Numerical Simulation of Co-Firing Biomass in a 660 MW Coal-Fired Boiler

Abstract

1. Introduction

2. Methodology

2.1. Basic Structure of the Boiler

2.2. Fuel Properties and Operating Condition Parameters

2.3. Selection of the Computational Model

2.4. Mesh Generation and Independence Verification

3. Results and Discussion

3.1. Analysis of Combustion Characteristics Under Pure Coal Combustion Conditions

3.1.1. Distribution of In-Furnace Velocity Field

3.1.2. Distribution of In-Furnace Temperature Field

3.1.3. Distribution of In-Furnace Components

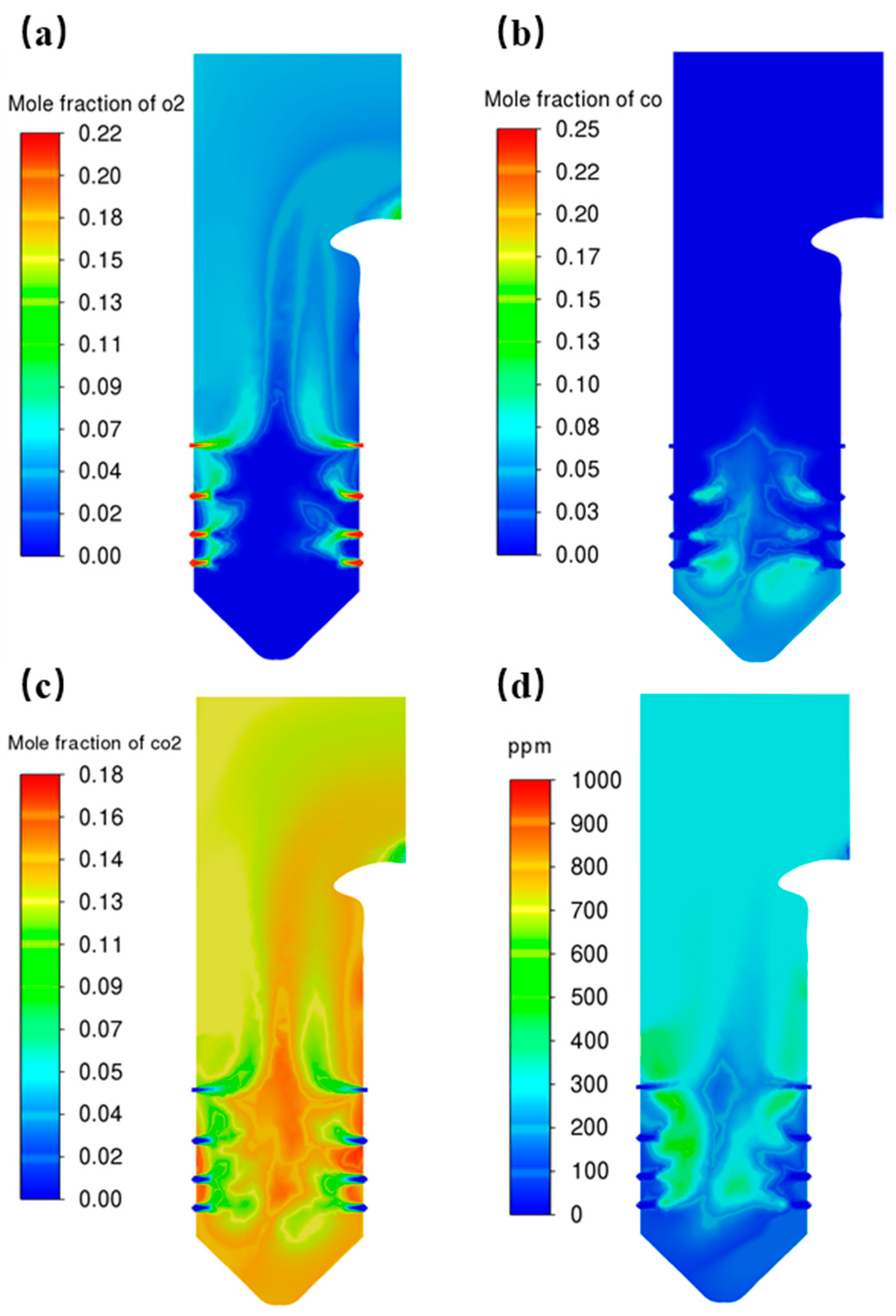

3.2. Effects of Different Biomass Co-Combustion Ratios on Boiler Combustion

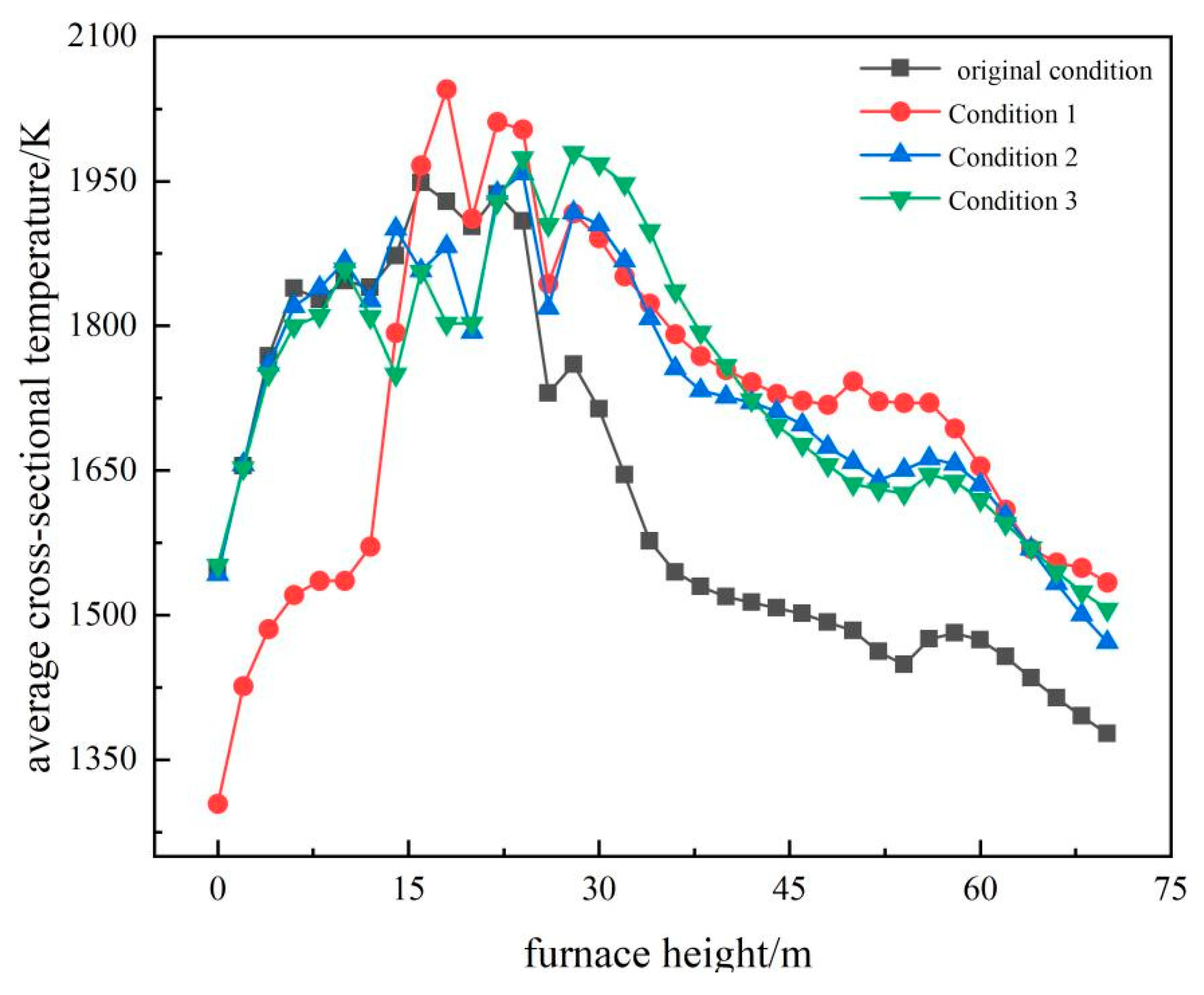

3.2.1. Variation Law of In-Furnace Temperature Field

3.2.2. Variation Law of In-Furnace Component Distribution

3.3. Effects of Different Biomass Injection Positions on Boiler Combustion

3.3.1. Variation Law of In-Furnace Temperature Field

3.3.2. Variation Law of In-Furnace Component Distribution

4. Conclusions

- The established numerical model exhibits high reliability. Under the BMCR condition, the relative errors between the simulated values of furnace outlet temperature and NO volume concentration and the actual operational data are 1.2% and 1.9%, respectively, which are within the acceptable range of engineering accuracy, confirming the model’s suitability for subsequent biomass co-combustion simulation studies.

- The biomass co-combustion ratio has a significant impact on the in-furnace combustion process and pollutant emissions. With the increase in the co-combustion ratio, the O2 content at the furnace outlet decreases progressively, while the CO2 content increases, indicating enhanced combustion