Abstract

Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 cathode materials were prepared by simple surface modification in water media through a sol-gel process with a dispersant. The crystallinity and surface morphology of the samples were characterized through X-ray diffraction analysis and scanning electron microscopy observation. The Li(Ni0.6Co0.2Mn0.2)O2 cathode material was of a polycrystalline hexagonal structure and agglomerated with particles of approximately 0.3 to 0.8 μm in diameter. The nanosized Al2O3 particles of low concentration (0.06–0.12 wt %) were uniformly coated on the surface of Li(Ni0.6Co0.2Mn0.2)O2. Measurement of electrochemical properties showed that Li(Ni0.6Co0.2Mn0.2)O2 coated with Al2O3 of 0.08 wt % had a high initial discharge capacity of 206.9 mAh/g at a rate of 0.05 C over 3.0–4.5 V and high capacity retention of 94.5% at 0.5 C after 30 cycles (cf. uncoated sample: 206.1 mAh/g and 90.8%, respectively). The rate capability of this material was also improved, i.e., it showed a high discharge capacity of 166.3 mAh/g after 5 cycles at a rate of 2 C, whereas the uncoated sample showed 155.8 mAh/g under the same experimental conditions.

1. Introduction

Current lithium-ion battery technology offers the highest energy density among the rechargeable battery technologies, dominating the market for mobile electronic devices for the past several decades. However, alternative forms of transportation, such as electric and plug-in hybrid electric vehicles, require significant improvements in energy density, safety, durability, cost, etc. The key to the successful development of novel and advanced rechargeable batteries is the materials [1].

Since Sony commercialized the lithium-ion secondary battery (C/LiCoO2 cell) in 1991, various cathode (positive electrode) materials, which account for approximately 30% of materials in the lithium-ion battery, have been studied by many investigators. LiCoO2 has been the dominating cathode material for commercial lithium-ion batteries owing to its high capacity, stable cycling, and easy production [2]. However, cobalt in LiCoO2 is a rare metal, expensive, and toxic, therefore alternative cathode materials such as ternary Li(Ni1-x-yCoxAly)O2 and Li(Ni1-x-yCoxMny)O2 compounds with layered structures, spinel-structured LiMn2O4, olivine-structured LiMPO4 (M = Fe, Mn, Co, Ni), and orthosilicates Li2MSiO4 (M = Fe, Mn, Co), have been intensively investigated [1,3,4,5,6,7,8]. Among these candidates, Li(Ni1-x-yCoxMny)O2 has been considered as a possible replacement for LiCoO2 [9,10,11,12].

Nickel-rich (Ni-rich) layered compounds (1 − x − y ≥ 0.5), such as Li(Ni0.6Co0.2Mn0.2)O2 are the most promising because high Ni and low Co content contributes to the improvement of specific capacity and the reduction of cost [10]. Recently, Erickson et al. [13] reported that cathodes prepared from Li-rich xLi2MnO3·(1 − x)Li(NiaCobMnc)O2 (a + b + c = 1) demonstrated extremely high discharge capacities. However, as the content of Ni in Li(Ni1-x-yCoxMny)O2 increases, its thermal, structural, and chemical stabilities decrease [14,15,16,17]. Accordingly, the cathode materials with high capacity and good thermal stability, simultaneously, are necessary. This could be achieved by improving the degradation of the electrochemical properties and thermal stability in lithium-ion batteries caused by the interface reaction between the cathode material and the electrolyte solution. This problem could be solved by coating the surface of the cathode material with a different material. This surface modification technology was introduced for a LiCoO2 cathode by coating with metal oxides, such as TiO2, Al2O3, Mg2TiO4, and NaAlO2 [2,18,19,20]; LiNi0.5Mn1.5O4 cathode by ZrO2, ZrP2O7, and AlPO4 coating [21,22]; and Li(Ni0.6Co0.2Mn0.2)O2 cathode by TiO2, Al2O3, and Li2ZrO3 coating [23,24,25]. Among the coating processes, wet chemical processes such as sol-gel and precipitation are widely applied, which typically require 0.3–5 wt % of coating material respect to the cathode material and resulted in substantially inhomogeneous coating. Recently ultrasonic-assisted process was introduced to coat Li(Ni0.6Co0.2Mn0.2)O2 with nano-Al2O3; Chen et al. [24] reported that the electrochemical performance of a Li(Ni0.6Co0.2Mn0.2)O2 cathode material coated with Al2O3 of 1.0 wt %showed initial discharge capacity of 197.1 mAh/g over 3.0–4.5 V and capacity retention of 91% after 30 cycles at 1 C. Here γ-Al2O3 nano-particles (d50 ca. 15 nm) and Li(Ni0.6Co0.2Mn0.2)O2 powder were dispersed by ultrasonic treatment in ethanol, stirred, and subsequently evaporated the ethanol. Finally the dried sample was heat treated at 500 °C for 6 h. The thickness of the coating layer is about 20–25 nm. Therefore, it is desirable to develop a simple process to provide coating layers, which are substantially thin, discrete, and uniform to provide hindrance of the interfacial reaction of the electrode/electrolyte and little inhibition in the diffusion of Li+ ions.

