Abstract

This paper presents a novel system for the fault diagnosis of induction motors, employing the Transient Motor Current Signature Analysis (TMCSA) method. The developed system operates in a laboratory environment and enables the detection of motor faults during transient conditions, specifically during the startup phase. The diagnostic process relies on tracking characteristic patterns in the time–frequency domain, which are extracted from current signals using advanced signal processing techniques, including the Gabor transform, Short-Time Fourier Transform (STFT), Wigner–Ville distribution, and Continuous Wavelet Transform (CWT). These transformations allow precise identification of fault-related components and their evolution over time. Experimental investigations were conducted for two distinct types of faults: a broken rotor bar and mixed eccentricity. The obtained results demonstrate a high accuracy of fault detection and confirm the robustness of the proposed method. Furthermore, the findings indicate its suitability for practical applications in variable-speed drive systems, where conventional steady-state diagnostic methods are often ineffective.

1. Introduction

Fault diagnosis of induction motors has been a subject of extensive research due to their widespread use in industrial applications and the critical role they play in ensuring process reliability. Traditional diagnostic techniques are most often based on steady-state measurements, which may fail to detect certain types of faults, particularly in systems operating under variable speed conditions. In such scenarios, transient analysis becomes essential, as it provides richer diagnostic information by capturing the dynamic behavior of the motor during startup or other non-stationary operating conditions.

This paper introduces a novel laboratory diagnostic system for induction motor fault detection, based on the Transient Motor Current Signature Analysis (TMCSA) method. Unlike previously reported approaches, the proposed system incorporates an innovative mechanism that estimates the motor’s rotational speed in real time and graphically extracts the trajectory of a fault-related characteristic harmonic on the time–frequency spectrogram. This unique capability enables continuous, visual tracking of the harmonic component associated with specific faults, allowing the operator to perform fault diagnosis on the fly.

To enhance fault detection accuracy, the system employs advanced time–frequency analysis techniques, including the Gabor transform, Short-Time Fourier Transform (STFT), Wigner–Ville distribution, and Continuous Wavelet Transform (CWT). Experimental verification was carried out for two representative types of faults—a broken rotor bar and mixed eccentricity—with results confirming not only the high sensitivity of the proposed method but also its practical applicability in monitoring induction motors in variable-speed drive systems.

During transient conditions, such as the startup of an induction motor, additional electromechanical phenomena become significantly more pronounced compared to steady-state operation. The rapid variation in slip, the high inrush current, and the dynamic redistribution of electromagnetic forces give rise to distinctive fault-related harmonic components whose amplitudes are often considerably higher than in the steady state. These components form well-defined trajectories on the time–frequency plane, which reveal characteristic patterns associated with specific types of mechanical or electrical faults. As a result, transient analysis provides an extended set of diagnostic features that are either weakly visible or completely absent in steady-state measurements. This enhanced visibility and richer harmonic content make transient conditions a valuable source of information for fault detection, allowing the diagnosis of rotor asymmetries, eccentricity, or other irregularities with greater sensitivity and reliability.

The novelty of the proposed diagnostic system does not lie in the individual time–frequency techniques themselves, but in the way they are integrated into a fully automatic transient-based diagnostic framework. Unlike many existing approaches that rely on artificial intelligence, image classifiers, or decision models trained on large datasets, the system developed in this work performs diagnosis by directly extracting and tracking characteristic harmonic trajectories on the time–frequency plane. This allows the method to exploit fundamental electromechanical phenomena that become strongly pronounced during startup, providing diagnostic information that extends beyond what can be observed in steady-state or through purely data-driven methods. By combining automatic harmonic tracking with physically interpretable transient signatures, the system offers a robust and explainable alternative to AI-based diagnostic schemes.

2. Literature Review

The diagnosis of induction motor faults remains a central topic in both academia and industry due to their prevalence in industrial systems and the severe consequences of unexpected breakdowns. Numerous works highlight the advantages of analyzing transient signals, particularly during motor startup, as they provide richer diagnostic information than steady-state signals [1,2,3]. Broken rotor bar (BRB) faults, one of the most common failures, have been widely investigated using stator current analysis and time–frequency methods such as the wavelet transform, S-transform, and recursive wavelet packet transform [1,2,4]. More recently, information entropy [5] and hybrid approaches combining wavelet decomposition with statistical or machine learning tools [6] have been proposed as low-cost and effective solutions.

Beyond BRBs, various types of electrical and mechanical faults have also been studied under transient conditions. Turn-to-turn short-circuit faults (TSCFs) in soft-starter-fed induction motors have been addressed through harmonic analysis, with the fifth harmonic shown to be a reliable indicator [7,8]. Stator turn faults were modeled considering fault location and extent, introducing polar plot indicators for online monitoring [9]. Wound rotor induction motors (WRIM) have also been examined, with transient current analysis proving effective for detecting both rotor and stator asymmetries [10]. In addition, rotor electrical faults in inverter-driven motors were analyzed using input and output currents [11], while analytical and theoretical investigations studied the transient evolution of current components caused by rotor asymmetries [12,13].

Mechanical faults have likewise been detected using transient current analysis, offering an alternative to vibration-based methods in cases of limited sensor accessibility [3,14]. Misalignment, unbalance, and soft foot have been diagnosed through advanced analysis of startup currents [3]. Stray flux analysis has also emerged as a promising non-invasive and low-cost diagnostic tool [15,16]. Some works extend the scope to inverter-fed machines, comparing time–frequency techniques for faults such as broken bars and mixed eccentricity [17]. Transient distortions in thyristor-driven motors were further studied, with error theory introduced as a diagnostic strategy [18].

At the methodological level, improvements have been made in both modeling and signal processing. The Virtual Blocked Rotor (VBR) approach reduces computation time in Time-Stepping Finite Element analysis of faulty motors [19]. Comparative studies of classifiers and feature extraction techniques have also been proposed, with Fourier–Bessel decomposition [20], decision-level fusion of multiple classifiers [21], and data-driven machine learning approaches such as support vector machines [22]. Furthermore, several review papers underline the growing importance of transient motor current signature analysis (TMCSA), particularly in variable-speed drives, and highlight adaptive techniques like notch filtering and observer-based methods for non-stationary signals [23].

Recent advancements in induction motor diagnostics demonstrate a growing interest in diverse monitoring techniques addressing both mechanical and electrical faults. Bearing-related issues continue to receive significant attention, with [24] proposing a torque-observer-based method for bearing fault diagnosis in induction motors. A broader methodological perspective is presented in [25], which reviews transfer-learning approaches for motor health monitoring, highlighting their increasing relevance in modern diagnostic systems. Stator winding faults, particularly inter-turn short circuits, are addressed in [26] through a digital-twin-based online diagnosis framework, showing the potential of physics-informed models in real-time monitoring.

Rolling-element bearing defects are further explored in [27], where classification is performed directly on phase-current signals, demonstrating the diagnostic value of electrical measurements for mechanical faults. Inverter-driven motor faults are considered in [28], which introduces mitigation strategies for open-circuit conditions under closed-loop volt-per-hertz control. Stator-related failures are also investigated in [29], where stray-flux measurements combined with machine-learning techniques enable accurate identification of stator winding faults.

