Abstract

High-voltage direct-current (HVDC) systems are essential for large-scale renewable integration and asynchronous interconnection, yet their complex topologies and multi-type faults expose the limits of threshold- and signal-based diagnostics. These methods degrade under noisy, heterogeneous measurements acquired under dynamic operating conditions, resulting in poor adaptability, reduced accuracy, and high latency. To overcome these shortcomings, the synergistic use of knowledge graphs (KGs) and pre-trained models (PTMs) is emerging as a next-generation paradigm. KGs encode equipment parameters, protection logic, and fault propagation paths in an explicit, human-readable structure, while PTMs provide transferable representations that remain effective under label scarcity and data diversity. Coupled within a perception–cognition–decision loop, PTMs first extract latent fault signatures from multi-modal records; KGs then enable interpretable causal inference, yielding both precise localization and transparent explanations. This work systematically reviews the theoretical foundations, fusion strategies, and implementation pipelines of KG-PTM frameworks tailored to HVDC systems, benchmarking them against traditional diagnostic schemes. The paradigm demonstrates superior noise robustness, few-shot generalization, and decision explainability. However, open challenges remain, such as automated, conflict-free knowledge updating; principled integration of electro-magnetic physical constraints; real-time, resource-constrained deployment; and quantifiable trustworthiness. Future research should therefore advance autonomous knowledge engineering, physics-informed pre-training, lightweight model compression, and standardized evaluation platforms to translate KG-PTM prototypes into dependable industrial tools for intelligent HVDC operation and maintenance.

1. Introduction

As the global demand for efficient and reliable power systems continues to grow, direct current (DC) transmission systems, particularly high-voltage direct current (HVDC), have emerged as a critical component of modern power networks [1,2]. HVDC systems play a critical role in integrating renewable energy, distributed generation, and power electronic devices, thereby supporting efficient long-distance transmission and flexible utilization of electricity [3,4,5,6]. However, the complex and diverse operating conditions of HVDC systems make fault diagnosis highly challenging. Various fault categories, including alternating current (AC)/DC faults, converter-valve failures, and inverter commutation errors, can seriously degrade system performance or even cause serious failures [7,8]. The timeliness and accuracy of fault diagnosis are critical for ensuring safe operation, minimizing downtime, and reducing maintenance costs [9,10]. In recent years, HVDC applications have expanded in areas including voltage source converter-based high voltage direct current (VSC-HVDC) and interconnecting asynchronous grids [11,12,13,14,15,16,17,18], enhancing system flexibility and renewable energy integration [19,20,21,22]. Nonetheless, these advancements intensify the need for intelligent fault diagnosis methods to address complex fault modes in DC systems [23,24].

Traditional fault diagnosis methods (TFDMs), such as rule-based expert systems and signal processing techniques, are no longer sufficient in complex HVDC environments [25,26,27,28]. They rely on fixed thresholds and mechanistic models, which struggle to process the massive, heterogeneous, and high-noise operational data generated by modern systems [29,30,31,32,33]. For instance, while methods combining wavelet transform (WT) and support vector machines (SVM) can achieve acceptable accuracy under stable, single operating conditions, they exhibit poor robustness against real-world uncertainties like equipment degradation, operating-point drift, and multiple concurrent faults [34,35]. Although model reference adaptive systems (MRAS) allow for online parameter adjustment, their effectiveness remains constrained by the requirement for accurate physical models, reducing generalization across different devices and scenarios [36,37]. Furthermore, while distributed sensing and edge-monitoring infrastructures can provide high-resolution data, the computational complexity of feature extraction and the curse of dimensionality often hinder conventional methods from achieving real-time fault localization with these data streams [38,39].

These limitations have driven a shift towards data-driven intelligent fault diagnosis technologies, which leverage machine learning to learn fault characteristics directly from operational data, enabling adaptive feature extraction and automated fault classification [40,41]. Literature [42] proposes an IoT-edge-cloud collaborative fault-diagnosis framework for distribution networks, demonstrating the potential of deploying lightweight deep neural networks (LDNN) and transfer learning (TL) models across hierarchical layers to achieve online adaptive feature extraction and cross-scenario knowledge reuse, significantly improving diagnostic timeliness. Nevertheless, large-scale deployment of intelligent diagnostics still face significant challenges, including dependence on scarce high-quality labeled data, poor model interpretability, and low fault-identification accuracy under extreme, small-sample scenarios [43,44].

Unfortunately, the current research landscape remains fragmented, where multi-technique fusion and end-to-end coordination remain underexplored. Concurrently, the generalizability, safety boundaries, and principled integration of artificial intelligence (AI) models with the underlying physics of power systems are still insufficiently understood. For instance, literature [45] presents a knowledge-graph-oriented framework for HVDC transmission fault diagnosis, yet its static view of the global graph neglects the dynamic collaboration among subsystems and the adaptive updating required for fluctuating operating states, limiting cross-system diagnostic efficiency. Literature [46] deploys an adaptive convolutional neural network-bidirectional long short-term memory network (CNN-BiLSTM) model with transfer learning to enhance accuracy under scarce data, but omits rigorous verification against the extreme fault regimes inherent to multi-energy coupled systems. Similarly, the literature [47] couples a fine-tuned robustly optimized BERT pretraining approach (ROBERTa) encoder with a graph neural network (GNN) -based knowledge-graph reasoner for fault diagnosis but does not address knowledge transfer across heterogeneous energy interfaces. Similarly, the literature [48] proposes a meta path-gated prompting chain framework leveraging a large language model to dynamically construct a knowledge graph (KG), but it fails to tightly couple the graph reasoning with the dynamic characteristics of HVDC transmission scenarios.

Given the critical need for advancing fault diagnostics in HVDC systems, a domain characterized by structural complexity, high fault criticality, and strategic importance in modern power grids, this review focuses specifically on HVDC as a representative and challenging research topic within the broader DC transmission context. The core emphasis of this review lies in investigating the integration of KGs and pre-trained models (PTMs) as a synergistic framework for intelligent fault diagnosis. KGs provide a structured and dynamically updatable representation of system topology and fault knowledge, while PTMs contribute robust few-shot learning capabilities derived from large-scale pre-training. By systematically examining this integration, the review aims to outline a coherent pathway toward resilient, adaptive, and semantically aware diagnostic systems tailored to HVDC applications.

To clearly articulate the added value of this work, Table 1 provides a systematic comparison between this review and existing representative surveys in HVDC fault diagnosis and KG applications. The matrix highlights coverage scope (e.g., fault types, technical pillars), methodological focus, and unique contributions based on literature evidence. This framework sharpens the research positioning by demonstrating how the current review bridges gaps left by prior studies.

Table 1.

Comparative framework of this review versus existing surveys on HVDC fault diagnosis and KG applications.

2. Review Screening Methods

To date, several reviews have addressed intelligent fault-diagnosis techniques in power systems, including those targeting HVDC applications, conventional approaches, and emerging data-driven methods. However, most existing surveys fail to provide an integrated perspective that combines advanced paradigms such as KGs and PTMs, thereby overlooking their complementary potential in managing dynamic fault scenarios, enhancing explainability, and enabling real-time adaptability. Specifically, Table 2 summarizes the main advantages and disadvantages of representative reviews in this field, highlighting gaps in comprehensive discussion on KG-PTM fusion strategies.

Table 2.

A chronological overview of relevant reviews on intelligent fault diagnosis in power systems.

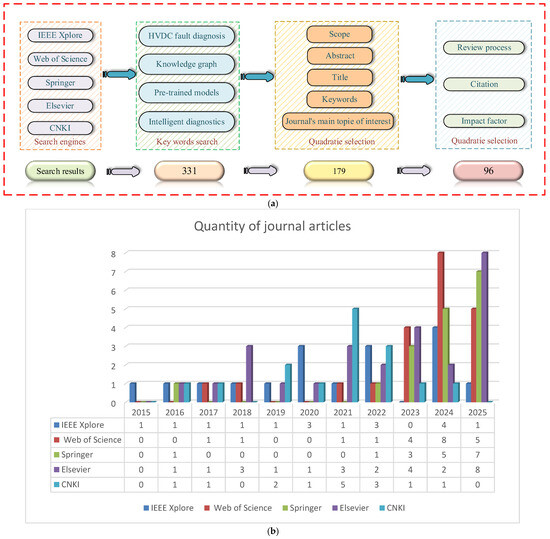

The literature screening followed a three-stage protocol with explicit criteria. First, publications from 2015–2025 were retrieved from IEEE Xplore, Web of Science, Springer, Elsevier, and CNKI using keywords: “HVDC fault diagnosis,” “knowledge graph,” “pre-trained models,” and “intelligent diagnostics.” Second, titles and abstracts were screened to exclude articles focusing solely on traditional methods or non-HVDC applications. Finally, 96 publications were selected based on citation impact, journal reputation, and relevance to KG-PTM integration. The screening workflow, depicted in Figure 1a, ensures reproducibility, while Figure 1b presents the annual publication trend from 2015 to 2025, revealing a steady rise in AI-driven diagnostic research.