Herein, we demonstrate the use of simple surface modification in water media to improve the electrochemical properties, especially high capacity and stable cycling, of the Li(Ni0.6Co0.2Mn0.2)O2 cathode. The Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 cathode materials were prepared by mixing cathode powder with Al2O3 precursor in water, drying the mixed slurry, and then annealing at various temperatures. The effects of the Al2O3 coating on the structural and electrochemical properties of the Li(Ni0.6Co0.2Mn0.2)O2 cathode material were systematically investigated.

2. Experimental Procedure

The Li(Ni0.6Co0.2Mn0.2)O2 cathode material (d10/d50/d90 = 7.77/13.38/22.72 μm) was a commercially available powder obtained from Ningbo Jinhe Lithium Battery Material Co., Ltd (Ningbo, China). Aqueous alumina (Al2O3) sol was prepared with a concentration of 10 wt % by peptizing Boehmite (-AlO(OH)) powder in acidic water. This sol is viscous, translucent, and stable for several months. The Li(Ni0.6Co0.2Mn0.2)O2 powder was added to a mixture of the alumina sol and an additive of polymeric dispersant based on polyethylene glycol in deionized water. The slurry concentration was approximately 80 wt %. The amount of alumina sol that was used varied from 0.06 to 0.12 wt % as Al2O3 with respect to the Li(Ni0.6Co0.2Mn0.2)O2 powder and the additive 0.04 wt %. The mixture was mixed with a stirrer for 1 h, heated to remove the water while stirring, and then dried in an oven. The dried coated powder was subjected to heat treatment at various temperatures from 400 to 600 °C and holding times varying from 2 h to 10 h.

The structural properties of the Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 cathode materials were characterized by a powder X-ray diffractometer (XRD, Miniflex II, Rikagu, Tokyo, Japan) with a 2θ scan from 10 to 90°, where Cu Kα (λ = 1.5414 Å) radiation was used for the X-ray source and the scan rate was 0.5°/min. The surface morphologies of the cathode materials were observed using a scanning electron microscopy (SEM, Nova 200, FEI, Hillsboro, OR, USA) operating at 10 kV and a scanning transmission electron microscopy (STEM, FEI, Talos F200X) operating at 200 kV with an energy dispersive X-ray spectrometer (EDS) for elemental mapping.

The cathode electrodes were prepared by mixing Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 as an active material, carbon black as a conducting material, and polyvinylidene difluoride (PVdF) as a binder with a weight ratio of 90:5:5; In addition, N-methyl pyrrolidone (NMP), as a solvent, was added to control the concentration of this slurry. The mixture was applied to aluminum foil and dried at 80 °C for 2 h in a vacuum oven. The dried foil was hot-rolled to improve the adhesion between the active material and aluminum foil, and cut into circular discs of 14 mm in diameter. These discs were placed in a vacuum oven at 80 °C for 24 h to vaporize any NMP that remained in the cathode.

To measure the electrochemical properties, standard coin cells (2032 type) were assembled inside a dry chamber and lithium foil was used as a counter electrode. The electrolyte was 1 M LiPF6 in a solution of ethylene carbonate, ethyl methyl carbonate, and dimethyl carbonate (1:1:1 in volume ratio). The charge and discharge tests were performed at various C rates over the potential range of 3.0 to 4.5 V at room temperature using a galvanostatic cycling system (WBCS-3000, WonAtech, Seoul, Korea). The charge and discharge tests were conducted as one cycle at 0.5 C, 2 cycles at 0.1 C and 0.2 C, 5 cycles at 0.5 C, 1 C, and 2 C, and then 30 cycles at 0.5 C for cycle performance. Thus, in this experiment, the total number of charge and discharge cycles was 53. Tests were carried out with 3 samples, and leave out the off value and take an average of the two.

