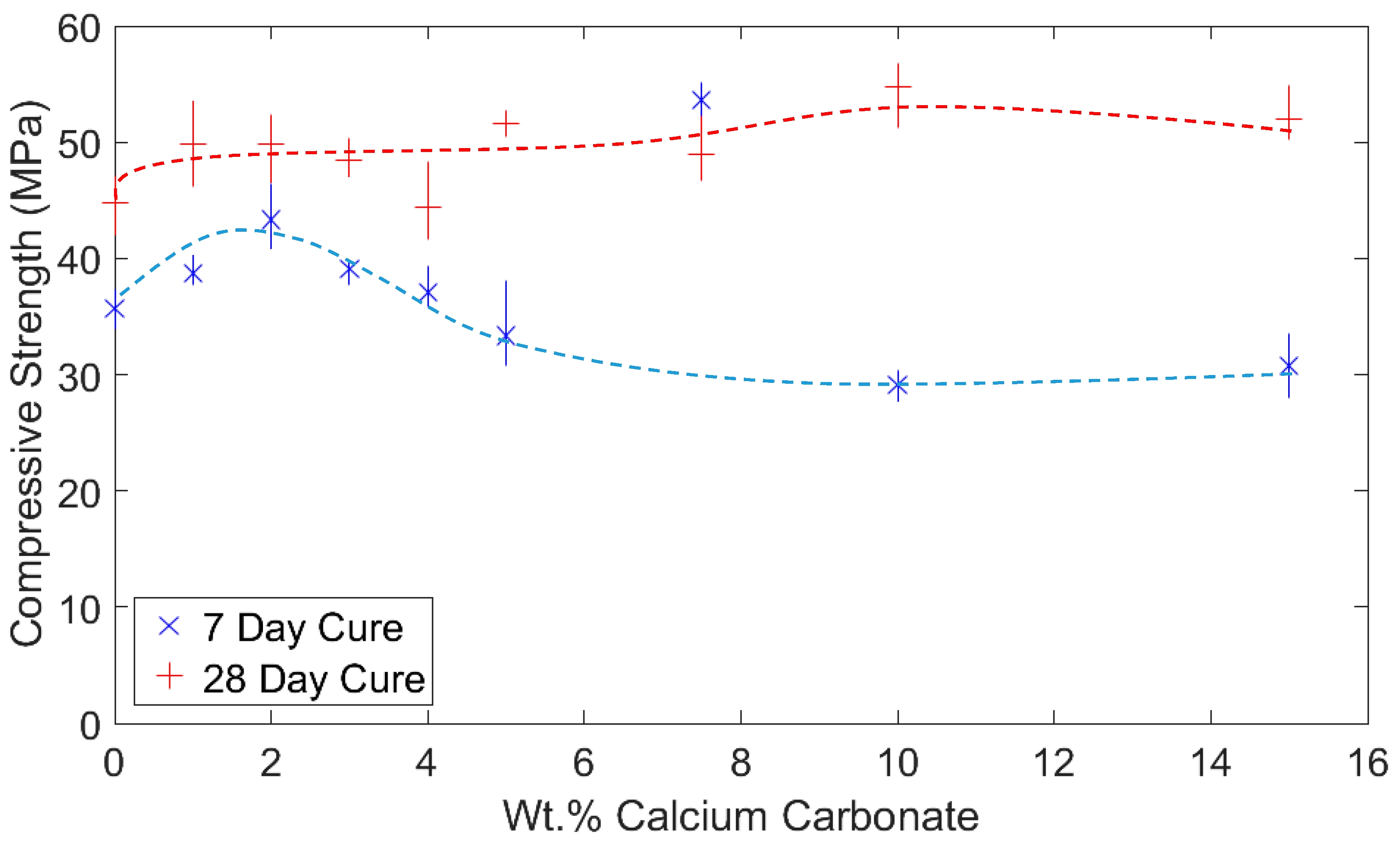

3.2. Determination of Strength

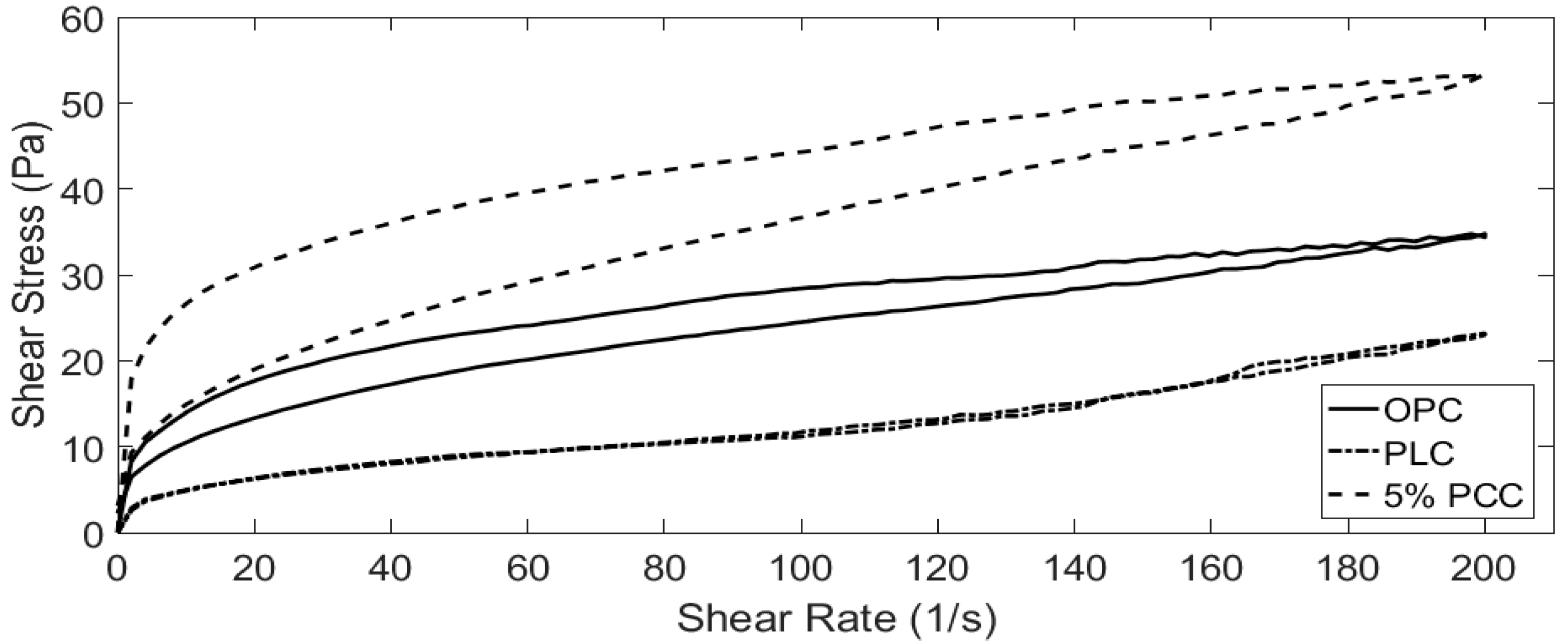

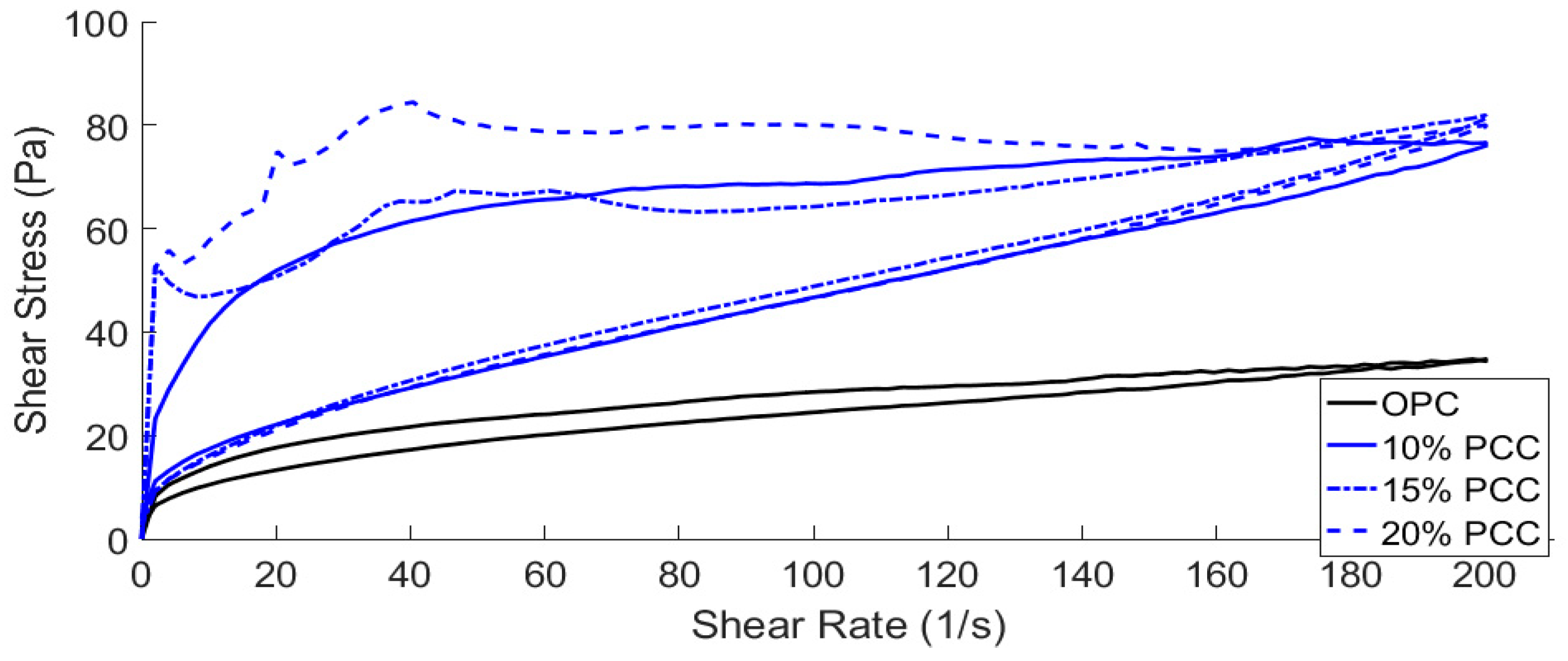

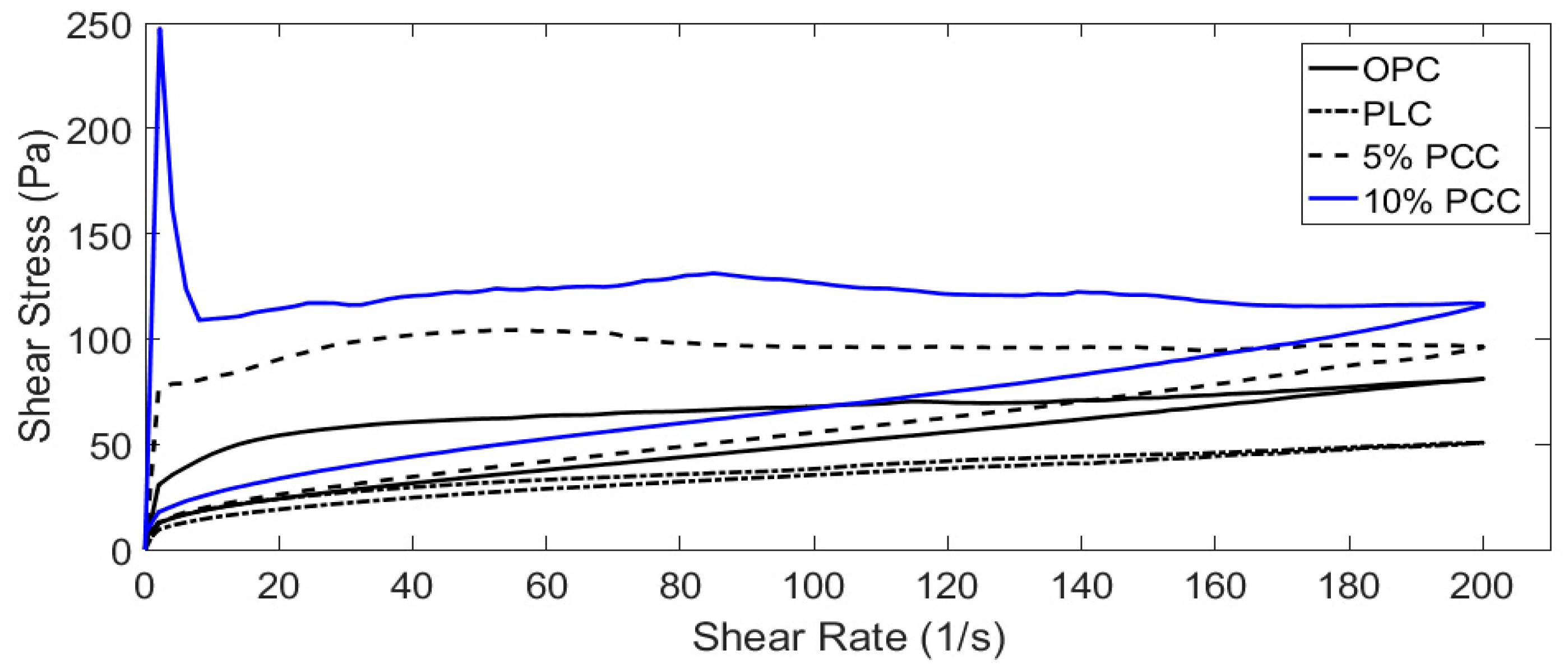

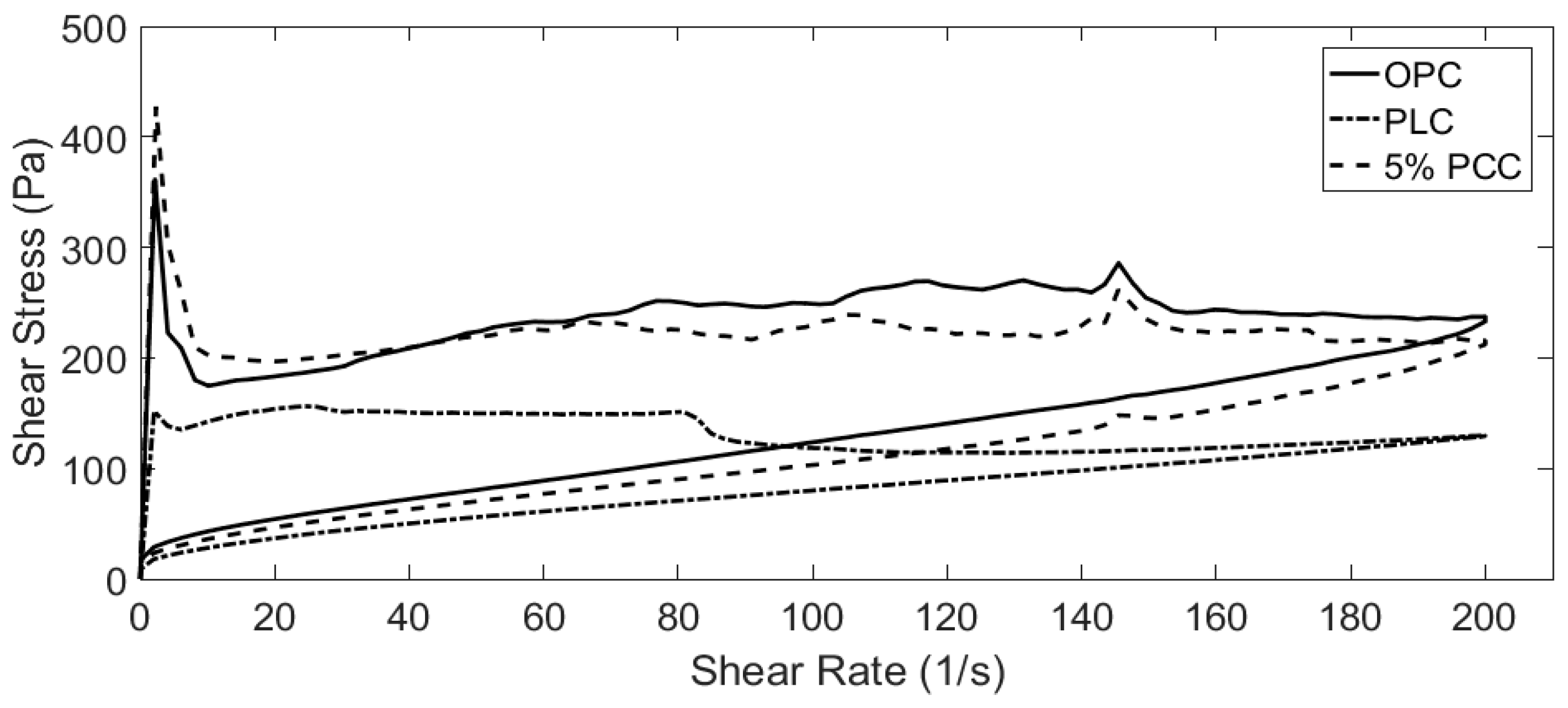

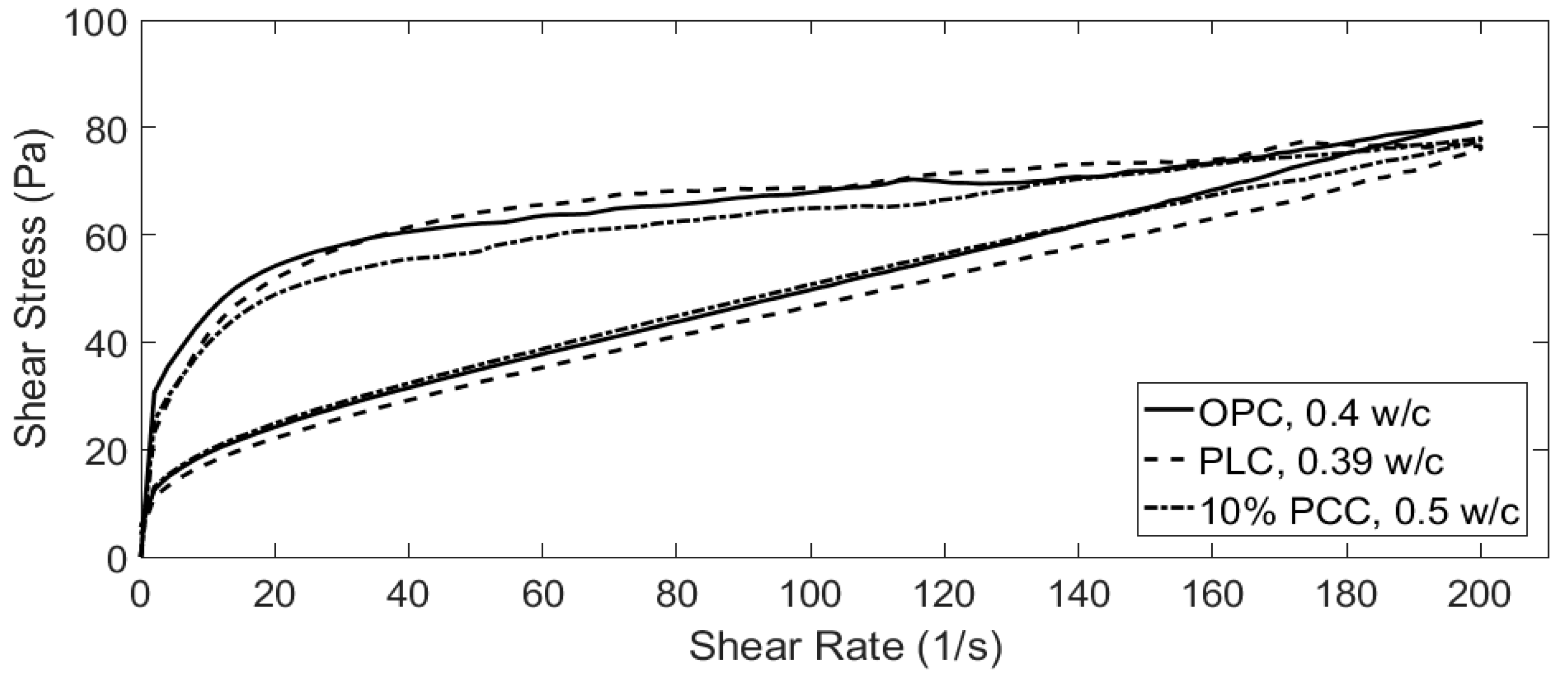

3.3. Rheological Analysis

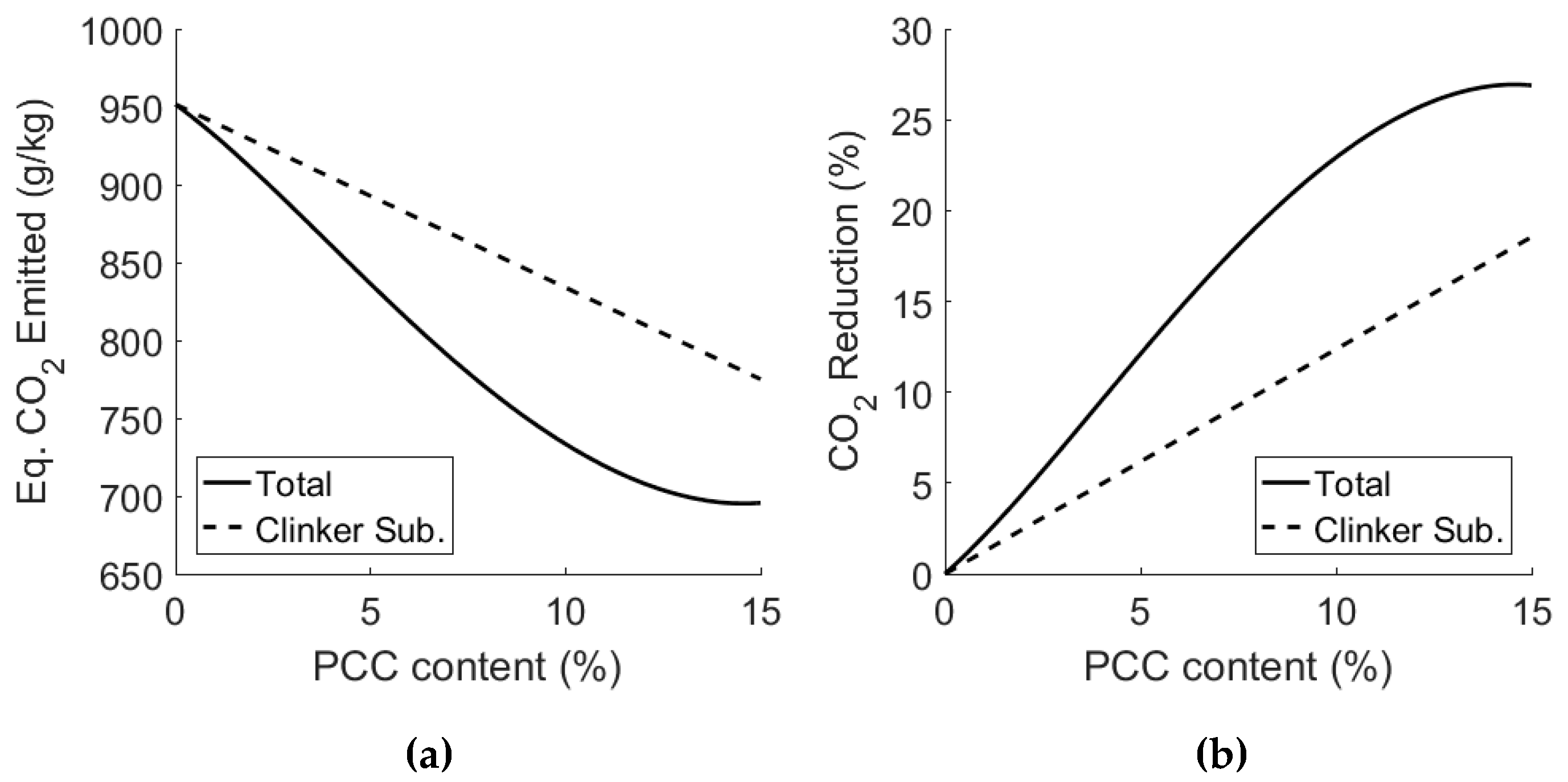

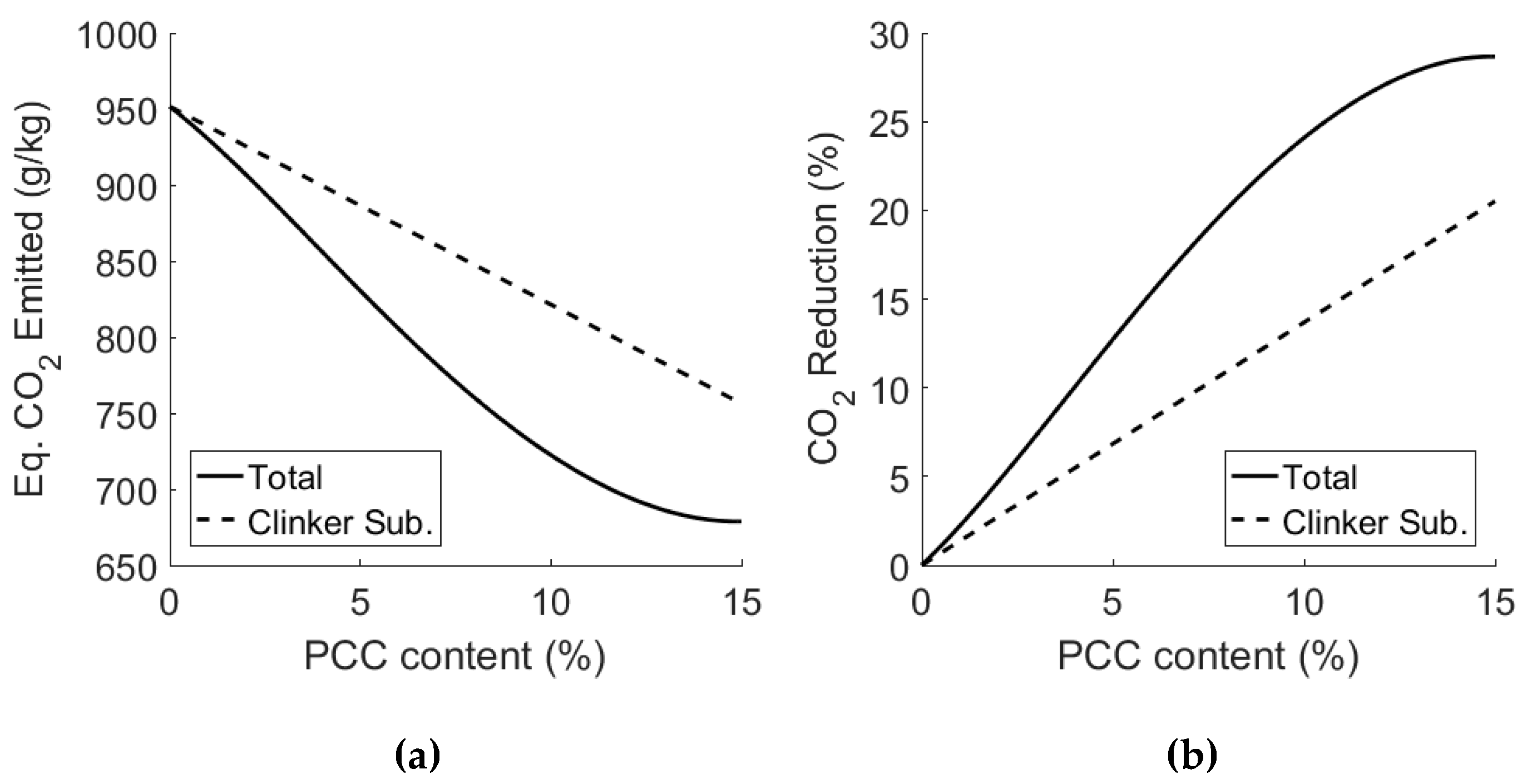

3.4. Scope for Emission Reduction of PCC-A Cement Blends

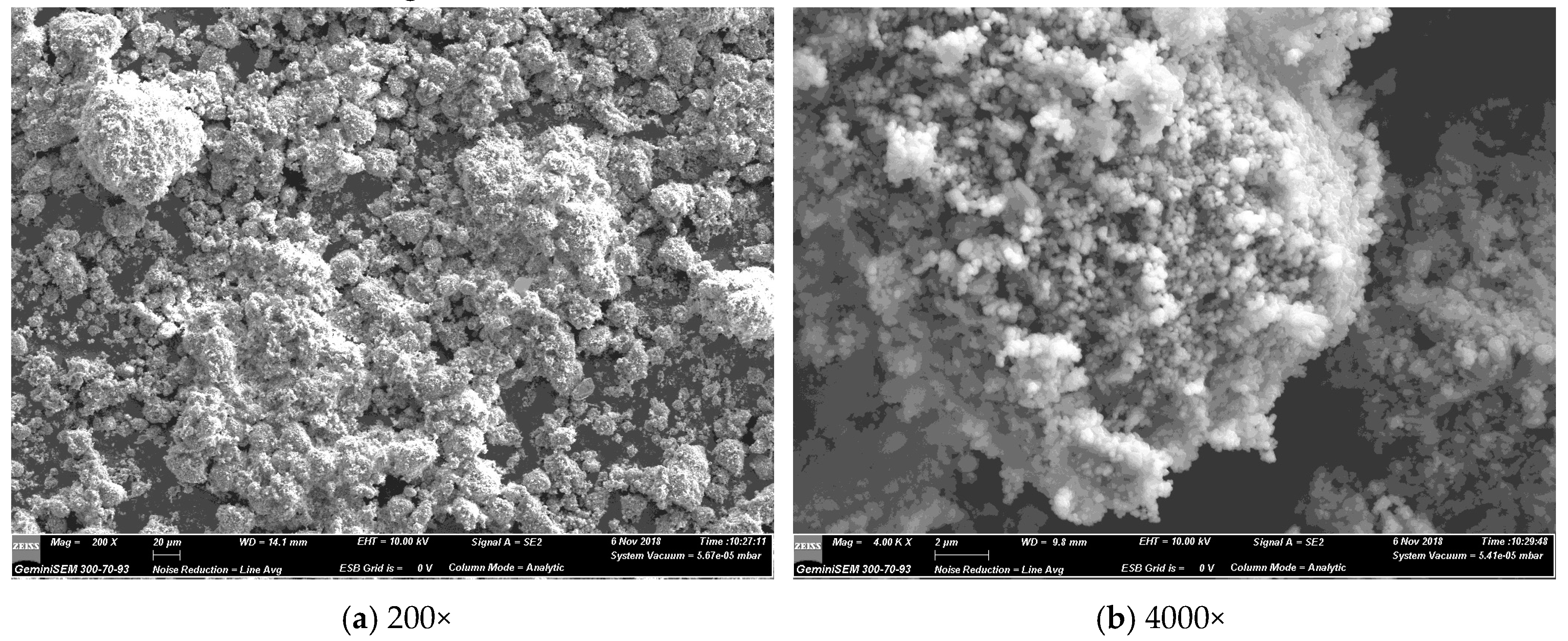

