Statistical Analysis on the Mechanical Properties of Magnesium Alloys

Abstract

:1. Introduction

2. Experimental section

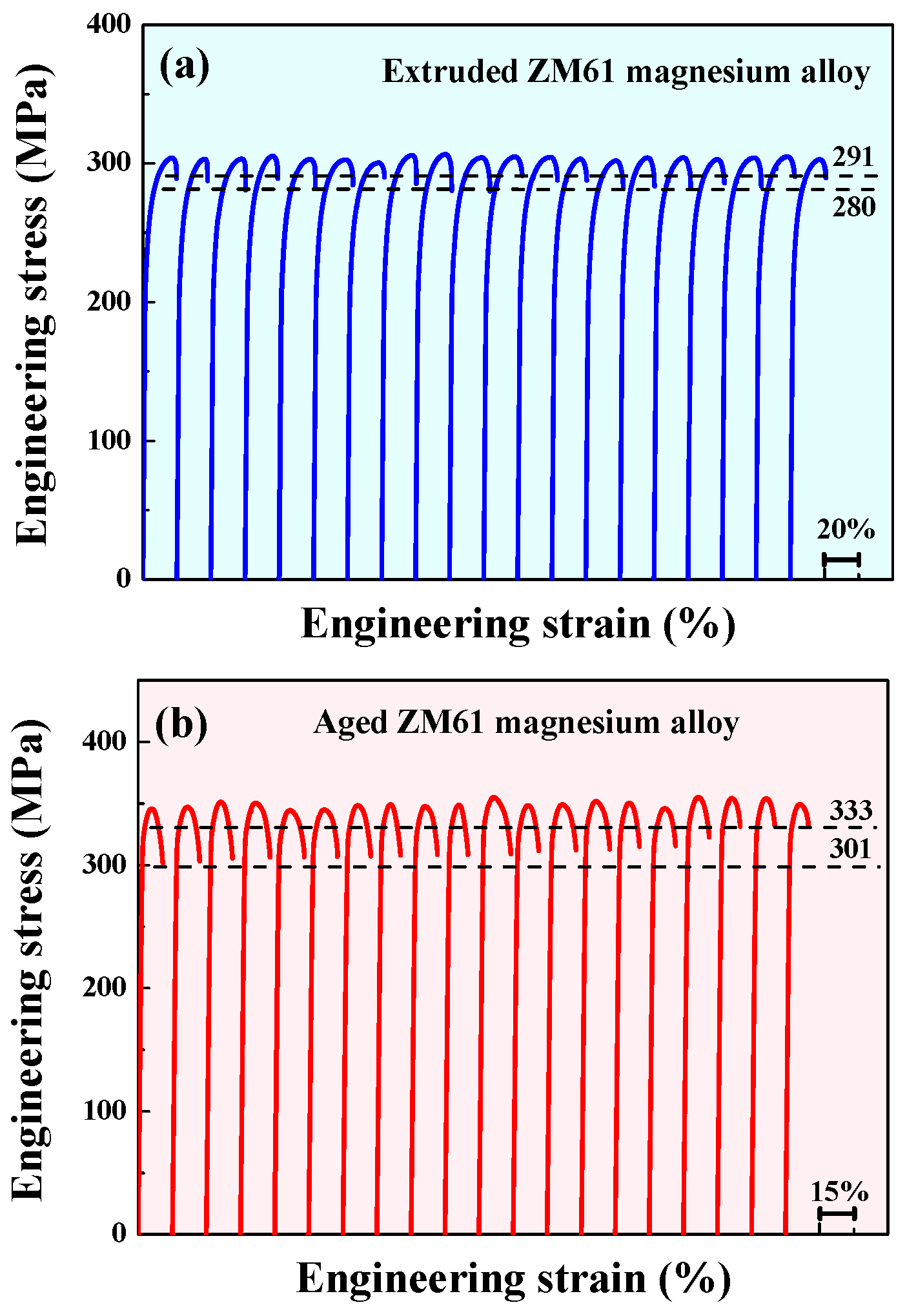

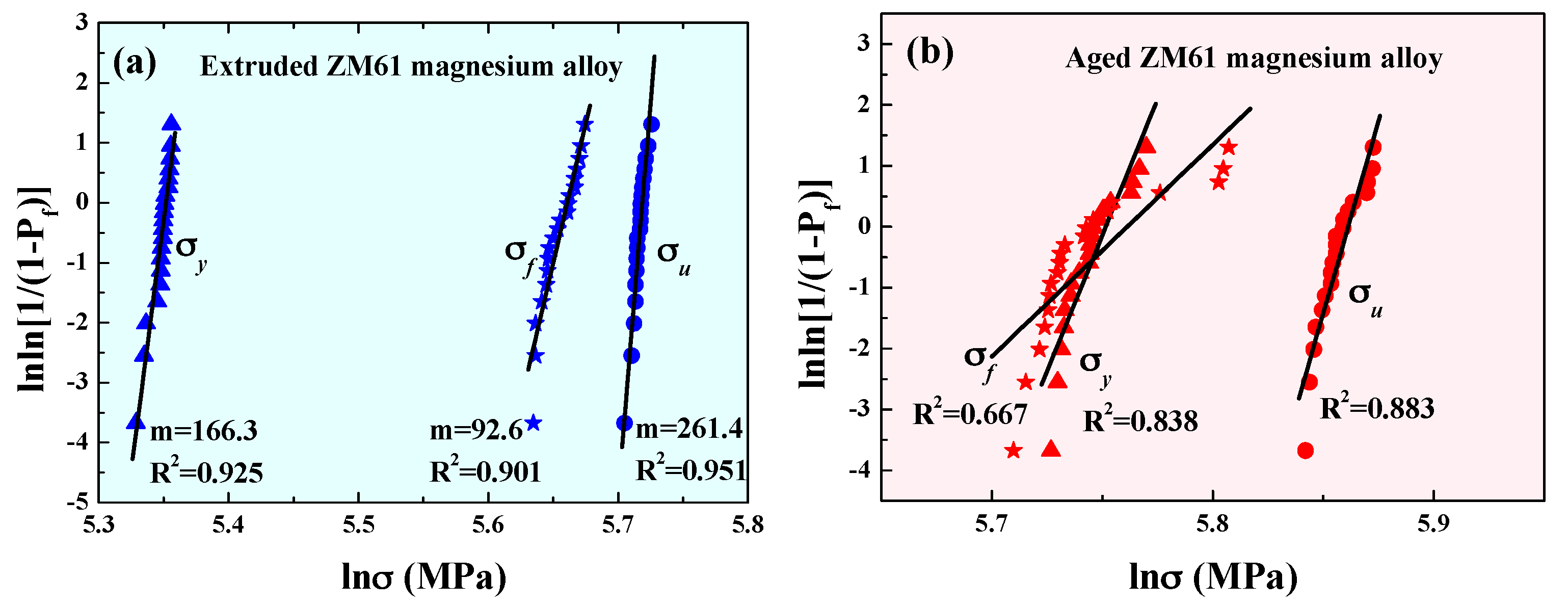

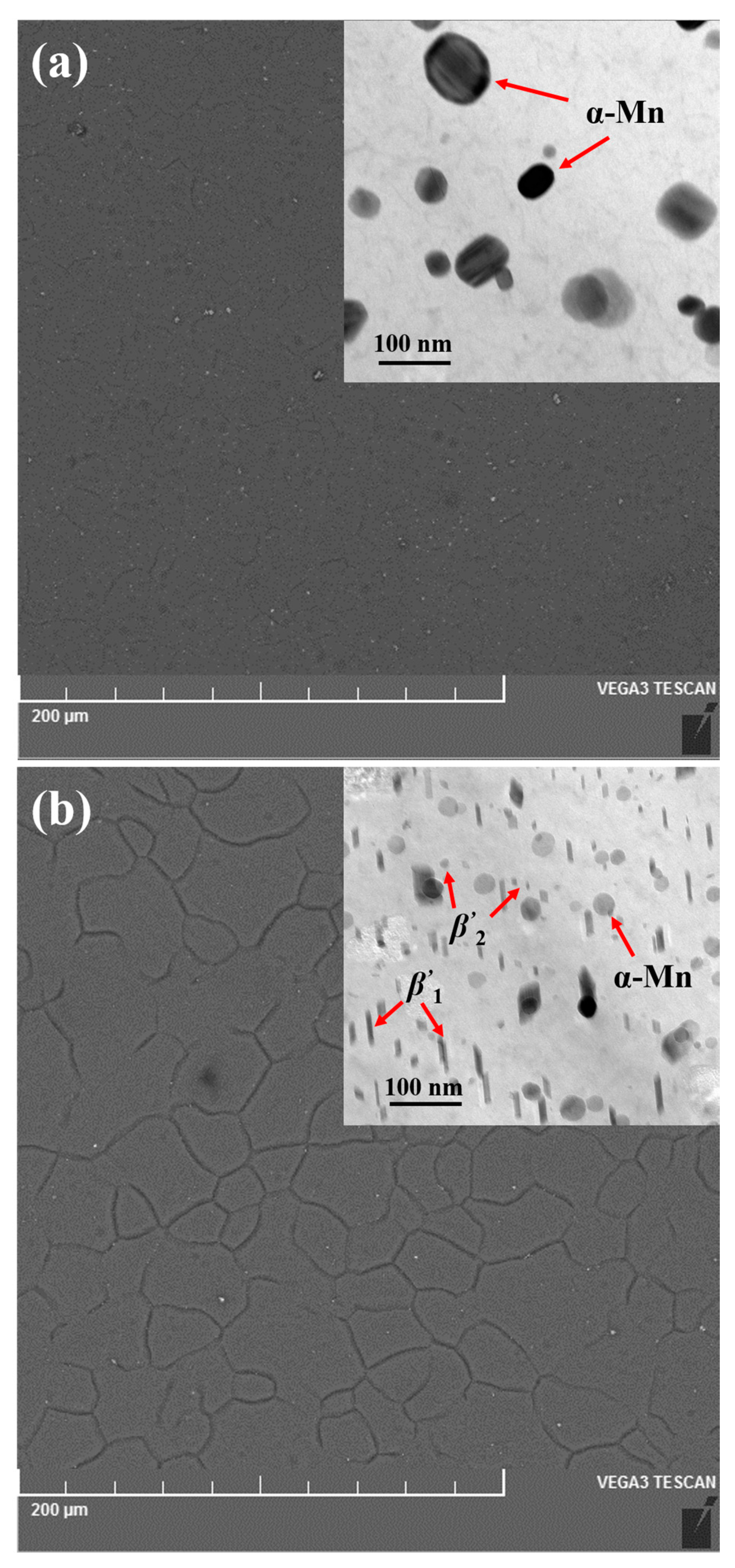

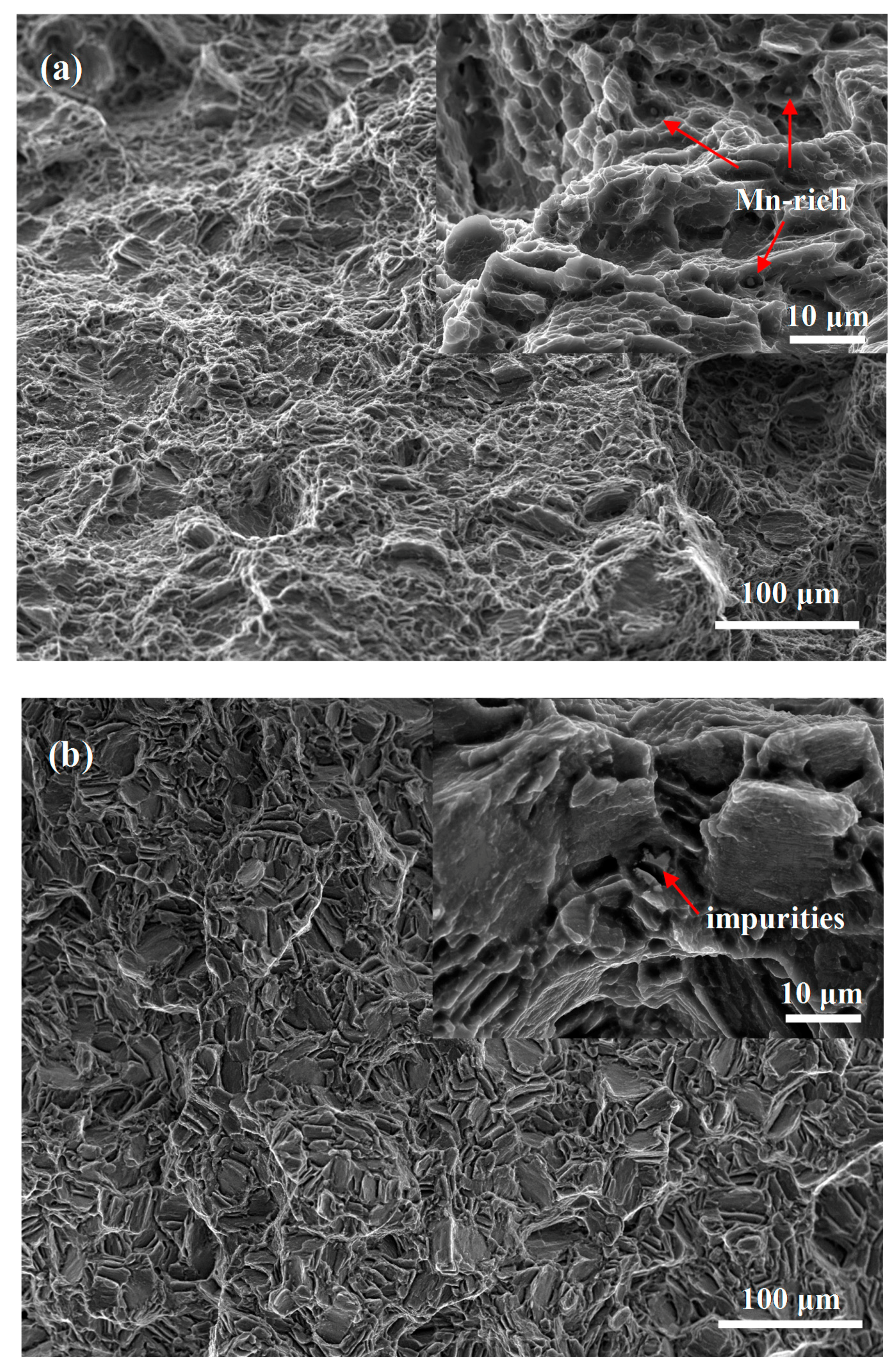

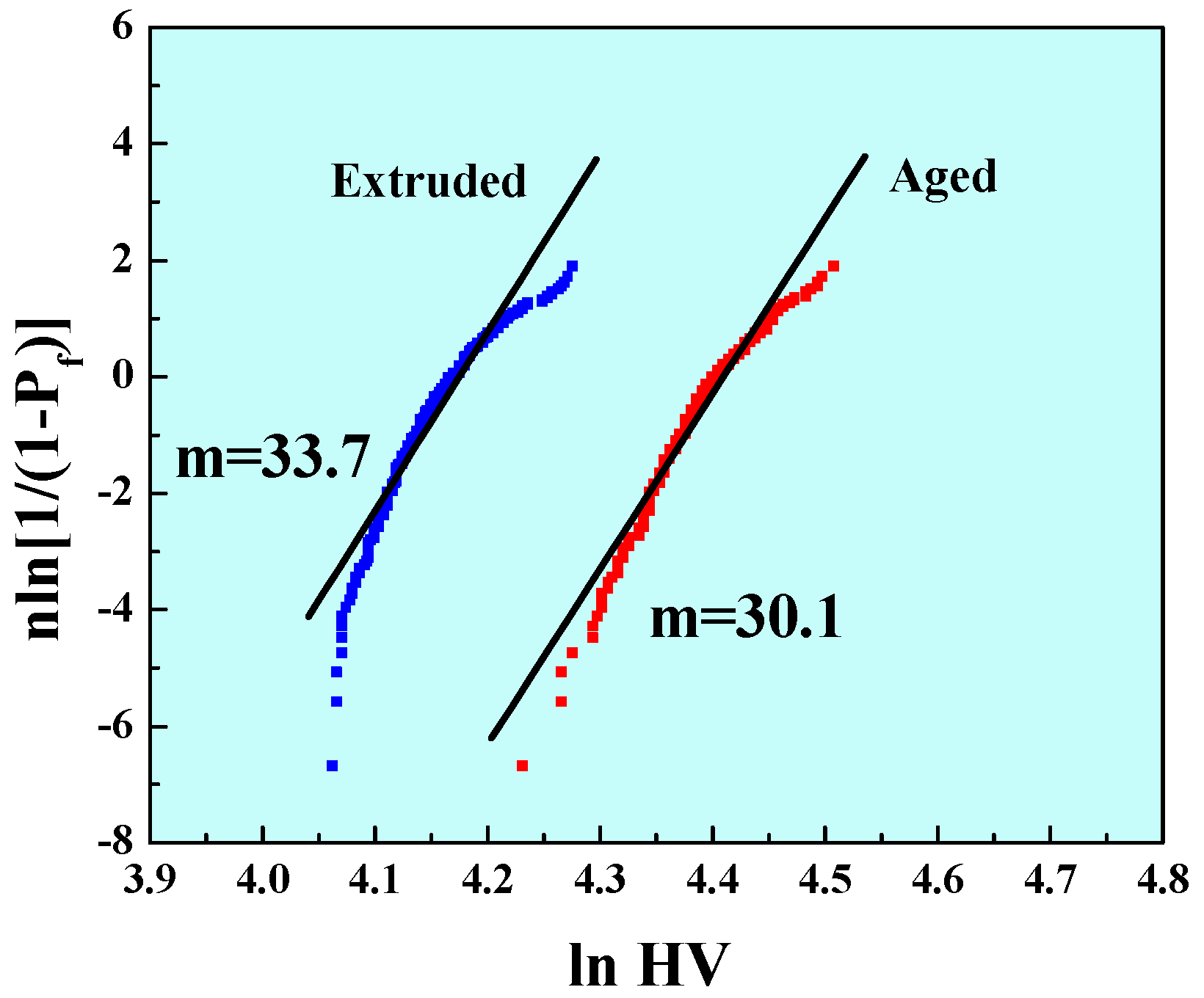