Neural-network-based approaches remain an active research direction, as shown in [30], which utilizes NARX models for diagnosing faults in three-phase systems. Additionally, Ref. [31] explores phasor-analysis and fuzzy-logic methods for detecting stator short circuits, emphasizing the ongoing need for interpretable diagnostic schemes. Together, these studies illustrate the breadth of recent research efforts and support the relevance of continued exploration of transient-state analysis for fault detection in induction motors.

Further recent studies expand the understanding of induction motor behavior and modern control strategies. In Ref. [32], Konuhova presents a detailed modeling approach for direct-on-line starting of induction motors, considering both cases with and without current displacement in the stator slots. Such modeling perspectives are valuable for improving the accuracy of transient-state simulations and offer insights relevant to diagnostic methods that rely on startup behavior. Complementing this, the review in [33] explores the integration of metaheuristic optimization techniques with model predictive control (MPC) in advanced motor drive systems. This work highlights the growing role of intelligent control and optimization frameworks in enhancing performance, stability and fault tolerance of electrical drives. Together, these contributions provide useful context for understanding modern trends in motor modeling and control, reinforcing the relevance of transient analysis and diagnostic automation.

Taken together, the literature confirms that transient-based methods—whether using stator currents [1,2,10], stray flux [15,16], harmonics [7,8], or hybrid techniques [6,20,21]—provide reliable tools for fault detection. However, it should be emphasized that among the reviewed works only one contribution [22] explicitly describes a complete diagnostic system rather than focusing solely on algorithms or analytical tools. This reveals a clear research gap and opens the way for further development of automatic diagnostic systems for induction motors, such as the prototype presented in this paper.

In summary, the recent literature reflects a strong and growing interest in developing advanced diagnostic and monitoring techniques for induction motors, spanning mechanical faults, electrical failures, data-driven approaches, and modern control strategies. Although significant progress has been made—ranging from torque-observer-based bearing diagnosis [24], transfer-learning frameworks [25], digital-twin methods for detecting stator short circuits [26], through direct phase-current analysis [27] and stray-flux machine learning solutions [29], to intelligent control and modeling techniques [32,33]—most of these studies focus on steady-state operation or rely on sophisticated control architectures. Only a limited number of works investigate fault signatures during transient states, despite the fact that startup conditions provide unique diagnostic information not observable in steady-state. This gap highlights the need for dedicated transient-state analysis methods and motivates the development of diagnostic systems capable of extracting and interpreting fault-related harmonic patterns during motor acceleration.

3. Experimental Test Bench

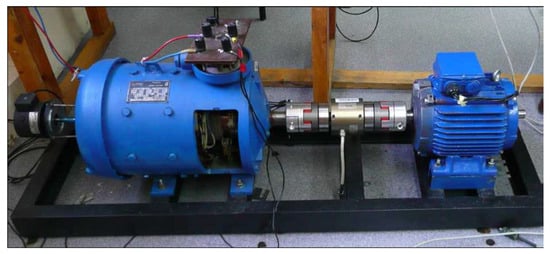

The experimental setup for the proposed automatic fault diagnosis system was developed at the Cracow University of Technology. The object of the study was a laboratory squirrel-cage induction motor Sg112M-4 (Figure 1), in which different faults were simulated using a set of interchangeable rotors (Figure 2). The motor was mechanically coupled to a DC generator serving as the load.

Figure 1.

Sg112M-4 induction motor in experimental test bench.

Figure 2.

Set of interchangeable rotors.

In this study, interchangeable rotors were specially manufactured to introduce controlled rotor faults in a reproducible manner. The defects were incorporated directly during the casting process of the squirrel-cage rotors, ensuring precise geometry and consistent electrical characteristics. Three faulty rotor configurations were prepared for the experiments:

- (1)

- a rotor with a single broken bar,

- (2)

- a rotor with two adjacent broken bars, corresponding to the first and second bars of the cage, and

- (3)

- a rotor with two broken bars separated by one intact bar, corresponding to faults placed in the first and third bars.

These configurations allowed us to simulate both mild and more severe rotor asymmetries while maintaining uniform mechanical balance and structural integrity of the rotors.

The mixed eccentricity fault used in this study was introduced by creating two coexisting forms of air-gap asymmetry. Dynamic eccentricity was generated by intentionally damaging one of the bearing balls, which caused the rotor to deviate from its ideal circular trajectory during rotation. At the same time, static eccentricity was produced by inserting thin shims under selected stator feet, resulting in a permanent displacement of the stator axis relative to the rotor. The combination of these two mechanisms ensured a controlled and reproducible mixed eccentricity condition suitable for experimental evaluation.

Rotational speed measurement was performed using a DATAFLEX® 22/50 electronic speed sensor. DATAFLEX is a maintenance-free device capable of measuring both torque and rotational speed. When combined with RADEX®-NC couplings, it forms a torsionally rigid measurement assembly with the ability to compensate for misalignments.

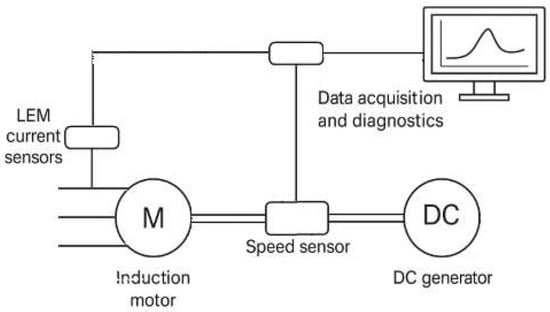

The complete diagnostic system is shown in Figure 1, while its schematic diagram is presented in Figure 3. The phase current signal was acquired using LEM current sensors, and the data acquisition process was carried out with a measurement card (Figure 4). The recorded signals were processed in a computer-based diagnostic program developed in LabVIEW and MATLAB2025b. The software overlays the trajectory of a characteristic fault-related harmonic onto the obtained time–frequency spectrogram, enabling real-time diagnostic evaluation.

Figure 3.

Schematic diagram of the test setup.

Figure 4.

National Instruments BNC-6259 data acquisition card.

The parameters of the tested induction motor are presented in Table 1.

Table 1.

Nameplate data of the Sg112M-4 motor.

In the presented diagnostic system, only a single-phase current is recorded and used for the analysis. This choice is justified by the fact that the characteristic fault-related harmonic components—both for broken rotor bars and mixed eccentricity—are present in all three phase currents due to the symmetry of the induction motor’s magnetic field. Therefore, the diagnostic information contained in one phase is fully representative and sufficient for reliable fault detection. Using a single-phase measurement is also advantageous, as it significantly simplifies the acquisition hardware, reduces computational load, and lowers the overall system complexity, while maintaining full diagnostic capability. This approach aligns with widely accepted practices in transient motor current signature analysis (TMCSA) and enhances the practicality of the proposed diagnostic solution.

During the measurements, the induction motor was mechanically coupled to a DC generator, which provided a constant load torque throughout all test scenarios. Each startup was performed as a direct-on-line connection to the three-phase supply network with a line voltage of 3 × 400 V and a nominal frequency of 50 Hz. For every rotor configuration, a single startup sequence was recorded in order to capture the characteristic transient behavior associated with the corresponding fault condition.