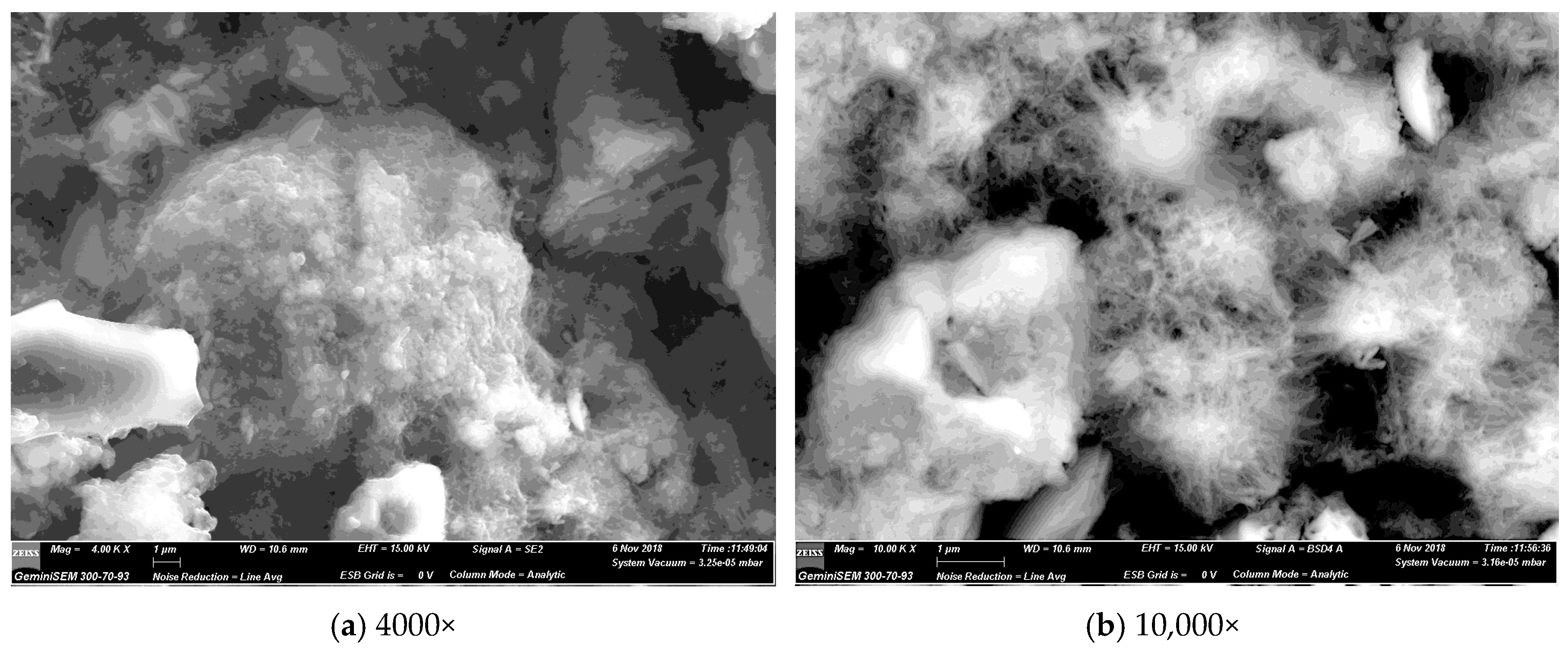

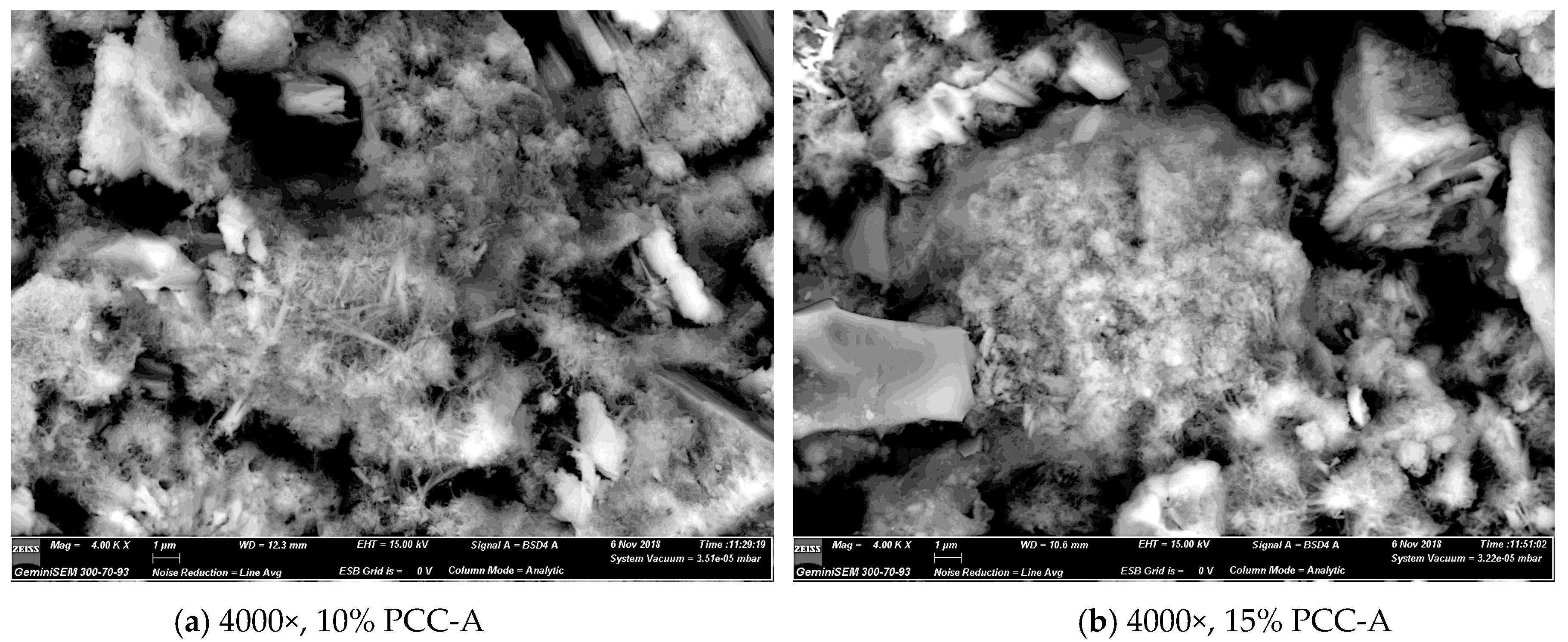

3.5. SEM Imaging

4. Conclusions

- The testing of PCC-A for use in mortars to determine the binding effects on aggregates;

- Examination of PCC-A cements after long curing times to study the evolution of carboaluminate phases;

- Investigation of the inverse effects on rheology compared with PLC;

- Full LCA of PCC-A blended cements using more alkali-efficient mineralisation processes;