3. Results and Discussion

4. Conclusions

Acknowledgments

Author contributions

Conflicts of Interest

References

- Kainer, K.U. Magnesium—Alloys and Technologies; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Xu, W.Q.; Birbilis, N.; Sha, G.; Wang, Y.; Daniels, J.E.; Xiao, Y.; Ferry, M. A high-specific-strength and corrosion-resistant magnesium alloy. Nat. Mater. 2015, 14, 1229–1235. [Google Scholar] [CrossRef] [PubMed]

- Qin, D.Z.; Wang, J.F.; Chen, Y.L.; Lu, R.P.; Pan, F.S. Effect of long period stacking ordered structure on the damping capacities of Mg-Ni-Y alloys. Mater. Sci. Eng. A 2015, 624, 9–13. [Google Scholar] [CrossRef]

- Lu, Y.Z.; Wang, Q.D.; Ding, W.J.; Zeng, X.Q.; Zhu, Y.P. Fracture behavior of AZ91 magnesium alloy. Mater. Lett. 2000, 44, 265–268. [Google Scholar] [CrossRef]

- Zberg, B.; Arata, E.R.; Uggowitzer, P.J.; Loffler, J. Tensile properties of glassy MgZnCa wires and reliability analysis using Weibull statistics. Acta Mater. 2009, 57, 3223–3231. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Distribution Function of Wide Applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Wu, W.F.; Li, Y.; Schuh, C.A. Strength, plasticity and brittleness of bulk metallic glasses under compression: Statistical and geometric effects. Philos. Mag. 2008, 88, 71–89. [Google Scholar] [CrossRef]