Figure 1.

The workflow and resulting statistics of the literature screening process for the past 10 years: (a) execution steps and (b) research distribution.

The flowchart in Figure 1a visualizes the evolution of the number of articles. Initially, the search was conducted from five databases and 331 records were obtained through four keywords. After filtering titles, abstracts, and keywords, the number of studies was reduced to 179, and 152 studies that did not meet the inclusion criteria were excluded. The last 96 studies were retained for in-depth analysis, and the flowchart clarified the reasons for exclusion at each stage, improving reproducibility.

3. Fault Diagnosis in HVDC Systems: Current Landscape

3.1. Common Failure Types and Characteristics

HVDC systems are composed of three primary components: converter stations, transmission lines, and grounding electrode systems [49]. Among these, the converter station represents the most critical and structurally complex element, frequently identified as a high-risk zone for various fault scenarios [50]. These systems are vulnerable to a wide range of failures, including AC and DC side faults, inverter commutation failures [51], converter valve malfunctions [52,53], single-phase and interphase faults, as well as faults triggered by lightning strikes [54].

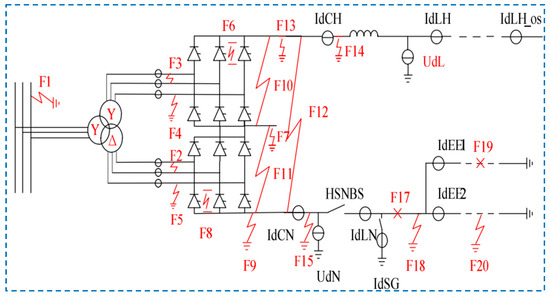

3.1.1. Grounding Faults on the Valve Side of Converter Transformers

Grounding faults occurring on the valve side of a DC converter exhibit significant spatiotemporal dispersion. The operational conditions of the valve bridge vary considerably when faults arise at different locations, such as the high-voltage and low-voltage bridges [55]. Furthermore, the spatial relationship between the fault point and the current transformer influences the measured current in the fault phase, while the timing of the fault inception also alters the fault characteristics. The schematic architecture of the testing system for simulating and analyzing faults in HVDC converter stations is shown in Figure 2.

Figure 2.

Architecture of the test system used for fault simulation and analysis in HVDC converter stations.

Single-phase ground faults in HVDC systems often generate sustained arc discharges, inducing approximately 1.732-p.u. overvoltage and possible resonance that can surpass insulation levels and damage the line. Sustained arcs age insulation, precipitating breakdown, relay trips and outages. Small-current grounding complicates faulted-feeder selection, location and distance estimation; therefore, recent research has focused on signature-based approaches for rapid and accurate fault localization in medium- and low-voltage networks.

3.1.2. Interphase Short-Circuit Fault at Converter Transformer Valve Side

An interphase short-circuit fault refers to a direct electrical connection between two or more phase conductors without passing through a load. Such faults are characterized by the presence of positive-sequence and negative-sequence currents, while zero-sequence current is absent [56]. These faults can be classified as either two-phase or three-phase short circuits. When an interphase short circuit occurs in an HVDC system, the harmonic components and their variation patterns are similar to those observed in single-phase grounding faults. However, the magnitude of harmonic components is generally higher in interphase fault conditions. As a result, the risk of maloperation in 50 Hz protection systems during fault recovery is increased due to the elevated harmonic content.

3.1.3. Converter Valve Arm Short-Circuit Faults

Converters serve as the core components in HVDC systems, performing AC/DC energy conversion. They convert AC power into DC power at the sending terminal and invert it back to AC at the receiving end, enabling inter-grid power transmission. Converter valve arm short-circuit faults are common failure modes in such systems. When these faults occur, the AC system may experience alternating two-phase and three-phase short circuits, preventing normal power transmission to the receiving converter station and disrupting the power supply to the receiving grid. This type of fault significantly impacts both the sending and receiving end AC systems. Valve-arm short-circuit faults can be classified into two categories: AC-side and DC-side faults. AC-side valve arm short circuits typically result from degraded interphase insulation on the valve winding side. DC-side valve arm faults include single-bridge arm short circuits, single-phase valve short circuits, and pole-bus or neutral-bus short circuits [57].

3.1.4. Faults in Converter Valve Groups

The inherent nonlinear switching characteristics of converter operation in HVDC systems lead to substantial harmonic generation even under normal conditions. These harmonics distort system voltage and current waveforms, thereby degrading overall power quality. At the core of the converter assembly is the valve group, which functions as the key operational unit. Hence, investigating the harmonic behavior exhibited under various valve group fault conditions, such as inadvertent valve opening or failure to open, is critically important for maintaining the security, reliability, and stability of HVDC system. The core characteristics, impacts, and diagnostic difficulties of the discussed fault types are systematically summarized in Table 3.

Table 3.

Analysis of main fault types and characteristics of HVDC converter stations.

To further quantify the risk of valve group failure, the modified Fine Kinney method [58] was used to calculate the Risk Index (). This equation takes into account the probability of fault occurrence (), severity (), and detectability ():

where is calculated based on historical fault frequency, with a value range of 0.1 (extremely low probability) to 1.0 (extremely high probability); According to the impact of faults on system stability, is classified from 1 (minor) to 10 (catastrophic); depends on the sensitivity of the monitoring system, ranging from 1 (difficult to detect) to 10 (easy to detect). When > 50, it is determined as a high-risk fault and needs to be prioritized for processing [58]. This formula provides a dynamic risk assessment tool for HVDC systems.

Table 3 shows that HVDC converter faults are complex, correlated, and nonlinear: valve-side ground faults are spatially scattered, interphase faults suffer from harmonic interference, valve-arm shorts require rapid fault isolation, and valve-group faults often present weak or latent early indicators. Addressing these disparate challenges requires intelligent algorithms that fuse multi-source data, embed topology awareness, and handle nonlinear dynamics to keep HVDC links secure and stable.

3.2. Traditional Fault Diagnosis Methods

The field of HVDC systems has historically relied on a range of traditional fault diagnosis methods to ensure system reliability and quick response to failures. Although limited in coping with the complexity of modern converter stations, these techniques constitute the classical foundation for detecting and mitigating the four major fault categories discussed in Section 3.1.

3.2.1. Grounding Faults on the Valve Side

Traditional diagnosis for grounding faults heavily utilizes time-domain reflectometry (TDR) and impedance-based methods. TDR injects a high-frequency pulse into the cable; the reflection of this pulse is analyzed to locate the fault based on the time delay and signature of the reflection [59]. Impedance methods calculate the fault distance by analyzing the change in impedance from the source to the fault point, using fundamental frequency components of voltage and current measurements [60]. While effective in simple or low-resistance fault cases, these approaches perform poorly for high-resistance or complex faults and remain highly sensitive to parameter uncertainties.

3.2.2. Interphase Short-Circuit Faults

The symmetrical-component method is the primary classical tool for identifying interphase faults. By decomposing the three-phase currents into positive, negative, and zero sequences, protection relays can detect the unbalance characteristic of an interphase fault (significant negative-sequence current, zero-sequence current) and trigger appropriate breakers [61]. Overcurrent and differential protection schemes are also widely employed. Differential protection, which compares current entering and leaving a protected zone (like a valve group), is particularly effective for fast isolation of severe interphase faults [62].

3.2.3. Converter Valve Arm Short-Circuit Faults

Given the critical functional role of the converter, several specialized traditional methods have been developed. Waveform analysis is a key method, where the distorted current and voltage waveforms from a specific valve arm are scrutinized for signatures of a short-circuit device, such as a missing firing pulse or a continuous current path [63]. Bridge arm current differential protection is a direct and fast-acting method that monitors the current balance between the upper and lower arms of a phase leg; a significant imbalance indicates an arm fault [64].

3.2.4. Converter Valve Group Faults

The inherent nonlinearity of converters makes harmonic analysis the cornerstone traditional method for diagnosing valve group malfunctions. The fast Fourier transform (FFT) is used to decompose the measured AC or DC voltage into its harmonic spectrum. Specific harmonic components (e.g., 5th, 7th, 11th, 13th) have well-defined magnitudes under normal operation. Noticeable deviations from these expected profiles can indicate a valve misfire (e.g., a valve failing to open or close) [65]. While highly informative, this method can be computationally demanding and requires a stable network frequency for accurate results.