3. Results and Discussion

The strategy attempted here is to produce a very thin and uniform Al2O3 coating on the Li(Ni0.6Co0.2Mn0.2)O2 cathode material by simply modifying a sol-gel process with a dispersant. This was accomplished through the following steps: the preparation of a stabilized coating solution, acid-base adsorption, a sol-gel process to form the thin film on the surface of the Li(Ni0.6Co0.2Mn0.2)O2 powder, and a subsequent heat treatment step. Because the aqueous slurry of the Li(Ni0.6Co0.2Mn0.2)O2 is basic, an acidic coating solution is preferred. The coating solution should be homogeneous and stable, so that the coating solution can be uniformly adsorbed on the surface of the Li(Ni0.6Co0.2Mn0.2)O2 powder. Proper additives are helpful to stabilize the coating solution as well as to disperse the Li(Ni0.6Co0.2Mn0.2)O2 powder in water. The adsorbed coating solution yields ultrathin films on the powder via gelling upon drying. These ultrathin films decompose to nano-Al2O3 upon heat treatment yielding adherent nano-Al2O3 particulates on the surface of the Li(Ni0.6Co0.2Mn0.2)O2 powder. To date, surface modification using wet processes has employed considerably large quantities of the Al2O3 precursor from 0.3 to 5 wt %. In the present study, we tried with a very low quantity of the Al2O3 precursor so that the solution coats the surface of the Li(Ni0.6Co0.2Mn0.2)O2 powder well and evenly. Moreover, coating of excess Al2O3 than the appropriate amount that will result in the deterioration of the electrochemical properties can be avoided.

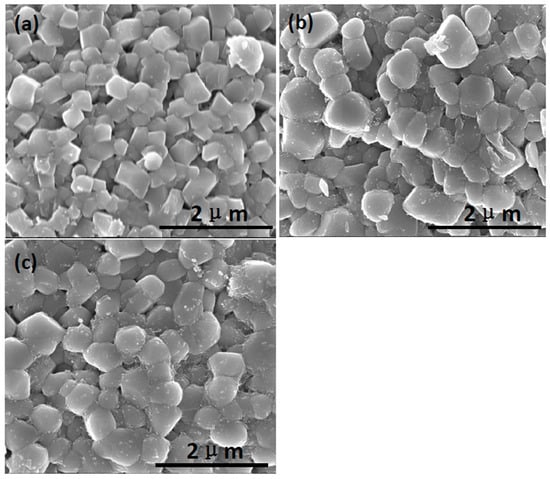

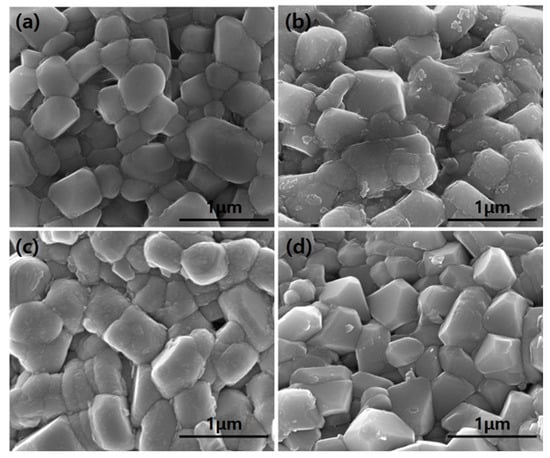

The results obtained by using a low concentration of the coating material are shown in Figure 1. The amount of Al2O3 in the sol was varied: 0.06 wt % for Figure 1a, 0.08 wt % for Figure 1b, and 0.12 wt % for Figure 1c. As the amount of Al2O3 increased, the adherent nano-Al2O3 also increased. The Al2O3 phase obtained by heat treatment at 500 °C for 4 h was γ-Al2O3, and this phase was maintained up to 700 °C [26]. The nanoparticles were dispersed uniformly and discretely in all three samples. Because 0.12 wt % of Al2O3 resulted in too many nanoparticles, 0.08 wt % of Al2O3 was chosen as a suitable amount for the Li(Ni0.6Co0.2Mn0.2)O2 powder. This was also supported by their electrochemical performance for the samples heat treated at 600 °C for 4 h as shown in Figure 2a. Thus, further studies were performed with this composition of 0.08 wt % Al2O3.

Figure 1.

SEM images of the Li(Ni0.6Co0.2Mn0.2)O2 powders coated with (a) 0.06 wt %; (b) 0.08 wt %; and (c) 0.12 wt % as Al2O3, and annealed at 500 °C for 4 h.

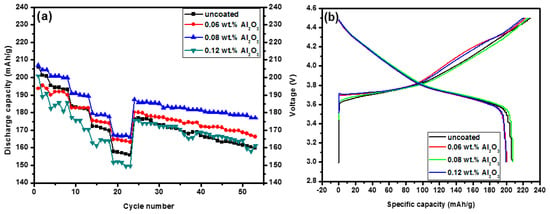

Figure 2.