Although the present study focuses on constant-load and direct-on-line startup conditions, future work may extend the analysis to different load levels and alternative supply methods, such as inverter-fed operation. Such investigations could further enrich the understanding of transient signatures and broaden the applicability of the proposed diagnostic approach.

4. TMCSA as a Method for Transient-State Fault Diagnosis

The application of time–frequency analysis techniques for induction motor fault diagnosis has been widely explored in the literature [34,35]. Early transient-state diagnostic methods emerged in the 1980s and 1990s, when researchers proposed analyzing startup currents to detect rotor faults such as broken bars. One significant approach involved identifying the left slip harmonic caused by rotor asymmetry during startup, initially using filtering techniques and later wavelet analysis with Gaussian wavelets [34].

Predictive diagnostics has gained industrial interest due to the high costs of unexpected failures, particularly in detecting early-stage rotor bar faults, which may propagate and cause sudden breakdowns if continuous monitoring is absent [35]. While Motor Current Signature Analysis (MCSA) in the steady state, based on Fourier spectrum analysis, is a proven non-invasive technique, it is unsuitable for non-stationary conditions. FFT requires long sampling times for high resolution, making it sensitive to operational changes and leading to spectral smearing that hinders accurate fault detection [36].

To overcome these limitations, Transient Motor Current Signature Analysis (TMCSA) extends MCSA to transient states, enabling detection of fault-related harmonics during speed changes. This is achieved through time–frequency analysis methods such as STFT, wavelet transforms, and Wigner–Ville distribution, which allow tracking harmonic evolution in both time and frequency domains [37]. TMCSA thus provides a more effective framework for diagnosing induction motor faults in variable-speed and non-stationary operating conditions.

5. Detection of Broken Rotor Bars

The problem of detecting broken rotor bars in induction motors has been widely addressed in the literature [34,37,38,39,40]. In this study, for transient-state detection, the most widely recognized TMCSA-based approach was selected—diagnosis using the left sideband slip harmonic (LSH).

Due to the high costs associated with unexpected motor failures and production downtime, numerous rotor fault detection techniques have been proposed [39]. Rotor asymmetry diagnostics in asynchronous machines has been extensively studied, with stator current spectrum analysis (MCSA) being the most prevalent industrial method, as it can utilize existing current transducers without additional sensors or intrusive measurements [40].

One of the most established approaches for detecting broken rotor bars is the identification of slip harmonics located around the supply frequency [39]. When a rotor bar is broken, current cannot flow through it, generating a fault-related magnetic field that interacts with the main air-gap field. In the steady state, this interaction induces specific frequency components in the stator current. Their amplitudes depend on machine construction parameters, load conditions, and the inertia of the motor–load system [34].

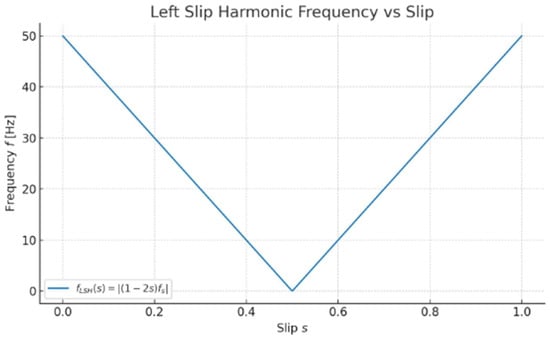

The most important of these components is the left sideband slip harmonic (LSH), calculated for k/p = 1 as:

where s is the slip and fs is the supply frequency [38,40] Figure 5.

fLSH(s) = (1 − 2s)fs

Figure 5.

Left Slip Harmonic Waveform.

This component arises due to asymmetry in the rotor cage caused by the cracked bar, which leads to an unbalanced distribution of rotor currents. The resulting disturbance introduces amplitude and phase modulations in the stator current, producing sideband components symmetrically placed around the fundamental frequency.

Under steady-state operation, the slip assumes a low constant value (typically 1–5%), resulting in the left sideband component appearing close to the main supply frequency and often with relatively small amplitude. Consequently, its detection may be difficult, especially in motors loaded lightly or moderately.

However, during transient operation—particularly the startup process—the behavior of this harmonic changes dramatically. When the motor begins acceleration, the slip momentarily approaches , creating strong interactions between the asymmetrical rotor magnetic field and the stator MMF. As a result, the modulation depth increases significantly, which in turn causes a substantial rise in the amplitude of the left sideband harmonic. At the same time, the starting current reaches values several times higher than the rated current, further enhancing the visibility of this component in time–frequency representations.

During the acceleration phase, the left sideband harmonic traces a characteristic trajectory across the spectrogram, moving from values near zero frequency toward the vicinity of the supply frequency as the slip rapidly decreases. This dynamic trajectory is clearly distinguishable from the background spectrum and provides strong diagnostic evidence of rotor asymmetry. The high amplitude, combined with its well-defined time–frequency pattern, makes the left sideband harmonic a particularly sensitive indicator of broken rotor bar faults during transient conditions.

6. Detection of Mixed Eccentricity

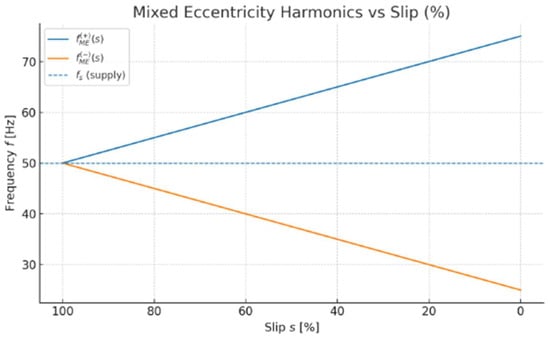

Mixed eccentricity occurs when both static and dynamic eccentricity are present simultaneously. In such cases, the stator current spectrum contains characteristic harmonics with frequencies close to the supply frequency [34,36,38]. These components can be expressed as:

where fs is the supply frequency, fr is the rotor rotational frequency, s is the slip, and p is the number of pole pairs. Detection of these harmonics enables identification of mixed eccentricity faults during transient or steady-state operation Figure 6.

fME(s) = fs ± fr = fs ± ((1 − s) fs)/p

Figure 6.

Mixed Eccentricity Harmonics vs. Slip.

In steady-state operation, the slip is small, which limits the modulation depth of these components and results in relatively low amplitudes. As a consequence, the harmonic signatures of mixed eccentricity may become weak or difficult to distinguish from the background spectrum, particularly at light or moderate loads.

During transient conditions—especially during the startup process—the situation changes fundamentally. When the motor accelerates from rest, the slip begins at , and the air-gap magnetic asymmetry interacts strongly with the rapidly increasing rotor magnetic field. This leads to a significant rise in radial electromagnetic forces and a pronounced modulation of the stator current. As a result, the amplitudes of the mixed–eccentricity–related harmonics become substantially higher than in steady-state operation.