Based on the literature provided above, the major fault categories, principal traditional diagnostic techniques, their operating principles, and main limitations are tabulated in Table 4.

Table 4.

Analysis of corresponding methods for each fault.

3.3. Development of Intelligent Fault Diagnostics

The comprehensive analysis of traditional fault diagnosis methods, as systematically summarized in Table 4, reveals a consistent set of challenges that limit their effectiveness in modern HVDC systems. While these methods provide a fundamental diagnostic capability, their reliance on precise system parameters, sensitivity to measurement noise and system imbalances, and often inadequate speed for fast-evolving faults highlight a critical performance gap. These inherent weaknesses have driven the transition toward intelligent, data-driven diagnostic frameworks. The evolution towards data-driven, AI-based methods represents a paradigm shift aimed at overcoming these constraints by enhancing the adaptability, accuracy, and robustness of fault management in HVDC systems.

3.3.1. Adaptability to Uncertainty and Noise

In contrast to model-based schemes, machine-learning (ML) algorithms, such as deep neural networks (DNNs) and support-vector machines (SVMs), can be trained on large datasets that inherently capture diverse noise characteristics and operational uncertainties. For instance, methods using SVM classifiers [66] and CNN-based approaches [67] demonstrate robustness in extracting fault features under noisy conditions, directly addressing limitations related to measurement errors and variable operating environments noted for valve-arm and interphase faults.

3.3.2. Handling Non-Linearity and Complex Patterns

Traditional harmonic analysis (e.g., FFT) struggles with subtle faults under dynamic conditions. Intelligent methods, such as CNNs [67] and techniques that integrate wavelet transforms [68], can autonomously learn discriminative representations from raw time-series or time–frequency data, thereby capturing transient and nonlinear behaviors that conventional FFT-based methods cannot resolve. This enables the detection of incipient and complex faults in valve-group and other non-linear scenarios.

3.3.3. Data-Driven Modeling and Generalization

Data-driven approaches mitigate the dependency of traditional methods on accurate system parameters. By learning from historical data, methods such as extreme learning machine (ELM) [69] and SVM regression [70] bypass explicit physical modeling, generalizing fault patterns across diverse operating points and system configurations. This results in higher diagnostic consistency and reduced need for parameter calibration, even in systems with uncertain or variable conditions.

3.3.4. Integration and Real-Time Capability

Recent advances focus on hybrid intelligent architectures that integrate multiple AI paradigms to improve real-time responsiveness. For instance, learning-based methods integrated with hybrid breakers [71] leverage computational advancements for real-time fault detection, overcoming speed limitations of traditional methods. However, challenges remain in computational efficiency and deployment complexity.

Table 5 provides a systematic overview of how intelligent fault diagnosis methods effectively mitigate the limitations of traditional approaches, highlighting the evolution towards data-driven solutions that enhance adaptability, accuracy, and robustness in HVDC systems. This table categorizes key fault types, such as valve-side grounding, interphase short-circuits, valve-group harmonics, and system-wide operations. Then, it delineates how intelligent algorithms like SVM, CNN, ELM, and wavelet-based techniques directly address specific traditional shortcomings, including sensitivity to noise, inability to handle non-linear patterns, dependency on precise parameters, and slow response times. By applying machine learning for feature extraction and generalization, these methods demonstrate superior noise tolerance, transient-fault detection, and real-time integration, ultimately bridging the critical performance gap identified in conventional diagnostics.

Table 5.

Summary of intelligent fault diagnosis methods addressing traditional limitations.

4. KG Application in HVDC Fault Diagnosis

4.1. Basic Concepts of KGs

A knowledge graph (KG) represents a paradigm shift from conventional keyword-based retrieval toward semantic-level understanding. By interpreting the intent underlying a user query, it can directly deliver structured information about relevant entities [72,73]. Technically, a KG is a structured knowledge base organized as a directed graph, enabling the conversion of natural language into graph form for efficient storage, management, and visualization of domain knowledge [74,75].

Structurally, a KG is a database of factual knowledge represented as a graph, consisting of nodes and the edges that connect them. Nodes typically denote real-world entities or abstract concepts contained within the data sources, while edges define the various semantic relationships that exist between these nodes. Its core functionality lies in processing textual information to extract semantic meaning and structured relations, which is then formalized using triplets following the “entity–relationship–entity” pattern [76,77]. This process ultimately leads to the formation of an interconnected web of knowledge, which enables more precise knowledge storage and richer semantic expression [78]. This graph-based model offers significant benefits in terms of both human interpretability and machine processability.

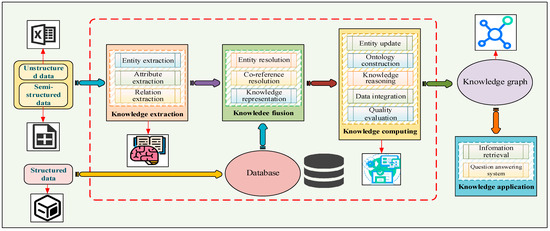

The overall process of constructing a knowledge graph, as illustrated in Figure 3, generally involves four major stages: knowledge extraction, knowledge fusion, knowledge computing, and knowledge application.

Figure 3.

Construct a KG summary diagram.

Knowledge data in this context is primarily derived from industry standards, technical specifications, and historical fault records within the power sector [79,80]. Knowledge extraction refers to the automated process of identifying and retrieving relevant information from massive, heterogeneous, and often unstructured data sources. The subsequent step, knowledge fusion, aims to integrate descriptive information pertaining to the same entity or concept obtained from multiple sources, while resolving any semantic conflicts or inconsistencies between them. Following fusion, knowledge computing involves a dynamic quality assessment of the newly integrated knowledge. This step entails adding qualified knowledge into the existing knowledge base, performing reasoning operations to infer new facts, and thereby expanding the current knowledge scope to derive novel insights. Finally, the KG leverages data visualization techniques to achieve knowledge visualization, enabling an intuitive representation of complex relational data. In practical applications, the visualization design is tailored to the characteristics and analytical requirements of the specific application.

The ultimate objective of constructing a KG lies in its application, which serves as the main driver for creating practical value. Through the application of KGs, fault characteristics can be rapidly analyzed and fault locations precisely identified. By integrating real-time fault data with the structured knowledge base, root causes of failures can be rapidly identified and addressed. This capability significantly enhances the management, operation, and maintenance capabilities of the system, leading to improved efficiency and reliability.

Although KG provides structured knowledge representation, its construction and validation face significant challenges. Firstly, knowledge validation needs to address semantic conflicts in multi-source data. For example, entity relationships extracted from heterogeneous data sources such as device manuals and fault records may have inconsistent descriptions or standard differences [79], requiring manual rules for conflict resolution, which increases the complexity of knowledge fusion. Secondly, maintaining logical consistency during dynamic updates is particularly difficult: when new fault cases conflict with existing knowledge topology (such as multiple causes corresponding to the same fault phenomenon), complex logical reasoning mechanisms need to be introduced for verification, which poses higher requirements for automated knowledge evolution.

4.2. Construction of a KG in HVDC Transmission System

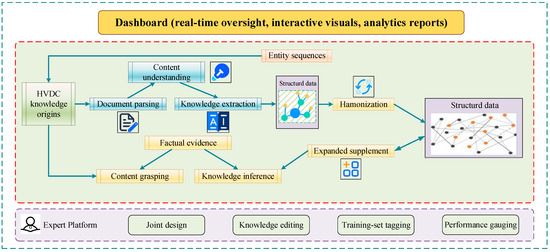

KGs, which structure information to enable intelligent knowledge management, represent a significant advancement beyond traditional databases. Their application in HVDC systems facilitates the integration of fragmented fault data, allowing for deep mining and analysis to extract critical insights. The construction of these graphs is being revolutionized by a novel, data-driven approach. Unlike traditional top-down methodologies, the emerging paradigm leverages large models and big data to facilitate a bottom-up, human–machine collaborative construction process. This modern technique substantially enhances the scale, quality, and efficiency of building industry-leading HVDC knowledge systems, as illustrated in Figure 4 [81,82,83].

Figure 4.

Schematic of HVDC knowledge system development.

HVDC knowledge sources function as a dynamic reservoir continuously ingesting large volumes of heterogeneous data, including design standards, system specifications, operation and maintenance logs, engineering drawings, and recent technical research outputs. This raw material is first preprocessed through cleaning and segmentation, after which domain experts reconstruct the fragments into a coherent HVDC knowledge base that practitioners can search, navigate, and analyze. In parallel, the same information fragments are processed through a bottom-up, human-in-the-loop graph construction pipeline [84], producing a machine-readable HVDC knowledge graph (KG) whose explicit relationships and semantic labels support automated reasoning and decision-making.