- Yu, D.L.; Zhang, D.F.; Sun, J.; Luo, Y.X.; Xu, J.Y.; Zhang, H.J.; Pan, F.S. High cycle fatigue behavior of extruded and double-aged Mg-6Zn-1Mn alloy. Mater. Sci. Eng. A 2016, 662, 1–8. [Google Scholar] [CrossRef]

- Sullivan, J.D.; Lauzon, P.H. Experimental probability estimators for Weibull plots. J. Mater. Sci. Lett. 1986, 5, 1245–1247. [Google Scholar] [CrossRef]

- Yao, J.H.; Wang, J.Q.; Lu, L.; Li, Y. High tensile strength reliability in a bulk metallic glass. Appl. Phys. Lett. 2008, 92, 041905. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Hudak, D. Guidelines for Two-Parameter Weibull Analysis for Flaw-Containing Materials. Metall. Mater. Trans. B 2011, 42, 1130–1135. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Ma, E.; Xu, J. Reliability of compressive fracture strength of Mg-Zn-Ca bulk metallic glasses: Flaw sensitivity and Weibull statistics. Scr. Mater. 2008, 58, 496–499. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Hudak, D.; Okten, G. On evaluating Weibull fits to mechanical testing data. Mater. Sci. Eng. A 2009, 527, 397–399. [Google Scholar] [CrossRef]

- Han, Z.; Tang, L.C.; Xu, J.; Li, Y. A three-parameter Weibull statistical analysis of the strength variation of bulk metallic glasses. Scr. Mater. 2009, 61, 923–926. [Google Scholar] [CrossRef]

- Pan, F.S.; Yang, M.B.; Chen, X.H. A Review on Casting Magnesium Alloys: Modification of Commercial Alloys and Development of New Alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- Zhang, D.F.; Shi, G.L.; Dai, Q.W.; Yuan, W.; Duan, H.L. Microstructures and mechanical properties of high strength Mg-Zn-Mn alloy. Trans. Nonferrous Met. Soc. China 2008, 18, s59–s63. [Google Scholar] [CrossRef]

- Khan, F.M.D.; Panigrahi, S.K. Age hardening, fracture behavior and mechanical properties of QE22 Mg alloy. J. Magnes. Alloys 2015, 3, 210–217. [Google Scholar]

- Jiang, L.Y.; Zhang, D.F.; Fan, X.W.; Guo, F.; Hu, G.S.; Xue, H.S.; Pan, F.S. Evaluating the morphology of precipitates and the room temperature mechanical properties of age hardened AZT802 magnesium alloy treated at different aging temperature. Mater. Sci. Eng. A 2015, 644, 25–31. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.; Liu, R.; Jiang, X.; Zhang, H.; Zhang, D.; Wang, J.; Pan, F. Statistical Analysis on the Mechanical Properties of Magnesium Alloys. Materials 2017, 10, 1271. https://doi.org/10.3390/ma10111271

Guo S, Liu R, Jiang X, Zhang H, Zhang D, Wang J, Pan F. Statistical Analysis on the Mechanical Properties of Magnesium Alloys. Materials. 2017; 10(11):1271. https://doi.org/10.3390/ma10111271

Chicago/Turabian StyleGuo, Shengfeng, Ruoyu Liu, Xianquan Jiang, Hongju Zhang, Dingfei Zhang, Jingfeng Wang, and Fusheng Pan. 2017. "Statistical Analysis on the Mechanical Properties of Magnesium Alloys" Materials 10, no. 11: 1271. https://doi.org/10.3390/ma10111271

APA StyleGuo, S., Liu, R., Jiang, X., Zhang, H., Zhang, D., Wang, J., & Pan, F. (2017). Statistical Analysis on the Mechanical Properties of Magnesium Alloys. Materials, 10(11), 1271. https://doi.org/10.3390/ma10111271