Moreover, because the rotor rotational frequency changes continuously during startup, the corresponding harmonic components trace distinctive curved trajectories across the time–frequency plane. These trajectories are clearly visible in the spectrogram and provide an extended diagnostic signature that is absent or poorly expressed during steady-state operation. The enhanced amplitude, combined with the unique time-varying pattern of these harmonics, enables more reliable detection of mixed eccentricity faults under transient conditions.

Thus, the transient-state analysis offers richer diagnostic information than steady-state methods, as it reveals both the increased energy and the characteristic evolution of eccentricity-related harmonic components throughout the acceleration process.

7. Time-Frequency Transformations

This section presents signal processing transformations that enable the representation of signals in the joint time–frequency domain.

7.1. Gabor Transform

One of the most widely used methods is the Gabor transform, which combines the Fourier transform with a time-localizing window to analyze non-stationary signals. It can be expressed as [41]:

where x(τ) is the analyzed signal, g(τ − t) is the window function (often Gaussian), f is frequency, and t is time. The window function allows the extraction of spectral components within a limited time interval, making the method effective for detecting transient phenomena. The Gabor transform is particularly useful in diagnostics, as it provides high resolution in both time and frequency for signals with localized events.

7.2. Short-Time Fourier Transform (STFT)

The Short-Time Fourier Transform is another method enabling the representation of signals in the time–frequency domain. It extends the classical Fourier transform by applying it to short, overlapping segments of the signal, isolated using a time window. The STFT is defined as [41]:

where x(τ) is the signal, w(τ − t) is the analysis window centered at time t, and f is frequency. By sliding the window along the time axis, STFT provides a sequence of spectra, revealing how the frequency content of the signal evolves over time. It is widely used for non-stationary signal analysis, offering a fixed compromise between time and frequency resolution.

7.3. Wigner–Ville Distribution (WVD)

The Wigner–Ville distribution is a quadratic time–frequency analysis method that provides high resolution in both time and frequency. Unlike linear transforms, it calculates a two-dimensional energy distribution of the signal, defined as [41]:

where x(t) is the analyzed signal and x∗(t) its complex conjugate. WVD effectively captures transient components and instantaneous frequency variations, making it powerful for non-stationary signal analysis. However, it can produce cross-term interference when multiple frequency components are present, which may require additional filtering or smoothing techniques.

7.4. Continuous Wavelet Transform (CWT)

The Continuous Wavelet Transform represents a signal in the time–scale domain, where scale is inversely related to frequency. It analyzes the signal using a wavelet function that is stretched or compressed to capture different frequency components while sliding along the time axis. The CWT is defined as [41]:

where x(t) is the signal, ψ(t) is the mother wavelet, a is the scale parameter (inverse of frequency), and b is the time shift. CWT provides variable time–frequency resolution: fine time resolution at high frequencies (small scales) and fine frequency resolution at low frequencies (large scales), making it highly suitable for analyzing transient and non-stationary signals.

Each of the applied time–frequency transforms offers different advantages and limitations in the context of transient analysis for induction motor fault diagnosis. The Gabor transform provides good joint time–frequency resolution and produces smooth, easy-to-interpret representations. However, its fixed window size limits the ability to simultaneously capture slow and fast spectral variations, which may reduce precision when harmonic trajectories evolve rapidly during startup.

The Short-Time Fourier Transform (STFT) is computationally efficient and widely used, making it suitable for real-time implementation. Its main limitation arises from the trade-off imposed by the window length: a narrow window improves time resolution but degrades frequency resolution, while a wider window has the opposite effect. Despite this, STFT often provides sufficiently clear harmonic trajectories for practical diagnostic purposes.

The Wigner–Ville distribution (WVD) offers superior time–frequency concentration compared to linear transforms, making fault-related components highly visible. At the same time, WVD suffers from cross-term interference when analyzing multi-component signals, which can complicate interpretation under noisy or complex transient conditions. This characteristic makes it powerful but less intuitive for operators.

The Continuous Wavelet Transform (CWT) provides a flexible, multi-resolution analysis that captures low-frequency components with high frequency resolution and high-frequency components with high time resolution. This adaptability is advantageous for transient fault detection, but CWT is computationally more demanding and can produce visually dense scalograms that require more expertise to interpret.

Overall, while all four transforms successfully reveal fault-related harmonic signatures, their relative strengths differ depending on the desired balance between interpretability, computational cost, robustness to noise, and precision in tracking rapidly changing harmonic structures.

In the proposed diagnostic system, time–frequency representations are not used merely as visualization tools, but as a functional component enabling automatic tracking of the characteristic harmonic phenomena described in Section 5 and Section 6. The generated spectrograms allow the system to identify and follow the trajectories of fault-related components—such as the left sideband harmonic for broken rotor bars or the rotational-frequency-related patterns for mixed eccentricity—throughout the entire startup process. These trajectories form distinctive and repeatable patterns on the time–frequency plane, which remain detectable even under challenging practical conditions with the presence of noise or measurement disturbances. By capturing these time-varying signatures, the system provides a robust basis for discriminating between different types of mechanical and electrical faults during transient operation.

8. Methodology for Broken Rotor Bar Detection

Using the developed automatic diagnostic system, rotational speed and current signals were recorded. The current signal was processed using the Discrete Wavelet Transform (DWT) to obtain an approximation component. For a sampling frequency of 5000 samples/s and a supply frequency of 50 Hz, the approximation level was set to 6, corresponding to a frequency band of 0–39.09 Hz.

The approximation level nf was determined according to:

where Fs is the sampling frequency and fs is the supply frequency.

The choice of the sampling frequency and the sixth-level DWT decomposition was made deliberately and based on empirical evaluation. The goal was to achieve an appropriate compromise between isolating the upper boundary of the approximation band at 39.09 Hz—where no residual traces of the 50 Hz supply component remain—while still preserving the characteristic fault-related harmonics, which appear clearly within the low-frequency region during transient operation. This decomposition level therefore provides a useful balance: it suppresses unwanted components associated with the supply frequency yet retains the diagnostic information necessary for detecting both broken rotor bars and mixed eccentricity. Preliminary tests with adjacent decomposition levels confirmed that level 6 offered the most distinct representation of the relevant harmonic signatures for the selected sampling frequency.

Startup current signals were then analyzed to produce spectrograms and scalograms (with instantaneous frequencies corresponding to scale values at a given time t), along with the extracted trajectory of the left slip harmonic fLSH. This enabled direct visualization and detection of fault-related harmonic behavior during motor startup.

