Abstract

Under high-temperature conditions in deep well formations, oil-based drilling fluids tend to show degraded rheological properties and reduced suspension capacity, which may impair wellbore cleanliness and circulation pump pressure and hinder drilling. To address this issue, a three-component composite thickener including fatty acid polymers and clay activator was developed, and then the composite agents were used as the core component in formulating a thermo-thickening oil-based drilling fluid. Experimental results demonstrated that at up to 200 °C and 153 MPa, the fluid’s low-shear-rate viscosity and yield point increased steadily, while high-shear-rate viscosity and plastic viscosity remained nearly unchanged. The composite thickener largely enhanced the fluid’s storage modulus and inner structural force, thus improving its rheological properties and suspension capacity under high-temperature and high-pressure conditions. Based on these findings, the thermo-thickening oil-based drilling fluid was supposed to address the critical diminished rheological stability and suspension capacity of conventional oil-based drilling fluids in complex formations with promising application prospects.

1. Introduction

With the increasing development of oil and gas exploration projects, drilling engineering has been increasingly shifting towards deep and ultra-deep wells, extended-reach wells, and long horizontal wells [1,2]. The amount of deep and ultra-deep oil resources in land oil and gas resources accounts for about 35% of total oil and gas resources. Drilling for deep and ultra-deep oil and gas reservoirs poses multiple technical challenges due to severe temperature and pressure systems in wellbores, which are even over 220 °C and 180 MPa, as well as irregular formation environments [3,4,5,6]. Consequently, there is a constant need to update equipment, technologies, and operating procedures in order to adapt to these increasingly refined demands [7,8,9,10,11,12]. Oil-based drilling fluids are indispensable tools in oil exploration and have become the primary choice for efficient drilling in high-temperature deep wells, extended-reach wells, and sensitive formations [13,14,15,16,17,18]. This preference stems from the advantages, including strong temperature resistance, potent inhibition properties, excellent lubricity, high contamination resistance, robust wellbore stability, and so on.

However, as a water-in-oil emulsion with oil as the primary base fluid, oil-based drilling fluid exhibits sensitivity of its rheological properties to temperature fluctuations [19,20,21,22]. While an increase in bottomhole pressure may initially enhance viscosity, the fluid still exhibits a decreasing viscosity trend under higher wellbore temperatures and pressures. Consequently, high-temperature conditions in deep wells often cause significant reductions in the viscosity and shear strength of oil-based drilling fluids, thereby impairing their rheological performance and gel thixotropy [23,24]. This can induce suspension instability and diminished cuttings-carrying capacity, even adverse effects on wellbore cleanliness. Additionally, changes in solid deposition may alter the fluid’s equivalent circulating density and pumping pressure during operations, thus compromising drilling efficiency. Therefore, enhancing the rheological performance and suspension capacity of oil-based drilling fluids constitutes a critical technical challenge in the exploration of unknown deep reservoirs [25,26].

With this in mind, this research aims to develop an oil-based drilling fluid suitable for deep and ultra-deep reservoirs. To counteract potential drilling fluid thinning tendencies, it is essential to realize moderate reverse thickening under high temperature and high pressure (HTHP). The core research objective is thus to investigate the rheological behaviors of drilling fluids under such extreme conditions. Notably, an ideal thickening drilling fluid must possess both dynamic flowability and static suspension properties in the wellbore. This means that it should flow smoothly under shear stress while rapidly suspending cuttings and weighting materials once shear is ceased. Excessive thickening impairs the fluid’s flowability, resulting in higher mechanical energy consumption. Therefore, the desired HTHP thickening effects should be characterized by a moderate increase in the drilling fluid’s low-shear-rate viscosity and yield point under equivalent conditions, whereas its apparent and plastic viscosities should not increase significantly [27,28,29].

Based on these technical requirements, this study screened multiple rheological modifiers and investigated their impacts on the rheological properties of drilling fluids under HTHP. A three-component composite thickener was developed as the core component of a thermo-thickening drilling fluid capable of withstanding temperatures of up to 200 °C. Comparative studies on the capacity of drilling fluid suspensions confirmed that enhanced rheological thickening properties under HTHP conditions exerted a positive effect on the suspension capacity of oil-based drilling fluids.

2. Materials and Methods

2.1. Materials

The critical thickening agents in the article included common rheological modifiers DyM-1 and DyM-2, screened PyA-1/PyA-2, Aim-1/Aim-2, and clay activator Ens. DyM-1/DyM-2 and Aim-1/Aim-2 were polyamide resins. DyM-1 and DyM-2 were made with polyamines, and DyM-2 was made with amines composed of more amide units than DyM-1; Aim-1 and Aim-2 were made with simple amides, and Aim-1 was made with more acid units than Aim-2. PyA-1 and PyA-2 were both fatty acid polymers, while PyA-2 contained more acid units as well. The Ens was the mixture of methanol and ethanol. DyM-1 and DyM-2 were purchased from Unitech Chemicals Zibo Company (Zibo, China), PyA-1~PyA-2 and Aim-1~Aim-2 were purchased from Lullaby Pharmaceuticals Chemical Company (Wuhan, China), and Ens was produced by Dow Chemical (Zhangjiagang, China). The materials were used without further purification. Other compounds used in the drilling fluids were general industrial products.

2.2. Methods

2.2.1. Preparation of Drilling Fluid

The needed drilling fluids were formed according to the procedures made by API (American Petroleum Institute) standards. The oil-based fluids were prepared mainly based on light mineral oil and brine, and the base solution was mixed in accordance with the oil-water ratio from 80:20 to 90:10. To meet the needs of fluids rheology and filtration, varied emulsifiers, rheological modifiers, fluid loss reducers, organophilic clays, and other related treatment agents were added; meanwhile, different amounts of the barites were added as weighing materials according to required density. The above materials used are listed in Table 1 as follows:

Table 1.