Within HVDC projects, knowledge keeps emerging from two complementary streams: (i) live production data generated during routine operation and maintenance, and (ii) incremental technical updates introduced by new equipment, revised standards, or lessons learned. Owing to this diversity of origin and format, the raw content must be systematically classified, deduplicated, and interlinked before its full value can be exploited. The construction process, therefore, harvests these disparate items, extracts entities and relations, and encodes them into a unified graph structure. Once the graph exists, keyword-triggered traversal instantly surfaces relevant evidence, shortens diagnostic time, and raises the overall efficiency of fault-location tasks.

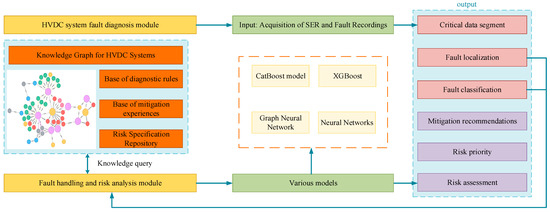

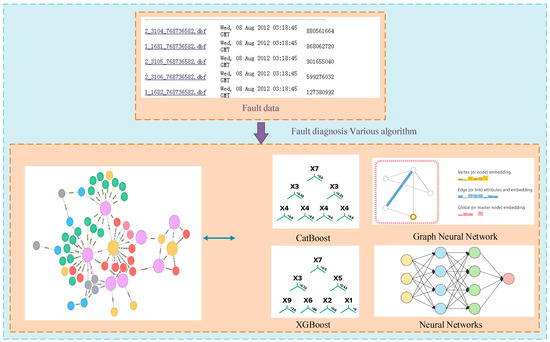

The development of distributed word vector representation has provided a critical foundation for applying artificial intelligence methods to natural language processing. In engineering domains, KG relational reasoning offers a powerful tool for knowledge verification, prediction, and inference. When applied to HVDC systems, the process begins by acquiring a sequence of events record (SER) data and fault records from the system’s knowledge base. The next step involves extracting key segments from this data [58]. Finally, the processed fault information is input into a risk analysis model specifically designed for HVDC systems, where fault classification is conducted. This complete framework, visually summarized in Figure 5, highlights the role of KG technology in enhancing fault analysis and risk assessment capabilities.

Figure 5.

Architectural diagram illustrating the hierarchical topology of KG for fault diagnosis and risk analysis in HVDC system.

Abnormal operational events are documented within SER data, which constitutes a form of unstructured document data. Equipment-related information is maintained in the resource management library, representing structured data. In addition, product documentation and alarm descriptions provided by various manufacturers comprise semi-structured data sources [85,86]. By extracting and integrating information from these heterogeneous data types, a KG is constructed in which knowledge elements are organized and stored within the schema and data layers of the knowledge base [87]. This KG model supports fault identification and analysis for HVDC systems. The implementation of the KG enables direct access to interconnected graph information, substantially improving the system’s troubleshooting capability and efficiency, thereby contributing to enhanced operational stability.

4.3. The Application of KGs in Fault Diagnosis

The integration of KG technology has significantly accelerated the digital transformation of modern power systems [88,89]. One of its most prominent applications lies in fault diagnosis [90], as illustrated in Figure 6. By diagnosing diverse fault scenarios and incorporating them into the system, similar future faults can be identified and analyzed more rapidly and accurately. This contributes markedly to the intelligence of power system operation and management.

Figure 6.

Application of KG in fault diagnosis.

In recent years, KG has shown significant potential in the field of fault diagnosis as an important tool for structured knowledge representation and intelligent reasoning. It integrates heterogeneous data from multiple sources (such as device parameters, historical fault records, real-time monitoring data, expert knowledge, etc.) to construct entity relationship networks, thereby supporting more accurate and interpretable fault diagnosis and decision-making. Table 6 summarizes the application characteristics, methods, and effects of KGs in fault diagnosis across six representative studies.

Table 6.

Comparative analysis of the application of KG in fault diagnosis.

Table 6 provides performance indicators for the application of KG in fault diagnosis, but its limitations need to be critically analyzed. For example, the accuracy of [47] (79.62%) is lower than that of [91] (95%), mainly because [47] increases the complexity of handling entity nesting problems, while [91] integrates multi-source data (such as SERs) based on the KG platform, improving generalization ability. The F1 value of [94] (93.45%) is higher than that of [92] (87.23%), because [94] uses the ALBERT BiLSTM Attention CRF model to enhance semantic feature extraction, while [92] relies on XGBoost to be sensitive to small samples. However, these comparisons are limited by differences in the dataset: [47] uses industrial field data (sample size ≈ 10 k), while [95] uses simulation data (sample size ≈ 5 k), resulting in unequal sample sizes; Refs. [91,94] focus on specific faults in HVDC, while [93] lacks scene consistency for general rotating machinery. In the future, it is necessary to quantify the gain of KG-PTM relative to pure deep learning (such as CNN-LSTM) on a unified benchmark (such as HVDC FaultBench).

From the comparative analysis of existing studies, it can be seen that the application of KG in fault diagnosis presents the characteristics of multi-domain coverage, technological integration, and strong effectiveness. This reviewed literature collectively indicate that KGs significantly improve the accuracy and robustness of fault diagnosis by integrating prior knowledge, real-time data, and deep learning models. For example, in complex industrial scenarios such as HVDC systems and intelligent production lines, KGs not only solve the problems of data heterogeneity and entity nesting but also enhance the interpretability of knowledge through visualization tools, providing intuitive decision support for maintenance personnel. Current research trends show that KG-based diagnostic models increasingly employ natural language processing (NLP) techniques (such as RoBERTa, ALBERT) for entity extraction, combined with graph neural networks (such as GCN) or sequence models (such as LSTM) for inference, highlighting the advantages of KGs as a bridge connecting data-driven and model-driven approaches. Looking ahead, as dynamic knowledge-updating mechanisms and multi-source fusion technologies continue to advance, KGs are expected to play an increasingly vital role in real-time fault diagnosis and adaptive learning within intelligent power systems.

To quantitatively evaluate the performance advantages of the KG-PTM framework over other modern diagnostic methods, Table 7 compares the performance of KG-PTM, pure deep learning, and mixed physics statistical models in key indicators such as accuracy, F1 score, and response time.

Table 7.

Quantitative comparison of KG-PTM with pure deep learning and hybrid physical-statistical models on HVDC fault diagnosis tasks.

There is a certain degree of inequality in the current performance comparison, mainly reflected in the differences in data sources and model dependencies. The KG-PTM method is mostly based on on-site measured data (with a large sample size), while pure deep learning models often use simulated data (with a limited sample size); Although the mixed physics statistical model performs well in response time, its performance is highly dependent on hardware configuration, resulting in higher costs. As shown in Table 7, the KG-PTP method (such as [91]) outperforms pure deep learning models (such as [66]) in accuracy, while the latter has advantages in response time due to its simple model structure and low computational complexity. This difference reflects that the KG method enhances generalization ability by introducing domain knowledge, but also increases computational overhead. To evaluate the true performance of different methods in the system, it is necessary to build an open benchmark platform such as HVDC FaultBench in the future, unify data format and sample size, and quantify the gain effect of KG-PTM on key indicators such as noise robustness and small sample generalization in a fair environment.

5. Pre-Trained Models for Enhanced Fault Diagnosis

5.1. Basic Concepts of PTMs

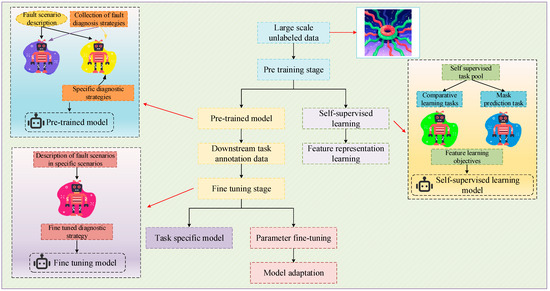

PTM, as an important breakthrough in the field of deep learning, has the core idea of mastering general data representation capabilities through pre-training on large-scale datasets, thereby providing high-quality initial parameters for downstream specific tasks. This “pre-training fine-tuning” paradigm effectively solves the dependency problem of traditional deep learning models on large-scale annotated data, especially in scenarios where training data is limited, demonstrating significant advantages.

The workflow of the pre-trained model consists of two key stages, and its overall architecture is shown in Figure 7. Firstly, during the pre-training phase, the model utilizes large-scale unlabeled data and employs self-supervised learning to grasp the intrinsic patterns and feature representations of the data. Subsequently, during the fine-tuning phase, the model is initialized based on pre-trained parameters, and supervised training is performed using labeled data specific to the task, in order to adapt to the requirements of the target task quickly.