Electrochemical performance of the Li(Ni0.6Co0.2Mn0.2)O2 samples uncoated and coated with different amounts of Al2O3 annealed at 600 °C for 4 h and cycled between 3.0 and 4.5 V; (a) Discharge capacity vs. cycle number; (b) initial charge and discharge curves; (c) rate capability, and (d) cycling performance operated at a rate of 0.5 C.

3.1. Structural Properties

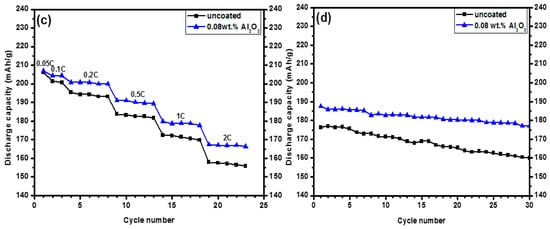

The XRD analysis of the uncoated and Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 samples was performed to determine the effect of the Al2O3 coatings on the crystal structure of Li(Ni0.6Co0.2Mn0.2)O2. Figure 3 shows the XRD patterns of Li(Ni0.6Co0.2Mn0.2)O2 uncoated and coated with 0.08 wt % Al2O3 annealed at 600 °C for 2, 4, and 10 h. As shown in Figure 3a, the uncoated Li(Ni0.6Co0.2Mn0.2)O2 sample was a hexagonal α-NaFeO2 type structure with a space group of Rm which agreed well with the JCPDS 87-1564 [27] and many earlier results [9,24,28,29]. There was no significant change in the XRD patterns for the 0.08 wt % Al2O3 coated Li(Ni0.6Co0.2Mn0.2)O2 samples compared to the uncoated Li(Ni0.6Co0.2Mn0.2)O2 sample. No impurity peak was observed from the XRD patterns.

Figure 3.

X-ray diffraction patterns of the Li(Ni0.6Co0.2Mn0.2)O2 samples uncoated and coated with 0.08 wt % Al2O3 annealing at 600 °C for 2, 4, and 10 h, respectively. (a) Uncoated; (b) annealed at 600 °C for 2 h; (c) annealed at 600 °C for 4 h; and (d) annealed at 600 °C for 10 h.

The effects of heat treatment were observed by SEM, and the results are shown in Figure 4. The samples dried at 150 °C (Figure 4a) and the annealed at 600 °C for 2 h (Figure 4b) show uniformly dispersed discrete nano-Al2O3 coated Li(Ni0.6Co0.2Mn0.2)O2 particles while maintaining the morphology of the pristine, but the discrete nano-Al2O3 particles were mostly disappeared and the sharp-edged morphology was developed after the heat treatment at 600 °C for 4 h (Figure 4c) and for 10 h (Figure 4d). It is noticeable that drying at 150 °C yields discrete adherent Boehmite nano-particles that resulted from the loss of volatiles of the films on the surface of the Li(Ni0.6Co0.2Mn0.2)O2 powder. This supports our strategy to produce thin films on the surface via a sol-gel process. Heat treatment at 600 °C transforms the phase to γ phase of discrete nano-Al2O3. The adherent nano-Al2O3 particles remain as coated particles at 600 °C for 2 h and seem to move to the cathode lattice upon heat treatment such as at 600 °C for >4 h. This observation is consistent with the findings of Dogan, who observed the transformation from “surface coating” to “dopants” by annealing at high temperature in LiCoO2 but not in Li(Ni0.5Co0.2Mn0.3)O2 [30].

Figure 4.

SEM images of the Li(Ni0.6Co0.2Mn0.2)O2 samples (a) uncoated without heat treatment (dried at 150 °C) and (b–d) coated with 0.08 wt % Al2O3 annealing at 600 °C for 2, 4, and 10 h, respectively.