Base formula of drilling fluids.

2.2.2. Performance Evaluation of Fluids

Based on API standards, the high-temperature and high-pressure filtration loss (FLHTHP) and electrical stability (ES) of the drilling fluids were measured before and after hot rolling at different temperatures. What is more, the specific rheological properties, including apparent viscosity (AV), plastic viscosity (PV), and yield point (YP), were calculated from readings at 3–600 rpm (Φ3–Φ600) measured in a Model 900 Viscometer, with the accuracy of the calibration being over 0.9990, which was produced by OFI Testing Equipment (Houston, TX, USA). Furthermore, to address the research needs, the same rheological properties, which mainly contained viscosity changes at varied rotation speed with expanded HTHP, were measured through a Fann iX 77 HTHP Rheometer (Houston, TX, USA), with the angle (deg) being within ±2 degrees after verifying Mechanical Zero.

For a deeper investigation into the influence of composite rheological modifiers on fluids, the rheological properties of emulsions were analyzed through Anton Paar MCR 102 Rheometer (Shanghai, China), with the initial normal force being less than 0.05 N, and after calibration as well. The tests were conducted at 50 °C, using the rotor model CC27 34774. The real-time viscosity changes were monitored as a function of the shear rate (0.01–1000 s−1). The viscoelastic index storage modulus G′ and loss modulus G″ were obtained in oscillatory mode with a fixed strain value (1%) for frequency scanning (0.01–100 rad/s).

2.2.3. Suspension Stability of Drilling Fluids

The assessment of the suspension stabilities of drilling fluids was performed at room temperature and high temperature, respectively. The stability in room temperature was evaluated by a Turbiscan Lab Stability Analyzer produced by Formulaction (Toulouse, France), which had reproducibility/repeatability on latex standards of 0.05%. By recording the backscattered (BS) and transmitted (T) signals irradiated by a near-infrared light source, the sedimentation changes in drilling fluids at the entire height from the bottom to the top can be reflected through the variations in optical signals. In addition, the turbiscan stability index (TSI) could be fitted to quantify the settling property [30].

The suspension stability of the drilling fluids at high temperature was evaluated by measuring the maximum settlement resistance. The samples were sealed and placed standing in the environment with a set temperature for 7 days before measuring. This experiment was performed through an RF-990LA/2 Sedimentation Resistance produced by Chengdu Ruifeng Instrument & Equipment (Chengdu, China). The minimum measurement accuracy of the instrument was 0.001 N. After setting the same descent rate and height, the instrument probe can measure the contact resistance of the fluids during the descent process. By comparing the maximum value of resistance, the sedimentation and suspension capacity of fluids after long-term high-temperature aging can be determined.

3. Results and Discussion

3.1. Rheological Properties of Drilling Fluids with Single Critical Treatment Agent in HTHP

In order to obtain an oil-based drilling fluid that exhibited thickening performance at HTHP, the rheological properties of the base drilling fluids in low or high temperature and pressure before and after hot rolling (BHR/AHR) at 150 °C were preliminarily explored. In this process, two types of drilling fluids (ρ = 1.8 g/cm3) were prepared and tested. In drilling fluid 1, no specific rheological modifier was added, while in fluid 2, the appropriate commercial treatment agent DyM-1 was added. The properties measured at 65 °C and atmospheric pressure are shown in Table 2 below.

Table 2.

Basic performances of oil-based drilling fluids 1~2.

The results revealed that the introduction of an appropriate amount of DyM-1 significantly enhanced both the overall viscosity and shear strength of the drilling fluid, whilst increasing its emulsion-breaking voltage dramatically. Although the FLHTHP exhibited a slight rise, it remained within an acceptable range.

To simulate the in situ wellbore environment, the HTHP rheological properties of the samples need to be examined under conditions of simultaneously elevated temperature and pressure. Therefore, the subsequent investigation analyzed the viscosity changes in both fluids after hot rolling under gradually elevated temperature and pressure conditions. The test range was set at 65–150 °C and 0.1–68 MPa.

The test results were shown in Table 3 and Table 4. Considering the degradation of rheological properties in oil-based drilling fluids at elevated temperatures and the detrimental impact of increased plastic viscosity on fluid flowability, the rheological performance of the fluid was primarily evaluated by comparing its low-shear-rate viscosity and PV and YP values.

Table 3.

The rheological performances of drilling fluid 1 after aging under increasing temperature and pressure.

Table 4.

The rheological performances of drilling fluid 2 after aging under increasing temperature and pressure.

Summarizing the rheological properties of the two drilling fluids under HTHP based on Table 3 and Table 4, it could be observed that, regarding Φ3 as a reference, the low-shear-rate viscosity value of drilling fluid 1 without a specific rheology modifier was relatively low, which was basically below 4.0. Both its low-shear-rate viscosity and PV values decreased significantly with increasing temperature span. At the same time, the increase in pressure could induce a slight viscosity rise at the same temperature. However, when ambient temperature and pressure increased simultaneously, the overall viscosity still exhibited a decreasing trend. Furthermore, considering a certain degree of instrument testing error, the YP essentially underwent minor fluctuations and remained stable. Under the same conditions, drilling fluid 2, modified with the rheology modifier DyM-1, exhibited higher low-shear-rate viscosity. However, its variation trend was identical to that of fluid 1, which exhibited a continuous decrease with increasing temperature, even with the decline rate exceeding that of high-shear-rate viscosity. It could be seen that compared with the readings at the initial (65 °C) and maximum test temperature (150 °C), the decline of readings of Φ3 exceeded 57%, while that of Φ600 was only 7%. This indicated that although this system exhibited significant thickening performance under ordinary testing conditions after rheology modification, it failed to maintain stable rheological performance under HTHP conditions similar to actual wellbore. By contrast, the PV and YP of fluid 2 have remained relatively stable with some improvement. Therefore, rheological evaluation of oil-based drilling fluids at ambient temperature and pressure cannot fully reflect their actual behavior in wellbore environments. A conventional single-component rheological modifier may be insufficient to meet the viscosity requirements of drilling fluids in HTHP wellbore environments. A more definitive evaluation system and reference standard must be established based on parameters measured under HTHP.