completeness. Meanwhile, the NO emission concentration continues to decrease due to the low nitrogen content in biomass and the promoting effect of volatile matter on NOx reduction reactions. A 20% biomass co-combustion ratio is determined as the optimal operating parameter, as it effectively balances combustion efficiency and NO emission control.

- The biomass injection position directly affects the spatial distribution of the in-furnace flow field, temperature field, and component concentration. Among the three injection positions (lower, middle, upper burners), injecting biomass at the middle burner’s primary air nozzle results in the most significant NO reduction effect, with a 22% decrease compared to the pure coal combustion condition. This is because the middle injection position facilitates the formation of a stable reducing atmosphere in the main combustion zone, maximizing the NOx reduction potential of CO and volatile matter. In contrast, injection at the upper position is less effective due to the inhibition of reducing atmosphere formation by the high O2 content from over-fire air, while injection at the lower position leads to higher CO emissions in the cold ash hopper region.

- Biomass co-combustion technology can effectively improve the combustion performance of coal-fired boilers and reduce pollutant emissions, which is of great significance for promoting the clean and low-carbon transformation of coal-fired power plants. Future research could focus on the coupled effects of variable load conditions and biomass co-combustion, as well as the optimization of burner structures to further enhance the synergistic effect of combustion efficiency improvement and pollutant control.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teng, X.; Liu, F.; Chiu, Y. The impact of coal and non-coal consumption on China’s energy performance improvement. Nat. Resour. Forum 2020, 44, 334–352. [Google Scholar] [CrossRef]