Figure 7.

Overall architecture diagram of the pre-trained model.

The pre training of PTM is usually based on a self supervised objective function. Taking Convolutional Neural Network (CNN) as an example [66], the convolution operation of its feature extraction layer can be expressed as

where represents convolution operation, and are the weights and biases of the l-th layer, respectively; () is an activation function such as ReLU; is the input feature map.

For sequence models such as BiLSTM, hidden state updates follow [94]:

where is the model parameter and is the input for time step . These equations form the basis for PTM feature extraction.

Although PTM has powerful feature extraction capabilities, its “black box” characteristics limit its application in security sensitive scenarios. Even when combined with KG, the decision-making process of PTM still lacks explicit semantic association. For example, the fault features extracted by CNN models from current signals [66] are difficult to directly map to physical meanings (such as “insulation aging”), while the heatmap interpretation provided by attention mechanisms [94] still belongs to statistical correlation rather than causal inference. This lack of interpretability makes it difficult for operations personnel to fully trust the model output, especially in complex scenarios with multiple fault couplings. The model may give incorrect diagnoses due to confusing features and cannot trace specific error links.

5.2. PTM Adapted to Power Scenario Analysis

Efficiently adapting a universal PTM is essential for developing an intelligent HVDC operation-and-maintenance system. The primary objective is to close the semantic gap between general-purpose large models and power-engineering domain knowledge. This is achieved by carefully choosing an appropriate model and applying parameter-efficient tuning techniques. As Table 8 shows, model choice must balance domain relevance, performance, and cost, whereas the fine-tuning strategy should be tailored to task complexity and data availability.

Table 8.

Core strategies for adapting PTM to power scenarios.

Table 8 indicates that, in model selection, the power domain’s dense jargon and scarce labels make a poor guide. A mid-size model with strong Chinese literacy and instruction-following ability is usually cheaper and more practical than a bloated general-purpose giant. For tuning, parameter-efficient methods reach full-model quality while updating only a few weights essential option when GPUs are tight. Among them, P-tuning v2 inserts trainable prompts into every layer, steering the model to link fault symptoms to root causes; it has become the go-to tactic for few-shot information extraction and text interpretation in power systems. With these adaptations, the PTM graduates from “generalist” to “power specialist,” ready to team up with KGs for downstream reasoning.

6. Fusion of KG and PTM for HVDC Fault Diagnosis

6.1. KG and PTM Collaborative Mechanism

The collaborative integration of KGs and PTMs establishes a bidirectional closed-loop cognitive framework for intelligent operation and maintenance in HVDC systems. At its core lies the coupling of symbolic structured knowledge with data-driven semantic understanding, enabling mutual reinforcement across both perceptual and reasoning layers. As a structured repository of domain expertise, the KG provides the PTM with an interpretable logical framework and contextual grounding. In return, PTMs leverage their advanced natural language capabilities to automatically extract and discover new knowledge from unstructured text—such as maintenance records and technical documentation—thereby facilitating the dynamic evolution and continuous refinement of KGs. This two-way feedback mechanism forms the foundation of their synergistic interaction.

In practical implementation, KGs enhance PTMs through knowledge injection and prompt engineering. By embedding structured information-such as entity representations and relational paths-into model inputs or prompt templates, PTMs gain a more precise understanding of domain-specific concepts, including power equipment, fault characteristics, and causal relationships. This results in improved accuracy and domain adaptability in tasks such as text analysis and information extraction. Simultaneously, PTMs contribute to KG construction and updating. Instruction-tuned PTMs can automatically extract entities, relations, and events from large volumes of unstructured textual data, significantly increasing the efficiency and coverage of knowledge acquisition. Furthermore, through semantic analysis, PTMs can identify potential knowledge associations, supporting graph completion and verification.

At the decision-making and reasoning level, KG and PTM jointly support an integrated “perception–cognition” workflow. PTMs act as the perceptual front-end, extracting key features and preliminary evidence from multi-source data. KGs serve as the cognitive core, performing verification, correlation, and causal inference based on embedded domain knowledge and topological constraints. This tight integration of data-driven perception and knowledge-guided reasoning not only leads to more reliable operational decisions but also enhances the transparency and trustworthiness of the process by providing interpretable logical paths. As a result, the deep collaboration between KG and PTM offers a key technical pathway toward highly reliable and explainable intelligent operation and maintenance for HVDC systems.

The collaborative mechanism presents a progressive approach in fault diagnosis: in the perception stage, PTM (such as the fine-tuned RoBERTa model [94]) extracts fault entities from SER logs, identifies key features with attention weights, and converts their outputs into KG recognizable RDF triplet format [83]; After entering the cognitive stage, KG uses graph neural networks (GCN) [93] for multi hop inference, such as tracing the entity from “current harmonic increase” to the root cause of “valve group aging”, and integrating the feature confidence provided by PTM to weight the inference path [70]; At the decision-making stage, the fusion result is generated by a rule engine (such as Drools) to generate a disposal plan. PTM, with its sequence generation capability (such as T5 model [48]), automatically outputs natural language explanations, while KG is responsible for ensuring that the plan complies with safety standards such as IEC 61850 [42], thus forming a complete closed loop from perception, cognition to decision-making.

6.2. Key Technologies for Intelligent Fault Diagnosis

The integration of KG and PTM enables a paradigm shift from traditional isolated diagnostic approaches to an intelligent, collaborative framework. This synergy is realized through three core technological pillars: collaborative perception and cognition, dynamic knowledge evolution, and multi-modal data fusion.

6.2.1. Collaborative Perception-Cognition Mechanism

The KG-PTM fusion establishes a closed-loop cognitive system. Its operation can be broken down as follows:

- PTMs as the perceptual front-end: Fine-tuned with power domain knowledge, PTMs extract multi-dimensional features from heterogeneous data sources (e.g., SCADA time-series, event logs) [66,94].

- KGs as the cognitive core: KGs perform logical reasoning based on topological constraints and fault evolution patterns, contextualizing PTM-extracted features [93].

- Synergistic benefit: This mechanism enhances diagnostic accuracy by combining data-driven sensitivity with knowledge-driven interpretability. The cross-modal attention mechanism (Equation (4)) optimizes the alignment between fault features and knowledge entities [94].

6.2.2. Dynamic Knowledge Evolution Framework

This framework addresses the static nature of KGs through:

- Automated knowledge extraction: PTMs automate the extraction of entities and relationships from unstructured text or sensor data when new fault events occur.

- Bidirectional flow: The KG guides PTM training via structured prompts, while PTMs facilitate dynamic KG updates, ensuring the system evolves with operational data.

6.2.3. Multi-Modal Data Fusion and Reasoning

HVDC fault diagnosis requires synthesizing diverse data modalities: time-series electrical measurements, topological graphs, and textual maintenance records. KG-PTM framework unifies these modalities through cross-modal attention mechanisms. PTMs encode non-structured data (e.g., wavelet transforms of fault currents) into latent representations, while KG structured queries retrieve relevant fault scenarios and mitigation rules. For instance, a transient voltage anomaly detected by a PTM triggers a subgraph query in KG to identify connected components prone to cascading failures. This fusion enables multi-step reasoning, such as predicting fault propagation paths and recommending isolation strategies.

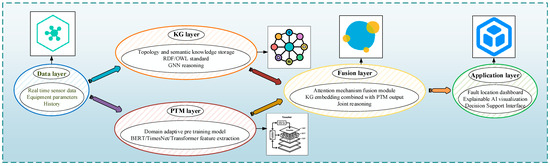

6.3. Implementation Architecture

To clearly illustrate the operational workflow, we propose a layered architecture that systematically transforms multi-source data into actionable insights through the seamless collaboration of KG and PTM. As shown in Figure 8, this architecture comprises five distinct functional layers.

Figure 8.

Implementation framework diagram of KG-PTM integrated diagnostic system.

- Data layer: This foundational layer is responsible for aggregating and preprocessing heterogeneous data from various sources, including

- (1)

- SCADA time-series data (compliant with IEEE C37.118 protocol).

- (2)

- Sequence of Events Records (SER logs) in JSON format.

- (3)

- Unstructured maintenance reports and technical documentation. The primary function here is to ensure data quality, consistency, and format standardization for subsequent processing.

- KG layer and PTM layer (parallel processing paths): These two layers operate in parallel to handle knowledge and data, respectively:

- (1)

- The KG layer organizes structured knowledge (e.g., equipment parameters, fault evolution patterns) into a graph database (e.g., Neo4j), enabling logical reasoning and topological queries.

- (2)

- The PTM layer utilizes pre-trained models (e.g., fine-tuned RoBERTa, CNN-BiLSTM) to extract deep semantic features from the unstructured data processed by the Data Layer.