Next, to obtain treatment agents and drilling fluids that meet thickening performance requirements, several potential treatment agents were screened, including fatty acid polymers PyA-1, PyA-2, and clay activator Ens. After preparing drilling fluids 3~5 containing the aforementioned rheological modifiers in batches, identical rheological tests were conducted.

As shown in Table 5, under common conditions, the addition of fatty acid polymers PyA-1~2 significantly improved the fluid viscosity and shear strength, while the clay activator Ens exhibited a relatively minor increase. Both treatment agents demonstrated the ability to improve drilling fluid rheology under low-temperature and atmospheric Pressure Conditions.

Table 5.

Basic performances of oil-based drilling fluids 3~5.

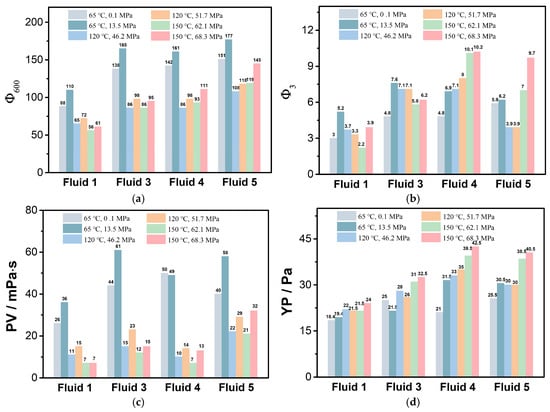

A comparison of the rheological properties of drilling fluids 3~5 with those of drilling fluid 1 in Figure 1 revealed that these fluids exhibited higher viscosity than fluid 1 overall. Their viscosity change trends under high shear rates were consistent, showing a slight decrease upon heating while maintaining stability (Figure 1a). Specifically, fluid 3 exhibited a relatively increased low-shear-rate viscosity for which Φ3 was above 7, compared to fluid 1 when heated to 120 °C, though it did not undergo a significant intrinsic change. However, this increase change was not sustained up to 150 °C and reduced to 6.2. Meanwhile, fluid 4 maintained a consistently favorable low-shear-rate viscosity trend, with the final Φ3 being above 10. While fluid 5 showed an increasing tendency only upon heating to 150 °C (Figure 1b), the Φ3 readings of fluid 5 were increased from 3.9 to 9.7 in the temperature range from 120 to 150 °C. In addition, all three additives exhibited an increasing effect on PV and YP. As demonstrated in Figure 1c, the enhancement trend of PV was most evident in fluid 5. The PV of fluid 1 declined to only 7 mPa·s after heating to 150 °C, which was enhanced to 32 mPa·s in fluid 5. Although an increase in PV was generally undesirable, minor variations remained within acceptable limits of below 70 mPa·s in oil-based muds. As illustrated in Figure 1d, PyA-2 exhibited a higher YP enhancement effect in comparison to PyA-1, causing an increase in YP to 42.5 Pa under 150 °C and 68 MPa. While Ens demonstrated a superior increasing effect at elevated temperature, the YP of fluid 5 increased by 18% from 65 to 120 °C, and reached 59% from 65 to 150 °C.

Figure 1.

Rheological performances of oil-based drilling fluids 3~5 under HTHP: (a) Φ600; (b) Φ3; (c) PV; (d) YP.

The above results indicated that all three additives exhibited distinct thickening effects on the rheology of drilling fluids under HTHP conditions. PyA-1 showed weakened thickening capacity and increased instability at elevated temperatures. PyA-2 exhibited excellent high-temperature thickening capability; however, it seemed to cause excessive augmentation of rheological properties, which may result in adverse effects on fluid performance under HTHP. Furthermore, it was found that the thickening effect of Ens was primarily manifested at higher temperatures, accompanied by a significant increase in PV. Consequently, these additives performed differentiated activation criteria and thickening behaviors in HTHP environments, while none of them can achieve stable performance when used individually. Additionally, it was hard to predict the behaviors exhibited by these agents at elevated temperatures over 150 °C and other pressures. In view of the necessity to preserve both the static suspension capability and dynamic flowability of oil-based drilling fluids under HTHP, subsequent experiments would adopt composite additives to achieve more stable thickening performance.

3.2. Rheological Properties of Drilling Fluids with Composite Treatment Agents in HTHP

In the preceding work, an experimental strategy was established to utilize composite treatment agents for improving the rheological properties of oil-based drilling fluids under HTHP conditions. Consequently, composite treatment agents were formulated through varying combination ratios. Furthermore, the derivative structures polyamide Aim-1~2 were introduced in combination with Ens. In accordance with the formulations previously delineated, drilling fluids comprising a range of treatment agents were meticulously prepared. The preparation details of the composite treatment agents were summarized in Table 6 below.

Table 6.

The composite treatment agents in drilling fluids 6~13.