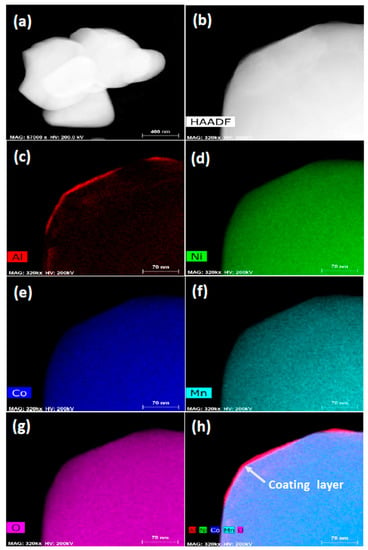

The elemental distribution of the Li(Ni0.6Co0.2Mn0.2)O2 samples in Figure 4 was studied using an EDS under STEM mode. As shown in Figure 5, Figure 5a is an image of the Li(Ni0.6Co0.2Mn0.2)O2 sample with the 0.08 wt % Al2O3 coating that had been annealed at 600 °C for 4 h, Figure 5b is a high-angle annular dark-field (HAADF) image of the EDS mapping region, and Figure 5c–h shows the distribution of Al, Co, Mn, Ni, and O in HAADF image, respectively. All elements are uniformly distributed on the surface of the Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 particles. EDS mapping of Al shows a uniform distribution on the surface, except for bright bands at the edges as shown in Figure 5c and the Al2O3 coating layer (red color, 10–15 nm in thickness) was confirmed from Figure 5h.

Figure 5.

(a,b) Images of the EDS mapping region; and (c–h) the elemental mappings of the 0.08 wt % Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 sample annealed at 600 °C for 4 h.

3.2. Electrochemical Properties

In order to study the electrochemical performance of Li(Ni0.6Co0.2Mn0.2)O2 samples coated with different amounts of Al2O3, coin cells were operated at various C rates within the cutoff voltage of 3.0–4.5 V.

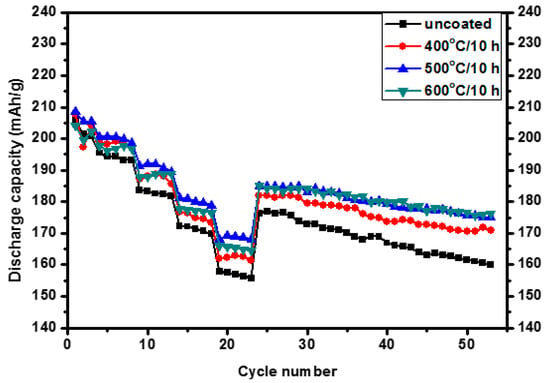

Figure 2 shows the electrochemical properties of the uncoated and Al2O3-coated samples annealed at 600 °C for 4 h between 3.0 and 4.5 V. Figure 2a shows the discharge capacity versus the total number of cycles according to the experimental procedure, as explained before. For detailed analysis, initial charge-discharge curves, rate capability, and cycle performance are displayed in Figure 2b–d, respectively. Figure 2b shows the initial charge-discharge curves of the samples cycled at a rate of 0.05 C. The initial discharge capacities for the samples uncoated and coated with 0.06, 0.08, and 1.2 wt % Al2O3 were 206.1, 200.6, 206.9, and 199.6 mAh/g, respectively. As shown in Figure 2a, the 0.08 wt % Al2O3-coated sample exhibits a good rate capability. Figure 2c shows the change in discharge capacities of the uncoated sample and the Al2O3-coated sample at various C rates. The discharge capacities of the uncoated sample were 206.1, 200.7, 193.1, 181.7, 169.8, and 155.8 mAh/g at 0.05 C, 0.1 C, 0.2 C, 0.5 C, 1 C, and 2 C, respectively. Under the same conditions, the discharge capacities of the 0.08 wt % Al2O3-coated sample were 206.9, 204.3, 199.9, 189.5, 177.7, and 166.3 mAh/g. With an increase in the C rate, i.e., the current density, the discharge capacity of the uncoated and Al2O3-coated sample both decrease, while the coated sample demonstrates a smaller discharge capacity decrease than the uncoated sample. The first discharge capacities were 206.1 and 206.9 mAh/g for the uncoated and coated samples, respectively; these samples had similar initial capacities. However, their discharge capacities after five cycles at a rate of 2 C were 155.8 and 166.3 mAh/g, respectively, demonstrating a notable difference in their values. The Al2O3-coated sample had a far greater improved rate capability than the uncoated sample. It is well known that the high rate capability of the coated sample is primarily due to the Al2O3 coating which protects the cathode material from reacting with electrolyte [24,31]. After being cycled from 0.05 C to 2 C, the recovered discharge capacity of 187.5 mAh/g at 0.5 C is almost identical to the initial discharge capacity at 0.5 C. This result indicates that there is good structural stability in the coated sample. The cycling performances of the uncoated and Al2O3-coated samples at 0.5 C over 3.0–4.5 V are shown in Figure 2a,d. The 0.08 wt % Al2O3-coated sample after 30 cycles also exhibited the best capacity retention of 94.5%, while the capacity retention of the uncoated sample was 90.8%. This indicates that the cycling stability of the 0.08 wt % Al2O3-coated sample could be improved by Al2O3 coating.