- Fusion layer: This is the critical integration point where the outputs from the KG and PTM layers are synergistically combined. An attention-based mechanism (as formulated in Equation (4) of the manuscript) dynamically weighs and aligns the data-driven features from the PTM with the symbolic entities and relationships from the KG, generating a unified, enhanced representation for diagnosis.

- Application layer: The top layer translates the fused insights into practical diagnostic applications. It supports functions such as

- (1)

- Fault identification and localization.

- (2)

- Root cause analysis with causal path visualization.

- (3)

- Generation of interpretable diagnostic reports and maintenance recommendations.

This layered design ensures both functional modularity and system-wide synergy, enabling a robust and transparent “perception–cognition–decision” process for HVDC fault diagnosis.

6.4. Fault Diagnosis Process

The intelligent fault diagnosis process based on KG-PTM achieves a complete cognitive closed loop from multi-source data perception to accurate decision-making through a hierarchical and progressive collaborative mechanism. Table 9 systematically summarizes the correspondence between core technologies and the component division of labor in the five key diagnostic stages, reflecting the deep synergy between knowledge-driven and data-driven methods.

Table 9.

Intelligent fault diagnosis process and technical comparison.

The KG-PTM framework achieves a complete cognitive closed-loop from data perception to decision-making. Its core innovation lies in

- Unifying data processing and knowledge reasoning, unlike traditional isolated methods;

- Enabling traceability across all diagnostic stages;

- Supporting dynamic evolution through continuous KG-PTM interaction;

- Providing interpretable decisions by combining symbolic reasoning with semantic understanding.

The outstanding advantage of this process design lies in the formation of a complete “perception–cognition–decision” closed loop, where the output results of each stage are interrelated, ensuring the traceability of the diagnostic process and achieving dynamic evolution of diagnostic capabilities through continuous interaction between KG and PTM. Of particular note is that this process combines knowledge-guided symbolic reasoning with data-driven semantic understanding, effectively solving the “black box” problem in intelligent operations and providing a highly reliable and interpretable fault diagnosis solution for HVDC systems.

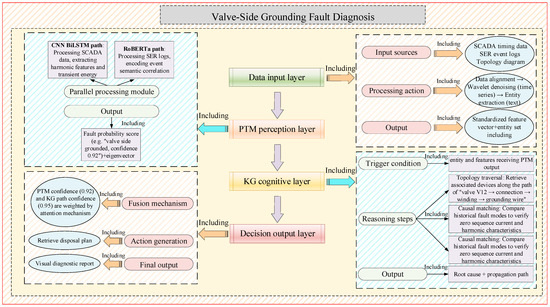

6.5. End-to-End Case Study: Valve-Side Grounding Fault Diagnosis

To concretely illustrate the operational pipeline of the KG-PTM integrated framework, we present a typical valve-side grounding fault scenario in an HVDC converter station. As documented in Section 3.1.1, such faults exhibit spatiotemporal dispersion and require rapid localization. Figure 9 depicts the end-to-end workflow, which seamlessly combines PTM-based perceptual analysis and KG-based symbolic reasoning.

Figure 9.

End-to-end workflow of KG-PTM integrated fault diagnosis for a valve-side grounding fault scenario.

6.6. Standardized Evaluation Framework

6.6.1. Core Evaluation Indicator System

Based on a comprehensive review of the evolution path of intelligent fault diagnosis technology for HVDC systems in this article, we systematically analyzed the common challenges of existing diagnostic paradigms in noise adaptation, real-time response, and interpretability. To overcome the bottleneck of insufficient comparability and inconsistent evaluation criteria in technology, this paper proposes to construct a hierarchical evaluation index system to quantitatively measure the collaborative effectiveness of the KG-PTM framework. The core logic of this system is to transform abstract diagnostic performance into computable and verifiable dimensional indicators, providing a basis for algorithm optimization, engineering selection, and standardization. As shown in Table 10, the system is developed from four dimensions: accuracy, timeliness, robustness, and interpretability. Each dimension is further refined into actionable second-level indicators, forming an evaluation framework that combines theoretical rigor and practical orientation.

Table 10.

Core evaluation index system for HVDC fault diagnosis.

6.6.2. Standard Test Scenario Design

In response to the evaluation requirements for intelligent fault diagnosis of HVDC systems, based on the analysis of typical fault modes (such as valve side grounding, phase-to-phase short circuit, etc.) in Section 3 of the document, we have designed a multi-level testing scenario framework. This framework aims to systematically validate the performance of diagnostic models under different complexity conditions, from basic single-fault handling to composite-fault resilience and extreme operating condition adaptability. Table 11 summarizes the scenario configuration, testing conditions, and data collection requirements to ensure the comprehensiveness and reproducibility of the evaluation.

Table 11.

Summary of Multi level Testing Scenarios for HVDC Systems.

This layered design spans a continuous testing spectrum from ideal conditions to harsh environments: focusing on model core accuracy in single-fault scenarios, evaluating system interaction and fault tolerance in composite scenarios, and testing algorithm robustness in extreme scenarios under non-ideal factors such as noise and missing data. By standardizing parameters (such as CIGRE system benchmarks) and quantifiable data acquisition specifications, this framework not only supports horizontal technical comparisons but also provides a practice-oriented validation benchmark for the engineering deployment of HVDC intelligent diagnostic tools.

7. Challenges and Future Perspectives

7.1. Existing Challenges

As the technology transitions from theoretical prototypes to large-scale industrial deployment, it faces four critical challenges:

- Low automation in knowledge acquisition and updating remains a primary barrier to achieving dynamic intelligent operation and maintenance. Currently, KG construction still heavily relies on expert experience and manual rules, making the process labor-intensive and costly. Although efforts have been made to automatically extract knowledge from unstructured texts such as maintenance reports and defect records, performance remains limited, especially when dealing with colloquial or non-standard technical language. This hinders the real-time and dynamic updating of KGs, leading to potential knowledge lag or obsolescence.

- Deep integration of physical mechanisms and data-driven models is still challenging. The operation of HVDC systems is governed by complex physical laws such as electromagnetic transients. However, existing KGs and PTMs are primarily data-driven and lack effective modeling of physical constraints. A key research difficulty lies in embedding prior knowledge, such as differential equations or physical rules-into graph reasoning and model training processes in a deeply coupled and interpretable manner, rather than through superficial hybridization. Models lacking physical consistency may produce physically implausible outputs under extreme or unseen conditions, potentially compromising system safety.

- Computational complexity is a key bottleneck in the actual deployment of KG-PTM systems. The PTM inference process (such as CNN based SCADA data processing [66]) relies heavily on matrix operations, making it difficult to meet the real-time requirements of relay protection systems for millisecond-level response on edge devices [70]; At the same time, KG’s real-time graph query and inference operations (such as shortest path search) grow exponentially with the number of nodes. When the system expands to thousands of nodes, inference delays may exceed seconds and cannot support online decision-making. In addition, the joint training of KG and PTM requires multiple iterations for knowledge embedding and parameter tuning, and the dependence on hardware resources (such as multi GPU clusters) also limits its popularity in small and medium-sized substations. Therefore, achieving lightweight edge deployment through techniques such as model compression, knowledge distillation, and neural architecture search while ensuring minimal performance degradation, balancing computational efficiency and real-time performance, has become an important technical challenge currently faced.

- The absence of authoritative benchmarks and trustworthy evaluation frameworks hinders technological progress and standardization. Currently, HVDC fault diagnosis domain lacks widely recognized benchmark datasets that cover diverse scenarios with high-quality annotations, as well as unified evaluation metrics. This makes fair and objective comparison between different models difficult, leading to redundant development and isolated research efforts. Moreover, studies on model trustworthiness, including uncertainty quantification, robustness against adversarial attacks, and failure modes under extreme conditions, remain insufficient. There is still a long way to go before building an AI system that is both explainable and trustworthy for practical operation and maintenance personnel.