The low-shear-rate viscosity Φ3 remained the principal indicator of thickening efficacy, thus enabling a viscosity comparison from drilling fluids 6 to 13 (Figure 2). Considering the actual usage requirements, the growth of low-shear-rate viscosity, especially of the Φ3 readings, should be kept within 5–15, and the YP should be kept within the 5–20 Pa. Excessive increase would cause the drilling fluid to be too thick, leading to the loss of fluidity and circulation pressure. Therefore, the screen of the most suitable thickener components was operated based on this principle. As demonstrated in the preceding section, PyA-1 and Ens exhibited thickening effects at lower and higher temperatures, respectively. Consequently, the proportion of Ens was reduced while that of PyA-1 was increased when the two were blended. However, a comparison of drilling fluids 6–8 revealed that while near-optimal thickening was achievable at 150 °C, no significant viscosity increase was observed when heated to 120 °C with this combination. It could be seen that the Φ3 was strengthened from 3 to 5 to 7–12 when heating from 65 to 150 °C, and could only be influenced to be 3–7 up to 120 °C. Consequently, the combination of PyA-1 and Ens exhibited limited stability in terms of thickening under conditions of lower temperature and pressure; optimal thickening effects were supposed to be achieved under certain conditions at higher temperatures and pressures. Among the remaining combinations, the PyA-2/Ens blend and the mixture of all three treatment agents, which were mixed at a 5:3:5 ratio, demonstrated remarkably effective low-shear-rate viscosity enhancement for drilling fluids 9 and 11. The Φ3 was strengthened to over 12 when heating to 150 °C, and it showed an obvious increasing trend along with the temperature from 65 to 120 and 150 °C. While the Aim/Ens blends demonstrated marginally diminished thickening performance in fluids 12 and 13, they still attained the requisite viscosity increase range.

Figure 2.

The Φ3 readings of oil-based drilling fluids 6~13 under HTHP.

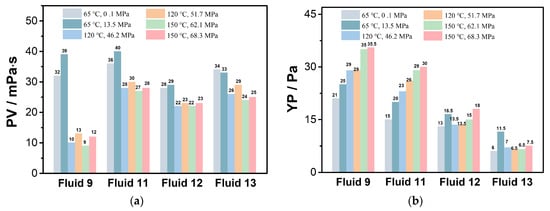

Further investigation was conducted on the effects of the above four combinations on PV and YP. As shown in Figure 3a,b, drilling fluid 9 exhibited a decrease in PV upon heating, with values remaining significantly lower than 20 mPa·s, which would cause a bad influence on the suspension capacity under high-speed shearing conditions as well, while its YP increased excessively. Therefore, the PyA-2 and Ens bend was unsuitable for use as a composite thickener. The remaining combinations were found to be capable of maintaining PV within an appropriate range in 20–30 mPa·s. Simultaneously, the composite combinations of the three treatment agents could achieve appropriate YP growth in fluid 11. Though the YP of fluid 12 containing Aim-1/Ens combination showed a slight decrease compared to fluid 1, the overall values remain steady and acceptable within 13–18 Pa. By contrast, the YP of fluid 13 containing Aim-2/Ens was too low at around 7 Pa when heating, revealing that this combination was not suitable for keeping fluid rheology. Consequently, as demonstrated by the aforementioned experimental findings, the composite treatment agents PyA-1, PyA-2, and Ens, in conjunction with the composite treatment agents Aim-1 and Ens, can be further utilized as thickeners within simulated wellbore conditions at HTHP.

Figure 3.

The PV (a) and YP (b) of oil-based drilling fluids 9, 11, 12, and 13 under HTHP.

3.3. The Drilling Fluids with Rheological Enhancement

Following the successful development of the composite treatment agents that demonstrated thickening efficacy at HTHP, the next stage of the research was targeted at investigating their adaptability in other drilling fluid systems. It aimed to explore the potential for composite agents as a core thickener to construct drilling fluids under higher temperature and pressure. Consequently, a drilling fluid 14 with 200 °C resistance, formulated with the commercial rheological modifier DyM-2, was developed on the basis of fundamental research. It was then replaced with a PyA-1/PyA-2/Ens combination and an Aim-2/Ens combination, yielding drilling fluids 15 and 16 (ρ = 1.9 g/cm3).

The fundamental properties of the drilling fluids 14~16 were first measured after hot rolling at 200 °C for 16 h in Table 7. In accordance with the standard testing conditions, the substitution of the treatment agent did not exert a substantial influence on the essential characteristics of the drilling fluid. Fluid 15 exhibited a specific increase in low-shear-rate viscosity, while drilling fluid 16 demonstrated an overall improvement in rheological performance.

Table 7.

Basic performances of oil-based drilling fluids 14~16.

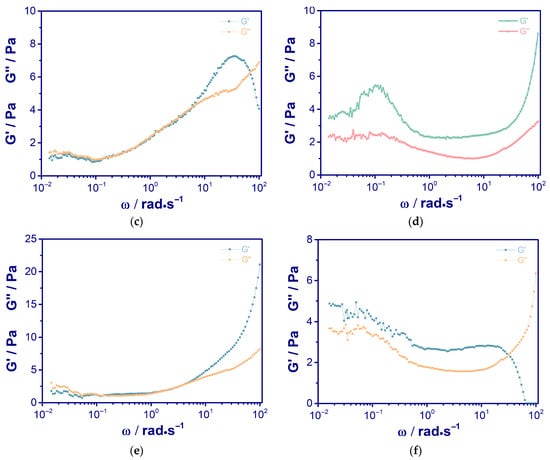

It was evident that the testing conditions for these drilling fluids, which were intended to simulate deep wellbore environments at HTHP, have undergone an expansion in terms of their enhanced temperature resistance. The temperature range of the testing process extended from 120 to 200 °C, while the pressure range encompassed 46 to 153 MPa. The results of these experiments were displayed in Figure 4.

Figure 4.

Rheological performances of oil-based drilling fluids 14~16 under HTHP: (a) Φ600; (b) Φ3; (c) PV; (d) YP.