- Eguchi, S.; Takayabu, H.; Lin, C. Sources of inefficient power generation by coal-fired thermal power plants in China: A metafrontier DEA decomposition approach. Renew. Sustain. Energy Rev. 2021, 138, 110562. [Google Scholar] [CrossRef]

- Zhou, P.; Lv, Y.; Wen, W. The Low-Carbon Transition of Energy Systems: A Bibliometric Review from an Engineering Management Perspective. Engineering 2023, 29, 147–158. [Google Scholar] [CrossRef]

- Jiang, Y.; Lee, B.-H.; Oh, D.-H.; Jeon, C.-H. Optimization of operating conditions to achieve combustion stability and reduce NOx emission at half-load for a 550-MW tangentially fired pulverized coal boiler. Fuel 2021, 306, 121727. [Google Scholar] [CrossRef]

- Chang, J.; Zhou, Z.; Ma, X.; Liu, J. Computational investigation of hydrodynamics, coal combustion and NOx emissions in a tangentially fired pulverized coal boiler at various loads. Particuology 2022, 65, 105–116. [Google Scholar] [CrossRef]

- Muthuraman, M.; Namioka, T.; Yoshikawa, K. A comparison of co-combustion characteristics of coal with wood and hydrothermally treated municipal solid waste. Bioresour. Technol. 2010, 101, 2477–2482. [Google Scholar] [CrossRef]

- Vamvuka, D.; Kakaras, E.; Kastanaki, E.; Grammelis, P. Pyrolysis characteristics and kinetics of biomass residuals mixtures with lignite. Fuel 2003, 82, 1949–1960. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, J.; Sun, S.; Sun, R.; Qin, M. Numerical investigation of low NOx combustion strategies in tangentially-fired coal boilers. Fuel 2015, 142, 215–221. [Google Scholar] [CrossRef]