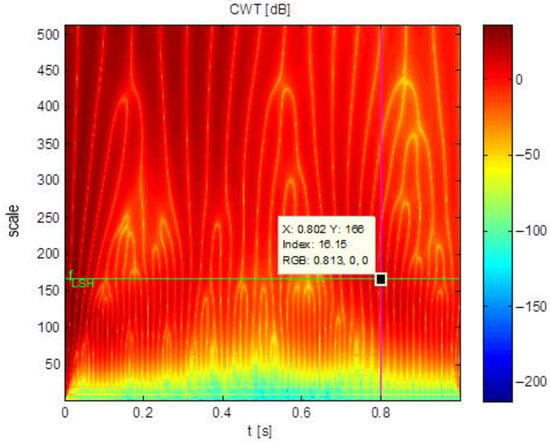

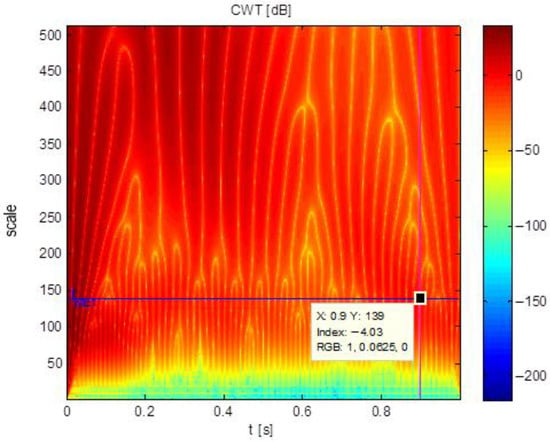

The obtained results are presented in the figures below. For the CWT analysis, the scale corresponding to the characteristic frequency at each moment in time has been indicated.

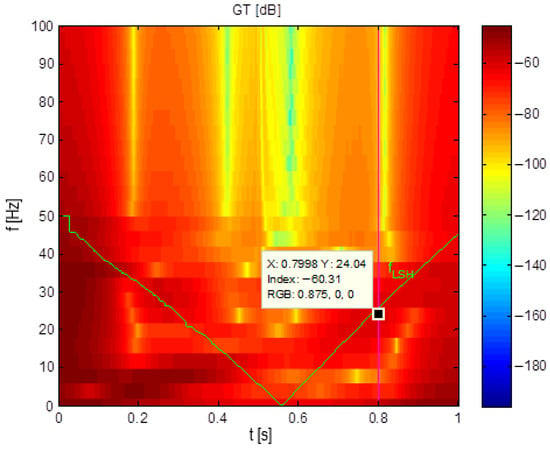

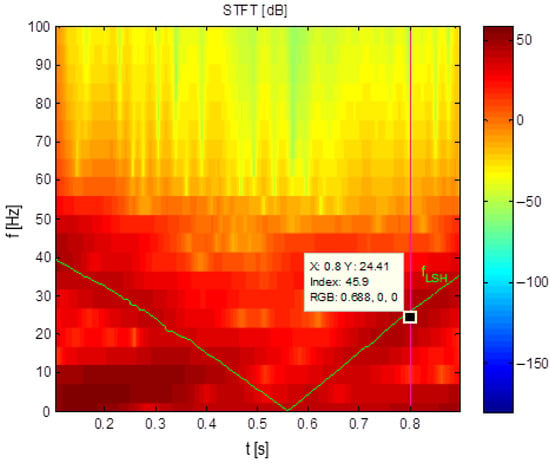

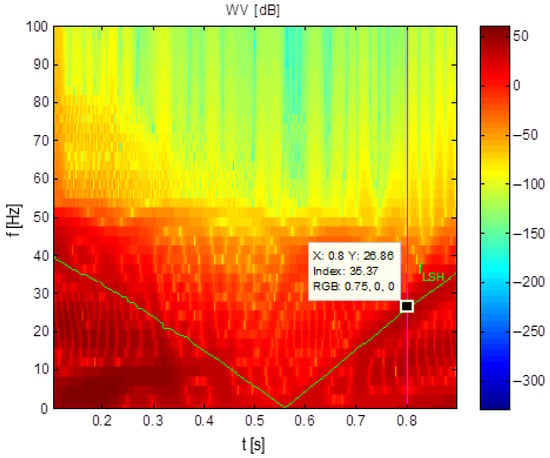

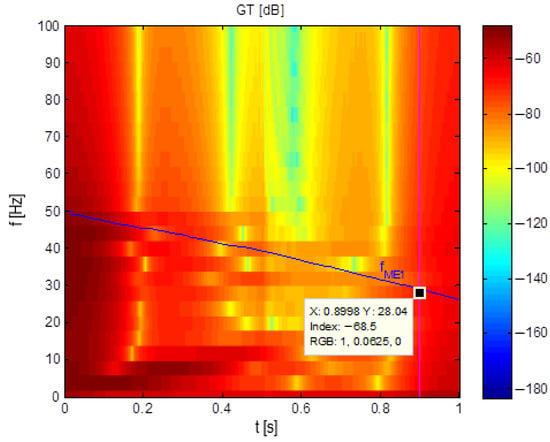

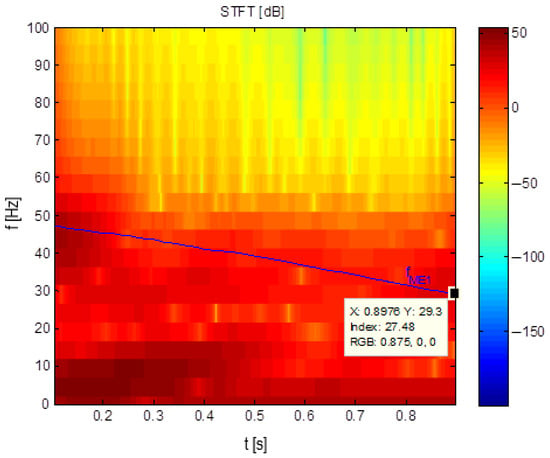

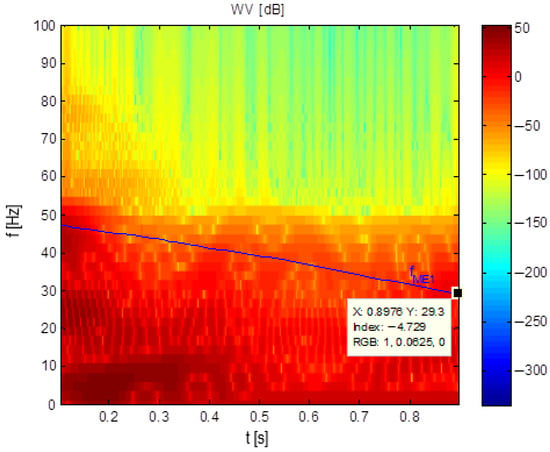

In the proposed diagnostic system, the time–frequency representations corresponding to the broken rotor bar fault (Figure 7, Figure 8, Figure 9 and Figure 10) illustrate how the left sideband harmonic evolves dynamically during the motor startup. As the slip decreases from s ≈ 1 toward its steady-state value, the characteristic harmonic component fLSH = fs(1 − 2s) traces a clear, continuous trajectory across the spectrogram. This behavior is strongly enhanced in the transient state due to the high inrush current and intensified electromagnetic asymmetry, which increase the modulation depth and result in a significantly higher amplitude of the left sideband harmonic compared to steady-state operation.

Figure 7.

Detection of a Broken Rotor Bar Using the Gabor Transform.

Figure 8.

Detection of a Broken Rotor Bar Using the STFT.

Figure 9.

Detection of a Broken Rotor Bar Using the Wigner–Ville Transform.

Figure 10.

Detection of a Broken Rotor Bar Using the CWT.