It could be seen that the Φ3 readings of drilling fluid 14 were getting lower from 5.3 to 3.6 along with the increasing temperature and pressure, and the valves were kept relatively stable, which meant DyM-2 had no thickening functions. In contrast, it was noteworthy that drilling fluid 15 exhibited elevated viscosity readings at all shear rates when compared to fluid 14. The high-shear viscosity Φ600 remained highly stable at around 90, only exhibiting a comparatively minor increase trend when the temperature and pressure grew to 200 °C and 153 MPa. While the low-shear viscosity Φ3 demonstrated a substantial rise from 10 to 13.3, thereby satisfying the requirement for specific low-shear viscosity growth in instances of weakened suspension capacity. Consequently, the PV of fluid 15 was shown to be essentially consistent with that of drilling fluid 14 within the range of 28–41 mPa·s. At the same time, the YP of fluid 15 demonstrated a more accentuated increase trend with rising temperature and pressure from 11.5 to 18 Pa. In conjunction with Φ3 readings, it suggested that the drilling fluid system in question exhibited an optimal thickening effect under conditions characterized by heightened complexity in terms of temperature and pressure. The drilling fluid 16, utilizing the Aim-1/Ens combination, did not attain the anticipated thickening effect. It only exhibited a modest increase in low-shear-rate viscosity compared to fluid 14, which was over 6 from 120 to 150 °C; however, it revealed a negligible growth in the 180–200 °C temperature range. Given the similarity of its PV and YP values and change trends to those of fluid 14, this composition can be considered as a viable alternative to commercial DyM-2 products in this system. In summary, a thickening oil-based drilling fluid resistant to 200 °C can be constructed solely through the composite treatment agents, including PyA-1, PyA-2, and Ens.

To deeper verify the rheological enhancement of the thickener in the fluid, other thickening fluids with different densities were constructed. Applying the DyM-2 and composite thickener as the core rheological modifier, the properties of drilling fluids 17–20 with ρ = 1.4 g/cm3 and ρ = 2.4 g/cm3, respectively, were tested and displayed in Table 8, Table 9, Table 10 and Table 11. According to the results, the thickening drilling fluids 17 and 19 with 1.4 and 2.4 g/cm3 showed rheological changes very similar to those of drilling fluid 15, with both low-shear-rate viscosity and plastic viscosity exhibiting steady and specific increases compared to traditional drilling fluids 18 and 20 with changes in temperature and pressure. In contrast, fluids 18 and 20 only maintained relative stability, further confirming the above experimental conclusions.

Table 8.

The rheological performances of drilling fluid 17 (ρ = 1.4 g/cm3) after aging under increasing temperature and pressure.

Table 9.

The rheological performances of drilling fluid 18 (ρ = 1.4 g/cm3) after aging under increasing temperature and pressure.

Table 10.

The rheological performances of drilling fluid 19 (ρ = 2.4 g/cm3) after aging under increasing temperature and pressure.

Table 11.

The rheological performances of drilling fluid 20 (ρ = 2.4 g/cm3) after aging under increasing temperature and pressure.

3.4. Rheological Performances of Emulsions

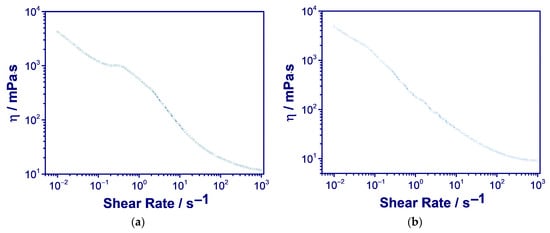

In order to ascertain the discrepancies between thickened fluid and conventional fluid, the shear viscosity and viscoelastic modulus were measured at 50 °C for water-in-oil emulsions containing organoclay and the composite thickener (PyA-1/PyA-2/Ens) or conventional rheological modifier agent (DyM-2) (Figure 5). As demonstrated in Figure 5a,b, with the absence of filter loss reducers and weighting materials, the shear viscosity trends and ranges of both emulsions exhibited consistent variations with shear rate. As the shear rate increased, the emulsion viscosity uniformly declined, exhibiting shear-thinning character.

Figure 5.

The shear viscosity and viscoelasticity of emulsions treated with conventional rheological modifier (a,c) and the composite thickener (b,d); the viscoelasticity of emulsions treated with PyA-1/PyA-2 (e) and PyA-1/Ens (f).

A comparison of Figure 5c,d revealed that during oscillatory sweep tests, the storage modulus G′ of the emulsion treated with DyM-2 exceeded its loss modulus G″ at high oscillation frequencies, while both moduli were nearly identical at medium-to-low frequencies. This finding suggested that the fluid displayed gel-like properties during oscillatory motions of medium to low frequency [31]. Conversely, the G′ of the emulsion containing the thickener invariably exceeded its G″ throughout the entire test. It suggested that the fluid underwent elastic deformation throughout the process, thereby exhibiting half-solid-like characteristics.

To further investigate the specific effects of the compounds of thickener, other combinations were tested under the same conditions. In order to preserve the fundamental properties of the emulsion, PyA-1 was used as the fixed modifier and was combined with PyA-2 and Ens, respectively. As shown in Figure 5e, applying PyA-1 and PyA-2 simultaneously to the emulsion resulted in a modulus variation trend resembling that of DyM-2. The only difference was that the combination exhibited a greater enhancement effect on the fluid’s storage modules G′ under high-frequency oscillation, resulting in significantly higher G′ than G″. With medium-to-low frequency oscillations, both modifiers performed similarly. This result indicated that the addition of mixing agents mainly promoted the elastic performance of the fluid under high-frequency oscillation, endowing the fluid with powerful solid-like properties. In contrast, it could be seen from Figure 5f that the combined effects of PyA-1 and Ens were opposite, which primarily led to an enhancement of the fluid’s elastic modulus during medium-to-low frequency oscillations, resulting in a value higher than G″ and stronger elastic characteristics. However, this performance cannot be maintained under high-frequency conditions. Within these conditions, the value of G″ exceeded and overtook that of G′, the fluid behaved more like a quasi-liquid state and displayed stronger plastic characteristics, indicating that the addition of PyA-1 and Ens mainly promoted the elastic performance of the fluid under medium-to-low frequency oscillation. The above conclusion suggested that both combinations enhanced the fluid elasticity under different oscillation conditions. Therefore, when the thickener formed from the above multi-components was used in drilling fluid, it demonstrated a comprehensive improvement in the elastic properties and structural force of the fluid throughout the whole time, effectively improving the suspension capacity, which was consistent with previous experimental results.