- Karampinis, E.; Nikolopoulos, N.; Nikolopoulos, A.; Grammelis, P.; Kakaras, E. Numerical investigation Greek lignite/cardoon co-firing in a tangentially fired furnace. Appl. Energy 2012, 97, 514–524. [Google Scholar] [CrossRef]

- Lu, H.; Huang, S.; Li, H.; Cheng, Z.; Chang, X.; Dong, L.; Kong, D.; Jing, X. Numerical simulation of combustion characteristics in a 660 MW tangentially fired pulverized coal boiler subjected to peak-load regulation. Case Stud. Therm. Eng. 2023, 49, 103168. [Google Scholar] [CrossRef]

- Tu, Y.; Li, J.; Chang, D.; Hu, B. Effect of biomass co-firing position on combustion and NOX emission in a 300-MWe coal-fired tangential boiler. Asia-Pac. J. Chem. Eng. 2021, 17, e2734. [Google Scholar] [CrossRef]

- Rad, S.D.; Ashrafizadeh, A.; Nickaeen, M. Numerical simulation of fluid flow and heat transfer in an industrial continuous furnace. Appl. Therm. Eng. 2017, 117, 263–274. [Google Scholar] [CrossRef]

- Ma, L.; Fang, Q.; Yin, C.; Wang, H.; Zhang, C.; Chen, G. A novel corner-fired boiler system of improved efficiency and coal flexibility and reduced NOx emissions. Appl. Energy 2019, 238, 453–465. [Google Scholar] [CrossRef]

- Yin, C.; Caillat, S.; Harion, J.-L.; Baudoin, B.; Perez, E. Investigation of the flow, combustion, heat-transfer and emissions from a 609 MW utility tangentially fired pulverized-coal boiler. Fuel 2002, 81, 997–1006. [Google Scholar] [CrossRef]

- Fang, Q.; Wang, H.; Wei, Y.; Lei, L.; Duan, X.; Zhou, H. Numerical simulations of the slagging characteristics in a down-fired, pulverized-coal boiler furnace. Fuel Process. Technol. 2010, 91, 88–96. [Google Scholar] [CrossRef]

- Gao, S.; Wang, B.; Yang, F.; Zhang, K.; Cheng, F. Effect of O2 concentration on combustion behavior and kinetics of coal gangue during oxy-fuel combustion and oxy-steam combustion. Asia-Pac. J. Chem. Eng. 2021, 16, e2713. [Google Scholar] [CrossRef]

- Siegmund, T.; Gollmer, C.; Scherzinger, M.; Kaltschmitt, M. A review of CO emissions during solid biofuel combustion—Formation mechanisms and fuel-related reduction measures. J. Energy Inst. 2024, 116, 101762. [Google Scholar] [CrossRef]

- Wu, X.; Song, Q.; Zhao, H.; Yao, Q. Synergetic effect of biomass volatiles on NO reduction and the influence of K/Na on it. Fuel 2015, 158, 634–640. [Google Scholar] [CrossRef]

- Liu, L.; Memon, M.Z.; Xie, Y.; Gao, S.; Guo, Y.; Dong, J.; Gao, Y.; Li, A.; Ji, G. Recent advances of research in coal and biomass co-firing for electricity and heat generation. Circ. Econ. 2023, 2, 100063. [Google Scholar] [CrossRef]

- Yuan, H.; Qiu, Q.; Sun, H.; Luo, S. Catalytic reduction behaviors of NOx and its use in biomass combustion. Therm. Sci. 2024, 28 Pt B, 4297–4306. [Google Scholar] [CrossRef]