The developed system automatically detects and follows this trajectory, enabling the identification of a distinct diagnostic pattern directly associated with rotor asymmetry. The visibility, continuity, and shape of the trajectory provide robust fault-related information, even under practical conditions with noise and measurement disturbances. By capturing this characteristic transient harmonic evolution, the system demonstrates a capability that goes beyond traditional steady-state analysis and forms a core scientific contribution of the proposed approach.

Characteristic harmonic fLSH was observed in the presence of a fault Table 2.

Table 2.

Amplitudes of the Characteristic Harmonic of the Broken Rotor Bar Fault fLSH.

The table below presents the absolute amplitude differences in [dB], illustrating the variation observed in the presence of a broken rotor bar Table 3.

Table 3.

Absolute amplitude differences [dB] observed in the presence of a broken rotor bar.

The calculation of the above results enabled the development of a simple decision-based classifier. By quantifying the amplitude differences under healthy and faulty conditions, it became possible to define a threshold-based criterion that allows the system to automatically distinguish the presence of a broken rotor bar.

The results presented in this section demonstrate that all applied time–frequency analysis methods were able to satisfactorily reveal the characteristic left sideband harmonic associated with the broken rotor bar fault. In each case, the absolute amplitude difference between the healthy and faulty conditions provided a clear and interpretable diagnostic indicator. Among the tested transforms, the Wigner–Ville distribution exhibited the strongest separation in terms of amplitude contrast. This observation is consistent with theoretical expectations, as the high energy concentration and superior time–frequency resolution of WVD naturally enhance the visibility of transient harmonic components.

Regarding robustness, the computational requirements of all methods are well within the capabilities of modern computer systems, even when applied to high-resolution time–frequency representations. As a result, the diagnostic procedure can be implemented without limitations on contemporary hardware platforms. The obtained findings confirm that the proposed transient-based approach constitutes a reliable and practical method for detecting broken rotor bar faults in induction motors.

9. Methodology for Mixed Eccentricity Detection

Using the developed automatic diagnostic system, stator current and rotational speed signals were acquired. As in the case of broken rotor bar detection, the current signal was filtered using the Discrete Wavelet Transform (DWT) to obtain an approximation component in the low-frequency band. This ensured that the diagnostic analysis was carried out in the relevant frequency range corresponding to the fault-related harmonics.

The recorded startup current signals were then processed in the custom-developed software, which generated spectrograms and scalograms. Onto these time–frequency representations, the actual trajectory of the characteristic mixed eccentricity harmonic fME1 was superimposed. In this analysis, only the negative-frequency component of Equation (2) was considered.

The obtained results, illustrating the evolution of the fault-related harmonic during motor startup, are presented in the figures below.

In the case of mixed eccentricity, the time–frequency representations (Figure 11, Figure 12, Figure 13 and Figure 14) reveal the presence and evolution of characteristic components associated with the rotor’s mechanical rotational frequency. During the startup process, the spectral components of the form fs ± kfr become significantly more pronounced due to the large slip, increased radial electromagnetic forces, and dynamic variations in the air-gap geometry. These conditions amplify the modulation imposed on the stator current, resulting in harmonic components with much higher amplitude compared to those observed in steady-state operation.

Figure 11.

Detection of a Mixed Eccentricity Using the Gabor Transform.

Figure 12.

Detection of a Mixed Eccentricity Using the STFT.

Figure 13.

Detection of a Mixed Eccentricity Using the Wigner–Ville Transform.

Figure 14.

Detection of a Mixed Eccentricity Using the CWT.

As the rotor accelerates, these components trace distinct and smoothly varying trajectories across the spectrogram, forming clear diagnostic patterns that reflect the evolving mechanical asymmetry of the machine. The proposed diagnostic system is capable of automatically capturing and tracking these trajectories, enabling reliable identification of mixed eccentricity even in the presence of measurement noise or other practical disturbances. The visibility and characteristic curvature of these transient harmonic paths provide richer diagnostic information than steady-state measurements, reinforcing the scientific contribution of the proposed transient-based analysis.

The amplitudes obtained for the symmetrical case i_sym and for the occurrence of mixed eccentricity are presented in the table below. In this case as well, an increase in the amplitude of the characteristic harmonic fME1 was observed in the presence of the fault Table 4.

Table 4.

Amplitudes of the Characteristic Harmonic of the Mixed Eccentricity Fault fME1.

The table below presents the absolute amplitude differences in [dB], illustrating the variation observed in the presence of mixed eccentricity Table 5.

Table 5.

Absolute amplitude differences [dB] observed in the presence of a mixed eccentricity.

The calculation of the above results enabled the development of a simple decision-based classifier. By quantifying the amplitude differences under healthy and mixed-eccentricity conditions, it became possible to define a threshold-based criterion that allows the system to automatically identify the presence of mixed eccentricity.

The analysis of mixed eccentricity demonstrates that all four time–frequency methods were able to reveal the characteristic harmonic components associated with this fault; however, the magnitude of the observed amplitude differences varied more noticeably between the transforms than in the broken rotor bar case. As expected from its superior time–frequency concentration, the Wigner–Ville distribution produced the largest absolute amplitude difference between the healthy and faulty conditions, making the fault signature particularly distinct. This aligns with the theoretical properties of WVD, which enhances low-frequency, slowly varying components such as those generated by eccentricity.

In contrast, the STFT and CWT exhibited relatively small amplitude differences—on the order of approximately 9 dB—between the healthy and mixed-eccentricity states. While these differences are still detectable, their lower contrast may pose potential challenges in more demanding industrial environments, especially in the presence of electrical noise or mechanical disturbances. Nonetheless, the results confirm that the proposed transient-based method remains applicable to mixed eccentricity detection, with the caveat that the choice of time–frequency transform can significantly influence diagnostic sensitivity.

Overall, the findings suggest that WVD provides the most robust diagnostic performance for mixed eccentricity within the tested conditions, while STFT and CWT may require more cautious interpretation or additional post-processing to ensure reliable fault detection.

10. Conclusions

In this work, an automatic diagnostic system for induction motors was developed and experimentally validated, demonstrating its capability to detect characteristic fault signatures associated with both broken rotor bars and mixed eccentricity. A key scientific contribution of the study lies in showing that transient operating conditions—particularly the startup process—reveal additional electromechanical phenomena that are either weakly visible or completely absent in steady-state operation. During startup, the rapid variation in slip, dynamic changes in air-gap forces, and the high inrush current amplify fault-related harmonic components. These enhanced signatures extend the diagnostic information available to the observer and significantly improve the detectability of mechanical and electrical asymmetries within the machine.

The proposed system leverages time–frequency representations not only as visualization tools but also as a functional mechanism for tracking the evolution of these characteristic harmonics. The ability to follow their trajectories on the time–frequency plane enables clear identification of transient patterns associated with specific faults. This provides a scientifically robust foundation for distinguishing different fault types, even under practical measurement disturbances. The obtained results confirm that the developed methodology offers a reliable and sensitive diagnostic approach, positioning transient-state analysis as a valuable alternative—and in some cases a superior complement—to conventional steady-state techniques.