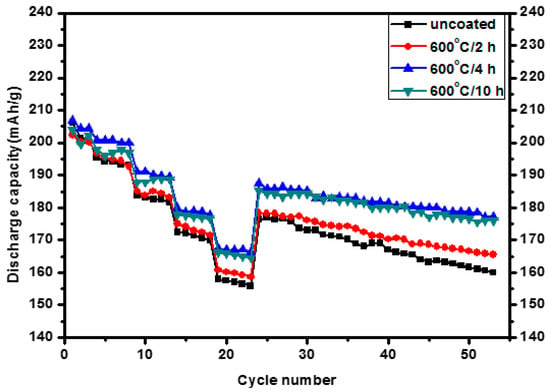

The effects of the temperature and holding time of heat treatment on the electrochemical properties of the Al2O3-coated samples are shown in Figure 6 and Figure 7, respectively. As shown in Figure 6, by increasing the temperature from 400 to 500, and 600 °C with the fixed duration of 10 h, the rate capability was improved for all the annealed samples, whereas the one at 500 °C showed better rate capability than that at 600 °C. But they became showing similarly improved cycling performances. Considering the SEM images in Figure 4, the coated nano-Al2O3 particles work better than the doped Al2O3 in the rate capability, but both improve the cycling performance similarly. As per holding time effects as shown in Figure 7, significant improvement in electrochemical performances were observed for both 4 h and 10 h at almost same extent, whereas only moderate improvement is observed for 2 h. Duration time of 4 h at 600 °C shows improvement as good as 10 h in both rate capability and cycling performance.

Figure 6.

Electrochemical performance of the uncoated and 0.08 wt % Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 samples annealed at different temperatures for 10 h and cycled between 3.0 and 4.5 V at various C rates.

Figure 7.

Electrochemical performance of the uncoated and 0.08 wt % Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 samples annealed at 600 °C for different holding times and cycled between 3.0 and 4.5 V at various C rates.

4. Conclusions

In the present study, Li(Ni0.6Co0.2Mn0.2)O2 cathode materials were coated with a relatively small amount of Al2O3 by simple surface modification in water media. The uncoated and coated Li(Ni0.6Co0.2Mn0.2)O2 powders formed a polycrystalline hexagonal phase with a space group Rm. From SEM observation, it was confirmed that the particles of Li(Ni0.6Co0.2Mn0.2)O2 cathode material were agglomerated and the discrete Al2O3 nano-particles of 10–15 nm were uniformly coated on the surface of the cathode material. The electrochemical properties of the samples were improved through Al2O3 coating of very low concentration; the optimum amount of Al2O3 additive was 0.08 wt % and the best heat treatment condition was 600 °C for 4 h. In the case of the 0.08 wt % Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 sample annealed at 600 °C for 4 h, the initial discharge capacity at a rate of 0.05 C over 3.0–4.5 V was 206.9 mAh/g and the capacity retention at 0.5 C after 30 cycles was 94.5%. It could be concluded that the Li(Ni0.6Co0.2Mn0.2)O2 coated with nano-Al2O3 by simple surface modification and annealed at 600 °C for 4 h demonstrated improved electrochemical properties, including initial discharge capacity, rate capability, and cyclic performance. Finally, 0.08 wt % Al2O3-coated Li(Ni0.6Co0.2Mn0.2)O2 fabricated by the above method could be commercially used for the cathode material of lithium-ion secondary batteries.

Acknowledgments

This work was supported by the 2016 Research Fund of the University of Seoul. Also, this work was supported by the KIST institutional program (Project No. 2E27062).

Author Contributions

K.S.Y., C.-S.K., and K.R.I. conceived and designed the experiments; K.R.I. and Y.H.K. performed the experiments and analyzed the data; C.-S.K. contributed reagents/materials/analysis tools; K.S.Y. and K.R.I. wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, J. Recent Progress in Advanced Materials for Lithium Ion Batteries. Materials 2013, 6, 156–183. [Google Scholar] [CrossRef] [PubMed]

- Zhou, A.; Lu, Y.; Wang, Q.; Xu, J.; Wang, W.; Dai, X.; Li, J. Sputtering TiO2 on LiCoO2 Composite Electrodes as a Simple and Effective Coating to Enhance High-voltage Cathode Performance. J. Power Sources 2017, 346, 24–30. [Google Scholar] [CrossRef]

- Yoo, K.S.; Cho, N.W.; Oh, Y.-J. Structural and Electrical Characterization of Li(Mn1-δTiδ)2O4 Electrode Materials. Solid State Ion. 1998, 113, 43–49. [Google Scholar] [CrossRef]