- Preparation of PCC-A blended cements containing polymorphs of PCC-A to determine if crystal structure plays a role in reactivity during hydration.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Summerbell, D.L.; Barlow, C.Y.; Cullen, J.M. Potential reduction of carbon emissions by performance improvement: A cement industry case study. J. Clean. Prod. 2016, 135, 430–442. [Google Scholar] [CrossRef]

- Habert, G. Environmental Impact of Portland Cement Production. In Eco-Efficient Concrete, 1st ed.; Pacheco-Torgal, F., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 3–80. [Google Scholar]

- Scrivener, K.L.; Vanderley, M.J. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Kittipongvises, S. Assessment of environmental impacts of limestone quarrying operations in Thailand. Environ. Clim. Technol. 2017, 20, 67–83. [Google Scholar] [CrossRef]

- Jeong, Y.; Hargis, C.W.; Chun, S.; Moon, J. Effect of calcium carbonate fineness on calcium sulfoaluminate-belite cement. Materials 2017, 10, 900. [Google Scholar] [CrossRef] [PubMed]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The role of calcium carbonate in cement hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, S.; Li, X. Mechanical attributes of uniaxial compression of calcium carbonate whisker reinforced oil well cement pastes. Adv. Mater. Sci. Eng. 2017, 13. [Google Scholar] [CrossRef]

- Ipavec, A.; Gabrovsel, R.; Vuk, T.; Venceslav, K.; Macek, J.; Meden, A. Carboaluminate phases formation during the hydration of calcite-containing Portland cement. J. Am. Ceram. Soc. 2011, 94, 1238–1242. [Google Scholar] [CrossRef]

- Kurdowski, W. Cement and Concrete Chemistry, 1st ed.; Springer: Dordrecht, The Netherlands, 2014; pp. 205–272. [Google Scholar]

- Péra, J.; Husson, S.; Guilhot, B. Influence of finely ground limestone on cement hydration. Cem. Concr. Compos. 1999, 21, 99–105. [Google Scholar] [CrossRef]

- Ipavec, A.; Gabrovšek, R.; Vuk, T.; Kaučič, V.; Maček, J.; Meden, A. Carboaluminate phases formation during hydration of calcite-containing Portland cement. J. Am. Ceram. Soc. 2010, 94, 969–1303. [Google Scholar] [CrossRef]

- Lehne, J.; Preston, F. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete; Chatham House Report, Energy Enivronment and Resources Department: London, UK, 2018; pp. 1–66. [Google Scholar]

- David, J.; Herzog, H. The cost of carbon capture. In Proceedings of the Fifth International Conference on Greenhouse Gas Control Technologies, Cairns, Australia, 13–16 August 2000. [Google Scholar]

- Solidia Technologies. Available online: Solidiatech.com (accessed on 13 December 2018).