In addition, the introduction of a simple decision-based algorithm, grounded in the calculation of absolute amplitude differences between healthy and faulty conditions, further enhanced the diagnostic capability of the system. This approach made it possible to establish practical threshold criteria for automatic fault identification. For the broken rotor bar fault, the transient analysis revealed that a conservative threshold of 10 dB reliably separates the healthy and damaged states. In contrast, for mixed eccentricity, the characteristic amplitude variations are smaller, and a threshold of approximately 6 dB provides a safe and effective decision boundary. These findings demonstrate that even a lightweight decision logic can significantly strengthen the diagnostic automation of the proposed system.

The computational performance of the applied time–frequency transforms, and the diagnostic inference procedure was also evaluated to assess the feasibility of real-time implementation. The obtained processing times confirm that modern embedded platforms are fully capable of executing the required operations within the time constraints imposed by transient motor startup. Both the generation of the time–frequency representation and the extraction of fault-related amplitude features can be performed with sufficient computational margin, allowing the system to operate continuously without violating real-time requirements.

These findings indicate that the proposed method is suitable for deployment in practical real-time monitoring systems, where automatic detection of broken rotor bars and mixed eccentricity must be performed reliably during each startup sequence. The efficiency of the processing chain demonstrates that the diagnostic framework can be integrated into industrial embedded hardware without significant computational limitations, further supporting its applicability in condition monitoring of induction motors.

Future work will aim to extend the methodology to additional fault types and to other forms of transient behavior, such as load variations or speed changes. Further research will also explore the integration of automatic trajectory extraction with intelligent classification methods, potentially enhancing the robustness and generalizability of the diagnostic system. These directions highlight the broad applicability and scientific potential of transient-based analysis in modern condition monitoring frameworks.

Author Contributions

Conceptualization, W.W.; Methodology, W.W.; Software, W.W.; Validation, W.W.; Formal analysis, W.W.; Investigation, W.W.; Resources, W.W.; Data curation, M.S.; Writing—original draft, W.W.; Writing—review & editing, M.S.; Visualization, W.W.; Supervision, M.S.; Project administration, W.W. and M.S.; Funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Siddiqui, K.M.; Sahay, K.; Giri, V.K. Air-gap eccentricity fault detection in the transient condition for inverter driven induction motor drives. In Proceedings of the 2016 International Conference on Circuit, Power and Computing Technologies (ICCPCT), Nagercoil, India, 18–19 March 2016. [Google Scholar]

- Amaral, T.G.; Foito, D.; Pires, A.J.; Miceli, R.; Viola, F.; Pires, V.F. Startup-based Induction Motor Fault Detection and Diagnosis Using Feature Extraction of the S-Transform Image. In Proceedings of the 2024 13th International Conference on Renewable Energy Research and Applications (ICRERA), Nagasaki, Japan, 9–13 November 2024. [Google Scholar]

- Antonino-Daviu, J.; Popaleny, P. Detection of Induction Motor Coupling Unbalanced and Misalignment via Advanced Transient Current Signature Analysis. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018. [Google Scholar]

- Hmida, M.A.; Braham, A. RSWPT for Induction Machine Fault Diagnosis Based on Transient Current Signal. In Proceedings of the 2018 15th International Multi-Conference on Systems, Signals & Devices (SSD), Yasmine Hammamet, Tunisia, 19–22 March 2018. [Google Scholar]

- Tierrafria-Baez, S.; Calderon-Lopez, P.M.; Cano-Valdez, V.; Aviles-Diaz, B.K.; Rodriguez-Donate, C.; Cabal-Yepez, E. Broken Rotor Bar Detection in Induction Motors through Information Entropy Analysis on the Start-up Transient and Steady-State Current Signals. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021. [Google Scholar]

- Xiao, X.; Chai, L.; Sheng, Y. Fault severity diagnosis of squirrel-cage induction motors in transient regime based on curve fitting. In Proceedings of the 2017 12th IEEE Conference on Industrial Electronics and Applications (ICIEA), Siem Reap, Cambodia, 18–20 June 2017. [Google Scholar]

- Manuel, A.; Mazzoletti, M.A.; Bossio, G.R.; Donolo, P.D.; Donolo, M. High-Frequency Voltage Analysis for Turn to Turn Short-Circuit Fault Detection in Induction Motor During Startup Transient. In Proceedings of the 2025 IEEE/IAS 61st Industrial and Commercial Power Systems Technical Conference (I&CPS), Montreal, QC, Canada, 11–14 May 2025. [Google Scholar]

- Mazzoletti, M.A.; Bossio, G.R.; Donolo, P.D.; Donolo, M. Turn to Turn Short-Circuit Fault and High-Resistance Connection Analysis for Induction Motor During Startup Transient. In Proceedings of the 2023 IEEE Industry Applications Society Annual Meeting (IAS), Nashville, TN, USA, 29 October–2 November 2023. [Google Scholar]

- Patel, D.C.; Chandorkar, M.C. Transient modeling and analysis of induction motors with position effects in stator turn faults. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Vina del Mar, Chile, 14–17 March 2010. [Google Scholar]

- Antonino-Daviu, J.A.; Zamudio-Ramirez, I.; Osornio-Rios, R.A.; Dunai, L.; Quijano-Lopez, A. Application of Transient Analysis to Detect Rotor and Stator Asymmetries in Wound Rotor Induction Motors: A Field Case. In Proceedings of the 2021 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Modena, Italy, 8–9 April 2021. [Google Scholar]

- Georgakopoulos, I.; Mitronikas, E.; Safacas, A. Broken bar detection using inverter currents in induction motor drives. In Proceedings of the 2010 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM 2010), Pisa, Italy, 14–16 June 2010. [Google Scholar]

- Tsoumas, I.P.; Georgoulas, G.; Antonino-Daviu, J.A. Analytical investigation of the startup transient in asynchronous motors with rotor asymmetry. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016. [Google Scholar]

- Tsoumas, I.P.; Georgoulas, G.; Antonino-Daviu, J.A. On the detectability of rotor asymmetries in induction motors from the start-up transient. In Proceedings of the 2017 IEEE 11th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Tinos, Greece, 29 August–1 September 2017. [Google Scholar]

- Garcia-Calva, T.A.; Morinigo-Sotelo, D.; Garcia-Perez, A.; Romero-Troncoso, R.J. A Comparative Analysis of Monitoring Signals for Bearing Wear Detection in VSI-fed Induction Motors During Startup Transient. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 1–5 September 2022. [Google Scholar]

- Antonino-Daviu, J.; Quijano-López, A.; Climente-Alarcon, V.; Razik, H. Evaluation of the detectability of rotor faults and eccentricities in induction motors via transient analysis of the stray flux. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar]

- Zamudio-Ramirez, I.; Mendoza-Ortiz, J.M.; Osomio-Ríos, R.A.; Antonino-Daviu, J.A. Stray Flux Signal Analysis for Faults Detection in Induction Motors During Startup Transient By Means Of Statistical Indicators. In Proceedings of the 2023 IEEE 14th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Chania, Greece, 28–31 August 2023. [Google Scholar]