7.2. Future Prospects

To response to the aforementioned challenges, future research must seek breakthroughs across multiple dimensions, including automation, mechanism integration, architectural innovation, and trustworthy evaluation, to advance this technological paradigm from advanced laboratory prototypes to reliable engineering applications. Based on the technical evolution trajectory presented in this work, future strategic research directions are proposed:

- Development of automated and self-evolving knowledge bases. To overcome the reliance on manual efforts for knowledge acquisition and updates, future work should vigorously develop automated knowledge engineering based on large language models (LLMs). By utilizing instruction-fine-tuned LLMs as domain knowledge experts, entities and relationships can be automatically and continuously extracted from massive unstructured operational reports, research literature, and equipment manuals, while performing logical validation and conflict resolution on existing knowledge. This will transform KGs from static, manually maintained databases into living knowledge systems with “self-learning, self-verifying, and self-evolving” capabilities that dynamically track system changes and provide real-time, accurate knowledge support for intelligent maintenance. To achieve closed-loop collaboration, dynamic adaptation issues need to be addressed: the incremental learning of PTM (such as EWC algorithm [66]) needs to be synchronized with the real-time updates of KG (such as stream graph processing [83]) to avoid cognitive bias. For example, when the system expands and adds a converter valve, PTM needs to recalibrate the feature extractor, while KG needs to synchronously expand the topology entity. The two ensure consistency through version control protocols (such as Git style management [42]). In extreme scenarios, collaborative mechanisms also need to introduce uncertainty quantification (such as Monte Carlo Dropout [70]) to assess decision risk.

- Exploration of PTMs deeply integrated with simulation and physical information. Bridging the gap between data-driven learning and physical modeling, physics-informed pre-trained models (PI-PTMs) represent a key research direction. Research should focus on embedding physical laws (such as electromagnetic transient equations) and mathematical constraints describing HVDC system dynamics into PTM training objectives and reasoning processes as differentiable regularization terms or hard constraints. This will give rise to a new generation of AI that possesses both powerful representation capabilities from data-driven models and strict adherence to physical principles-creating “physics-aware AI” that significantly enhances extrapolation generalization and decision reliability under extreme conditions and small-sample scenarios, producing results that are not only accurate but also physically plausible.

- Research on novel model architectures and efficient computing paradigms. To balance model performance with power system real-time requirements, innovations are needed at both the model and computational architecture levels. At the model level, new architectures better suited for power time-series graph data characteristics, such as graph transformers, should be designed to handle coupled graph-structured and temporal dependencies efficiently. At the computing level, federated learning and cloud–edge collaborative architectures offer promising paradigms for distributed model training, ensuring data privacy and security while maximizing the value of heterogeneous operational data. These innovations will enable scalable, low-latency AI deployment in real-world HVDC environments.

- Promotion of standards development and trustworthy AI research. To foster a sustainable research ecosystem and build operational trust, efforts on standards development and trustworthy AI are essential. The urgent priority is to collaborate with industry and academia to promote the establishment of open, comprehensive HVDC domain benchmark datasets covering diverse fault scenarios and unified evaluation platforms, providing a fair measuring stick for technological development. Simultaneously, in-depth research on model uncertainty quantification, explainable AI (XAI), and adversarial robustness must be conducted, enabling models to not only output diagnostic results but also indicate decision confidence levels, provide clear reasoning paths, and withstand potential data disturbances. This represents the necessary pathway for advancing intelligent maintenance systems from usable to trustworthy and reliable, ultimately achieving comprehensive implementation.

- Due to the challenges of data privacy, resource constraints, and integration of heterogeneous data from multiple sources in the current independent construction of large-scale real datasets, we will include a layered promotion plan in our future outlook.

- (1)

- Phase 1: benchmark development and synthetic data generation (short term: 1–2 years)

- Objective: To establish a foundational, reproducible benchmark for initial algorithm development and validation in the absence of large-scale real-world data.

- Core activities:

- ▪

- Utilize high-fidelity simulation tools (e.g., PSCAD/EMTP) to generate comprehensive synthetic datasets based on the CIGRE standard model and defined fault types (e.g., valve-side grounding, phase-to-phase short circuit).

- ▪

- Develop and publish standardized evaluation metrics (e.g., F1 score, detection delay, confidence calibration error) and testing scenarios (e.g., single-fault benchmark, composite fault resilience testing).

- Expected outcome: An open-source, synthetic benchmark dataset that enables fair comparison of different KG-PTM algorithms, addressing the initial data scarcity issue.

- (2)

- Phase 2: federated learning and trusted data alliance (mid term: 2–4 years)

- Objective: To enable knowledge learning from real operational data while strictly preserving data privacy and security, moving from simulation to real-world validation.

- Core activities:

- ▪

- Initiate a data alliance jointly with industry organizations.

- ▪

- Implement privacy-preserving technologies such as federated learning, data anonymization, and trusted execution environments (TEEs) to allow model training across multiple utilities without sharing raw data.

- ▪

- Establish protocols for restricted, privacy-compliant access to real fault records.

- Expected outcome: An operational framework for secure multi-party collaboration, leading to KG-PTMs validated on real-world, distributed data, significantly enhancing model practicality and robustness.

- (3)

- Phase 3: Standardization and Industrial Deployment (Long term: 4+ Years)

- Objective: To transition the validated KG-PTM framework into industrial standards and widely deployable tools, ensuring interoperability and long-term sustainability.

- Core activities:

- ▪

- Promote international bodies (e.g., IEC or CIGRE) to take the lead in developing international benchmark protocols.

- ▪

- Focus on creating standards for data formats, model interfaces, and evaluation procedures.

- ▪

- Foster the development of commercial-grade software platforms and integration guides for utility adoption.

- Expected outcome: Widespread industry adoption of KG-PTM-based diagnostic systems, supported by international standards, achieving the ultimate goals of technical comparability, model interpretability, and reliable industrial implementation.

This path will gradually achieve the technical comparability, model interpretability, and industry implementation goals advocated by the reviewers, while avoiding the bottleneck of current data scarcity.

Through continuous exploration in these directions, the integration of KGs and PTMs is expected to fully close the data-knowledge-decision loop for HVDC intelligent maintenance, laying a solid foundation for achieving highly autonomous and reliable next-generation power systems.

8. Conclusions

This work has systematically reviewed the integration of KGs and PTMs for intelligent fault diagnosis in HVDC systems. The rapid expansion of HVDC systems, coupled with increasing structural complexity, has exposed the limitations of traditional fault diagnosis methods, which struggle with data heterogeneity, model generalization, and decision interpretability. Through a comprehensive analysis of the “data–knowledge–decision” closed-loop framework, this review clarifies the technical core and synergistic mechanisms of KG and PTM integration, providing a clear technological pathway and theoretical reference for constructing a new generation of intelligent maintenance systems. The key conclusions are as follows:

- The effectiveness of the technical integration is fully demonstrated. The fusion of KGs and PTMs is not a superficial combination but achieves deep cognitive and perceptual complementarity. KGs provide a structured semantic network, endowing fault diagnosis with explainable logical reasoning capabilities, for instance, by dynamically representing system topology and fault evolution patterns to enable transparent root cause analysis. PTMs, leveraging large-scale pre-training, can efficiently extract deep features from multi-source heterogeneous data. This synergistic mechanism significantly enhances diagnostic accuracy and timeliness.

- The synergistic mechanism effectively addresses key industry challenges. In the context of intelligent HVDC maintenance, the fusion of KG and PTM effectively tackles key challenges such as data silos, feature extraction complexity, temporal reasoning, and knowledge application. Specifically, PTMs act as the perceptual front-end, automatically identifying anomaly patterns in real-time sensor data, while KGs serve as the cognitive core, performing contextual reasoning through entity relationship mapping and historical fault case analysis. For example, when a PTM detects abnormal current harmonics, the KG can rapidly correlate device topology and fault causality paths, achieving precise fault localization and transparent decision-making. The actual effectiveness of the collaborative mechanism has been verified in empirical research: in a mixed DC engineering case [70], PTM (CNN model) increased the fault detection F1 score to 92.5%, while KG’s causal reasoning reduced the false alarm rate by 34% (confirmed through ablation experiments [93]). In addition, closed-loop design reduces the need for manual intervention. In a VSC-HVDC project in Jiangsu, the average diagnostic time was compressed from minutes to seconds [42].

- Practical applications lay the foundation for intelligence. This technical framework provides theoretical support and a practical pathway for building highly reliable and adaptive intelligent maintenance systems for HVDC. Case studies demonstrate that the synergy between KG and PTM not only reduces misdiagnosis rates but also enhances system robustness under extreme operating conditions. Furthermore, its “perception–cognition–decision” closed-loop design improves the traceability of diagnostic results, offering intuitive decision support for maintenance personnel.

In summary, the deep integration of KG and PTM establishes a new technical paradigm for HVDC fault diagnosis, driving power systems towards greater intelligence and efficiency. This integrated solution is not only applicable to existing HVDC systems but also provides a scalable framework for fault management in future multi-energy coupling scenarios.