- Bakierska, M.; Świętosławski, M.; Gajewaka, M.; Kowalczyk, A.; Piwowarska, Z.; Chmielarz, L.; Dziembaj, R.; Molenda, M. Enhancement of Electrochemical Performance of LiMn2O4 Spinel Cathode Material by Synergetic Substitution with Ni and S. Materials 2016, 9, 366. [Google Scholar] [CrossRef] [PubMed]

- Rozier, P.; Tarascon, J.M. Review—Li-rich Layered Oxide Cathodes for Next-generation Li-ion Batteries: Chances and Challenges. J. Electrochem. Soc. 2015, 162, A2490–A2499. [Google Scholar] [CrossRef]

- Yan, J.; Liu, H.; Wang, Y.; Zhao, X.; Mi, Y.; Xia, B. Enhanced High-temperature Cycling Stability of Li(Ni1/3Co1/3Mn1/3)O2-coated LiMn2O4 as Cathode Material for Lithium Ion Batteries. Ionics 2015, 21, 1835–1842. [Google Scholar] [CrossRef]

- Yue, P.; Wang, Z.; Li, X.; Xiong, X.; Wang, J.; Wu, X.; Guo, H. The Enhanced Electrochemical Performance of Li(Ni0.6Co0.2Mn0.2)O2 Cathode Materials by Low Temperature Fluorine Substitution. Electrohcim. Acta 2013, 95, 112–118. [Google Scholar] [CrossRef]

- Huang, H.; Yin, S.-C.; Nazar, L.F. Approaching Theoretical Capacity of LiFePO4 at Room Temperature at High Rates. Electrochem. Solid-State Lett. 2001, 4, A170–A172. [Google Scholar] [CrossRef]

- Cao, H.; Zhang, Y.; Zhang, J.; Xia, B. Synthesis and Electrochemical Characteristics of Layered Li(Ni0.6Co0.2Mn0.2)O2 Cathode Material for Lithium Ion Batteries. Solid State Ion. 2005, 176, 1207–1211. [Google Scholar] [CrossRef]

- Liu, W.; Hua, W.; Zheng, Z.; Zhong, B.; Zhang, Z. Facile Synthesis of Hierarchical Porous Ni-rich Cathode Material with Superior High-rate Capability. Ionics 2016. [Google Scholar] [CrossRef]

- Cheng, K.-L.; Mu, D.-B.; Wu, B.-R.; Wang, L.; Jiang, Y.; Wang, R. Electrochemical Performance of a Nickel-rich Li(Ni0.6Co0.2Mn0.2)O2 Cathode Material for Lithium-ion Batteries under Different Cut-off Voltages. Int. J. Miner. Metall. Mater. 2017, 24, 342–351. [Google Scholar] [CrossRef]

- Fu, C.; Zhou, Z.; Liu, Y.; Zhang, Q.; Zheng, Y.; Li, G. Synthesis and Electrochemical Properties of Mg-doped Li(Ni0.6Co0.2Mn0.2)O2 Cathode Materials for Li-ion Battery. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 211–215. [Google Scholar] [CrossRef]

- Erickson, E.M.; Schipper, F.; Penki, T.R.; Shin, J.-Y.; Erk, C.; Chesneau, F.-F.; Markovsky, B.; Aurbach, D. Review—Recent Advances and Remaining Challenges for Lithium Ion Battery Cathodes II. Lithium-rich xLi2MnO3·(1-x)Li(NiaCobMnc)O2. J. Electochem. Soc. 2017, 164, A6341–A6348. [Google Scholar] [CrossRef]

- Wu, F.; Tian, J.; Su, Y.; Wang, J.; Zhang, C.; Bao, L.; He, T.; Li, J.; Chen, S. Effect of Ni2+ Content on Lithium/nickel disorder for Ni-rich Cathode Materials. ACS Appl. Mater. Interfaces 2015, 7, 7702–7708. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhu, S.; Huang, J.; Yan, C. Acacia Gum-assisted Co-precipitating Synthesis of Li(Ni0.5Co0.2Mn0.3)O2 Cathode Material for Lithium Ion Batteries. Ionics 2015. [Google Scholar] [CrossRef]

- Luo, W.B.; Li, X.H.; Dahn, J.R. Synthesis, Characterization and Thermal Stability of Li[Ni1/3Mn1/3Co1/3-z (MnMg)z/2]O2. Chem. Mater. 2010, 22, 5065–5073. [Google Scholar] [CrossRef]