- Fernandez-Cavero, V.; Morinigo-Sotelo, D.; Duque-Perez, O.; Pons-Llinares, J. A Comparison of Techniques for Fault Detection in Inverter-Fed Induction Motors in Transient Regime. IEEE Access 2017, 5, 8048–8063. [Google Scholar] [CrossRef]

- Sun, Z.; Li, K.; Yuan, F. Research on The Transient State Fault Diagnosis of Asynchronous Motors Based on Error Theory. In Proceedings of the 2024 43rd Chinese Control Conference (CCC), Kunming, China, 28–31 July 2024. [Google Scholar]

- Koti, H.N.; Chen, H.; Sun, Y.; Demerdash, N.A.O. On Shortening the Numerical Transient in Time-Stepping Finite Element Analysis of Induction Motor Under Broken Rotor Bar Faults. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019. [Google Scholar]

- Tran, V.T.; AlThobiani, F.; Ball, A.; Choi, B.-K. An application to transient current signal based induction motor fault diagnosis of Fourier–Bessel expansion and simplified fuzzy ARTMAP. Expert Syst. Appl. 2013, 40, 5372–5384. [Google Scholar] [CrossRef]

- Niu, G.; Widodo, A.; Son, J.-D.; Yang, B.-S.; Hwang, D.-H.; Kang, D.-S. Decision-level fusion based on wavelet decomposition for induction motor fault diagnosis using transient current signal. Expert Syst. Appl. 2008, 35, 918–928. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.-S.; Gu, D.-S.; Choi, B.-K. Intelligent fault diagnosis system of induction motor based on transient current signal. Mechatronics 2009, 19, 680–689. [Google Scholar] [CrossRef]

- Yakhni, M.F.; Cauet, S.; Sakout, A.; Assoum, H.; Etien, E.; Rambault, L.; El-Gohary, M. Variable speed induction motors’ fault detection based on transient motor current signatures analysis: A review. Mech. Syst. Signal Process. 2023, 184, 109737. [Google Scholar] [CrossRef]

- Oh, G.; Kim, S.; Ko, J. Bearing Fault Diagnosis Using Torque Observer in Induction Motor. Energies 2025, 18, 5872. [Google Scholar] [CrossRef]

- Kumar, P. Transfer Learning for Induction Motor Health Monitoring: A Brief Review. Energies 2025, 18, 3823. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, L.; Li, L.; Liu, K.; Ye, C. Digital Twin-Based Online Diagnosis Method for Inter-Turn Short Circuit Fault in Stator Windings of Induction Motors. Energies 2025, 18, 3063. [Google Scholar] [CrossRef]

- Frankiewicz, O.; Skowron, M.; Jarosz, J.; Weisse, S.; Valire, J.; Szabat, K. Classification of Rolling Bearing Defects Based on the Direct Analysis of Phase Currents. Energies 2025, 18, 2645. [Google Scholar] [CrossRef]

- Alathamneh, M.; Ghanayem, H.; Nelms, R.M.; Allafi, I.M. Open-Circuit Fault Mitigation for Inverter-Driven Induction Motor Based on Closed-Loop Volt-per-Hertz. Energies 2025, 18, 1596. [Google Scholar] [CrossRef]

- Louzada, A.O.; Souza, W.A.; Vitor, A.L.O.; Castoldi, M.F.; Goedtel, A. Detection of Stator Faults in Three-Phase Induction Motors Using Stray Flux and Machine Learning. Energies 2025, 18, 1516. [Google Scholar] [CrossRef]

- de Araújo, V.; Bissiriou, A.; Villanueva, J.; Villarreal, E.; Salazar, A.; de Andrade Teixeira, R.; de Moura Fonsêca, D. Monitoring and Diagnosing Faults in Induction Motors’ Three-Phase Systems Using NARX Neural Network. Energies 2024, 17, 4609. [Google Scholar] [CrossRef]

- Reyes-Malanche, J.A.; Ramirez-Velasco, E.; Villalobos-Pina, F.J.; Gadi, S.K. Short-Circuit Fault Diagnosis on the Windings of Three-Phase Induction Motors through Phasor Analysis and Fuzzy Logic. Energies 2024, 17, 4197. [Google Scholar] [CrossRef]

- Konuhova, M. Modeling of Induction Motor Direct Starting with and without Considering Current Displacement in Slot. Appl. Sci. 2024, 14, 9230. [Google Scholar] [CrossRef]

- Wang, Q.; Shi, H.; Ye, C.; Zhou, H. Synergizing Metaheuristic Optimization and Model Predictive Control: A Comprehensive Review for Advanced Motor Drives. Energies 2025, 18, 4831. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Pineda-Sanchez, M.; Puche-Panadero, R.; Perez-Cruz, J. A General Approach for the Transient Detection of Slip-Dependent Fault Components Based on the Discrete Wavelet Transform. IEEE Trans. Ind. Electron. 2008, 55, 4167–4180. [Google Scholar] [CrossRef]

- Antonino-Daviu, J.A.; Riera-Guasp, M.; Pineda-Sanchez, M.; Pérez, R.B. A Critical Comparison Between DWT and Hilbert–Huang-Based Methods for the Diagnosis of Rotor Bar Failures in Induction Machines. IEEE Trans. Ind. Appl. 2009, 45, 1794–1803. [Google Scholar] [CrossRef]

- Pineda-Sánchez, M.; Riera-Guasp, M.; Pons-Llinares, J.; Climente-Alarcón, V.; Perez-Cruz, J. Diagnosis of Induction Machines under Transient Conditions through the Instantaneous Frequency of the Fault Components. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010. [Google Scholar]

- Pineda-Sanchez, M.; Riera-Guasp, M.; Antonino-Daviu, J.A.; Roger-Folch, J.; Perez-Cruz, J.; Puche-Panadero, R. Diagnosis of Induction Motor Faults in the Fractional Fourier Domain. IEEE Trans. Instrum. Meas. 2010, 59, 2065–2075. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Pineda-Sánchez, M.; Perez-Cruz, J.; Puche-Panadero, R.; Roger-Folch, J.; Antonino-Daviu, J. Diagnosis of Induction Motor Faults via Gabor Analysis of the Current in Transient Regime. IEEE Trans. Instrum. Meas. 2012, 61, 1583–1596. [Google Scholar] [CrossRef]

- Puche-Panadero, R.; Pineda-Sanchez, M.; Riera-Guasp, M.; Roger-Folch, J.; Hurtado-Perez, E.; Perez-Cruz, J. Improved Resolution of the MCSA Method Via Hilbert Transform Enabling the Diagnosis of Rotor Asymmetries at Very Low Slip. IEEE Trans. Energy Convers. 2009, 24, 52–59. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Roger-Folch, J.; Pilar Molina Palomares, M. The Use of the Wavelet Approximation Signal as a Tool for the Diagnosis of Rotor Bar Failures. IEEE Trans. Ind. Appl. 2008, 44, 716–726. [Google Scholar] [CrossRef]

- Wronski, W.; Sulowicz, M.; Dziechciarz, A. Dynamic and Static Eccentricity Detection in Induction Motors in Transient States. Tech. Trans. 2015, 2-E, 171–194. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).