- Shu, Y.; Zhang, F.; Wang, H.; Zhu, J.; Tian, G.; Zhang, C.; Cui, Y.; Huang, J. An experimental study of NO reduction by biomass reburning and the characterization of its pyrolysis gases. Fuel 2015, 139, 321–327. [Google Scholar] [CrossRef]

| Name | Symbol | Numerical | Unit | |

|---|---|---|---|---|

| Elemental analysis | carbon | C | 64.72 | % |

| hydrogen | H | 2.94 | % | |

| oxygen | O | 6.57 | % | |

| nitrogen | N | 1.2 | % | |

| sulfur | S | 2.63 | % | |

| Industrial analysis | Moisture content | Mad | 2.82 | % |

| Ash content | Ash | 21.94 | % | |

| Volatile matter | VM | 54.09 | % | |

| Fixed carbon | FC | 23.97 | % | |

| High calorific value | Q | 24.29 | MJ/kg | |

| Name | Symbol | Numerical | Unit | |

|---|---|---|---|---|

| Elemental analysis | carbon | C | 45.53 | % |

| hydrogen | H | 5.81 | % | |

| oxygen | O | 38.80 | % | |

| nitrogen | N | 0.74 | % | |

| sulfur | S | 0.18 | % | |

| Industrial analysis | moisture | Mad | 20 | % |

| Ash content | Ash | 8.94 | % | |

| Volatile content | VM | 61.06 | % | |

| Fixed carbon | FC | 10 | % | |

| High calorific value | Q | 14.38 | MJ/kg | |

| Project | Wind Speed/(m/s) | Wind Temperature/K |

|---|---|---|

| Central wind | 0.5 | 348 |

| Primary wind | 55 | 348 |

| Swirling inner secondary air | 35 | 573 |

| Swirling outer secondary air | 50 | 573 |

| Over-fire air | 70 | 573 |

| Model Type | Selection of the Model |

|---|---|

| Solver | Pressure basis, steady state |

| Turbulence equation | Realizable -ε model |

| Gas–solid two-phase flow model | Discrete phase model (DPM) |

| Gas-phase combustion model | Non-premixed combustion model |

| Volatile release model | Two-step competitive response model |

| Coke combustion model | Dynamic/diffusion control reaction rate model |

| Radiation heat transfer model | P-1 radiation model |

| Blending Ratio | 0 | 5% | 10% | 15% | 20% | |

|---|---|---|---|---|---|---|

| Coal | Heat input (MJ/s) | 1700.3 | 1615.3 | 1530.3 | 1445.3 | 1360.3 |

| Mass Input (kg/s) | 70 | 66.5 | 63 | 59.5 | 56 | |

| Biomass | Heat input (MJ/s) | 0 | 85 | 170 | 255 | 340 |

| Mass input (kg/s) | 0 | 5.9 | 11.8 | 17.7 | 23.6 | |

| Total heat input (MJ/s) | 1700.3 | |||||

| Simulated Working Condition | Average Particle Size of Biomass Particles/μm | Biomass Flow Rate/kg∙s−1 | Biomass Nozzle Position |

|---|---|---|---|

| Original condition | No | No | None |

| Condition 1 | 56 | 23.6 | Lower primary air nozzle |

| Condition 2 | 56 | 23.6 | Middle primary air outlet |

| Condition 3 | 56 | 23.6 | Upper primary air nozzle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Z.; Liu, L.; Li, M.; Zhang, X.; Li, Y.; Hao, M.; Gao, J.; Ren, X. Numerical Simulation of Co-Firing Biomass in a 660 MW Coal-Fired Boiler. Energies 2025, 18, 6082. https://doi.org/10.3390/en18236082

Du Z, Liu L, Li M, Zhang X, Li Y, Hao M, Gao J, Ren X. Numerical Simulation of Co-Firing Biomass in a 660 MW Coal-Fired Boiler. Energies. 2025; 18(23):6082. https://doi.org/10.3390/en18236082

Chicago/Turabian StyleDu, Zhihua, Liu Liu, Mingdong Li, Xiangyu Zhang, Yuhang Li, Miaomiao Hao, Jiamin Gao, and Xiaohan Ren. 2025. "Numerical Simulation of Co-Firing Biomass in a 660 MW Coal-Fired Boiler" Energies 18, no. 23: 6082. https://doi.org/10.3390/en18236082

APA StyleDu, Z., Liu, L., Li, M., Zhang, X., Li, Y., Hao, M., Gao, J., & Ren, X. (2025). Numerical Simulation of Co-Firing Biomass in a 660 MW Coal-Fired Boiler. Energies, 18(23), 6082. https://doi.org/10.3390/en18236082