Consequently, the fluid with the composite thickener demonstrated higher inner strength compared to other systems, translating to superior suspension stability under HTHP environments, and achieving the objective of this research to cause an improvement in the rheological property and suspension stability of oil-based drilling fluids in high-temperature conditions.

3.5. Suspension Stability of Thickening Drilling Fluids

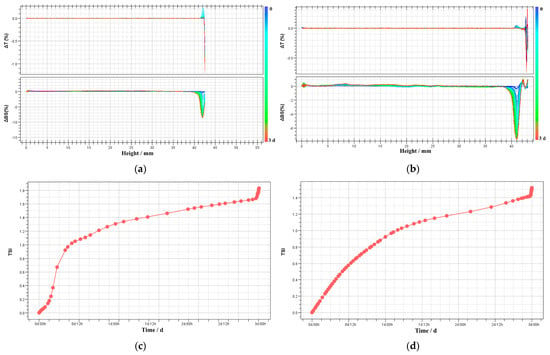

After obtaining drilling fluids with thickening effects at HTHP constructed using the thickener, the suspension stability of the conventional drilling fluid 14 and thickened drilling fluid 15 was tracked and compared following prolonged static storage at both ambient temperature and elevated temperature. Firstly, the sedimentation behavior during static storage for a period of three days at 30 °C was characterized by the monitoring of optical signal changes. As demonstrated in the Figure 6a,b, minimal optical signal variation was observed in the middle and bottom layers of the samples, while both backscatter and transmission signals at the top layer exhibited slight decrease. It was calculated that the backscatter signal of fluid 14 exhibited a decline exceeding 9%, while the transmission signal demonstrated a decrease over 1%. Furthermore, fluid 15 demonstrated a backscatter reduction below 8%, accompanied by a final transmittance decrease of approximately 0.7%. Concurrently, the TSI value of fluid 14 increased substantially, exceeding 1.0 within 12 h and subsequently rising gradually to surpass 1.6. Conversely, the maximum TSI value recorded for fluid 15 did not surpass 1.0 within a 24-hour period, and it maintained a consistent level around 1.4 until the end of the test. It was evident from the comparative results that thickening system 15 exhibited superior suspension stability at room temperature. This finding also suggested that rheological property enhancement played a significant role in improving stability.

Figure 6.

The optical signals and TSI changes in oil-based drilling fluids 14 (a,c) and 15 (b,d).

Based on the sedimentation behavior of the drilling fluids at room temperature described above, it could be concluded that although static standing at lower temperatures could induce sedimentation differences in drilling fluids with varying rheological properties, the overall stability of the system remained steady, with minimal impact on sedimentation status. Consequently, the impact of elevated temperatures on the sedimentation behavior of the system was further investigated. After a seven-day storage period at 200 °C, the resistance to vertical penetration through the drilling fluid was measured through a probe to assess sedimentation behavior. As demonstrated in Figure 7, the sedimentation resistance of thickened drilling fluid 15 was found to be consistently lower than that of 14, with maximum values of 1.565 N and 1.655 N, respectively. This finding suggested that the former fluid exhibited superior sedimentation stability at high temperature, thereby validating the hypothesis that the thickened system continued to exert a positive influence on the drilling fluid suspension properties under high-temperature conditions. This outcome was in alignment with the findings reported in the above explorations.

Figure 7.

The sedimentation resistance in oil-based drilling fluids of 14 and 15.

3.6. Application of Thickening Drilling Fluids

In recent years, with the implementation of 10,000 m well projects, significant breakthroughs have been achieved across various technologies. Our research indicated that during the drilling project of ultra-deep wells exceeding 10,000 m, field operations imposed extremely high demands on drilling fluids’ rheological properties and suspension stability under HTHP downhole environments. For instance, the construction requirements for the Chuanke-1 Well demanded that the used oil-based drilling fluid maintained high stability throughout a continuous heating process to 220 °C and pressurization to 180 MPa. However, test results indicated that some oil-based drilling fluids applied in the field exhibited performance degradation when heated and pressurized to 170–190 °C and 150–165 MPa, characterized by short-term excessive thickening of rheological parameters. To address these issues, it was necessary to provide drilling fluids with enhanced stability as technical support for similar ultra-deep well conditions. Therefore, based on the strengthened performance on rheological properties of thickening drilling fluids under HTHP described in this article, this category of drilling fluid can serve as a potential technical reserve to meet the field requirements for highly stable oil-based drilling fluids in extreme HTHP environments.

4. Conclusions

This study investigated the potential of commercial rheological modifiers DyM-1 and DyM-2, fatty acid polymers PyA-1 and PyA-2, polyamides Aim-1 and Aim-2, and organoclay activator Ens as thickeners for oil-based drilling fluids, while a thickening oil-based drilling fluid capable of withstanding temperatures up to 200 °C was formulated using composite components from these materials. The drilling fluid exhibited stable thickening properties under HTHP up to 200 °C and 153 MPa.

1. Experimental results indicated that single-component treatments were unable to achieve stable thickening under HTHP conditions. However, the composite thickener comprising three components—PyA-1, PyA-2, and Ens (blended at a ratio of 5:3:5)—could effectively increase the low-shear-rate viscosity and YP of the drilling fluid within an appropriate range, while causing only minor changes in PV and high-shear-rate viscosity. With the Φ600 of the thickening drilling fluid kept highly stable at around 90, and the PV was kept within the range of 28–41 mPa·s under rising temperature and pressure to 200 °C and 153 MPa, the low-shear viscosity reading Φ3 demonstrated a substantial rise from 10 to 13.3, forming a contrast with the conventional fluid of that was declining from 5.3 to 3.6. In addition, the YP exhibited a similar rising trend from 11.5 to 18 Pa, satisfying the requirement for specific low-shear viscosity growth in instances of weakened suspension capacity.