- Santhanam, R.; Rambabu, B. High Rate Cycling Performance of Li1.05Ni1/3Co1/3Mn1/3O2 Materials Prepared by Sol-gel and Co-precipitation methods for Lithium-ion Batteries. J. Power Sources 2010, 195, 4313–4317. [Google Scholar] [CrossRef]

- Yano, A.; Shikano, M.; Ueda, A.; Sakaebe, H.; Ogumi, Z. LiCoO2 Degradation Behavior in the High-voltage Phase Transition Region and Improved Reversibility with Surface Coating. J. Electrochem. Soc. 2017, 164, A6116–A6122. [Google Scholar] [CrossRef]

- Shim, J.-H.; Cho, N.-H.; Lee, S. Synthesis and Characterization of Mg2TiO4-coated LiCoO2 as a Cathode Material for Lithium Ion Batteries. Electrochim. Acta 2017, 243, 162–169. [Google Scholar] [CrossRef]

- Shen, B.; Zuo, P.; Fan, P.; Yang, J.; Yin, G.; Ma, Y.; Cheng, X.; Du, C.; Gao, Y. Improved Electrochemical Performance of NaAlO2-coated LiCoO2 for Lithium-ion Batteries. J. Solid State Electrochem. 2017, 21, 1195–1201. [Google Scholar] [CrossRef]

- Wu, H.M.; Belharouak, I.; Abouimrane, A.; Sun, Y.-K.; Amine, K. Surface Modification of LiNi0.5Mn1.5O4 by ZrP2O7 and ZrO2 for Lithium-ion Batteries. J. Power Sources 2010, 195, 2909–2913. [Google Scholar] [CrossRef]

- Shi, J.Y.; Yi, C.-W.; Kim, K. Improved electrochemical performance of AlPO4-coated LiMn1.5Ni0.5O4 electrode for lithium-ion batteries. J. Power Sources 2010, 195, 6860–6866. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Chen, B.; Wang, Z.; Lu, C. An Approach to Application for Li(Ni0.6Co0.2Mn0.2)O2 Cathode Material as High Cutoff Voltage by TiO2 Coating. J. Power Sources 2014, 256, 20–27. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Wang, F.; Wang, Z.; Zhang, Q. Improve the Structure and Electrochemical Performance of Li(Ni0.6Co0.2Mn0.2)O2 Cathode Material by Nano-Al2O3 Ultrasonic Coating. J. Alloys Compd. 2014, 611, 135–141. [Google Scholar] [CrossRef]

- Sun, S.; Du, C.; Qu, D.; Zhang, X.; Tang, Z. Li2ZrO3-coatedLi(Ni0.6Co0.2Mn0.2)O2 for High-performance Cathode Material in Lithium-ion Battery. Ionics 2015, 21, 2091–2100. [Google Scholar] [CrossRef]

- Xu, X.; Lee, S.; Jeong, S.; Kim, Y.; Cho, J. Recent Progress on Nanostructured 4 V Cathode Materials for Li-ion Batteries for Mobile Electronics. Mater. Today 2013, 16, 487–495. [Google Scholar] [CrossRef]

- JCPDS-ICDD #87-1564, version 2.1; The International Centre for Diffraction Data: Newtown Square, PA, USA, 2000.

- Manikandan, P.; Periasamy, P.; Jagannathan, R. Microstructure—Twinning and Hexad Multiplet(s) in Lithium-rich Layered Cathode Materials for Lithium-ion Batteries. RSC Adv. 2014, 4, 40359–40367. [Google Scholar] [CrossRef]

- Hua, W.; Zhang, J.; Zheng, Z.; Liu, W.; Peng, X.; Guo, X.-D.; Zhong, B.; Wang, Y.-J.; Wang, X. Na-doped Ni-rich LiNi0.5Co0.2Mn0.3O2 Cathode Material with Both High Rate Capability and High Tap Density for Lithium Ion Batteries. Dalton Trans. 2014, 43, 14824–14832. [Google Scholar] [CrossRef] [PubMed]

- Song, H.G.; Park, Y.J. LiLaPO4-coated Li(Ni0.5Co0.2Mn0.3)O2 and AlF3-coated Li(Ni0.5Co0.2Mn0.3)O2 Blend Composites for Lithium Ion Batteries. Mater. Res. Bull. 2012, 47, 2843–2846. [Google Scholar] [CrossRef]

- Shi, S.J.; Tu, J.P.; Mai, Y.J.; Zhang, Y.Q.; Tang, Y.Y.; Wang, X.L. Structure and Electrochemical Performance of CaF2 coated Li Mn1/3Ni1/3Co1/3O2 Cathode Material for Li-ion Batteries. Electrochim. Acta 2012, 83, 105–112. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).