- Carbon Cure. Available online: Carboncure.com/technology (accessed on 13 December 2018).

- Carbon Upcycling UCLA. Available online: www.co2upcycling.com (accessed on 13 December 2018).

- Zhang, D.; Ghouleh, Z.; Shao, Y. Review of carbonation curing of cement-based materials. J. CO2 Util. 2017, 21, 119–131. [Google Scholar] [CrossRef]

- Klemm, W.; Berger, R. Accelerated curing of cementitious systems by carbon dioxide: Part I. Portland cement. Cem. Concr. Res. 1972, 2, 567–576. [Google Scholar] [CrossRef]

- Seo, J.H.; Amr, I.T.; Park, S.M.; Bamagain, R.A.; Fadhel, B.A.; Kim, G.M.; Hunaidy, A.S.; Lee, H.K. CO2 uptake of carbonation-cured cement blended with ground volcanic ash. Materials 2015, 11, 2187. [Google Scholar] [CrossRef] [PubMed]

- Rostami, V.; Shao, Y.; Boyd, A.J. Carbonation curing versus steam curing for precast concrete production. J. Mater. Civil Eng. 2011, 24, 1221–1229. [Google Scholar] [CrossRef]

- Böhni, H. Corrosion in Reinforced Concrete Structures, 1st ed.; Woodhead Publishing: Cambridge, UK, 2005. [Google Scholar]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and developments in green cement and concrete technology. Int. J. Sustain. Built Environ. 2012, 1/2, 194–216. [Google Scholar] [CrossRef]

- Zevenhoven, R.; Fagerlund, J. Mineralisation of carbon dioxide (CO2). Carbon Dioxide Storage Util. 2010, 2, 433–462. [Google Scholar]

- The Carbon Capture Machine. Available online: https://ccmuk.com/technology (accessed on 13 December 2018).

- Brinckerhoff, P. Accelerating the Uptake of CCS: Industrial Use of Captured Carbon Dioxide; Global CCS Institute: Melbourne, Australia, 2011; pp. 54–71. [Google Scholar]

- Bonavetti, V.L.; Rahhal, V.F.; Irassar, E.F. Studies on the carboaluminate formation in limestone filler-blended cements. Cem. Concr. Res. 2001, 31, 853–859. [Google Scholar] [CrossRef]

- British Standard Institution. BS EN 196-1:2016; BSI: London, UK, 2016. [Google Scholar]

- Egerton, R.F. Physical Principles of Electron Microscopy, 1st ed.; Springer Science + Business Media Inc.: New York, NY, USA, 2005; pp. 125–139. [Google Scholar]

- Profex. Available online: Profex.doebelin.org (accessed on 10 December 2018).

- ICSD Web. Available online: Icsd.cds.rsc.org/search/basic.xtml (accessed on 10 December 2018).

- Boesch, M.E.; Hellweg, S. Identifying improvement potentials in cement production with life cycle analysis. Environ. Sci. Technol. 2010, 44, 9143–9149. [Google Scholar] [CrossRef]

- Thannimalay, L.; Yusoff, S.; Zawawi, N.Z. Life cycle assessment of sodium hydroxide. Aust. J. Basic Appl. Sci. 2013, 7, 421–431. [Google Scholar]

- Industrial Efficiency Technology Database. Available online: Ietd.iipnetwork.org (accessed on 18 December 2018).

- Lombardo, G.; Agrawal, R.; Askander, J. Chilled Ammonia Process at Technology Center Mongstad—First Results. Energy Proced. 2014, 51, 31–39. [Google Scholar] [CrossRef]

| Mineralogical Composition | Phase Wt. % | Chemical Composition | Oxide Wt. % |

|---|---|---|---|

| C3S | 59.65 | SiO2 | 20.28 |

| C2S | 15.24 | Al2O3 | 4.71 |

| C3A | 11.81 | Fe2O3 | 3.27 |

| C4AF | 8.65 | CaO | 67.13 |

| CH2 | 4.65 | SO3 | 2.54 |

| MgO | 0.67 | ||

| K2O | 1.40 |

| Mineralogical Composition | Phase Wt. % | Chemical Composition | Oxide Wt. % |

|---|---|---|---|

| C3S | 60.11 | SiO2 | 15.23 |

| C2S | 7.66 | Al2O3 | 3.33 |

| C3A | 9.42 | Fe2O3 | 2.75 |

| C4AF | 1.03 | CaO | 64.40 |

| CH2 | 3.51 | SO3 | 1.41 |

| CaCO3 | 18.27 | MgO | 0.64 |

| K2O | 0.83 | ||

| CO2 | 11.41 |

| Compound | Wt. % |

|---|---|

| Calcite | 99.8 |

| Aragonite | 0.0 |

| Vaterite | 0.0 |

| Halite, NaCl | 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McDonald, L.; Glasser, F.P.; Imbabi, M.S. A New, Carbon-Negative Precipitated Calcium Carbonate Admixture (PCC-A) for Low Carbon Portland Cements. Materials 2019, 12, 554. https://doi.org/10.3390/ma12040554

McDonald L, Glasser FP, Imbabi MS. A New, Carbon-Negative Precipitated Calcium Carbonate Admixture (PCC-A) for Low Carbon Portland Cements. Materials. 2019; 12(4):554. https://doi.org/10.3390/ma12040554

Chicago/Turabian StyleMcDonald, Lewis, Fredrik P. Glasser, and Mohammed S. Imbabi. 2019. "A New, Carbon-Negative Precipitated Calcium Carbonate Admixture (PCC-A) for Low Carbon Portland Cements" Materials 12, no. 4: 554. https://doi.org/10.3390/ma12040554

APA StyleMcDonald, L., Glasser, F. P., & Imbabi, M. S. (2019). A New, Carbon-Negative Precipitated Calcium Carbonate Admixture (PCC-A) for Low Carbon Portland Cements. Materials, 12(4), 554. https://doi.org/10.3390/ma12040554