2. The emulsion containing the composite thickener exhibited shear thinning characteristics, with its storage modulus G′ consistently higher than loss modulus G″, indicating that the thickened fluid had more elastic performance and thixotropy, while it could effectively suspend solids under static conditions.

3. The thermo-thickening drilling fluid demonstrated excellent suspension performance at ambient and elevated temperatures. At an ambient temperature of 30 °C, the TSI value of thickening drilling fluid was kept at around 1.4 in a three-day sedimentation test, which surpassed 1.6 in conventional fluid. While in a 7-day sedimentation test at 200 °C, the maximum sedimentation resistance value of the thickened drilling fluid and conventional one was found to be 1.565 N and 1.655 N, respectively, which suggested a superior sedimentation stability at high temperature. Therefore, compared to conventional drilling fluids, it displayed improved suspension functions and showed promise for use in deep wells.

Author Contributions

Conceptualization, X.Z. and W.H.; formal analysis, G.Z., X.Z., and W.H.; investigation, X.T., L.W., and H.Z.; data curation, X.Z., J.Z., and L.W.; writing—original draft preparation, W.C. and H.M.; writing—review and editing, W.C., A.C., and J.Z.; visualization, W.C., H.M., and A.C.; supervision, H.Z., X.T., and G.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Tianjin Science and Technology Program (19PTSYJC00120), China National Petroleum Corporation’s (CNPC) R&D Program (2020E-2803(JT) and 2023ZZ20), Bohai Drilling Engineering Co., Ltd.’s Major R&D Program (2023ZD08F), and Bohai Drilling Engineering Co., Ltd.’s Postdoctoral Program (2024B38F).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

Authors Weijie Chen, Xiaoming Tang, Leilei Wang, Hong Ma, Anliang Chen, Jian Zhang and Xianbin Zhang were employed by the Drilling Fluid Technology Services of CNPC Bohai Drilling Engineering Company Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The funders were not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication. The authors declare that this study received funding from Bohai Drilling Engineering Co., Ltd.; Bohai Drilling Engineering Co., Ltd.’s. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

Abbreviations

The following abbreviations are used in this manuscript:

| HTHP | High temperature and high pressure |

| API | American Petroleum Institute |

| FLHTHP | High-temperature and high-pressure filtration loss |

| ES | Electrical stability |

| AV | Apparent viscosity |

| PV | Plastic viscosity |

| YP | Yield point |

| Φ3–Φ600 | Viscometer readings at 3–600 rpm |

| BS | Backscattered optical signals |

| T | Transmitted optical signals |

| TSI | Turbiscan stability index |

| BHR | Before hot rolling |

| AHR | After hot rolling |

References

- Lei, Q.; Xu, Y.; Cai, B.; Guan, B.; Wang, X.; Bi, G.; Li, H.; Li, S.; Ding, B.; Fu, H.; et al. Progress and prospects of horizontal well fracturing technology for shale oil and gas reservoirs. Pet. Explor. Dev. 2022, 49, 191–199. [Google Scholar] [CrossRef]

- Fang, T.; Ren, F.; Liu, H.; Zhang, Y.; Cheng, J. Progress and development of particle jet drilling speed-increasing technology and rock-breaking mechanism for deep well. J. Petrol. Explor. Prod. Technol. 2022, 12, 1697–1708. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, X.; Li, Y.; Liu, W.; Luo, M. Application a novel thermo-sensitive copolymer as a potential rheological modifier for deepwater water-based drilling fluids. Colloids Surf. A Physicochem. Eng. Aspects 2019, 581, 123848. [Google Scholar] [CrossRef]

- Ren, F.; Fang, T.; Cheng, X.; Cheng, J. Failure volume under particle water-jet impact in deep well drilling engineering: Mathematical modeling and verification analysis. Alex. Eng. J. 2021, 60, 1839–1849. [Google Scholar] [CrossRef]

- Liu, S.; Yang, Y.; Wu, W.; Huang, R.; Lei, L.; Zhong, L. Study on friction and wear failure mechanism of coiled tubing and casing at high temperature. Mater. Today Commun. 2025, 48, 113454. [Google Scholar] [CrossRef]

- Wu, X.; Lai, X.; Hu, J.; Lu, C.; Yang, X.; Zhou, Y.; Wu, M. Efficiency-safety coordination optimization in drilling process under complex formations. Neurocomputing 2025, 630, 129732. [Google Scholar] [CrossRef]

- Hossain, M.E.; Wajheeuddin, M. The use of grass as an environmentally friendly additive in water-based drilling fluids. Pet. Sci. 2016, 13, 292–303. [Google Scholar] [CrossRef]

- Wang, G.; Song, X.; Shi, Y.; Zheng, R.; Li, J.; Li, Z. Production performance of a novel open loop geothermal system in a horizontal well. Energy Convers. Manag. 2020, 206, 112478. [Google Scholar] [CrossRef]

- Ma, J.; Xu, J.; Pang, S.; Zhou, W.; Xia, B.; An, Y. Novel environmentally friendly lubricants for drilling fluids applied in shale formation. Energy Fuels 2021, 35, 8153–8162. [Google Scholar] [CrossRef]

- Li, Y.; Wang, M.; An, Y.; Li, K.; Wei, Z.; Bo, K.; Cao, P.; Guo, M. In situ shale wettability regulation using sophisticated nanoemulsion to maintain wellbore stability in deep well drilling. Langmuir 2022, 38, 12539–12550. [Google Scholar] [CrossRef]

- Wang, G.; Dong, M.; Wang, Z.; Ren, T.; Xu, S. Removing cuttings from inclined and horizontal wells: Numerical analysis of the required drilling fluid rheology and flow rate. Gas Sci. Eng. 2022, 102, 104544. [Google Scholar]