Author Contributions

Conceptualization, B.Y. and Q.L.; methodology, Q.L. and Y.M.; validation, S.C., S.Z. and P.Z.; formal analysis, Q.L. and Y.M.; investigation, Y.M. and J.Y.; resources, P.Z.; data curation, J.Y.; writing—original draft preparation, Q.L.; writing—review and editing, B.Y.; visualization, S.C.; supervision, B.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Research on Key Technologies of DC Transmission Oper-ation and Maintenance Knowledge Iteration and Intelligent Decision-Making Based on Multi-modal Generative Pre-Trained Models-Topic 2: Research on DC Transmission Operation and Maintenance Intelligent Decision-Making Technology Based on Multimodal Pre-trained Models (CGYKJXM20240120).

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

The authors gratefully acknowledge the financial support provided by the research grant CGYKJXM20240120, which facilitated this study. We also extend our sincere thanks to the editors and anonymous reviewers for their insightful comments and suggestions, which significantly improved the quality of this review.

Conflicts of Interest

Author Qiang Li, Yue Ma, Jinyun Yu, Shenghui Cao, Shihong Zhang, Pengwang Zhang were employed by the company EHV Power Transmission Company of China Southern Power Grid Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial intelligence |

| AC | Alternating current |

| BP | Backpropagation |

| CRF | Conditional random field |

| CNN-BiLSTM | Convolutional neural network-bidirectional long short-term memory network |

| DC | Direct current |

| DNN | Deep neural networks |

| ELM | Extreme learning machine |

| FFT | Fast Fourier transform |

| GCN | Graph convolutional network |

| GNN | Graph neural network |

| HVDC | High-voltage direct-current |

| KG | Knowledge graph |

| LSTM | Long short-term memory |

| LLM | Large language model |

| LDNN | Lightweight deep neural networks |

| ML | Machine learning |

| MRAS | Model reference adaptive systems |

| NLP | Natural language processing |

| PNN | Probabilistic neural network |

| PI-PTM | Physics-informed pre-trained model |

| PTM | Pre-trained model |

| RNN | Recurrent neural network |

| ROBERTa | Robustly optimized BERT pretraining approach |

| SA | Structural analysis |

| SER | Sequence of events record |

| SVM | Support vector machines |

| TDR | Time-domain reflectometry |

| TL | Transfer learning |

| TFDM | Traditional fault diagnosis method |

| VSC-HVDC | Voltage source converter-based high voltage direct current |

| WT | Wavelet transform |

| XAI | Explainable AI |

References

- Yang, B.; Liu, B.Q.; Zhou, H.Y.; Wang, J.B.; Yao, W.; Wu, S.C.; Shu, H.C.; Ren, Y.X. A critical survey of technologies of large offshore wind farm integration: Summary, advances, and perspectives. Prot. Control Mod. Power Syst. 2022, 7, 17. [Google Scholar] [CrossRef]

- Ruan, J.Q.; Liang, G.Q.; Zhao, J.H.; Zhao, H.; Qiu, J.; Wen, F.H.; Zhao, Y.D. Deep learning for cybersecurity in smart grids: Review and perspectives. Energy Convers. Econ. 2023, 4, 233–251. [Google Scholar] [CrossRef]

- Su, Y.; Teh, J.S.; Luo, Q.; Tan, K.M.; Yong, J.Y. A two-layer framework for mitigating the congestion of urban power grids based on flexible topology with dynamic thermal rating. Prot. Control Mod. Power Syst. 2024, 9, 83–95. [Google Scholar] [CrossRef]

- Chen, X.Q.; Haddadi, A.; Farantatos, E.; Kocar, I.; Bu, S.Q. Power swing in systems with varying penetration of grid-forming IBRs: Protection and dynamics. Prot. Control Mod. Power Syst. 2025, 10, 116–129. [Google Scholar] [CrossRef]

- Yang, B.; Jiang, L.; Yu, T.; Shu, H.C.; Zhang, C.K.; Yao, W.; Wu, Q.H. Passive control design for multi-terminal VSC-HVDC systems via energy shaping. Int. J. Electr. Power Energy Syst. 2018, 98, 496–508. [Google Scholar] [CrossRef]

- Deng, Z.Y.; Wang, H.; Qin, Y.; Yang, R.X.; Cai, X. Enhanced inertia response control of grid-forming PMSG-based wind turbines considering safe operation boundary. Prot. Control Mod. Power Syst. 2025, 10, 56–67. [Google Scholar] [CrossRef]

- Abdelemam, A.; Zeineldin, H.; Al-Durra, A.; El-Saadany, E. Interharmonic current differential protection scheme for converter-based hybrid AC/DC microgrids. Prot. Control Mod. Power Syst. 2025, 10, 68–83. [Google Scholar] [CrossRef]

- Zuo, Y.; Han, M.X.; Liu, B.; Egamnazarova, T. Analysis of multi-infeed receiving AC system with incompletely segmented VSC-HVDC. Glob. Energy Interconnect. 2025, 8, 338–348. [Google Scholar] [CrossRef]

- Farkhani, J.S.; Özgür, C.; Ma, K.Q.; Bak, C.L.; Chen, Z. Fault detection, classification, and location based on empirical wavelet transform teager energy operator and ANN for hybrid transmission lines in VSC-HVDC systems. J. Mod. Power Syst. Clean Energy 2025, 13, 840–851. [Google Scholar] [CrossRef]

- Zhang, W.J.; Xu, S.X.; Qi, W.C.; Peng, Z.Y.; Sun, W.T. Impact of short-term power shortage from low voltage ride through and dc commutation failure on power grid frequency stability. Energy Eng. 2025, 122, 2371–2387. [Google Scholar] [CrossRef]

- Xing, P.X.; Yang, Y.H.; Peng, J.S.; Yu, L.L.; Si, R.H.; Jia, P.; Wang, C.J.; Wen, Y.F. Analysis of VSC-HVDC support capability for power grids with large-scale renewable energy and multi-infeed HVDC links. Energy Rep. 2023, 9, 1084–1091. [Google Scholar] [CrossRef]

- Fayazi, M.; Joorabian, M.; Saffarian, A.; Monadi, M. A single-ended traveling wave based fault location method using DWT in hybrid parallel HVAC/HVDC overhead transmission lines on the same tower. Electr. Power Syst. Res. 2023, 220, 109302. [Google Scholar] [CrossRef]

- Niaki, S.H.A.; Farkhani, J.S.; Chen, Z.; Bak-Jensen, B.; Hu, S.J. An intelligent method for fault location estimation in HVDC cable systems connected to off shore wind farms. Wind 2023, 3, 361–374. [Google Scholar] [CrossRef]

- Sun, Q.; Tang, J.J.; Peng, S.; Zhong, W.J.; Zhu, L.; Zhao, Y. Operational reliability evaluation and risk mitigation of asynchronous grids coupled through flexible HVDC systems. J. Mod. Power Syst. Clean Energy 2025, 13, 1701–1713. [Google Scholar] [CrossRef]

- Gomis-Bellmunt, O.; Sau-Bassols, J.; Prieto-Araujo, E.; Cheah-Mane, M. Flexible converters for meshed HVDC grids: From flexible AC transmission systems (FACTS) to flexible DC grids. IEEE Trans. Power Deliv. 2020, 35, 2–15. [Google Scholar] [CrossRef]

- Alassi, A.; Bañales, S.; Ellabban, O.; Adam, G.; Maciver, C. HVDC transmission: Technology review, market trends and future outlook. Renew. Sustain. Energy Rev. 2019, 112, 530–554. [Google Scholar] [CrossRef]

- Hou, J.J.; Song, G.B.; Fan, Y.F. Fault identification scheme for protection and adaptive reclosing in a hybrid multi-terminal HVDC system. Prot. Control Mod. Power Syst. 2023, 8, 403–419. [Google Scholar] [CrossRef]

- Li, Y.; Jia, N.; He, J.W.; Li, B.; Wang, H.Y.; Zhang, S.B. Non-unit protection scheme based on cooperation with control strategy for multiterminal hybrid HVDC system without line boundary. Prot. Control Mod. Power Syst. 2025, 10, 41–55. [Google Scholar] [CrossRef]

- Ding, X.; Liao, S.Y.; Xu, J.; Sun, Y.Z. An active power support control strategy in VSC-HVDC power systems considering load characteristics of electrolytic aluminum. Prot. Control Mod. Power Syst. 2025, 10, 1–17. [Google Scholar] [CrossRef]

- Tan, S.N.; Liu, J.L.; Du, X.; Su, J.Y.; Fan, L.J. Multi-port network modeling and stability analysis of VSC-MTDC systems. J. Mod. Power Syst. Clean Energy 2024, 12, 1666–1677. [Google Scholar] [CrossRef]

- Li, J.P.; Li, Y.J.; Wang, M.H.; Xu, Z. DC fault detection in hybrid MTDC systems using transient average of DC reactor voltage. Int. J. Electr. Power Energy Syst. 2023, 150, 109093. [Google Scholar] [CrossRef]