- Zhang, X.; Yang, Z.; Wang, Q.; Chen, W.; Liu, T.; Zhou, T.; Li, S.; Xin, T.; Cao, J.; Xin, X. Preparation and evaluation of a novel branched polymer as thickener for calcium chloride-based drilling and completion fluids. Molecules 2024, 29, 5542. [Google Scholar] [CrossRef]

- Li, J.; Yang, P.; Guan, J.; Sun, Y.; Kuang, X.; Chen, S. A new type of whole oil-based drilling fluid. Pet. Explor. Dev. 2014, 41, 538–544. [Google Scholar] [CrossRef]

- Guo, Y.; Li, X.; Huang, L. Experimental investigation on the sudden cooling effect of oil-based drilling fluid on the dynamic compressive behavior of deep shale reservoirs. Energy 2023, 282, 128680. [Google Scholar] [CrossRef]

- He, Y.; Du, M.; He, J.; Liu, H.; Lv, Y.; Guo, L.; Zhang, P.; Bai, Y. An amphiphilic multiblock polymer as a high-temperature gelling agent for oil-Based drilling fluids and its mechanism of action. Gels 2023, 9, 966. [Google Scholar] [CrossRef]

- Dai, F.; Luo, P.; Wu, C.; Wang, R.; Liu, Y.; Huang, W. Study on artificial filter cake evaluation method of oleophilic nano-plugging agent. Energies 2023, 16, 3559. [Google Scholar] [CrossRef]

- Du, H.-Y.; Lv, K.-H.; Sun, J.-S.; Li, M.-C.; Geng, Y.; Huang, X.-B.; Shen, H.-K.; Khan, K.A. Mesoporous SiO2 nanoparticles with low surface energy and multi-level roughness as shale wellbore stabilizers in oil-based drilling fluid. Pet. Sci. 2025, 22, 384–397. [Google Scholar] [CrossRef]

- Zhang, Y.; Lv, K.; Huang, X.; Li, Z.; Zhang, Y.; Yuan, Z. An amide-carboxylic acid compound as gel structure breaker to improve the rheology of oil-based drilling fluids. Gels 2025, 11, 97. [Google Scholar] [CrossRef]

- Fakoya, M.F.; Ahmed, R.M. A generalized model for apparent viscosity of oil-based muds. J. Pet. Sci. Eng. 2018, 165, 777–785. [Google Scholar] [CrossRef]

- Zhuang, G.; Zhang, Z.; Jaber, M. Organoclays used as colloidal and rheological additives in oil-based drilling fluids: An overview. Appl. Clay. Sci. 2019, 177, 63–81. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, R.; Zhou, J.; Chen, H.; Tan, Y. A novel hyper-cross-linked polymer for high-efficient fluid-loss control in oil-based drilling fluids. Colloids Surf. A Physicochem. Eng. Aspects 2021, 626, 127004. [Google Scholar] [CrossRef]

- Lei, H.; Cai, C.; Zhang, B.; Luo, J.; Chen, P.; Xiao, D. Experimental study and rheological modeling of water-based and oil-based drilling fluids under extreme temperature–pressure condition. Energies 2025, 18, 4687. [Google Scholar] [CrossRef]

- Ghavami, M.; Hasanzadeh, B.; Zhao, Q.; Javadi, S.; Kebria, D.Y. Experimental study on microstructure and rheological behavior of organobentonite/oil-based drilling fluid. J. Mol. Liq. 2018, 263, 147–157. [Google Scholar] [CrossRef]

- Ye, Y.; Fan, H.; Liu, Y. A new approach for predicting the rheological properties of oil-based drilling fluids under high temperature and high pressure based on a parameter-free method. Appl. Sci. 2023, 13, 8592. [Google Scholar] [CrossRef]

- Sun, J.; Huang, X.; Jiang, G.; Lyu, K.; Liu, J.; Dai, Z. Development of key additives for organoclay-free oil-based drilling mud and system performance evaluation. Pet. Explor. Dev. 2018, 45, 764–769. [Google Scholar] [CrossRef]

- Yan, L.; Li, Q.; Guo, X.; Guan, X.; Wang, Y.; Liu, L.; Jiang, J.; Song, J.; Han, C. Environmentally friendly bio-based additives in oil-based drilling fluids: Efficient synthesis, well-ordered self-assembly, exceptional ultra-high-temperature resistance, and excellent anti-settling properties. Colloids Surf. A Physicochem. Eng. Aspects 2025, 719, 137014. [Google Scholar]

- Mohamed, A.; Basfar, S.; Elkatatny, S.; Al-Majed, A. Prevention of barite sag in oil-based drilling fluids using a mixture of barite and ilmenite as weighting material. Sustainability 2019, 11, 5617. [Google Scholar] [CrossRef]

- Murtaza, M.; Alarifi, S.A.; Kamal, M.S.; Onaizi, S.A.; Al-Ajmi, M.; Mahmoud, M. Experimental investigation of the rheological behavior of an oil-based drilling fluid with rheology modifier and oil wetter additives. Molecules 2021, 26, 4877. [Google Scholar] [CrossRef]

- Mahmoud, A.; Gajbhiye, R.; Elkatatny, S. Enhanced performance of oil-based drilling fluids under HPHT conditions using an organophilic phyllosilicate. Sci. Rep. 2025, 15, 22447. [Google Scholar] [CrossRef] [PubMed]

- Ostolska, I.; Wiśniewska, M. Removal studies of Cr2O3 colloidal particles using cationic poly(l-lysine) and its block copolymers with poly(ethylene glycol). J. Mol. Liq. 2017, 241, 952–958. [Google Scholar] [CrossRef]

- Gautam, S.; Guria, C. Optimal synthesis, characterization, and performance evaluation of high-pressure high-temperature polymer-based drilling fluid: The effect of viscoelasticity on cutting transport, filtration loss, and lubricity. SPE J. 2020, 25, 1333–1350. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).